-

Posts

137 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Lee J H

-

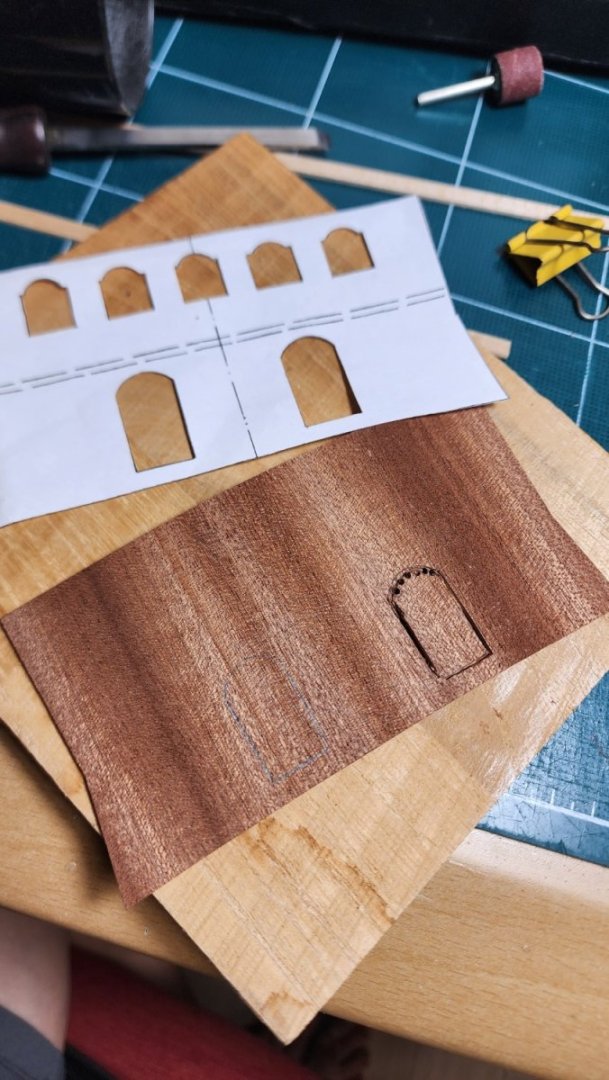

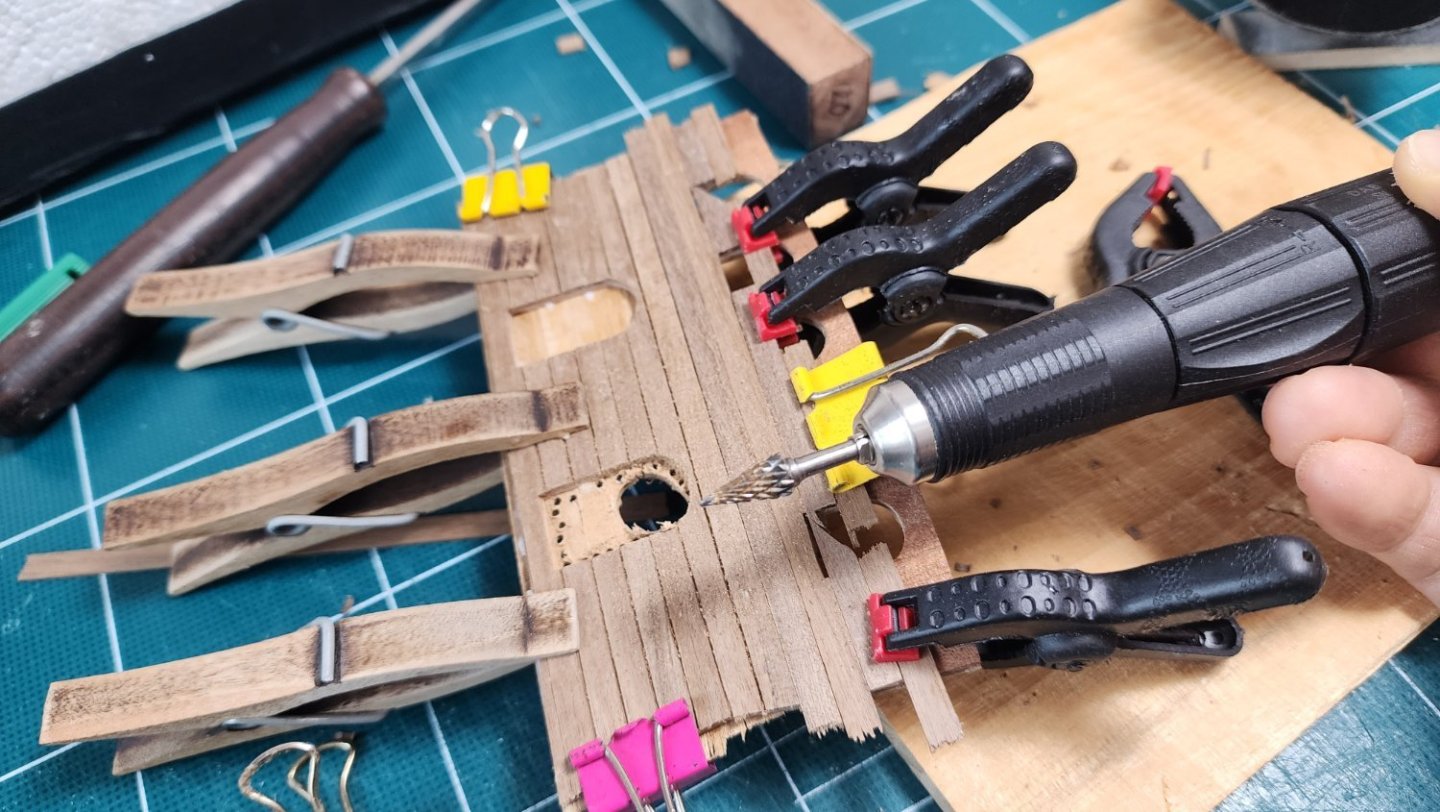

The political situation in Korea is not good these days. I think it has been widely reported overseas through foreign media. I hope that politics will stabilize soon. I made the main deck gate frame. Since it is difficult to do it according to the drawing dimensions, the actual size is different, so I made a compromise with the lower gate frame and the drawing and marked it with a pencil.

-

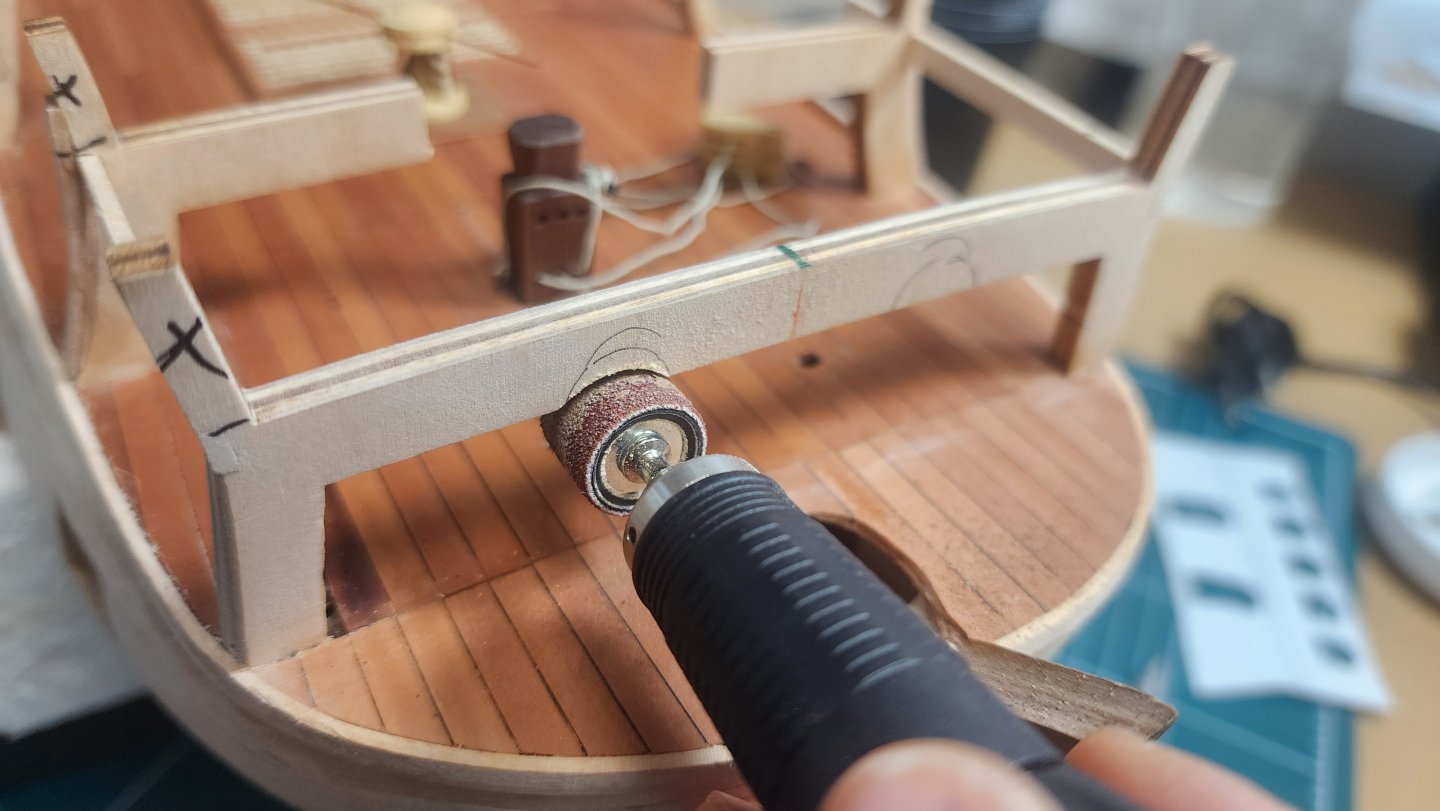

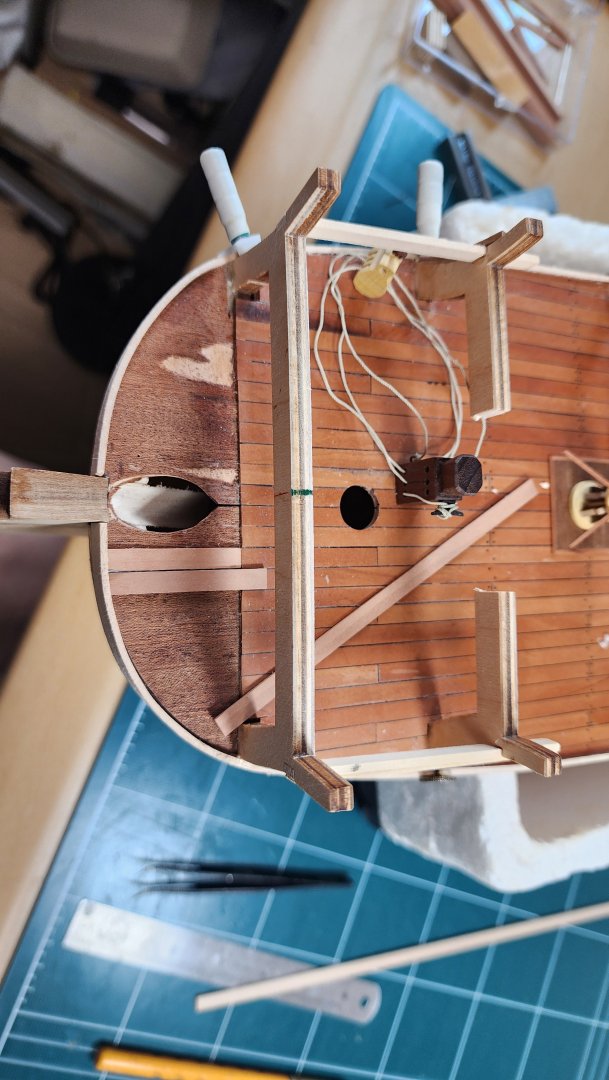

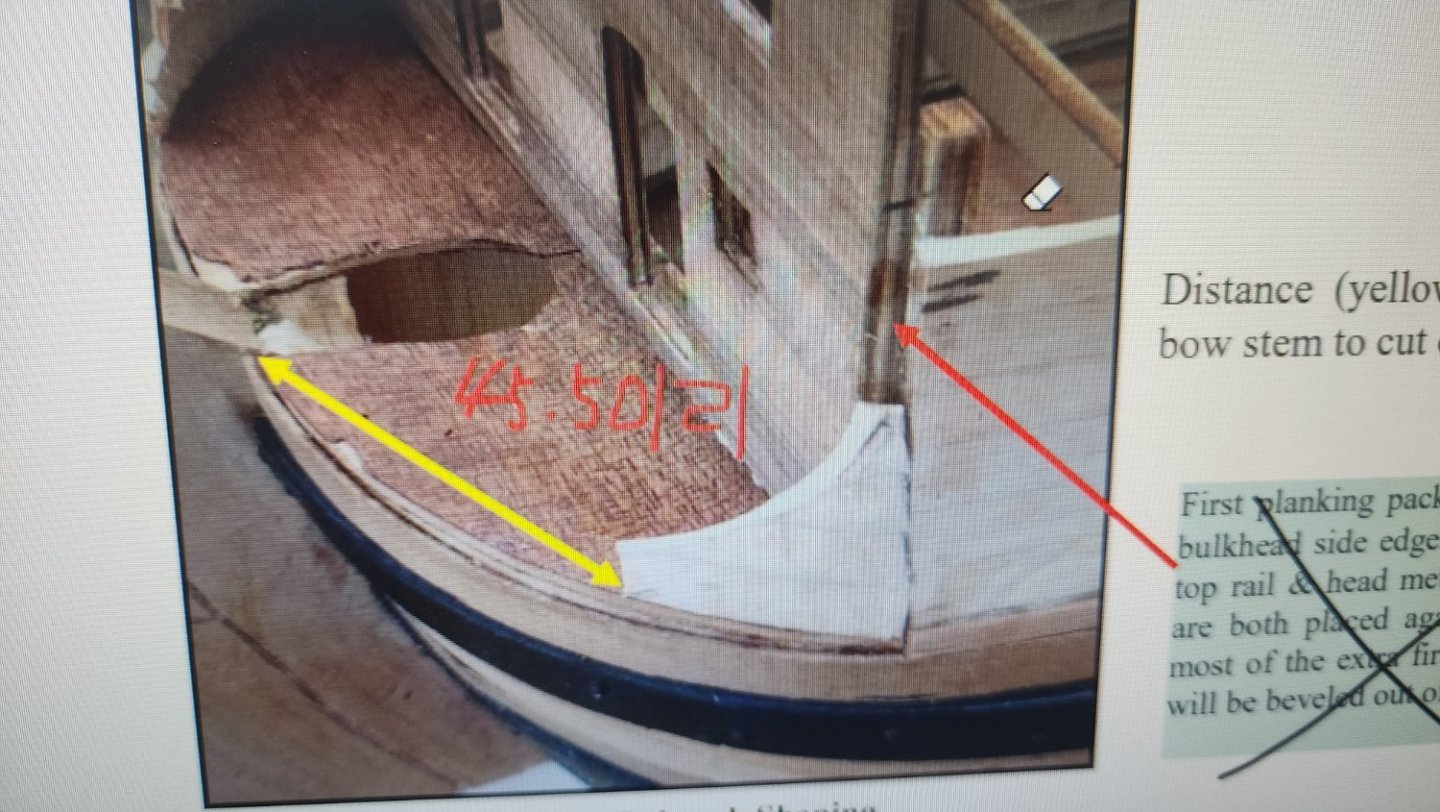

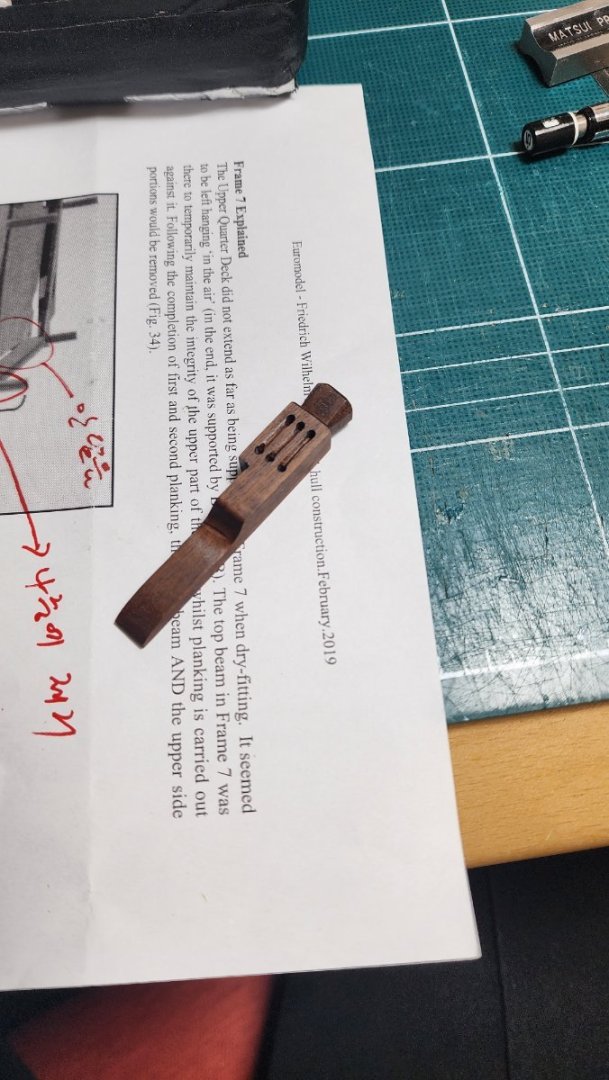

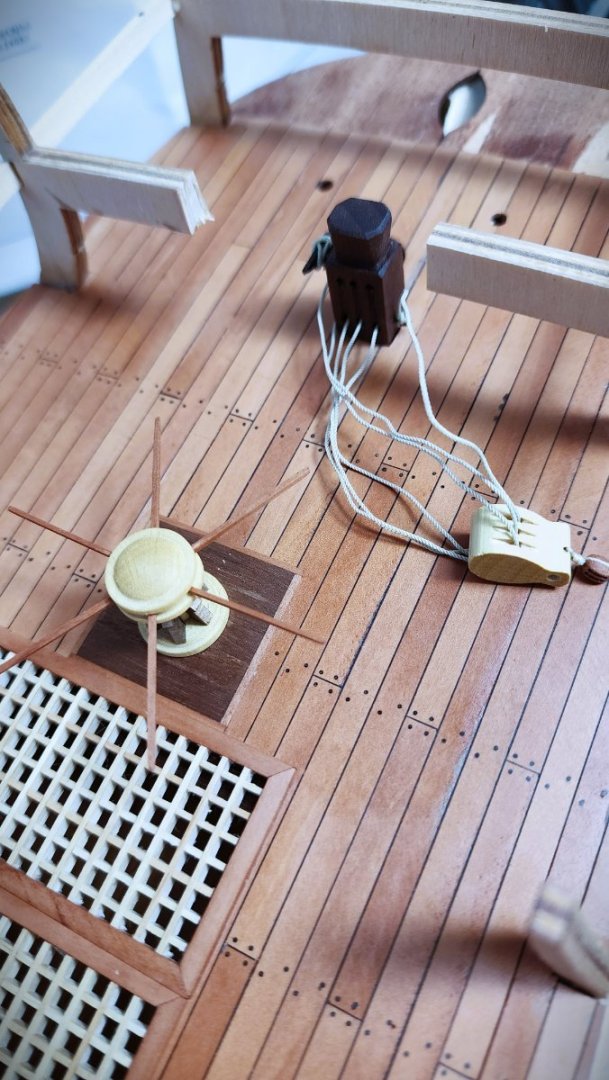

According to the manufacturing machine provided by the company, the bent part of the wiring wire is supposed to be worked on later. I'm trying to get connected and working. I don't know the name of this part, but according to the drawings, it is marked with a slight curve, so I try to bend it with an iron after soaking it in water. It's not thick, so it warps easily. You need to cut it out by marking where the door is and where the window is. It was flanked with 1 mm thick walnut wood, and pear wood was used for the window rimming. After this preparation, we plan to work on the details later.. By the way, the ribs in this kit look like they have a lot of places to mend them. I need to clean up my ribs. There are a lot of steps.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.