gsxdent59

Members-

Posts

85 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by gsxdent59

-

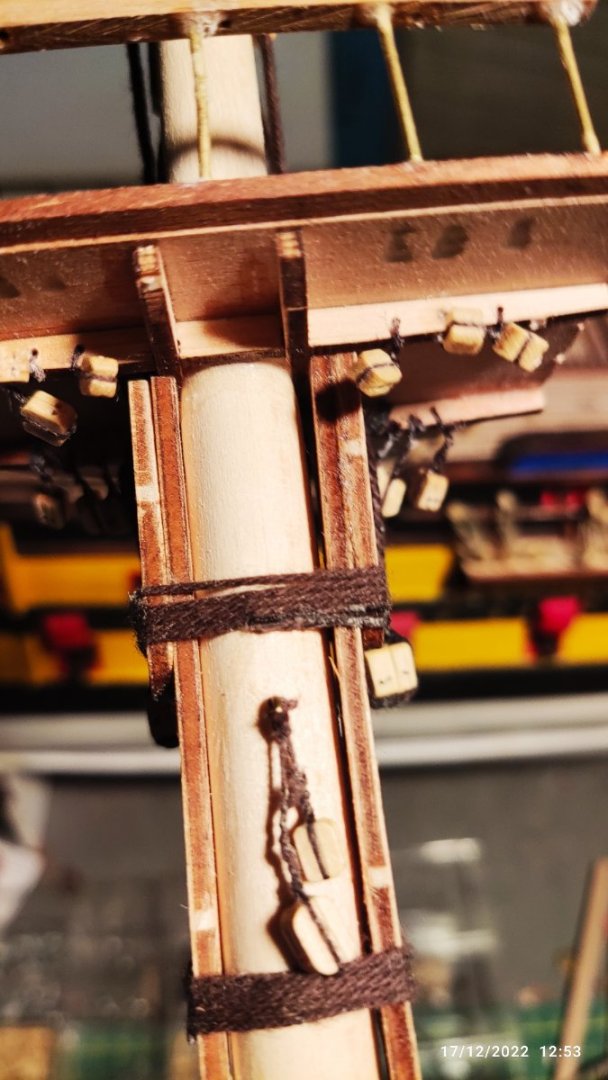

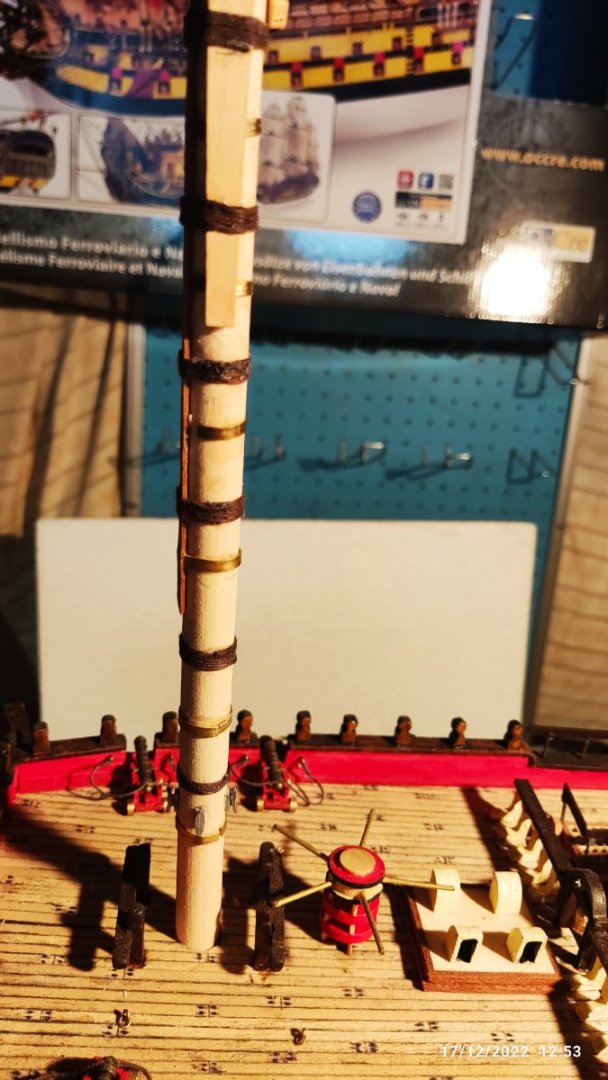

Now i have finish the front mast. Three parts. Placed all the blocks,pulleys and wires. Start the yards now.Four for each mast...I finish the lower. A lot of work ...wood,metal,and prass parts...I don't cement the yards now. First i will make all the ladders for each mast and after i cement the yards,for easier work.

-

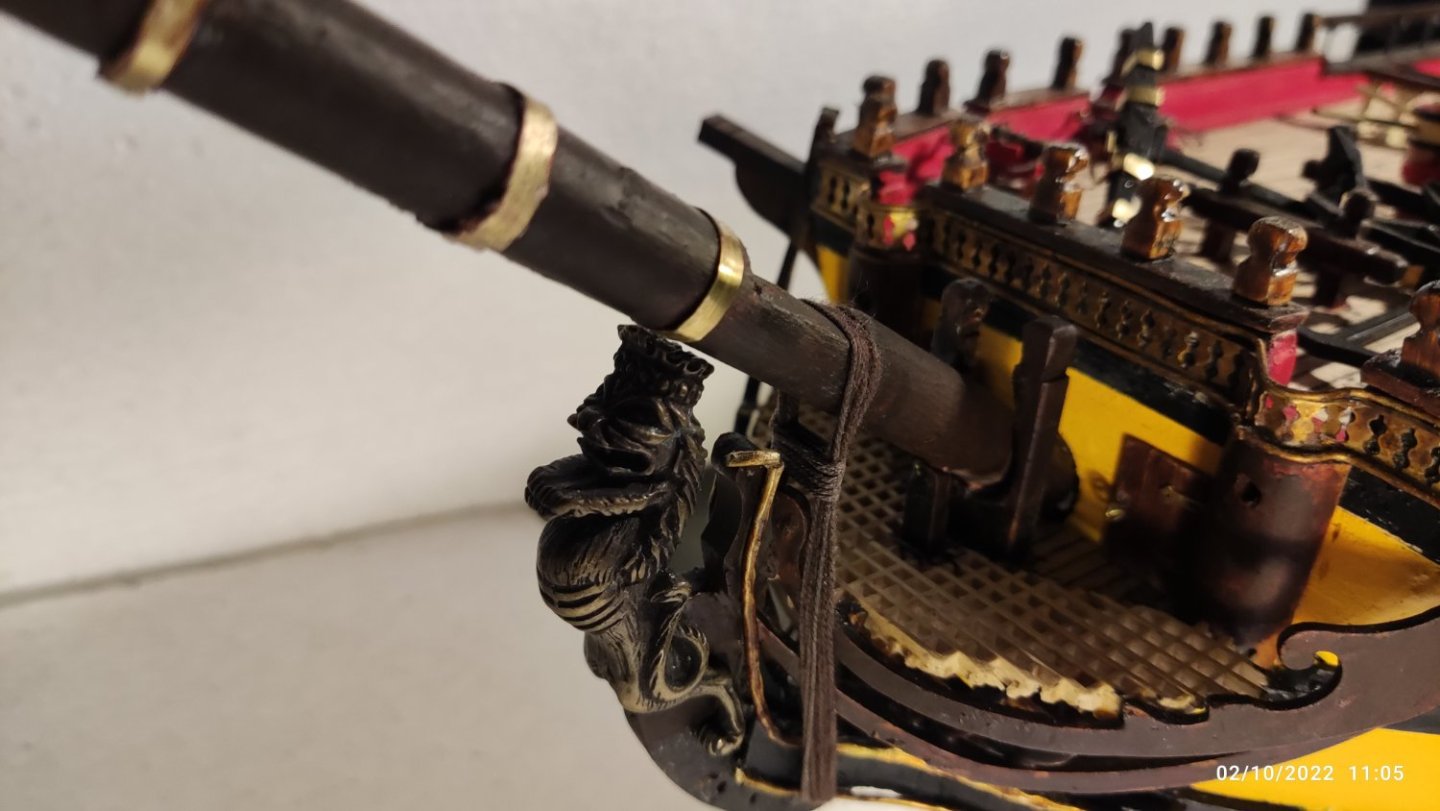

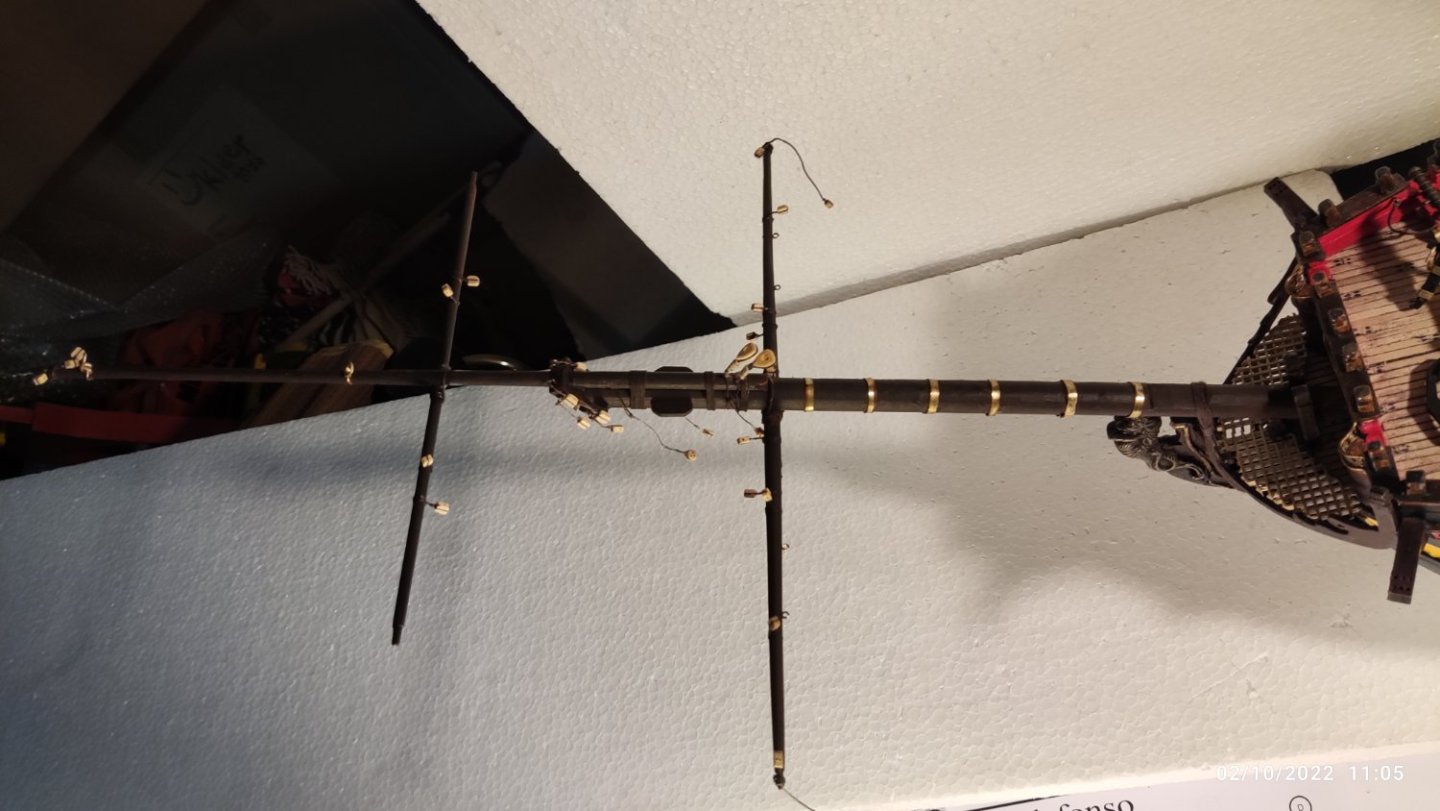

Now i start the Main bowsprit. Two pieces ,one 12mm diameter and the boom from 6mm on base 4mm at the end. I use sand paper to give the right shape. Assembled together by viewing the plans that are 1:1 in scale. I put all the eyebolts and pulley blocks as shown in the plans, using cotton thread. That will be used leater for threads from musts. With the bowsprit in place, the length of the model is completed. Now is 49,21 inch long or 1,25 meter

-

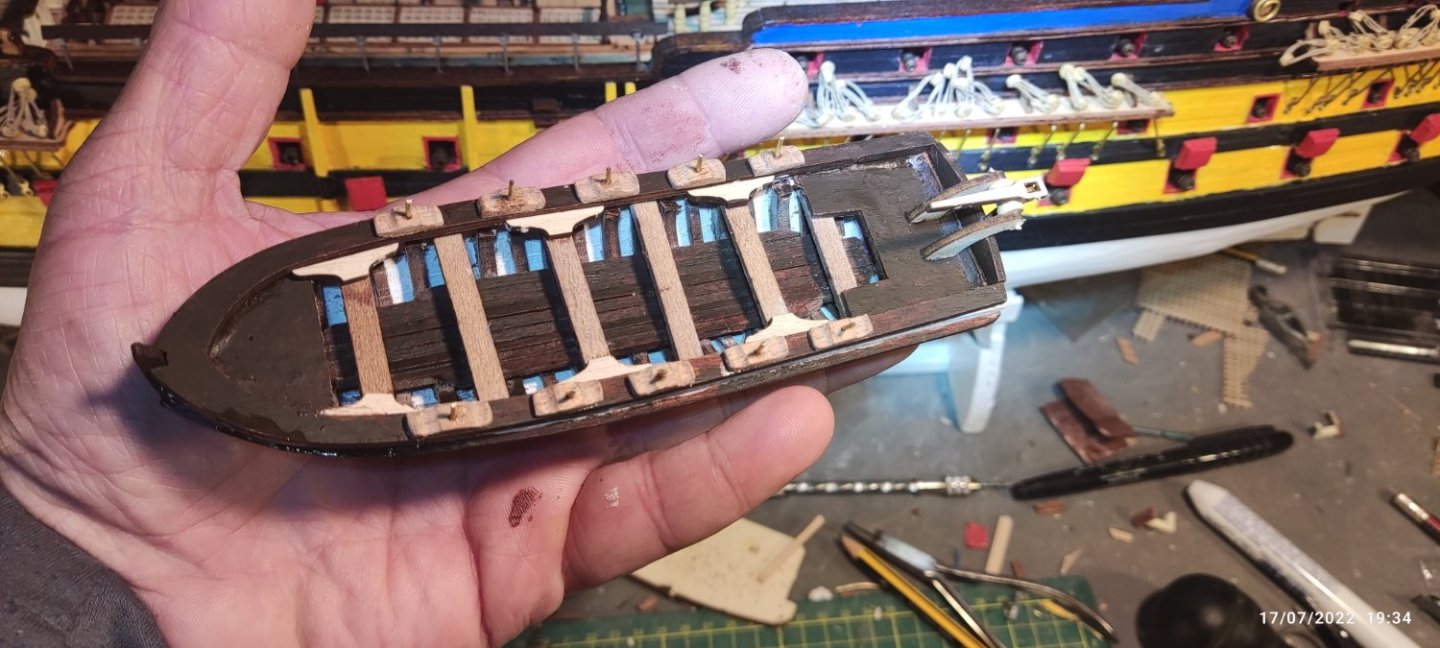

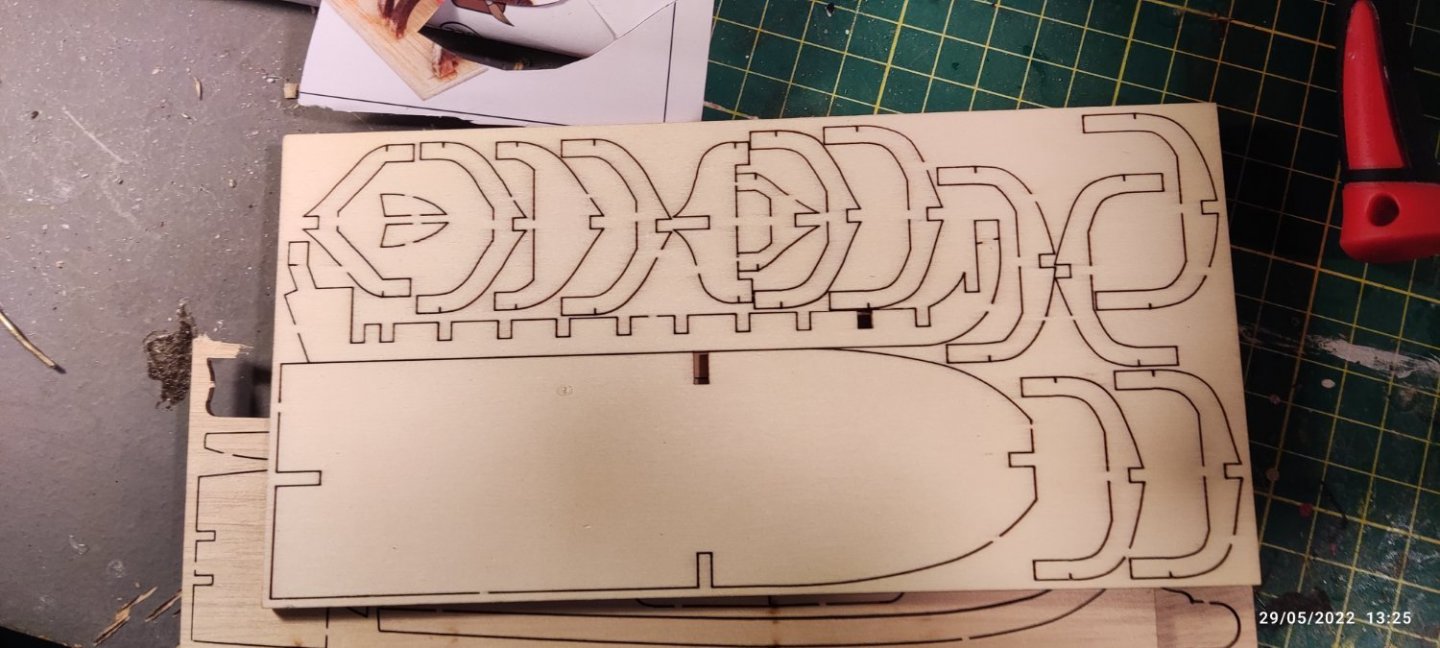

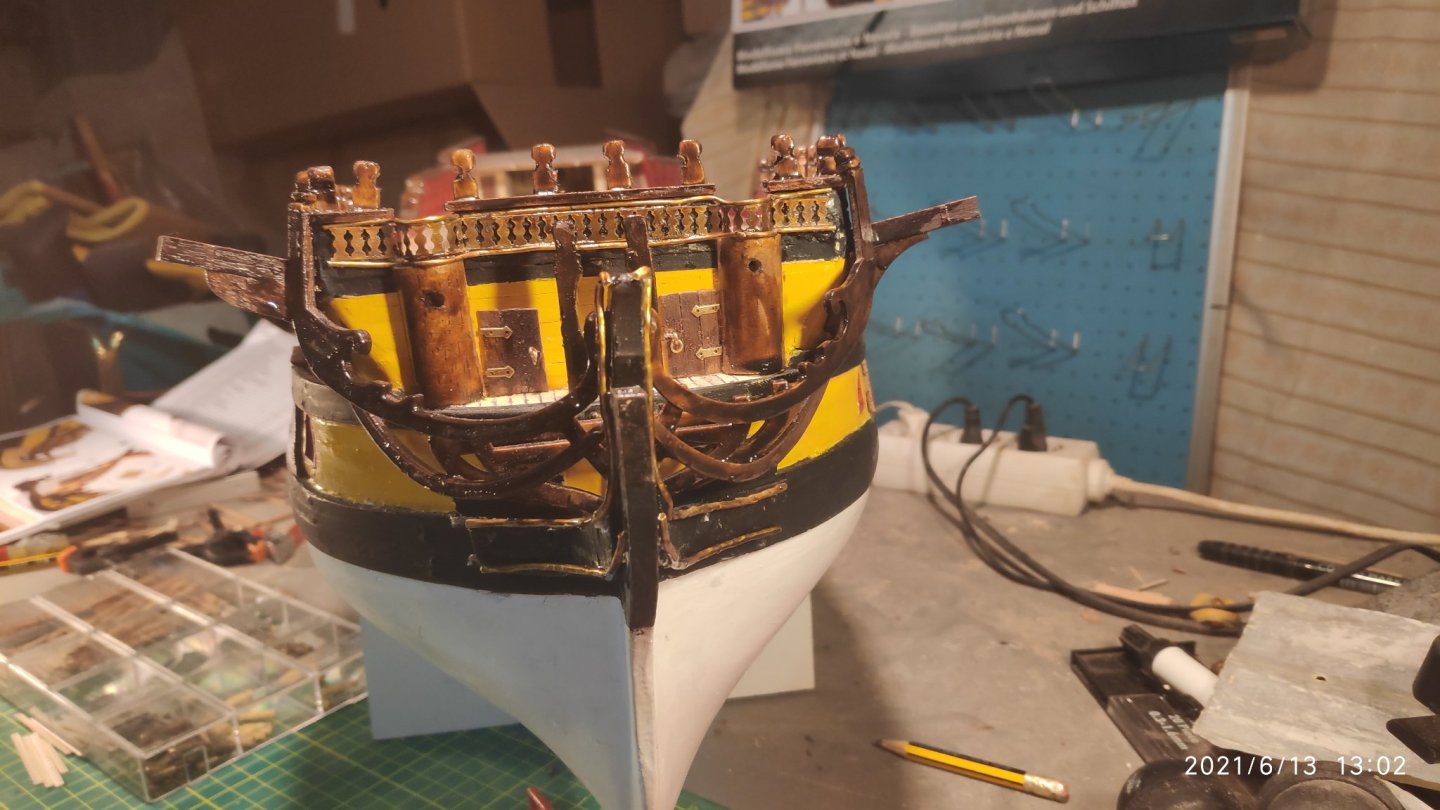

Now i finish the stern cabin. Too many pieces, from wood,metal and brass. After painting, i put the chain as show in the manual. Many columns side by side close all the stern balkony. Three lanterns are made and glued as show in the pictures. Also i make the four anckors from a metal part and wood with brass inforcments. Is't glued in place yet,because these parts must be the last to be fitted, as i will need to have all of the masts in place first. Now is time to make the barge (helping boat) .I make the two support for the barge, glued in the center of the lower deck The barge will be made the same as the ship....nothing easy in this model....

-

At last i finish all channels,fitting all clump blocks (72 total) both sides of hull and nailed with pins...In the upper free block will be attached the threads from ladders for the three musts,just as the manual said...Attention needed that the clump blocks doesn't cover the gunbarrels from behind in any way

-

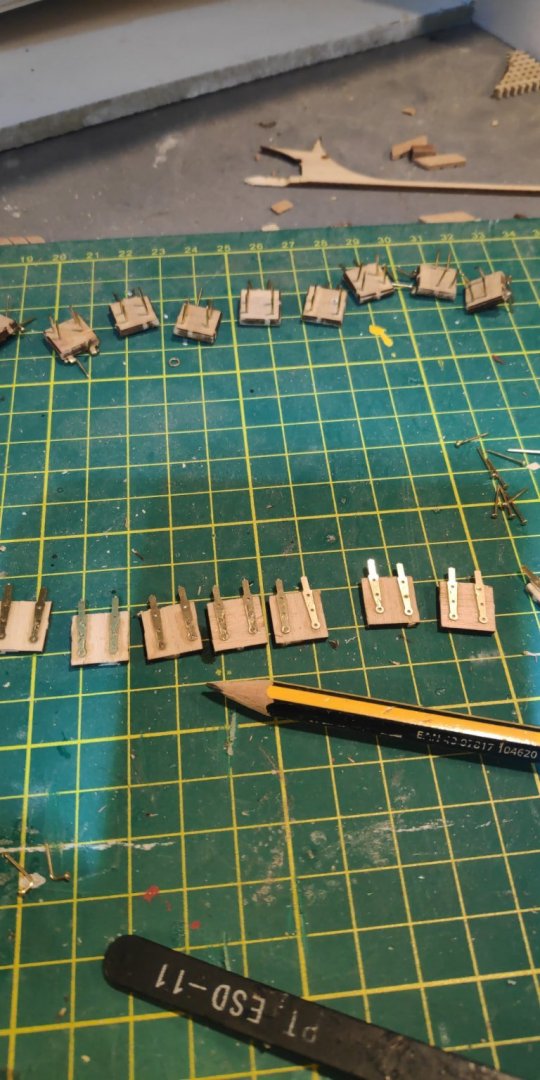

Two years after i start the kit....Now i make the the channels,three for one side and other three for the other. I make the necessary holes on them to fit the the clump block slings. For that i use a simple after market equipment to make all the the clump block easy and the same lenght. Then fit the clump blocks using lengths of brass wire and pass them through the holes in the channels. See fotos. They will be held from below by a length of wire and pinned directly to the hull using pins and brass links. All this job must be done for all six channels,both sides of the hull.

-

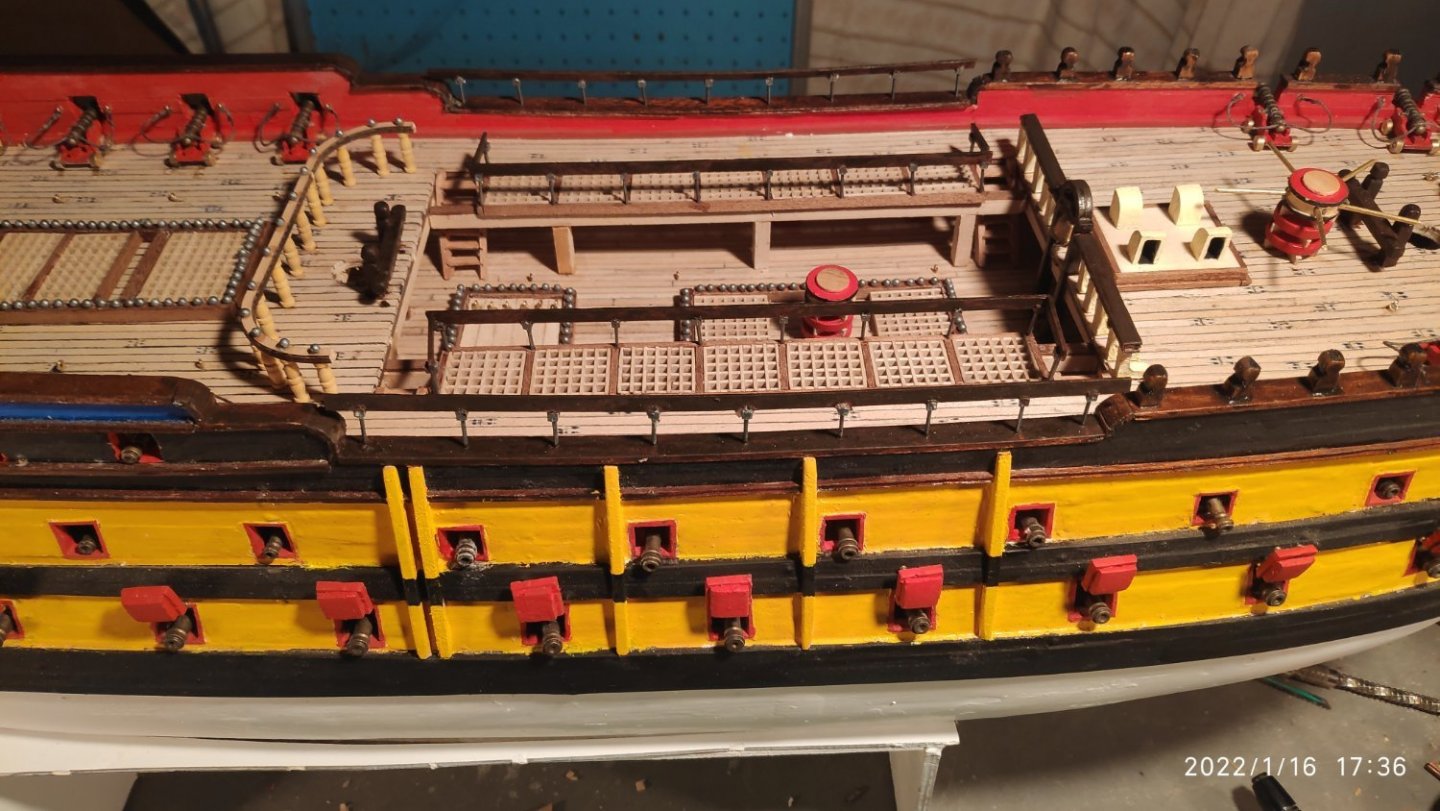

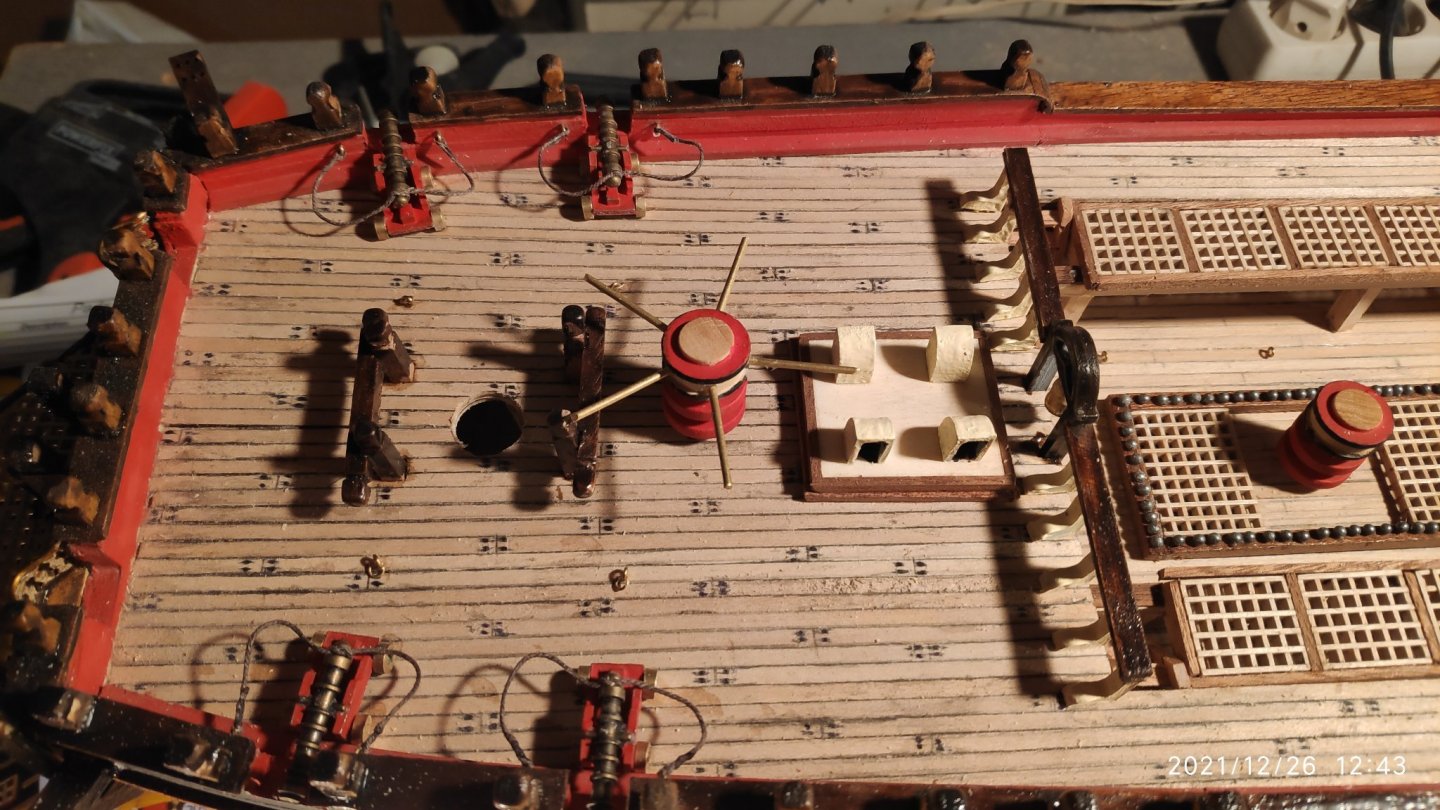

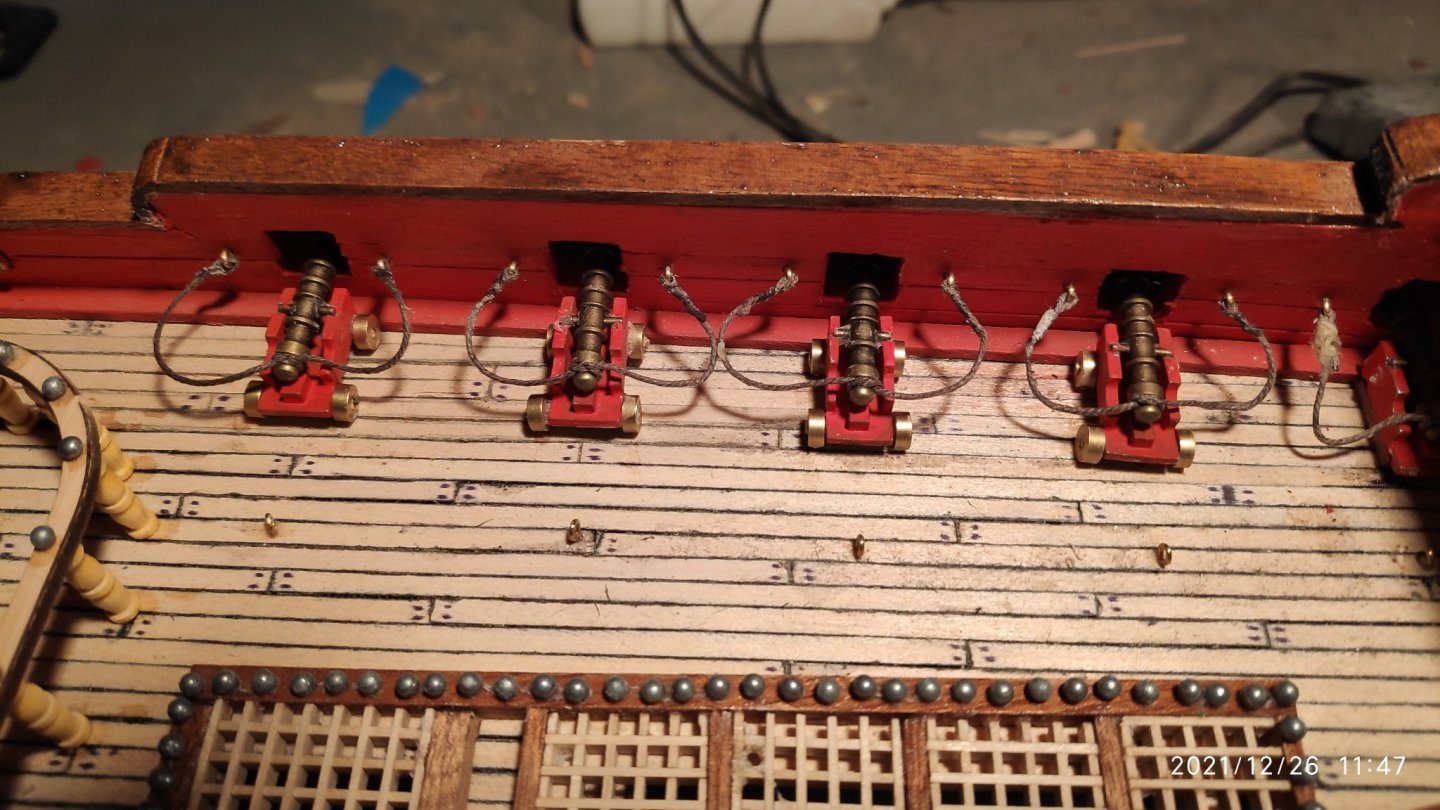

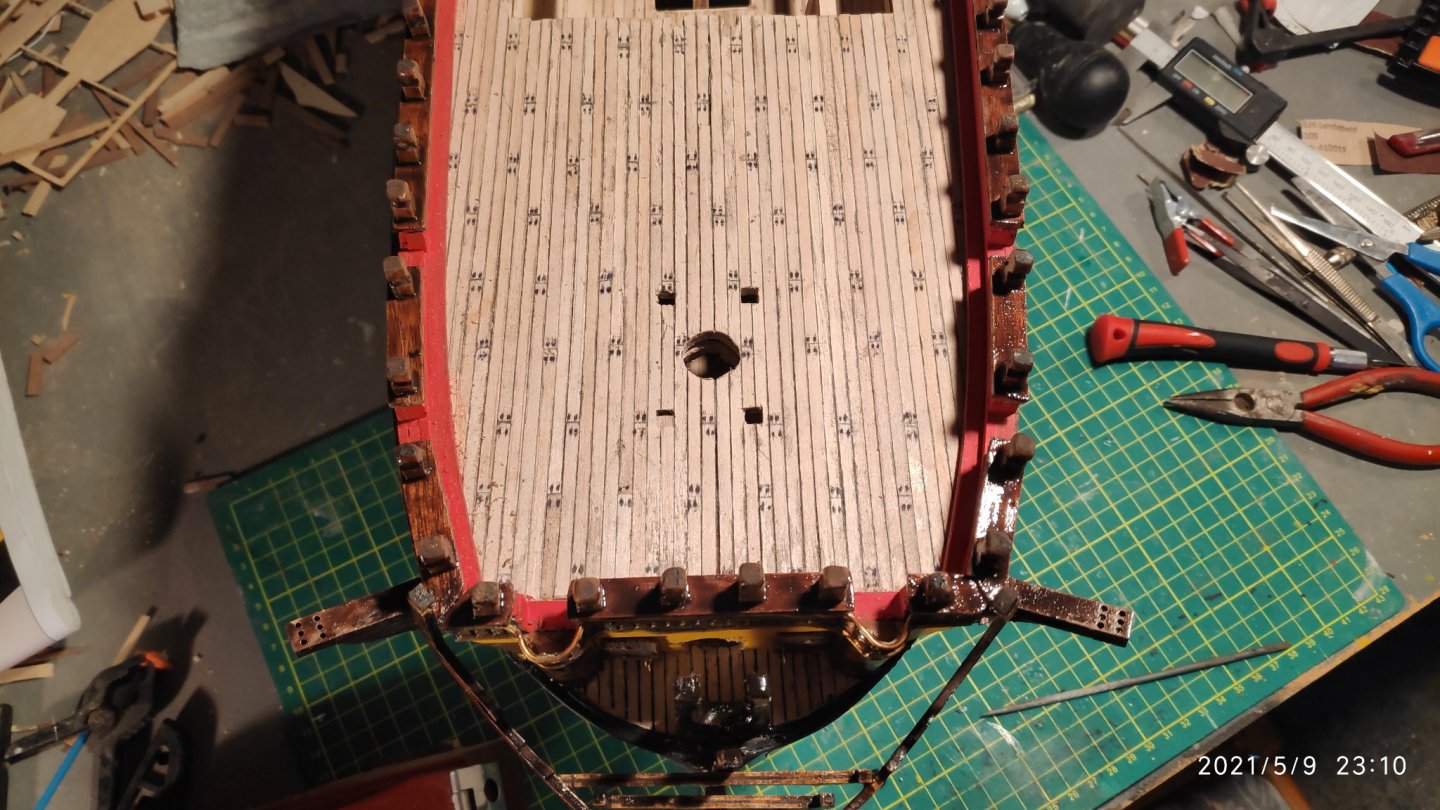

Now is time for the cannons that are visible from the deck. Each cannon consists of : The metal carriage, that was painted red, the cannon barell that is also metalli made from copper, four metal wheels and two axes made from brass wire 1mm diameter. 22 such complexes were made and placed in the corresponding gun ports, in order to complete the armament of the ship. In their place they were attached with a 1.5 mm cottom wire lashing with two eyebolts that were fixed to the bulwarks on either side of the gun ports. Also on the deck behind each cannon were put eyebolts as indicated in the drawing. The two capstans were painted and glued in place with the front having brass handles for its rotation by hands from the crew of the ship

-

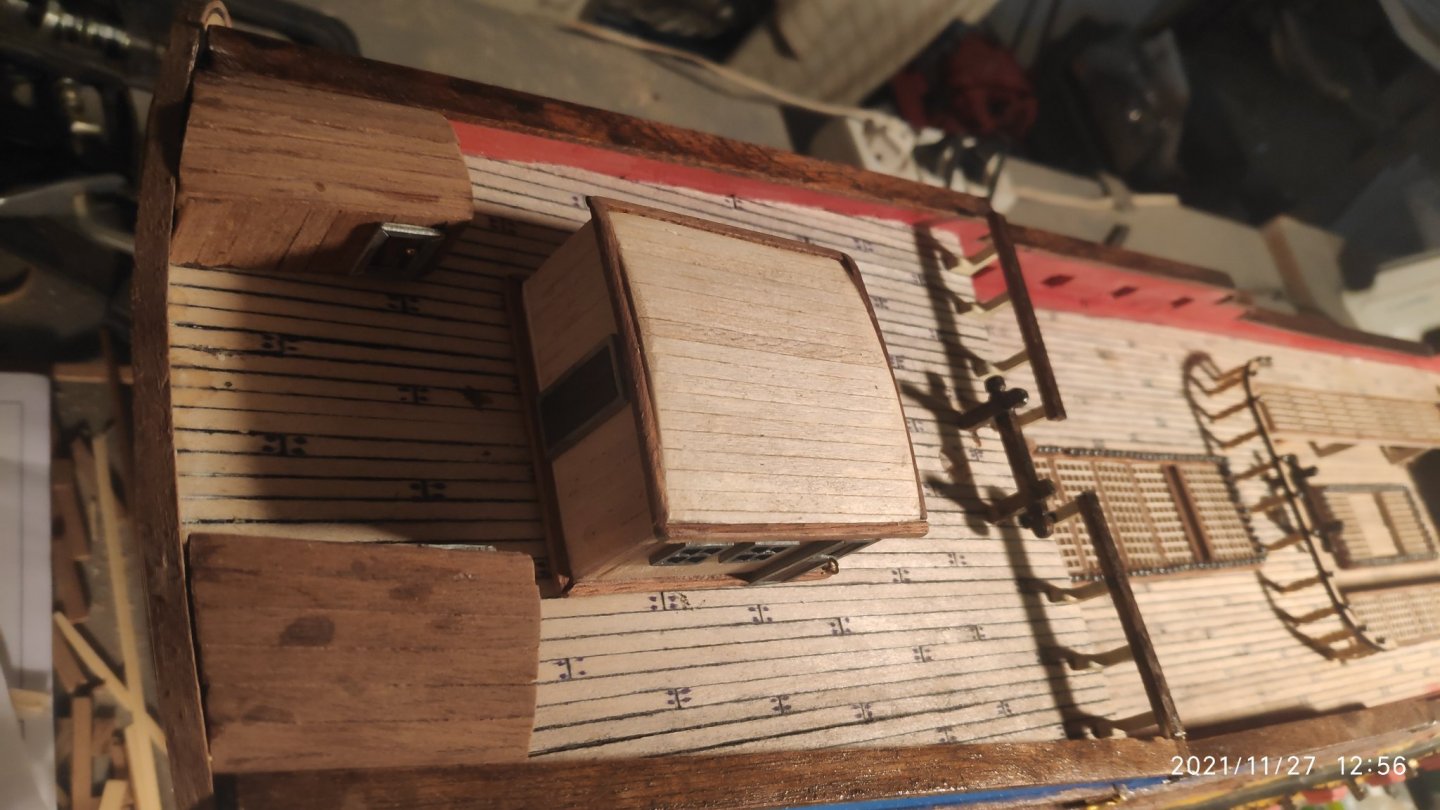

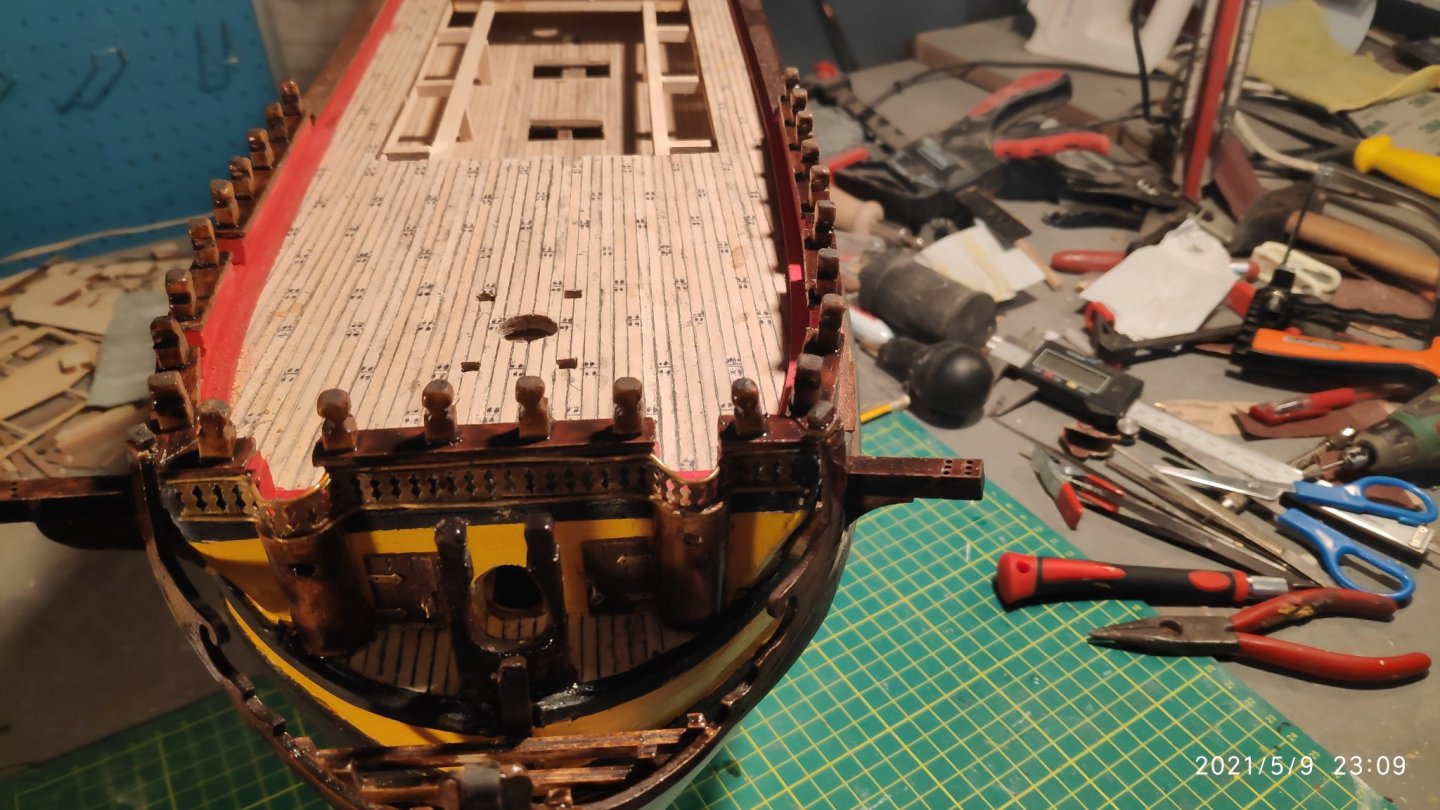

Now i make the rear upper deck cabin. A rectangular construction,lined outside using the same lining strips as in the deck. I glue the front roof and baseboard finishes, the sides of the roof and the side baseboards all with sapelli wood. Then i glue the the metal doors and windows and put the knobs for the doors. Then i place the cabin on the deck. One more job is done....many others come....lucky me....

-

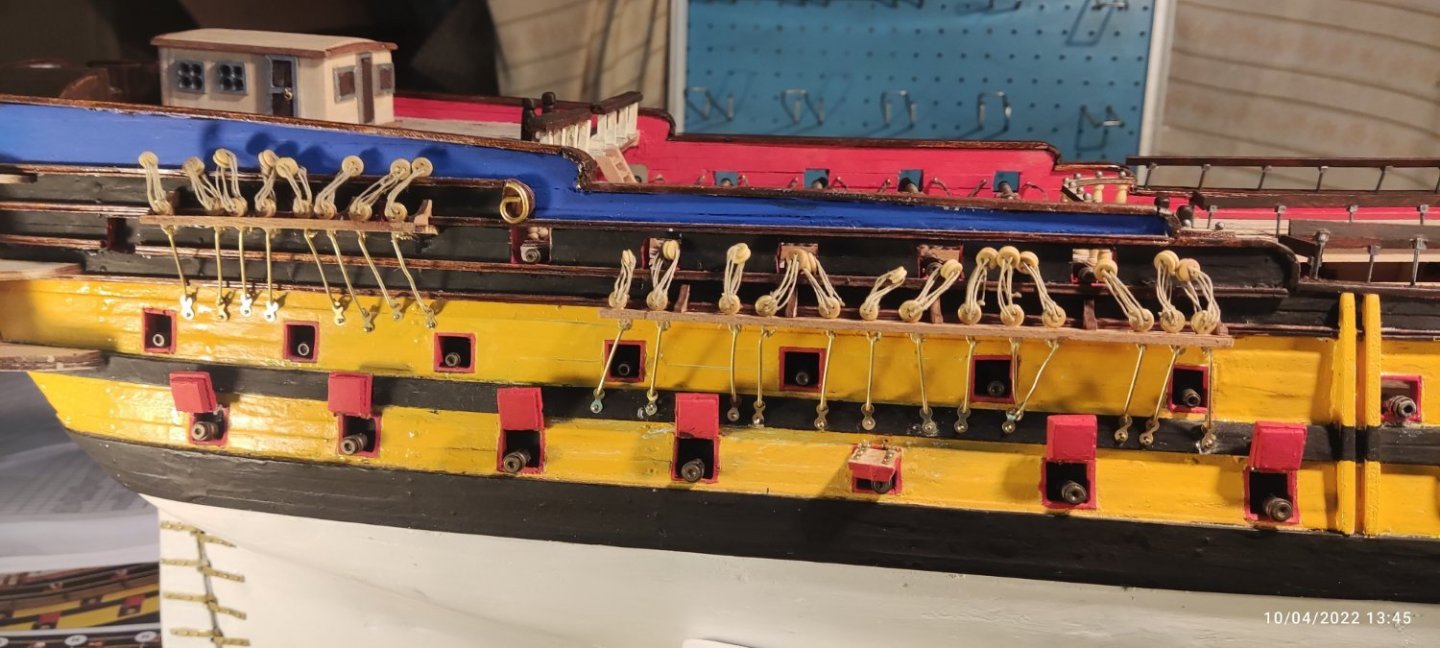

Now is time to fit the gun barells. In gun ports that aren't seen now after fitting the decks, i have glue vertical pieces of wood near the gun ports,before installing the decks.You can see that in earlier fotos,when i make the deck fitting. So in that vertical wood pieces,that i have paint black,i make a hole and in that hole i glue the gun barell in every gun port. The rest guns will be full detailed,because they are in the deck and is visible.

-

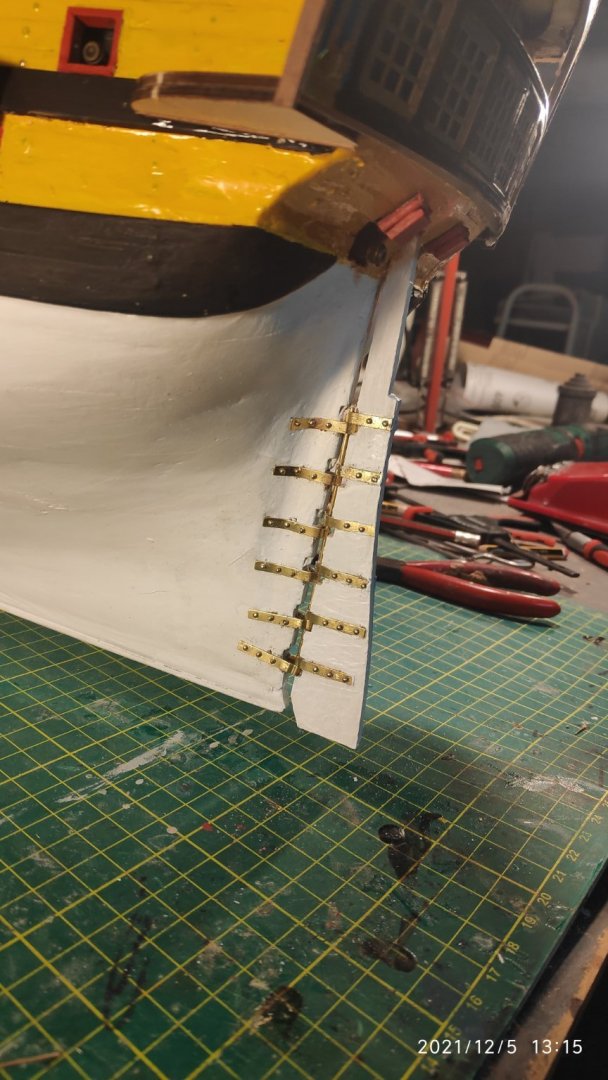

Now is time for the gun ports,they will be fitted in the lower deck only. I must make 28 gunports, from 2 piece of wood,an external (the biggest) and an internal (smaller) glued together an in each external piece i must glue two brass hinges and make the gunport lids using pins bending them 90 degrees. This a very difficult job and time spending job,because all part are very small....

-

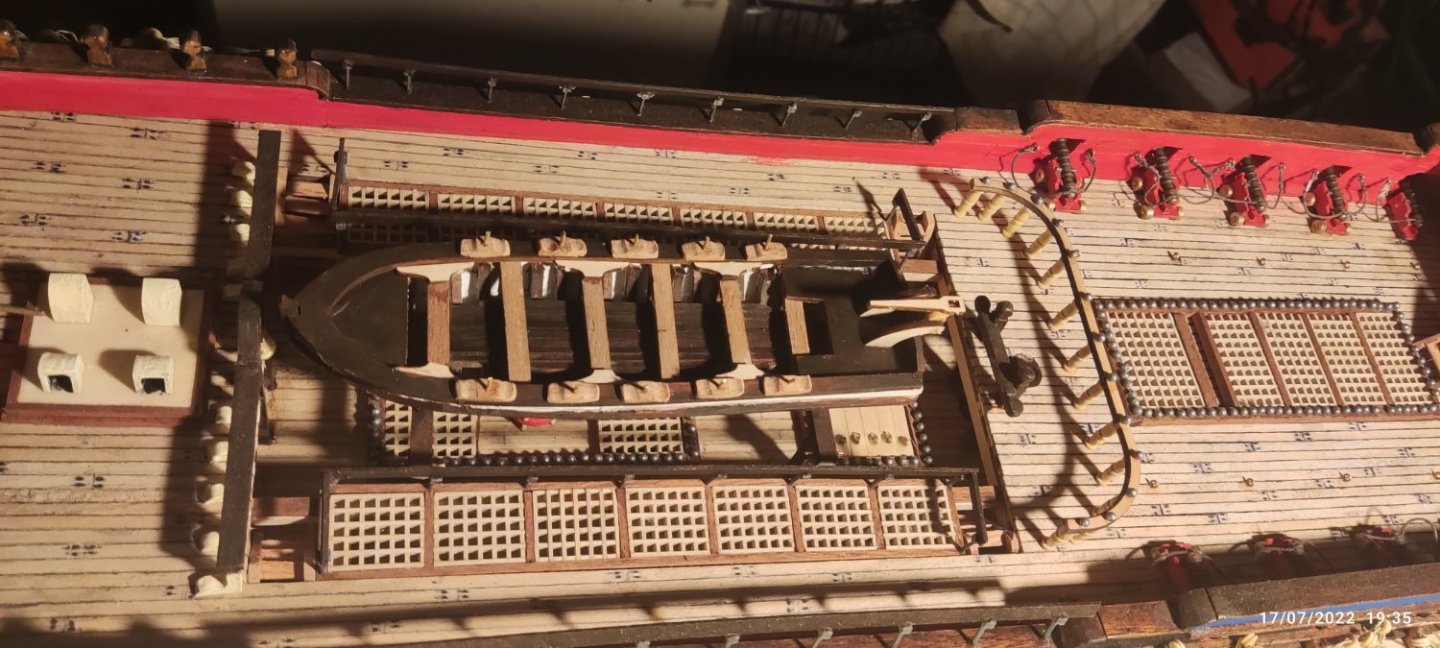

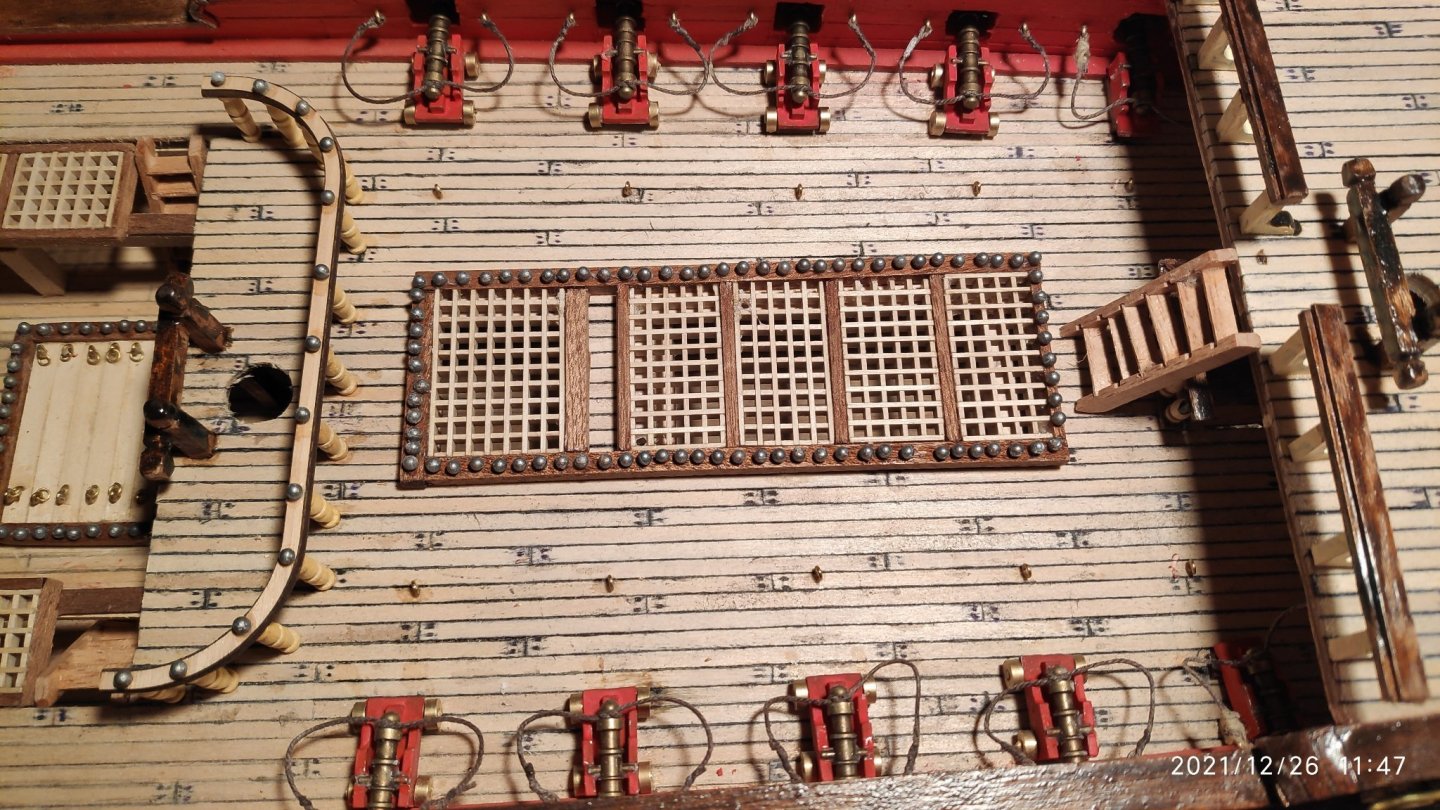

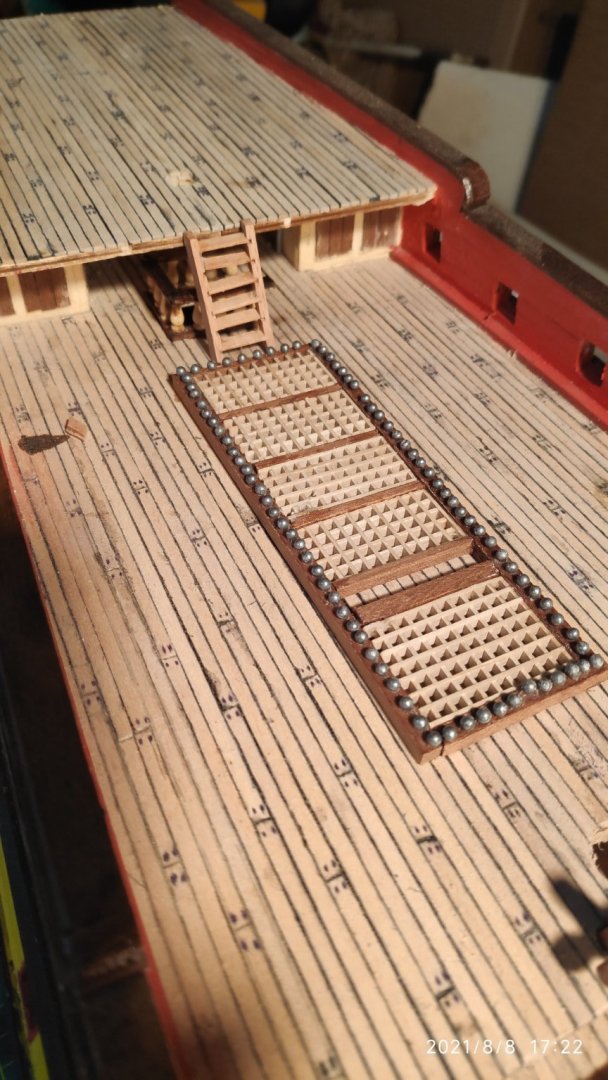

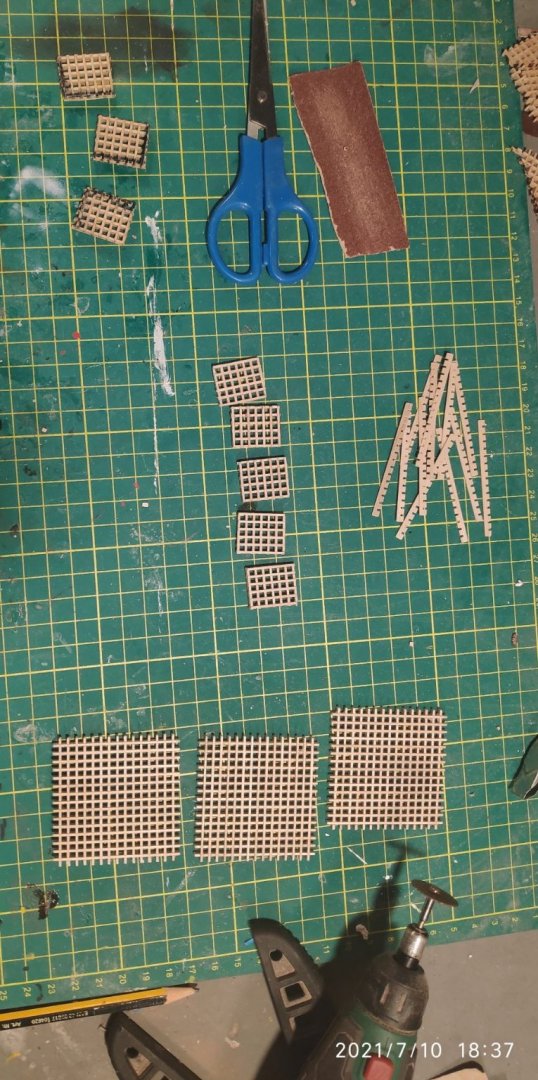

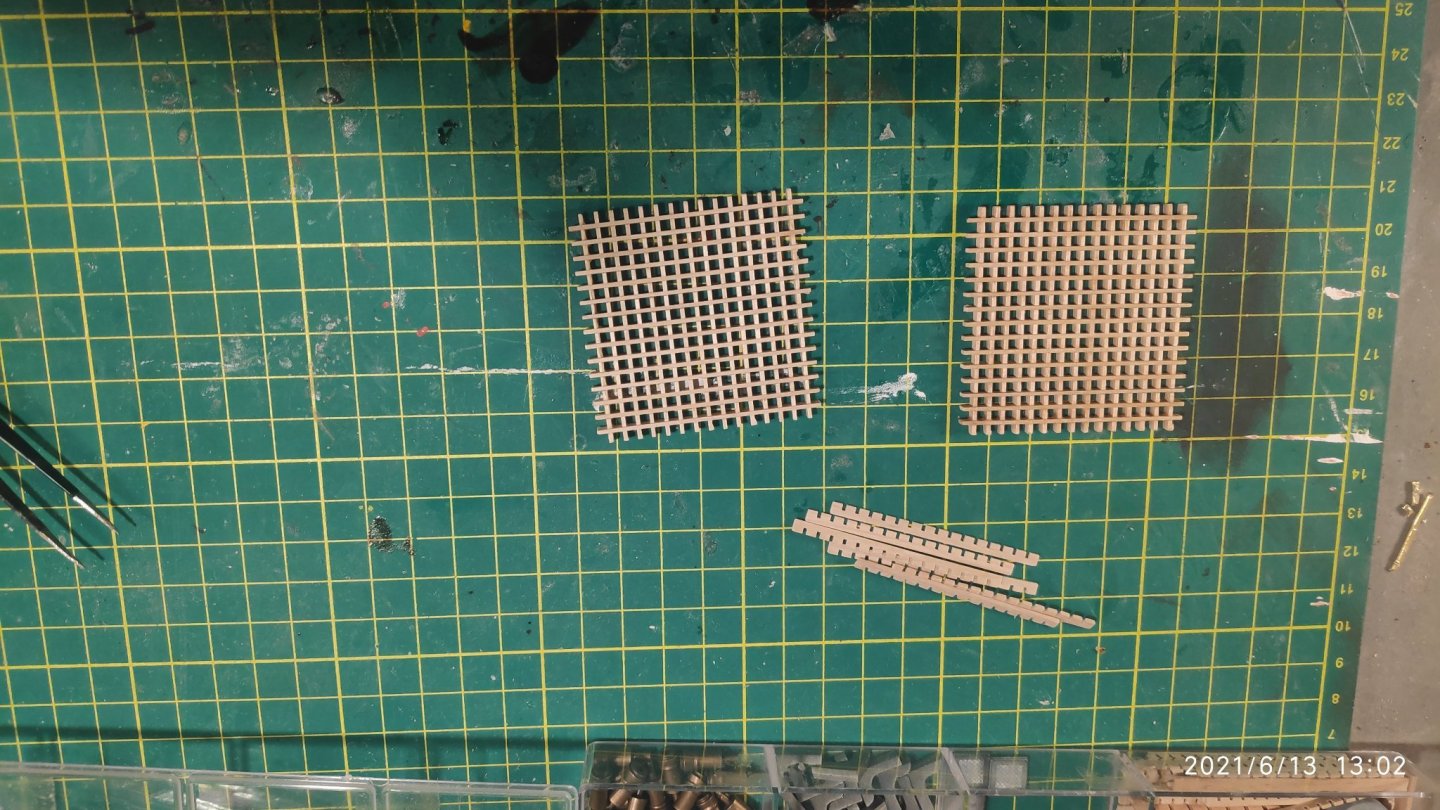

Now i made the grating sections,7 for each side and the frames also... I made also the grating sections of the lower deck. Above this sections will be placed the small boat of the ship. The difficult job here is the iron balls, the ammunition for the cannons,that must glued all arround in the frames. To do this is make small blind holes,so the balls can be placed and glued...See the attached fotos...Continued...

-

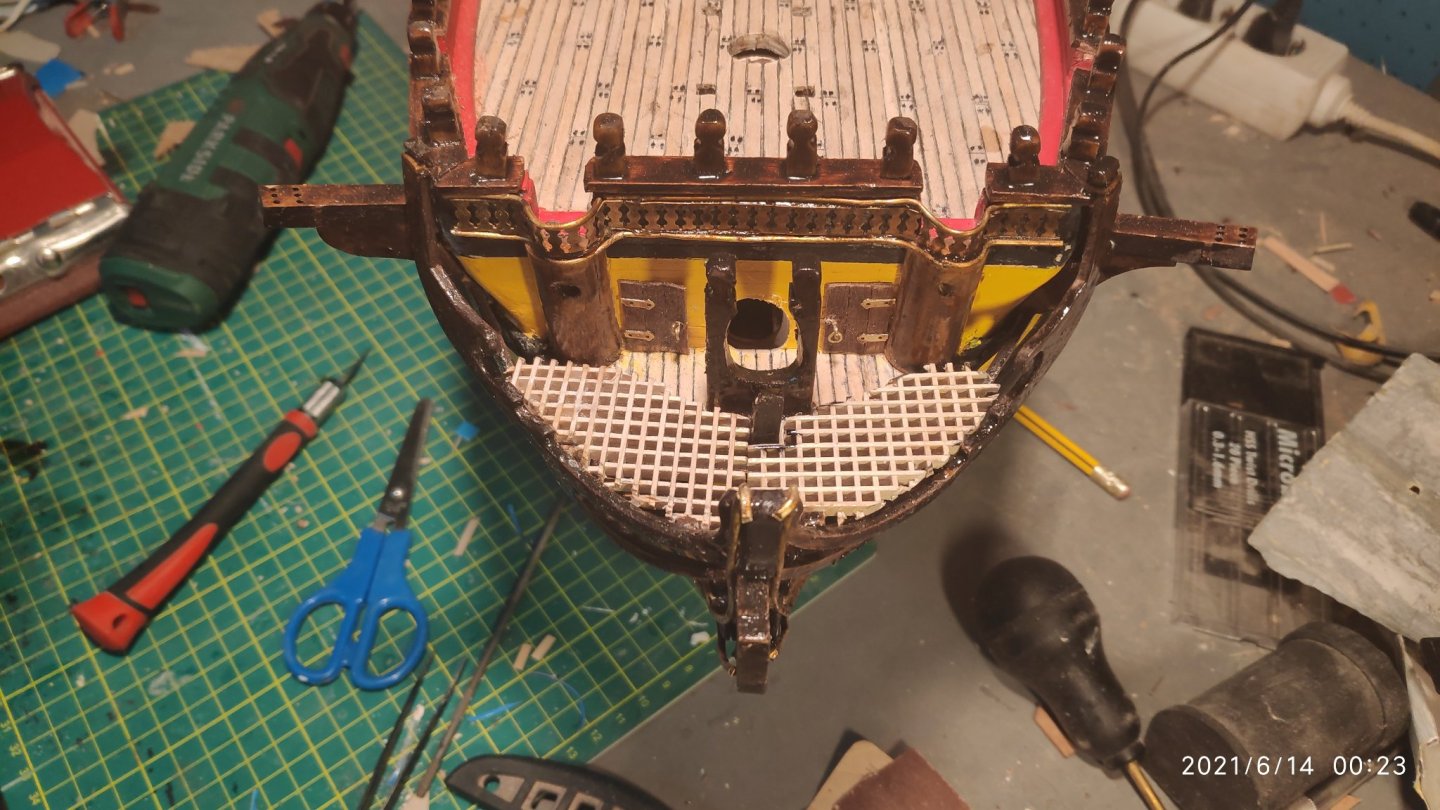

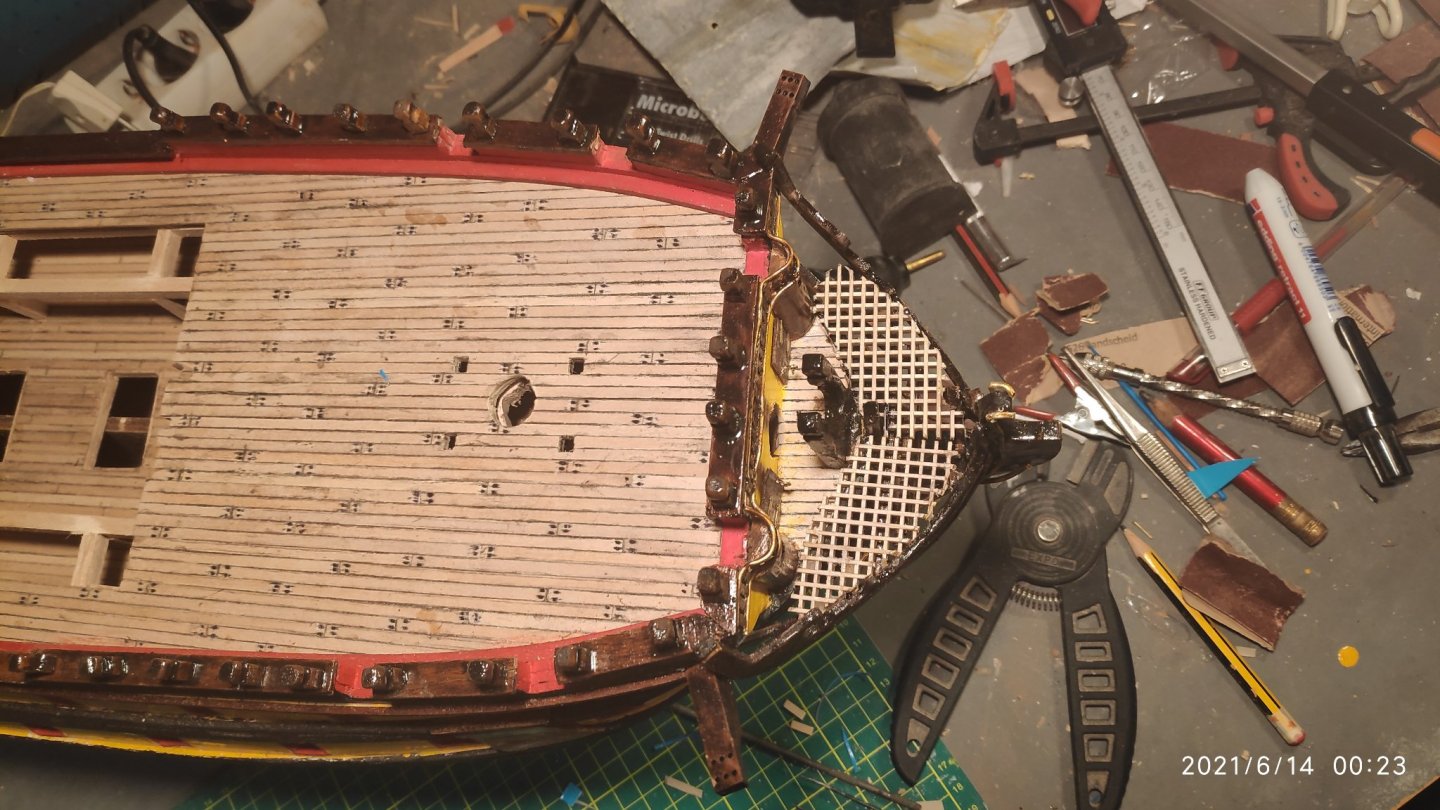

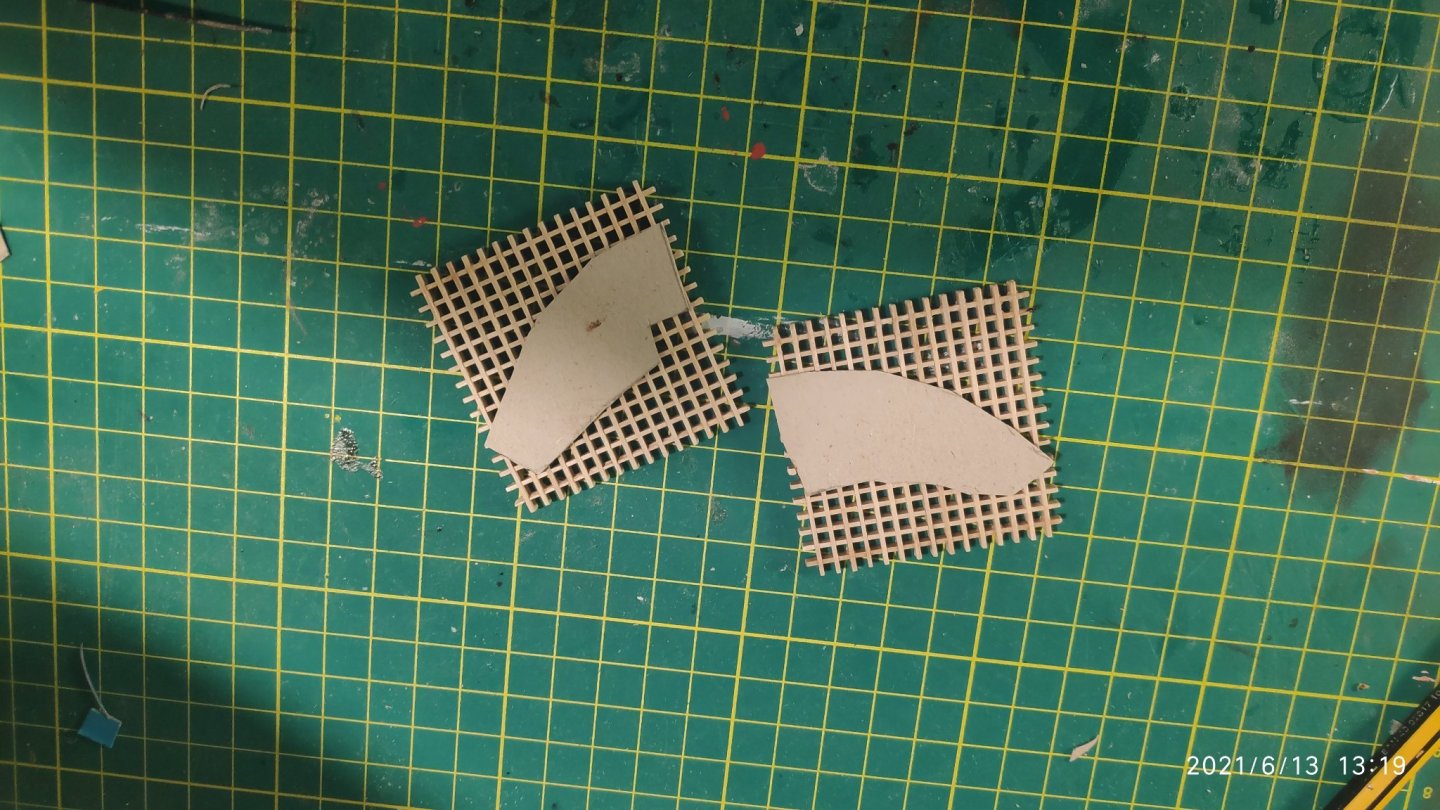

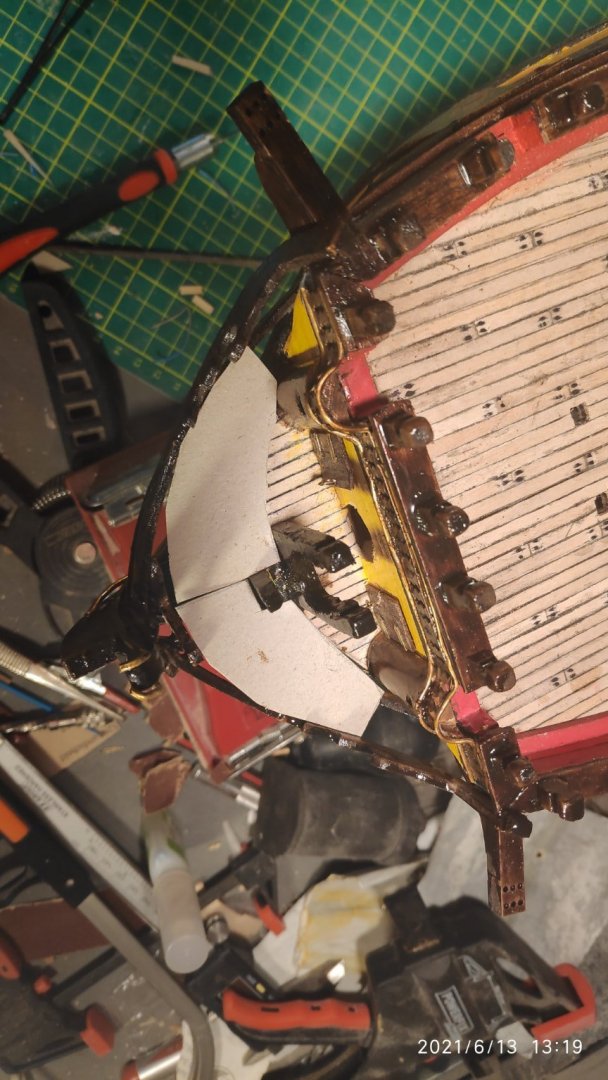

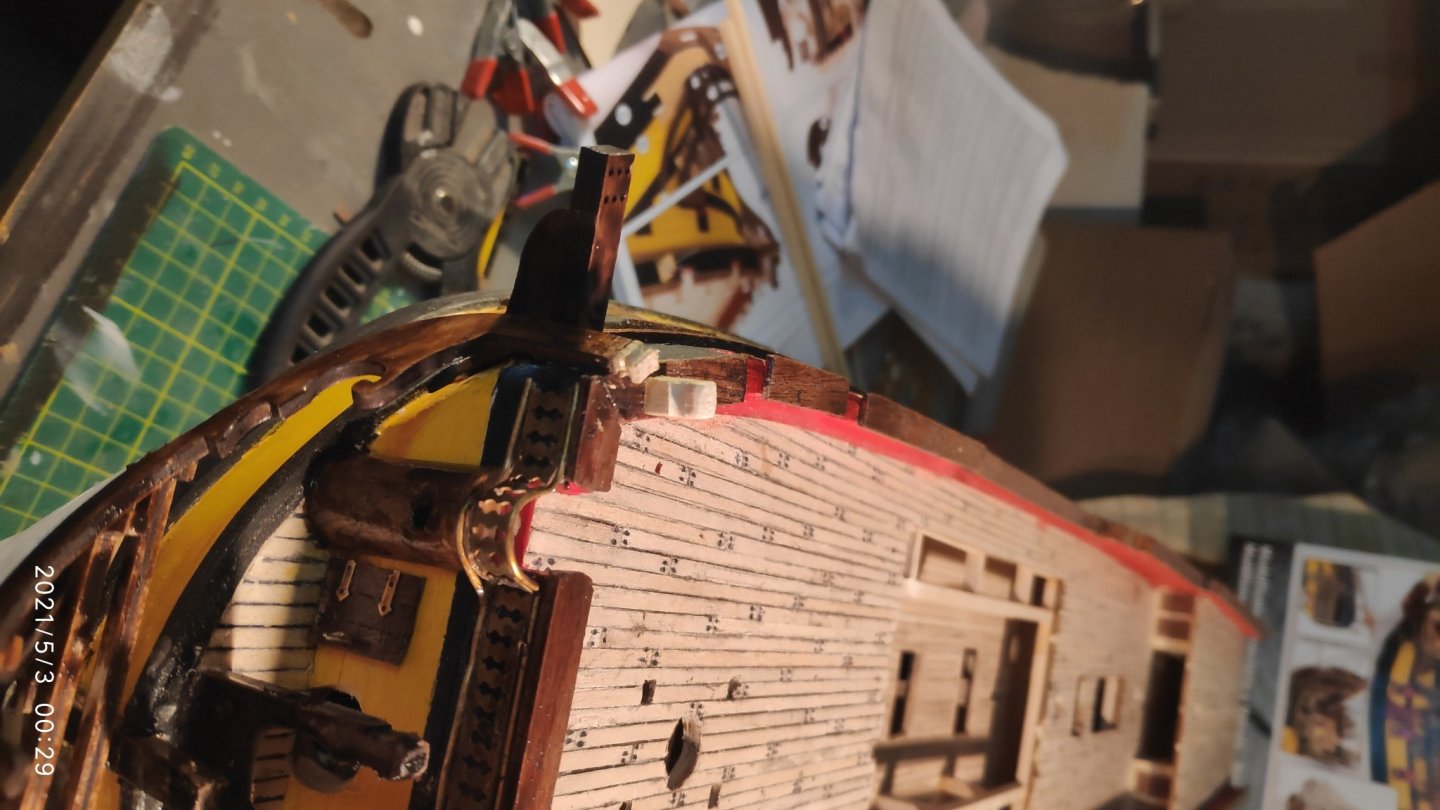

Now i make the stem rubbing strake brackets and the decoration using brass wire, make it a little flat using a hammer. Two holes 3mm also for the anchor ropes. Make up two gratings, 5X5 cm square shape. I must cut them,to adjust their shape,so can fit in place..i use a part of paper,as a guide,cut it an adjust it,so can fit properly. After i use it as a patron,to cut the gratings,and glue them in place...Be continued...

-

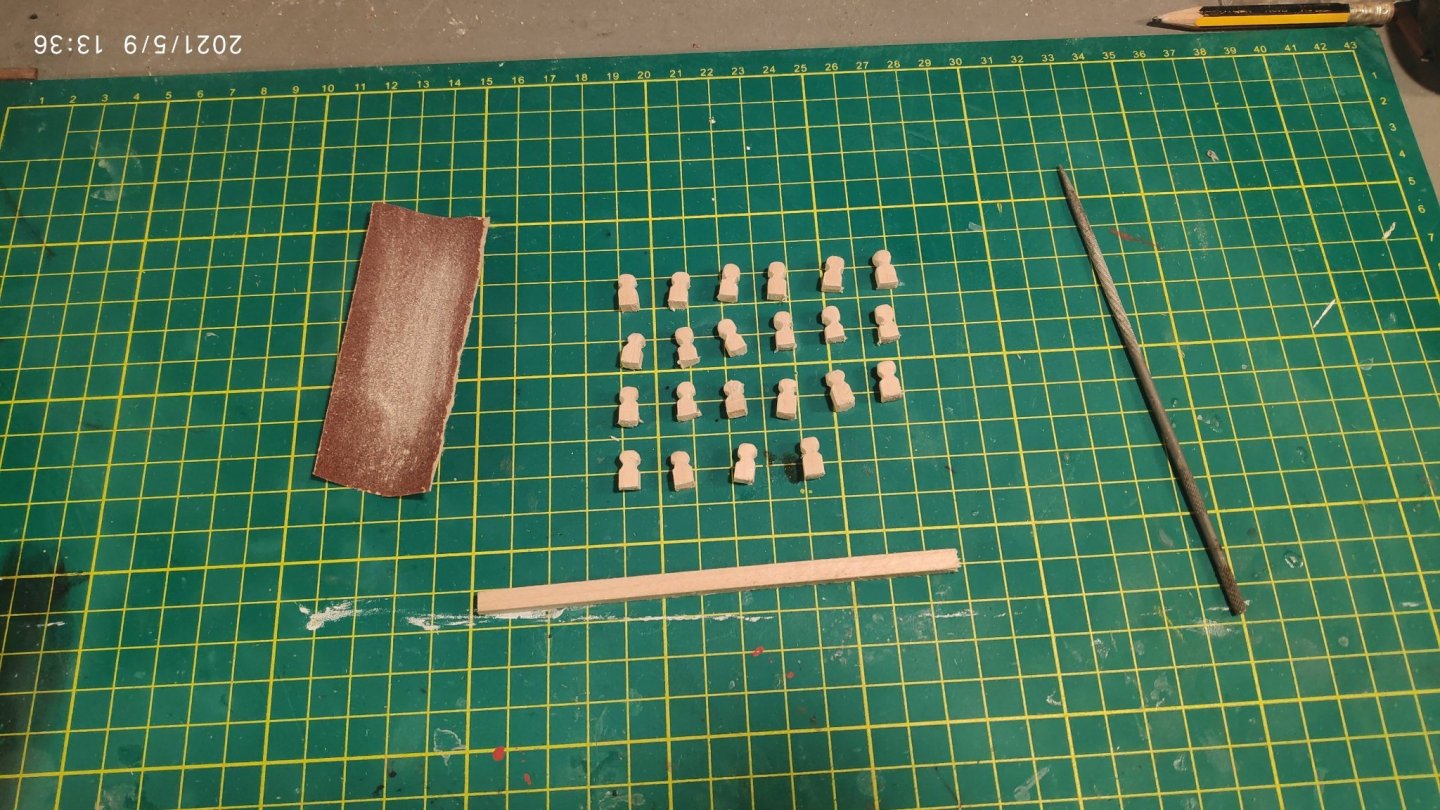

The decoration of the bow continued. The two pieces must glued making the right curve,as seen in photos,so a left them some hours in water to be more soft and not to be cracked,just like we made with hull planking, but this wood is more easier to bend. So in photos you see the painted parts in place. Also the two davids...i thing that are used to raise the small boat of the ship...are clued in place with the brackets to support them. Now i must make by hand...26 samson post to glue them in the front gallant raills of the ship 10 left and right and 6 in the front, made from a piece of wood 5X5X10mm and using a hand file,to make the neck,as you see in photos....now we have job to do.,.....and the decoration of the bow is continued with new pieces....

-

First the two heads glued just under the gun ports of the front frame. After glue the decoration (Brass) after i give the right shape. Above and unter a brass wire 1mm diameter is glued. I make the twoo doors,from 3 planks (1X4mm) i put the hinges and the doors handles (one eyebolt and one small ring..). The decoration of the bow continued...

-

Finish the gallant rails and varnish them dark brown. i put in place the rubbing strakes and paint the colors between them,as instructed. I made with a hand wood file a slot allong them. Difficult job in a 2X2 mm strake...For the curved strake,between upper and second strake,i use brass wire as instructed.Now the same to the other side of the ship...

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.