-

Posts

31 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Meekes

-

I made and attached the hatchway, bilge pump, and deckhouse to the deck and it looks great! It took a bit of time but the result is well worth it, it adds so much to the ship. I've got to admit that i slightly messed up the placement of the deckhouse though, it's not fully center. 😅

- 35 replies

-

I’ve made and attached all the small deck items, which were actually quite fun to work on. I’ve got to say, though, it wasn’t easy to accurately measure where all the items needed to be placed. You really need a solid reference point to start from, which you can then use to measure the placement of most of the other items. Like many other builders, I glued a small piece of brass wire to the bottom of these parts and drilled holes in the deck to make them more secure. After that, I painted the stern section black as instructed and glued on the bent brass wires in a (somewhat) correct shape. I definitely need better bending tools, but for now it’ll do.

- 35 replies

-

Thanks! I'm honestly suprised that the results have been this good so far.

- 35 replies

-

Thank you so much! I hope you'll enjoy the Polaris kit as much as i've been enjoying it. I hope mine and other build logs will help you along the journey!

- 35 replies

-

I made and attached the rudder and i found it suprisingly simple. I do recommend making the opening for the rudder earlier than the instructions do, before you start painting the inside white. Making the rudder itself didn't take too long but making the opening for it did. In the i used the dremel from Hardell to shape after first drilling a few holes with it. I did notice afterwards that i probably should've made the opening for the rudder a bit wider.

- 35 replies

-

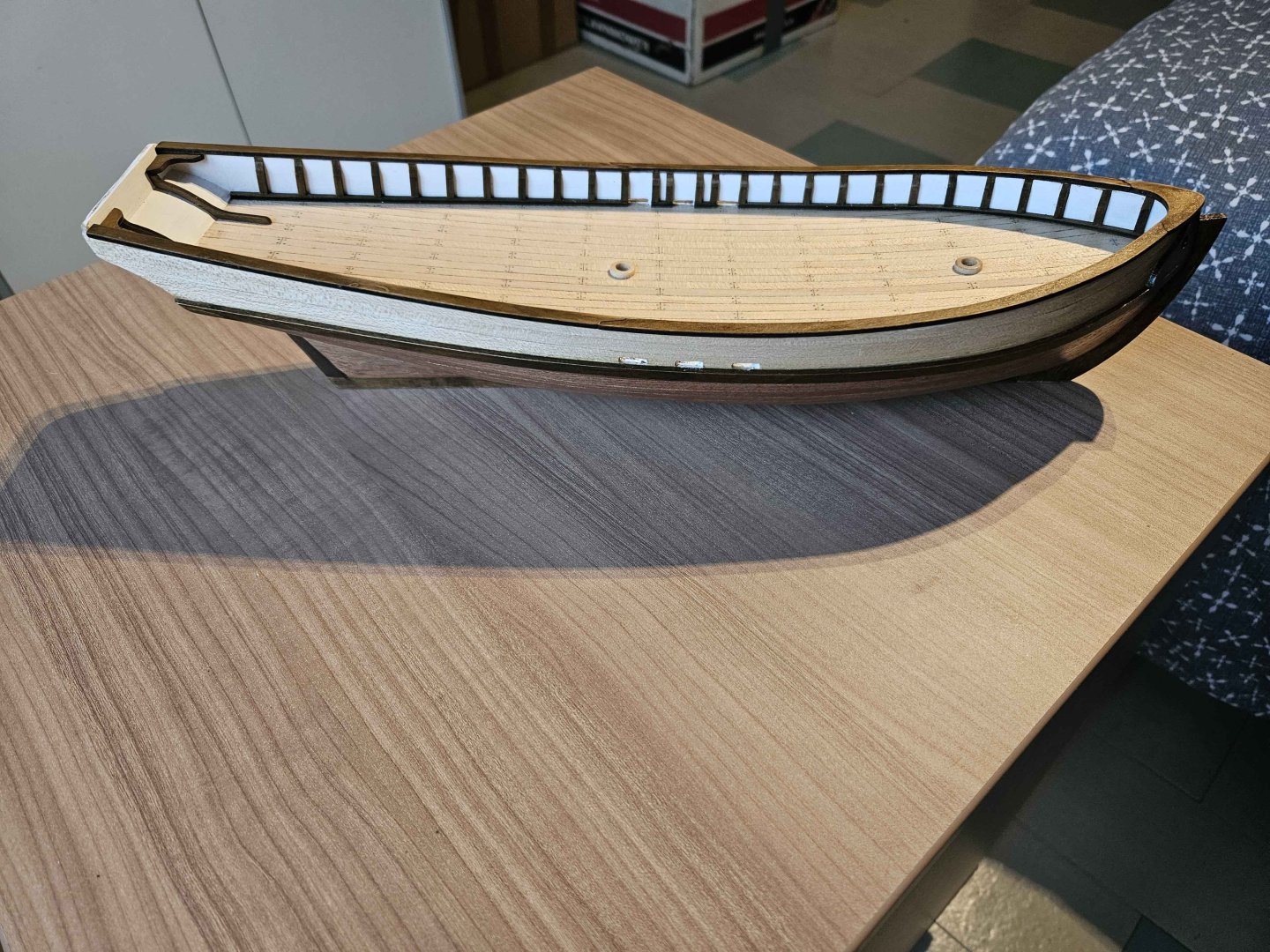

The progress has been decent over the last month. I didn't take too many pictures so this post will be a little messy. I glued on a few more parts like the stern post and the wales and then gave the hull 3 layers of varnish, making it look quite good! Painting the inside of the bulwarks wasn’t much fun for me, but I did learn a lot from it. I applied two layers of primer, expecting it would make painting them white easier, but I found out the hard way that it really didn’t. In the end, it took six (!) layers of white acrylic paint to make it look somewhat decent. After that, I glued on the footrails and the bulwark stands, having first stained them with walnut dye. I then sanded the stands at an angle. A few of them popped off while sanding, but luckily they didn’t damage the paint. It’s not perfect, but since it’s only a minor detail, I can live with it. One thing I noticed is that when you apply white glue to walnut-stained parts, the glue turns a yellowish color, which leaves nasty marks. It was a real pain to clean and/or hide. Finally, I glued on the rail caps and the stern trim, which was a bit tricky but not too difficult overall. Now onto giving the railcaps a few layers of varnish.

- 35 replies

-

Another long time later, I can finally post an update! I’ve got to say, the second planking has been a real rollercoaster. There were plenty of ups and downs, mistakes and fixes, but once it’s done you’re a huge step closer to the detailing stage. To make fitting the second planking against the keel easier, I decided to glue the keel on earlier than the instructions suggested. This is where I made my first silly mistake: I completely forgot to stain the keel parts with walnut dye 😅. I’ll do this once the second planking is finished, and I don’t expect it to cause any problems. I started with the starboard side and, for some reason, decided not to follow the instructions and instead go my own “logical” way of planking. This turned out to be big mistake number two. It caused far more difficult placements and a lot of small pieces that needed extra cutting and sanding. In the end, this side took me about three months to complete. I was so worried about making mistakes that I ended up burning myself out a bit, especially while being very busy with work. Once the starboard side was finished, I switched to the port side, and this went incredibly smoothly. I managed to finish it in just a week by actually following the instructions. A fresh wave of motivation, along with more experience, made a huge difference. The next step was the second planking of the upper part. I struggled more with this than I expected, mainly because the planks really didn’t want to bend along the curves. In some areas I had to cut the planks in two to make things easier. It definitely isn’t as pretty as I’d hoped, but it’ll work. You’ve got to learn somehow, right? After that, I used small amounts of white spirit to remove leftover contact cement that was sticking out between the planks. This worked surprisingly well. I then sanded everything down to smooth it out. I can still feel some grooves, but I’m afraid to sand too much since the planks are so thin. My biggest mistake, and the one that will probably bother me forever, is that I rushed the placement of the front part of the keel. As a result it isn’t fully centered or straight. I really hope it won’t be too noticeable by the end of the build, but if it is, it will be a good reminder of a very important rule. Do not rush. Even with a few mistakes here and there, I’m very happy with the result so far. And thanks to some Black Friday temptation, my next build is already waiting… OcCre’s La Candelaria 😉

- 35 replies

-

I hope to have the time to work on it again soon! I really want to have the second planking done this year still. It's really between the looks of the La Candelatia and the history of The Endurance for me. But yeah those mortars look stunning. I've got the work stand but don't have the organizer yet, tempting.

-

As the title suggests, I’m curious how everyone here picks their next model ship project. Do you go for something with strong historical significance? A vessel with a certain prestige or aesthetic that just speaks to you? Or do you choose based on the level of challenge, either because you want to push your skills or because you want something more comfortable and relaxing? I’m asking because I’m currently stuck between two kits from OcCre: Shackleton’s Endurance and La Candelaria. The Endurance has such a well-recorded and compelling history behind it, which makes the build feel like it would carry more personal meaning. But La Candelaria, on the other hand, is the more beautiful ship in my eyes even without its accurate history, though that also means it might be a bit more challenging. I’d love to hear how you all decide what your next build will be, and what factors matter most to you when choosing.

-

I'm currently in the same boat as you (pun intended) that i'm still working on my first build the Polaris and i'm tempted to already buy my second model while it's on sale. I just can't decide between La Candelaria or The Endurance!

-

Little update as it has been a long time. I've been stuck at the second planking, mainly due to live being busy but also because the second planking seems to really stress me out everytime i'm about to start on it because i don't want to make mistakes on the finishing and i don't find it the easiest. I know, it's my first modelship so mistakes are there to learn from, but i'm still a massive perfectionist so i'll have to get over it and get it done. More (actual) updates will hopefully come soon!

- 35 replies

-

Thank you! i'm quite proud of how well it went for my first planking ever! I mostly did it by dry-fitting the planks with nails and sanding slightly to get it alligned very closely. I do need to try the lining off way some day

- 35 replies

-

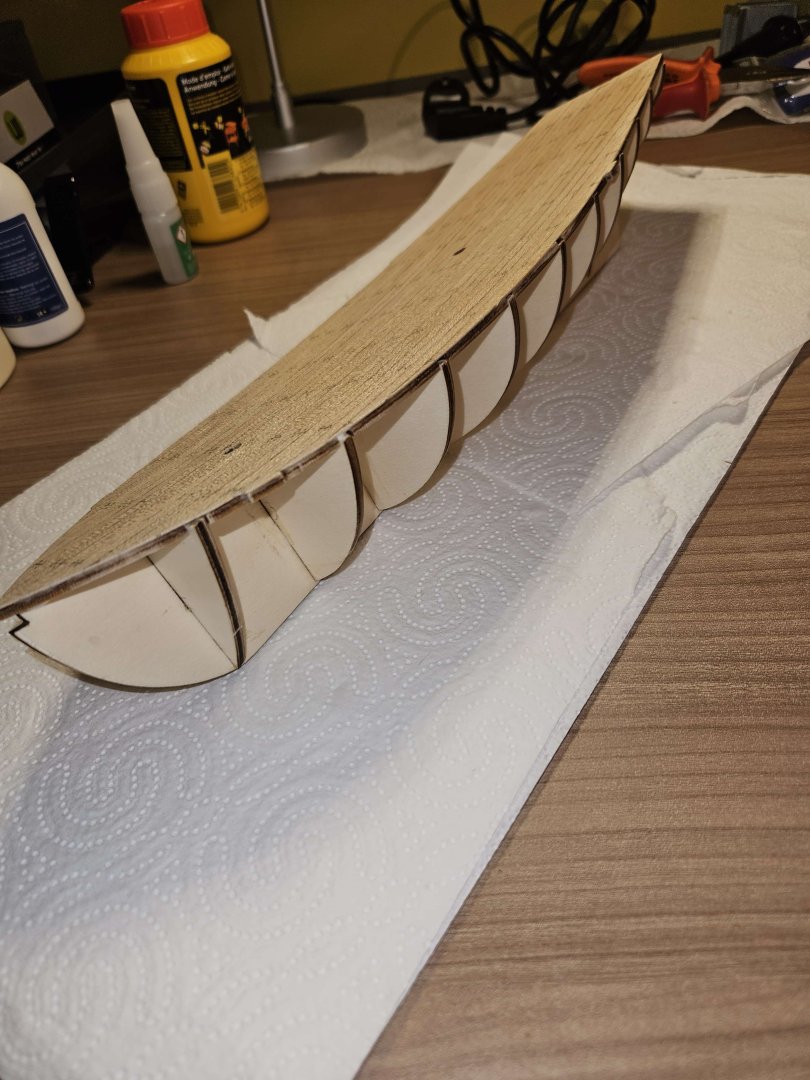

Nearly 3 months later i've finally finished fitting all the planks and sanding them down perfectly for the finishing layer of the second planking. It was tedious work but it still went fairly smooth! I didn't have any issues or made any major mistakes (the small ones i did make were easily fixed). With some putty i filled in any major gap and then sanded it down evenly to make it all as smooth as possible. So far i've been loving this project, my least favorite part definitely has to be the sanding though. 😅 Here's a small photodumb from during the planking and a small photodumb of the finished planking which has been sanded down. I look forward to gluing on the second planking, although it makes me nervous because mistakes here you can't really hide anymore. Photodumb #1 Photodumb #2, really happy with how it looks so far.

- 35 replies

-

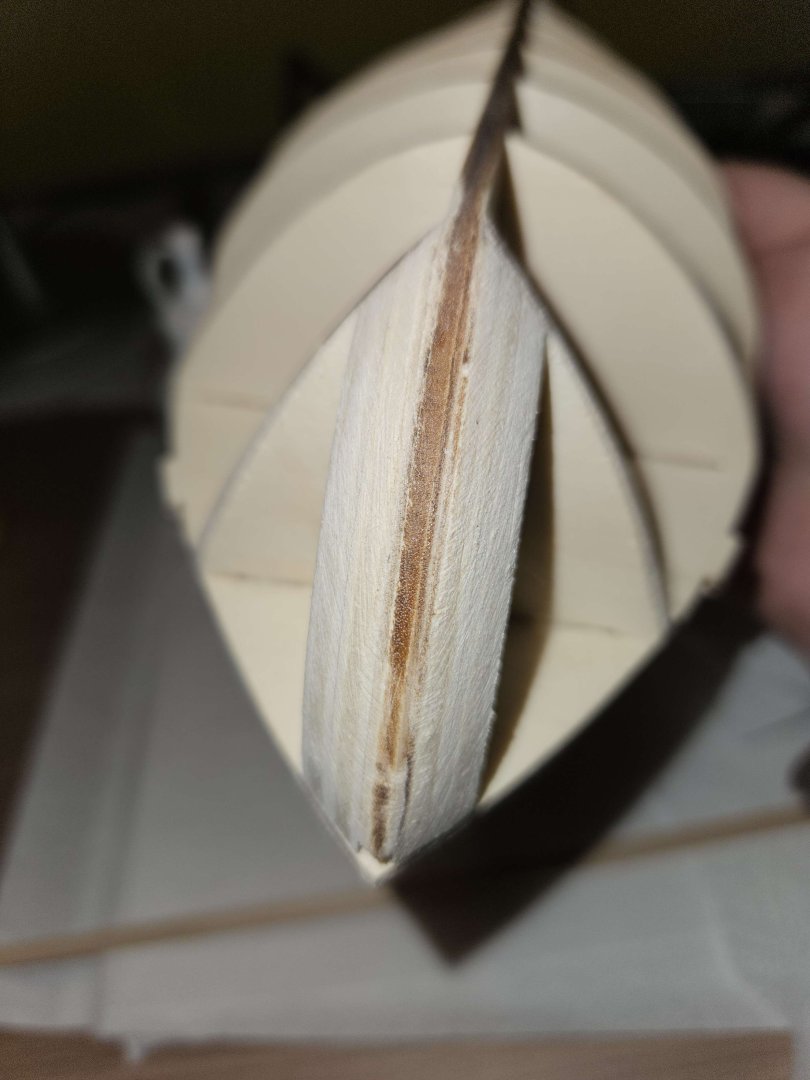

So it's been almost 2 weeks now and i've made slow but steady progress. To bend my planks i soaked them in water for atleast 5 minutes, bent them slightly around a can and then used a soldering iron to finalize the shape. I've glued on 4 upper planks and 1 lower plank so far on each side and currently have 1 dry-fitted with nails on each side. On the ribs i had to glue on a few thin planks from the cutouts of the deck to shape a few of them better as i found out i sanded a slight bit too much off. I'm well aware it's not the prettiest and far from perfect, but i hope i'll be able to hide all the imperfections under the second planking. The ends of the planks haven't been fully cut/sanded to the perfect fit yet but i felt like it'd be better to do that at the end when all planks are glued on.

- 35 replies

-

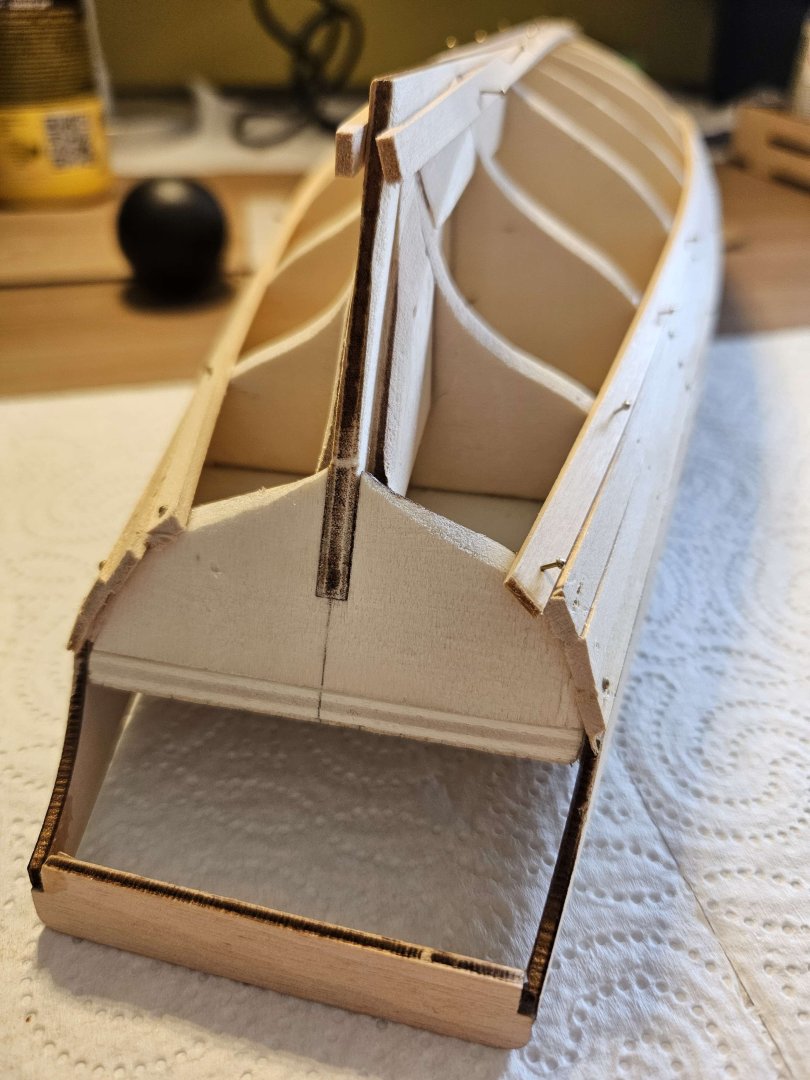

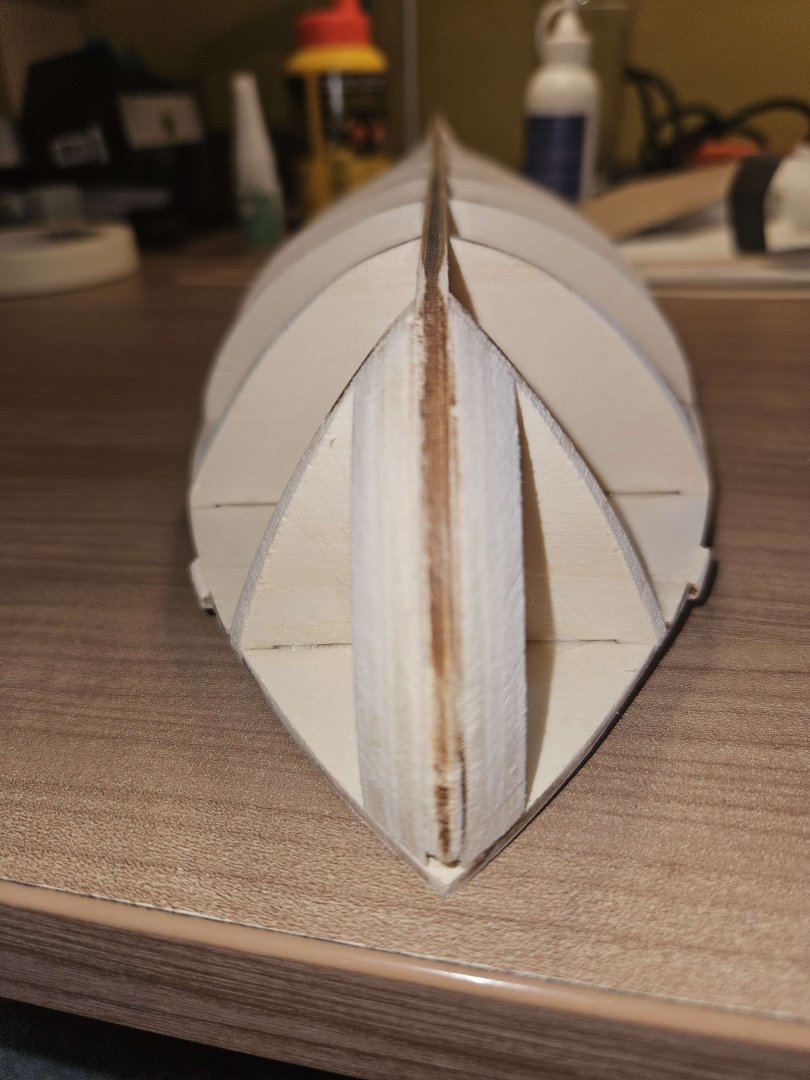

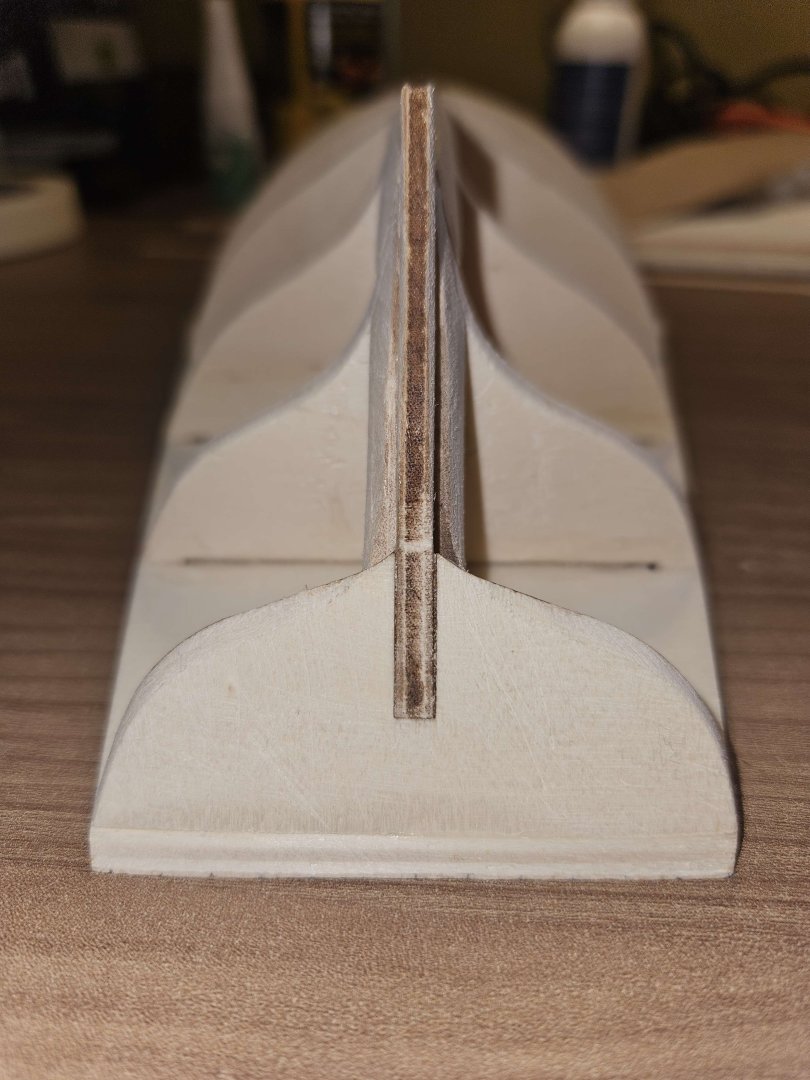

Alright time for a tiny update as i've been extremely busy. I've sanded the rest of the bulkheads so that, as far as i can see, the planks sit nicely flush on the bulkheads. I've got to say though, this part has been quite stressfull as i'm afraid i'll either have sanded too little or too much and will only find out during planking when it's too late. But, here goes nothing as i've probably just been overthinking it. Here are a few pictures from different angles, hopefully these will help some others in the future, or someone will spot something that i've missed or messed up. Bow side: Stern side: I do have to admit that the curved sander from OcCre has been amazing for the stern side, i've seen some smart ways to make your own curved sander but for any beginners that are thinking about getting this, i can definitely recommend it.

- 35 replies

-

That's what i'm thinking aswell! I've mainly been following your finished build log as it's extremely detailed and the ship's very well made. I have a question for you though (and anyone else who can help), when sanding the ribs to make it flush for the planks on the hull. How and when do you know that they're sanded enough and in the right angle? I've been slowly working on it but when holding planks to it it seems that in one way or another the plank won't sit nicely flush on it and i'm too afraid to put more force as i fear i'd snap a plank.

- 35 replies

-

Yeah right now it's the only real silly thing i've done, other than that i sometimes feel like i rushed something and could've made some details look better. And yeah, either something else will be covering it up or you just won't be able to spot it once the whole ship is detailed.

- 35 replies

-

Some time later and i'm extremely happy with the progress i've made! When planking the deck i found out the majority of my planks were bending sideways, some even so much it would've been hell to use. I first looked for all the straight ones and then looked for the ones with partially straight planks or ones with just a very slight bend, these i would use the outer parts of the deck as i didn't need to use the whole length there. Then i started planking the deck using contact glue, first i drew a straight line in the middle so i could nicely place my first plank. And here, i made my first major (and very silly) mistake, i was so focussed on placing it perfectly on the line i didn't pay attention to the length and i reached short at the end! ouch... As the plank was already stuck on i decided to cut a small piece from another plank and glued it on the leftover part. Hoping it won't be too obvious to see in the end. I then drew on the lines and nails with a pencil and put on two layers of satin varnish. Sadly, i noticed afterwards that some of my pencil lines and drawn nails were badly visible or fully gone after the varnish. i tried to fix it up a bit more but not everywhere was as visible as before. oh well, not the end of the world. After that was one of the parts with stressed me a bit, although, afterwards i realized that wasn't necessary at all. I dry fitted the deck on the frame and with a bit more sanding i felt like it would fit quite easily. I put on some wood glue and pushed the deck on, forcing it on with my hands for a good 5 minutes untill i felt like it was stuck enough to let go, adding a drop of super glue at each rib to make sure it would definitely be properly attached to the deck. Overall i'm very happy with how it turned out. After the varnish i also found that the small part i glued on separately wasn't too noticable.

- 35 replies

-

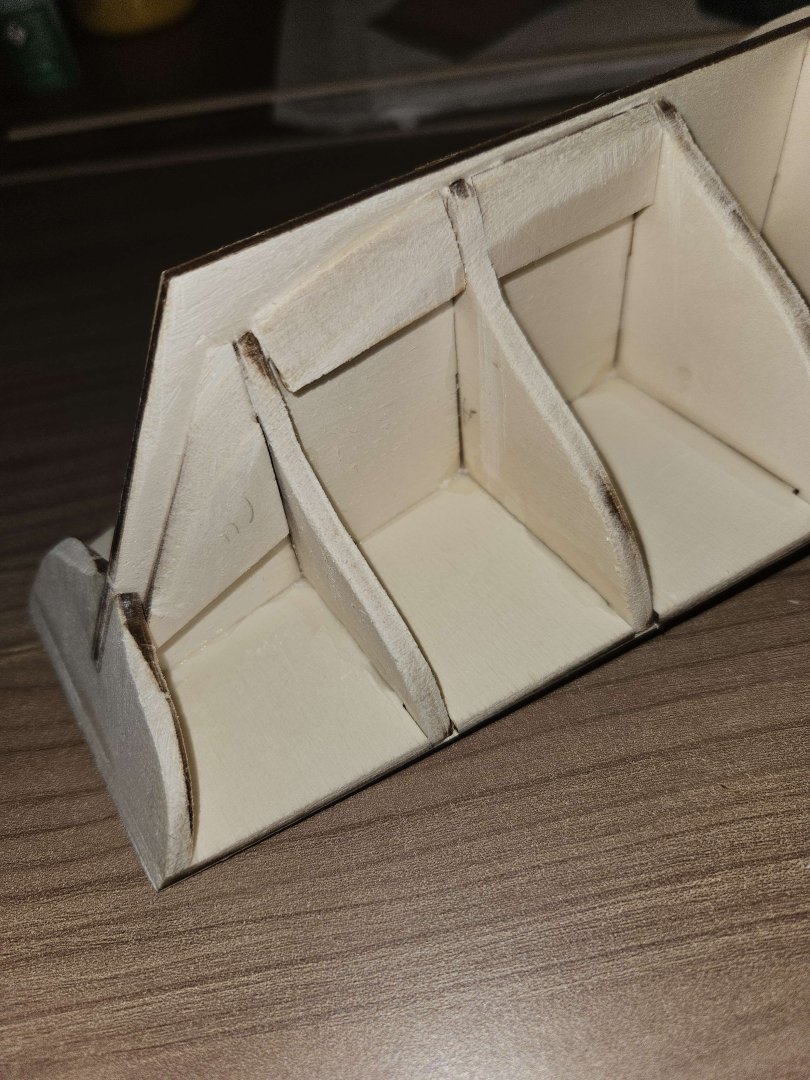

So, two days later and i've finished attaching the ribs to the false keel, this went suprisingly well and using lego blocks to keep it at a perfect 90 degrees went smoother than expected (honestly cutting each piece out and sanding them was the most tedious part and took the most time). The next step is planking the deck, but while preparing some of the planks i noticed some of them bend quite a bit sideways along the width. I haven't seen anyone else post about this so maybe it won't be an issue in the long run? Does anyone have any experience with something similar?

- 35 replies

-

I have indeed read a few build logs before about this kit and i will definitely look at them again before each part! This forum is an ocean of knowledge so it would be silly not to use it.

- 35 replies

-

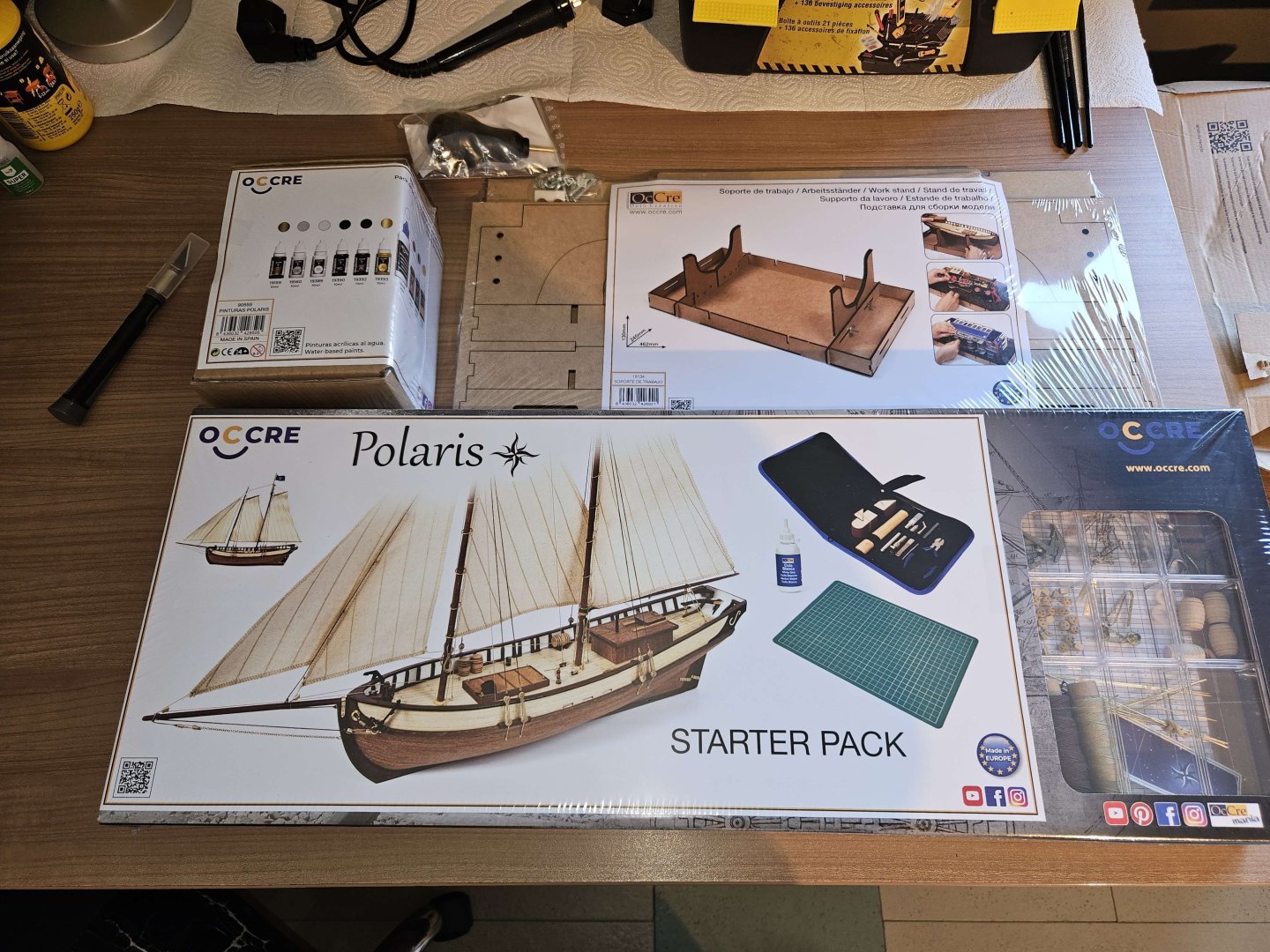

Some of you may have seen my roam around on the forums for the past few weeks looking for advice, inspiration and information... Well, here it is, my first build! After getting the Polaris by OcCre suggested to me the most i figured it would be stupid for me to not listen, so i went for the starter kit and also bought the paint set for the Polaris. A little about me, i'm a total inexperienced beginner when it's about model building but i'm eager to give it a shot and try my best to learn and adapt. My life is quite busy and filled so my posts and updates might be really slow and far apart from eachother but i will definitely try to respond whenever i receive a question or comment. Oh, and apologies if my vocabulary or grammar isn't the best at times, i'm from Belgium so my English isn't the best. First of to get atleast a little bit familiar with sanding, gluing and clamping in proper 90 degree angles i started with the OcCre workstand. I got this because i felt like i would end up using it quite a bit even if it's not during my first build, and i thought it would also be a fun way to get a tiny taste of woodwork before the actual build. After succesfully having built the workstand i do feel like i can i've learned some stuff that i will take with me on the build. Now onto numbering all the parts of the boat, cutting them from the frames and sanding them to get them ready!

- 35 replies

-

I went ahead and looked for my old soldering iron, whilst it doesn't have the big bending block at the end , it'll still do the job (i hope). As for clamps, i hope i'll be fine with about 30 to start haha

-

I was thinking of using the good old soaking method and then letting it dry while clamped. I do perhaps have a soldering iron i could modify in the future but that's not for my first build. Yeah i could indeed look for some wood pieces to use instead. As for lego pieces, i don't have any! I might have to ask around to get a few haha

-

So a little update: I'll be starting my buildlog next week as i'll be ordering the Occre Polaris starter set (+ the paint) and i'll be buying a bunch of tools this week. Here's my current list of tools i'll be getting, i probably have too many listed to start with? Mitre box, some paint brushes, bulldog clips, clamps, exacto knife and a box of #11 blades, putty filler, the Occre work stand, Occre curved sander and the Occre pin pusher. Really looking forward to starting this first build!

-

I will definitely be doing a buildlog!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.