mysticlee

Members-

Posts

33 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mysticlee

-

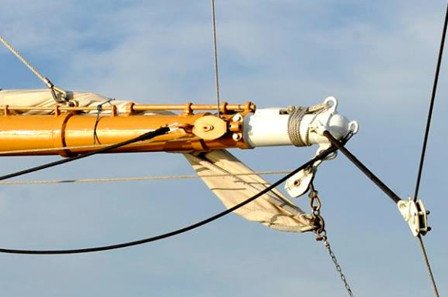

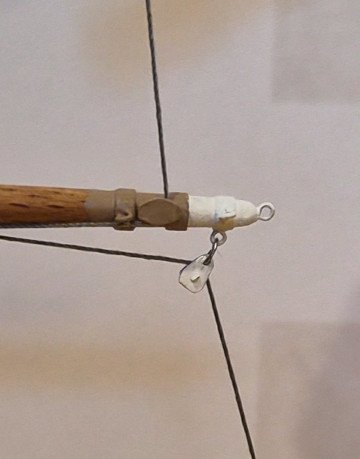

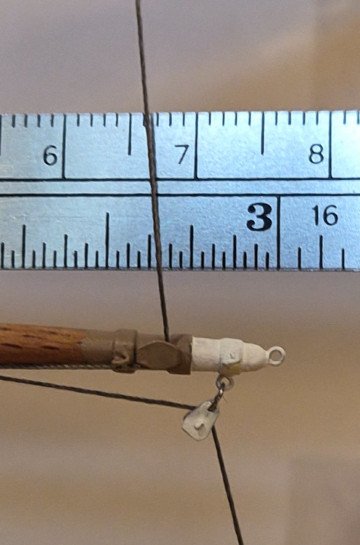

As previously mentioned, the Eagle uses metal blocks for guiding wire ropes for sheets, clews, halyards, and braces. The working ends of the wire ropes eventually connect to wooden blocks that guide fiber ropes down to the deck for the cadets to handle. Below is what the upper topsail yard/yard arm looks like on the Eagle. I experimented with several methods of fabricating metal blocks like the two white ones shown in the photo (one for the clew, and the other for the brace), and settled on using pieces of sheet aluminum for the sides, a piece of a straight pin for the axle, and a loop of wire sandwiched between the sides and around the axle for the sheave. I used CA to glue all the pieces together. It's not intended to be a working block, just to look like one. I drilled a hole at the end for use in connecting the block to either an eye attached to a yard, or to another wire rope (or in the case of some of the braces, a piece of wire simulating a length of metal bar). I'll be using gray thread to replicate the wire rope. I made several sizes of blocks, wanting to keep as close as possible to the scale size of the actual blocks. I estimated the smallest ones (which is the majority of the blocks) are between 6 and 9 inches long, so to scale would be 1/16" to 3/32". I was able to make decent ones at 3/32" but the attempts at 1/16" were unacceptable. The largest ones will be 1/8". I previously developed a method, in post #28, for making the sheet sheeve that is attached directly to each yard, as shown in the photo above. I decided to make a test yard/yard arm with the metal blocks, sheet sheeve, and attachment points (eyes) for the brace, foot rope, and Flemish horse. I omitted the eye on the top end of the yardarm, and haven't decided yet on how to replicate the jackstays on top of the yard. The photos below show my test yard/yard arm (which is suspended by the arms of a Quad Hands, not visible in the photo). The size of this test yard is actually a bit smaller than the size of the royal yard, so I should have no problem constructing all of the yards with the various attachment points. I ended up using thin blue masking tape for the metal bands around the yard at various places. The eyes are formed from 28 gauge wire and fastened using CA in hand-drilled holes. First I painted the yard/yard arm with two coats of shellac, lightly sanded, and then painted the yard arm and metal block white, and a portion of the yard light tan color (two coats of Testors enamel paint for each color; I'll probably go with a third coat for the actual model since the paint is still a little thin as is evident in the photo). For production, I'll use a color for the yard (and many other parts of the model) that is much closer to Coast Guard spar; True North Precision Paints has a color they show as an exact match, and I have some on order...will be testing once the order is received. I ran two threads on the test jig to approximate how the sheet (from the sail above) and the clew (for the sail attached to this yard) will show in the model. The hardest part of putting the parts together was attaching the metal block to the eye, using a small loop of 28 gauge wire. I'm happy with the overall look of the yard/yard arm, and especially of the metal blocks, so I'll continue making the ones I need (8 made so far, 62 to go). That's all for now. Lee

-

Thank you rwnw for the links to the Eagle Plans (and sorry for the delay in responding, I've been distracted by other projects around the house until recently). I already had found the plans (per my post #30) and found the sail plan especially useful. I didn't do anything with the body plan or engineering arrangement since my build is already well along, and I'm not inclined to make changes to the hull at this point. In the past several days I've been completing my tests in constructing metal blocks that are used extensively on the Eagle (since it uses wire ropes for much of the running rigging), and also doing some preliminary paint tests. I'll have more on these efforts soon. That's all for now, Lee

-

Time to report on my latest work...upper crosstrees. First is a picture of the Eagle's mainmast upper crosstree, viewed from below. The structure is metal beams/bars (painted Spar color), with the area surrounding the main and topgallant masts covered with wood deck planks (hard to see in the picture). Note how the base of the topgallant mast extends below the crosstree structure, which allows for lowering the mast when transiting under bridges, etc. Also note the two futtock shrouds on each side, and the corresponding turnbuckles for the topgallant shrouds that are attached to the futtock shrouds where they pass through the crosstree and decking. Several standing rigging lines (main topmast stay in front; topmast shrouds from below, etc.) pass through openings on either side of the main mast and are secured around the mast (not visible in the pic). My construction plan is shown below, along with pictures of the crosstree after fabrication. The metal frame pieces, shown in blue on the drawing, are made of copper wire, bent to the shape shown (for the outer piece), hammered flat, and filed to smooth the sides and ends. The tan area shown in the drawing is made of thin brass sheet, with holes cut for the two masts and two openings for standing and running rigging. Tiny holes drilled are for the futtock shroud terminating in eyes above the crosstree for attaching the turnbuckles. In order to provide a secure attachment to the main and topgallant masts, I made a pair of mast bands (one below the crosstree, the other at the top of the mainmast above the crosstree) by bending a strip of brass around both masts, pinched in the middle, with a 1/16" space in between to separate the masts. The copper wire pieces and the mast band were then soldered to the bottom of the brass plate. Two side supports were also soldered to the brass plate. The decking was made from basswood, scored to resemble decking, and with holes cut to match the holes in the brass plate. Here's a few pictures of the crosstree test-fit to the masts. Still a bit of clean-up to do (such as removing the solder resin), and eventually, painting. That's all for now. Lee

-

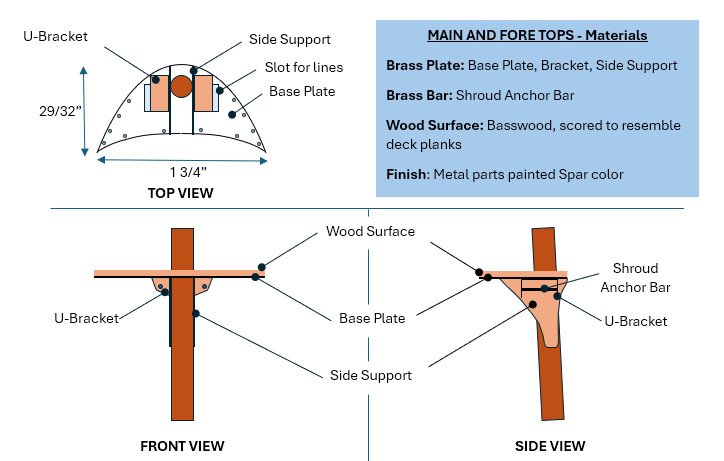

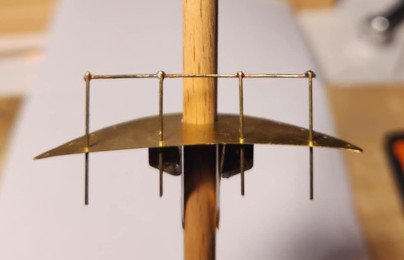

Finally back to work on the Eagle model! As noted previously, the ship's tops are constructed of metal framework with a wood plank surface. After considering several ways to model the tops, I settled on using brass sheet metal for the base plates and side supports, thicker brass metal for the U-bracket, and basswood on top. My plan is shown below: I needed a way to anchor the main and fore shrouds underneath the top surface, and it needed to be strong enough to withstand the pull of the shrouds when they are pulled taught. After forming the U-brackets and filing their profiles as shown in the front view, I soldered the U-brackets to the port and starboard sides of the the base plate bottom, then soldered the side supports to the base plate and U-brackets, followed by soldering the anchor bar through holes in the U-bracket. I drilled a small hole for the mast opening, just enough to use a round metal file to enlarge it to just fit the mast. Same with the wood surface. I also drilled holes in the base plate for the upper ends of the futtock shrouds to pass through the top and as anchor points for the topmast shrouds. Holes along the back edge of the top are for a safety railing, on which is fastened rope netting on the ship. I was originally going to use wood veneer for the wood surface, but I found that it wasn't stiff enough to make a rigid structure (the brass sheet has a lot of flex). So instead, I used 1/16" basswood, and to simulate planks, I scored the top surface using a blunted straight pin along a ruler, following several suggestions and techniques I found online. Below are pics various view of the base plate/bracket assembly, wood surface, and railing, test fitted to the mast. I'll clean up the solder resin before painting the various parts (railing is white, all other metal parts are spar color). I'll also stain the wood surface to resemble the wood on the ship, and paint the edge white (as it was in 1972 on Eagle). I haven't glued the wood surface to the base plate yet. Once that's done, I'll drill through the holes in the baseplate through the wood surface. I'll also drill and file the slots for the running rigging at that time. The railing bottoms will be cut flush with the bottom of the base plate at final assembly. When I (eventually) get to mounting the masts to the ship's deck, I'll tie the shroud threads to the shroud anchor bar and seal with a touch of CA, and leave the ends long until I'm ready to fasten the lower ends to the turnbuckles attached to the deck. Then I'll add the futtock shrouds, since once they're installed, it will be hard to reach the shroud anchor bar. I already fabricated the top for the mizzen, which is more simple and smaller (about 60% the size of the main and fore tops). The mizzen top has no railing, and no slots for running rigging. Next will be the upper tops/cross trees, once I finalize the plan/drawing. That's all for now. Lee

-

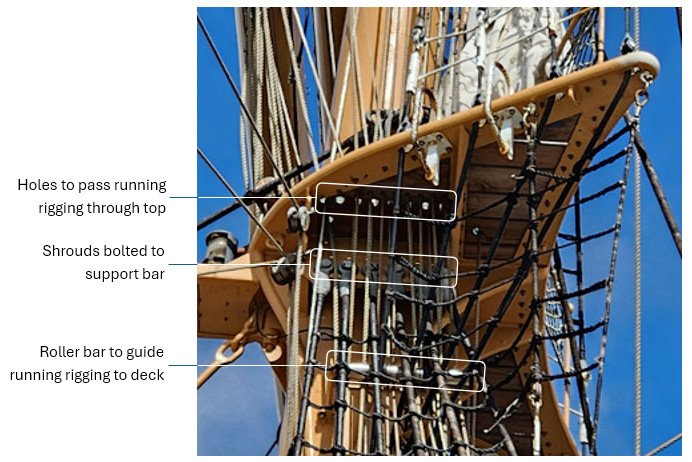

The tops on the Eagle's fore and main masts are made of metal framework with wood planks on the upper surface, as shown in the below picture. Highlighted in the picture are: 1. Holes in the planks to pass the running rigging (both wire and fiber rope) from above (similar to lubbers holes on 19th century and earlier ships) 2. A roller bar (behind the shrouds) to guide the running rigging down to the deck 3. Shrouds bolted to a support bar Other items visible in the picture are the four futtock shrouds, and the turnbuckles for the topmast shrouds that are attached to the tops of the futtock shrouds as they pass through the metal framework and planks. The top on the mizzen mast is similar but smaller. I'm developing a plan for modeling the key features of the Eagle tops using brass sheet metal for the metal pieces, and wood veneer for the planks. More on that in an upcoming post. BTW, the upper tops/crosstrees are also constructed of metal framework and wood planks, but have a different design. I'll discuss the details and modeling plan for those in a separate post. That's all for now, Lee

-

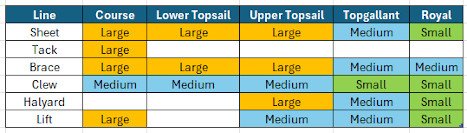

It’s been a month since I posted on my build log…other projects compete with my ship building (yard work, roof repairs, new hardwood on the second floor, maintenance of my family history website, golf, etc.). But I have done some work on the model. I finished my research of the sizes of standing and running rigging lines, using several sources, including: Horst Wessel (now USCGC Eagle) blueprint that I discussed previously; Underhill's Masting and Rigging the Clipper Ship & Ocean Carrier; Rigging spreadsheet at Model Ship World for size of blocks and diameter of ropes; Lloyd’s standard specification for standing and running rigging; and Size of lines used by a few other modelers for model ships of similar scale to mine. After factoring all the data from the various sources, I have selected the following thread sizes and sources for the various standing and running rigging: My selection of the black and tan thread sizes was driven in part by the selection of dark gray thread from WAWAK for the wire running rigging. WAWAK has several sizes of Gutermann Mara threads, but not all of them come in dark gray. Once I found two sizes that were acceptable, I selected sizes for the black and tan threads from Ropes of Scale, keeping in mind that the dark gray threads, representing wire running rigging, should be smaller than their corresponding fiber running rigging. And the black threads for the standing rigging (also wire on the real ship) should be similar or a bit larger than the running rigging. Note the oddball entry in the above table: linen thread. When I first started this ship model in the 1970s, I purchased a 50-yard spool of Ashaway Cuttyhunk linen line, Zane Gray No. 3, Twisted 50’s LEA, as a replacement for the fuzzy thread that came with the model. From what I’ve read, linen was the thread of choice for ship models until polyester (Gutermann, etc.) became widely used, so I wanted to make use of this thread if it would blend with the other threads in both size and color. I couldn’t find any specification that told me the diameter of the linen line, so I counted the 60 turns on the one-inch wide spool, resulting in a diameter of 0.0167 inches, a close match to the large size running rigging. It’s light tan in color, and I’ll find out if it will blend well with the tan thread from Ropes of Scale when I receive that line. I summarized the relative sizes of running rigging lines for the square sails as follows: For simplicity, I have decided not to model buntlines or leach lines, and I’m still on the fence regarding whether to model no sails or furled sails (I’m leaning towards the latter). I’m still working on the threads needed for the stay sails, gaff and spanker, but I’m limiting which lines to represent for these sails, probably to only halyards. Once I determine the total length of thread I need for each size, I’ll place my orders for the thread. I’ll conclude with a note about my overall work plan. You’ll note that I haven’t painted or assembled any of the deck fittings that I fabricated in the past weeks and months. The majority of the deck fittings, and all of the masts, yards, tops, crosstrees, booms, and bowsprit will be painted in spar color (with other colors as accents, such as white for the yard arms). Spar is not a standard model paint color; and I had previously painted several items on the model with a spar color that I custom-mixed using a combination of off-the-shelf colors. I didn’t record the formula I used, so I’ll need to experiment a bit to replicate the spar color. Once I get the right shade, I’ll paint all the affected parts, meaning I’ll need to have all the parts ready for painting at that point. So my next work tasks will be to fabricate the tops and crosstrees, then finish the masts, yards, and booms with their attachment points. I’ll also be fine-tuning the holes in the deck for each of the three masts to be sure they have the correct rake, and that the mounts are tight (without glue). When I get into painting, I’ll be re-painting the hull, for two reasons. First, the white paint above the waterline has several smudges and thin spots. Second, the waterline is tilted (not sure why I painted it the way I did back in the 70s). I’ve already determined how it needs to be re-positioned, parallel to the keel. The black boot topping will also need to be repainted. After painting is complete, I’ll begin assembly, first with deck fittings, followed by the masts, then the standing rigging, yards and booms, and finally, running rigging. That’s all for now. Lee

-

As I mentioned in my previous post, a significant portion of the sheets on the Eagle are wire rope, starting from their attachment to sheet chains fastened to the sail clews, then routing through the sheet sheaves and on down to wood blocks. In photos of the ship (and in person), the diameter of the wire rope is noticeably smaller than the hemp rope that runs through the wood blocks and eventually to the fife rail or other deck fixture. Any recommendations for how to (or whether to) model the wire rope segments? I'm wondering if it would be an acceptable compromise to treat them as normal rope, and size them accordingly (i.e., same size and color as other rope, rather than smaller diameter and different/gray color resembling wire rope). The same issue appears on portions of several other lines of running rigging, where the Eagle uses wire rope instead of regular rope (clews, halyards, lifts, etc.) For that matter, since wire rope is used for all of the standing rigging, and is in some cases of smaller diameter than some of the hemp running rigging, will it look strange to model the standing rigging with smaller thread than some of the running rigging? I got access to an online copy of Harold Underhill's Masting and Rigging the Clipper Ship & Ocean Carrier, which contains tables for steel wire standing rigging, and approximate size of running rigging (hemp and wire), for various size ships (by registered tons). The Underhill tables correspond fairly well with the standing rigging sizes I previously identified on the Eagle blueprint. I'll use the tables to determine the size of all the running rigging for my model, once I decide whether or not to model wire rope as wire or hemp. That's all for now. Comments and recommendations are very welcome. Lee

-

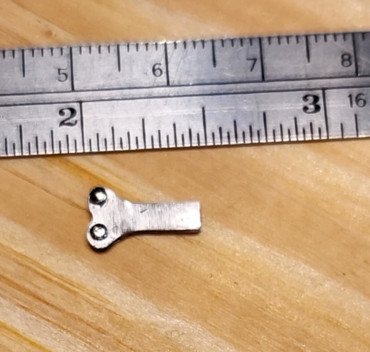

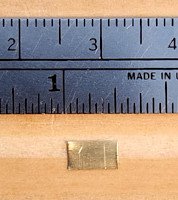

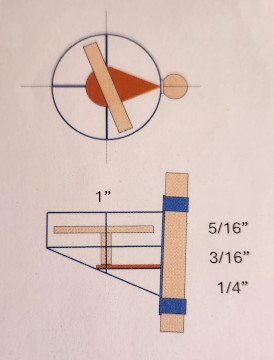

Metal sheet sheaves are used on each of the Eagle's fore and main yards (except the royal yards). The sheet sheave attached to the main course (for the lower topsail sheets) is shown below. On the Eagle, chain extends for about 6-8 feet from the clew of each square sail (except for the courses), and then connects to a wire rope, which leads through each side of the sheet sheave and on down to where it is attached to a double or triple wood block. The block and its opposing block are connected with hemp rope that terminates at the fife rail (the exception being the course sheets). I tried various ways to model the sheet sheave, and eventually I found inspiration from George K. (gak1965) and how he crafted the sheet blocks on his build log of the Flying Fish (1:96), entry #442. Whereas his was made of pieces of brass sheet with holes drilled for three small brass nails, I used aluminum sheet metal (slightly thicker than the brass sheet he used), and drilled only two holes for two straight pins. I inserted a piece of veneer between the two layers of metal, and used mini-files to shape the structure. (I tried using my Dremel tool to shape the metal, but it's a new tool for me, and I wasn't getting the results I expected.) I chose aluminum because it more closely resembled the steel used on the Eagle, and it was a bit more rigid than the brass sheet I have for other components. Below are a few pics of my construction process. The first pic shows the rectangles of metal, with a pattern taped on, that I drew in MS Word. Second pic shows the sheave after shaping the metal pieces. Third pic shows the sheave on edge; note the layer of veneer that provides enough of a gap for the line to run through (eventually). Last pic shows the size of the sheave, about 1/4" wide by about 1/2" long. I'll cut the sheave to length (about 3/16") before attaching to the yard with CA. I'm happy with the process and results, so I'll proceed to make the additional 7 sheaves for the other yards. That's all for now. Lee

-

I finally finished updating my spreadsheets for the sizes and attachment points on each of the masts and yards, per the Eagle drawing. Besides the detailed dimensions of the masts and yards in the Eagle rigging drawing, two other key measurements are shown. 1. Mast rake (German: "mastfall") is specified for each of the three masts: Fore: 52mm per 1 meter Main: 70mm per 1 meter Mizzen: 87mm per 1 meter These convert to 3.0, 4.0, and 5.0 degrees respectively. Now I can accurately set the rake on each of the masts. My estimates based on photographs were in the ballpark, but nothing beats the design specs. 2. Standing rigging (wire) rope sizes. There are six different sizes listed on the drawing (50, 60, 70, 80, 90, and 100mm), the largest (100mm) for the fore and main topmast stays, and the smallest (50mm) for the mizzen upper backstay. The diagram also shows that the primary fore/aft stays for each mast are double ropes (which is evident in vintage and current photos). Now, are these figures diameters or circumferences? The main shrouds are listed as 90mm. If 90mm is a diameter, it converts to 3.50 inches in diameter. If 90mm is a circumference, it converts to 1.11 inches in diameter. Looking at a closeup of two cadets grasping the shrouds, I'd say the shroud diameter is almost certainly 1 inch rather than 3.5 inches (also note that the shrouds are served with small stuff; I'm not planning to model that). Rather than trying to scale and use six different line sizes, I'll use the two most prominent sizes, 70mm and 90mm, for all of the standing rigging. These scale (102.2) to .22mm (0.009 in.) and .28mm (0.011in) respectively, which seem considerably smaller than I would have expected. I'll address the sizes of running rigging later, but the above picture gives a clue as to the size of some of the lines (those pictured are clewlines and buntlines). Note how much smaller they are compared to the shrouds (half or less in diameter). I may need to re-think the scale size of lines for the standing rigging as compared with the running rigging. In any case, I plan to use black line for the standing rigging (rather than dark brown), and tan (or similar) for the running rigging. That's all for now. Lee

-

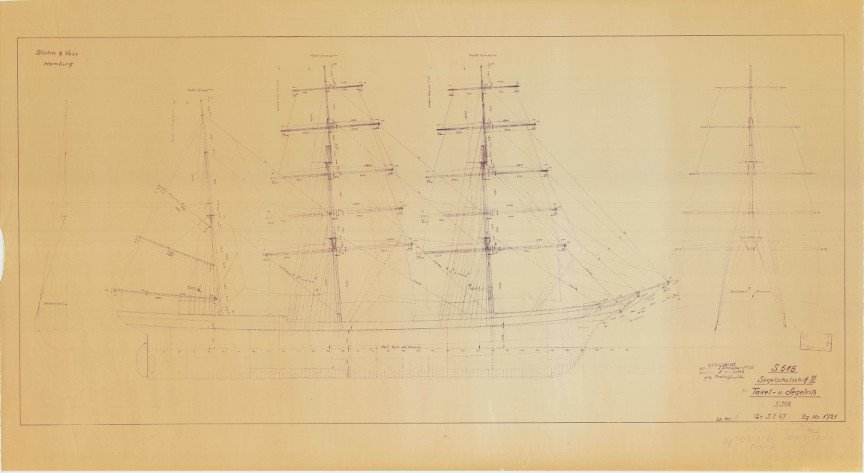

One thing my project was sorely lacking was actual plans of the Eagle. I've come across several of the drawings by Harold A. Underhill for the Gorch Fock (sister ship), with sections showing how the Eagle differs from the GF, but those documents didn't provide dimensional details. I did come across plans for a model of the Gorch Fock that had considerable detail, but many of the sizes and dimensions didn't match up with what I already knew about the Eagle. Well, while browsing the internet recently for additional Eagle details, I found a reference to drawings available from the National Archives. It took a while to search the NA catalog, but I finally found a set of three drawings of the Eagle, held by the War Department, Department of Defense, Department of the Navy, 9/18/1947: 1. Body Plan, U.S.C.G. Eagle, ex German Training Vessel Horst Wessel, created by US Coast Guard naval architects, dated 2 September 1947 2. Inboard Profile, Horst Wessel, created by Blohm & Voss, Hamburg (the original builder), dated 6 October 1936 3. Rigging / Onboard Profile, Segelschulschiff III [which is Horst Wessel, later USCGC Eagle], created by (apparently) a German naval architect, dated 2 January 1937. All three drawings are listed as in the public domain by the Archives. The Rigging drawing is highly detailed, with dimensions of each segment of the masts and yards, in millimeters, along with the sizes of the standing rigging lines, also in mm. The pic below is a low resolution copy of the drawing. Per this drawing, the length of the ship, dimensions of the masts, yards, booms, and bowsprit, and other particulars, all match extremely well with the published specs of the Eagle. This now allows me to accurately finalize the dimensions of the various masts, yards, etc., on my model. I've already determined that two of the yards on each mast (topgallant and upper topsail) are considerably short, and will need to be remade. The bow also needs a small adjustment so that the bowsprit conforms to the drawing. I'm also updating my spreadsheets for this new-found information, especially the standing rigging details. All for now, Lee

-

In the past week I've been updating my spreadsheet for placement of attachment points on the yards and masts. I came across an issue with the standing rigging. The original model plans called for eight stays fastened for each of the port and starboard sides of the fore and main mast. I knew when I started the model in 1977 that that was wrong (as are many other details shown in the plans), and instead reverted to the standing rigging configuration as shown in my copy of Eagle Seamanship (the cadet's bible for learning all things Eagle). It names 14 stays as follows: Shrouds (6) Cap Stay Topmast Backstays (3) Topmast Cap Stay Topgallant Backstays (2) Royal Backstay The diagram in the book shows that the royal backstay and one of the topgallant backstays originating from the same point, and so in my ignorance at the time, I mounted 13 eyes on the model for the attachment points, as shown in the below pics (port-side fore stays on the left, port-side main stays on the right). Of course, I've confirmed in both old and recent photos that there are indeed 14 stays, each with its own attachment (i.e., a turnbuckle attached to a stanchion fastened to the deck through the waist pin rail). What to do? I can see three possibilities: 1) Add an eye either at the aft end of the row, forward end, or somewhere in the middle of the row of eyes. Not a problem for the foremast stays, there's room at the aft end to add an eye with the same spacing as the others. But there's no room at the aft end of the row of mainmast stays, and adding a stay in the middle would, I think, look ugly (that's my technical term for irregular spacing). In the alternative, adding an eye at the forward end of the mainmast stays would put that stay (the first of the six shrouds) forward of the mast...that would be noticeable and certainly not like the actual ship...but relatively easy to do. 2) Double up two stays on one eye (either two at the aft end of the row, or two somewhere in the middle). This would mean two turnbuckles mounted side by side, which would probably mean one or the other would be at an odd angle and not in line with the stay. Again, ugly. 3) Use modeler's discretion and include only two of the three topmast backstays (all three terminate at the same point under the crosstree, so one fewer wouldn't be a problem). Easy to do, not ugly, and not noticeable to the average person. It would be "our" secret. I'm leaning toward option 3). Any thoughts or suggestions? Lee

-

I've been taking a break from deck fittings to start planning for the masts and yards. The Eagle is a modern steel hull ship, and the yards and masts are also steel, although my model will use wood for those structures (painted spar color). Metal sheaves are used in several places where wooden blocks would be used on wood-hull ships. The picture below shows part of the upper topsail yard and yardarm, with a sheave mounted to the yard to direct the sheet from the topgallant sail above, down and through the sheave, and across the bottom of the upper top yard toward the center. Also note the smaller metal sheave for the upper topsail clew, directing its line also across the bottom of the upper top yard, below the sheet line. I thought I'd try modeling the sheet sheave using brass sheet metal. I cut a 1/8" strip from a sheet of .005" brass, and cut lengths 1/4" long. On each piece, I cut 3 tabs on each end, leaving a 1/8" square within the tabs. Then I cut the outer tabs on each end, leaving a diamond shape with a single tab on each end. I filed the points to a rounded shape, bent the tabs 90 degrees, and cut the tabs short, leaving a little less than 1/32". Using a common pin, I stamped a depression on the inside of the piece, and soldered a short length of 24 gauge wire in the depression. The wire post is inserted in a hole in the yard until the sheave is snug against the yard. This leaves a narrow slot that will accept the sheet line (or chain, as is used for lower yards, if I can find small enough chain), which curves around the wire post. See the pics below for the construction sequence, and showing the sheave test fitted to a dowel similar in size to the modeled yards. The final two pics show the first sheave I made. On all the subsequent ones I cut and filed the tabs a bit shorter to narrow the opening. I made a total of 16 sheaves, two for each of the course, lower top, upper top, and topgallant yards, and ditto for both the fore and main mast yards. The royal yard does not have this sheave, since there is no sail/sheet above. The sheaves will be painted spar color along with the main part of the yard. For the smaller sheave shown in the first pic above, I'm thinking to use a similar technique, but with a second piece as a backing, and tabs only on one end. I'll drill a hole through both front and back pieces, inserting the wire through both, solder the wire on the outside of each disk, and trim/file the wires flush. I'll use a thin spacer (such as wood veneer) in the gap during drilling and soldering. I'll leave tabs long, bend them outward, and shape them into a strap to attach to the yard arm (or in other cases to a line for attachment elsewhere). There's also a double sheave below the center of each yard that redirects the sheet line from each side, downward to the deck. I'll model that sheave similarly. That's all for now. Happy modeling! Lee

-

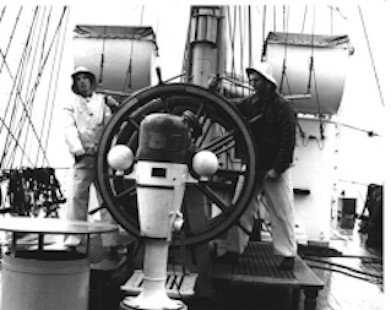

Next is the binnacle forward of the main steering. The 1972 photo below (showing two of my classmates manning the helm) shows the binnacle as it was then (now, all but the hood is boxed in with cherry wood). The size of the binnacle is distorted in this photo due to the angle and perspective. I used actual measurements from my visit to Eagle last fall to craft my binnacle. The body and stem are wood, the balls are round ball head pins, and the support bar is brass. The top hood will be painted brass color, the support bar black, and the rest white. I'll add a base ring before mounting on the model.

-

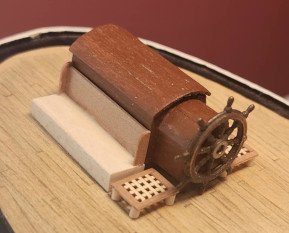

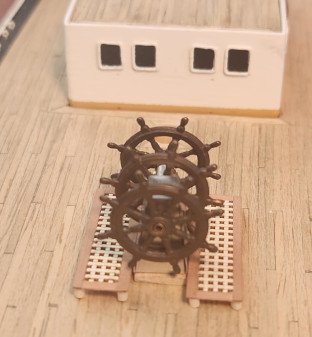

The Eagle's aft steering (called the Captain's Coffin) is shown below, along with my fabrication. The grid platforms match those I made for the main steering. I fabricated the benches using a block of basswood for the lower part, and pieces of veneer for the sides and back. The benches will be stained to match other bare wood components. I'll add cushions later (using material TBD).

-

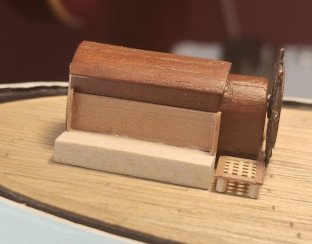

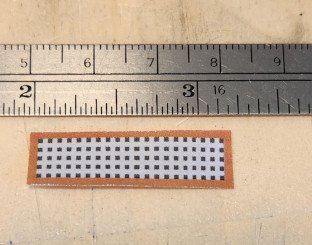

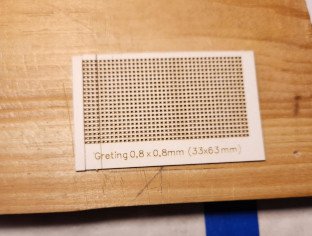

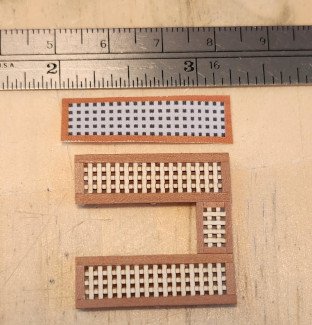

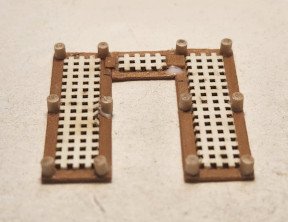

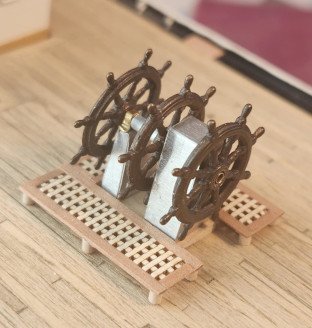

The Eagle's main steering consists of three ten-spoke ship's wheels on a common shaft, with a large support between the forward and middle wheels (which houses the gears), and a small support between the middle and aft wheels. Cadets man the steering, standing on grid platforms on both sides. A small section of grid platform aft of the wheels connects the two side platforms. The pics below are from last fall; the wheels and platforms have not changed over the years (although the aft platform was moved out of view in the right picture below). I had two issues in constructing the ship's wheels and platforms. First, what to use for the wheels? The ideal model wheel would be 18mm in diameter (including the spokes, equal to 6 feet at my model's scale), and would have 10 spokes. And I needed four of them (three for main steering, one for aft steering). The wheels that came with my model are brown plastic, about 13mm diameter (much too small), six spoke, and ugly. I was excited to find the laser cut ship's wheel kit at the Syren Ship Model Company website...10 spokes, wonderful detail, but alas, 15/16" diameter (about 24mm). Unfortunately, being 33% larger than my desired size, I had to look elsewhere. After finding only a few other possibilities, I ended up buying 20mm wheels made by Amati (unfortunately, larger than I wanted, and only 8 spoke, but they're the closest I could find. The second issue was how to fabricate the grid platforms. Again, I found nice boxwood grating kits at Syren, with 3/64"/1.19mm gratings. That grating size would have been larger than desired, but I would have settled for that, had their grids been thinner. Instead, I found .8mm x .8mm laser cut cardboard grating at ModelNet (UK), still larger than desired, but the absolute smallest I could find. While I was waiting for delivery (several weeks), I drew and printed a rough pattern, and planned the dimensions for all of the grids (include two needed for aft steering). Once the grid material arrived, I cut sections to the appropriate size, and attachd strips of veneer for the edging. I used small pieces of dowel for the feet. I glued the three sections of grid together with PVA, and reinforced the joints underneath. Shown below are the pattern and grids. I made the wheel supports from pieces of sheet metal around a wooden core. As a compromise (designer's choice), I omitted the large openings that show on the actual supports, and the fore-aft dimension of the smaller support is a bit larger than actual. The larger support will be painted a brass color (If I get ambitious I may re-make it using brass metal), and the smaller support will be painted spar color. The borders of the grid platforms will be stained to match other bare wood components. I may stain or paint the grids too, as long as I can do so without filling in the holes in the grids. Testing on a few scraps will tell me what can be done.

-

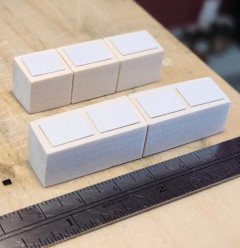

A set of storage bins are mounted on the railing along each side of the aft foredeck, overhanging the narrow part of the waist deck between the galley, scullery, etc., and the railing, ending forward at the ladders up to the foredeck. In 1972, the bins on the starboard side were shorter than those on the port side. The pics below facing aft, starboard on the left, port on the right (the latter pic showing only part of the bins) are from my Europe cruise in 1972. I modeled these with basswood. Each set of bins is one piece of wood, with lines scored to divide the sections. The lids are low-tech, pieces of card stock cut to shape. All will be painted white (they look white in the pics, that's just the lighting), and eventually affixed to the railing.

-

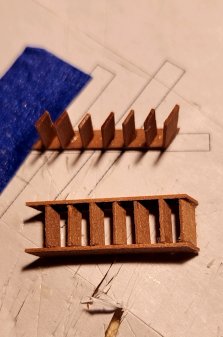

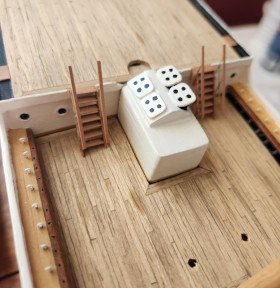

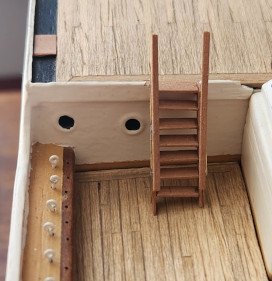

The Eagle has four ladders (staircases for landlubbers): two (port and starboard) from the foredeck to the waist (main deck), and two (port and starboard) from the waist to the mizzen deck. The pictures below that I took on the Eagle in August 2024 show a closeup of the starboard aft ladder. As best I can tell from pics I took in 1972, the ladders have not changed. A plug for the Eagle permanent crew: I was given topside access to the Eagle one day in the fall last year, before normal visiting hours, to take as many pictures as I wanted. Many thanks! I had the good fortune of a friend giving me a box of 50 sheets of furniture veneer samples. The pearwood sample was a nice color with very straight grain. I used it for constructing the steps, stringers, and railings. The support bars are made from 24 gauge wire soldered together. The bars were glued to the wood components using CA. The pics below show the steps being built, and the completed steps test fitted at the aft end of the waist. I'll be finishing the wood with stain and (probably) poly later, along with all other bare wood fixtures. I made use of the veneer in a few other fixtures, as I'll show in upcoming posts.

-

Thank you Kenneth! The Eagle sails with two motor surf boats housed on davits. The model of motor surf boat has changed over the years (generally about 30 foot), but I was able to identify the model that we had in 1972. I used multiple photos to determine the size and configuration of the davits and boats, and crafted them from basswood as shown below. The davits are not quite finished; I still need to add the hand-crank handles. The davits will be painted with Coast Guard spar color, as will the interior of the boats. The boat hulls will be totally white (no racing stripe!), with black trim along the rub rail. The rudder is temporarily fitted in the picture below, and the propeller and shaft are not shown but have been fabricated. I'll be adding eyes fore and aft on the boat deck for the lifting points. Another little detail was the ship's bell. I had several photos of the bell, both from 1972 (shown below) and current; it has not changed over the years. I attempted to make a bell from a piece of copper grounding wire. It was looking decent, although not how I really wanted it to look. About that time, a friend offered me a ship's bell from another model of very similar scale, so I used that instead, and made the support pole and bracket. The bell will remain brass, while the pole and bracket will be painted spar color. More to follow!

-

The barque Eagle has steel masts and steel yards, and metal bands are used at various attachment points (which are either eyes or tabs in most cases). Examples are shown below. On the model, the diameter of masts and yards range from 7/32" (on the masts) to 3/32" (on the royal yardarms). The widths of the various bands will scale (actually, wider than proper scale) to as small as 1/16", or maybe 3/32". I'd like to fabricate bands wherever there's an attachment point (as opposed to omitting the bands entirely), so the question is how to fabricate? I searched on the forum and found modelers using several techniques such as soldered brass bands on larger models, and other materials glued on smaller models (including car detailing tape, masking tape, electrical tape, circuit layout tape, paper, etc.). Considering the size of my model, I wanted bands that would look relatively realistic, easy to fabricate and install, and reasonably easy to drill through (with a #78 or 0.016" bit) without distorting the band. I tested two materials. First I used 1/16" wide strips of heavy bond paper, affixed to a 1/8" test piece using PVA glue, then drilled and installed two test eyes. These were easy to make, although gluing required some fiddling to keep the bands straight. Drilling through was easy enough, although the end of one of the bands lifted when I drilled. See below. I'm wondering if a coat of shellac before drilling would hold the band together. This might possibly be an acceptable method, especially once it's painted Coast Guard spar color (as all of the masts and yards will be, except white for the yardarms). Next, I tried fabricating a band using a strip of aluminum flashing (because I had some available). I didn't glue it in place for this test, but I would use CA if I end up using this method. This looks a lot nicer, although the metal may be thicker (i.e., stands out more from the mast) than it should be. Bending the strip into the proper size circle was tedious (and would be even more so for the smallest size I need), and drilling was more difficult (these tiny drill bits don't drill through metal very well). I'll try testing a few other materials to see if I can improve on the results above. And I'll continue to document other fittings that I made over the past seven months.

-

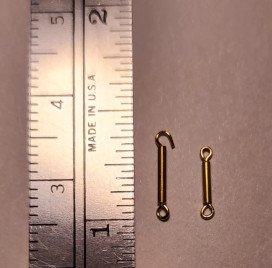

It's been far too long since I last posted progress on my Eagle model. Over the last seven months, I've been working on many of the deck fittings, and my amateur modeling skills has made it slow going (learning as I go), but I've been particularly negligent about documenting my work. I'll take the time over the next several days to catch up on what I've accomplished so far. As I showed on an earlier post, I was making turnbuckles from brass tube and wire. I finished 80 long turnbuckles (for the lower shrouds and stays) and 40 short turnbuckles (for the upper shrouds and bowsprit stays). Samples are shown below. One end of each turnbuckle is left open so it can be attached to the corresponding attachment point on the deck. I needed to fabricate eyes for several deck attachment points (other than ones that I had already installed), and I elected to use a different method than I used previously. Having searched in this forum for various techniques, I settled on a twisted stem technique, expecting it to have stronger holding power, and being quite easy to make. I looped a length of 26 gauge brass wire around a straight pin (anchored to my work surface), and hand-wound the ends to form the eye using a wooden handle drill chuck to hold the ends. I made 16 of these eyes, as shown below. I'll cut them to length when I drill the holes, and I'll use CA to glue them in place.

-

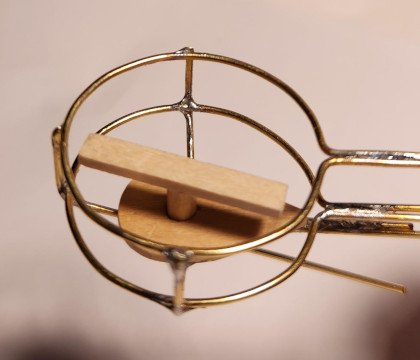

Taking a break from my production line of turnbuckles, I turned my attention to the radar enclosure which is mounted on the foremast (below the fore yard). Using numerous photos both from my archive and from current sources, I determined the size and shape of the enclosure for my model. The radar enclosure in 1972 consisted of a pair of horizontal concentric circles of steel bars about 8 feet in diameter, separated by about 30 inches, and connected by several vertical bars, and about 20 inches below which was a small platform connected to the above circles with additional bars, to support the actual radar sweep mechanism. The current radar enclosure is more oblong and includes an additional support for other electronics. Below is my plan for the radar enclosure, and two photos of the fabricated enclosure, made with 1mm brass rods and wood for the platform, radar sweep and mount. For simplicity, I elected to place the support bars at the front and both sides, whereas the actual enclosure has more bars at different points around the circles. I left the attachment points longer than needed until I determine the exact rake of the foremast. The enclosure will be painted Coast Guard spar color, the radar sweep and its mount will be painted white, and the circular bars will be covered with baggywrinkle which will hide some of the imperfections (I haven't decided how to make baggywrinkle yet).

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.