-

Posts

35 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

SiriusVoyager reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

SiriusVoyager reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

-

SiriusVoyager reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

SiriusVoyager reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

-

Pitan reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

Pitan reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

-

Pitan reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

Pitan reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

-

Pitan reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

Pitan reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

-

Nirvana reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

Nirvana reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

-

robert952 reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

robert952 reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

-

robert952 reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

robert952 reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

-

robert952 reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

robert952 reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

-

eatcrow2 reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

eatcrow2 reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

-

- 33 replies

-

- Model Shipways

- 18th Century Armed Longboat

-

(and 1 more)

Tagged with:

-

TheFace reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

TheFace reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

-

- 33 replies

-

- Model Shipways

- 18th Century Armed Longboat

-

(and 1 more)

Tagged with:

-

- 33 replies

-

- Model Shipways

- 18th Century Armed Longboat

-

(and 1 more)

Tagged with:

-

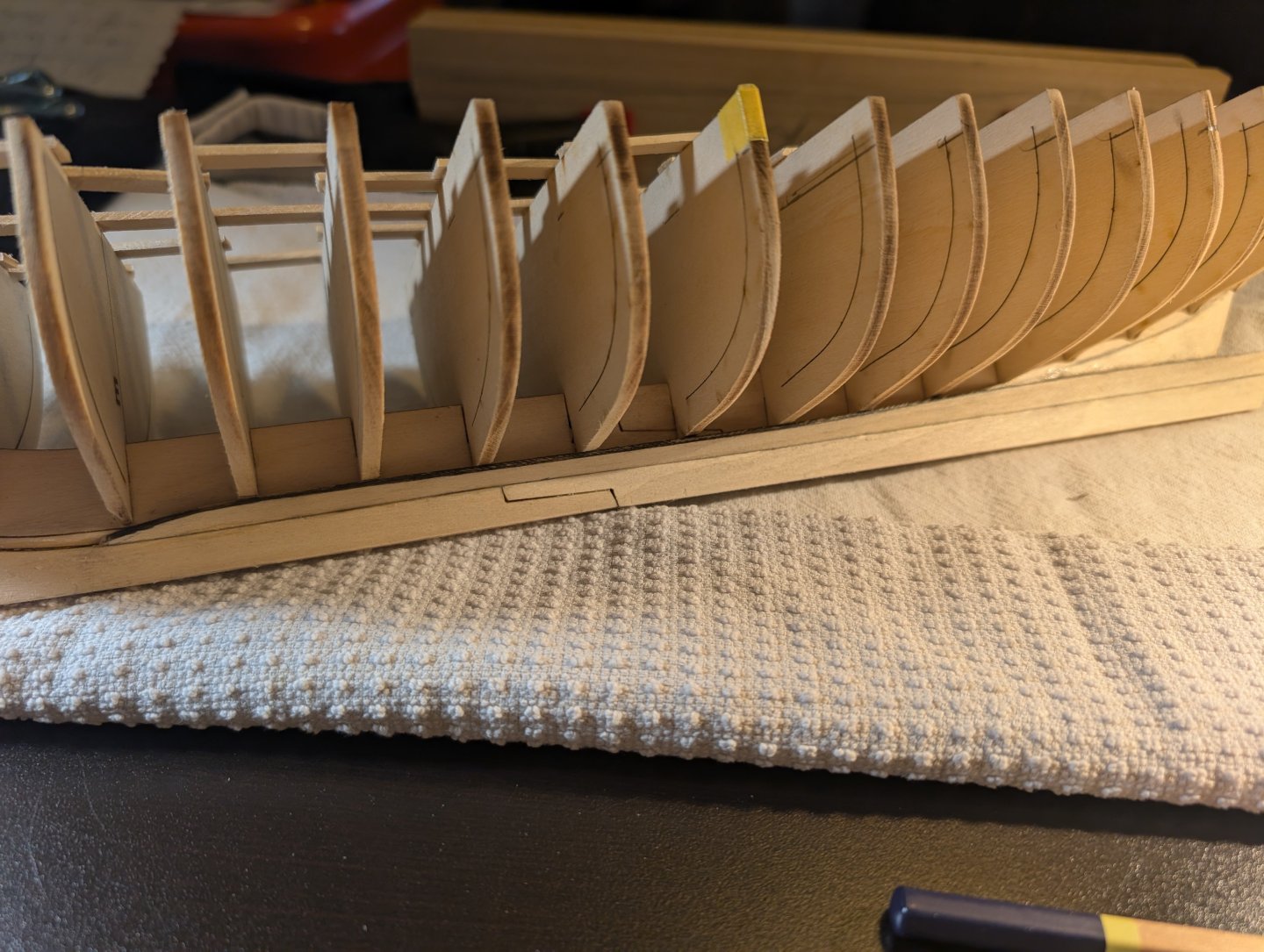

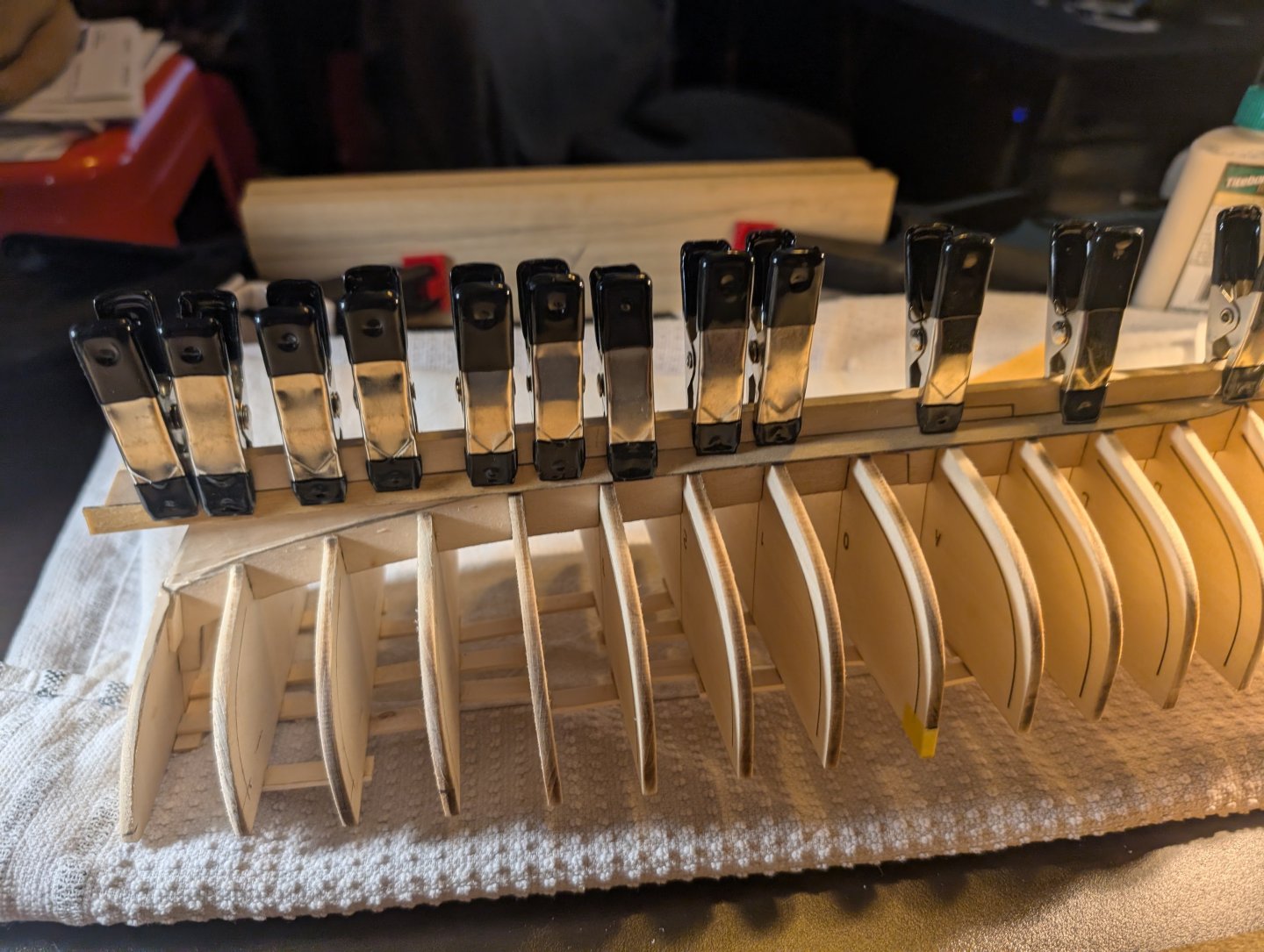

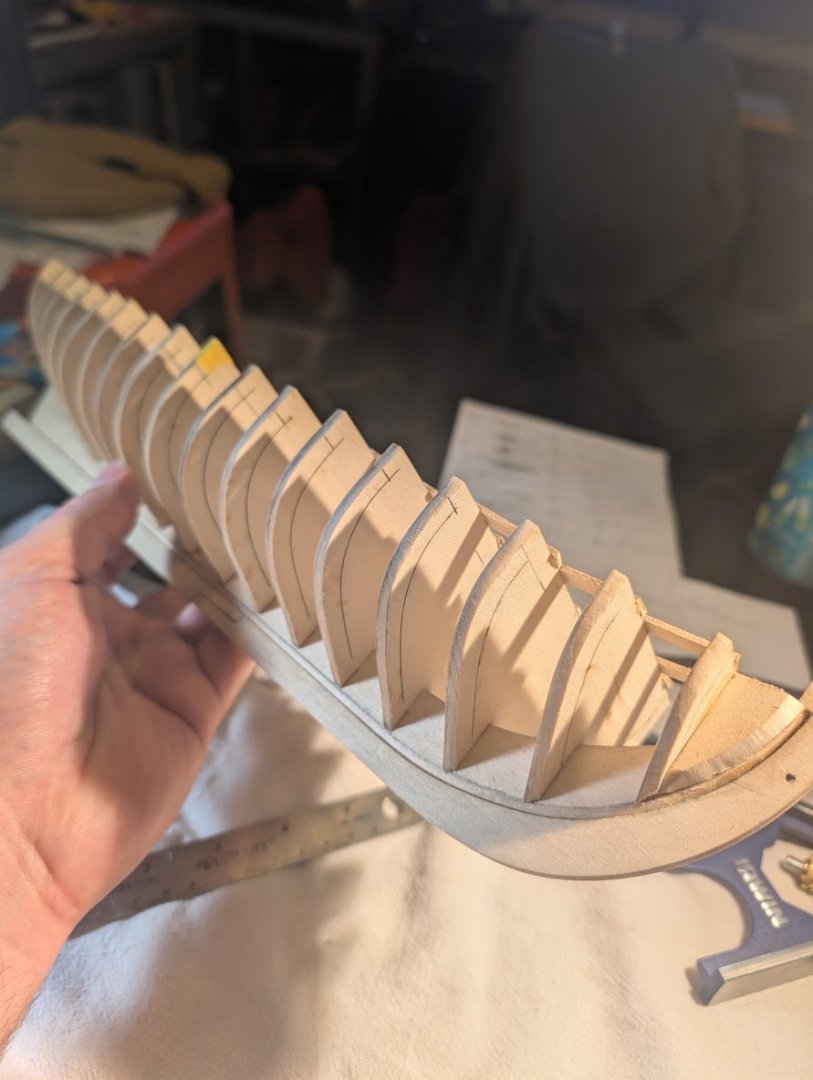

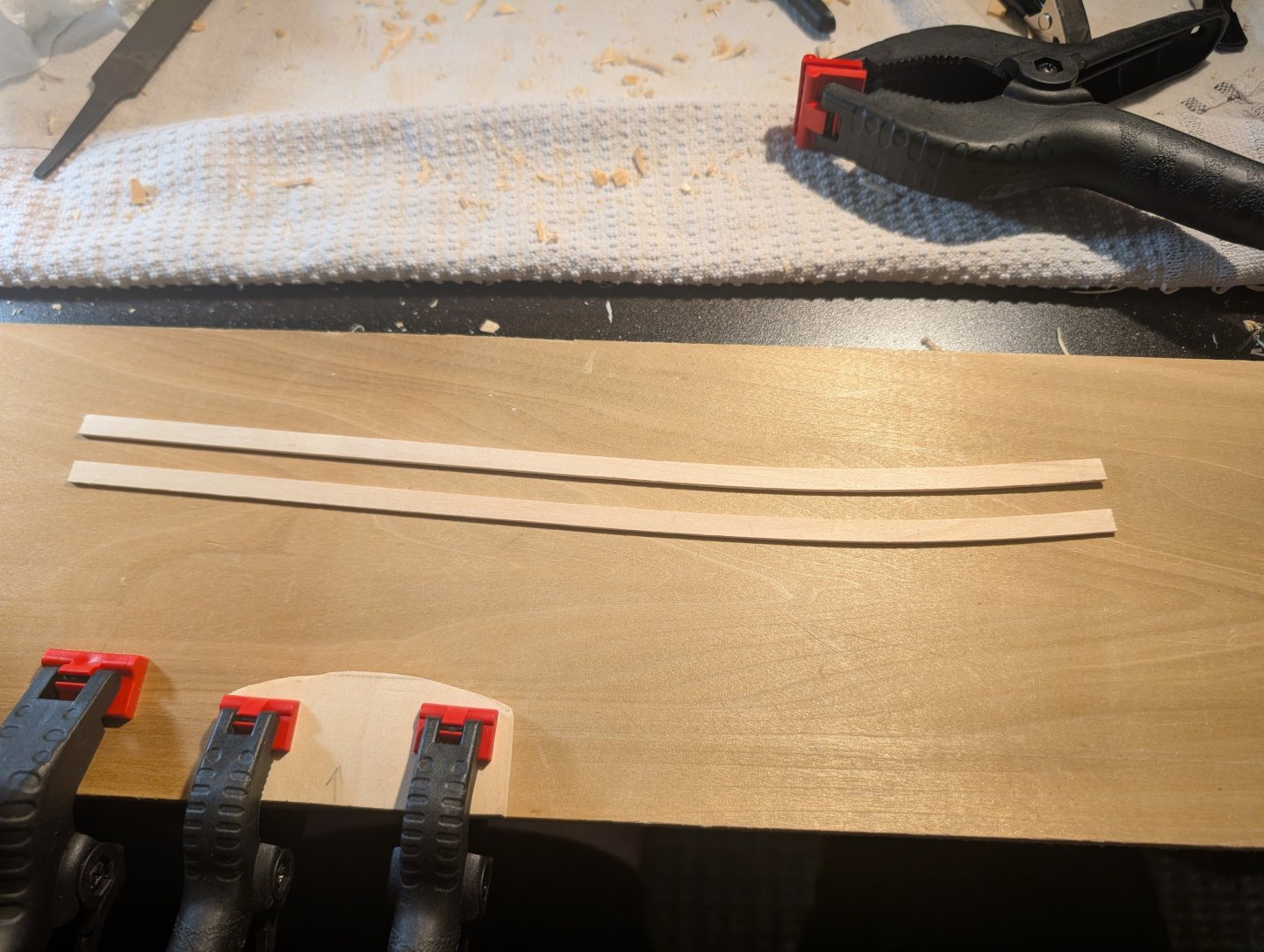

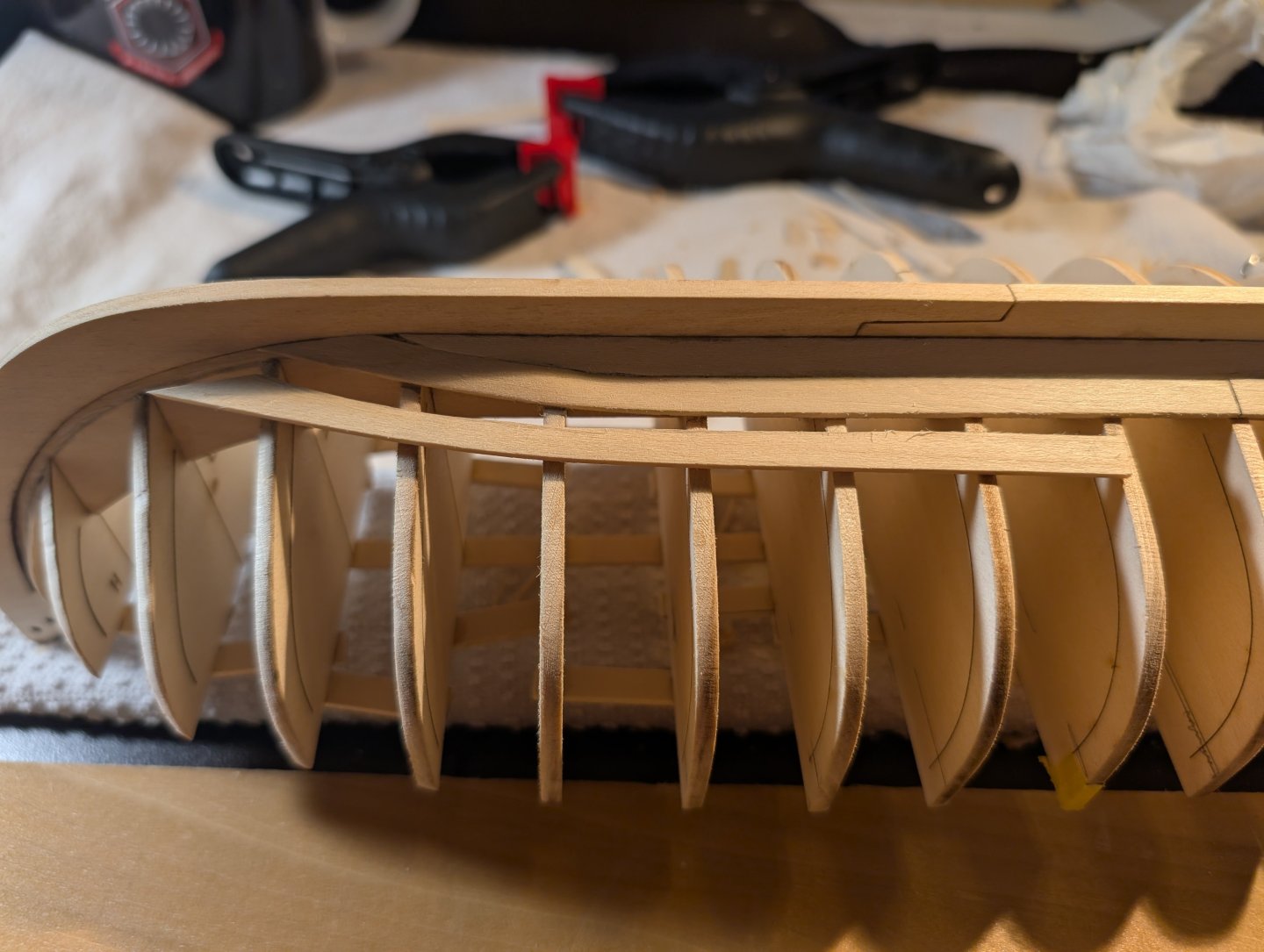

#3 strakes on both sides installed. I started with Chuck's method of planking with a jig and a clothes iron. I feel that this method is nice to get the edge curve, and the wood is ready to lay down after the shape is bent in. I don't think I would have had an issue with #2 strake having a slight bit of pinch had I used this method for #2. Stern is out of alignment now, mostly because the false keel cracked underneath, so some minor surgery was needed to repair it.

- 33 replies

-

- Model Shipways

- 18th Century Armed Longboat

-

(and 1 more)

Tagged with:

-

- 33 replies

-

- Model Shipways

- 18th Century Armed Longboat

-

(and 1 more)

Tagged with:

-

I had to adjust the garboards slightly, but after adjusting the garboard, the first side plank #2 is in place. There is only a small odd spot toward the front that should sand out.

- 33 replies

-

- Model Shipways

- 18th Century Armed Longboat

-

(and 1 more)

Tagged with:

-

- 33 replies

-

- Model Shipways

- 18th Century Armed Longboat

-

(and 1 more)

Tagged with:

-

- 33 replies

-

- Model Shipways

- 18th Century Armed Longboat

-

(and 1 more)

Tagged with:

-

TheFace reacted to a post in a topic:

Yellow Cedar Barrel by TheFace - Syren Ship Model Company

TheFace reacted to a post in a topic:

Yellow Cedar Barrel by TheFace - Syren Ship Model Company

-

- 33 replies

-

- Model Shipways

- 18th Century Armed Longboat

-

(and 1 more)

Tagged with:

-

Yellow Cedar Barrel by TheFace - Syren Ship Model Company

TheFace replied to TheFace's topic in Non-ship/categorised builds

Off to the hardware store to get some conditioner and finish to apply. -

Yellow Cedar Barrel by TheFace - Syren Ship Model Company

TheFace replied to TheFace's topic in Non-ship/categorised builds

-

Yellow Cedar Barrel by TheFace - Syren Ship Model Company

TheFace replied to TheFace's topic in Non-ship/categorised builds

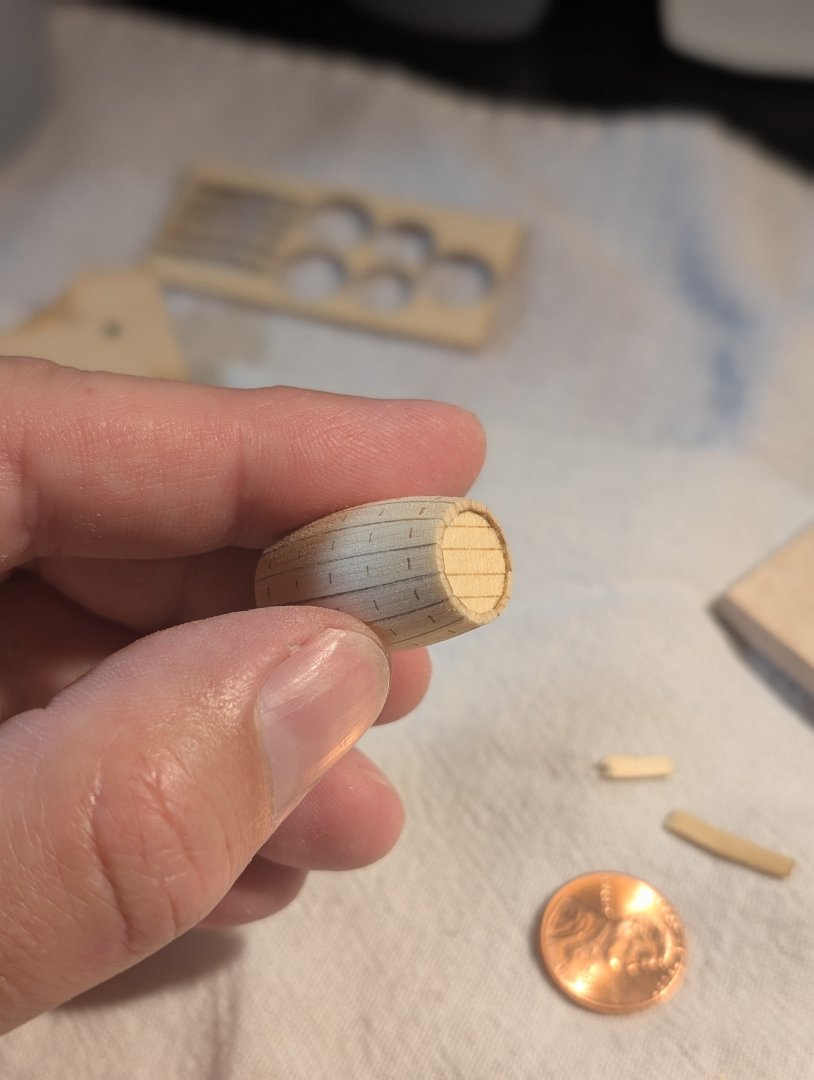

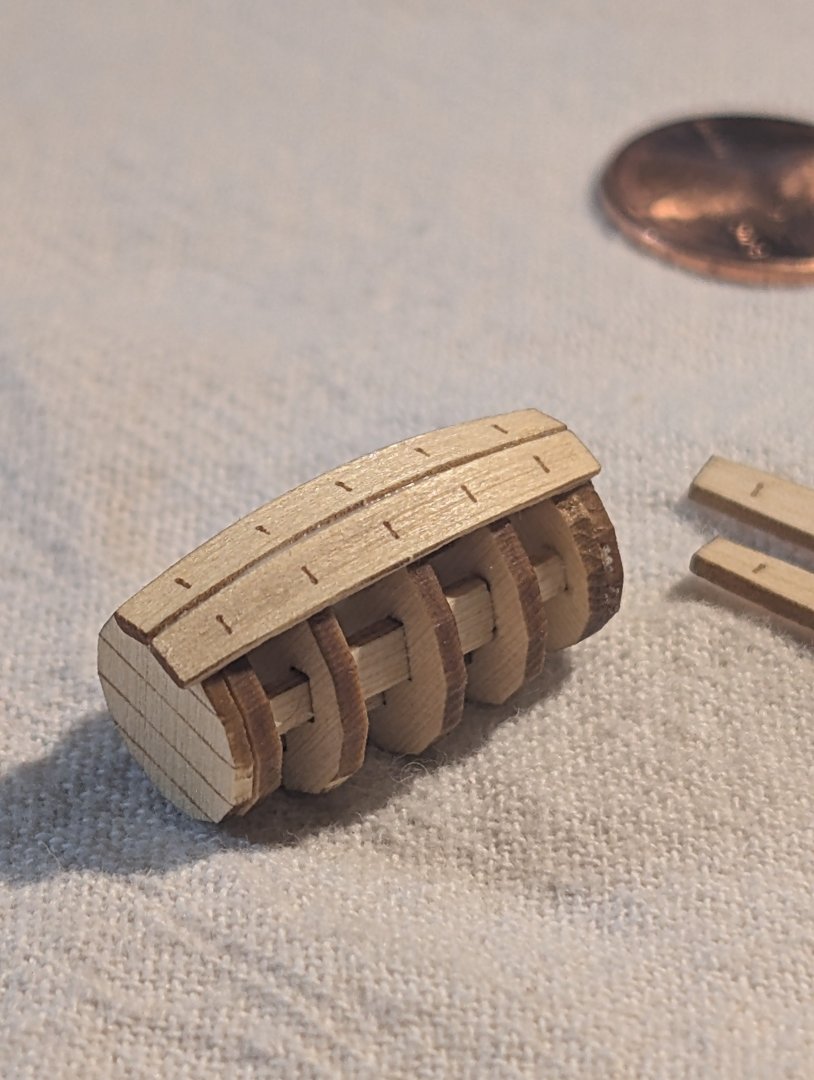

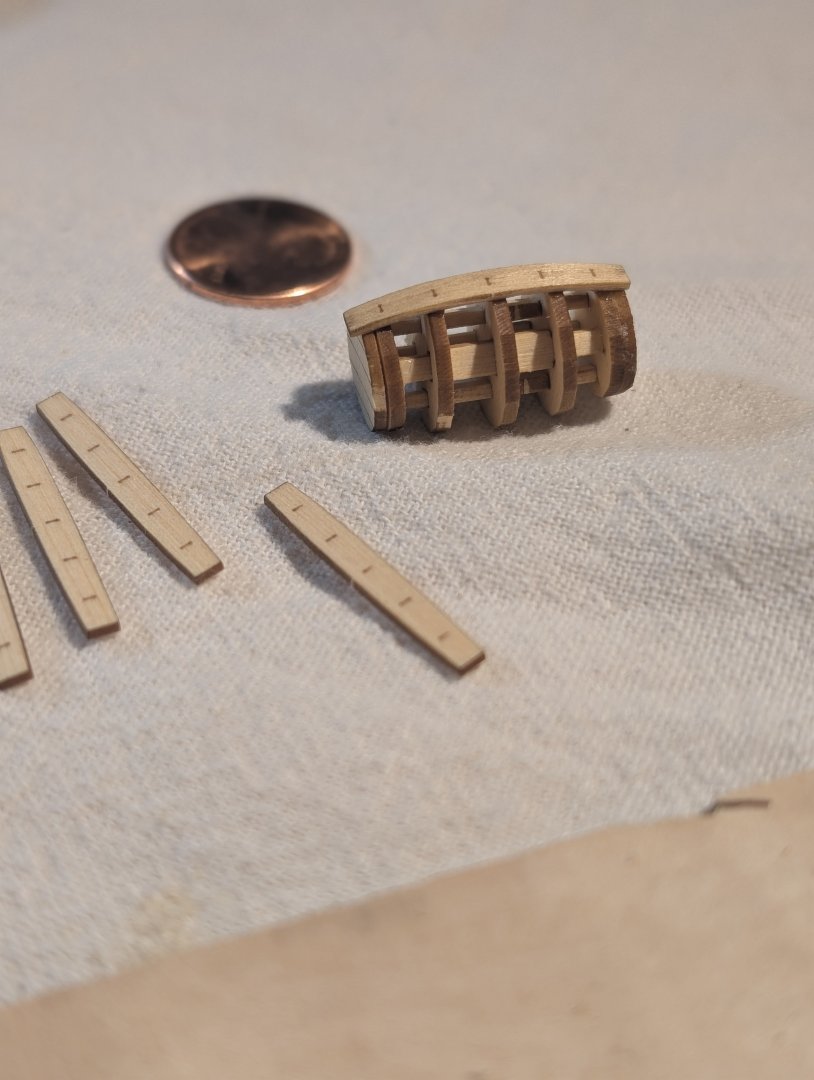

Full planking went well, and the last plank used one of the smaller spacers Chuck includes. The kit has 3 different size spacers to help with making the last plank fit really well. -

Yellow Cedar Barrel by TheFace - Syren Ship Model Company

TheFace replied to TheFace's topic in Non-ship/categorised builds

Next is planking the barrel framework. I used Tightbond on the edges, and thick CA dots on the frame connections. Plankes were given an angle to the edges with a #11 blade. They were bent using Model Shipways plank bender. Super easy and only broke one plank. -

Yellow Cedar Barrel by TheFace - Syren Ship Model Company

TheFace replied to TheFace's topic in Non-ship/categorised builds

Once everything fitted together, I dry fitted and then glued the frames. Then the caps with the laser cut frame details glued on each end.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.a081e032dc8725f4708fe7e17f4e6ff2.jpg)