Thanks for the answers and encouragement!

There's always those moments when you are doing something new and you ask yourself, "Is this enough?".

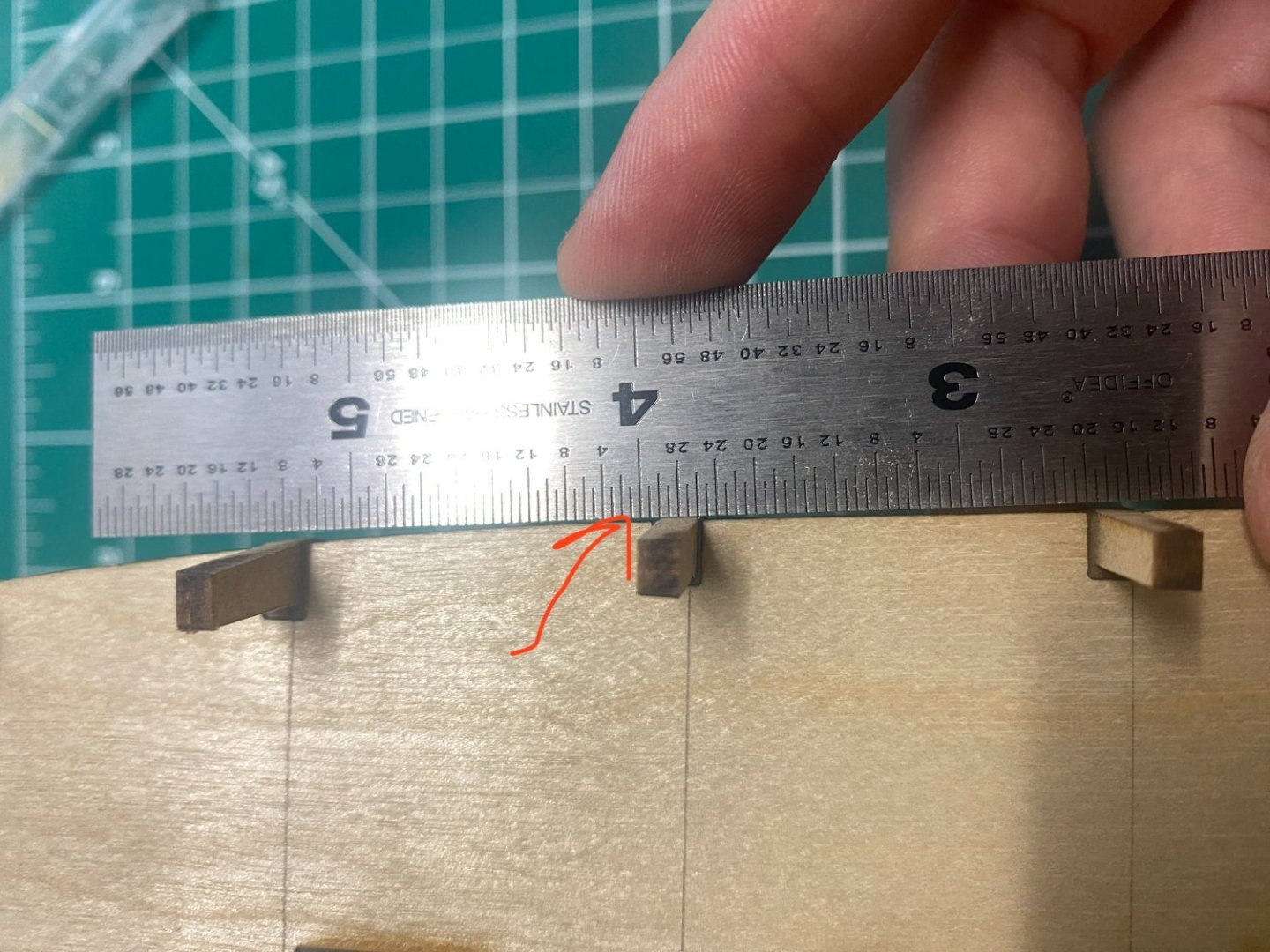

Answer: No. Can't tell if you can see in the picture but bulkhead #9 has a huge gap. Lesson for all modelers/woodworkers. Always test joints/dry fit. I went back and sanded quite a bit more to get everything to lay flat.

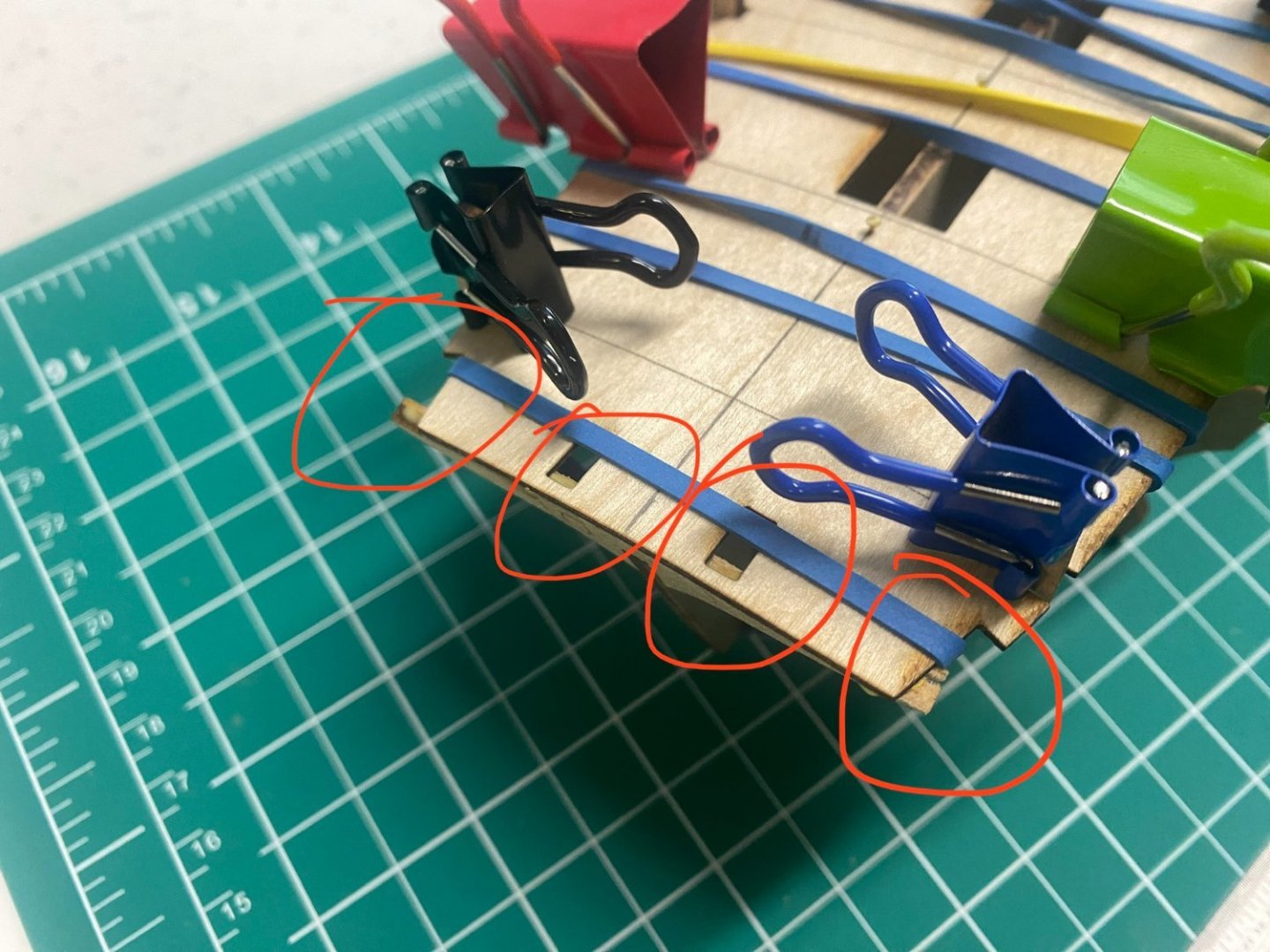

Rubber bands do work really well for this.

This caught my eye. Didn't love how pieces of #10 stood out under the false deck. I thought I did something wrong. I don't think I did, but these did end up collecting glue that I had to then go back and clean out before 11 and 12. Shoulda seen that coming.

Beveling all the bulkheads off really had me worried. I know what I'm trying to do here, just not sure by how much to do it. Never planked before so I don't know how all these angles should lay, especially at the stern and bow. I tried to create a bevel for planking in the MDF material, before gluing on the keel. It would have been easier had I seen what glbarlow did and do it at the very start (before gluing any bulkheads).

Thinking through how I'm going glue on bulwark. Started to notice not all these posts are sitting inside the false deck outline. I'm not sure if I'm allowed to criticize my first kit, but I'm not seeing how I could have avoided this. I drew a center line down the false deck and lined it up strait down the keel. The false deck is flat and tight to every bulkhead. It just seems there's a little too much play and some of these seem too proud on both the starboard and port side. Would love thoughts if I'm missing something. Either way, went back and filled everything as needed. Bulwark should fit nicely.

Seems like most used this method, but not everyone. I'm not sure I think it's best. My bulwark came out fine overall, but not as precise as I would have liked, especially towards the bow. Bending the last few mm's that go into the prow proved difficult with just closely set nails. I'd probably try one of the different methods out there next time.

Nonetheless it's on. Binder clips works well. You can see I tried pins. Rather useless I think. I predrilled and tapped them home with a peen hammer, but I'm thinking this is too cumbersome for model work. I guess that's why they have pin pushers?!

I'm noticing that these binder clips are damaging/denting some of the softer wood, something I think should be fine at this point but have to find a solution for when I start clamping other show wood.

Overall I'm pleased with the learning and progression. The always present doubt of "Is this right?" sometimes get's in the way, and there's always that tension of 1) this is the first one and is a learning experience and 2) I want it to still be as good as I can get it.