-

Posts

16 -

Joined

-

Last visited

About Steve1970

- Birthday 11/09/1970

Profile Information

-

Gender

Male

-

Location

New Jersey

-

Interests

Woodworking, sailing

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

thibaultron reacted to a post in a topic:

Dust collector jig for sanding drum....

thibaultron reacted to a post in a topic:

Dust collector jig for sanding drum....

-

palmerit reacted to a post in a topic:

Lady Isabella by palmerit - Vanguard Models - 1:64 - Zulu

palmerit reacted to a post in a topic:

Lady Isabella by palmerit - Vanguard Models - 1:64 - Zulu

-

Nightdive reacted to a post in a topic:

Lady Isabella by palmerit - Vanguard Models - 1:64 - Zulu

Nightdive reacted to a post in a topic:

Lady Isabella by palmerit - Vanguard Models - 1:64 - Zulu

-

Three thoughts on shellac. 1) Shellac is an excellent sealer and the raised grain and 'fuzz' can be sanded off in 10-15 minutes. You can reapply many coats and sand in a single sitting and get a really nice smooth surface. This is extremely nice if you are working with end grain that you want smooth. 2) Shellac is repairable since it will dissolve with denatured alcohol. 3) You can always use WOP over the shellac if you prefer the look or sheen of it.

- 50 replies

-

- Lady Isabella

- zulu

-

(and 1 more)

Tagged with:

-

Dust collector jig for sanding drum....

Steve1970 replied to Sterling59's topic in Modeling tools and Workshop Equipment

Dale, that's a good idea and I was curious what is out there, so I did some searching... https://www.etsy.com/listing/1351686357/rotary-tool-dremel-to-1-78-shop-vac -

JacquesCousteau reacted to a post in a topic:

Swampscott Dory by Steve1970 - BlueJacket Shipcrafters - 1:12

JacquesCousteau reacted to a post in a topic:

Swampscott Dory by Steve1970 - BlueJacket Shipcrafters - 1:12

-

JacquesCousteau reacted to a post in a topic:

Swampscott Dory by Steve1970 - BlueJacket Shipcrafters - 1:12

JacquesCousteau reacted to a post in a topic:

Swampscott Dory by Steve1970 - BlueJacket Shipcrafters - 1:12

-

JacquesCousteau reacted to a post in a topic:

Swampscott Dory by Steve1970 - BlueJacket Shipcrafters - 1:12

JacquesCousteau reacted to a post in a topic:

Swampscott Dory by Steve1970 - BlueJacket Shipcrafters - 1:12

-

JacquesCousteau reacted to a post in a topic:

Swampscott Dory by Steve1970 - BlueJacket Shipcrafters - 1:12

JacquesCousteau reacted to a post in a topic:

Swampscott Dory by Steve1970 - BlueJacket Shipcrafters - 1:12

-

JacquesCousteau reacted to a post in a topic:

Swampscott Dory by Steve1970 - BlueJacket Shipcrafters - 1:12

JacquesCousteau reacted to a post in a topic:

Swampscott Dory by Steve1970 - BlueJacket Shipcrafters - 1:12

-

JacquesCousteau reacted to a post in a topic:

Swampscott Dory by Steve1970 - BlueJacket Shipcrafters - 1:12

JacquesCousteau reacted to a post in a topic:

Swampscott Dory by Steve1970 - BlueJacket Shipcrafters - 1:12

-

JacquesCousteau reacted to a post in a topic:

Swampscott Dory by Steve1970 - BlueJacket Shipcrafters - 1:12

JacquesCousteau reacted to a post in a topic:

Swampscott Dory by Steve1970 - BlueJacket Shipcrafters - 1:12

-

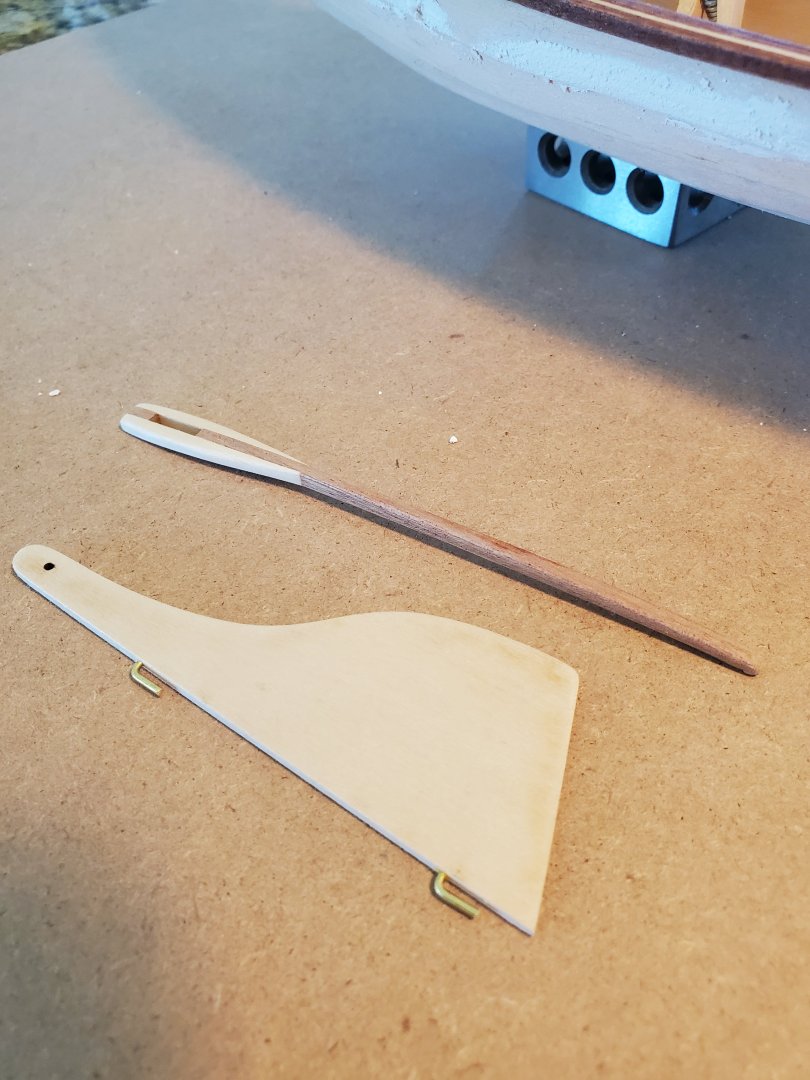

The rudder and tiller done. I had fun making the tiller. The choice of the mahogany tiller looks cool. I don't know how authentic that would be though. You can see in the background I used some spackle to try to get rid of an irritating wavy spot where the plank dried wrong. I blame too much or misplaced clamping of the wet plank. I ended sanding almost all of it away anyway and will have to live with the wave.

- 12 replies

-

- Swampscott Dory

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

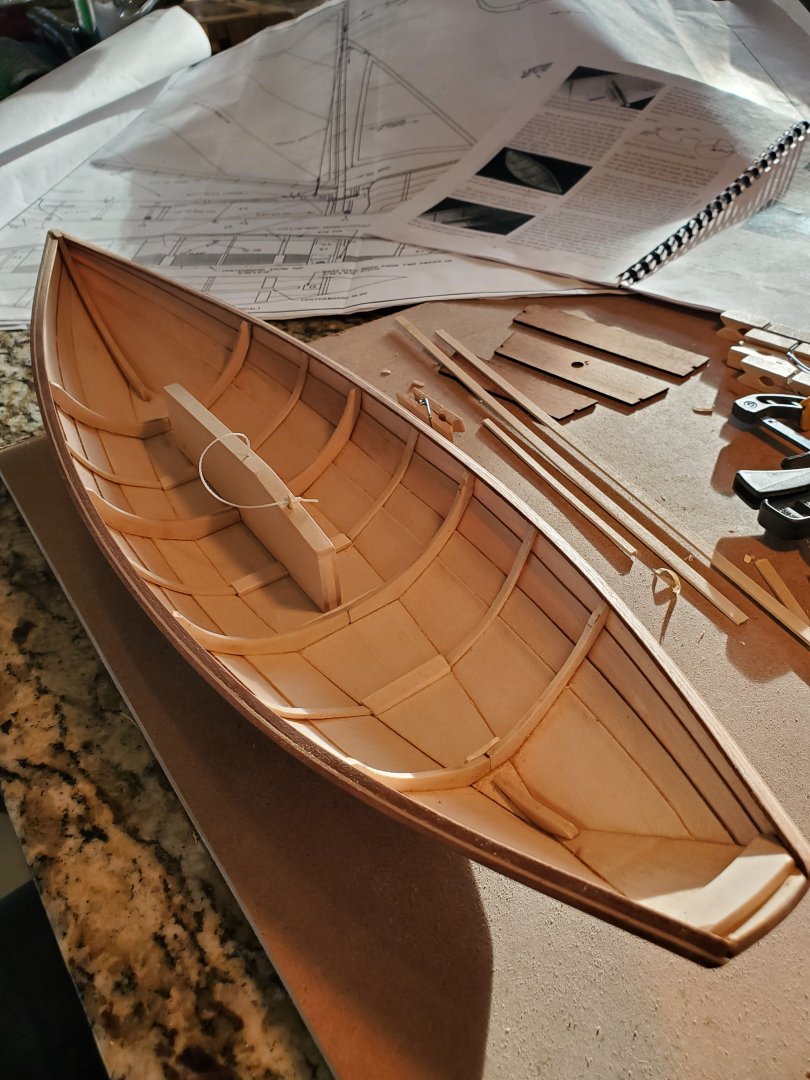

Seats were next. I made sure to trim the angles of the knees so they made contact with the hull planking. I had to cut back the top of the centerboard trunk because I did not dry fit everything and realize how they intersected.

- 12 replies

-

- Swampscott Dory

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

The stem cap when on nicely after filing down the intersection of the planks on the outside of the stem

- 12 replies

-

- Swampscott Dory

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

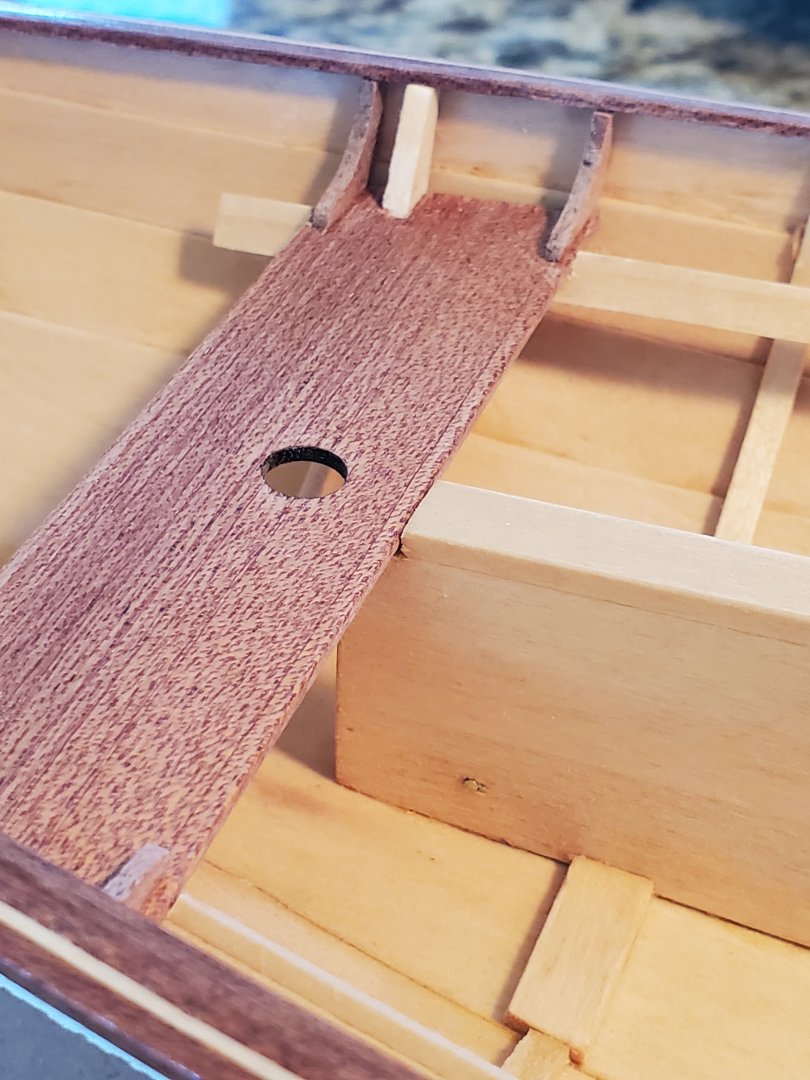

Centerboard trunk installed. If I had it to over, I would have used mahogany for the cap of the trunk.

- 12 replies

-

- Swampscott Dory

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

I was very happy with how the rails came out. I tapered all the frames so they ended flush with the rail. Following this picture, I spent an inordinate amount of time picking glue out the seems of the planks. I will be varnishing the inside, so I will not be covering up anything.

- 12 replies

-

- Swampscott Dory

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

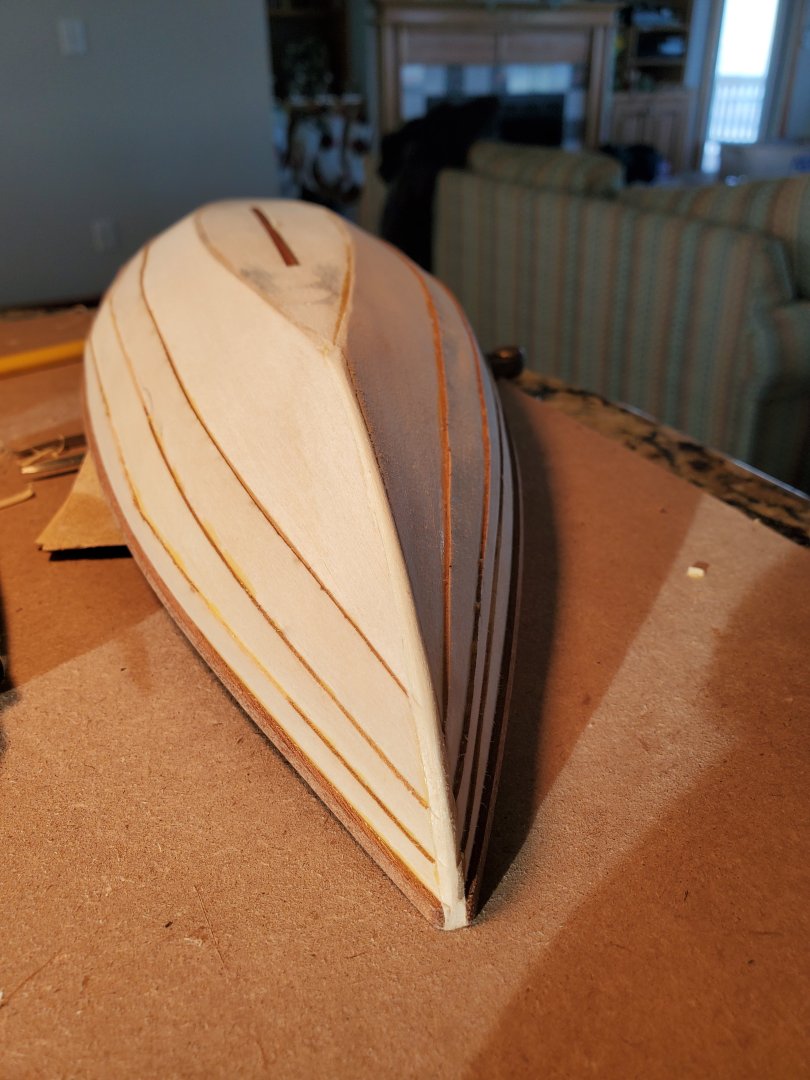

A closeup of the bow and all the glue I am going to have to pick out before painting. If I had it to do over again, it would (a) trim the plank with a small hand plane so I got a nice clean, crisp and square line and (b) use less glue. Is there a trick to not having a glue line here if you are using wood glue?

- 12 replies

-

- Swampscott Dory

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

- 12 replies

-

- Swampscott Dory

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

I figured out a trick to scribe a precise line for the overlap I wanted. I have since seen this exact technique used by others so I feel less proud than I did.

- 12 replies

-

- Swampscott Dory

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Well...it has been awhile since I posted. I did do some work on the boat in the intervening time, but life got busy with a house move into a fixer-upper, two more grandkids, and a wedding of one of my children. So, to catch up, the following are some photos and some thought on them that got me to where I am today.

- 12 replies

-

- Swampscott Dory

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

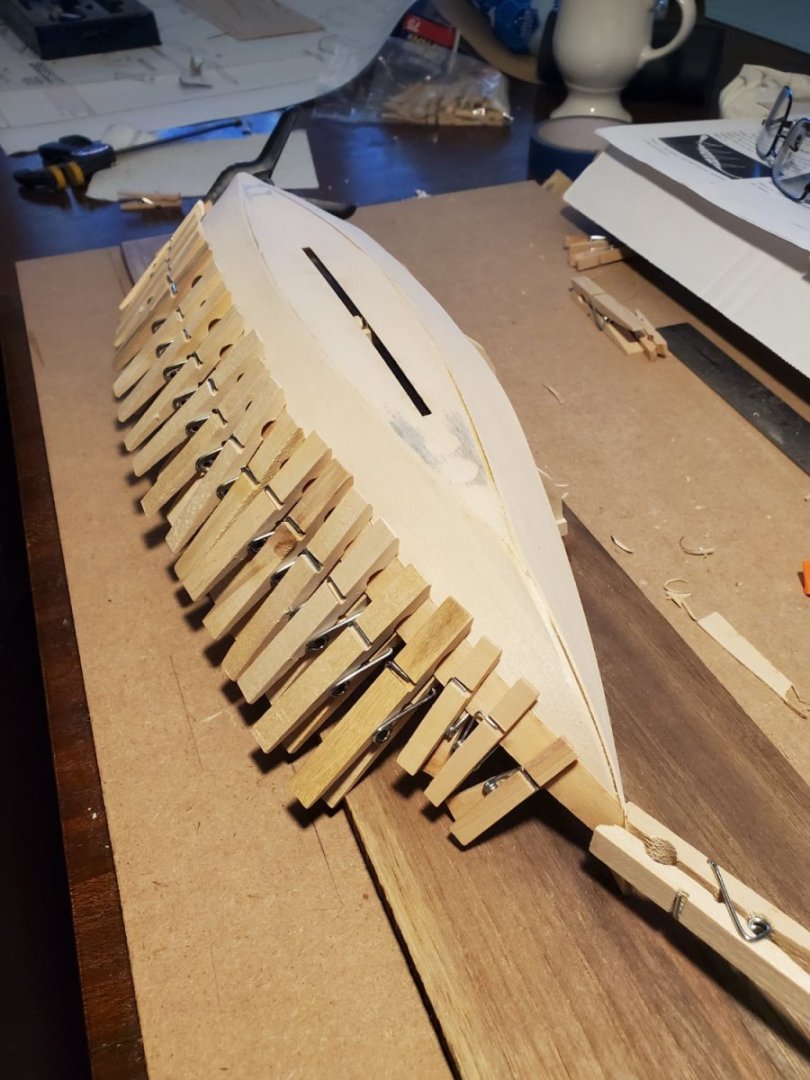

Okay, i glued down the frames to a board and beveled the bottom, stem and transom for better seams and glue surface when installing the the planking.

- 12 replies

-

- Swampscott Dory

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

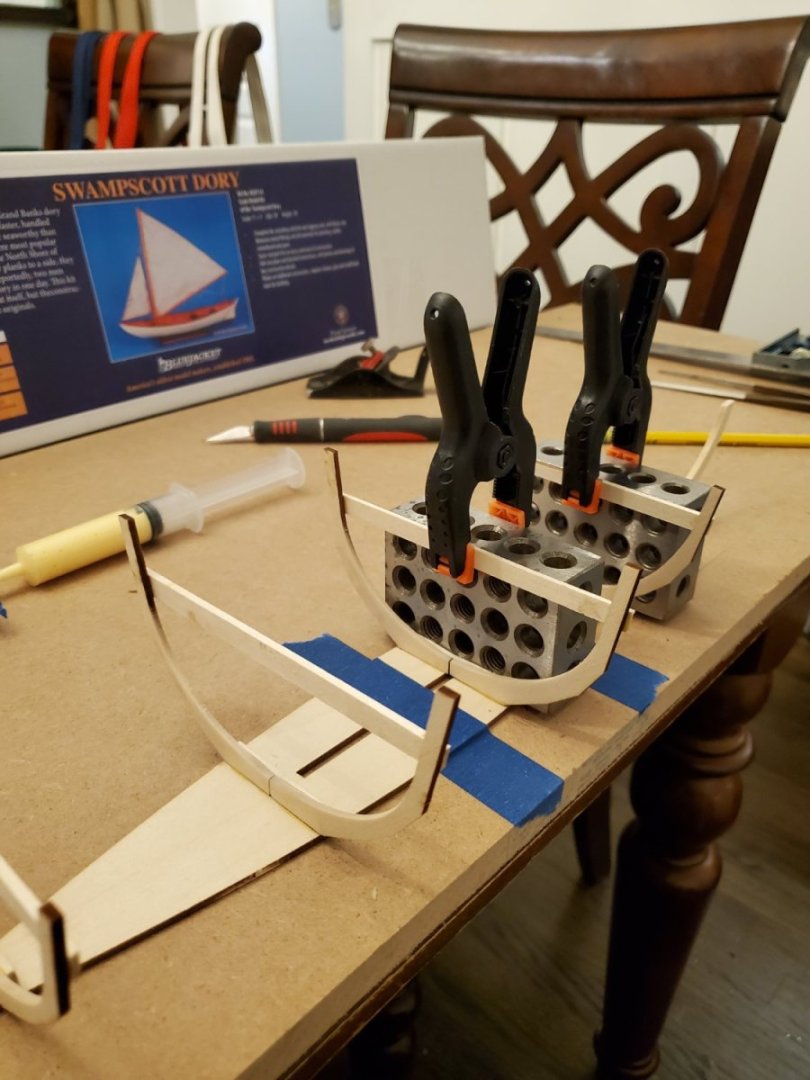

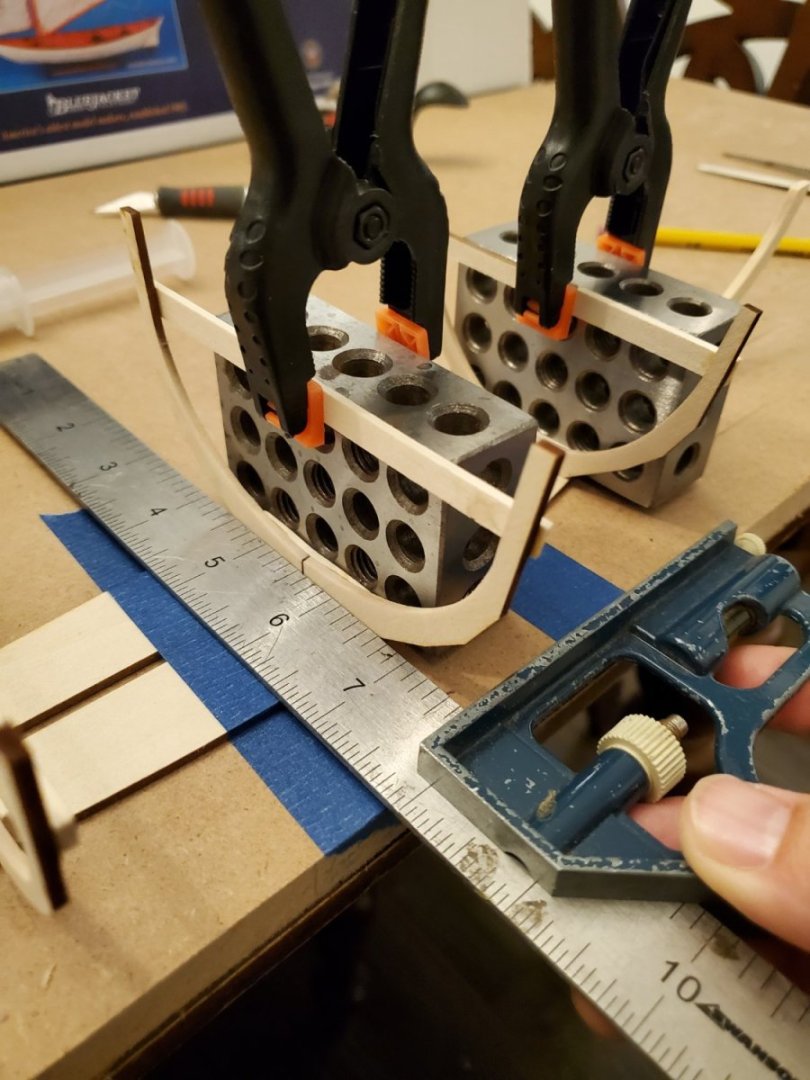

Well, I started my first model. It took a little time to acclimate. The first thing I noticed was that the instructions were very basic. You have to read the detailed plans to answer your questions about how something goes together. This makes sense now that I have spent some time examining the plans and realized it is the separate skill of reading the plans that needs to be developed first to be a successful model builder. For gluing up the frames, I uses some setup blocks I had from my workshop. They are exactly 1x2x3", are perfectly square, and they have good weight to them. I thought they worked out very well. I had drawn a line on my work surface and taped the boat bottom square to the edge of the board. That way, I could use a square to make sure they placed exactly square to the centerline and each other.

- 12 replies

-

- Swampscott Dory

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Steve1970 reacted to a post in a topic:

Greetings from New Jersey

Steve1970 reacted to a post in a topic:

Greetings from New Jersey

-

Steve1970 reacted to a post in a topic:

Greetings from New Jersey

Steve1970 reacted to a post in a topic:

Greetings from New Jersey

-

Steve1970 reacted to a post in a topic:

Greetings from New Jersey

Steve1970 reacted to a post in a topic:

Greetings from New Jersey

-

Steve1970 reacted to a post in a topic:

Greetings from New Jersey

Steve1970 reacted to a post in a topic:

Greetings from New Jersey

-

Melissa--thanks! I had looked through your entire build log earlier this week. Lots of info in there--should help me a lot.

-

Thank you all for you warm welcomes. Look forward to getting to know you all.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.