PC52

Members-

Posts

29 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by PC52

-

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

thanks for the suggestions. It's pretty crowded now and wont be easy with all the ropes hanging around but I'll give it a try. Thanks again Gregory. -

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

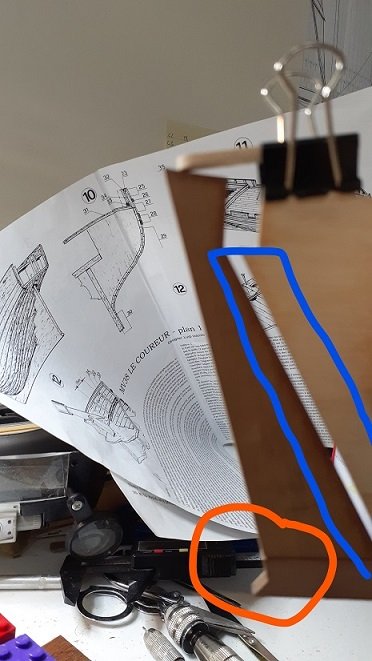

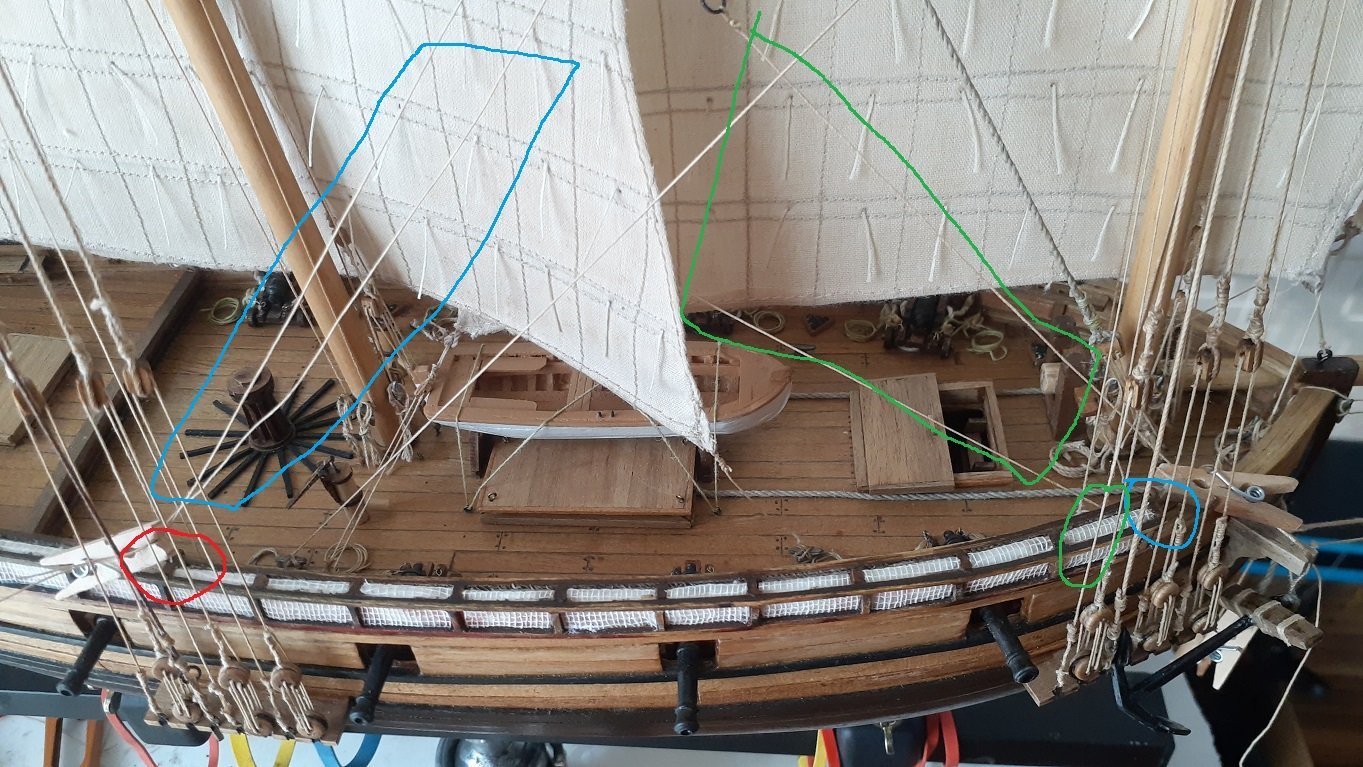

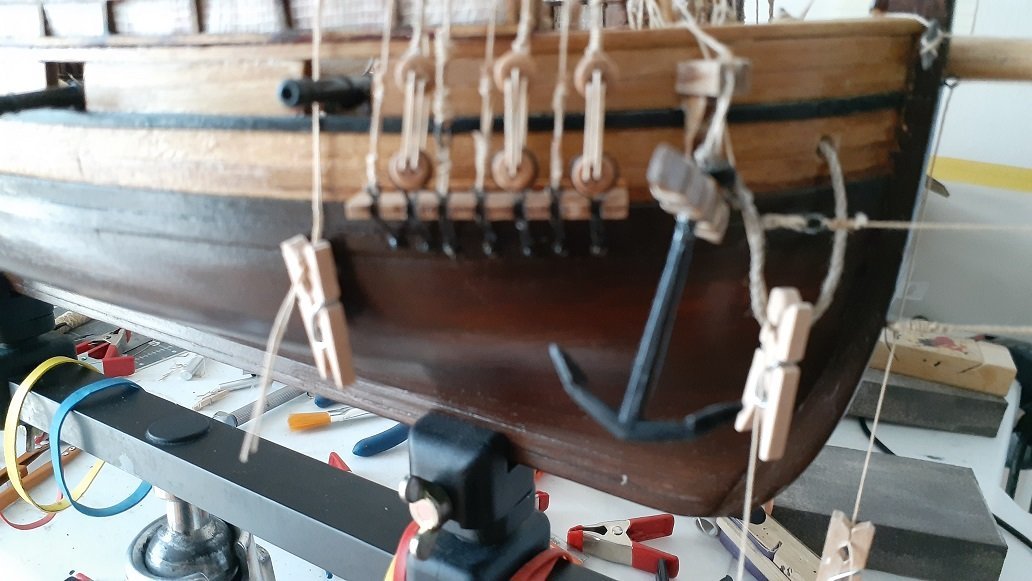

Thank you for the suggestion Gregory. I took a look at it (page 25) and it looks excellent. My issue is that there is no belaying pin available inside to attach the anchor rope to. I have a picture below of what I could do to free up a belaying pin. Here is my thinking but it could be heresy: the two ropes in the green box have to be tied together on belaying pin 3 (green circle) and the two ropes in the blue box are supposed to be tied to belaying pin 4 (blue circle), next to pin 3. To free up pin 4 for my anchor, could I tie the two ropes in the blue box to the free pins under the red circle? There are a couple of pins available there. (Note that the laundry pins are only temporarily holding the lines in place.) Thank you! -

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

Hi all, This is another call for help. I am finishing my Le Coureur and I don't know how to rig its anchors. As expected no instruction from Mamoli on this topic. Any suggestion? Thank you in advance. PC -

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

Here is a picture of my finished transom. Although not part of the instructions I decided to add transparent tape to mimic glass windows. -

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

Thank you Gregory. I applied several coats of wood stain. And thanks for the tissue suggestion for the hammock. Daniel Dusek suggested using the extra gauze so that's what i did. More to come. -

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

Well it's been quite a while since last time i posted. I hit several snags but also took pictures so i am going to share with you what happened the last 4 weeks. First i planked the hull again with 0.5x 5. It looks much better now the i stained the hull About the basswood supplied with the kit: First the basswood is not good quality. The 1x1 broke when I attempted to bend it and the 1x3 brittles under a band new blade. I tried to strengthen it with a mix of white glue and water but it didn't work Also I replaced the 1x1 with 2x2 and sanded it Next issue was the plans scale. With very skimpy instructions i wanted to use the plans for positioning parts. The plans are not 1:1 scale Next the transom rough opening were cut too wide. I had to resize them More to come later. Unfortunately my impression is that Mamoli cut a lot of corners. I would not recommend this kit for a beginner. There is too much guessing work to be done and without experience it could become overwhelming. -

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

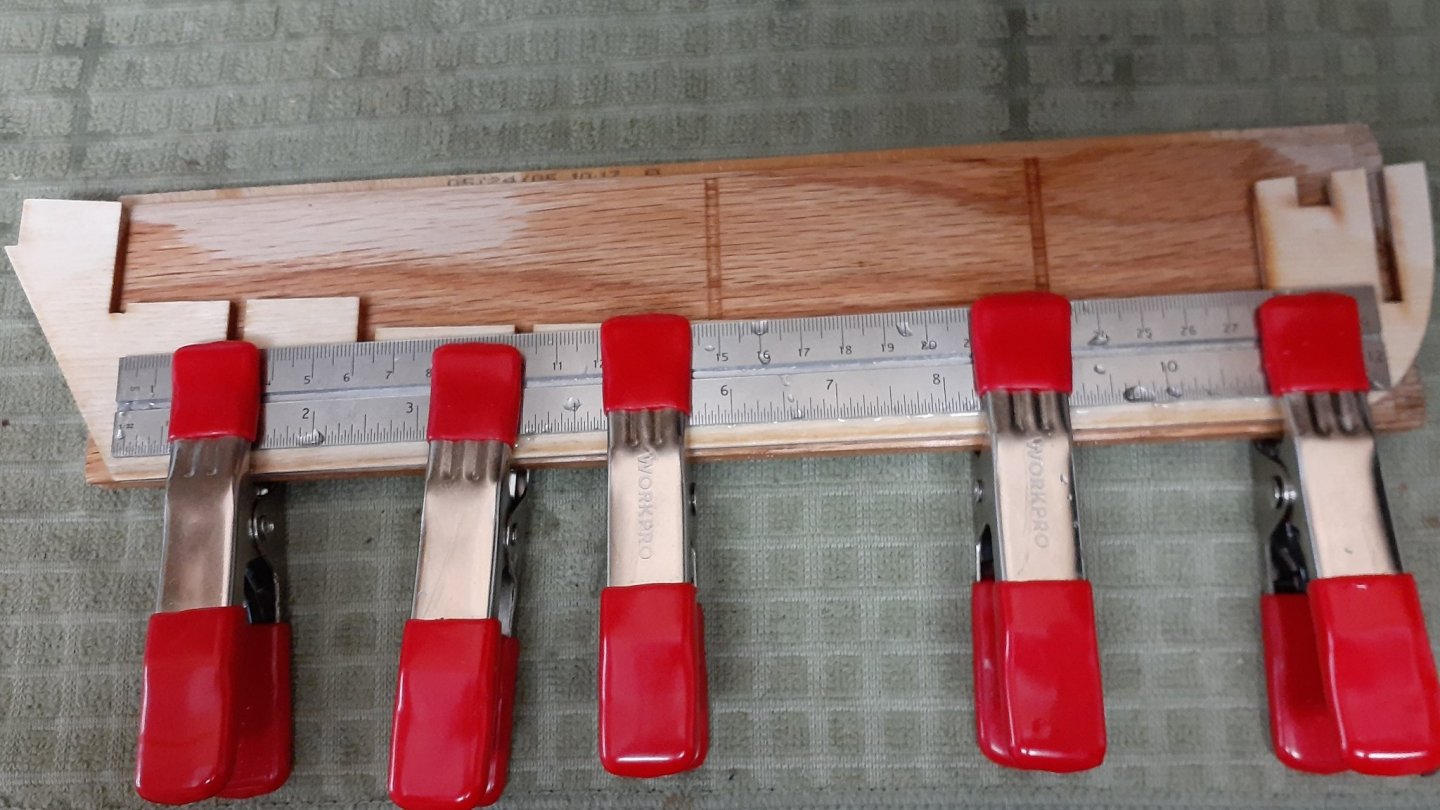

thanks for the suggestion Gregory. BTW I bent my new transom successfully. A home made jig, 20 minutes in the over at 400F (350F then 375F was not enough) and voila! -

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

Although i thought the maple strakes were similar in color the result is awful. I will cover the entire hull with some 0.5 by 5. Oh well... -

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

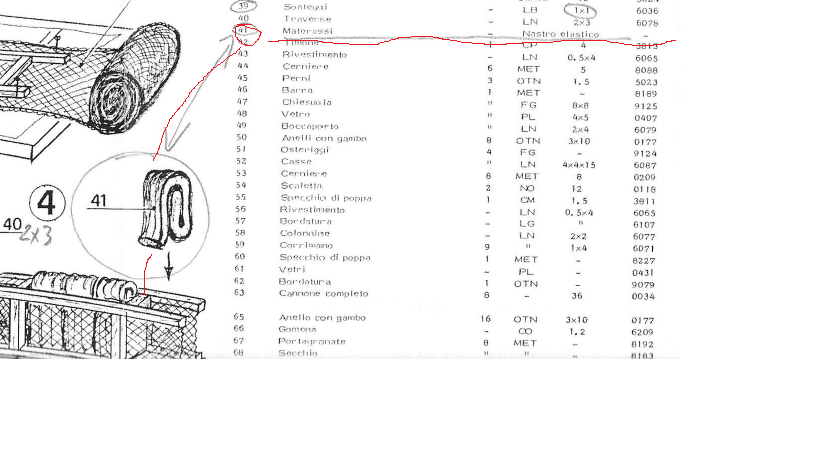

Hi all, New snag with this Mamoli kit. As I am moving along Part 41 is missing (nastro elastico). Unfortunately this part has no reference number so I am sending you a copy of the instruction sheet for help. I contacted Daniel Dusek but he cannot find this part either. The description goes like this : false mattresses made from rolled up resilient cotton ribbon or "nastro elastico" I guess it's a ribbon that is missing. Any suggestion as to how to replace this part? Thanks in advance. Phil -

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

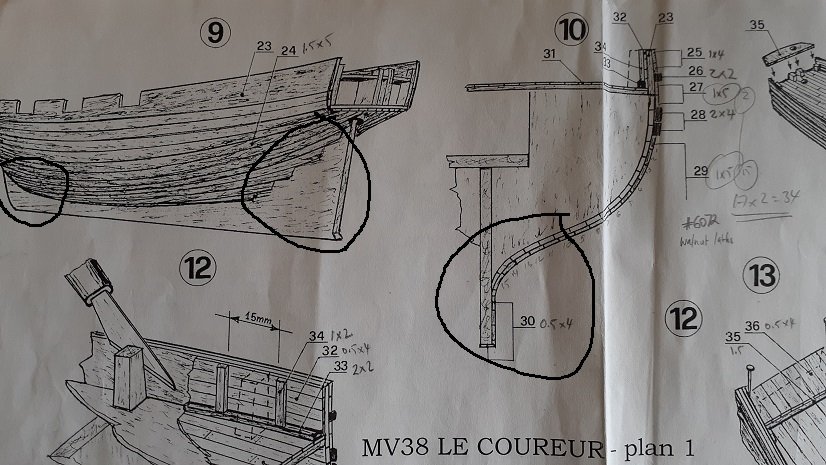

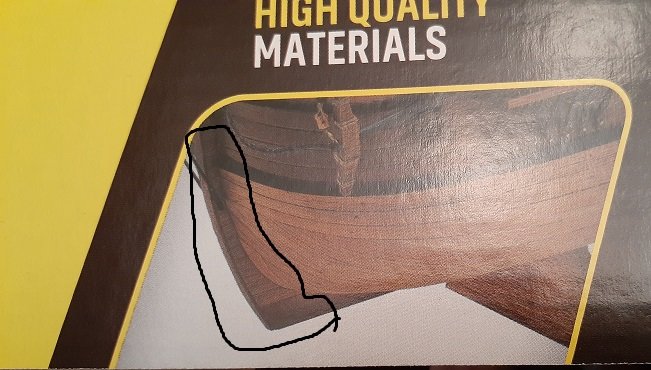

Thanks for the tip Gregory. Back to my project. As I wrote initially the instructions are very skimpy and the drawings quite imprecise, which leaves lots of room for pondering/dreaming/fuming/extrapolating and more -ing... Here we go with the second planking: Basically the instructions say plank with number 25 or 30. The rest is up to one's interpretation of the drawings. Luckily i noticed a small picture on the box cover. I enlarged it and saw what the second planking should look like around the keel I also ran out of strakes for the second planking (about 10 short).. Fortunately i had some 1x5 walnut strakes from a previous jb so I'll be able to complete the second planking without contacting Daniel Dusek again. The color is not an exact match but i plan the stain the hull so it should not be too much of an issue. -

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

Thanks for the tip, Gregory. This part is 3.3 mms thick or 0.12 in. Seems thick to me. Out of curiosity what did you use to sand your zinc alloy parts? -

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

Started the second planking. Will have to send and stain the wood to get rid of the glue blotches... -

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

It's my lucky day. Not only will Dusek send me a new transom, it will be bent. Great customer service. For the inquiring minds the transom is zinc alloy, it is possible to bend it after heating it in oven (100-150 degrees celsius). -

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

Unlucky. Someone who built Mamoli Le Coureur told me he was able to bend the metal transom by hand. So i tried and mine broke. I emailed Dusek and asked if they could provide a new one. I am keeping my fingers crossed. -

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

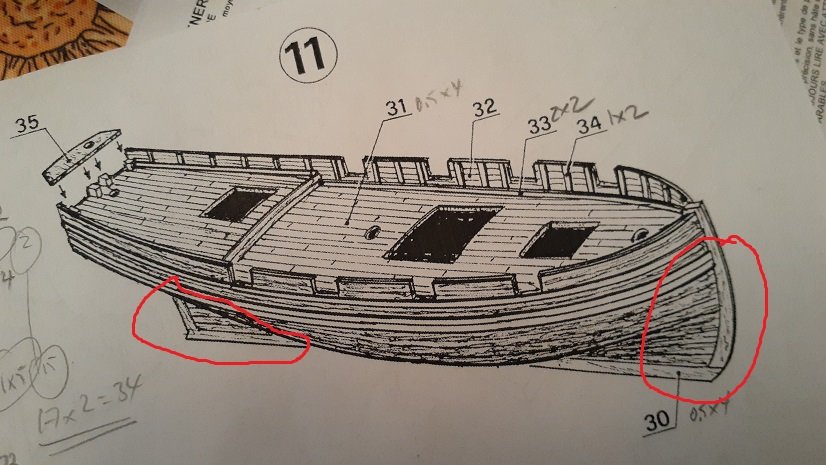

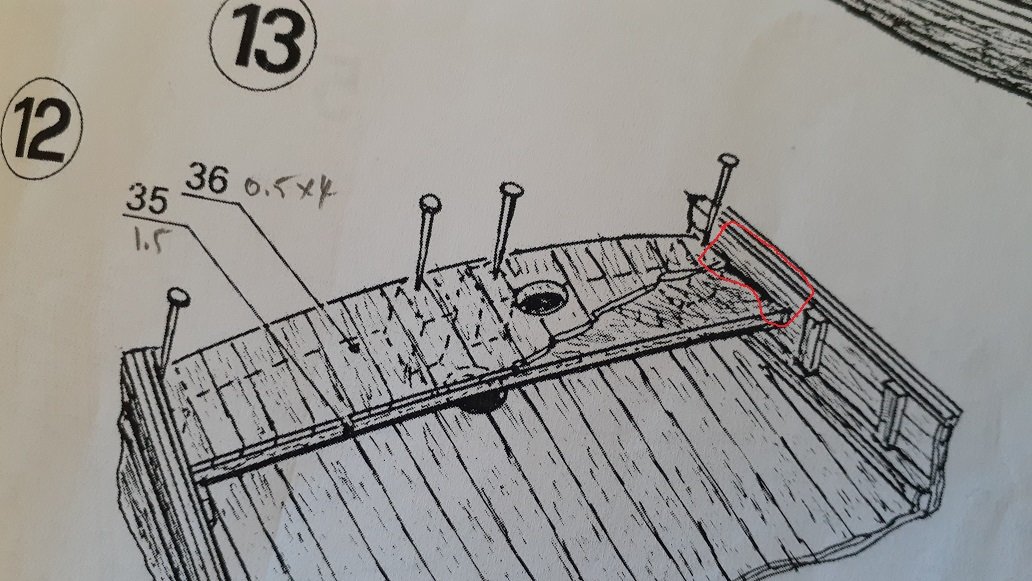

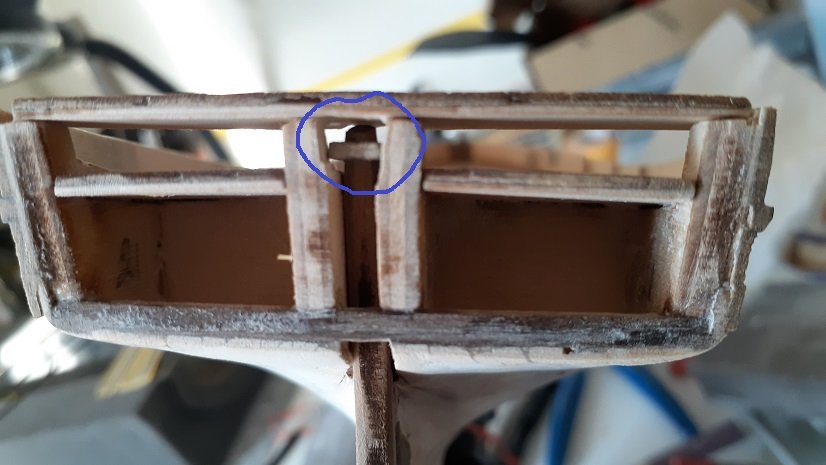

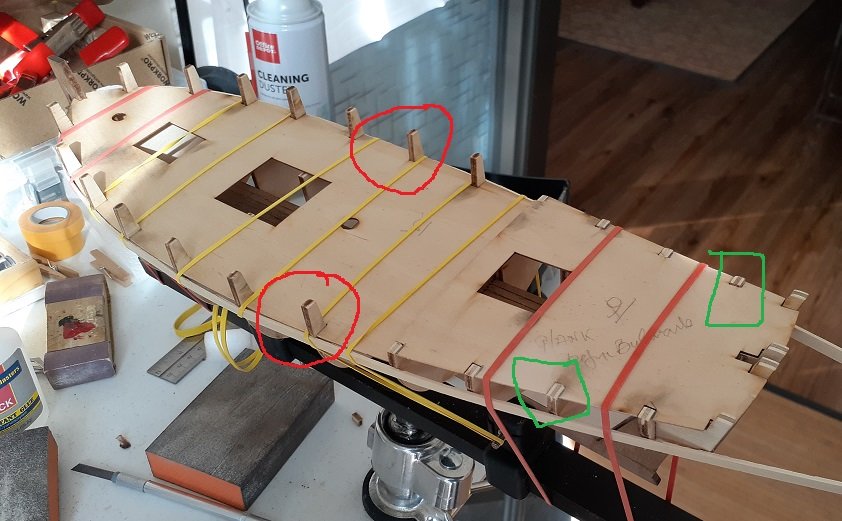

Today I hit a snag with the small quarterdeck. The instructions are pretty skimpy: Glue the small quarter-deck 35 and sheathe the planking 36. The snag is that the quarter-deck will sit too high. On the drawing it shows the quarterdeck is sitting about the height one strip below (circled in red) Here is what happens The quarter-deck sits flush. If i shorten the posts i have an issue with the rudder post and tiller. If i cut the top of the posts then the quarter-deck will sit too low for to squeeze the tiller on to the rudder post. I hesitate between setting the quarter-deck on the posts and let it sit flush or cut the top of the external posts and bend the quarter-deck... which may spilt... Suggestions? Thanks in advance. -

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

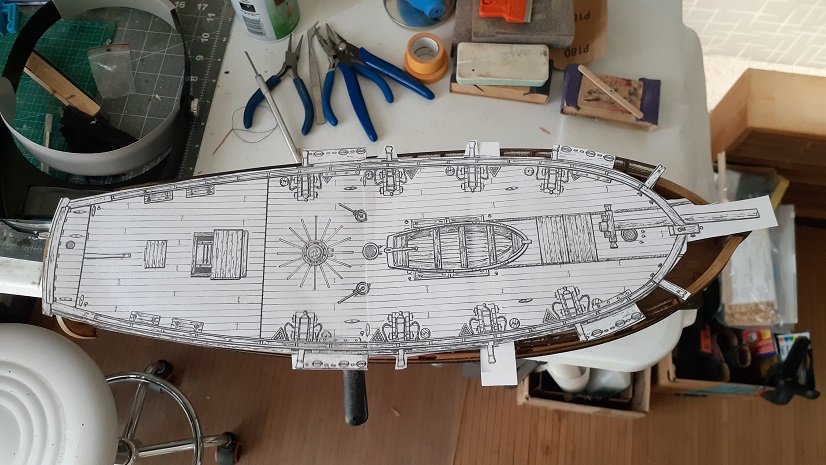

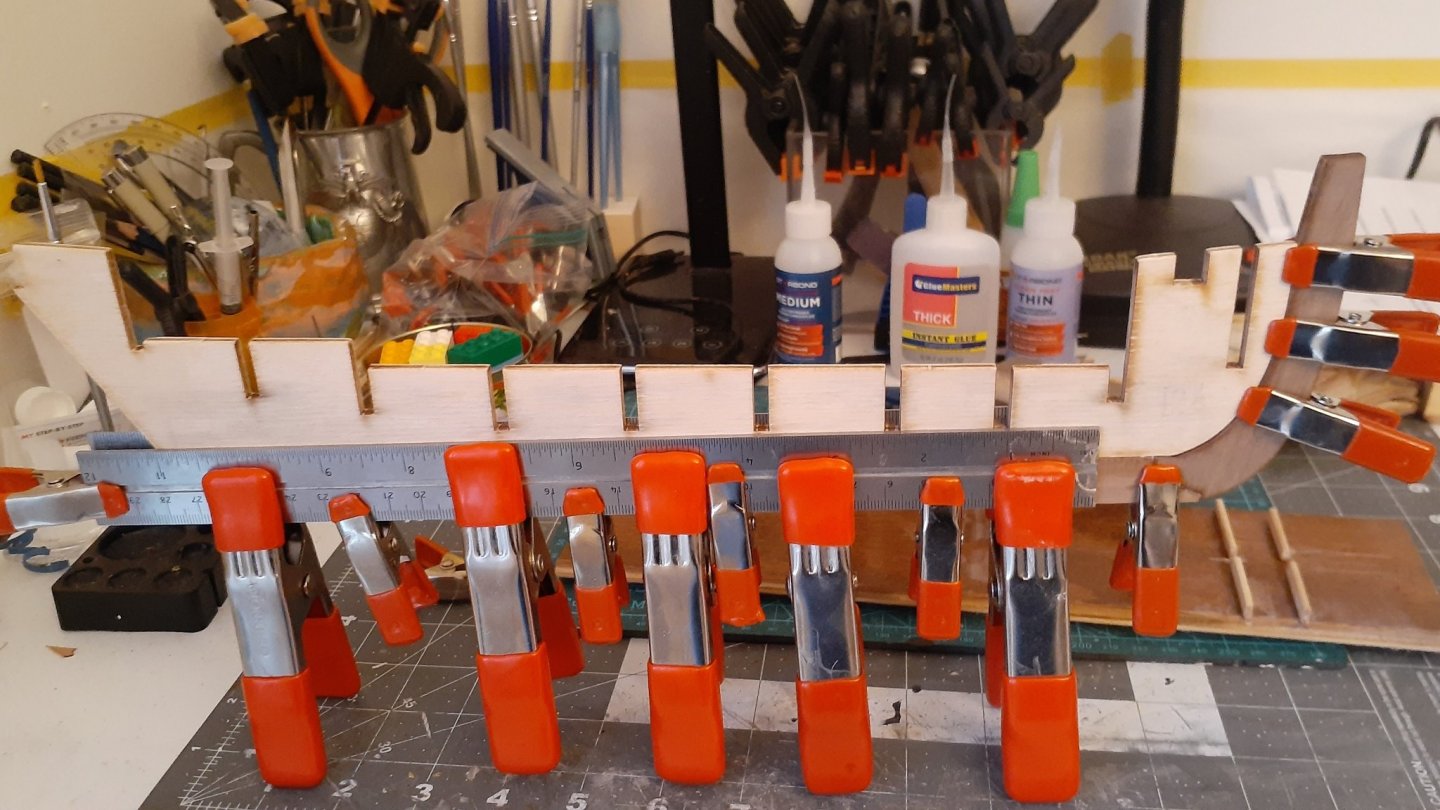

Happy New Year to all. Well it's been two weeks since the last time i posted. With the holiday season I worked piecemeal on my project but forgot to take pictures. Sorry. Here is where it stands: I bent the bulworks I planked the decks I planked the hull (nopics sorry) After some more patching, sanding and cleaning i will start the second planking. Thanks in advance for your feedback/support/interest. -

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

Hi VTHokiEE, It's a very slight arc but an arc nevertheless. Cannot be ignored... -

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

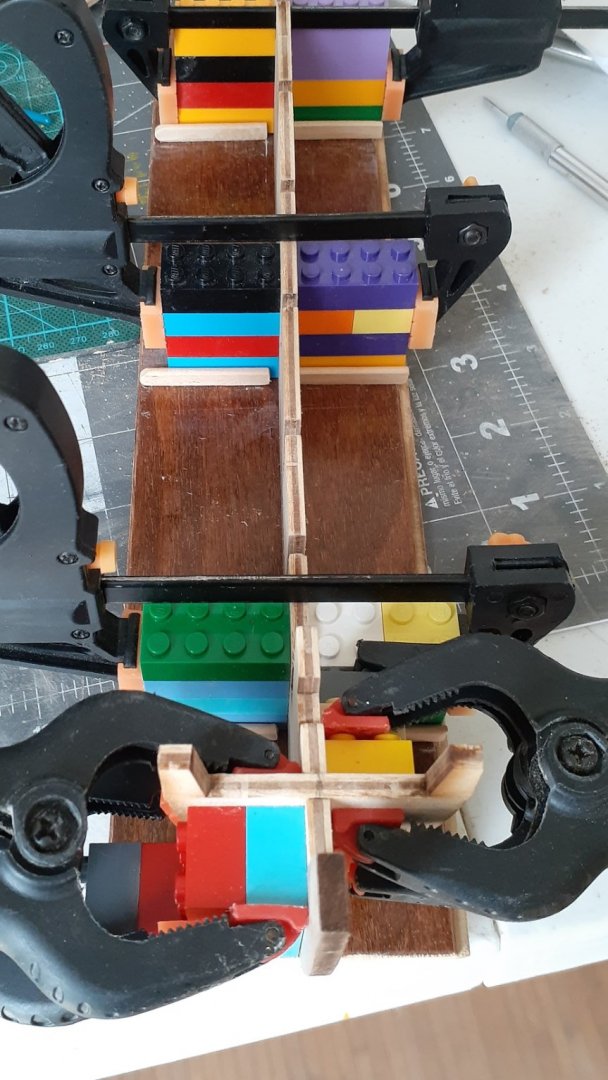

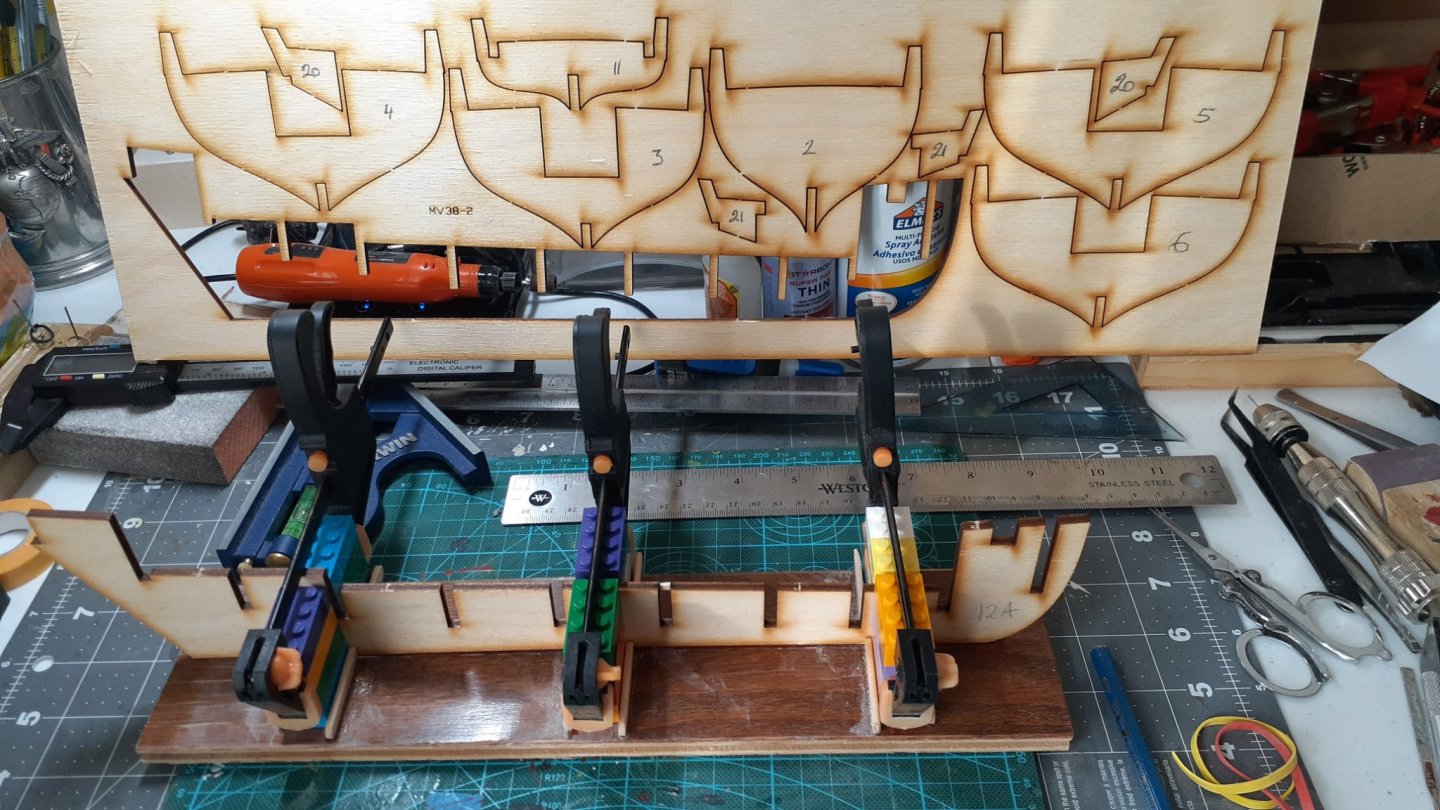

Hi VTHokiEE and thank you for your feedback and offer. You are right that's what the cat ears are for but cutting them after the planked decks and the bulwarks are glued would have been too much of a challenge for me. So i called Lego to the rescue 🙂 As for the metal transom here it is. I don't know what kind of metal this is. I sent an e-mail to Dusek who now owns the mamoli catalogue but he has yet to respond. -

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

I decided not to follow the instructions as the progression seemed strange to me. It said to start with gluing the deck and the bulwarks then planking the hull and finally cutting the "cat ears" (circled in red) I found it more logical to cut those "cat ears" first (they are not very useful since the bulwark will sit 2 mms below the fore deck line and 10mms or so against the aft deck) then lay the planked deck and glue it. The decks are now planked and varnished. The wood for the strips to plank the hull seems low quality. It's called soft wood and indeed it is. However it's only 1.5 mms thick so it bends nicely. A question if someone can help. At some point there is a metal transom that needs to be bent. It doesn't say what metal type it is. Does anyone have a suggestion? Thanks in advance. -

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

I hit a snag this week end with the keel and false keel assembly. I have a 3mm gap per the pics below. Any suggestion? -

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

-

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

I made some progress this week. The false keel is now straight and i glued the keel on to it. However there is a small problem here. A gap at the bottom between the two parts. Some sawdust and glue will be de rigueur. While my glue work is drying i explored the bundle of wood provided. I mean a real bundle. here it is and figure it out. Using shape, color, width, length, thickness i manage to regroup them all by similarity. However i still don't know what is what. Nothing in the instructions to figure that out. And since the instructions say take part number X , it looks like it's a guessing game. To be continued... -

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

Hi Bruce D. No problem watching and feel free to comment. -

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

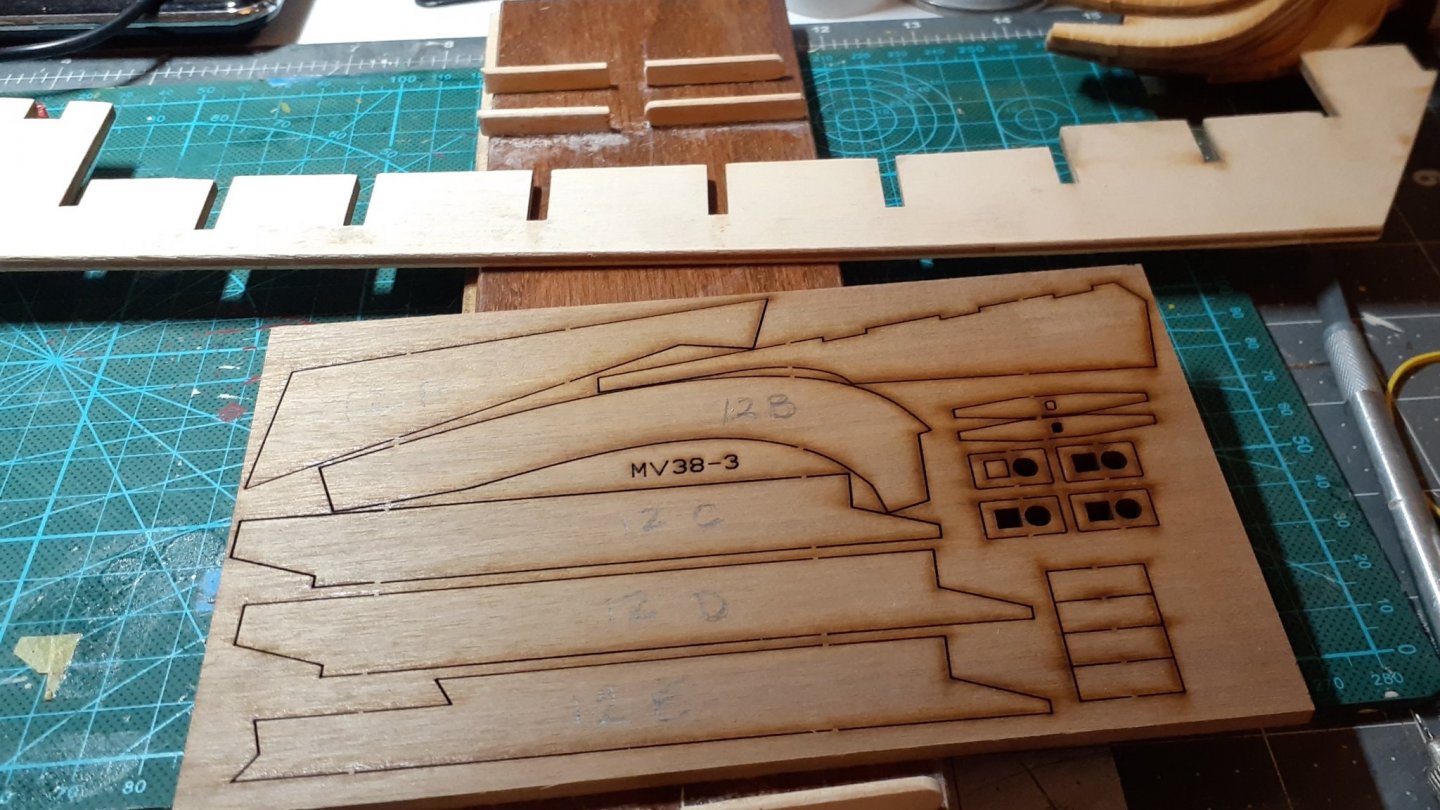

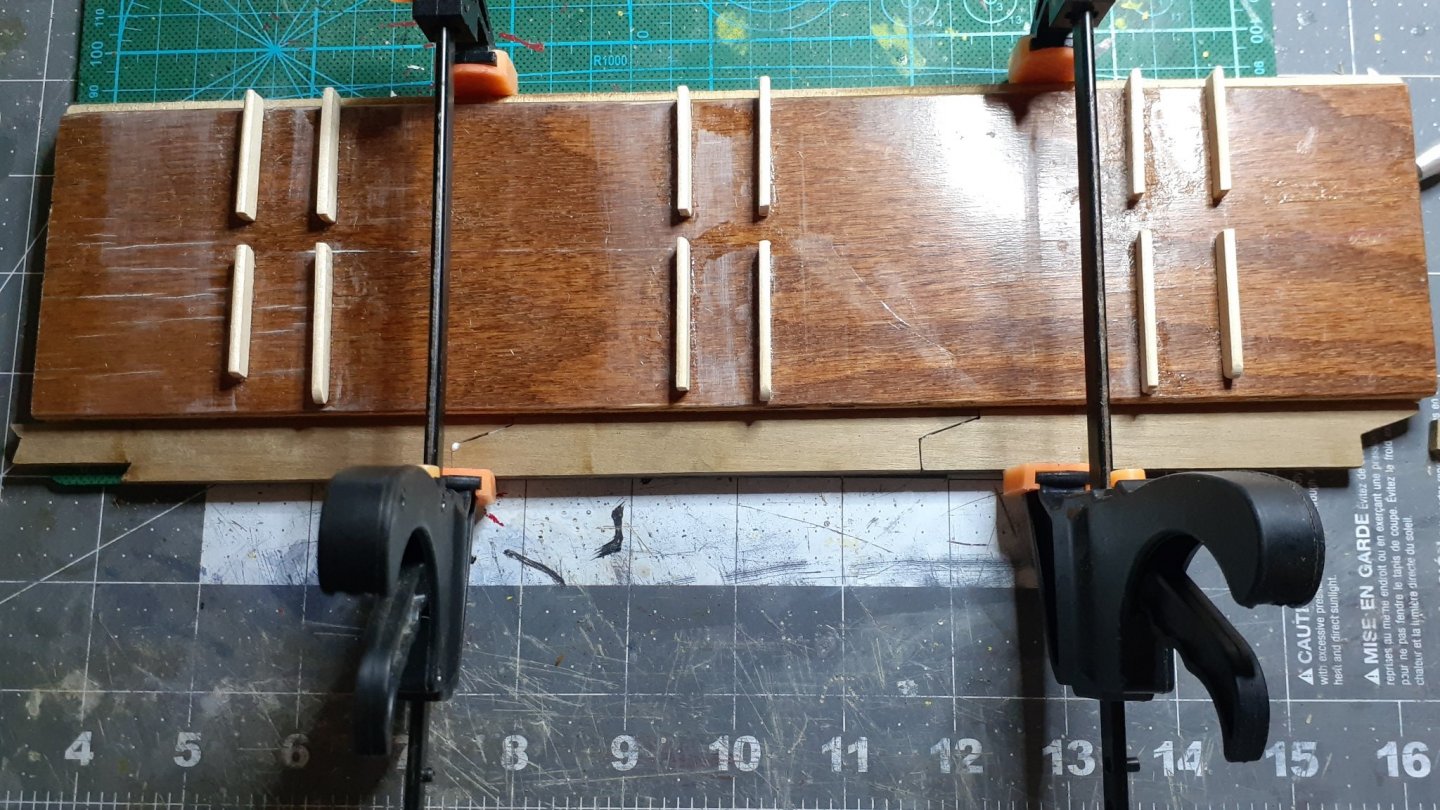

No instructions on how to assemble the keel. Could be a challenge for someone without experience. No mention of 12B, 12 C, 12 D and 12E in the text pages nor on the plans :-( I decided to go ahead and glue the parts together. I am using white glue for this part (you can see a little spot which i wiped out after taking the picture). -

Le Coureur by PC52 - Mamoli - 1:54

PC52 replied to PC52's topic in - Kit build logs for subjects built from 1751 - 1800

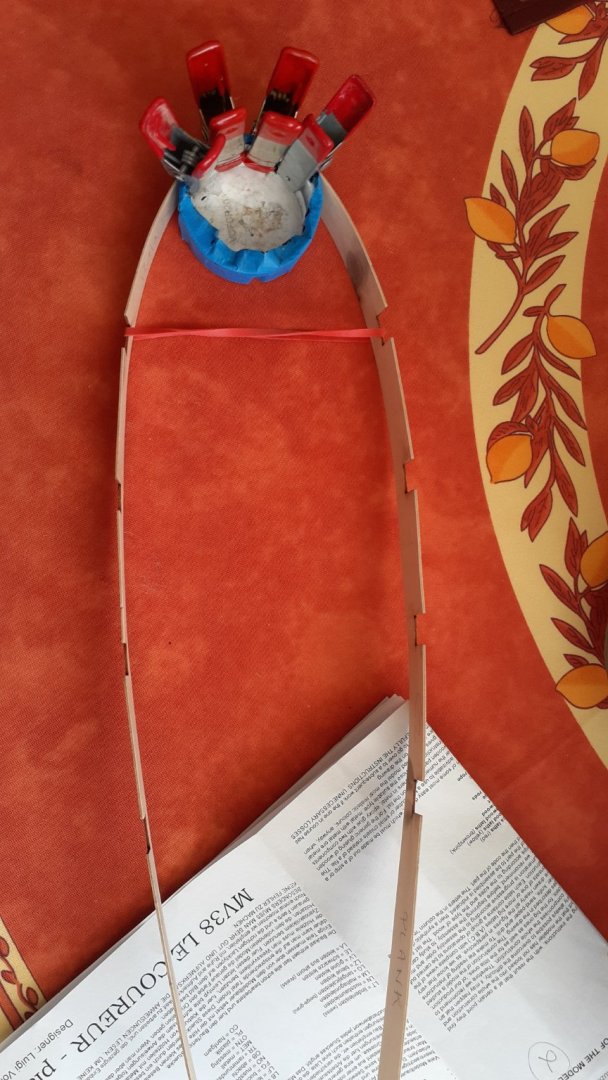

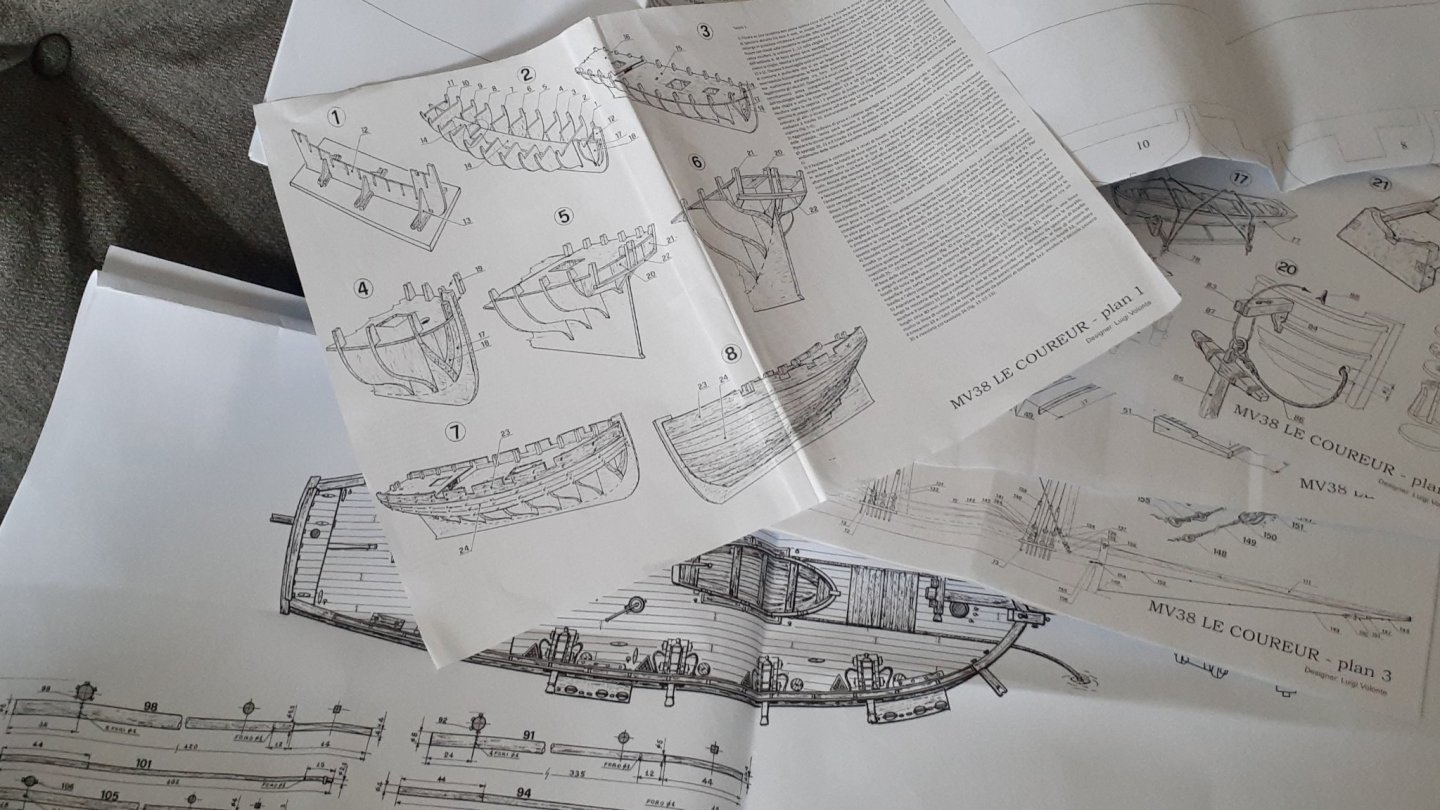

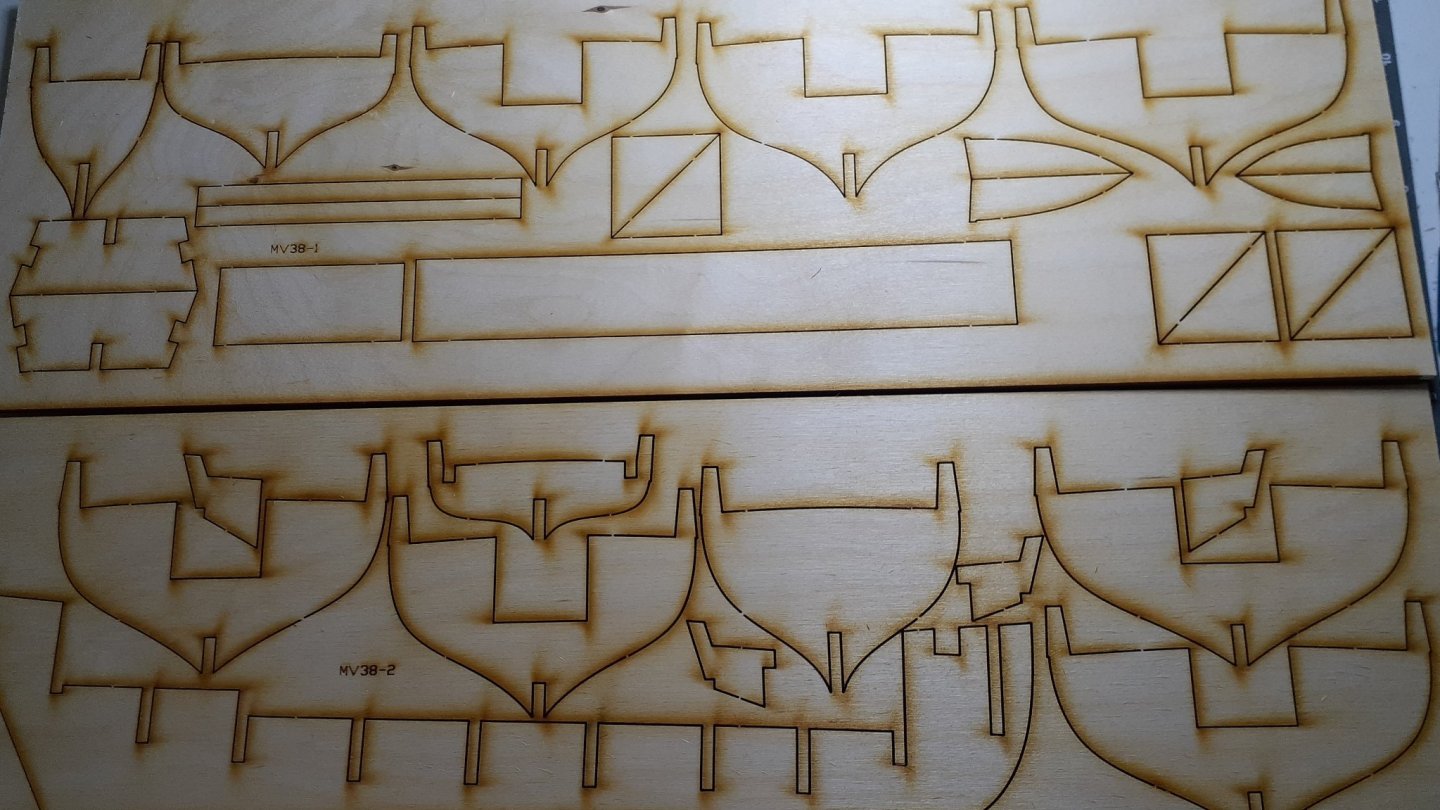

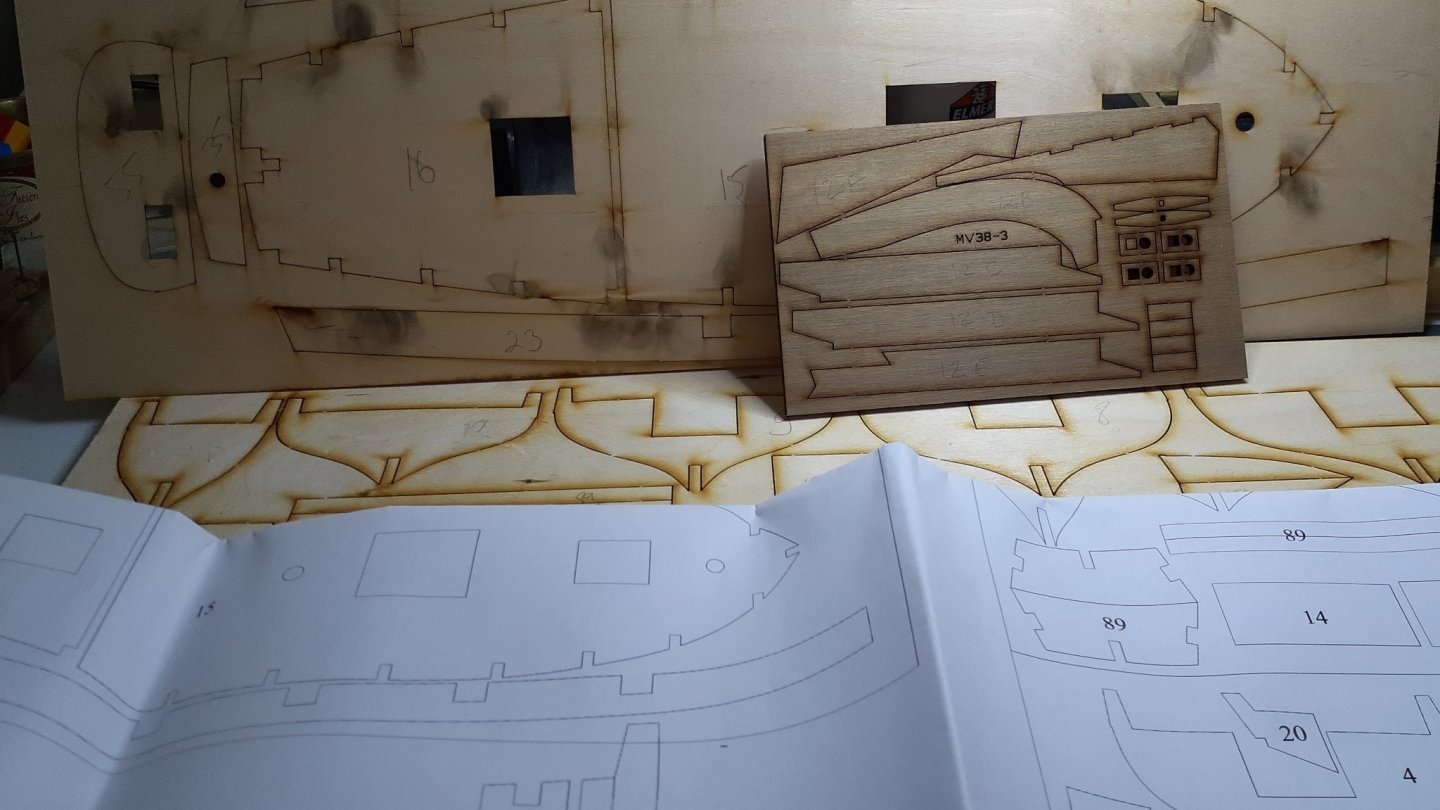

Time to get to work. So here is the open box. As I wrote, first surprise is the loose sheet instructions. Second surprise the parts are not numbered. The i discovered that the false keel is slightly warped. Below are a few pictures: I dont like the fact that all the planking and dowels are bundled together. We'll see what happens... Also the life boat is cast in metal. I may want to built one from scratch. All instructions are in multiple languages. The font is very small (size 8?). No pictures, only black and white drawings. Nice 4mm thick wood for the false keel, bulkheads and the likes, but no numbers on parts 😞 Using the one of the plans as reference i numbered the parts. Home made jig with legos. It's adjustable 🙂 The false keel needed some attention. By tomorrow it should be straight.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.24827e11c1a727bd7cf6cfa9c12072d3.jpg)