Thank you for many comments.

Hi Mark P,

In fact, I have already prepared a step-by-step manual that explains the steps from learning software to actual creation work. It seems to be the best for learning this method. Please wait until I finish writing this topic on how to make it open.

Hi jaager,

This is an easy and much faster drawing method as you say to create accurate shapes at scaled size, correction drawings according to various processing machines, etc.

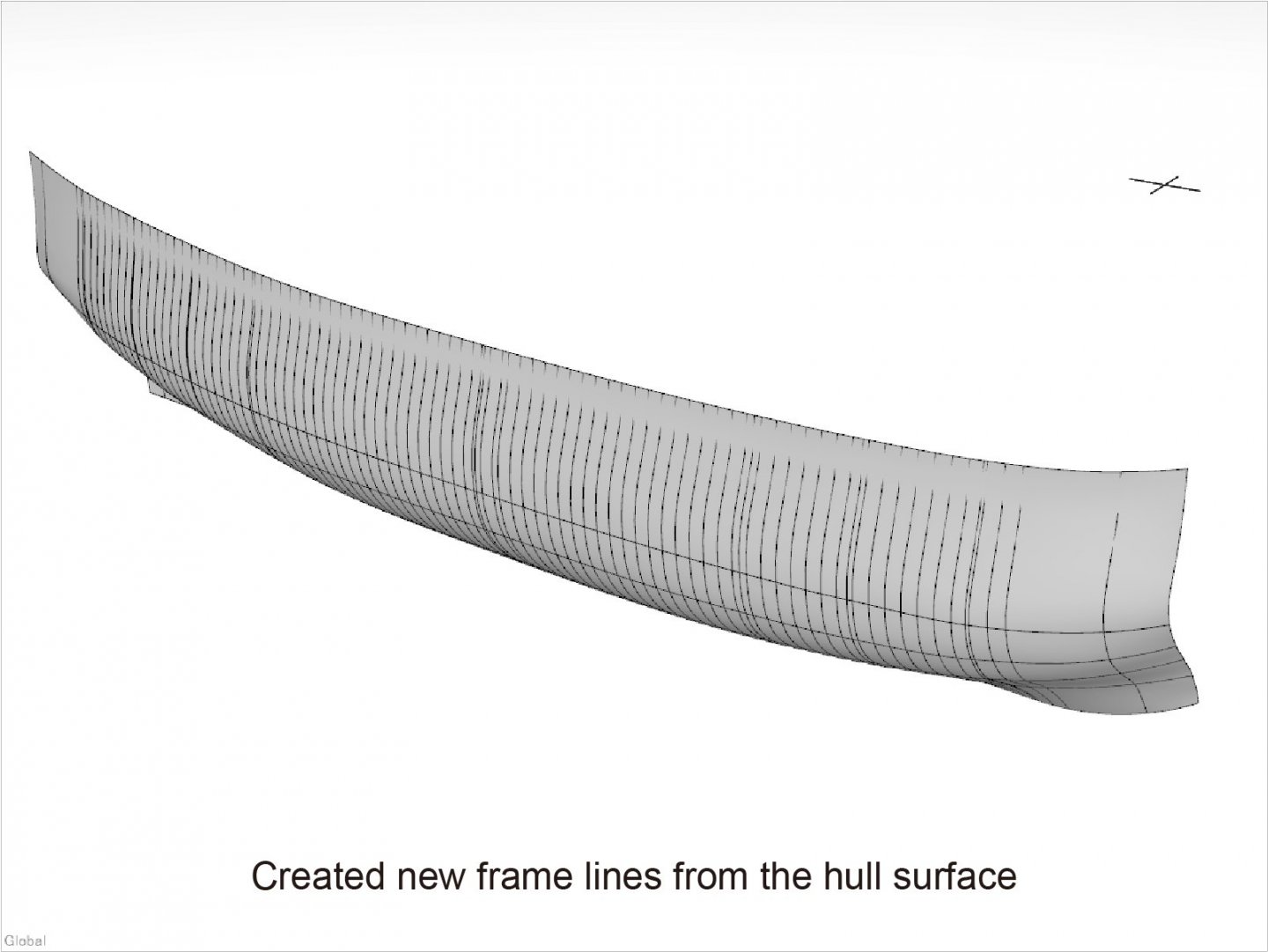

The number of lines for inside shape is as good as 10 when creating the outer shape. Actually, the lines drawn with the outer shape are copied and shifted the control point inward by the thickness according to the height.

In case the laser machine I am using in rental shop, the data machine recognize can still be used in Illustrator format. Therefore, there is no malfunction due to conversion. As far as I know, laser cutters seem to be able to use 2D graphics data such as Illustrator, CorelDraw, etc. as they are.

If this can be said to be a development product, I want to have ownership. However, the purpose of my posting on this topic is because I want anyone to use this technology openly. I think there are some things that need to be addressed for that. I'm old enough.

At first, I was skeptical about the use of lasers, especially for scratch builds, but since the advantages are much greater than the disadvantages, I put them to practical use after considering how to avoid the disadvantages.

Workarounds will be described soon in this topic.

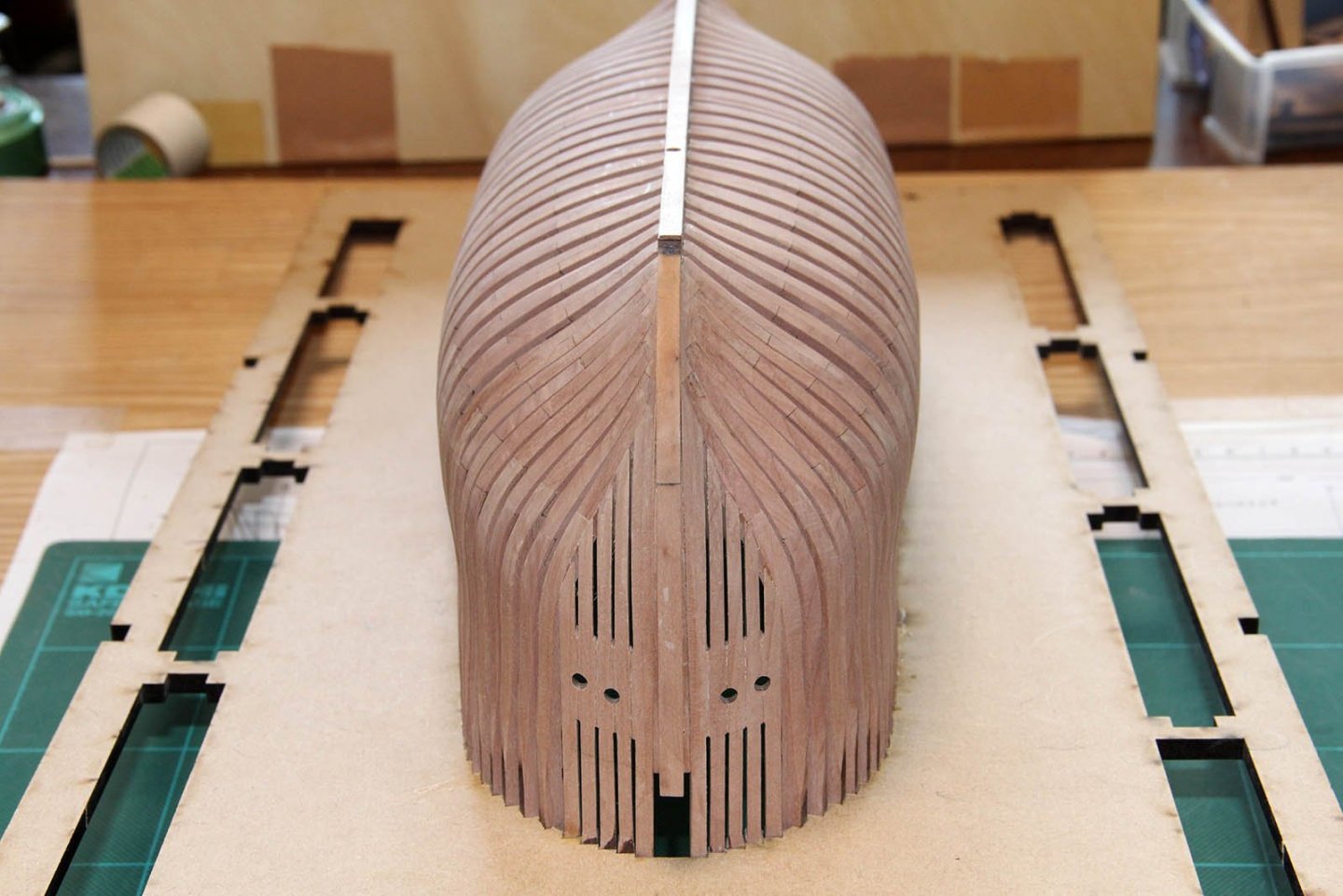

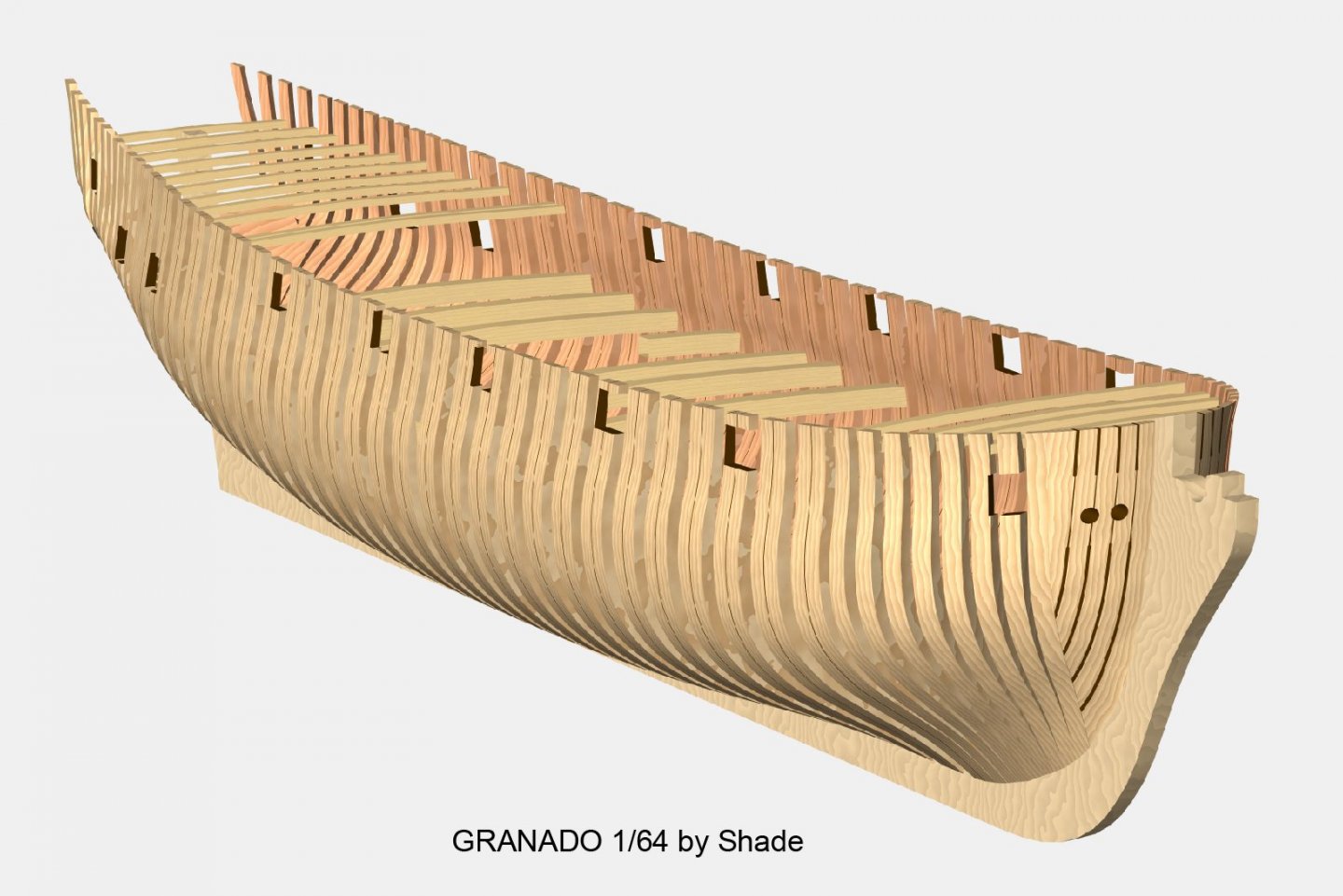

I actually designed a part equivalent to one structural model kit, processed it with laser cut, and am currently in building for verification. I have cut over 1,500pcs of parts within 8 hours. This picture is hull made parts by laser cut (just lightly sanded to remove burn mark). Also the cross section that took out some of it is my thumbnail.

To evaluate this method, please read this topic until it is over. I hope it will meet your expectations.

Hi PietFriet,

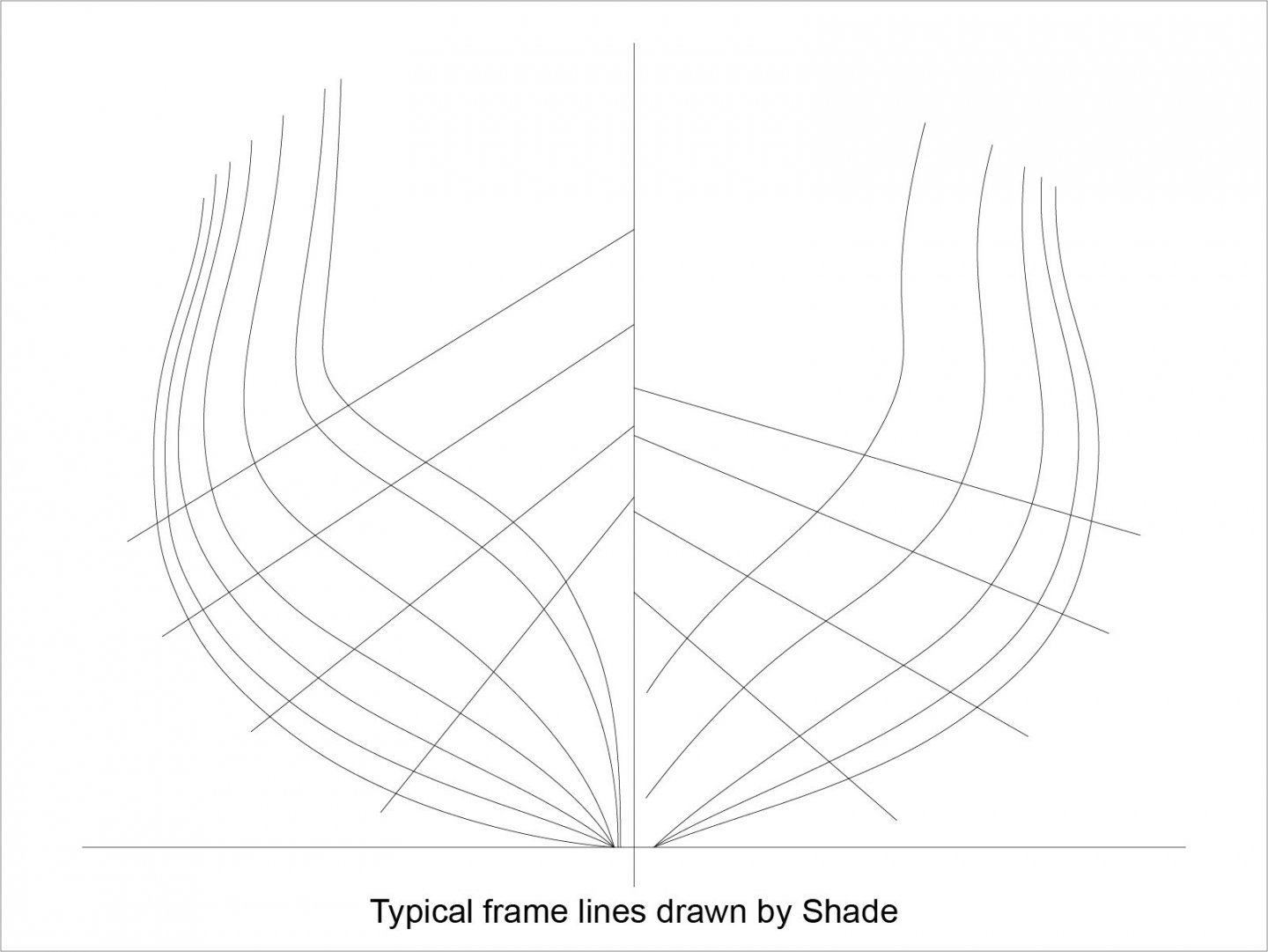

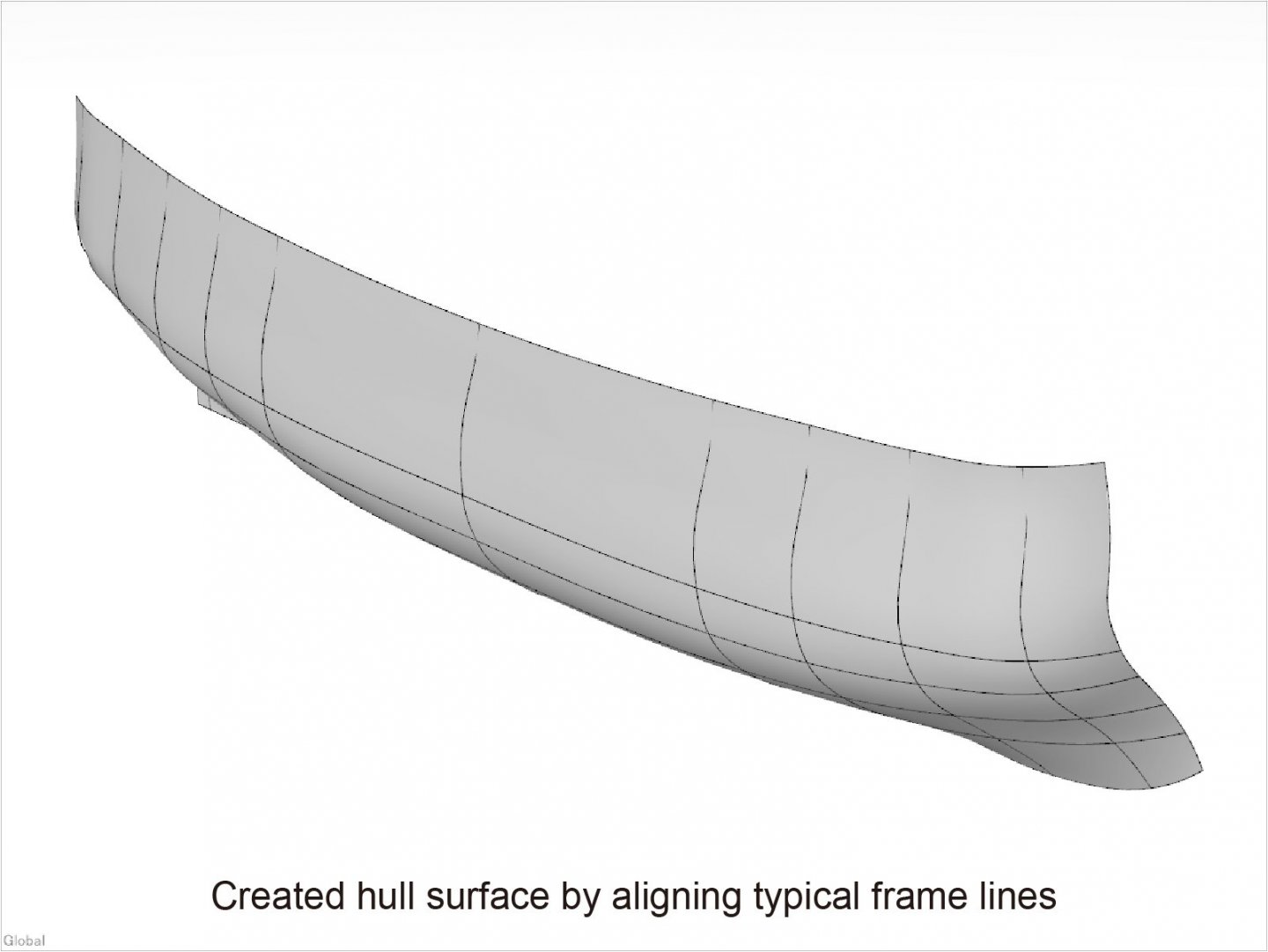

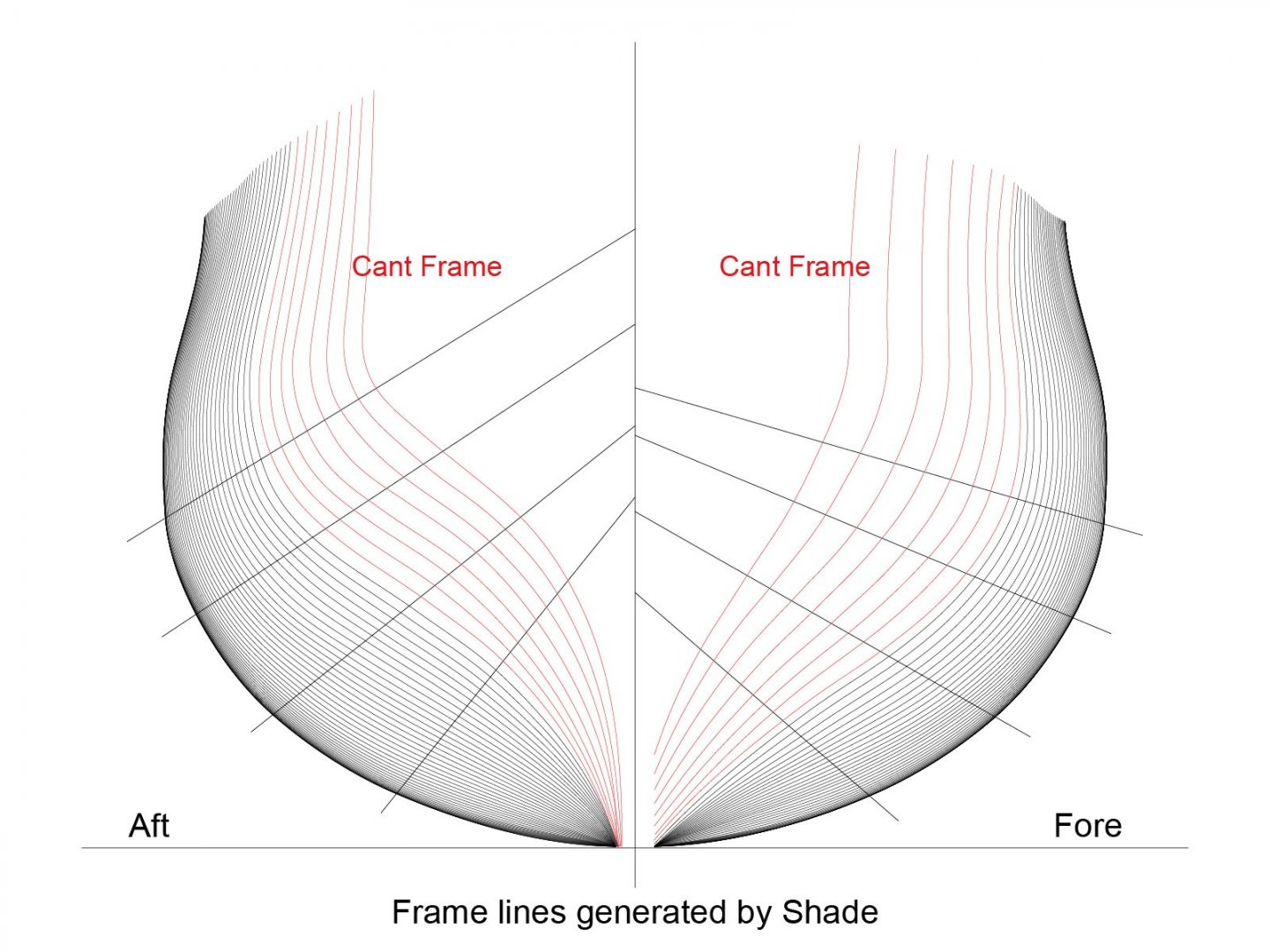

I have no knowledge of Delftship at all, but I think it can be used if it is software with similar functionality to the 3D graphics software I use. It is a free-form surface creation function by Bezier curve and numerical control function for dimensions and coordinates.

Thanks again,

Kiyoo