Steve20

NRG Member-

Posts

168 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Steve20

-

Matt/Glenn, I stand corrected: the bulkheads are not Chapter One. However, I plan to cut the stem, keel pieces etc. myself using some timber I've got (see sample pieces in pics, above). In response to a post I put in the Building, Framing, Planking section (thanks Chuck) I've received some excellent advice from Bob Creek and Jaager on how to do this. They've given me a lot of very useful information which I will need to read again to properly take it all in. https://modelshipworld.com/topic/30532-planking-edge-cut-or-face-cut/

-

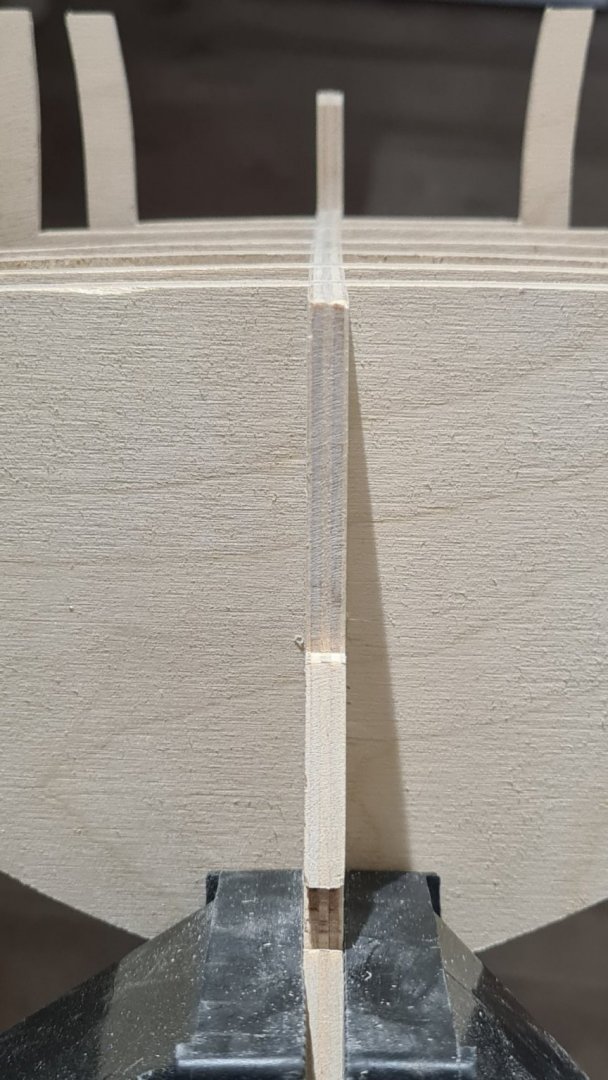

By making the bulkheads a tight fit with the stiffeners, Mike, they lock the false keel into a straight position and will prevent any future longitudinal distortion. Chuck certainly knew what he was doing when he split the false keel into three parts as I have more than one piece of Birch ply that's warping. I will also put stiffeners on the midships section. It doesn't take long to do. I cut the bulkhead slots on a bandsaw, sit several of these next to each other on a dummy piece of ply (same as you would sit them on the false keel), then put them in a vice and get a tight, uniform, fit by using a wood file. I should add that the pieces that sit together should all be from locations where the deck sheer is fairly similar. If fact what I do is to angle the dummy ply slightly to represent the sheer.

-

I'm about to cut some planks for the first time but I'm not sure how I should cut the timber. I've read posts on the subject but have come across conflicting opinions so I'd be very grateful if someone could help find clarity on this for my particular case. I've got Castello Boxwood (Brazilian Lemonwood), Pear and Sycamore - see a sample of each in the pic. From these should I saw the wood in such a way that I end up with the edge of the timber becoming the face of the cut planks (edge cut, I believe) or should they be from the face.

-

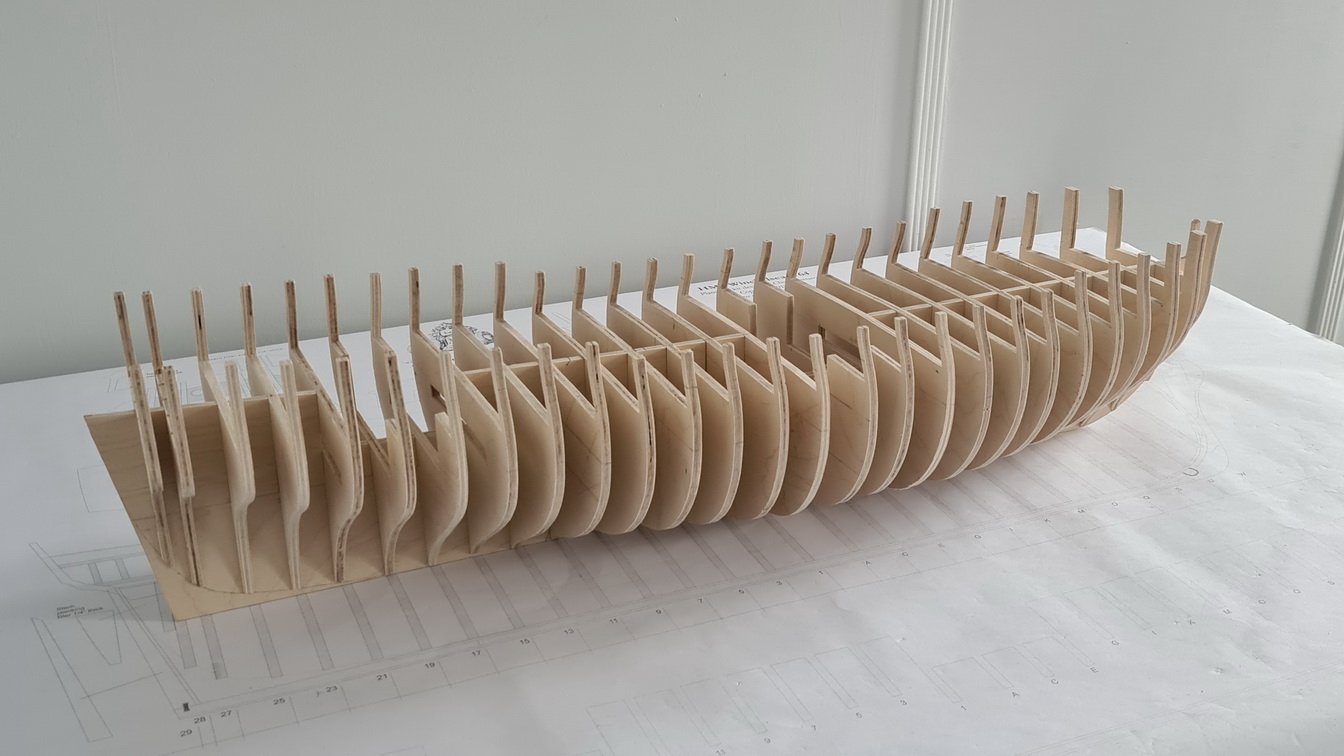

Thanks for the tips Chuck/Frank/Glenn, maybe I shouldn't have been so bothered about this. What I did initially was to cut in a couple of stiffeners and this did cure the problem then I decided to cut a new piece anyway. So what I have now is in the pic below. To be honest I'm happy with the stiffeners. They only took an hour or two to make and install, and they really firm up the bulkheads as well. Not being from the kit my bulkheads lack the same accuracy and it may be a while before I get to placement of the temporary battens and port sills.

-

In the mean time, I would really appreciate some advice on the following: I've got some Castello Boxwood (Brazilian Lemonwood), Pear and Sycamore, which I bought several years ago and can now finally put to use. I thought I would use the Pear for the Winchelsea hull and the Sycamore for the decks and possibly items to be painted. However, I'm not quite sure how I should cut the timber. I've read posts on the subject and from these it seems that I should saw the wood in such a way that I end up with the edge of the timber becoming the face of the cut planking. i.e as the Sycamore is 1 1/4" thick then I might just get four 1/4" wide planks from it, each of which I would then cut to 3/64" thickness. I have, though, come across a few conflicting opinions on this. So before I do the irreversible, I'd be very grateful if someone could confirm the above.

-

I bought the birch from a reputable model shop, Matt, so I assume it to be true Baltic. However, when I did the dry-fit I found some distortion on the forward bulkhead former which is out about 1.5mm over its length. I check for straightness before use, but this was the first piece I cut so I don’t know whether I missed it or if the the distortion developed later.

-

Years ago, I built the Unicorn and Endeavour kits, and my efforts were very amateurish to say the least. Anyway, I now have the time to build ship models again and whilst looking for another kit, I luckily came across this project. Although I’ve always wanted to do a scratch-build (I previously even bought raw timber for it), I know it to be well beyond my capability. However, thanks to Chuck putting together the Winchelsea build and sharing it, I can now make the attempt. For me this is as much about learning from the build process as the finished product, so although I was tempted to buy Chucks Chapter One kit, I bought some sheets of ¼” Birch Ply instead. I’ve also been buying the necessary tools and at present I’ve nearly finished the bulkheads.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.