-

Posts

86 -

Joined

-

Last visited

About CommodoreErie

- Birthday 07/18/1989

Profile Information

-

Gender

Male

-

Location

Erie, PA, United States

Recent Profile Visitors

-

aaronc reacted to a post in a topic:

Grand Banks Dory by CommodoreErie - FINISHED - Model Shipways - 1:24

aaronc reacted to a post in a topic:

Grand Banks Dory by CommodoreErie - FINISHED - Model Shipways - 1:24

-

aaronc reacted to a post in a topic:

Grand Banks Dory by CommodoreErie - FINISHED - Model Shipways - 1:24

aaronc reacted to a post in a topic:

Grand Banks Dory by CommodoreErie - FINISHED - Model Shipways - 1:24

-

Ryland Craze reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

Ryland Craze reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

-

SiriusVoyager reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

SiriusVoyager reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

-

MajorChaos reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

MajorChaos reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

-

robert952 reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

robert952 reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

-

Bryan Woods reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

Bryan Woods reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

-

JacquesCousteau reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

JacquesCousteau reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

-

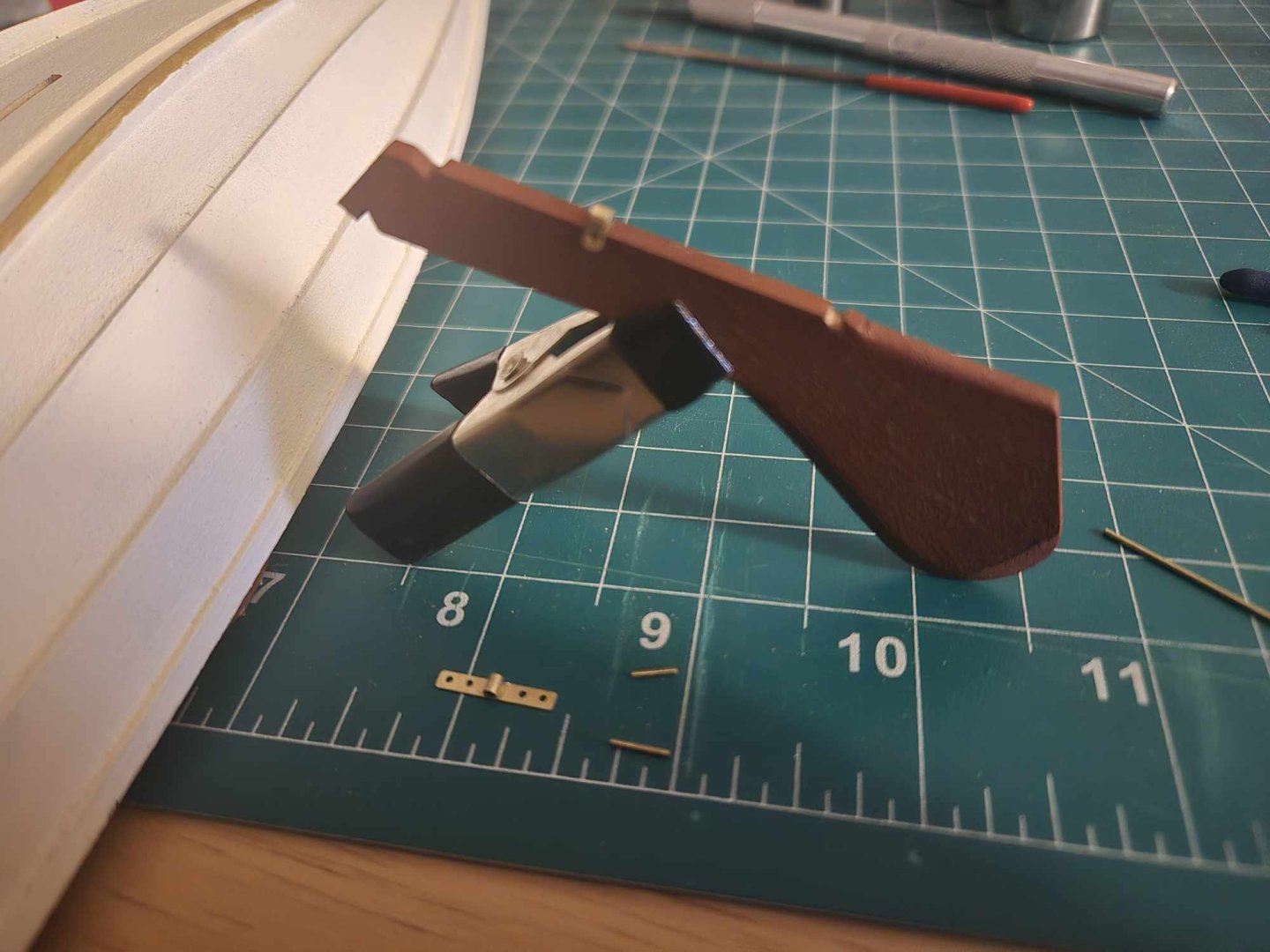

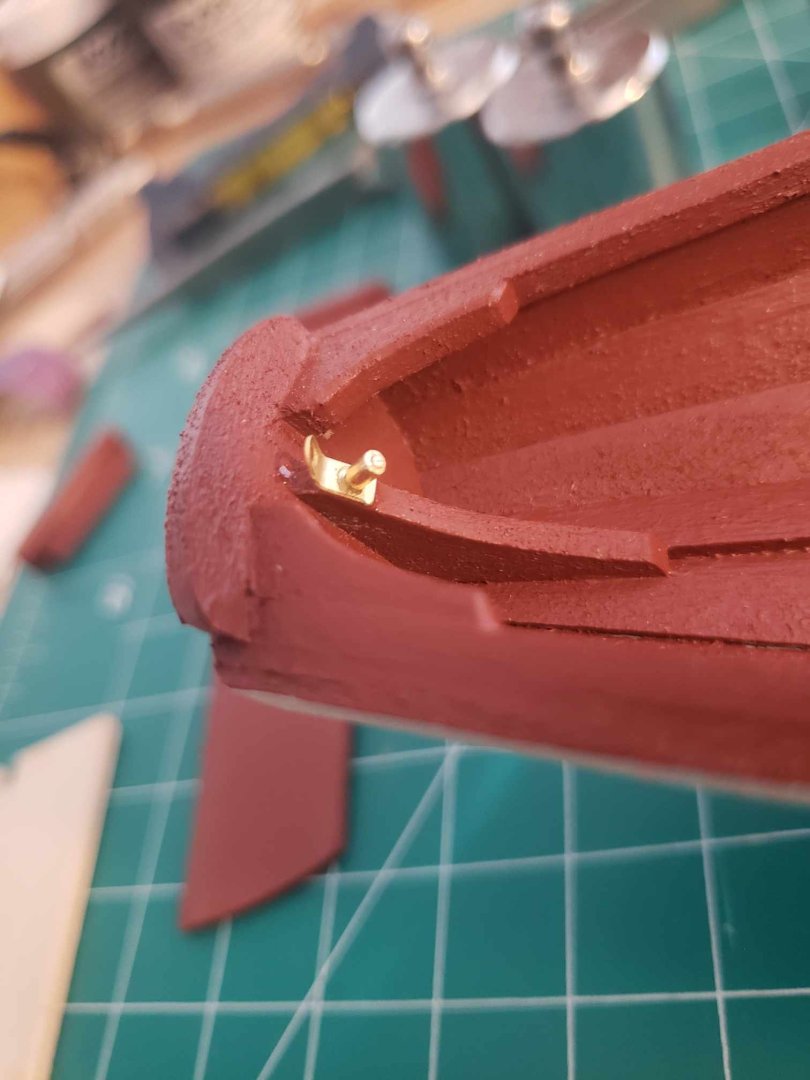

Okay, I promise this is still being worked on. Summer was very hectic for me, and I somehow acquired an actual boat (an 18' Dunphy seagull, for the curious), so this kind of fell by the wayside. That said, I'm working on getting the rudder attached, or at least in a condition that I can attach it when ready. I found the laser etched brass straps for the pintels are a touch shorter than I would like, but I can still make them work. I did have one fly off my tweezers while I was trying to attach it, so now I'm in a waiting game for replacement parts because I doubt I'm finding a piece that small in my den. Pintel pins are cut and ready to glue, and the lower gudgeon in attached. Need to attach and drill the upper one.

-

SiriusVoyager reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

SiriusVoyager reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

-

MajorChaos reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

MajorChaos reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

-

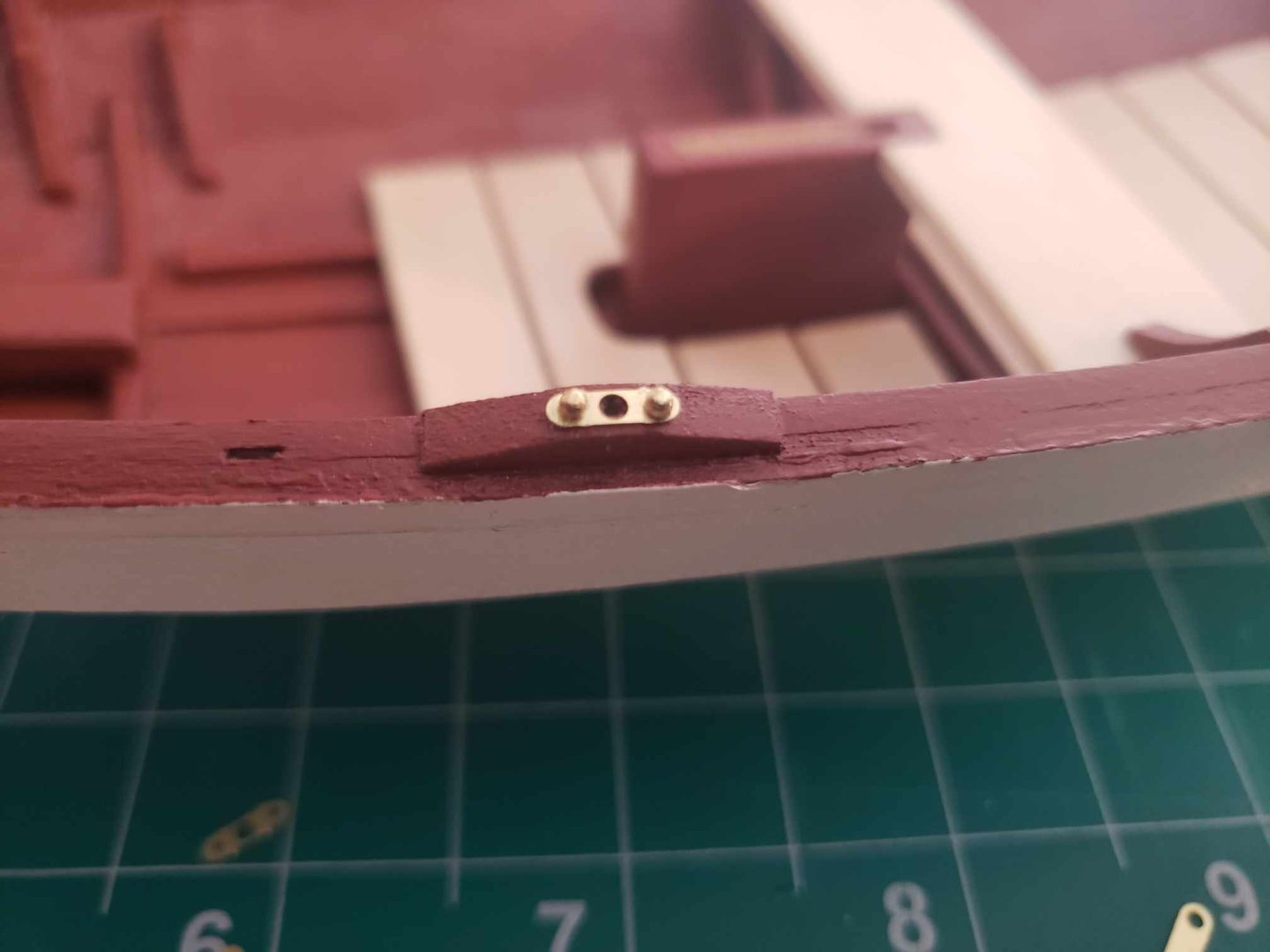

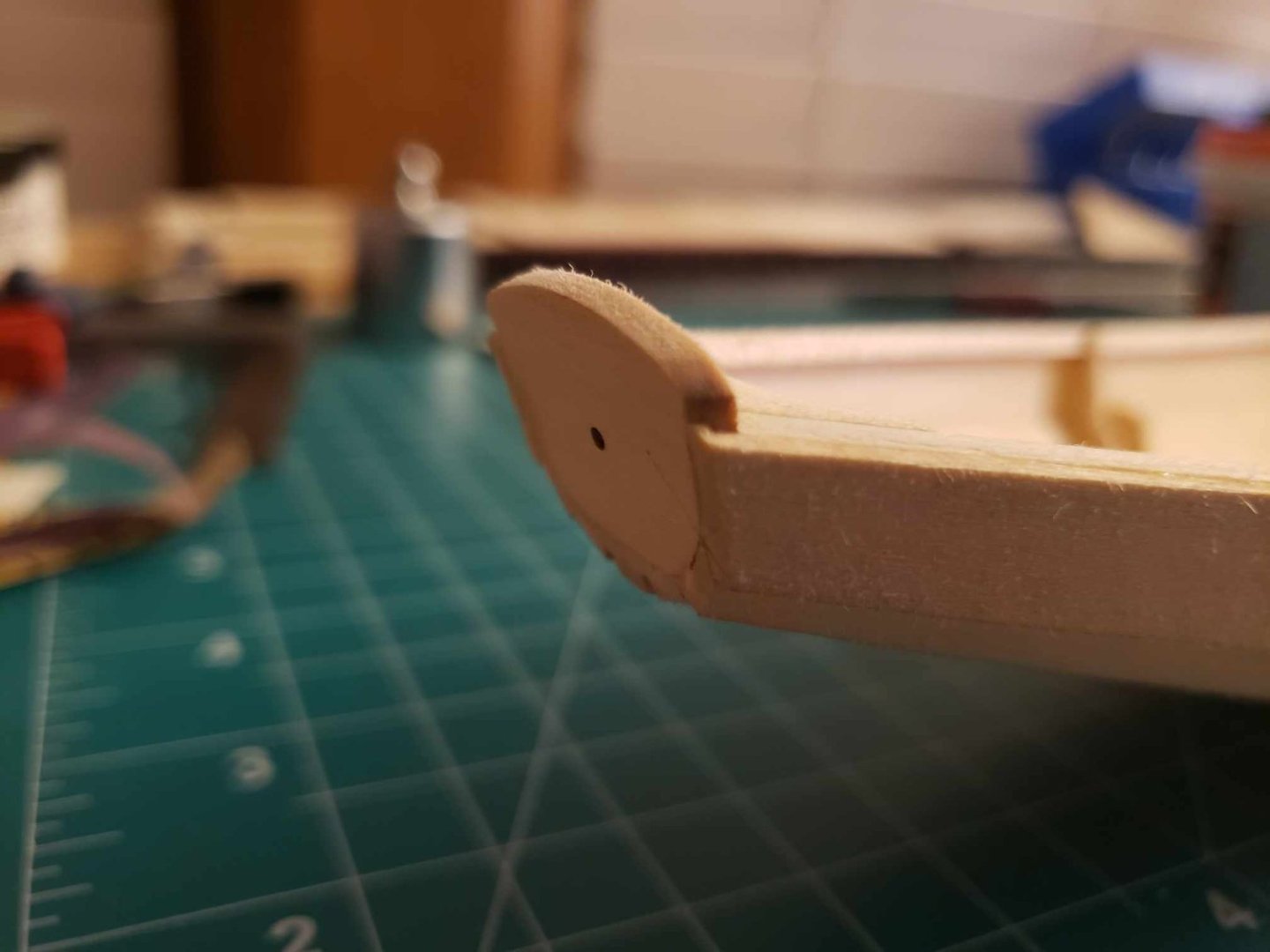

I ended up changing out the nails that were supplied with the kit, since they're a bit too large (at least to my eye). Fortunately, I had a number of smaller brass nails from a previous failed kit, so I can use those now. They work pretty well. First picture is the backstay plate secured with the supplied nails, second is secured with the replacement pins. These work out great for the oarlock pads too.

-

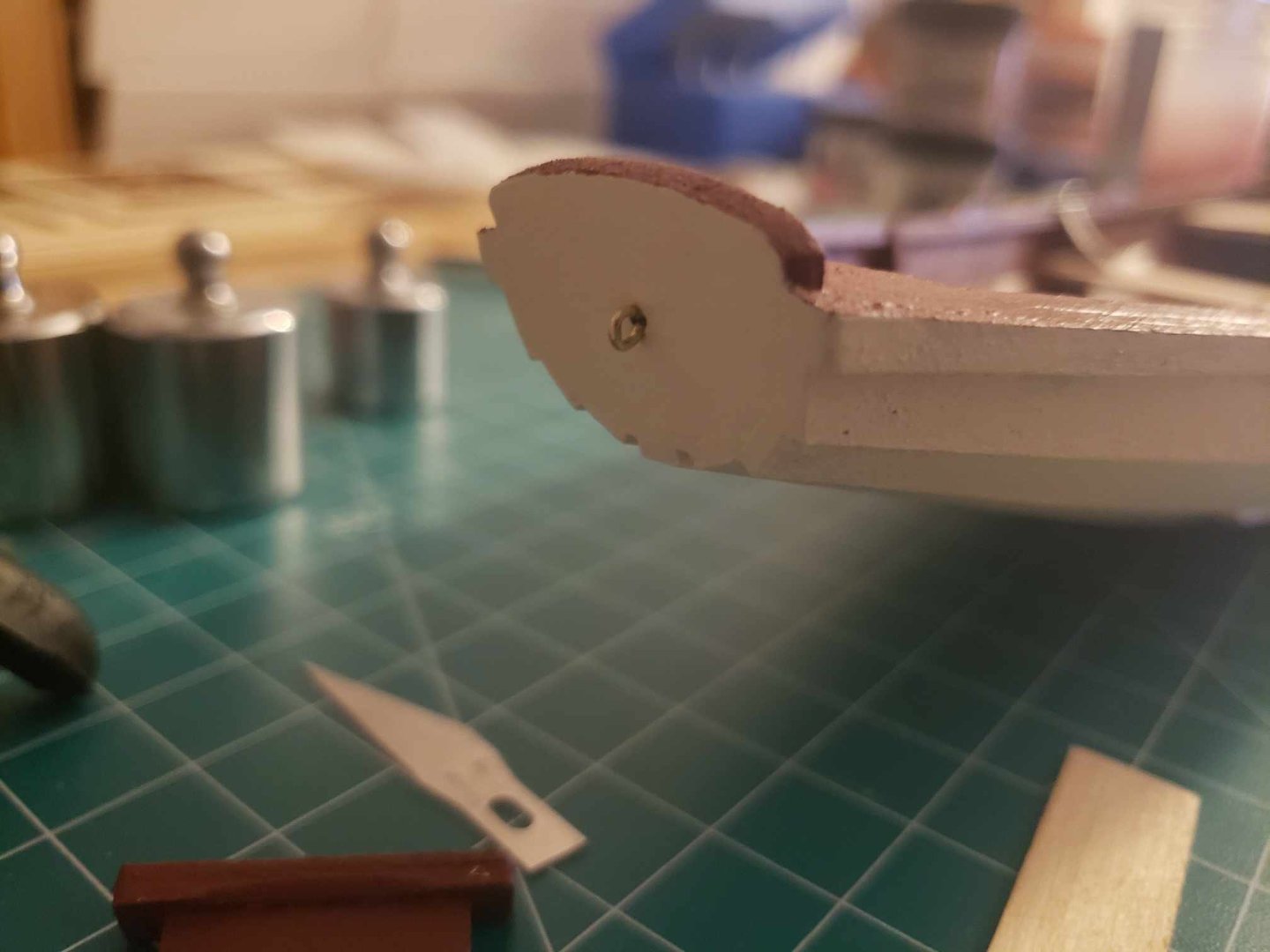

I'm still working on the sole boards, but a miscalculation led to some screw ups, and now I'm waiting on replacement parts. In the meantime, I'm moving onto some brass fittings. Currently I have the anchor point for the forestay attached. Took me four tries because I kept dropping the pipe cutoff and losing it in the carpet, so I'm happy there's so much extra. These pieces are held in place using CA glue as opposed to wood glue. Works pretty well. Semi-related pro tip, if you need to polish brass but don't have the right chemicals for it, toothpaste works in a pinch.

-

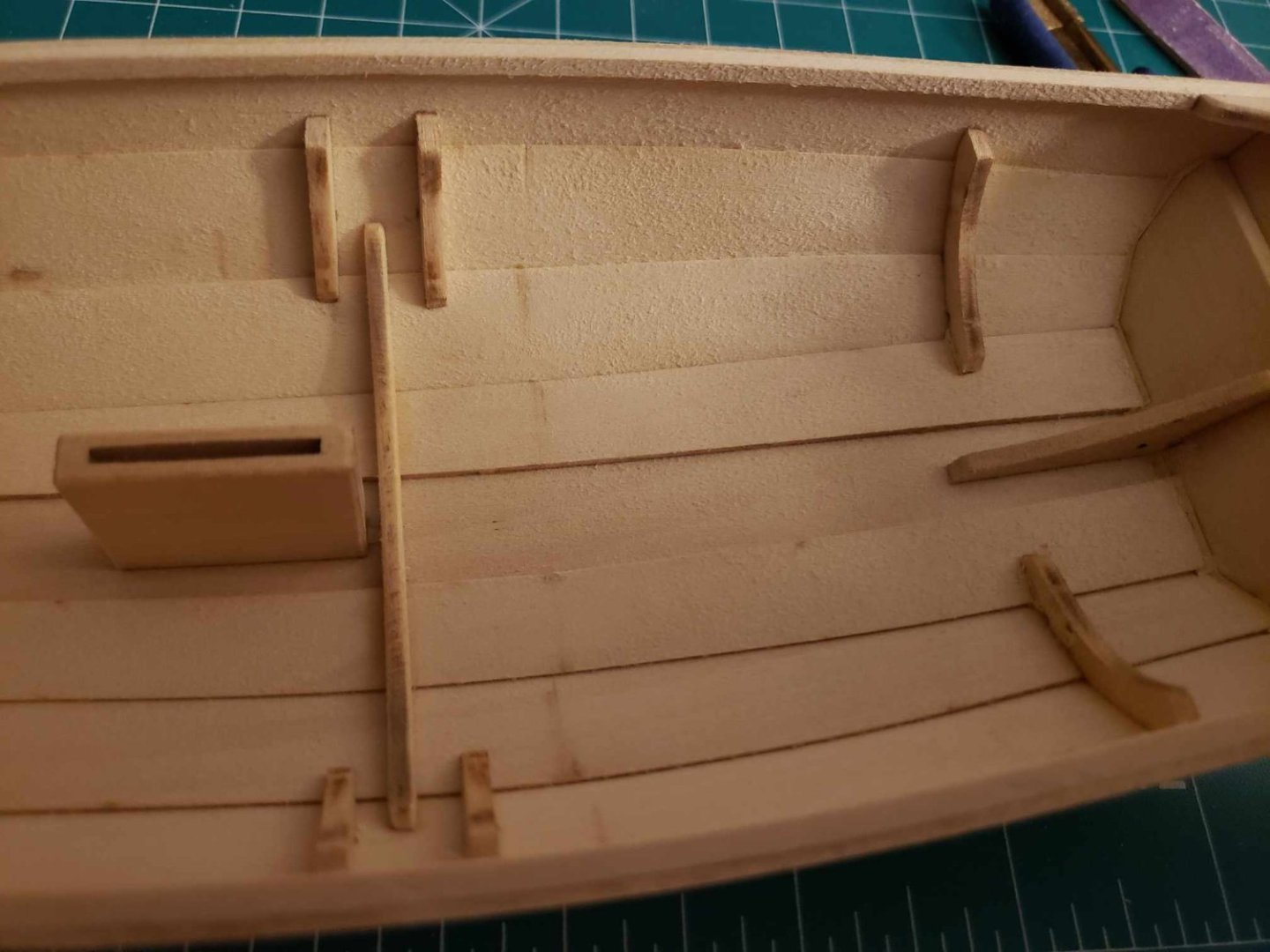

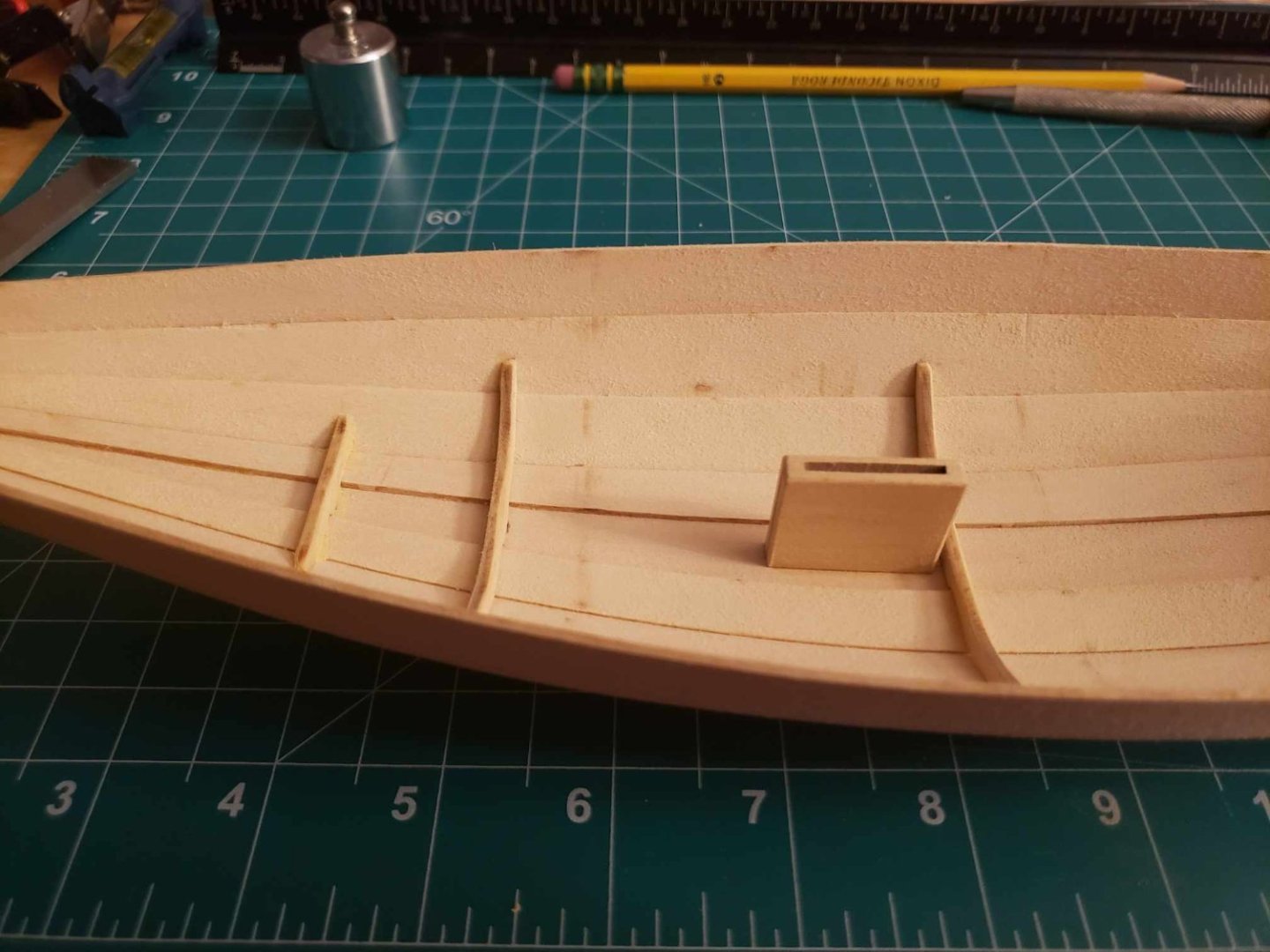

Took a while, but I got the rest of the thwarts fitted. I had to request some replacement parts from Model Expo (the knees were miscut) which took a little time. I also made a cover for the daggerboard case, which turned out rather well. Now that the thwarts are fitted, I can take them off and paint the hull. I'm doing dull red for the interior and warm white for the exterior. I also picked up some metallic brass to paint the bottom of the bilge keels, mimicking weather strips.

-

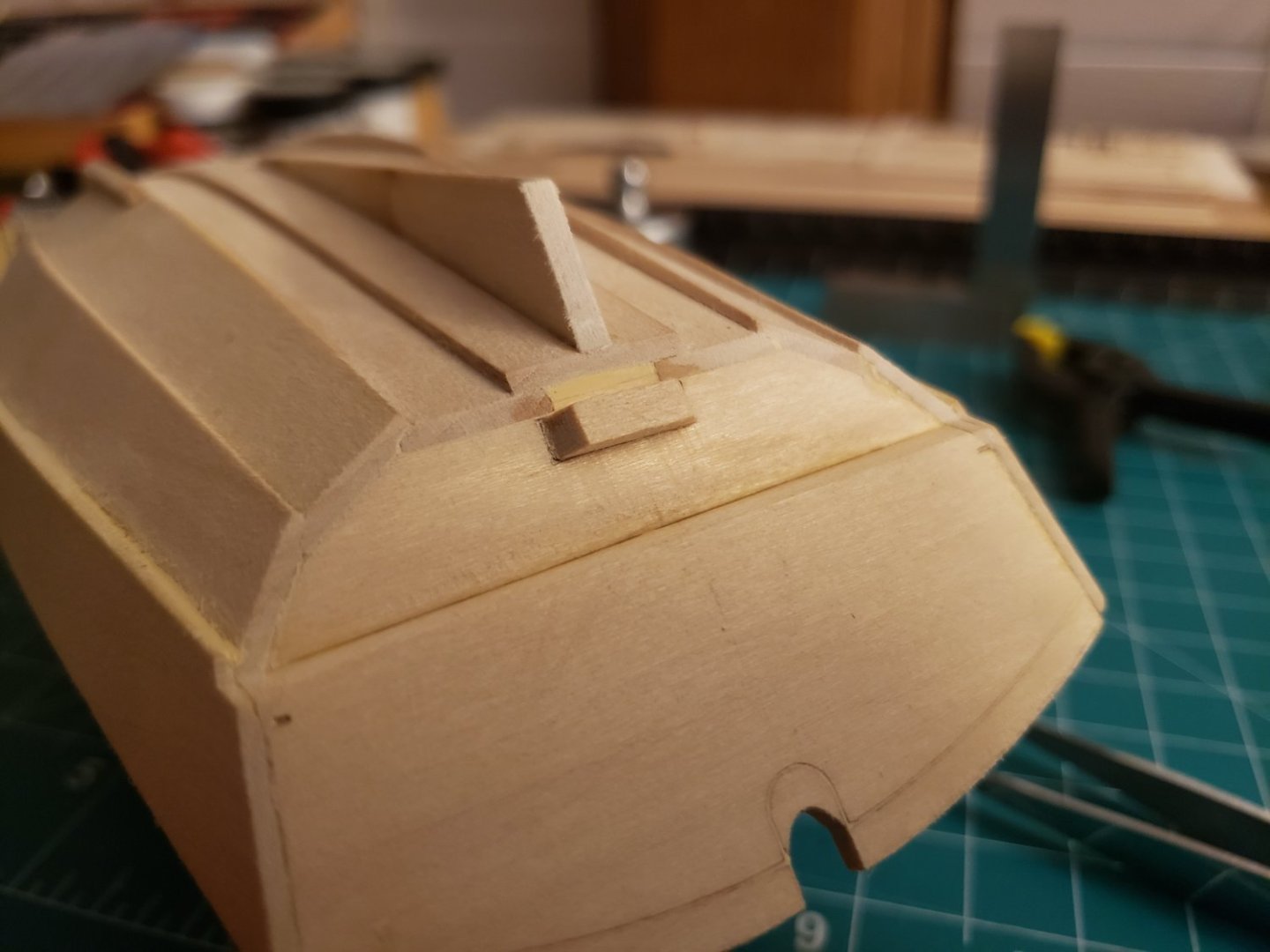

Sorry about the hiatus, I've been on the tall ship LYNX for the past month and just got home yesterday. So, back to work. I got the slots for the stay plates cut, and fit the fore thwart. I like to think I learned a trick or two from the dory build, because I wasn't entirely happy with how those turned out, but I'm MUCH more please with this one.

-

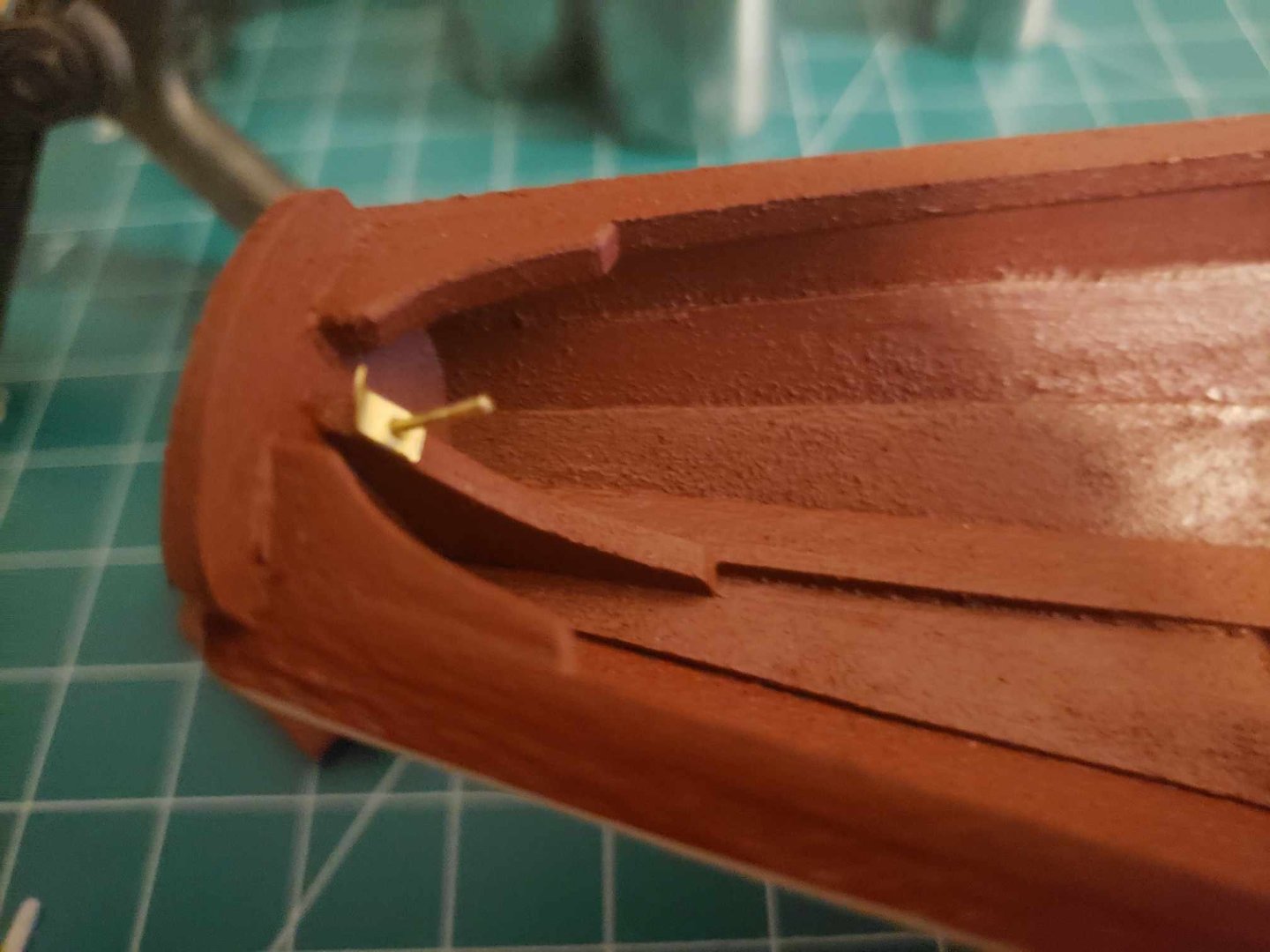

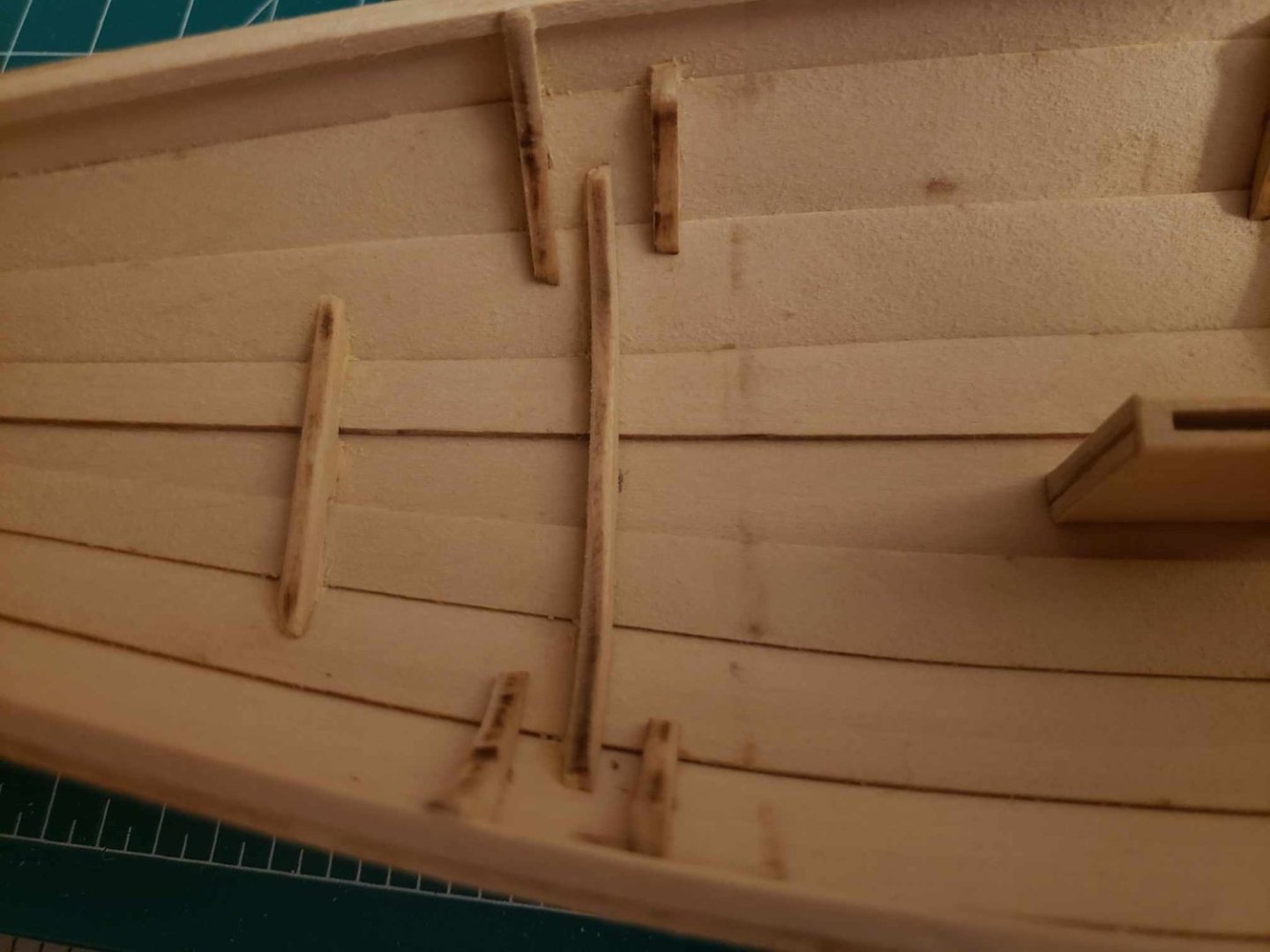

Lot of stuff in one here. I got the gudgeon cut and attached, I unglued and reglued the skeg to make it more center, I lowered thwart frames B slightly, and I attached the floorboard cleats. For the measurements for those, I started with two each of 2 7/8", 2 3/4", and 1 7/16" and filed down to size from there. I had hoped to the slots cut for the backstays before I have to set the model down for a bit (long story short, I'll be on the tall ship LYNX for a month and won't be around to work on the pram), but I didn't have the saw blade. I'm hoping I can finish the oarlock pads, and maybe the rub rail. We shall see.

-

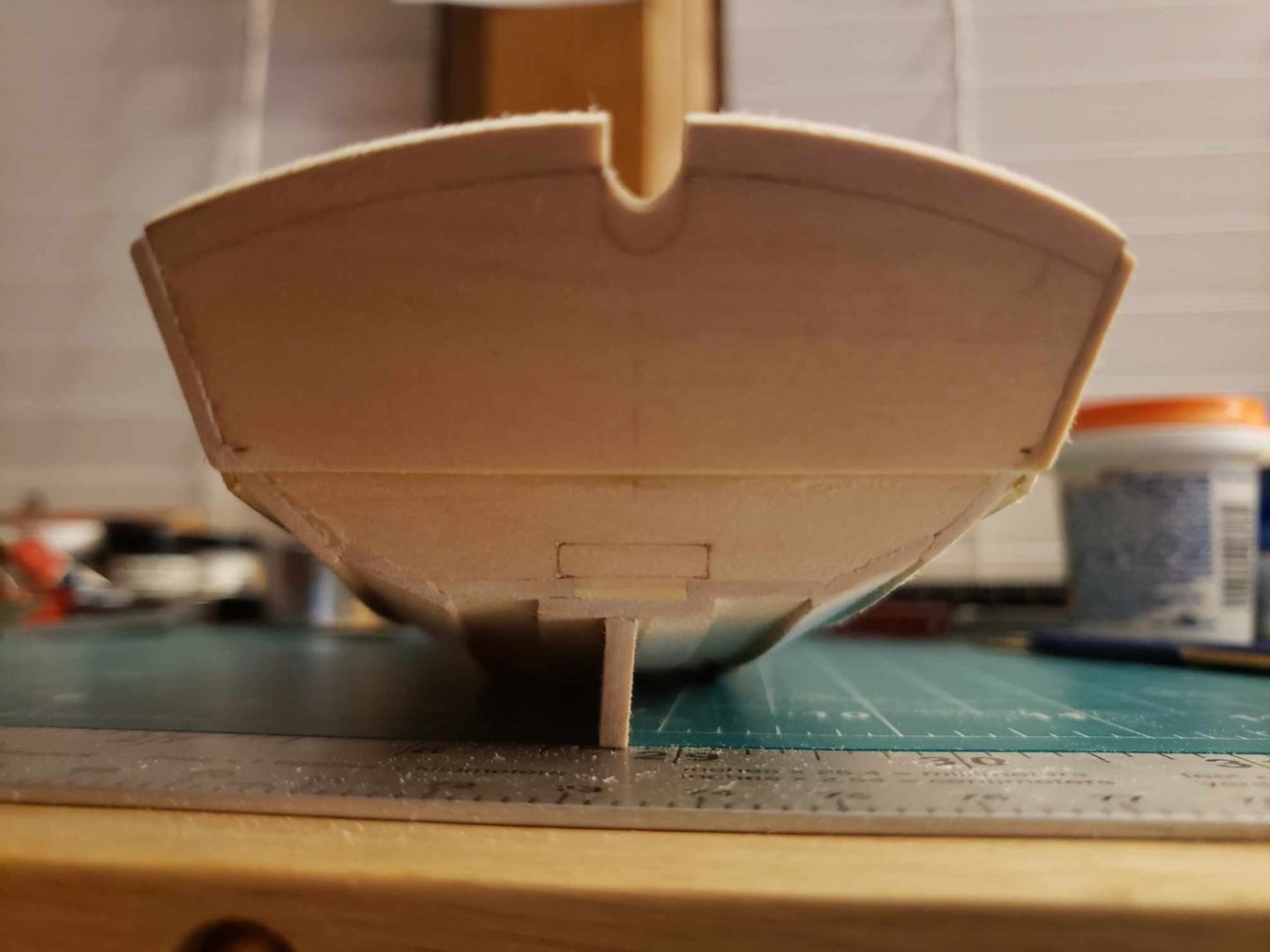

Still need to put the soleboard cleats on, but things are coming along. I had a little bit of trouble with over-beveling some of the thwart frames, and again, wood putty is my best friend. If you've been following this build, you'll know I had worries about the transom. For a freehand sketch and a LOT of sanding with dull files, I think I did pretty alright. I might see about adjusting the skeg at some point. It's off just slightly enough to bug me. I know, I know, looks right is right, but I think I can make it look better.

-

CommodoreErie reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

CommodoreErie reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

-

CommodoreErie reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

CommodoreErie reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

-

CommodoreErie reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

CommodoreErie reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

-

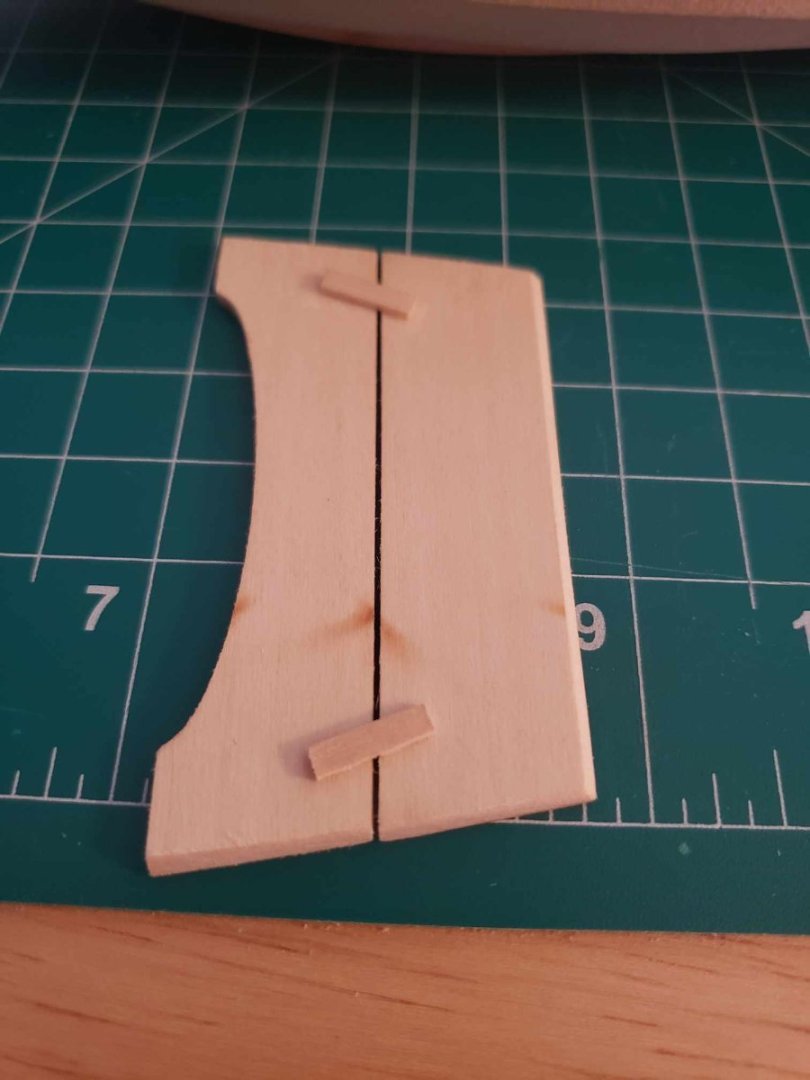

Before I put the thwart supports in, I wanted to jump ahead slightly and work on transoms, since they've been on my mind a fair bit. The bow transom went as well as I expected (that is to say, quite), but I'm hesitant on the stern. As stated earlier in my log, the planks at the stern rose above the line provided where the stern transom would be shaped by around 1/8". Now, my thought is to raise the line by that much, which if my math is correct would equate to having an extra 1.5" of transom if this were full scale, which on the real thing wouldn't matter too much I don't think, but I'm curious how it would look on the model. In any event, I'd welcome any thoughts on how yinz think this idea will work, if it will affect the rudder or anything like that, etc. before I make any cuts and shaping to the stern.

-

CommodoreErie reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

CommodoreErie reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.