Brian Falke

Members-

Posts

99 -

Joined

-

Last visited

Profile Information

-

Location

Jacksonville, FL

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

ccoyle reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

ccoyle reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

-

schooner reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

schooner reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

-

Ryland Craze reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

Ryland Craze reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

-

Ryland Craze reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

Ryland Craze reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

-

schooner reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

schooner reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

-

g8rfan reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

g8rfan reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

-

The Bitter End reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

The Bitter End reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

-

schooner reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

schooner reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

-

schooner reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

schooner reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

-

schooner reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

schooner reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

-

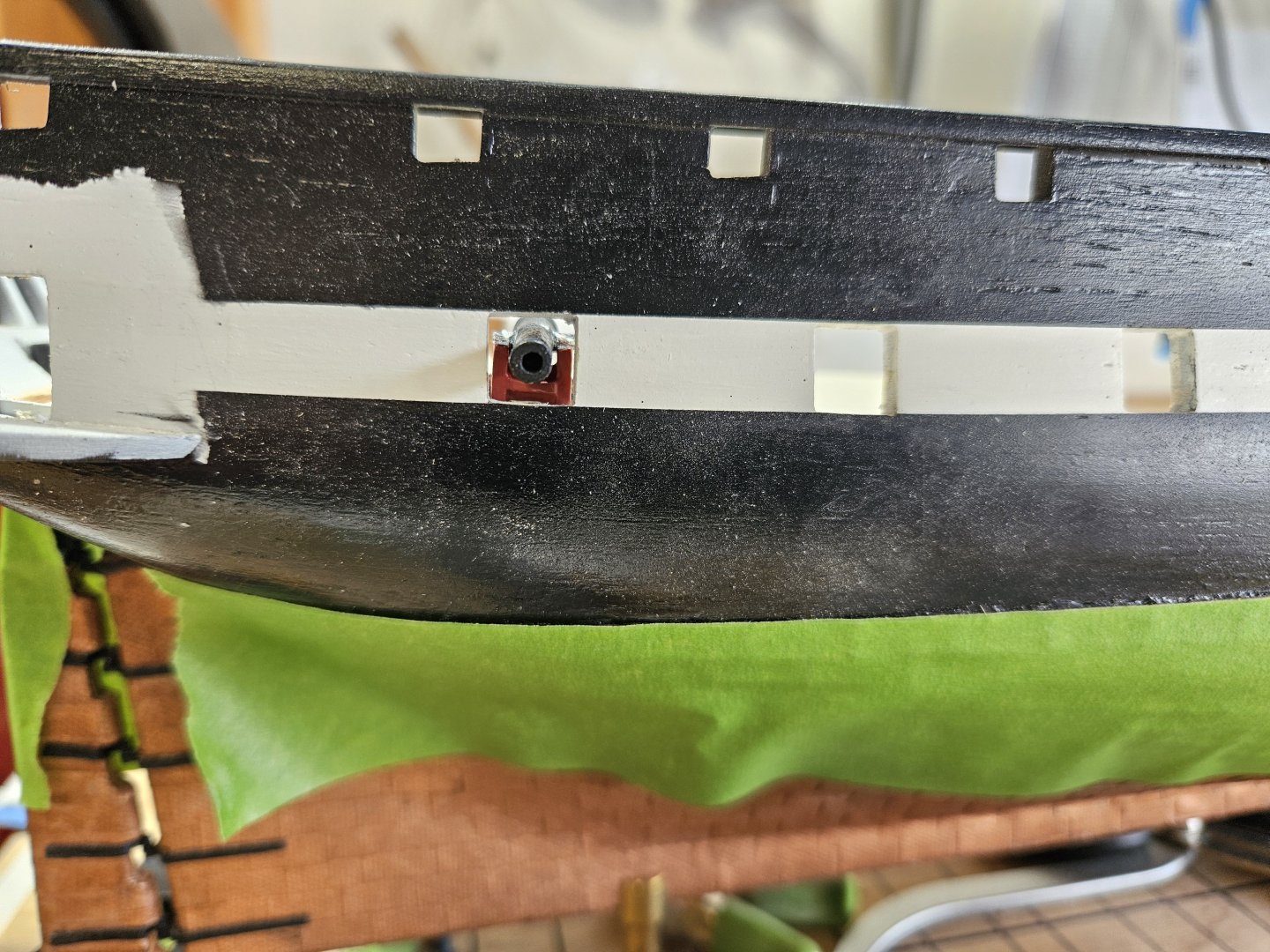

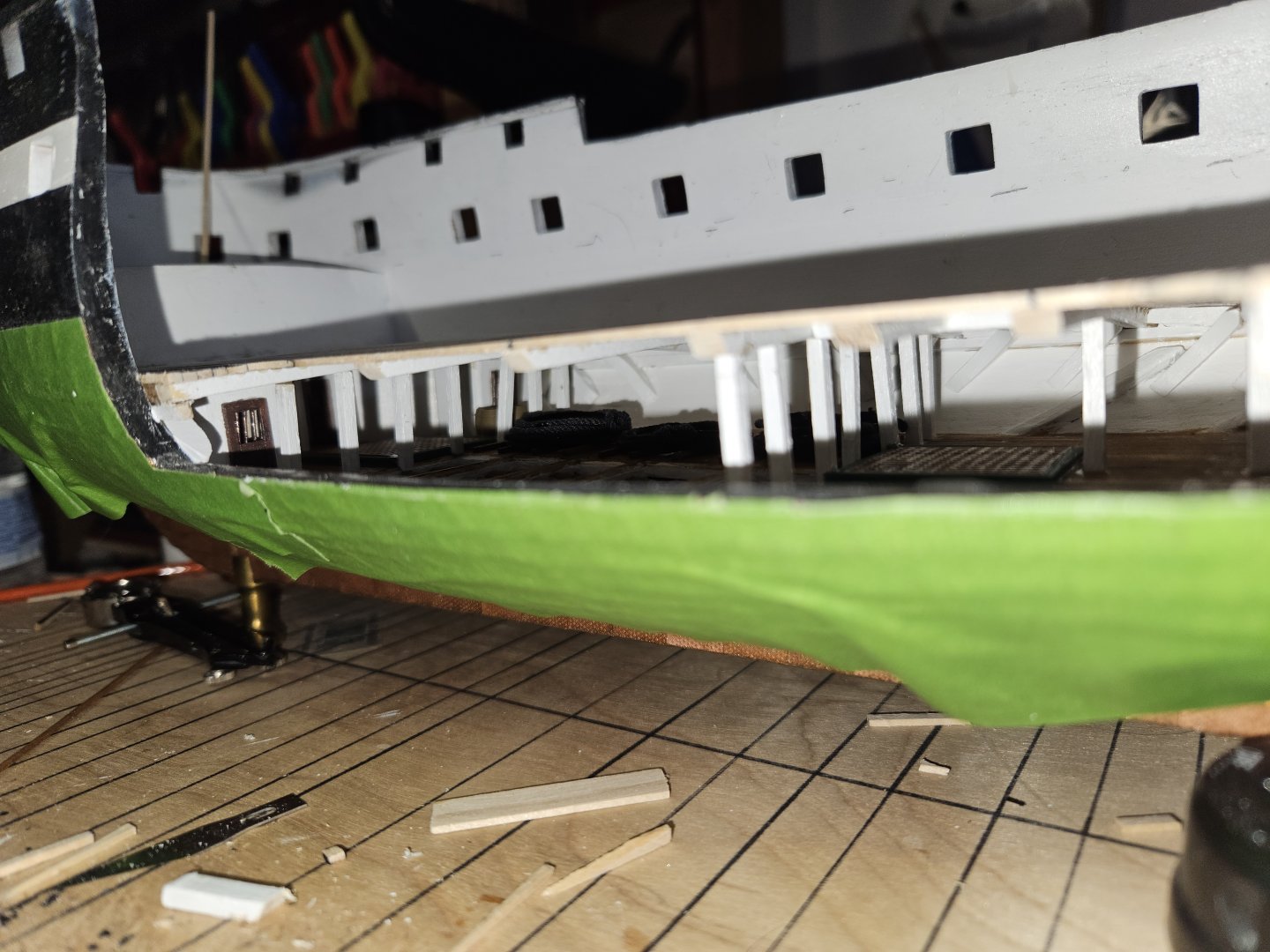

The decking is complete for the Berth Deck. I have started on the Gun Deck. My intention is to start installing the Gun Deck beams from Aft to Forward. Once I get to the green false bulkhead base, I will then have to install the knees with each beam. This is a lot more complex than the knees for the berth deck beams. Also, with the deck beams being about 6' apart, it would be near impossible to install the knees and if it was, they would not come out to my expectations.

-

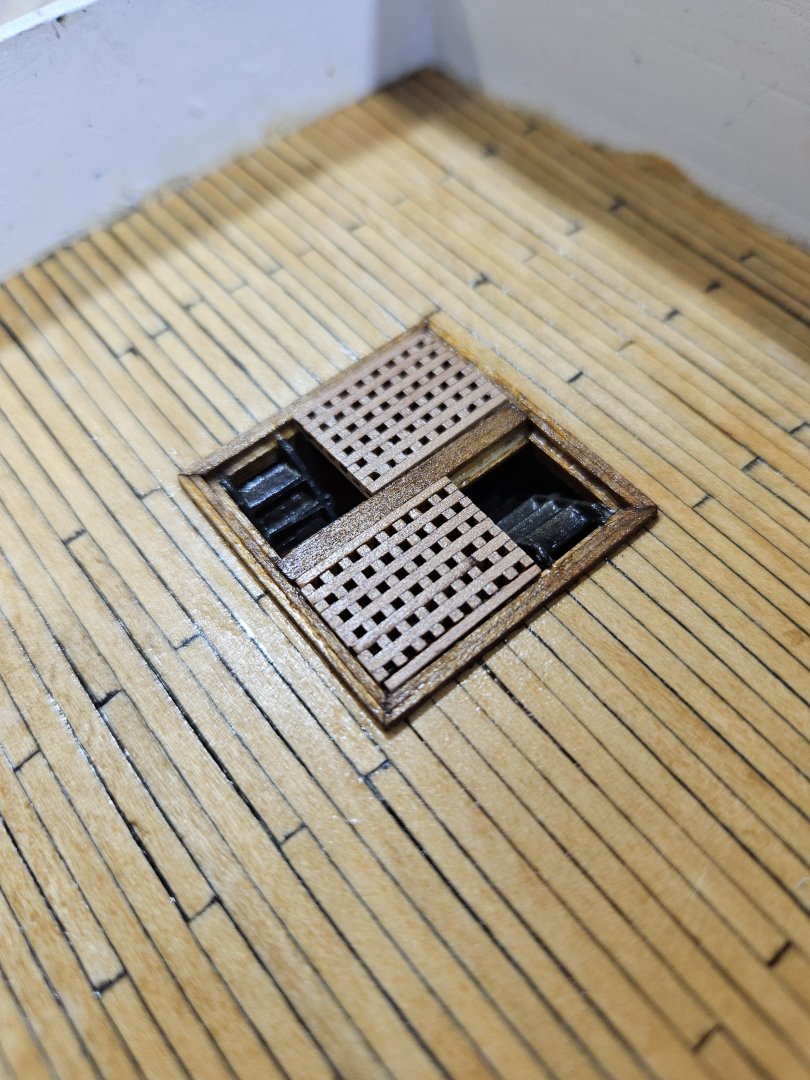

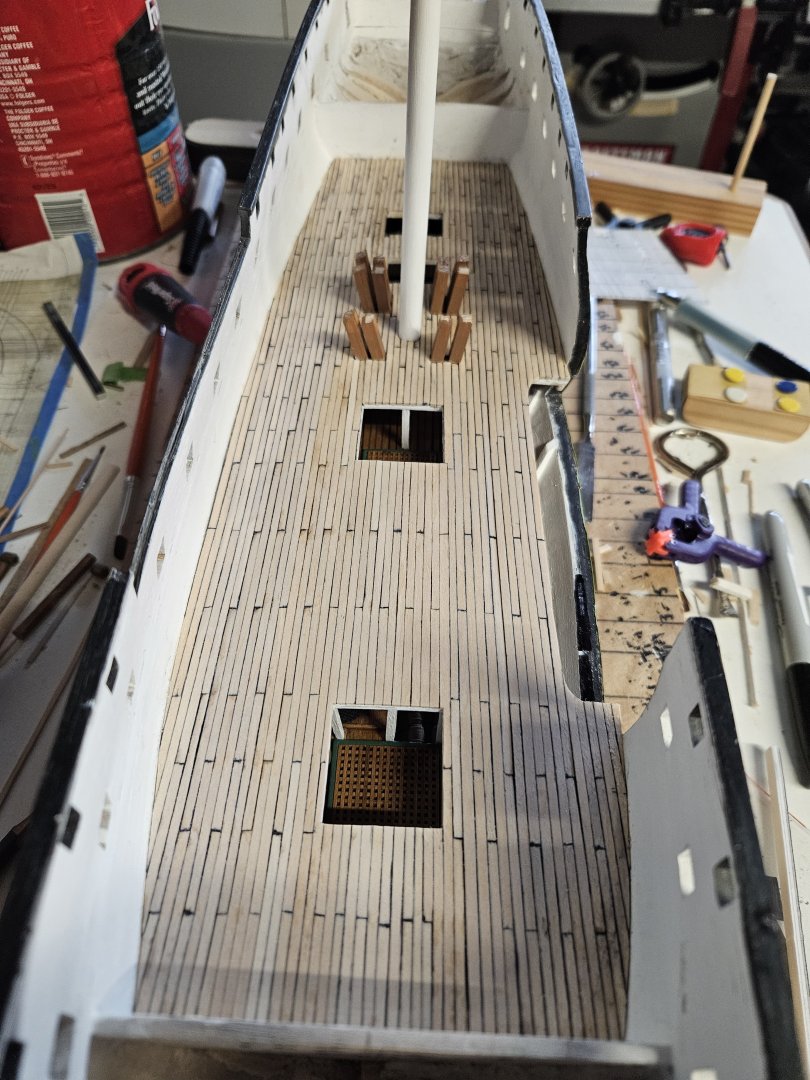

The Berth Deck decking is installed (still need to stain and varnish). For the port side opening, once I planked to just beyond the cable tier stanchions. Once the glue dried, I cut away the remaining beams and stringer. This opened up the viewing of the Orlop Deck. Next steps are to stain and varnish the deck. After that, move onto the hatch coamings and gratings, then install the ladders to the Orlop deck.

-

Started the decking. Using wood glue instead of superglue. Found that since superglue cured so fast, I could not get the plank tightly against the others thus leaving gaps between them. And, I admit, I am not the neatest when it comes to superglue. I have to sand my finger tips at the end of the day to get the glue off. With the wood glue, soap and water takes care of it. If you look closely, on the port side I made marks where I intend to stop the decking so the Orlop deck can be better seen from the side.

-

I feel the Orlop Deck is complete. Here are the views from overhead, looking forward and aft. The last pieces to put in were the up and down comers for the bilge pumps. That took a little research as the current CONSTITUTION has pipes. I found that they are square made from wood. This is so after battle, they could be easily repaired and put into use. Next step is to step the Main Mast, but first it would not be appropriate to step the mast without placing the good luck coin at the base. Since a normal coin would not fit, using a leather hole punch, I cut a piece of copper as substitute. Cheers, Brian After stepping the mast, it will be laying the decking for the Berthing Deck.

-

Thank you all for the recommendations and links. I did review them and analyzed the effort it would take to "adjust" the figurine to fit and have action, and it is too much. I would be working on the model until the end of time if I were to do what I feel is appropriate with regards to adding figurines. I am going to keep adding other items. Like in the cockpit, the surgeons table is setup with two casks for...well, limbs, etc. In the forward section of the Orlop, I intend to set up what it would be like for the carpenter. Also, there are a couple of casks by the main hatch ready to be hoisted up to the galley on the gundeck. Thanks again.

-

I have come to a decision on the figurines. Not doing it. First, could not find a good quantity of figurines that have some action. For the most part, they are just standing there. Second, could not find any at 1:96 that are US 1812 Sailors. And, felt I could not alter those that I did have into that era. So, instead, I will place those objects that give the observer the opportunity to place themselves in the action. On the Orlop deck I place a table and a couple of small casks in the Cockpit as if the Doctor were back there working on a Sailor (probably amputation). Up forward of the Fwd Hatch, I have placed a couple of larger Casks as if they are being readied to hoist up to the Galley. Amidships, on the Cable Tier, I have coiled line that would be the size used for the Anchor line. I still have to put something (have not researched deep yet) that has the Carpenter working on something forward. Now, will the observer be able to see these once I am finished? I do not know. But, I would rather have them there and not be able to see them than have nothing and be able to see a blank, dead space. Cheers.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.