Don Quixote

Banned-

Posts

1,689 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Don Quixote

-

Dominoff Serving machine

Don Quixote replied to Don Quixote's topic in Modeling tools and Workshop Equipment

Is this his website? https://www.shipworkshop.com/ Otherwise what is it? Anyone know how to search for members? I used the search dialogue box above but all I get are messages ABOUT him and his products. I can't find one I can reply to. -

Dominoff Serving machine

Don Quixote replied to Don Quixote's topic in Modeling tools and Workshop Equipment

Never had a problem with speed. I just crank it up and let it rip. For stroping I go manual. I have "most" of the machine, but I haven/t built a model in several years. I'm moving my shop from the garage to an empty bedroom in the house and can't find the power supply or the hooks and can only fing 1 alligator clip. Also I'm very familiar with it. I did just buy the one gidale suggested, but I'd sure love to have my old one. Even searched ebay. All it knows is Domino's:( -

Dominoff Serving machine

Don Quixote replied to Don Quixote's topic in Modeling tools and Workshop Equipment

Does it strope blocks? I love the electric motor. -

Dominoff Serving machine

Don Quixote replied to Don Quixote's topic in Modeling tools and Workshop Equipment

I'm looking for this: https://www.youtube.com/watch?v=o5gZQRN6yoU&t=442s That doesn't look at all as sturdy. -

It looks like one can no longer buy a serving machine from Dominoff. Does anyone know where to get one? Otherwise I'd like a recommendation on the best and most versatile machine available.

-

vacuum for power tools

Don Quixote replied to Don Quixote's topic in Modeling tools and Workshop Equipment

That's way beyond my skill set:) -

I have several proxxon tools, like the table saw and disk sander that have ports to attach a vacuum. I have a wet/dry vac that I have to move each time I use a different tool. I'm sure there's a splitter that I can attach 3 tools to so I don't have to move each time. Suggestions?

-

Good grief, this is a lot more difficult than I imagined. I just wanna make masts and spars.

-

What size should I consider for turning square pcs. into round masts? Probably never use it on metal, but nice to know I can if the opportunity arises.

-

I take it a metal lathe would do wood a well? What can you suggest?

-

Is this product any good, or can someone recommend a good one for less than $600? https://www.amazon.com/gp/product/B072JBP61N?psc=1

-

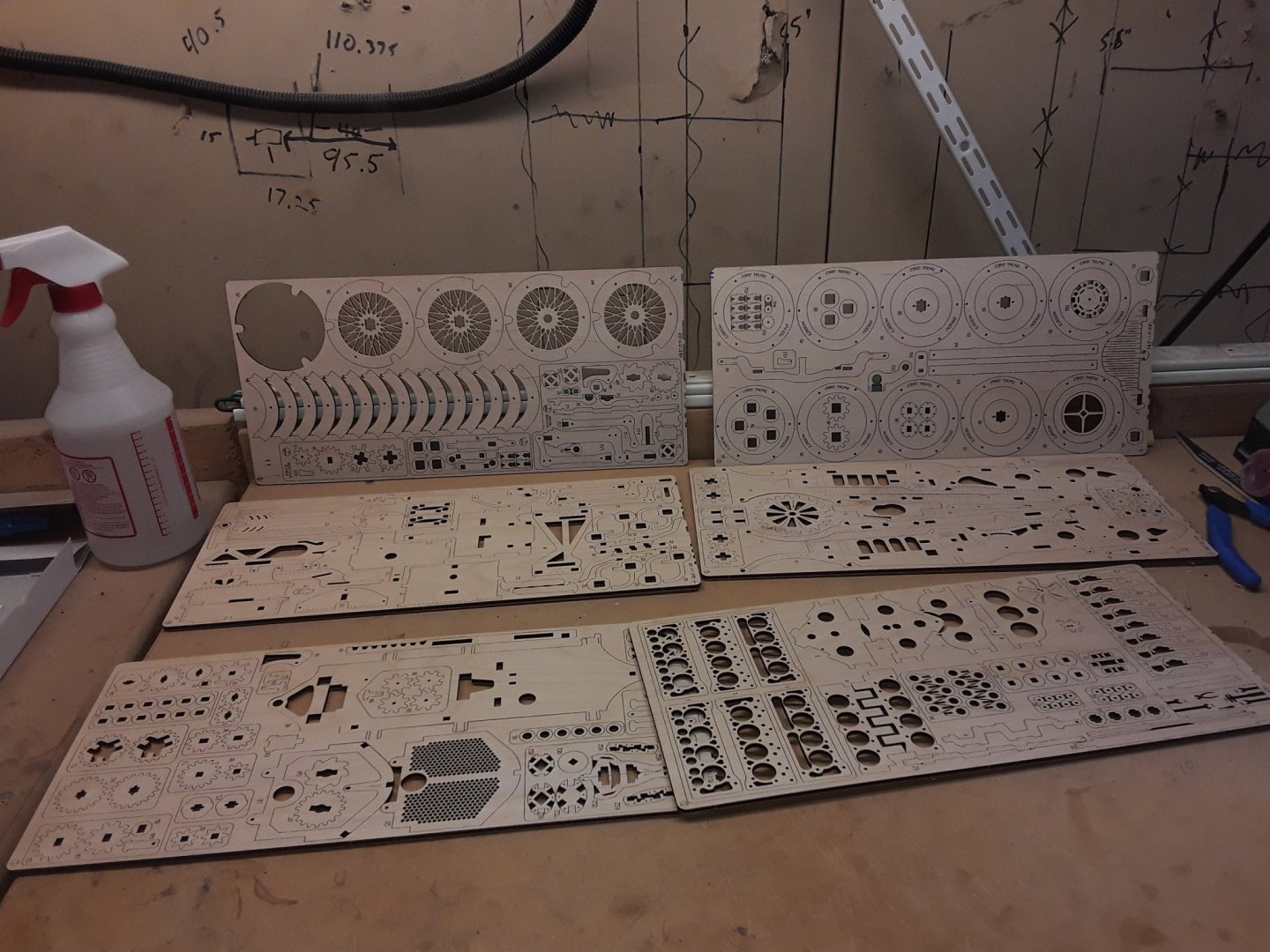

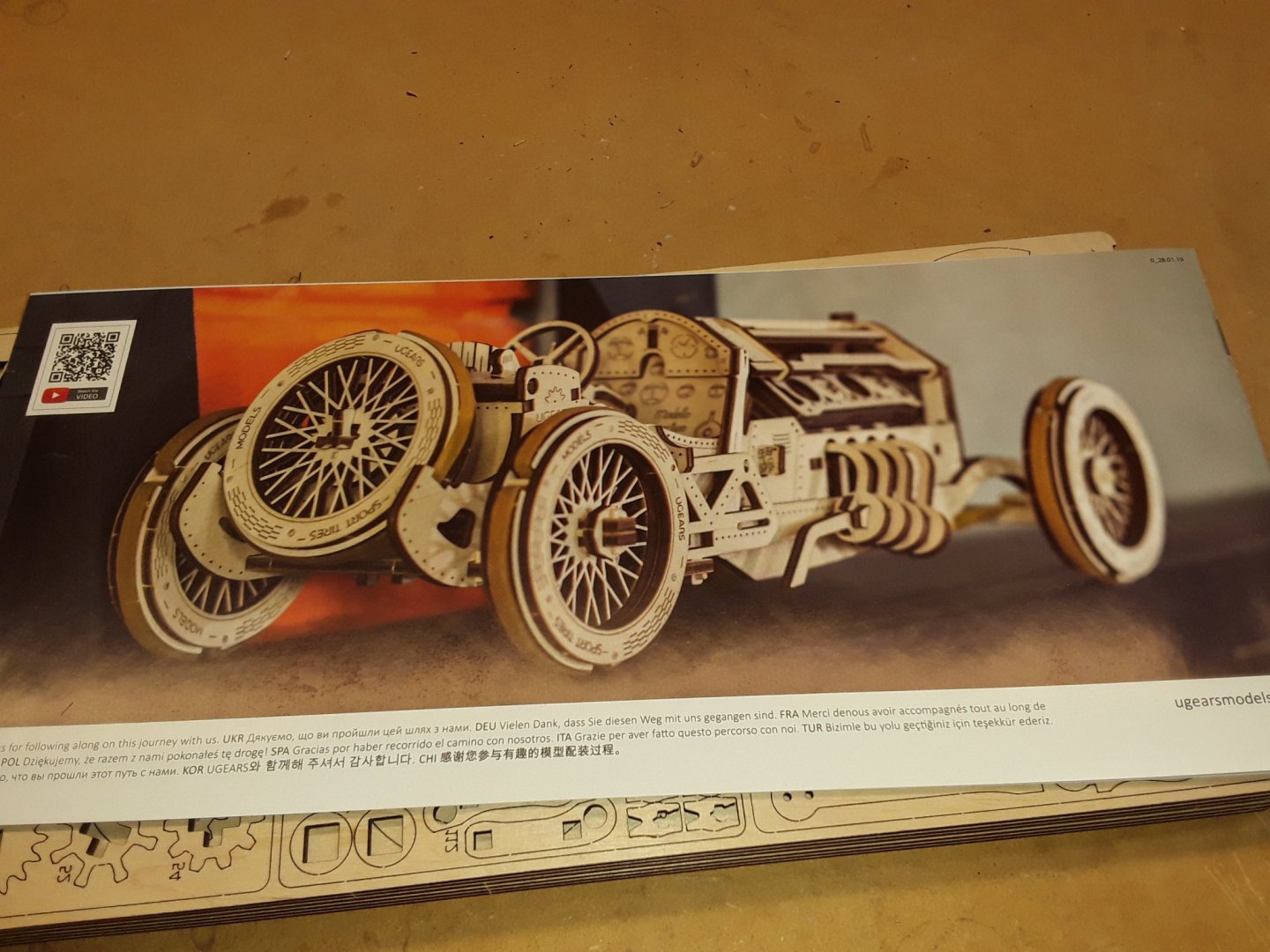

U-9 Grand Prix Car by Don Quixote - Ugears - 1:12

Don Quixote replied to Don Quixote's topic in Non-ship/categorised builds

I don't get it. The cam lobes flow freely. They all hang down into the connecting rods. Every engine I ever rebuilt the cam lobes didn't move:) I used some CA glue to immobilize them. The valves wont move, but they won't bind up the whole works. Thanks for looking in. Stay safe and stay at home, everyone! Here in tiny little Oakdale, California we have 4 confirmed Covid cases. We are 90 minutes from San Fransisco and a lot of bay area people live in Oakdale and commute to the bay area for work. I think it's those that brought it here. It amazes me how many kids are gathering at the park scross the street. I think the parents are probably the ones with all the buttocks wipe. -

U-9 Grand Prix Car by Don Quixote - Ugears - 1:12

Don Quixote replied to Don Quixote's topic in Non-ship/categorised builds

-

U-9 Grand Prix Car by Don Quixote - Ugears - 1:12

Don Quixote replied to Don Quixote's topic in Non-ship/categorised builds

-

U-9 Grand Prix Car by Don Quixote - Ugears - 1:12

Don Quixote replied to Don Quixote's topic in Non-ship/categorised builds

-

U-9 Grand Prix Car by Don Quixote - Ugears - 1:12

Don Quixote replied to Don Quixote's topic in Non-ship/categorised builds

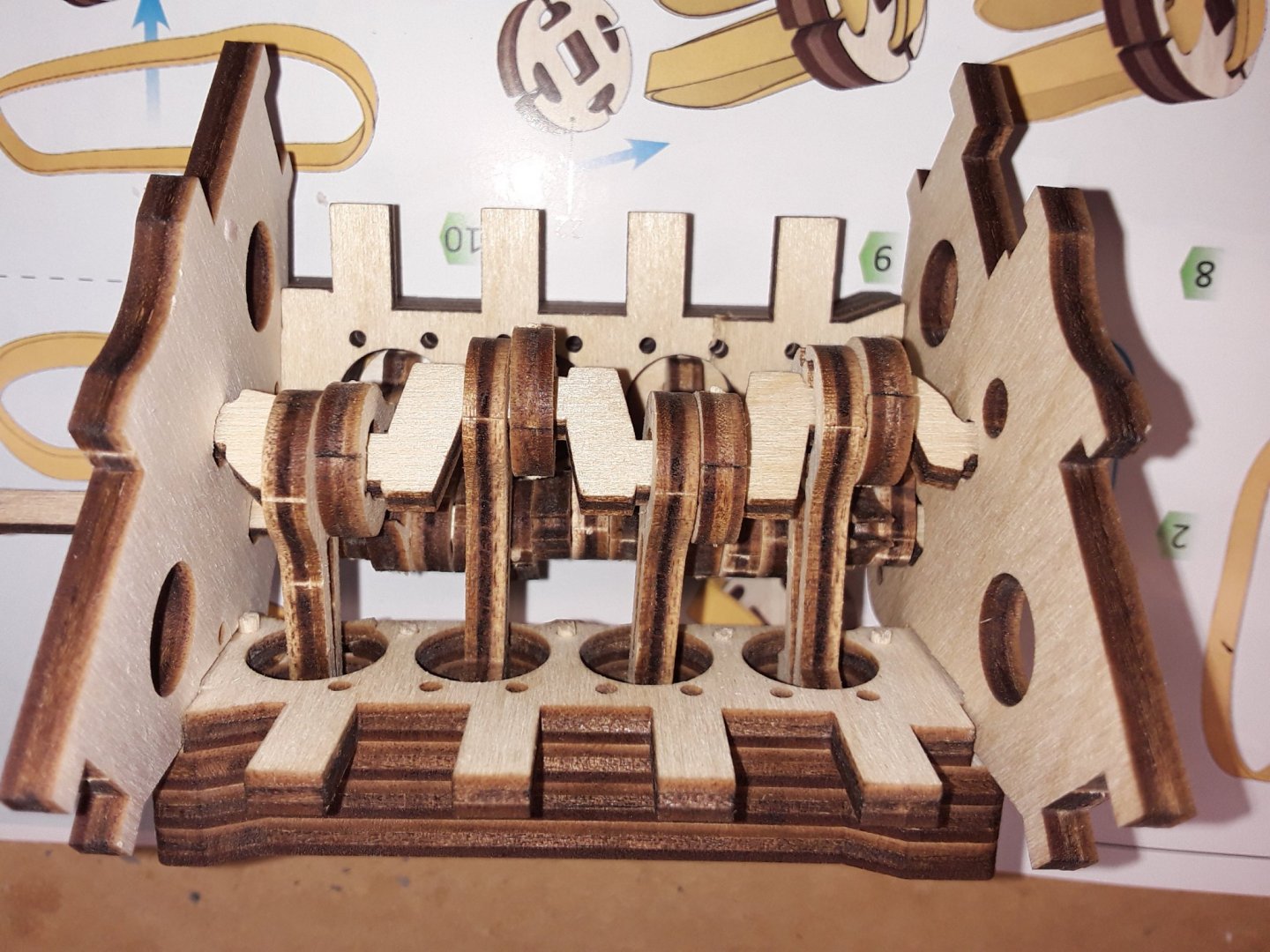

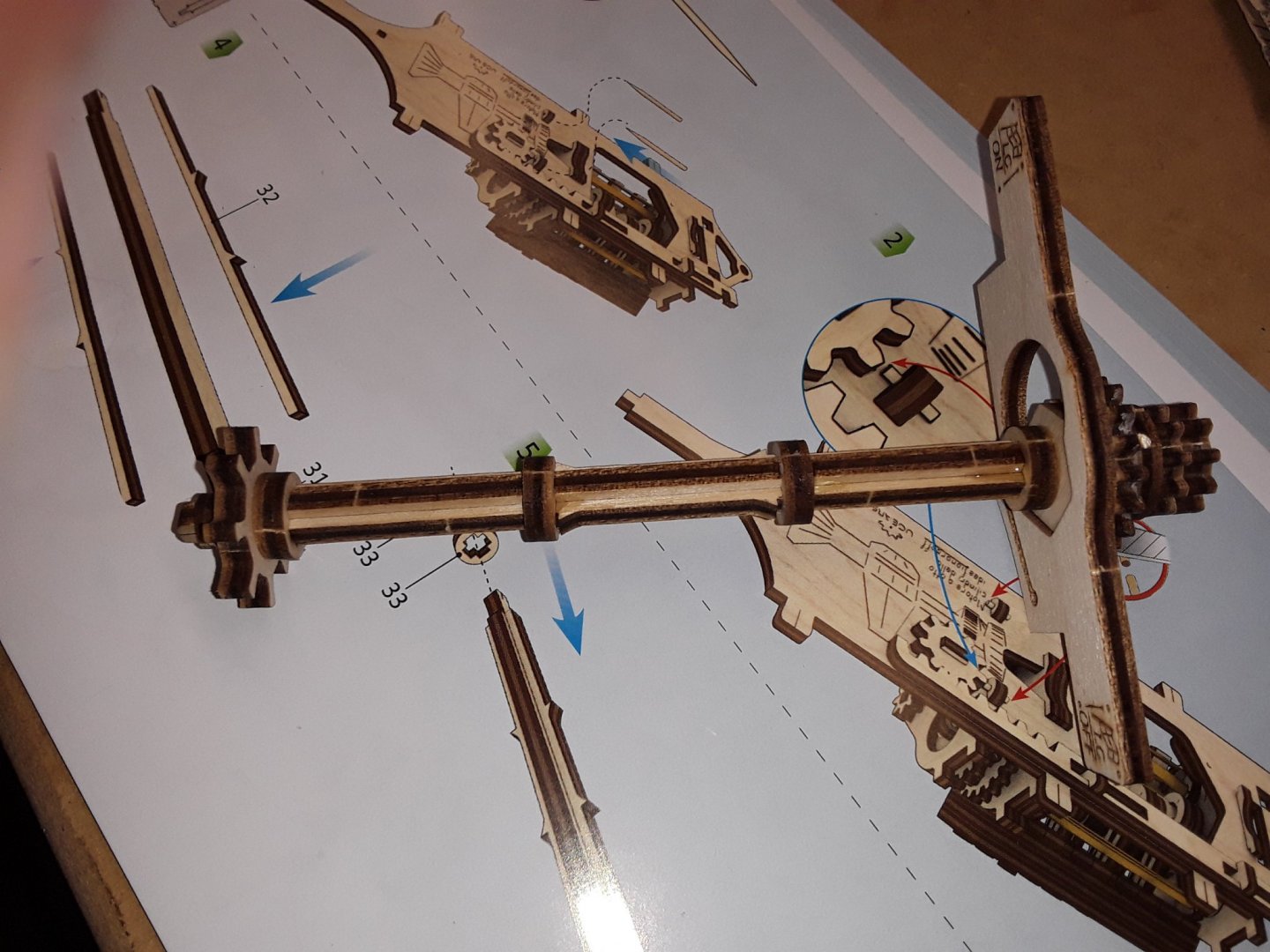

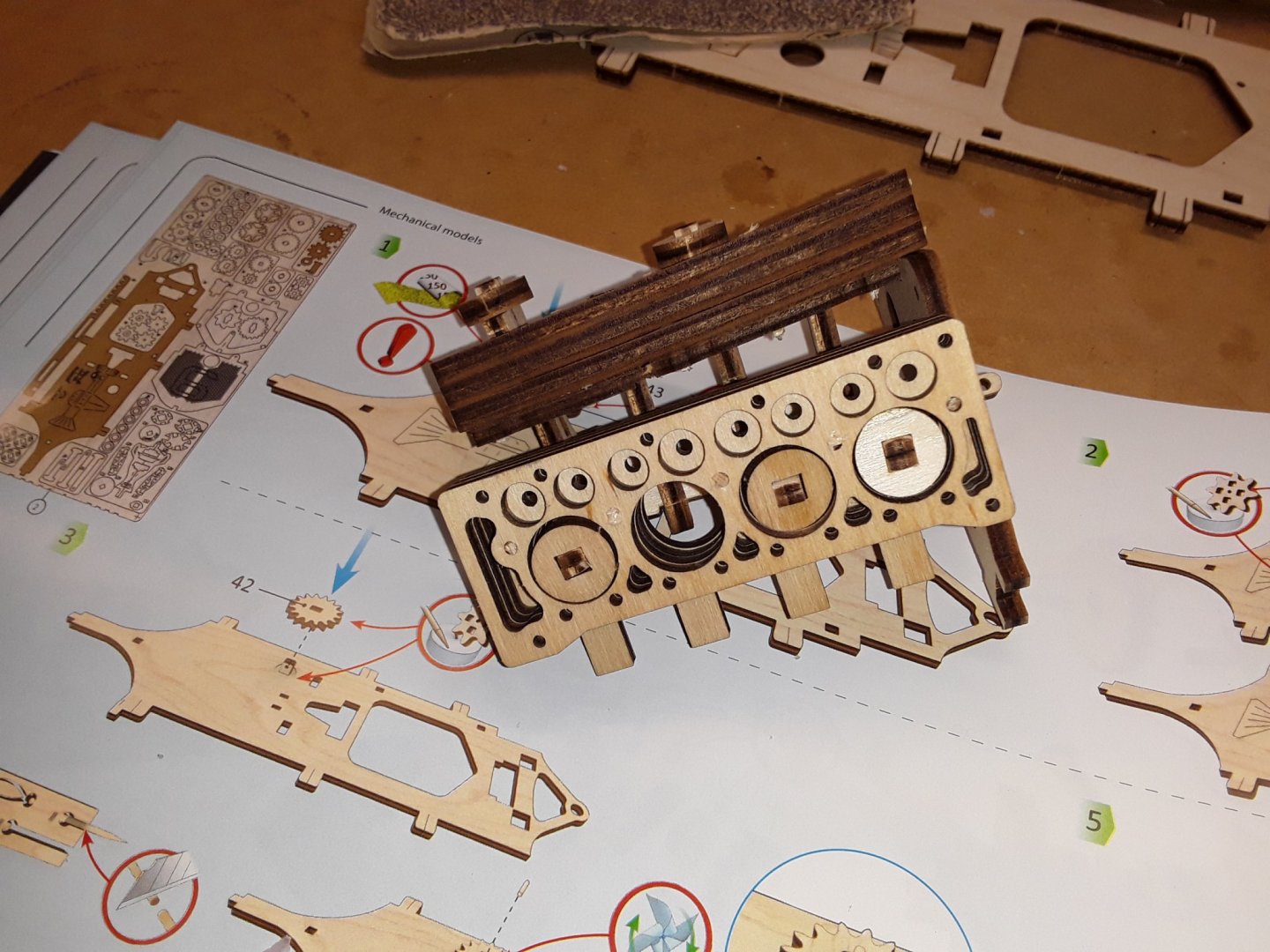

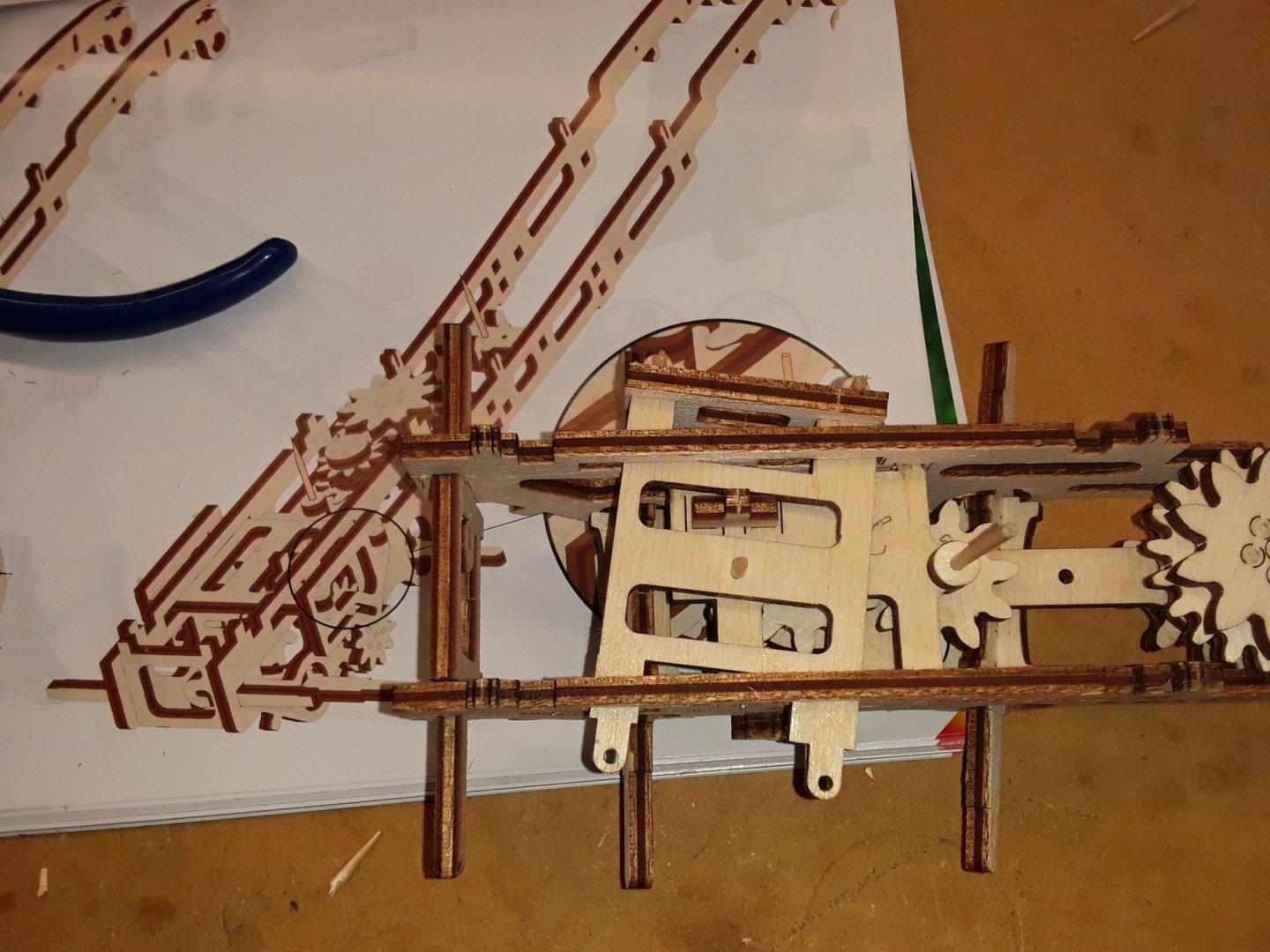

Was making great progress on the engine. I was testing how well the crank moved when a connecting rod broke. Ugears has a facebook site and they are sending me new parts. I get to take half the engine apart to put the rod and piston back in. The reason the pistons are sticking up too far is because the crank is sitting on the table pushing the rods up. But on a good note, the crank moves freely. I put candle was around the pistons and crank. -

Shawn is my son's step son. They don't get along too well, but they did recently build a plastic model car that they kinda sorta almost bonded over. I just bought the train that I did and will send it to him soon. Should take a lot longer than a plastic car and he'll for sure need my sons help. If for nothing else than his strength. Those parts fit tight. Especially the tooth picks. And there are a lot of them. Shawn gets frustrated pretty easy and my son has the patients of a saint. Didn't get that from me! I'm hoping it doesn't back fire.

-

I am a nobody. Nobodies perfect. Thanks for the kind words. I had no idea those sets were still around. I gotta get one for my grandson. My brother and I had a half dozen sets back in the day and we once built a robot. If I recall, my brother built a control box and could make it walk. Big sucker too.

-

I used to be "Justblowinginthewind". I started out as clewless, I thought it was clever. I changed to JBITW when I found a picture of Sara Palin with her hair blowing. When Trump was elected I changed the avatar to one I found with his comb-over blowing in the wind, but I got a warning from some complaints. Someone else snagged clewless so I decided since I can't do anything with wood, I'd use my current handle. Fact is, I'm bi-polar and have seizures, and the meds I take make it hard to focus or concentrate so I have a hard time with anything that takes planning and concentration. I was an electronic information security officer for a multi-national LLP, but I retired because I can't learn anything new. I can't keep up with new technologies. I used to be great at chess, but now I can't finish a game without getting frustrated. Probably because I always lose:) I can build a ship until it comes to to rigging. I did a fantastic job on the Niagara until it came time to hang the spars. I can't get the rigging taught. But I enjoy the quiet of a ship so I will never quit trying. I LOVE tall ship. BIG fan of C.S. Forrester.

-

I'm not going to bother. I searched Amazon for ugears and didn't realize this was not a ugears product. Went back to Amazon to check the rating and it gets 2 stars. Ordered a couple more ugears that got 4.5 stars. I'll finish it but I don't care if it moves or not. Would have been cool to see the pistons going, but I'm not that patient. Unless it's a ship which I won't be doing until we move this summer. I found several issues in the instructions. It'll say to put a part on the passenger side, when in fact it goes on the drivers side. Too late to fix now without completely taking it apart which loosens the parts so they don't fit tight.

-

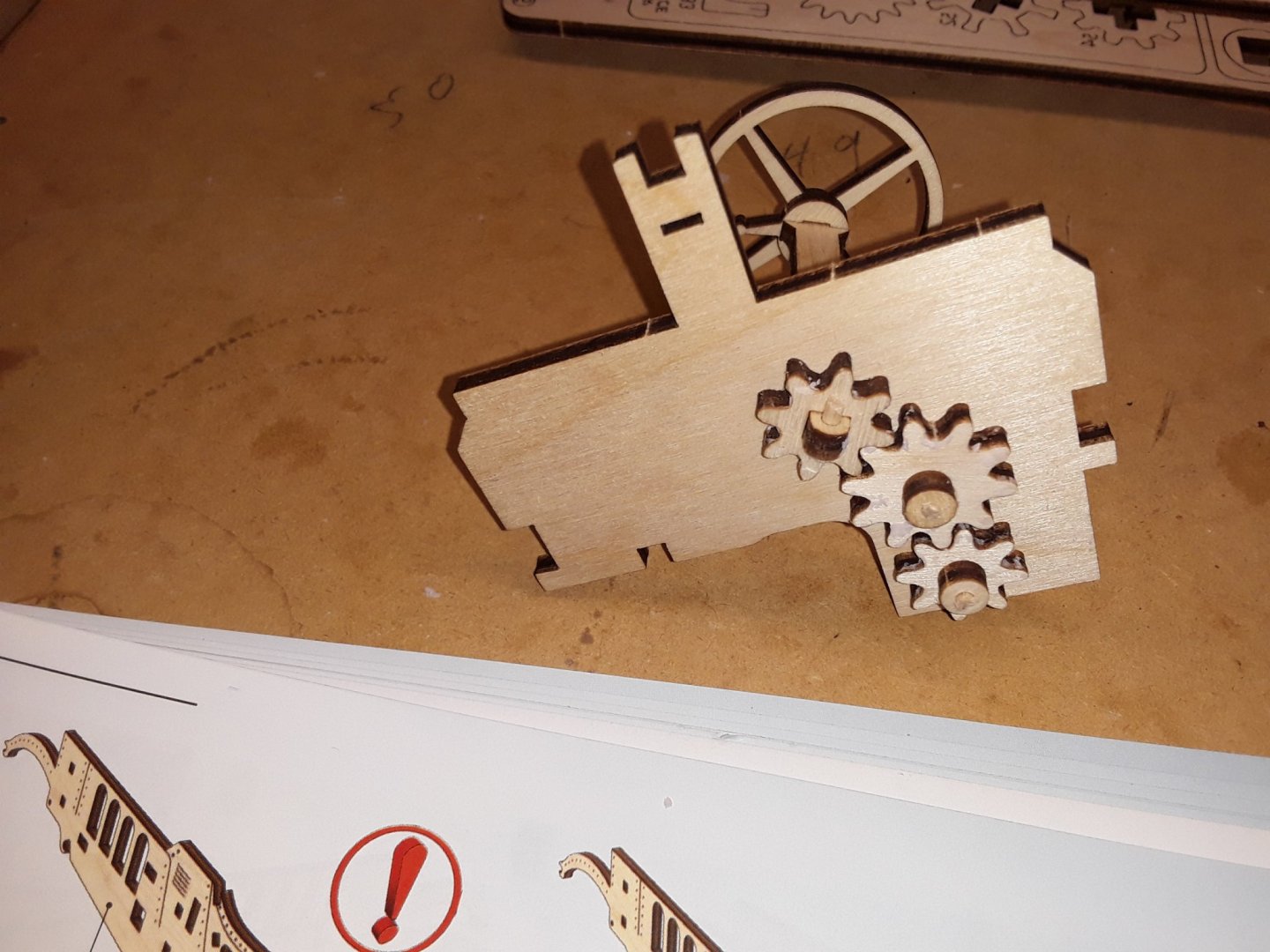

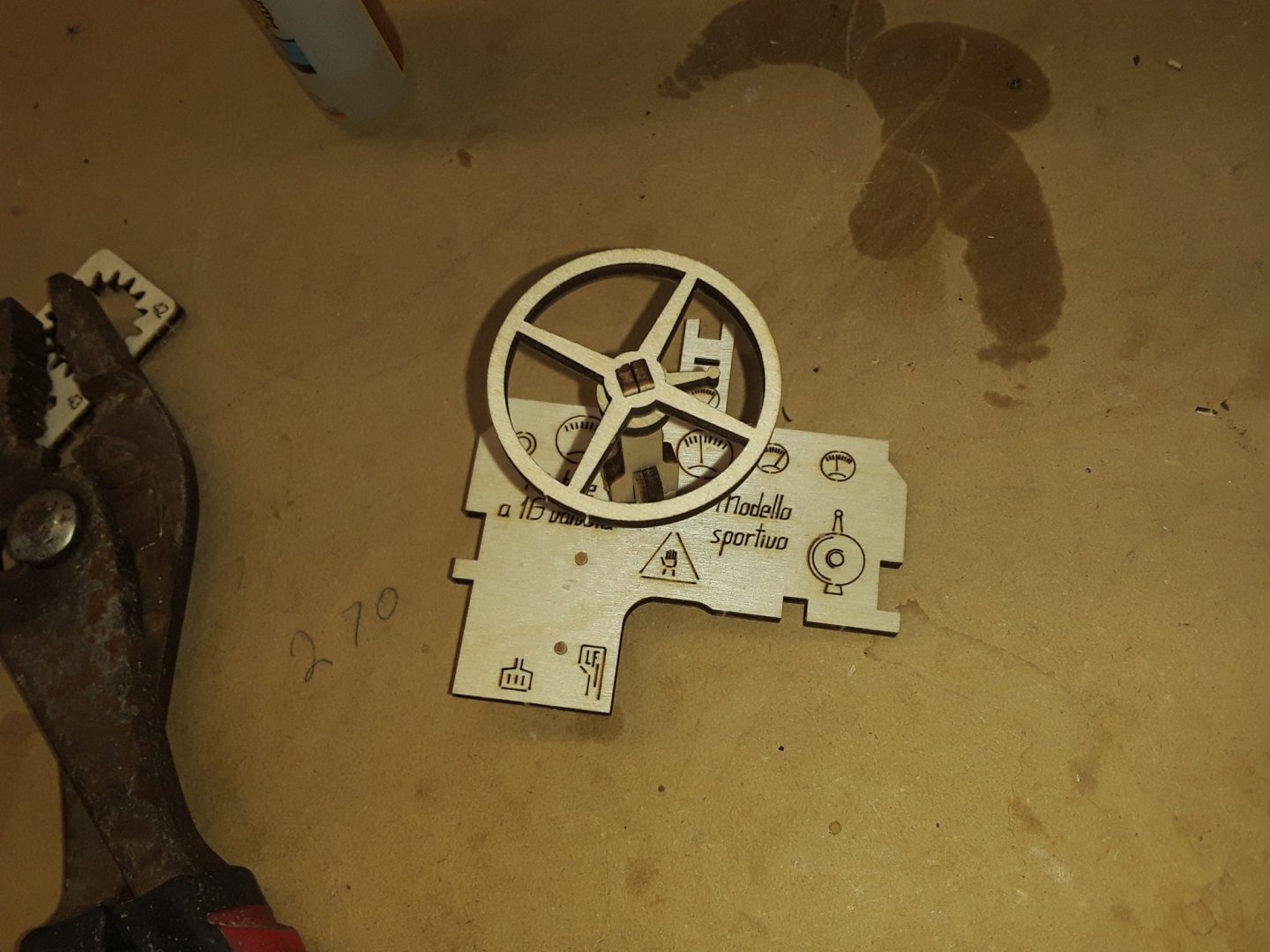

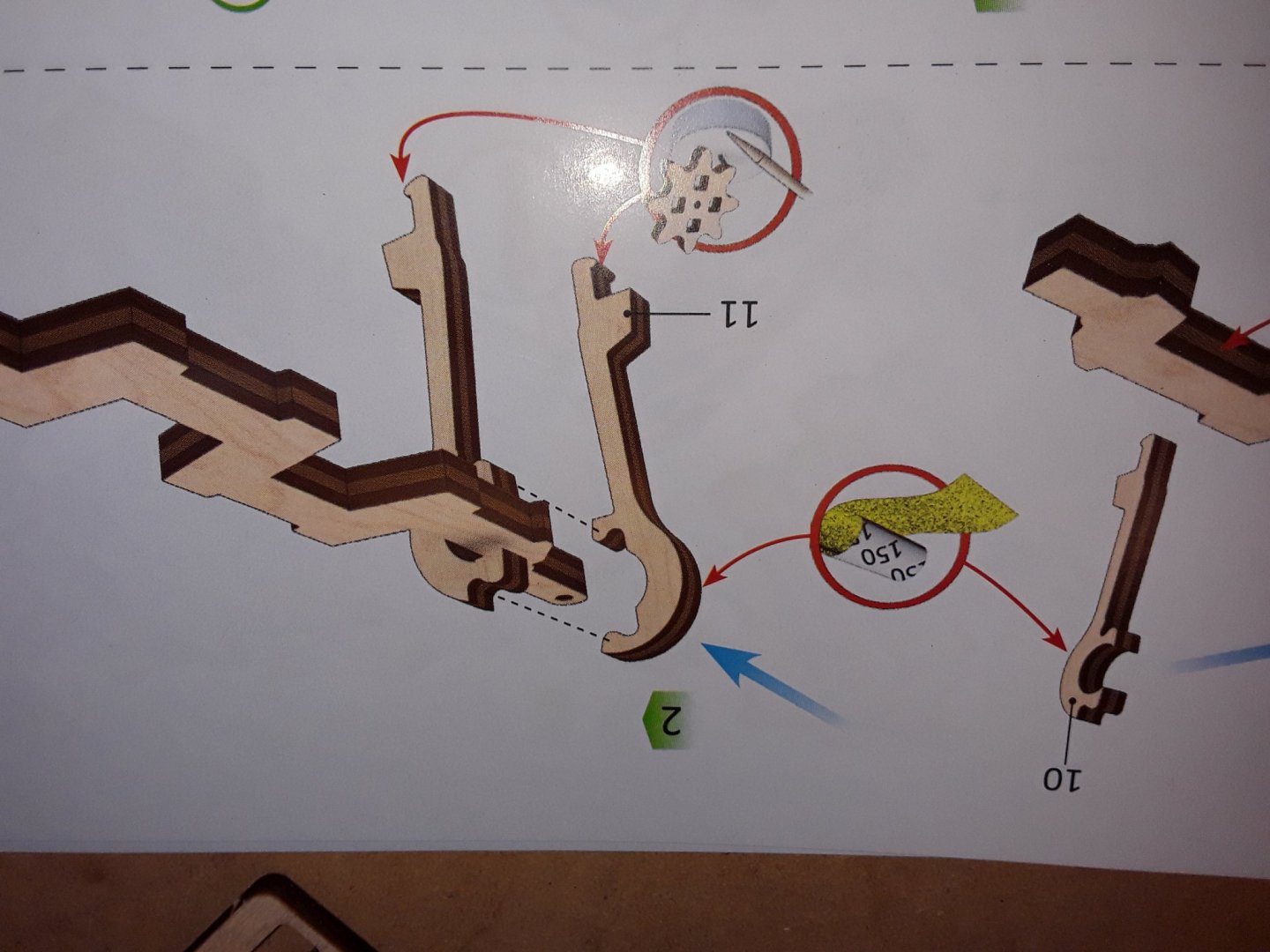

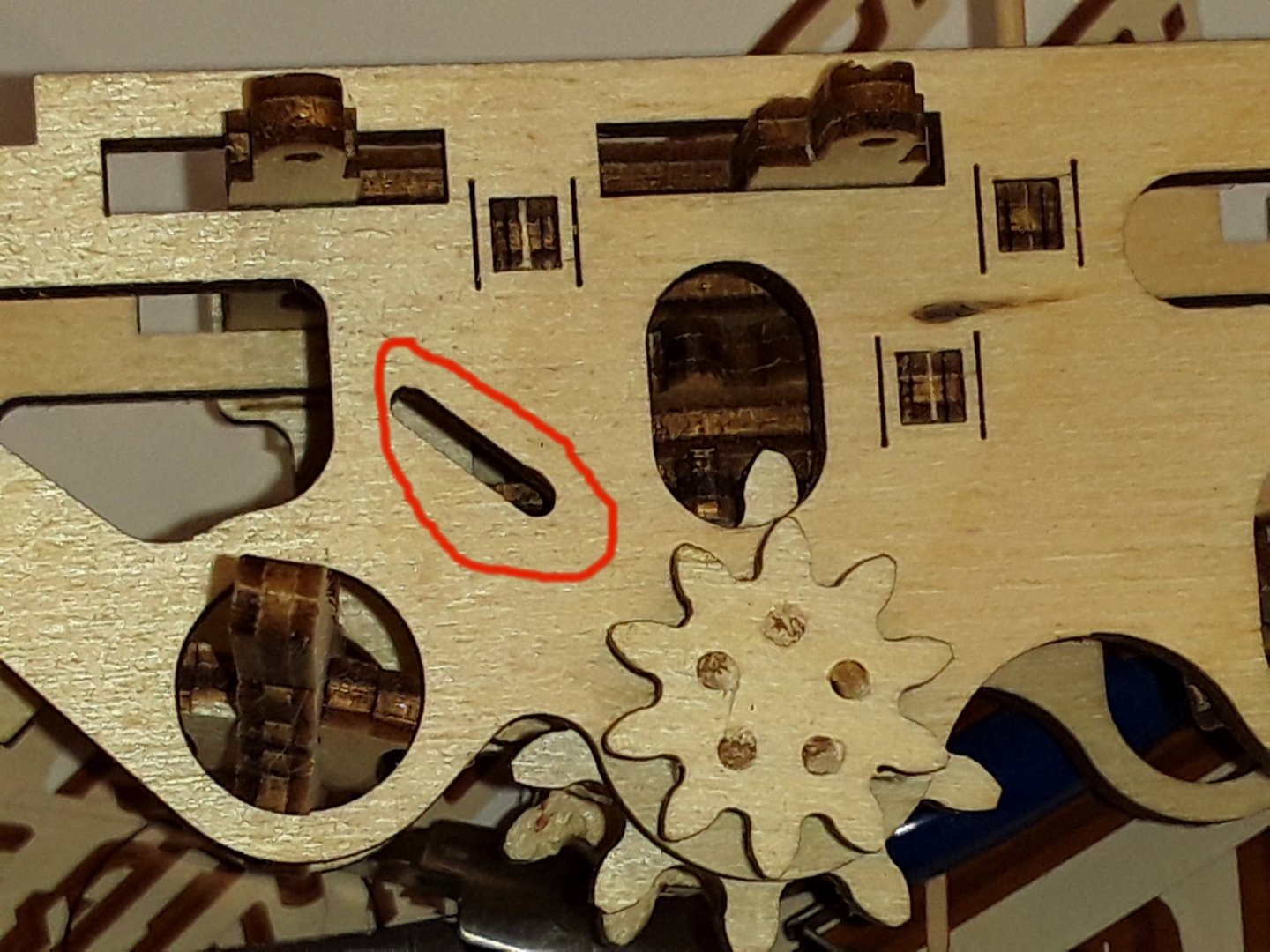

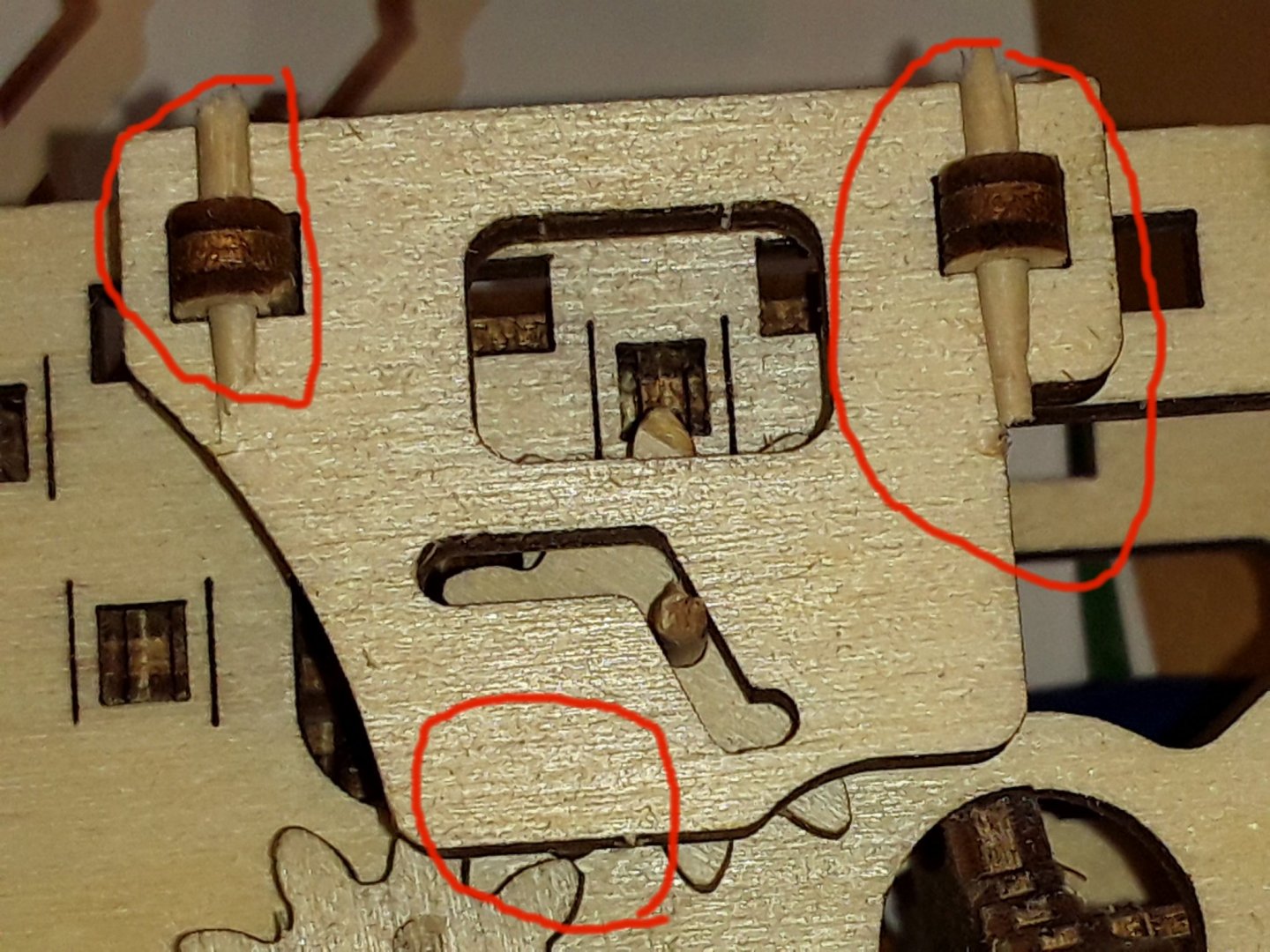

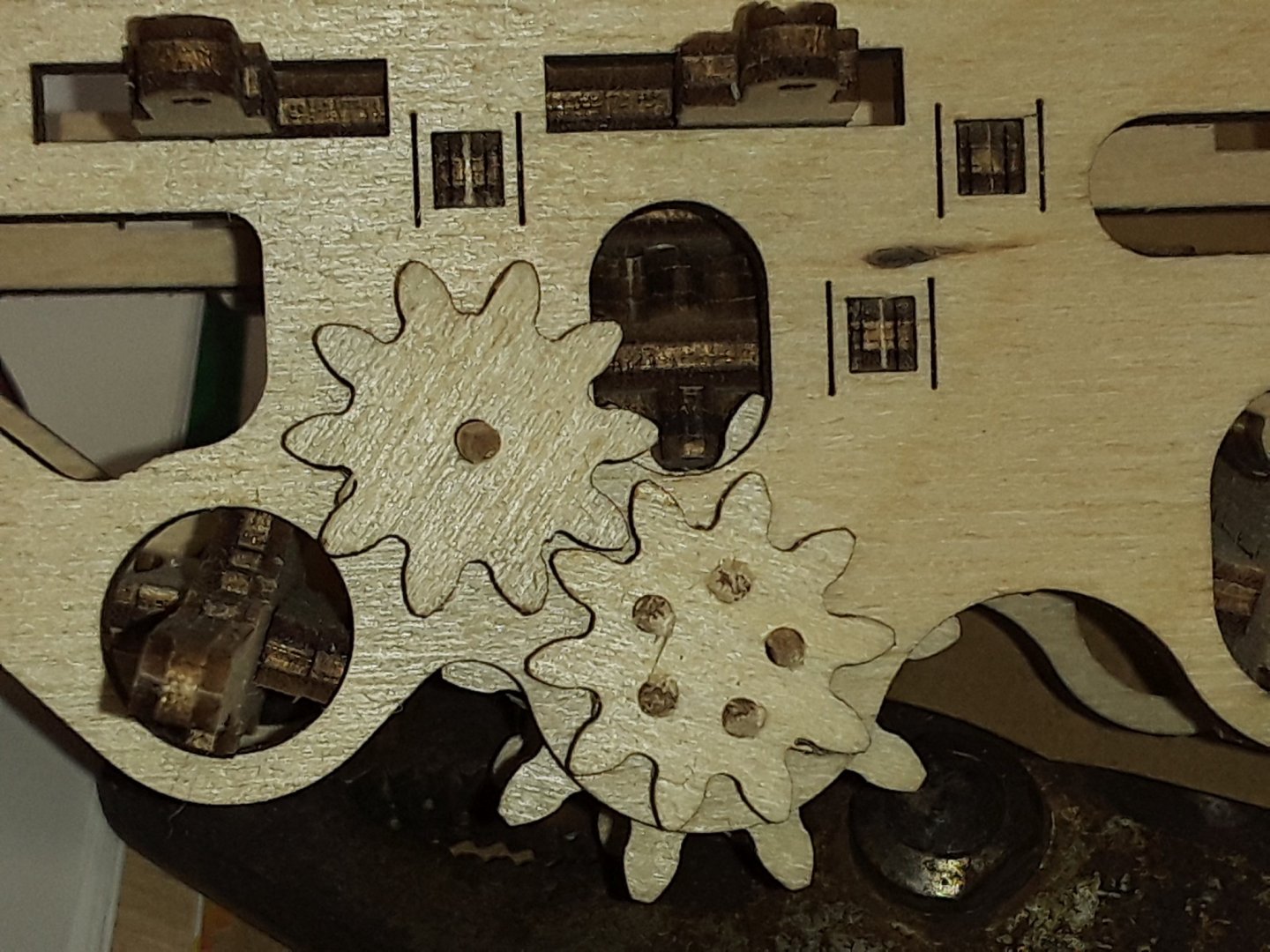

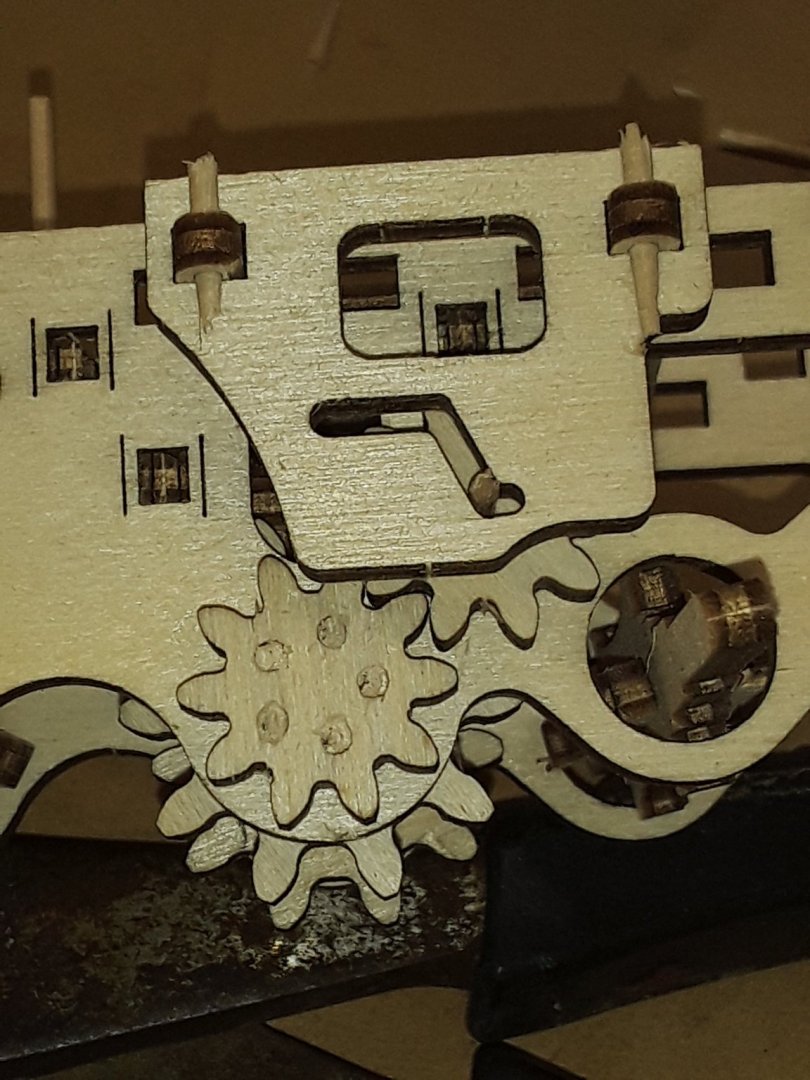

Here's hoping pictures are worth a thousand words. I'm having a hard time getting the pictures and the text to appear in the right order so I'm numbering the pics so you can hopefully see what I'm talking about. 1. This is where the next gear is supposed to go. Not a hole, but a place where it can move. 2. This is a part that goes across the top. You'll see it better in picture number 5. See how much room there is for travel? 3. This part is supposed to hold the gear in place. Notice it too can move. A couple tooth picks hold that top piece in place. 4. As you can see the gears don't mesh. 5. This is how scewed the top piece can be. 6. Removed the cover and tried again doing nothing different (That I know of) and it lines up. 7. Cover back on and good news! 8. This is where the gear goes on the other side. 9. The other side again. No matter how many times I try I cannot get that gear in. I can't hold the top in place at the same time I hold the gear in place at the same time I put the cover on it. Obviously nothing is moving:) Even before adding these gears, it's very difficult to move the gears. The gears are supposed to go all the way to the front and move the pistons. Unless someone else can see something I can't I'm thinking the engine is seized before it ever starts the 1st time.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.