danl

Members-

Posts

17 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by danl

-

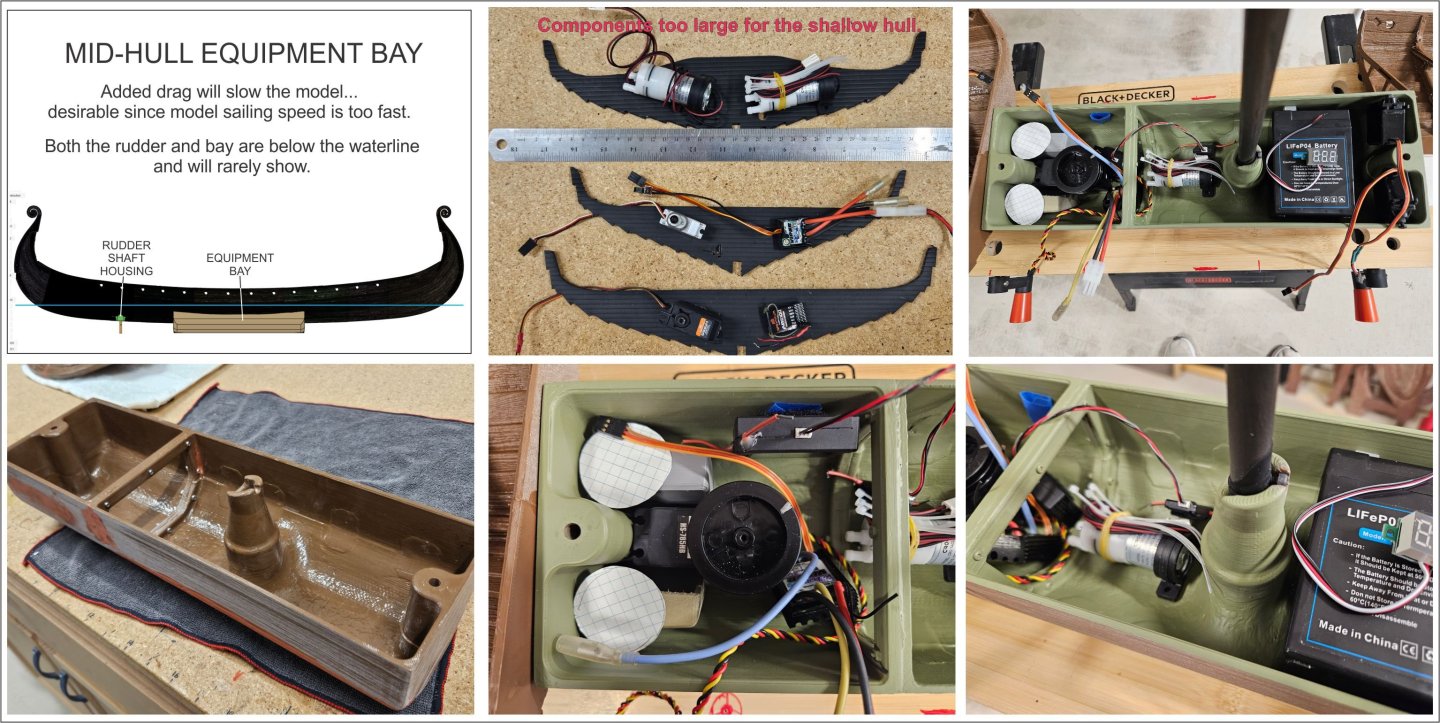

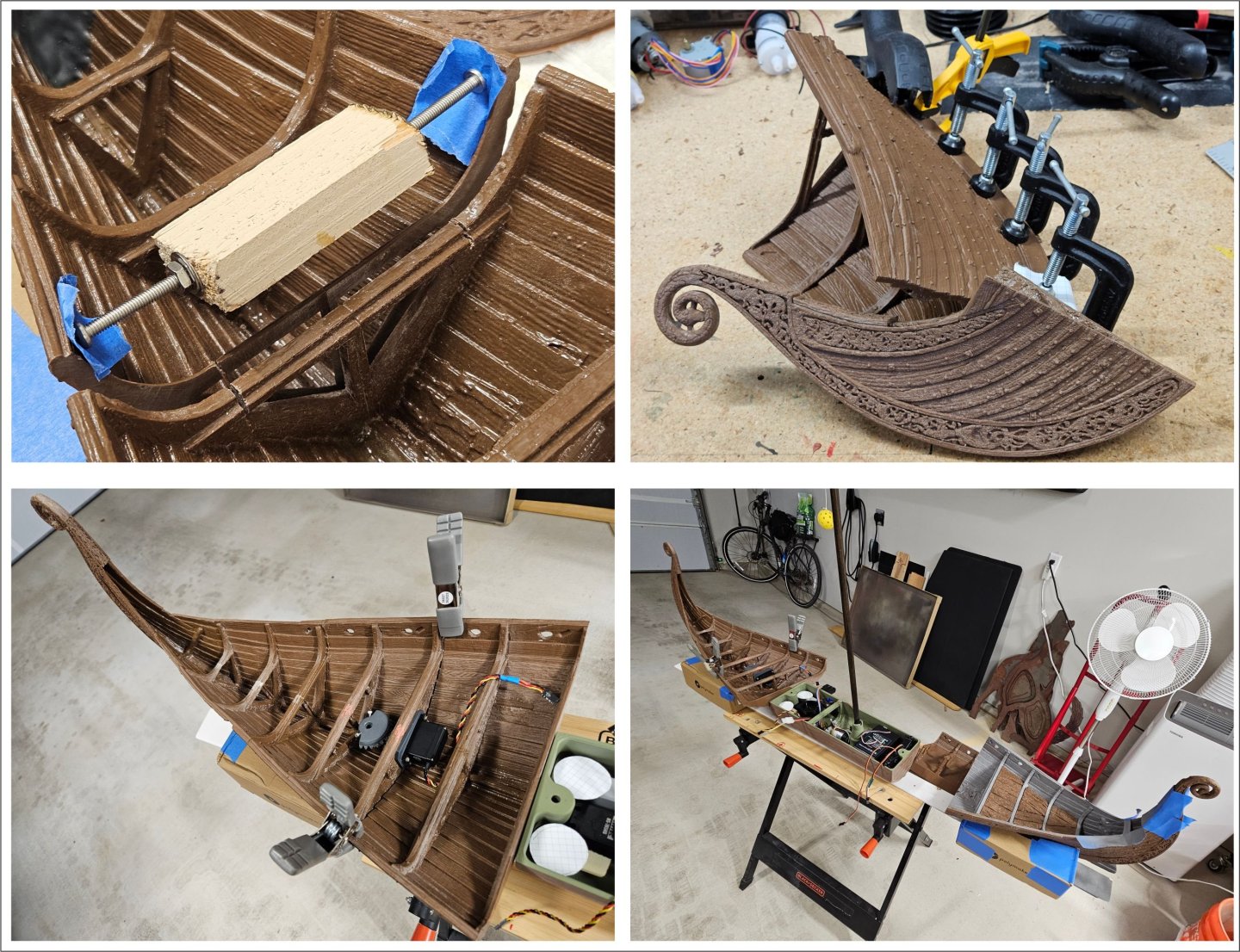

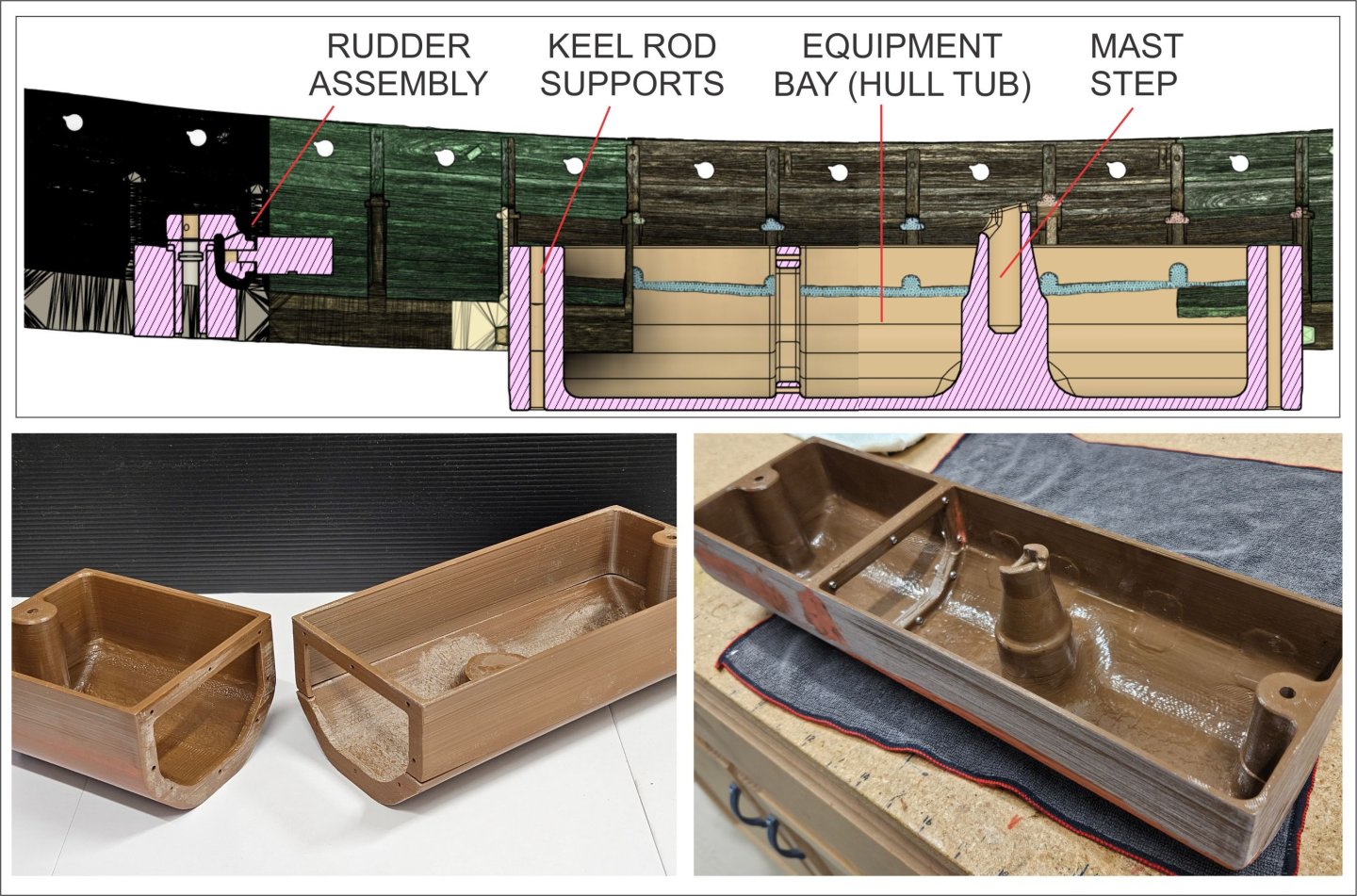

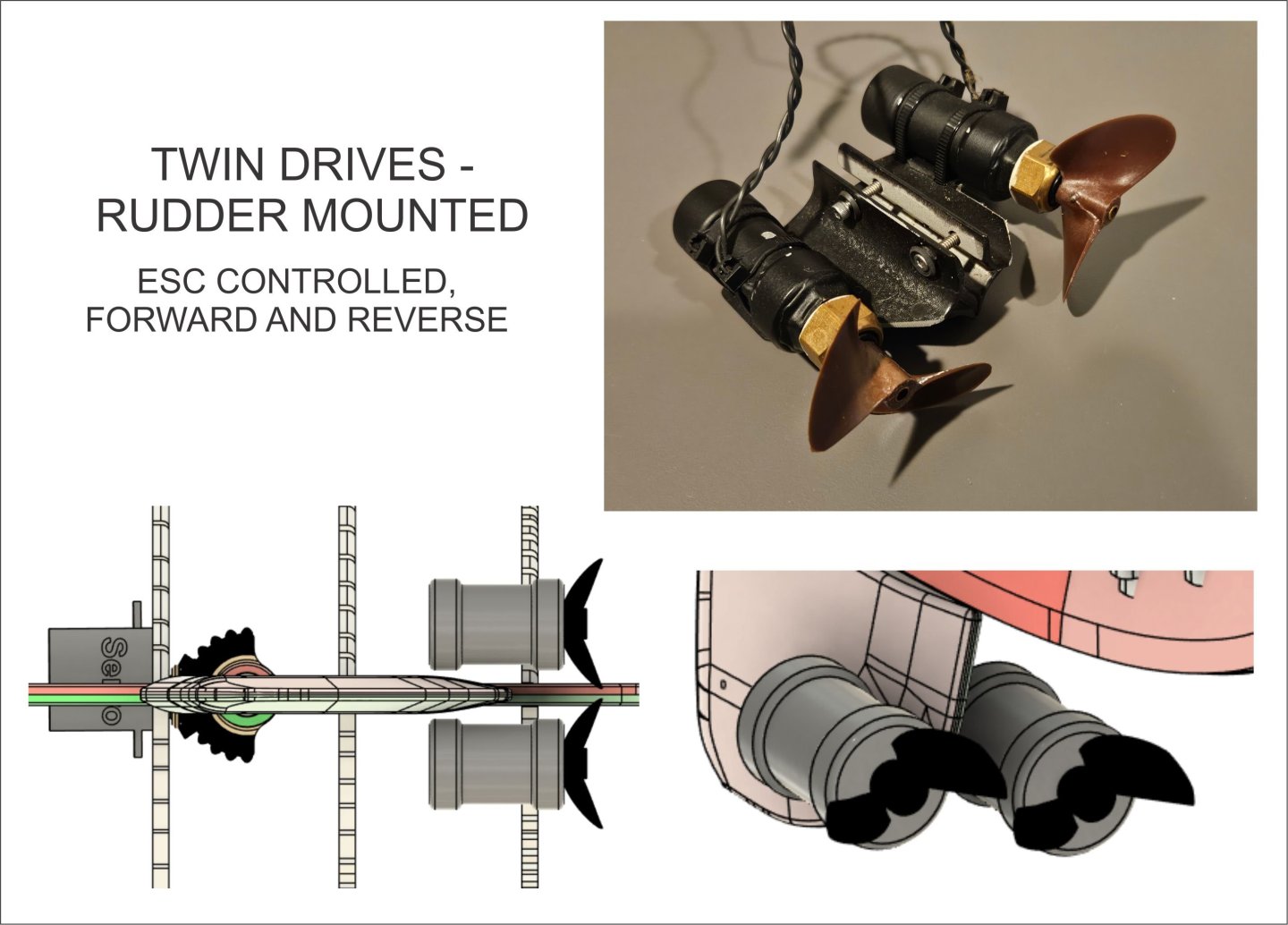

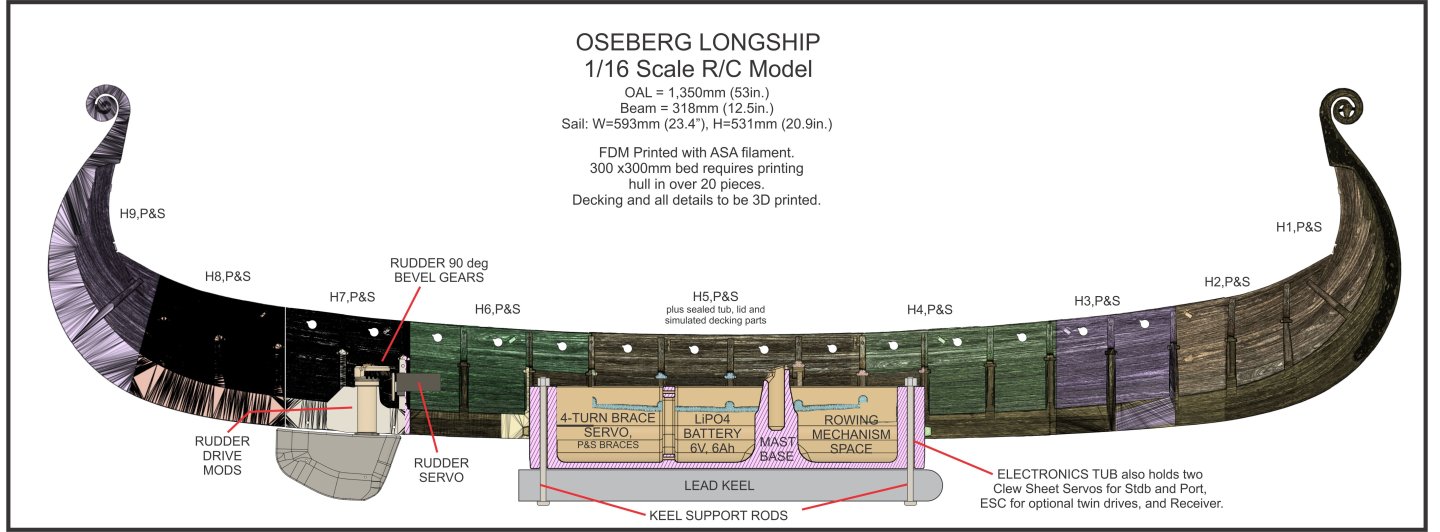

Another long post, but it tries to capture the all the work and learning so far. Pics of progress are attached. The 1/16th scale R/C build based on the Oseberg longship is a fair way along. The overall length will be 1350mm (53”) and beam 319mm (12.5”). The hull is being 3D printed in ASA, a tough, weather and UV resistant plastic. The STL files for the hull were purchased from Black Forge Models, and compare very closely with the plans published in the Vibeke Bischoff Oseberg dissertation. The files were scaled up by a factor of 2.7 to produce the 1/16 scale size. 3D printed plastic was chosen for the hull because I no longer can build, or figure out how to build, the complex curved lapstrake hull. And having seen so many instances of large wood hulled sailing models exhibiting water damage over time, plastic became the material of choice. Finally, the 3D printer puts in the long build hours, requiring very little of my time or skill. The model is so large that the hull files had to be broken up into 24 separate parts to fit the 300x300mm print bed. Dealing with the extremely large mesh STL files was painfully slow using Autodesk Fusion that typically ate up nearly 32Gig of ram for processing. The separate ASA parts are fused together with a solvent blend of MEK and acetone. Nitrile gloves and organic respirator were used, in addition to ventilation. The separate parts fuse and essentially become one. The sailing objectives for this model require a yard brace winch servo, two independent sail clew winch servos, a yard lift servo and a functional rudder servo. The use of one servo to control the yard rotation and one independent servo at each of the sail clews is based on testing using a full-scale dummy test rig with a large fan. The independent clew sheets allowed trimming to get the best prototype “look” and control of the large square sail. That testing also allowed exact measurement of the line pull required for each winch servo, needed to calculate the rotation and diameters of the winch drums. HiTec HS-785HB winch servos will be used. The yard lift servo may or may not be added, but after scores of hours sailing a 2 meter (six-plus foot) R/C brig on open water, I’ve found that the ability to douse the sails is critical when wind gusts whip up or the model runs away. On the brig, the fore and mainmast sails could be opposingly-rotated to stall the model, but with only one large sail on this model, I think the ability to lower the sail remotely will be necessary. Given the length and mass of this model, the scale prototype rudder would likely not be effective, so an additional functional rudder was added to the hull. The initial shape may need to be changed after testing. The scale rudder will be static. In addition, a twin-motor/prop drive will be mounted on the rudder. In our boat club shows on a small pond with many other boats around, the drives are necessary to maneuver in the limited sea-room and to avoid collisions. The motors also allow sailing past weedy shorelines out to open water. Eventually, I’d like to add a rowing mechanism with crew. I have a preliminary design, but a lot of testing and development will be needed. And printing and installing over twenty 100mm tall Vikings that will likely weigh almost a kilogram, in addition to the mechanism weight, will be a challenge. To fit all the above, along with a 6V,6Ah LiFePO4 battery, RX, ESC, rowing mechanism, etc., the very shallow draft hull needed to be modified. A midship equipment bay was added. It does not show above the waterline, and the model can be displayed without the external R/C modifications showing: the rudder can be removed and a stand and name plaque can hide the hull addition. The two main build challenges so far have been targeting a suitable buoyancy-to-weight ratio with a lightweight hull and secondly, fitting all the R/C equipment: - Buoyancy: Because of the large, single sail area that can be very close-hauled, the hull weight above water needs to be kept at a minimum to allow keeping the center of gravity well below the center of buoyancy with a heavy and deeply suspended keel. That should help minimize knockdowns in gusty winds. - R/C equipment fit: Scale frames were printed early on to test fit the R/C gear. It was obvious that with the very shallow hull a deeper equipment bay needed to be added to the hull as shown in the pictures. The equipment bay structure will be under the waterline and should help lower the overall center of gravity. Rigging function and deck details will be kept prototypical looking, similar to the approach on the Syren build. The line will be made on a ropewalk with 100% polyester at various needed scale diameters. The sail material will be Supplex, a lightweight, UV resistant nylon fabric. The above covers most of the design considerations. Following is some of the work already completed: The hull sections take a long time to print – 8 to 13 hours each. They are printed in a 50 deg.C heated chamber to prevent warping. Dimensional shrink has been about 1% and the hull sections have mated very closely, allowing tight fit joints for gluing and appearance. Clamps and a spreader, as shown in the pics, were used to precisely align hull sections for bonding. A fair amount of print support structure cleanup is necessary, with roughly a 70% part:30% support material ratio seen with the use of “column supports” in early print sections. Switching to “tree supports” in a different slicer reduced the print times, waste and cleanup effort significantly in later prints. The external surfaces of the printed parts are brass-wire brushed to smooth out the print layer lines and other print artifacts. Assembled sections are filled and sanded to blend joint lines where necessary. The internal structure of the 3D printed parts is porous (at 70% fill), so water intrusion needs to be prevented. Three solid outer walls are used and then the whole part is brushed with solvent to “skin-over” the surface. Multiple paint layers will also help. Krylon spray paint will be used - it has held up extremely well on my heavily sailed brig since about 2009 - 16 years now. After all the hull sections are printed and assembled, the buoyancy will be tested, hoping for the best. The parts were printed at 70% infill and seem light enough, but if too heavy the whole hull would have to be re-printed at lower fill – a tremendous setback. I should have given this more thought and research before all the printing – hopefully not a significant mistake. The hull equipment bay is designed to support keel suspension rods, so ballast weight will also be determined with a test keel. For the keel, I plan to use a piece of flattened and shaped PVC pipe filled with lead pellets, sized and made after the initial ballast weight determination. The rudder, servo and gear mechanism has been printed, assembled and tested. The twin motor drive from my R/C brig, Syren, will be used on this model. It only needs to be fitted to the rudder. The drive mounted on the rudder gives very high maneuverability on a large model, needed in small water bodies, around other models, to get to clear, non-weedy sailing areas and to get to shore if winds die or sail control fails. The next step will be figuring out the decking and sealing to prevent flooding, yet allow access for the future addition of a rowing mechanism. After that, electrical and mechanical installation, detailing, painting, sailmaking and rigging will be started. I'm still looking for STL files for figures to be used as Viking oarsman. I have one set, but there are only three different figures and they are in helmets and armor - an unlikely look for working oarsman. Any hints on sourcing a 3D printable crew would be much appreciated. Any helpful hints or comments are very much appreciated. Thank you.

-

If I could start with some background, please... My largest R/C build, a 1/24 scale model of the US Brig Syren that's over 5ft long, dates back to 2009. I sailed her many, many hours over the years. I'm now getting a bit old and a bit unable to get the 80-pound-with-keel model in and out of the water and very rarely sail any more. But then after a recent trip to Norway, I became convinced I had to build a large R/C model of the Oseberg ship, a bit smaller, lighter and easier to rig and transport than Syren. I found the excellent Ships of Pavel Nikitin Oseberg kit, but after learning more about the complexity of the hull build, the size being just a little small for the R/C features planned, and my declining modelling capability, I gave up the plan to build. Then, randomly, I saw a "model" of the Oseberg ship offered by a New Zealand company, Black Forge Games. They sell STL files for gaming figures and props. In their Viking collection, they offer a 50 cm long "Oseberg Ship - Echoes of the Corrupted". They are STL files, not a physical model. The model is super detailed and seems very accurate when compared to the Bischoff paper and other available research. I can no longer model well, but I can 3D print, and the files can be upscaled to any print size. So, $35 later, with instant file download, and upscaling to 1/16th, the build is on it's way. The model will have an OAL of 1350mm (53"). I only need to upscale the files, slice them, and the printer does the work, able to run almost 24/7. I have an excellent printer, but with a 300x300mm bed the hull will need to be printed in over 20 pieces. ASA, an outdoor, UV resistant, very strong plastic is being used and the hull parts can be solvent welded. The hull design, with its shallow draft, doesn't have room for the R/C equipment I want to use, even at this large scale. So an "equipment tub" will be added midships. It will only show below the waterline, and allows clearing the hull frame structure that is in the way of the equipment. Many other much smaller R/C longships have, I think, been built - I'm not sure how all the gear was fit in. My goal, as it was for Syren, is long hours of prototypical sailing on fairly large lakes (sailing from a kayak), requiring heavy duty design and R/C equipment. Attached is an initial hull diagram showing some of the gear and design modifications to the Black Forge STL's.

-

Siggi, An absolutely beautiful model, and an amazing interpretation of and attention to detail. If I could, please, ask some questions about your sailmaking methods...not here, as to spoil your thread... but would you please suggest how you might prefer I ask you those questions. I am building a 1350mm (53 inches) OAL, 1/16 radio control, full sailing version of this ship. I am nearly at the sailmaking and rigging steps, and luckily found your build thread. Thank you. Dan L, Minnesota, USA

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.