native one

Members-

Posts

65 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by native one

-

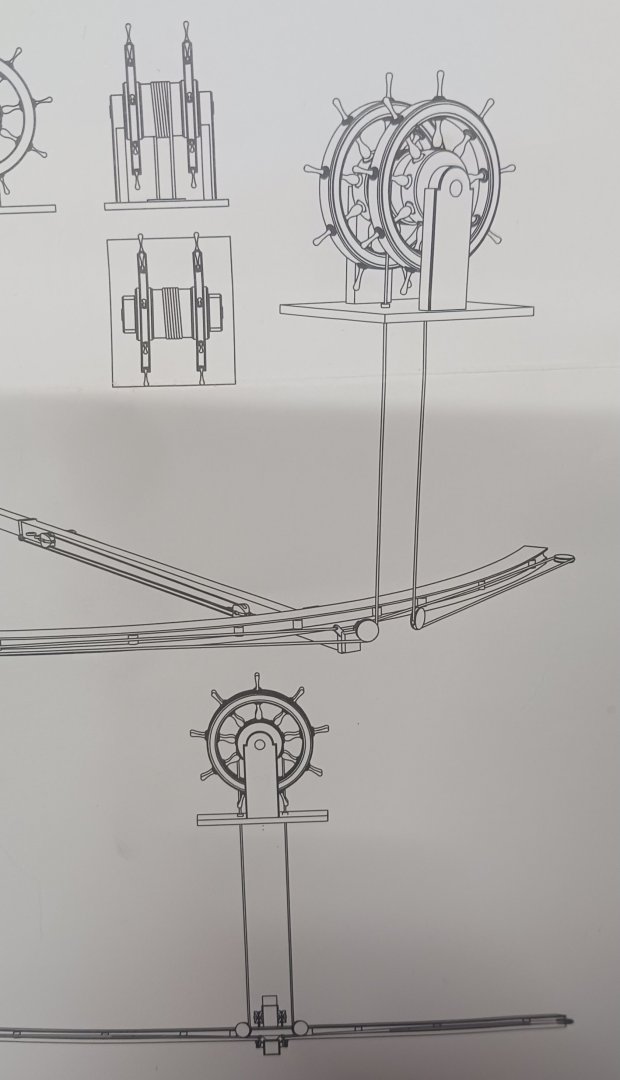

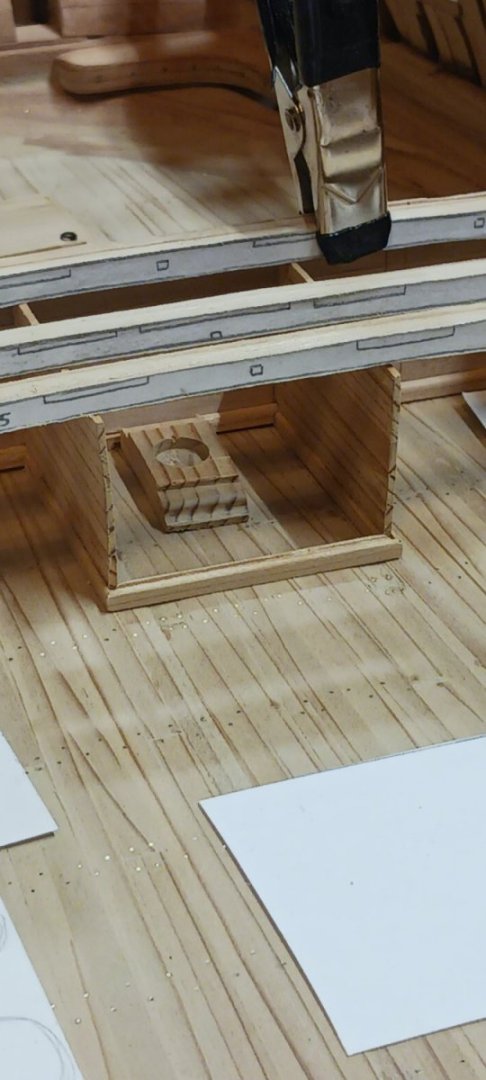

Been working on the getting the ships steering put together,made up the pulleys and some scale rope, made the ships steering wheels drum and positioned it where it would be so I can get the rope tension right,everything seems to line up and now I need to make the tension pulleys that run down the side of the tiller ,I deviated on the plans a bit on the first set of pulleys that are right under the orlop deck,they called for them to be set parallel with the center line of the ship but everytime I put pressure on the line the rope jumped off the pulley,so I decided to give them a slight offset, now the lines run alot smoother back to the second set of pulleys.

-

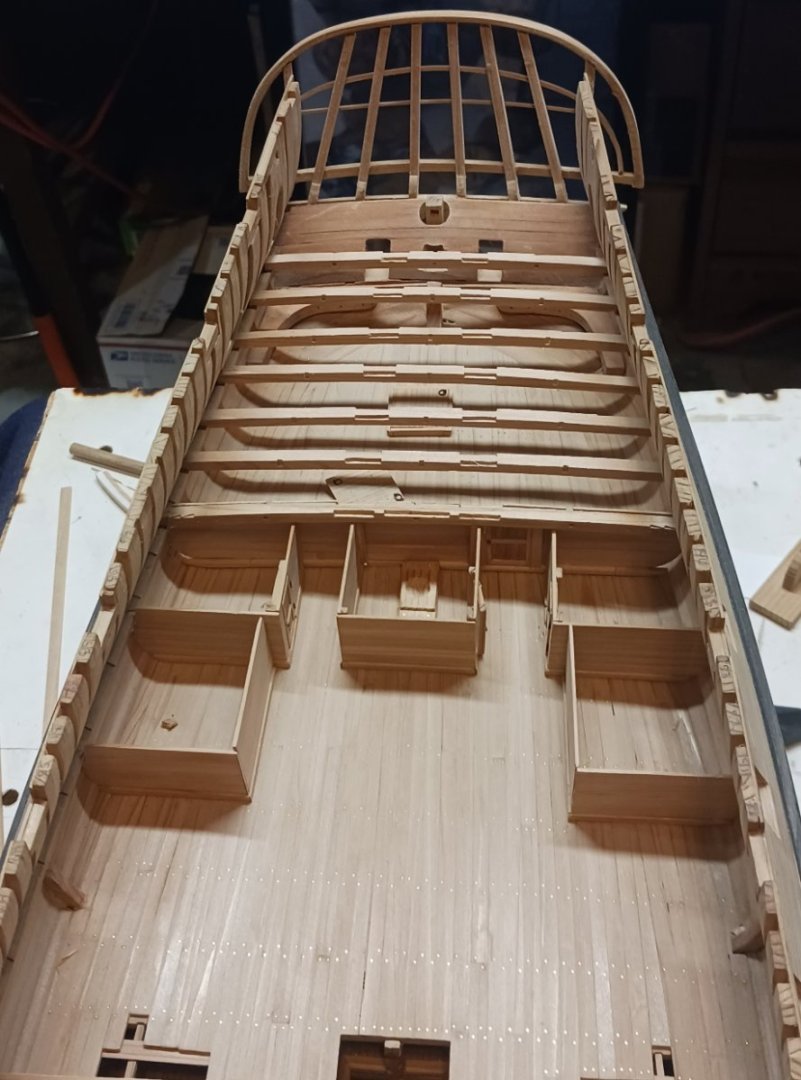

Cold weather has come around in my part of the world,so time to pull the dust cover off the Mahonesa's and resume working her,not much has been done,still working on the gundeck beams and building the gratings,need to build a different stand so I can mount the rudder and began working on the tiller and sweep.

-

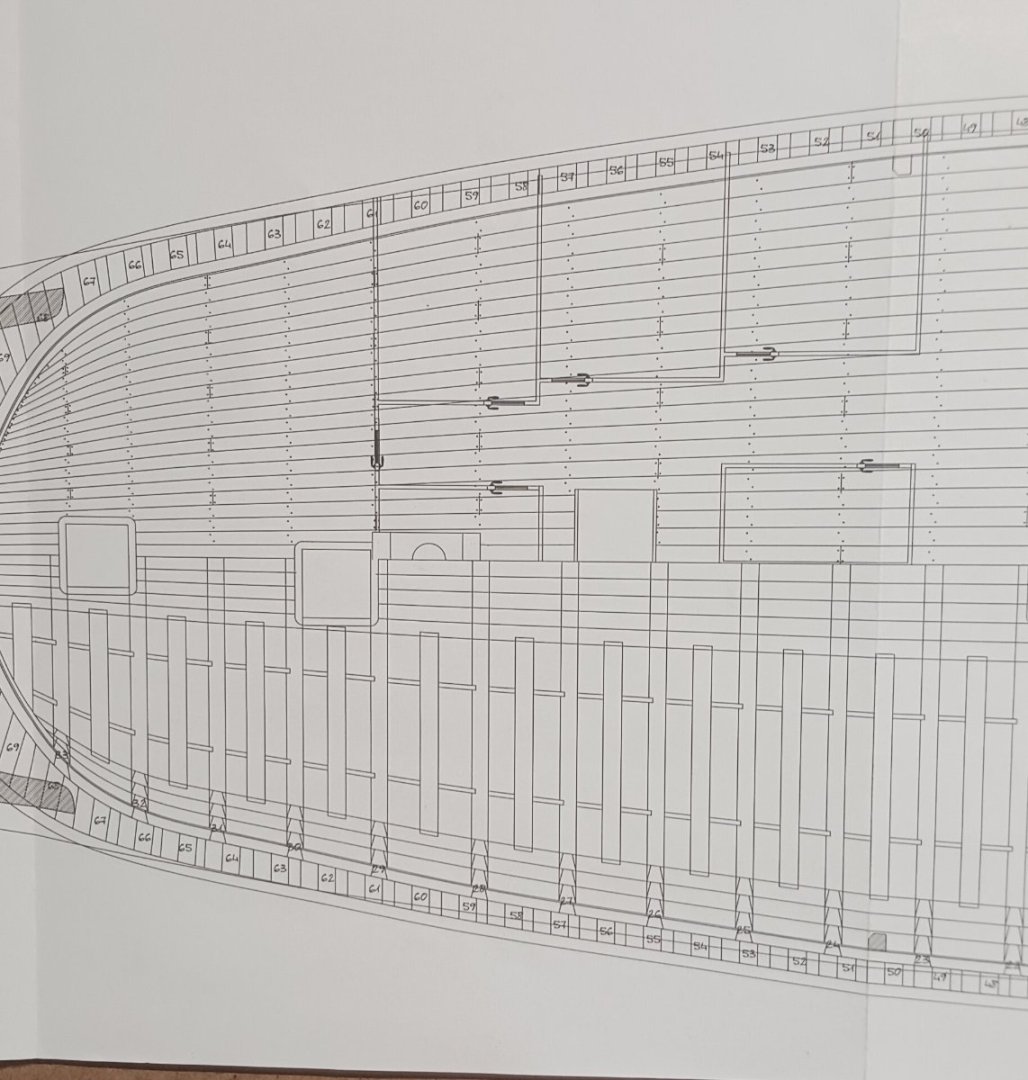

Finally came to an decision on how much deck I was going to leave off,just enough so you can view some of the lower deck structure but I retained enough in the stern area so when I get around to building the bulwarks and quarters there will be enough decking underneath to give them support,now for the tedious job of nailing the deck off.

-

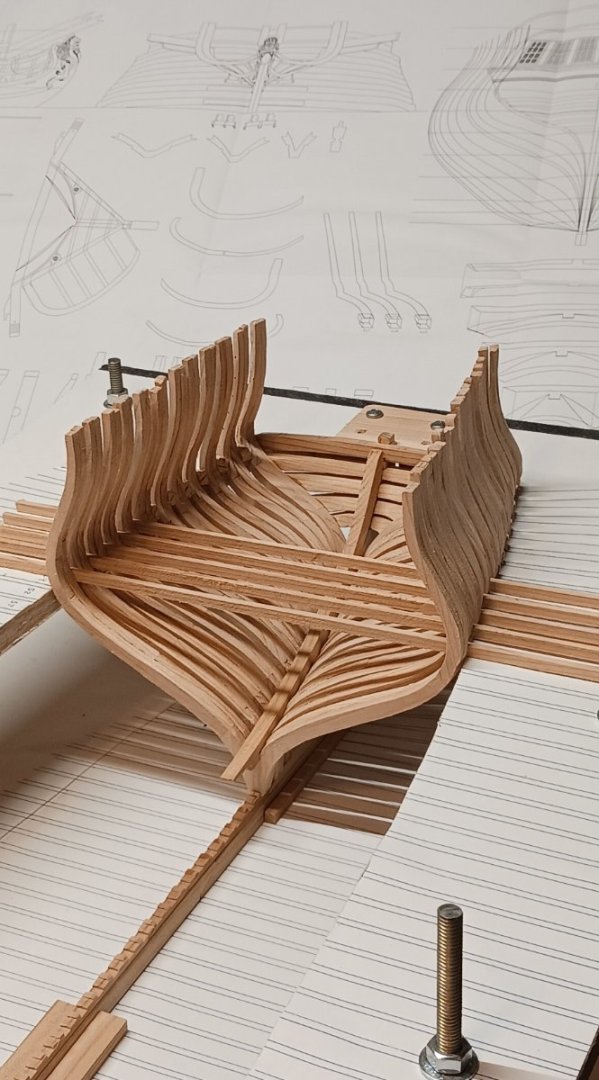

For the stern and bow my model never left the build board so I could retain my extreme breadth line which helped keep it at the width the frames needed to be set at,and by drawing the frame locations on the upper board made it easier to keep the cant frames evenly spaced.

- 99 replies

-

- ancre

- La Mahonesa

-

(and 1 more)

Tagged with:

-

A scroll saw is very useful especially when it comes to cutting out all the pieces for the frames,11 total for each frame for the Mahonesa's.

- 99 replies

-

- ancre

- La Mahonesa

-

(and 1 more)

Tagged with:

-

Before starting on the decking of the orlop I decided to plank between the waterway and spirketing in the stern of the ship,kind of a tricky task on the Mahonesa's because the waterway starts out nearly flat then makes a gradual climb towards the deck clamps,the bend of the planking in the stern area is so much that I had to make templates for every piece then cut each piece out of thicker material then sand in the curve top and bottom before fitting them in place.

-

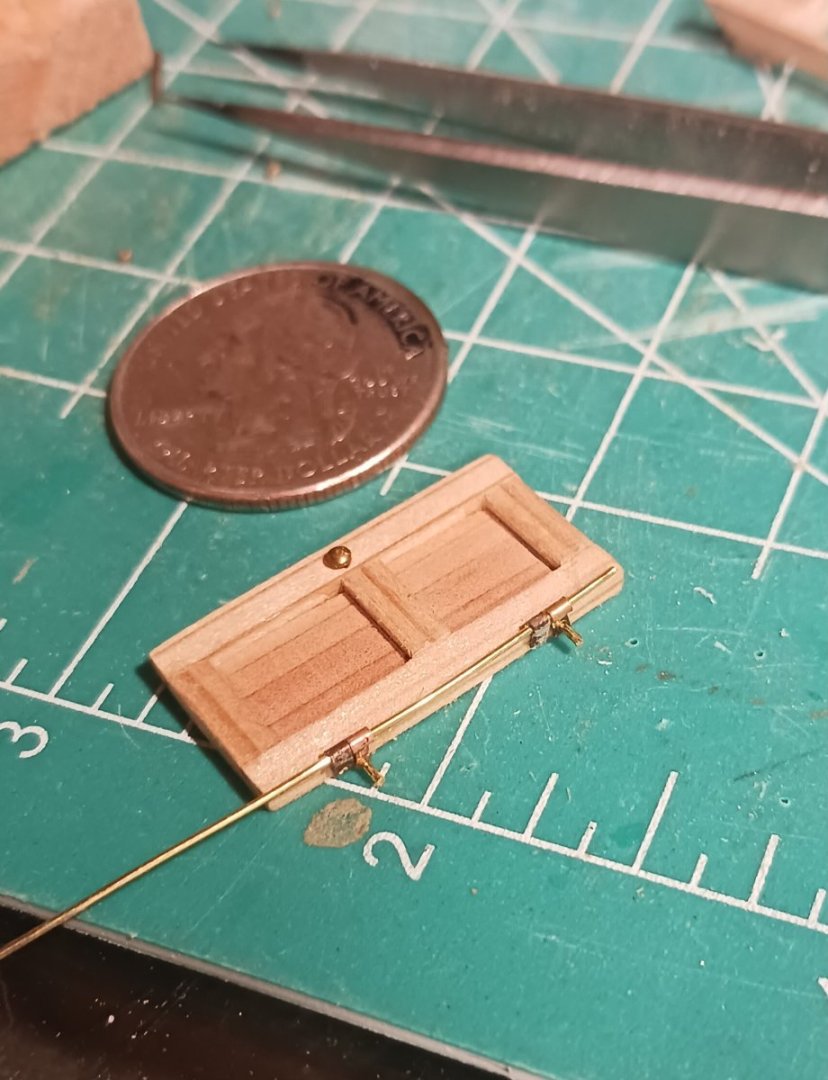

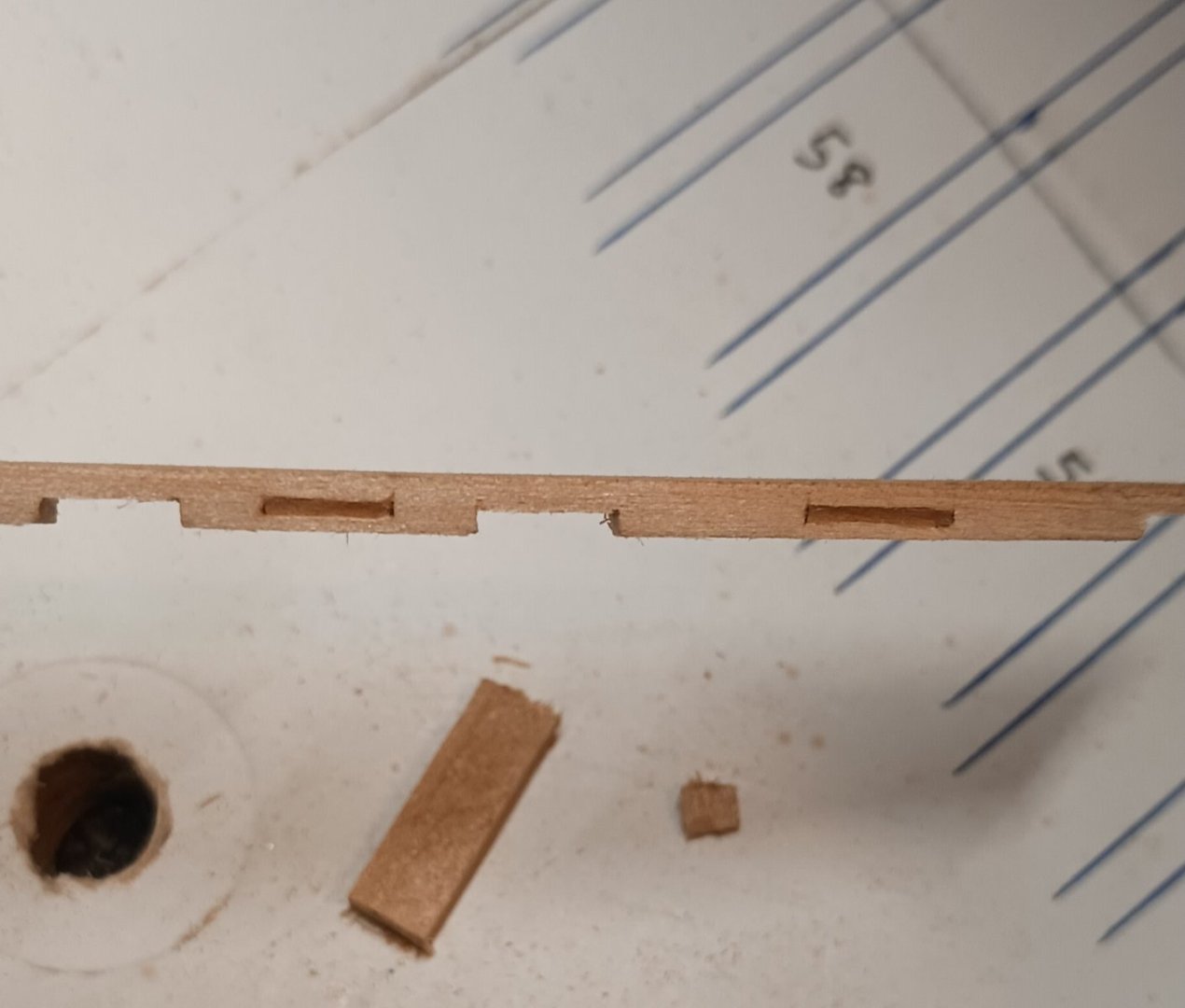

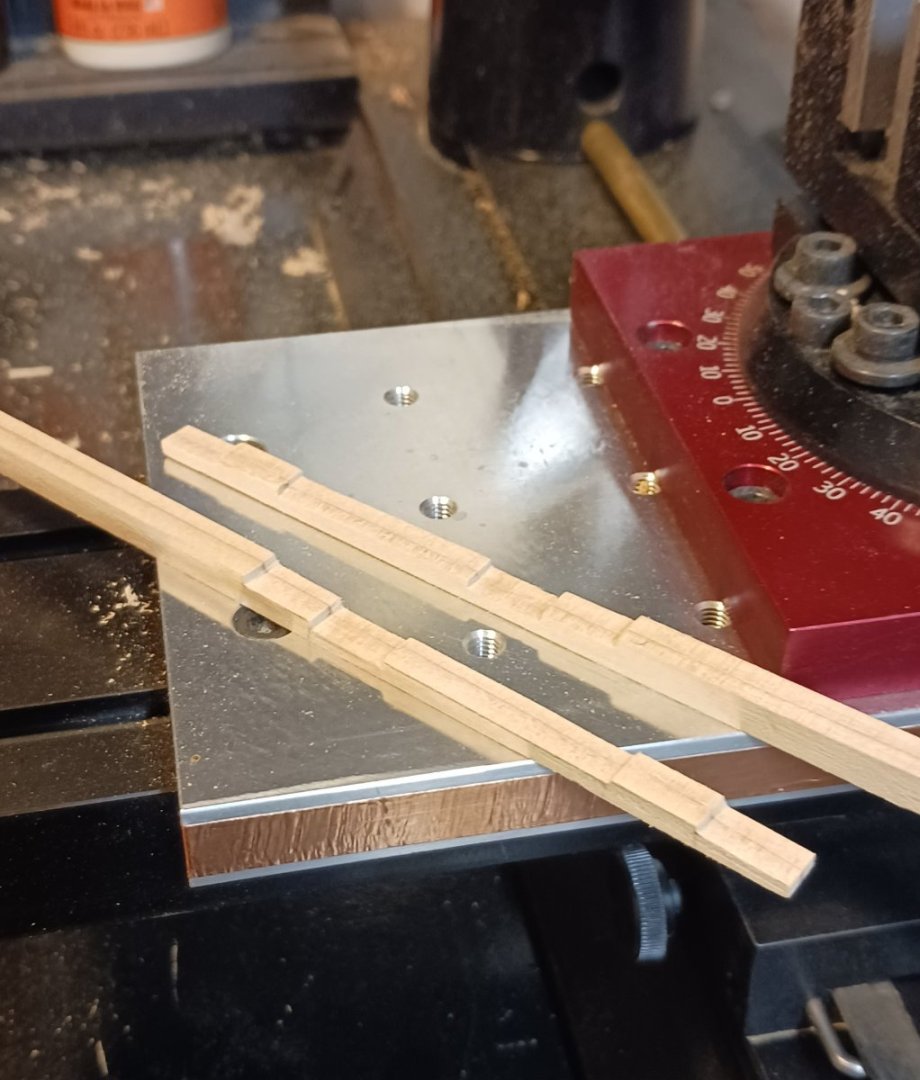

finished all the storage rooms in the rear of the hold,then milled out all the two piece beams midship, still need to mark out and cut in all the notches in the beams for the carlings, began working on the storage rooms in the forward part of the hold,alot of metal work in this area because of the four doors in this area.

-

Planked the floor in the hold, now to began construction of the storerooms that fill in that part of the hold,and still need laders down to light room and powder magazine,but first I'll probably need to put in some more deck beams of the orlop deck so I can tell which ones cut thru the walls of the storage rooms.

-

Finally finished the pump well and mounted it permanently, there are two beams in the hold that go thru the pump well and they have to be placed so the front one is right in front of the mast when it is put in and the rear one that the down tube for the chain pumps has to sit against,took me some time to get them exactly where they go but I got them,then I moved on up to the front of the hold and installed the forward platform which numerous storage rooms will be built,and with the pump well in place I was able to continue building the beam supports for the orlop deck.

-

Hello everyone from Spain

native one replied to Jose Luis Verdejo's topic in New member Introductions

Welcome aboard.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.