-

Posts

201 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by François de Saint Nazaire

-

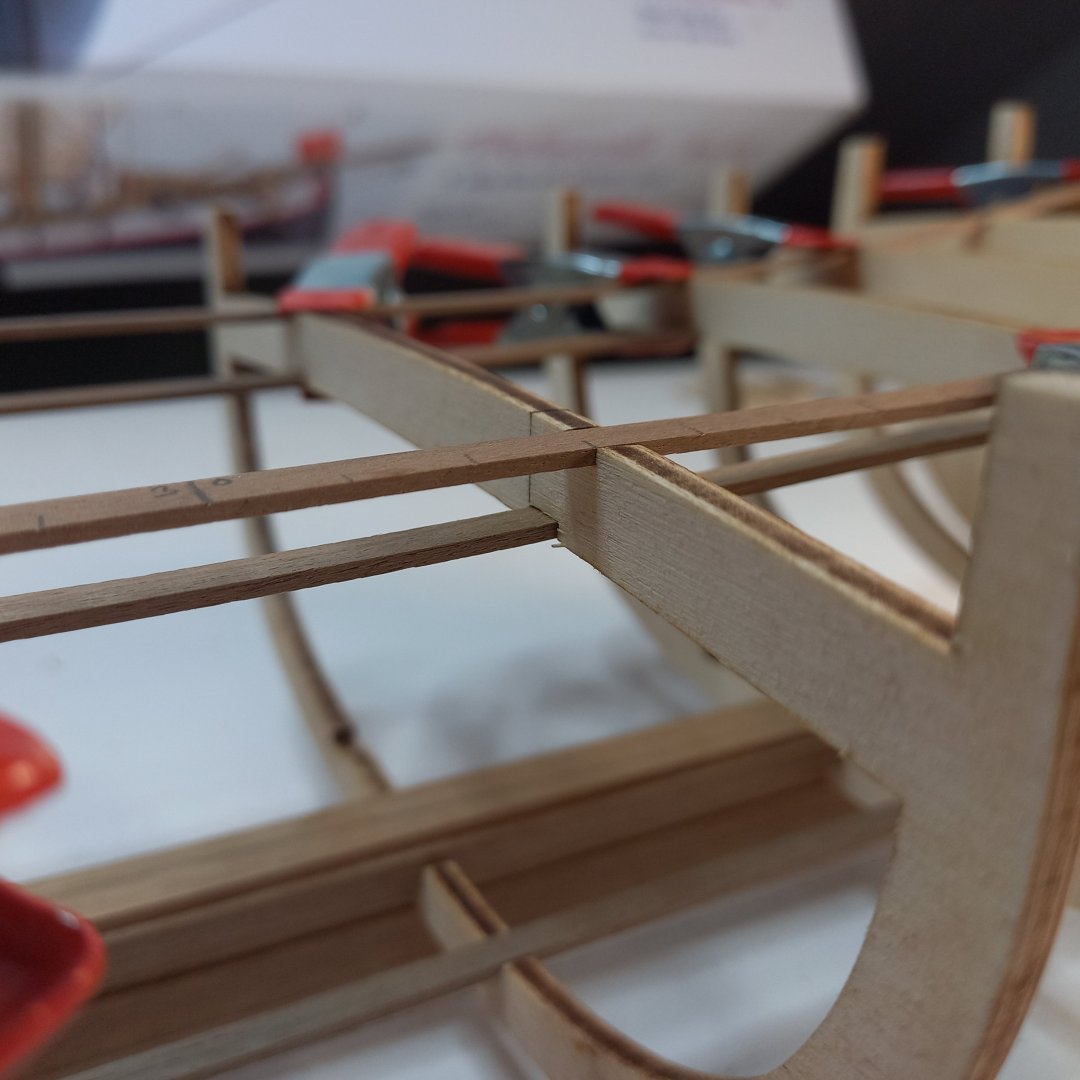

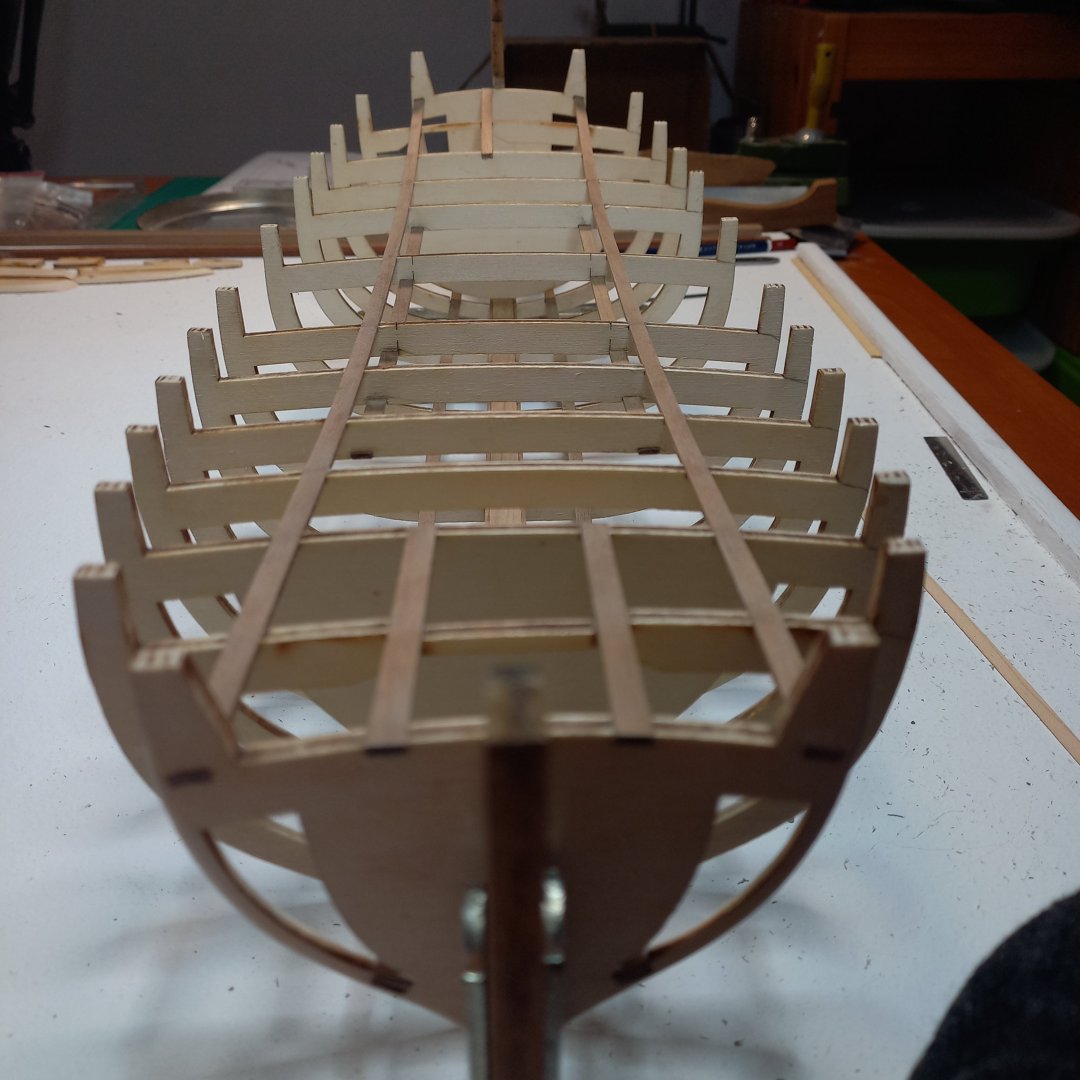

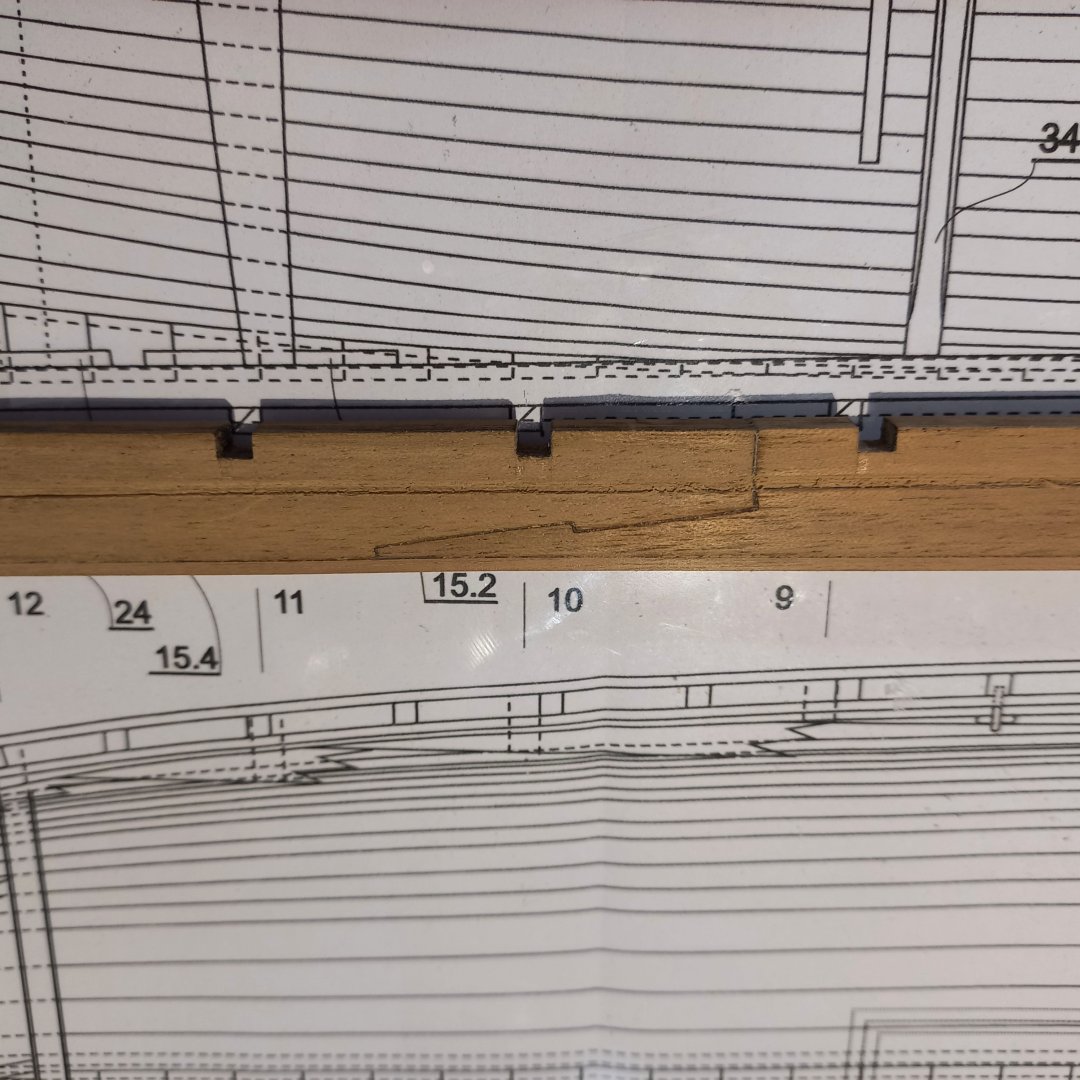

Hello, I've started the planking process. The first two planking strips below the main deck are 4 mm wide, and the next four below them are 5 mm wide along their entire length. I'm installing one strip per day ! All planking strips are made from 1.5 mm x 5 mm strips. After the first six strips, the remaining strips will require tapering and shaping. @+

-

- 139 replies

-

- ancre

- Bateau de Lanveoc

-

(and 2 more)

Tagged with:

-

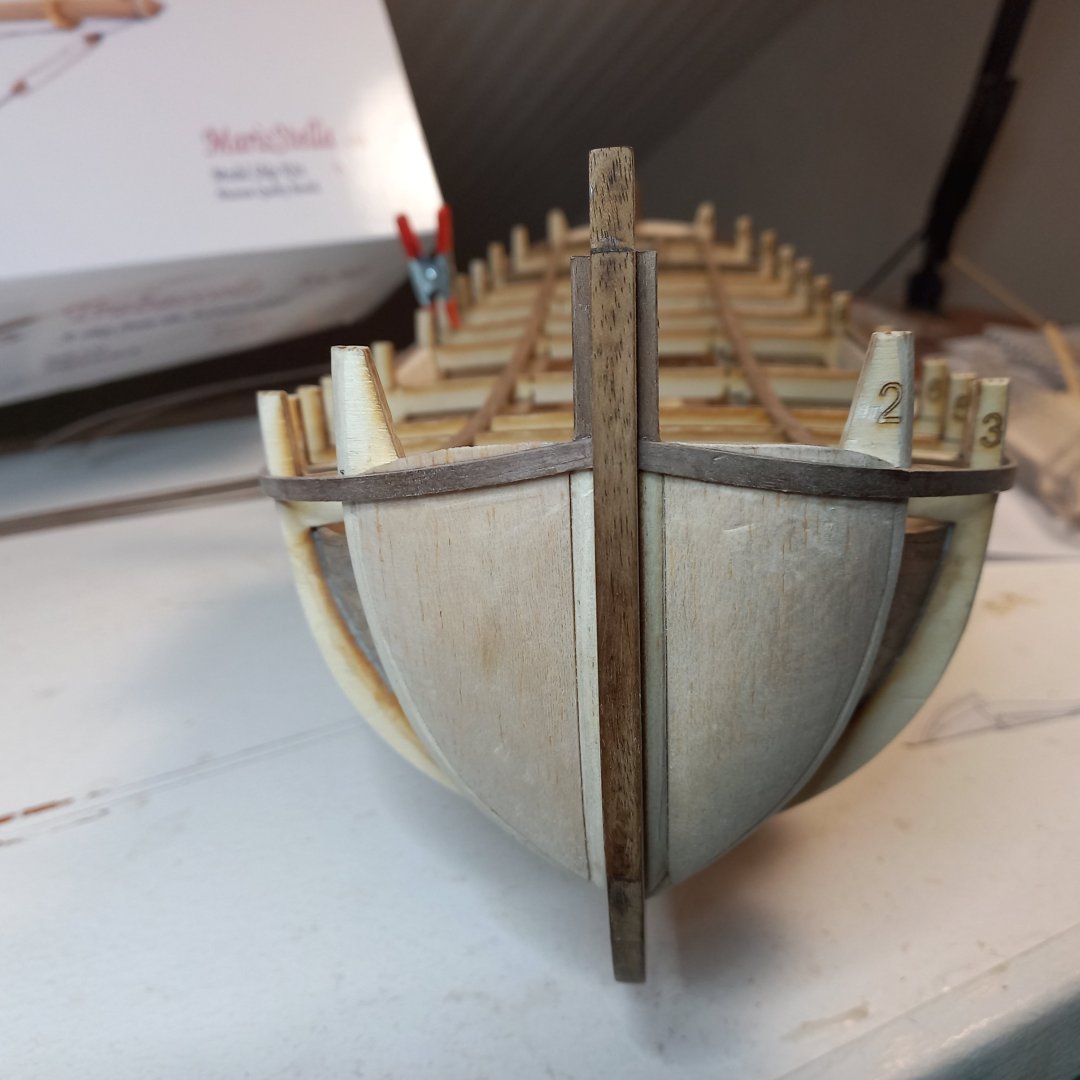

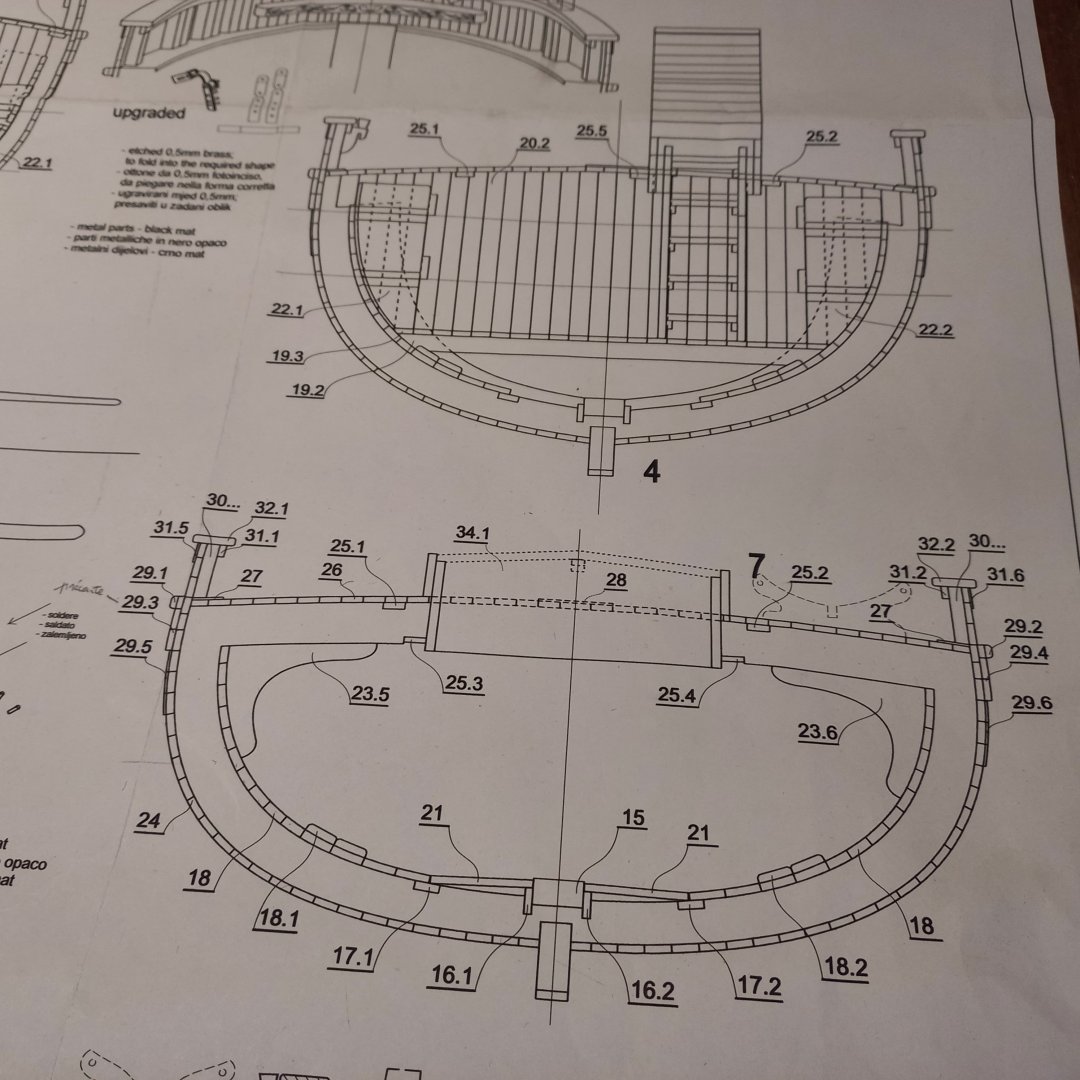

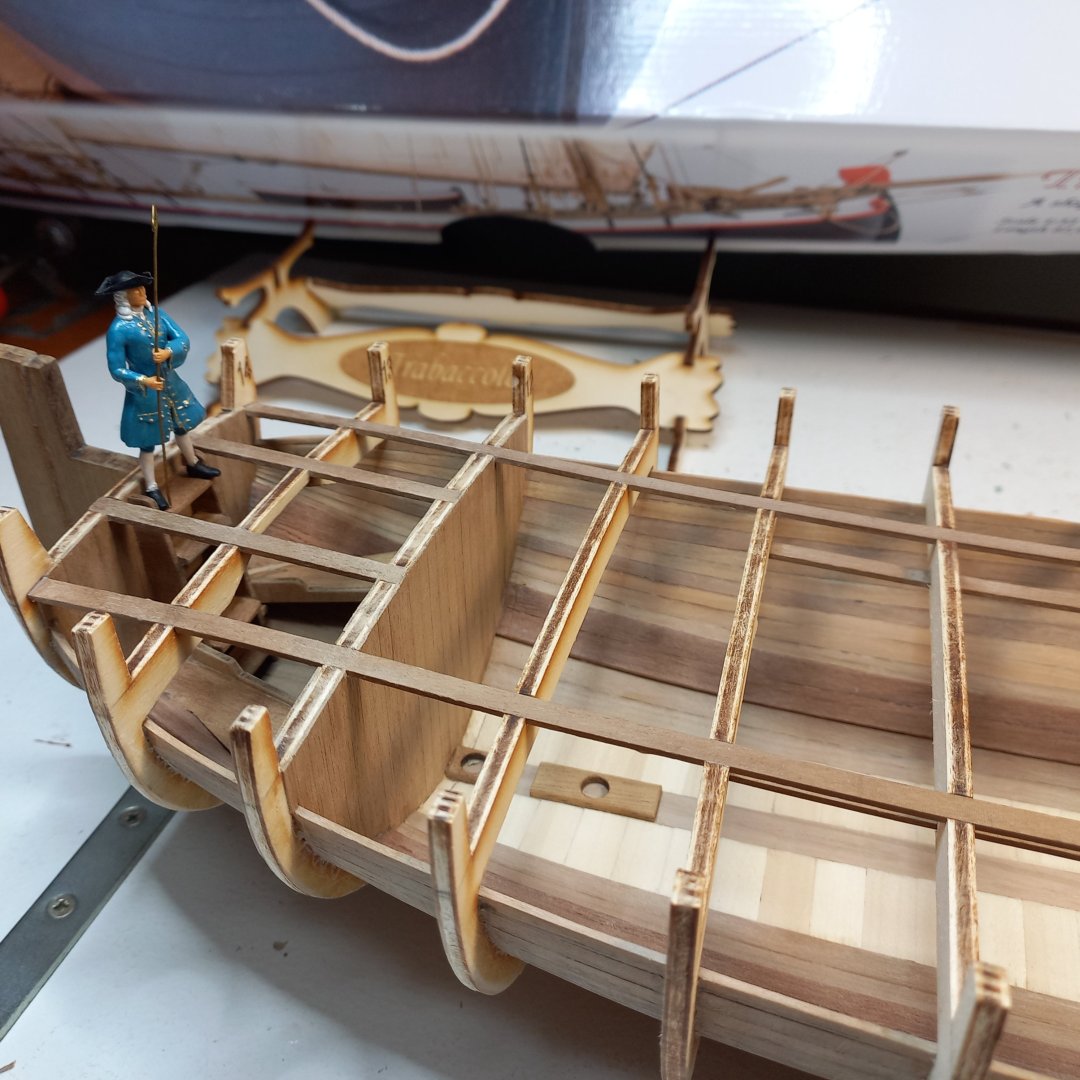

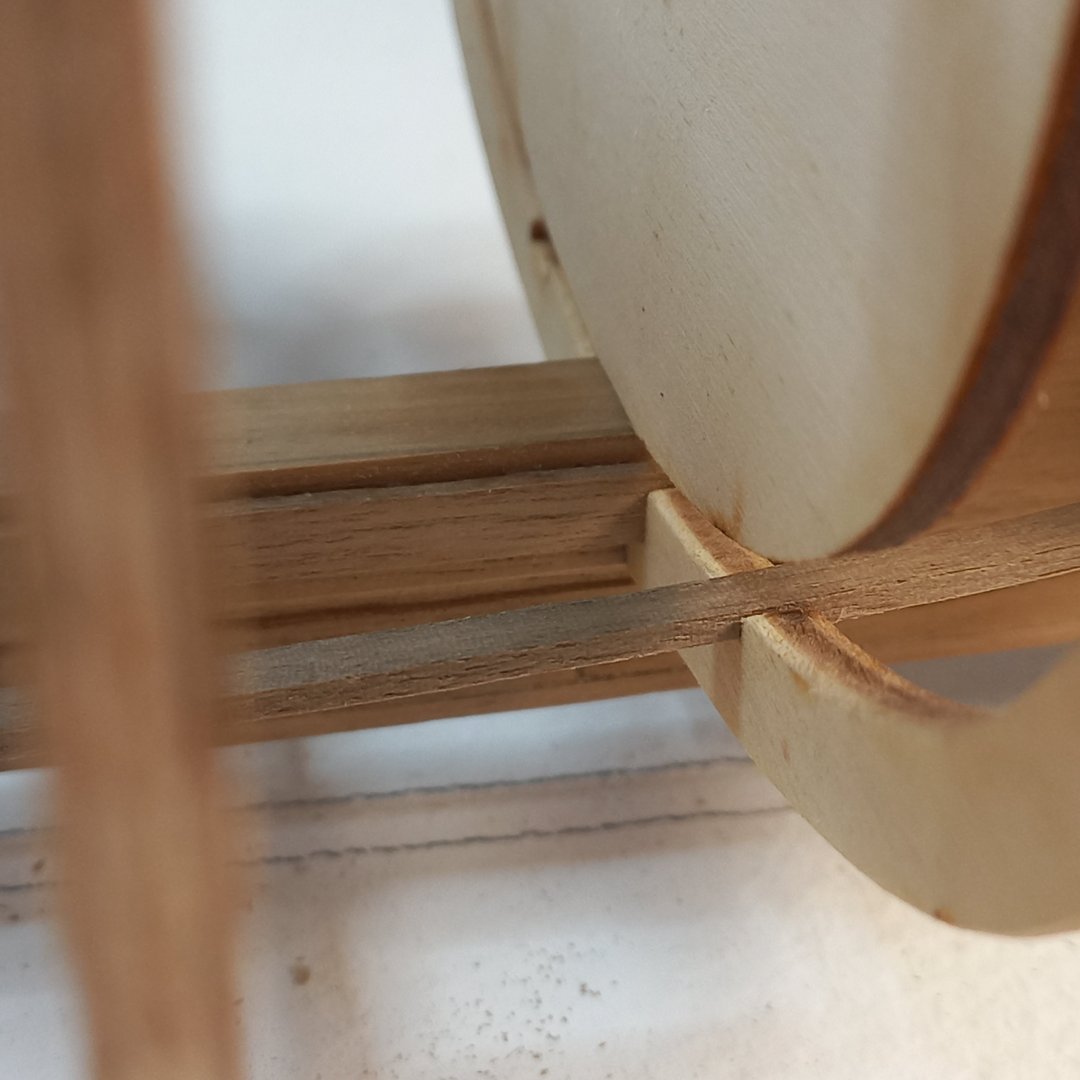

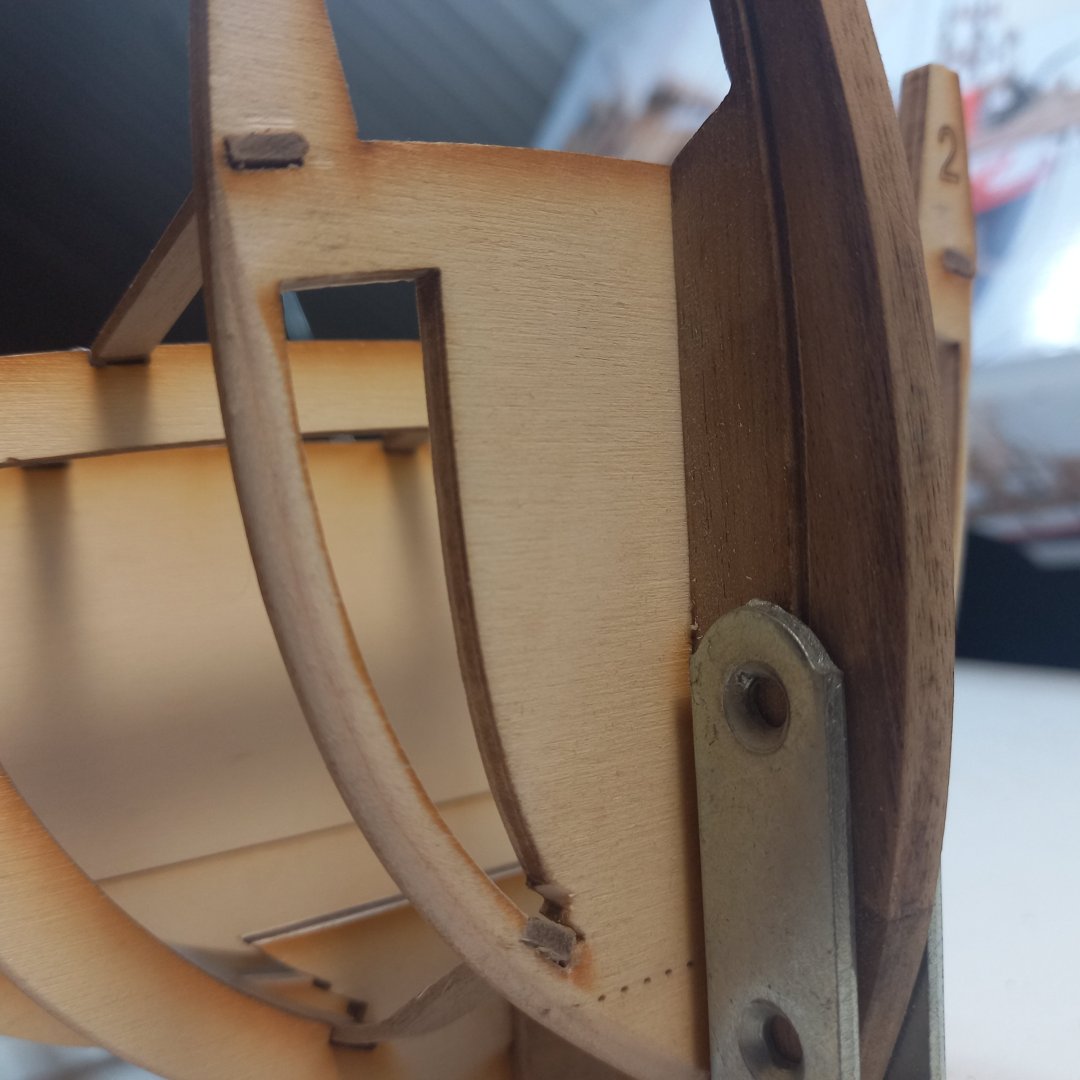

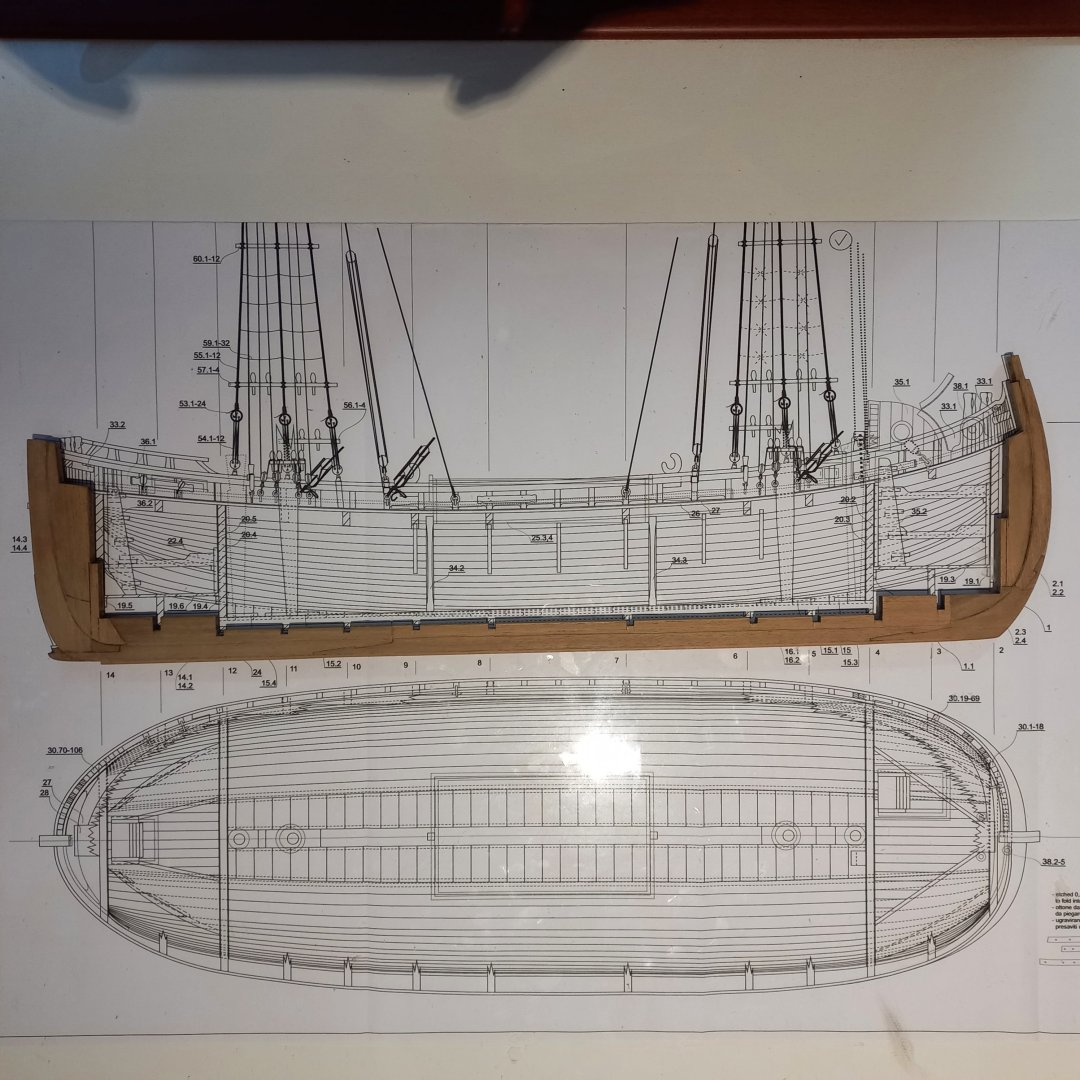

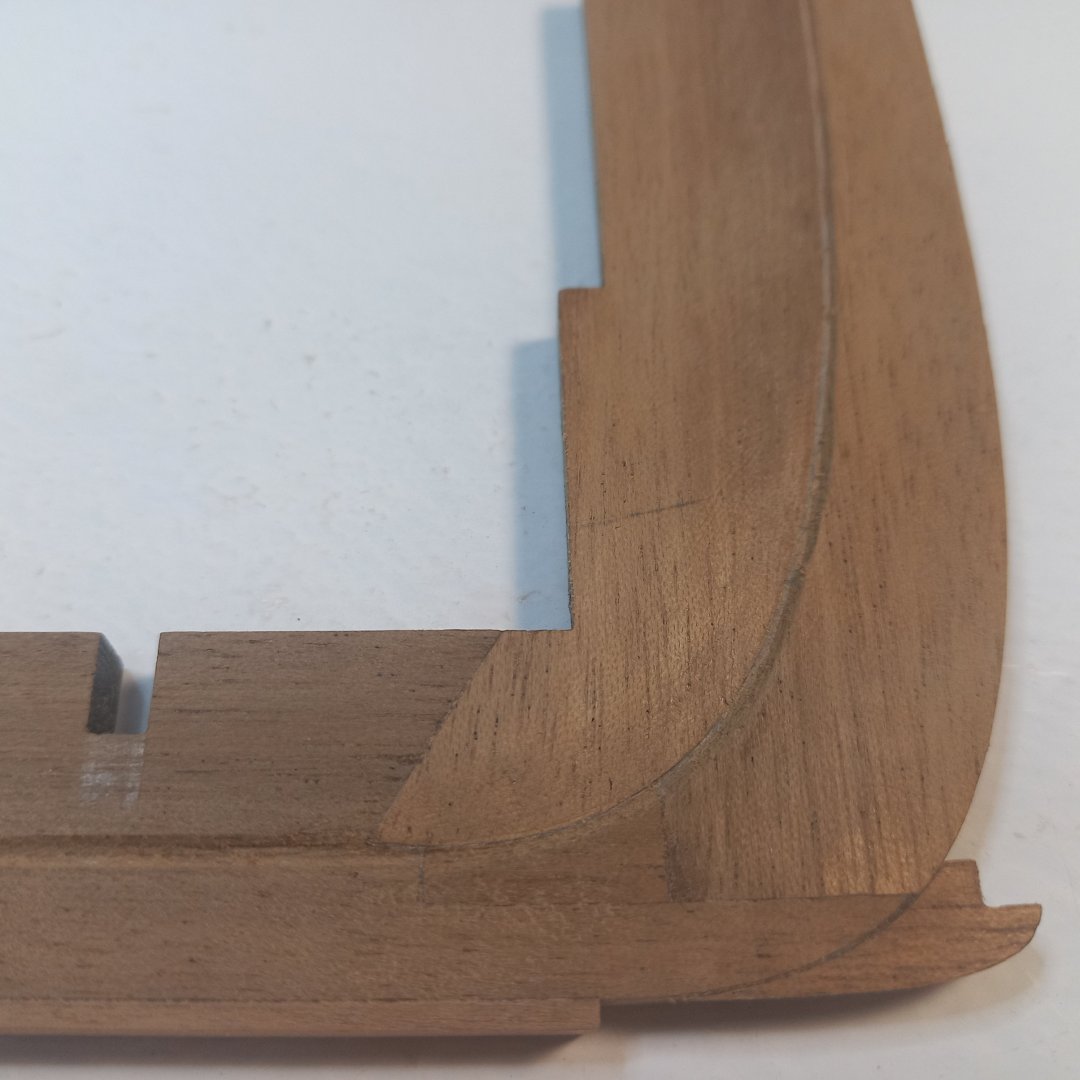

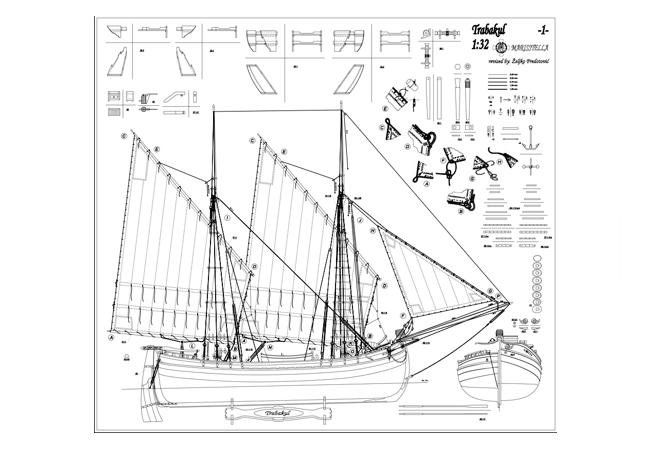

I finish the interior of the model. We now prepare the model for planking the hull. Begin by sanding and beveling the edge surfaces of the bulkheads at both the bow and stern. This will allow the planking strips to fit correctly. For the bow, bevel the bulkheads while preserving the integrity of their rear (aft) surfaces. Bulkhead 2 requires the most significant bevel. Additionally, bevel the outer side edges of components 2.1, 2.2, 2.3, and 2.4, and then affix them in their designated positions. For the stern, bevel the bulkheads, ensuring the front (forward) surfaces remain untouched. Bulkhead 14 requires the most extensive beveling. Similarly, bevel the outer side edges of components 14.1, 14.2, 14.3, and 14.4, and then secure them in their respective locations. For the next step, I will fill the spaces between the bulkheads, particularly the bow and stern, with balsa supplied by MarisStella in the box.

-

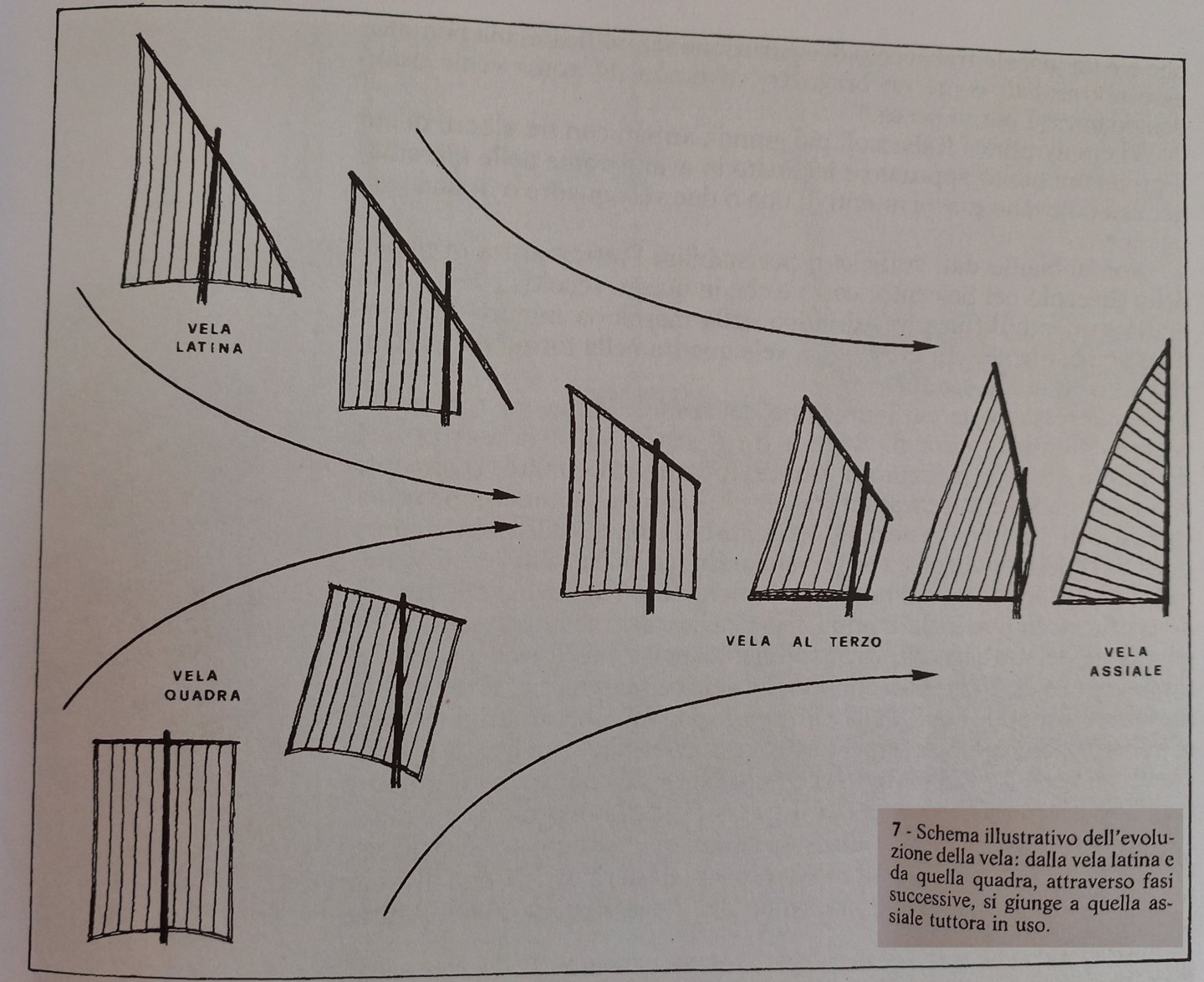

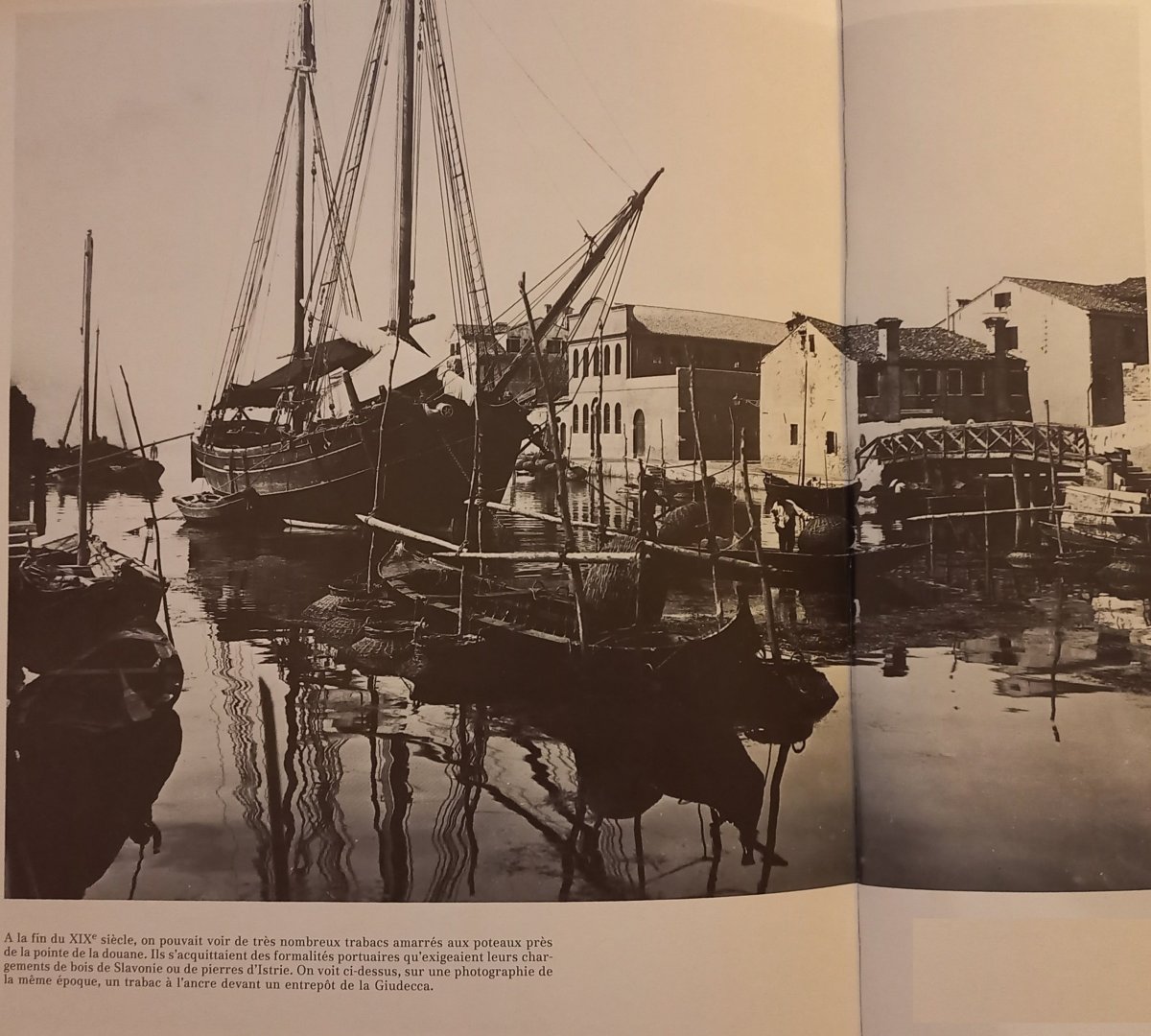

Thank you Jacques, I've learned many things. I'm sure you will find the answers. The picture comes from Mario Marzari's book (Trabaccoli)

- 139 replies

-

- ancre

- Bateau de Lanveoc

-

(and 2 more)

Tagged with:

-

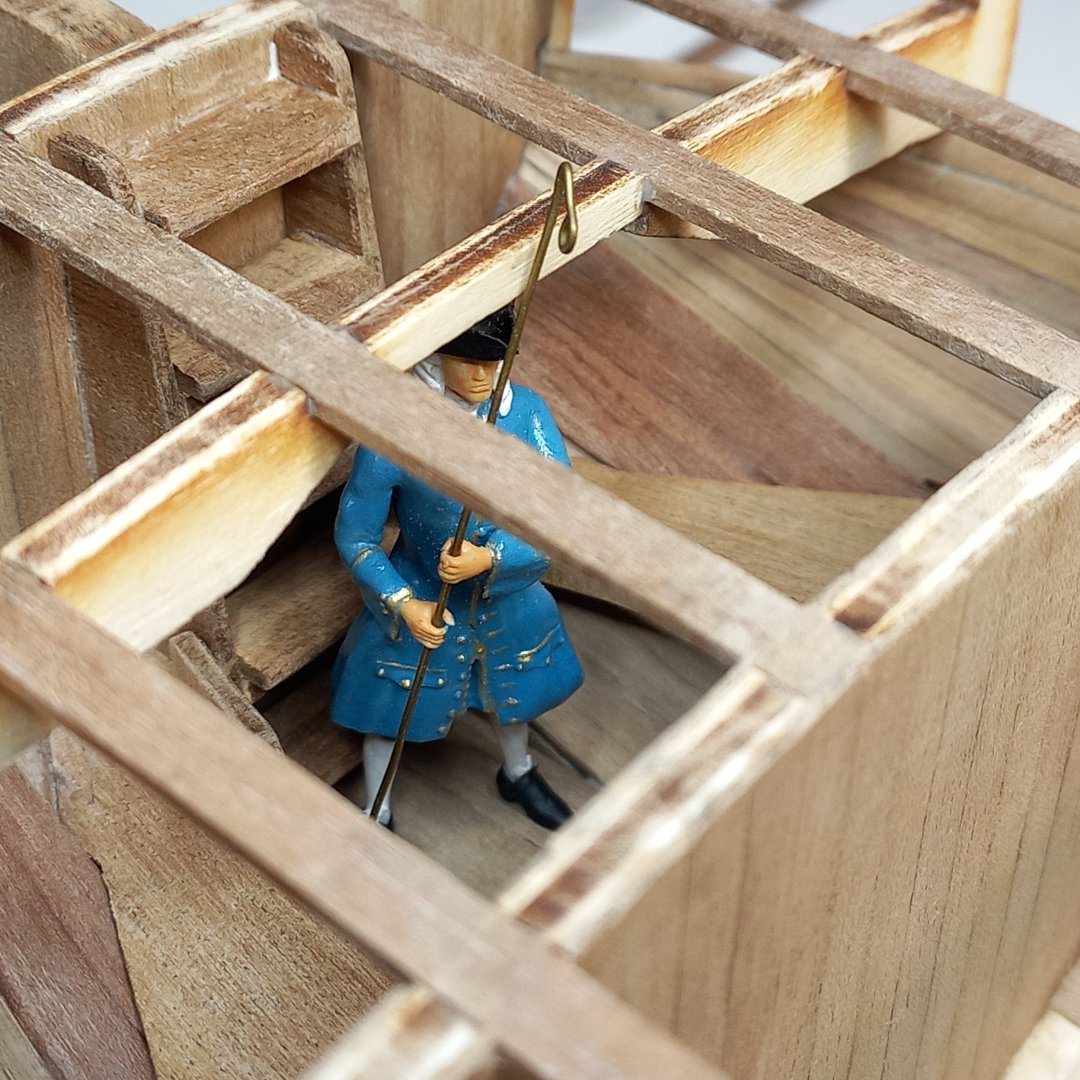

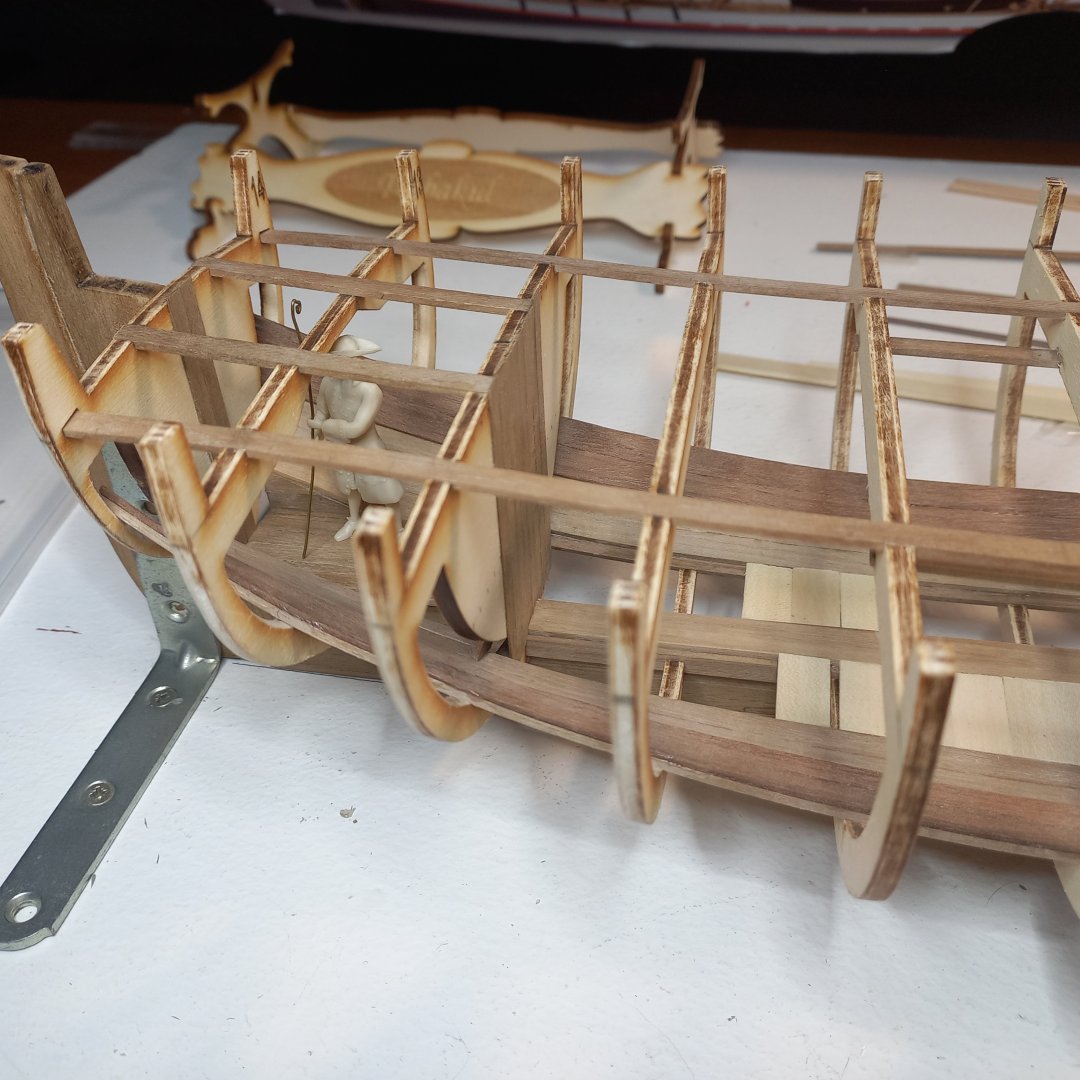

Hello, For the trabaccolo, the crew consisted of a captain (pàron), often a co-owner and three to seven sailors depending on the size of the trabaccolo. The master could also be a co-owner of several units. This was the case with seafaring families. Members of the same family served on different boats belonging to several members of that family. This way, the risks were also spread out. The trabaccolo could be commanded by a sailor who had embarked as early as their twelfth year. The "master" was not only responsible for the boat but also for the crew and supplies. The proceeds from cabotage were distributed among all the crew members after paying all the expenses. It sometimes happened that the master's wife accompanied him on board. This could pose some problems. The sailors lodged in the bow above the hawsers and the master in the stern in a spacious cabin. The crew cabin for four sailors is finished. I've started fitting the pillars and the supporting knees, also known as hanging knees.

-

Hello Jacques, I will follow your project with interest. Lanveoc is a small town near Brest in French Brittany. Bon courage Tonnerre de Brest ! as captain Haddock said

- 139 replies

-

- ancre

- Bateau de Lanveoc

-

(and 2 more)

Tagged with:

-

Bonjour, I've just finished installing the beds in the aft cabin. The ladder is in place, although it is not positioned as close to the wall as indicated in the plan. I hope this will not cause any problems later. The horizontal bed boards need to be sanded to fit properly in the cabin. I had also a small piece of wood to fill a hole close the ladder. The 'paron' should be approximately 160cm tall, which is 5.0cm at the given scale. I got it from the Ancre edition, and it looks like the naval architecture in Boudriot's books.😉 The next step will be the forward beds. 😅

-

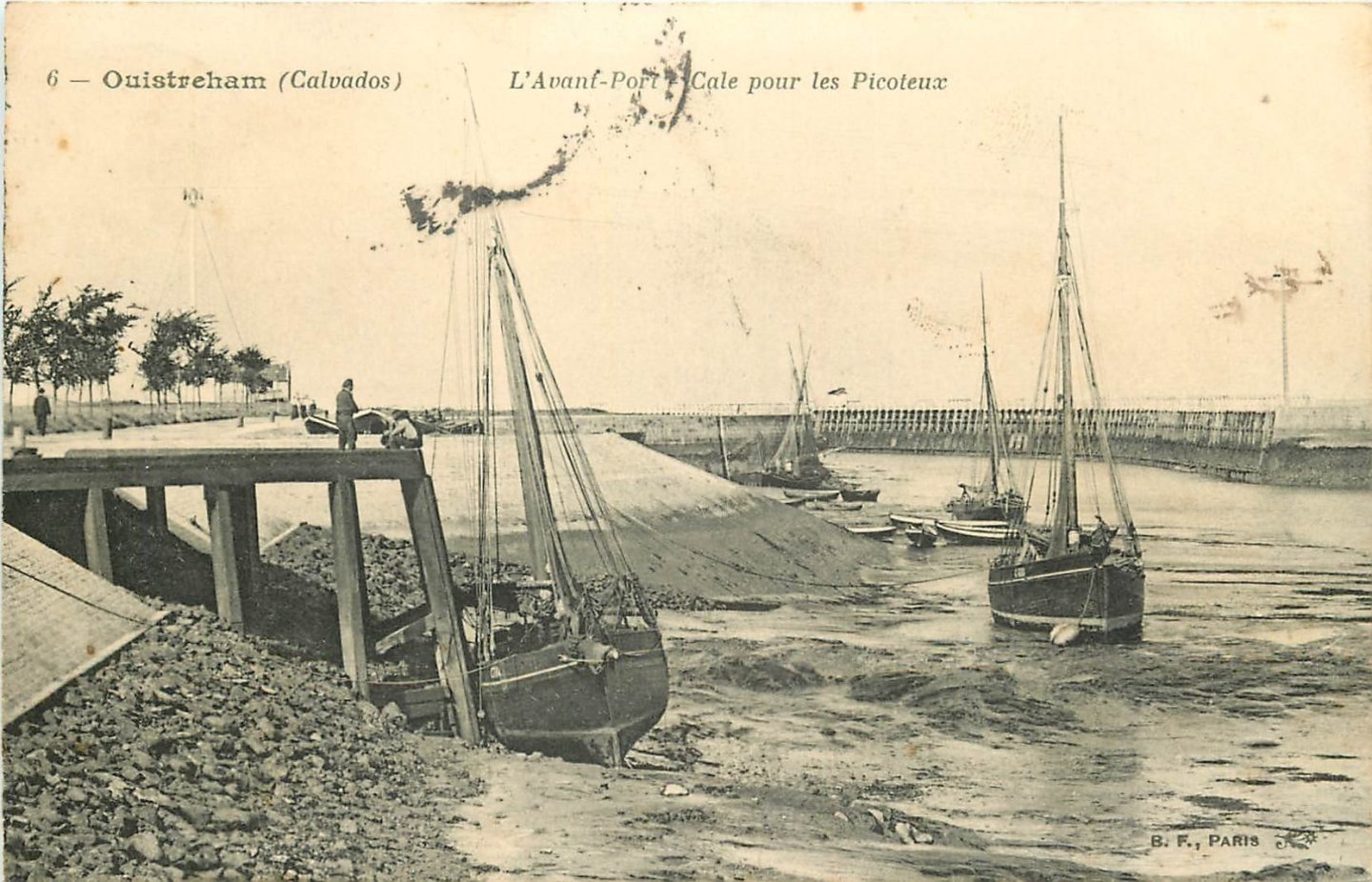

Information about the ship 'Picoteux' that changed throughout its history. Les Labrèques, Trois générations de charpentiers-ébénistes

- 9 replies

-

- Esperance

- Billing Boats

-

(and 1 more)

Tagged with:

-

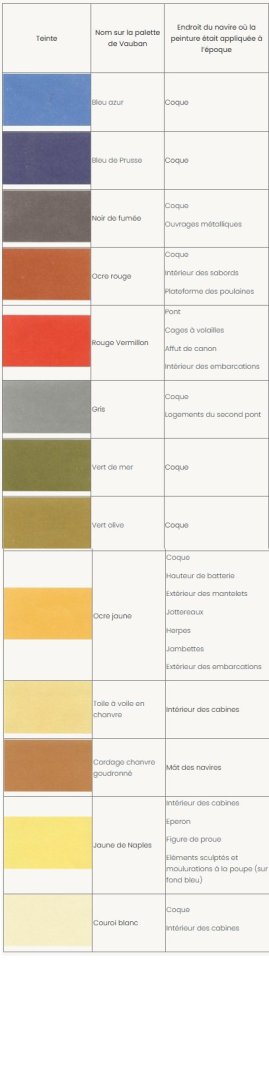

hello Here's some information from France to help you reflect. In the 17th century, Louis XIV's goal was to master the seas and become the world's leading naval power. To succeed in this ambitious undertaking, he implemented measures commensurate with his ambitions: he increased the budget allocated to the navy tenfold, equipped seaports, multiplied naval bases, created specific training programs for naval officers, and so on. To further emphasize his power and dominance, he chose to visually standardize his maritime fleet by implementing a very specific set of specifications: all ships had to be identical. In other words, each element of any ship (hull, deck, cabin, cannon, boat, masts, etc.) had to correspond to a specific shade. It is this palette of colors, used in the Royal Navy between 1650 and 1850, that is known as the "13 colors of Vauban." Each of the colors present was selected by Vauban, the Sun King's architect" Thanks to the research of the renowned architect Jean Boudriot, we know a little more about this fascinating period. It is in his book "La Compagnie des Indes" that this naval architecture enthusiast sheds light on these 13 Vauban colors used in the French military navy. frigate Hermione : In his book, Jean Boudriot reveals that the quotes of the time mentioned the use of 57 pots of white, 51 pots of black, 110 pots of red, 42 pots of yellow, 21 pots of blue and 24 pots of glue white to paint a single ship. The dominance of the color red is reminiscent of the bloody battles that took place on these ships, thus visually attenuating the recurring blood stains. Vauban's 13 colors, and the place each occupied on the ships, can be seen at the Musée de la Marine in Paris, through very realistic models. It is also an opportunity to admire the diversity of hues used at the time. "Jean Boudriot, la couleur dans la Marine classique 1650 - 1850, Collection Archéologie Navale"

-

In France we use Wood filler ( call Fondur) it is an impregnation that penetrates the pores of the wood and follows its dilatory movements. Therefore, it does not crack. The final appearance is a soft satin. Depending on your needs or preferences, you can leave it as is or cover it with a wax or shellac finish

-

Hello Alistair, I hope you feel better soon. I've just finished the ceiling. I'll finish planking the bulkhead and then start on the beds. I'm taking my time. I adjusted the stern floor, but it wasn't necessary and made things more complicated. just for fun 😉 I'm sure that the bed will be a big challenge Overall, I'm extremely happy with this kit and its construction. If I encounter something I don't understand, a quick email to Zoran (MarisStella) clarifies things for me. MarisStella's customer support is simply incredible.

-

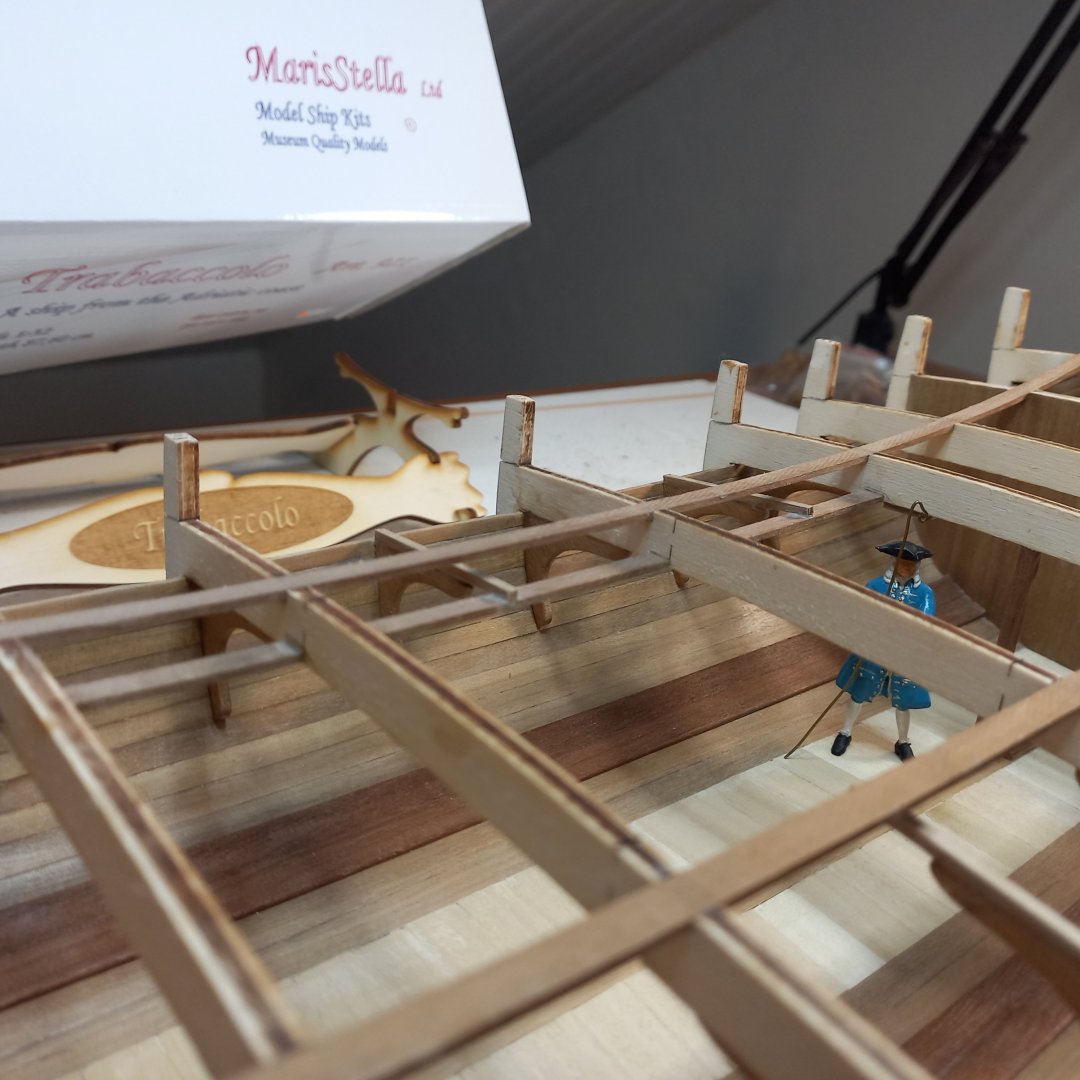

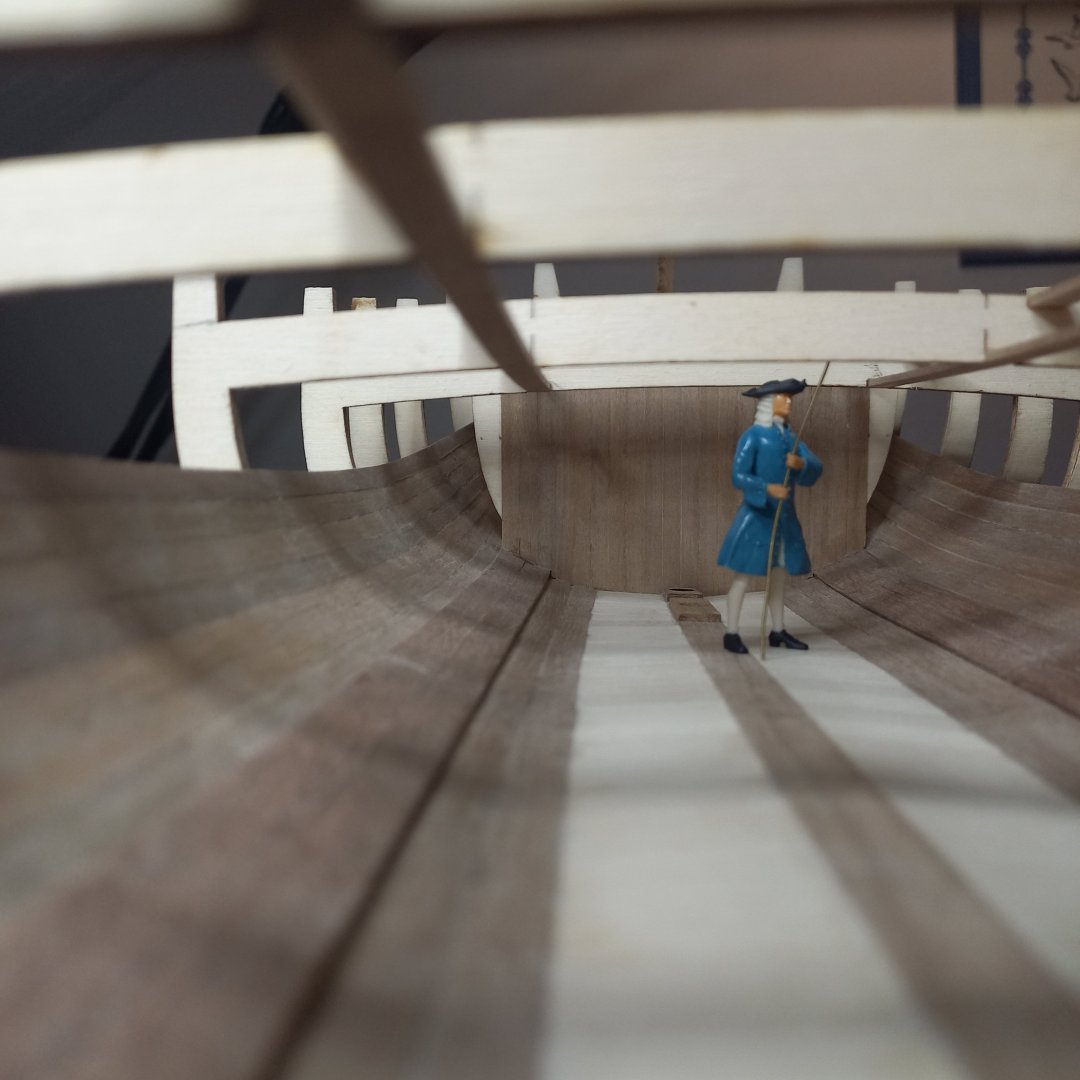

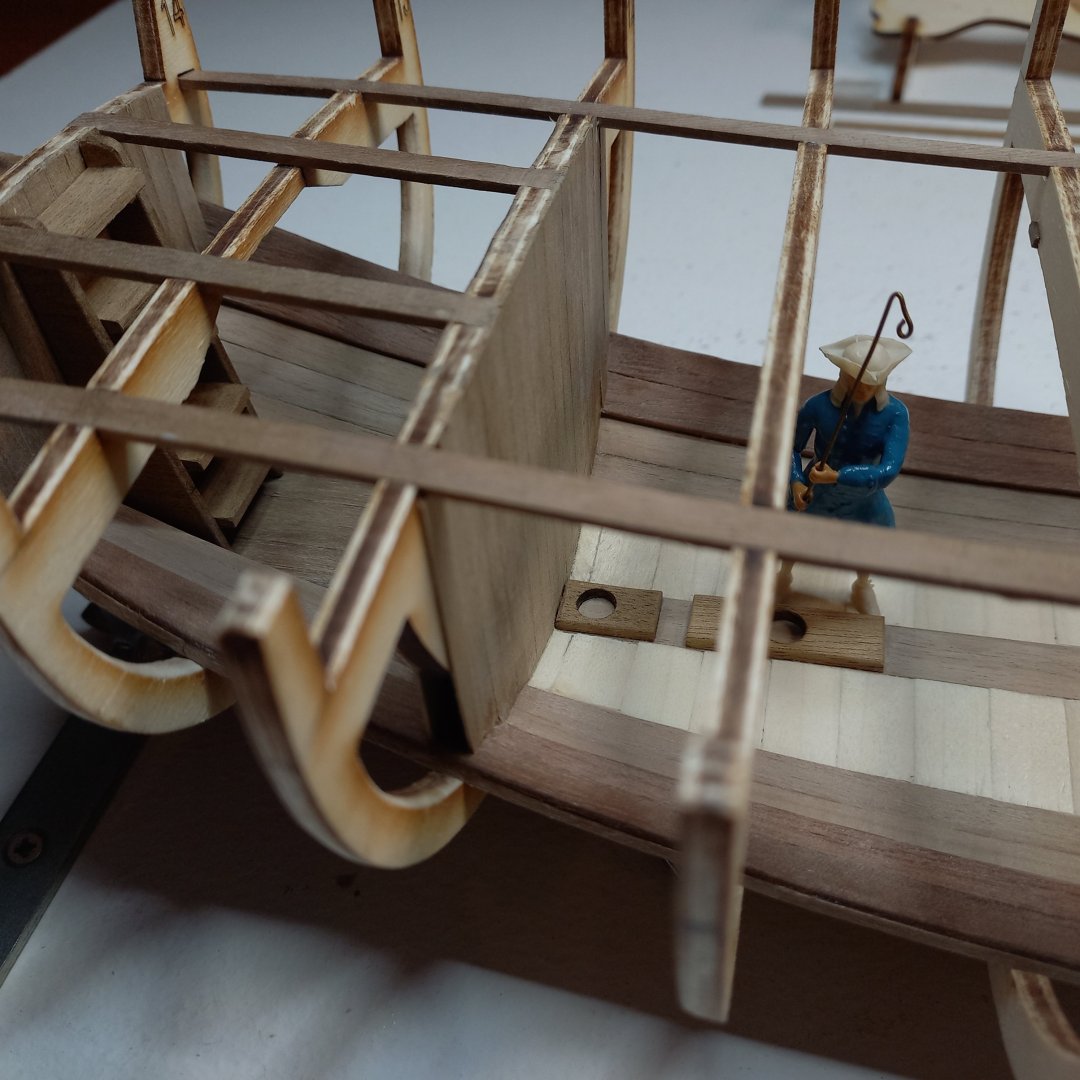

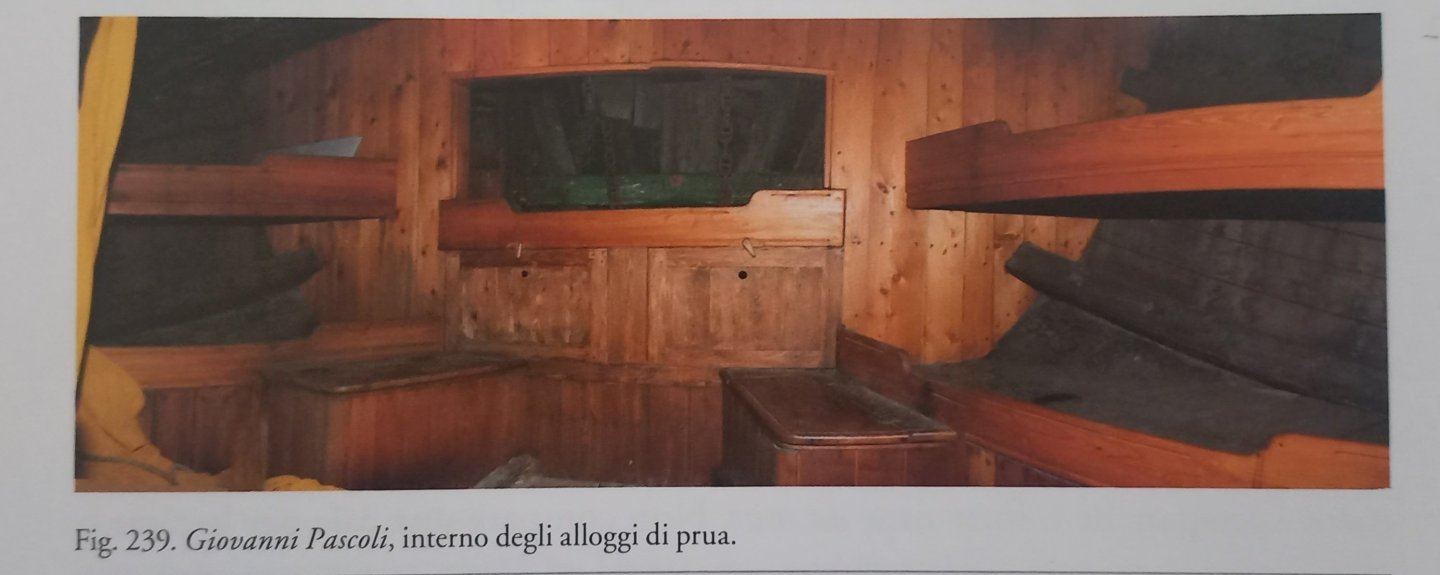

I propose some photos of the progress. The sailor is starting to take on brilliant colors! This sailor is from the 18th century, and this is not absurd, even if his clothe suggests that he is more of a shipowner than a simple sailor. Mario Marzari informs us that the first reference to a Trabaccolo found so far dates back to 1667 and is attributed to Francesco Maria Appendini, even if it might be an interpretation of documents made by the author himself. The first actual documents that refer to this type of boat, found in Rimini by the historian Maria Lucia De Nicold, date from 1683. In Venice, on the other hand, Levi mentions the presence, in 1711, of a trabaccolo and a trabaccoletto inside the Arsenal itself. The oldest reference to the trabaccolo found in Trieste dates back to 1721, while Kandler specifies that no less than three armed trabaccoli were part of the new Austro-Triestine fleet in 1733. In 1735, this same Navy purchased several trabaccoli to arm them with cannons and swivel guns. [...] According to the old documents consulted, it therefore appears that it is only from the 18th century onwards that reference is made to a real ship called trabaccolo. It remains that the kit version is closer to the architectures of the 19th century. The vaigrage (fasciame interno) is finished up to the stringers. The mast steps of the main mast and the foremast are in place on the keelson. The mast steps of the two mooring bitts (bitta di ormeggio) are also positioned next to their respective mast. The captain's cabin is well advanced. I will have to refine the steps of the staircase; there are also the beds to install. Gilberto Penzo gives us some information on the accommodations. "The accommodations were spartan, but almost luxurious compared to those of fishing boats, due to their height and the presence of real berths. In the drawing of the Souvenirs by François Edmond Paris, in the forecastle accommodation, we can distinguish a bunk with a profiled edge, towards the bow a raised shelf that could be the third bunk and two chests or perhaps tide boxes (casse da mar). There is no hold for ropes or anchor chains. The stern one, where one could only stand between the beams, measured 240 cm long, separated from the hold with removable floorboards (palgioli) and from the stern by thin partitions (parapetti). On the wall, we see a square opening that could be the access to the bunk. The spartan furnishing is completed by a simple chest and a shelf towards the stern that could also serve as a bed. Fig. 239. Giovanni Pascoli, interior of the forecastle accommodations.

-

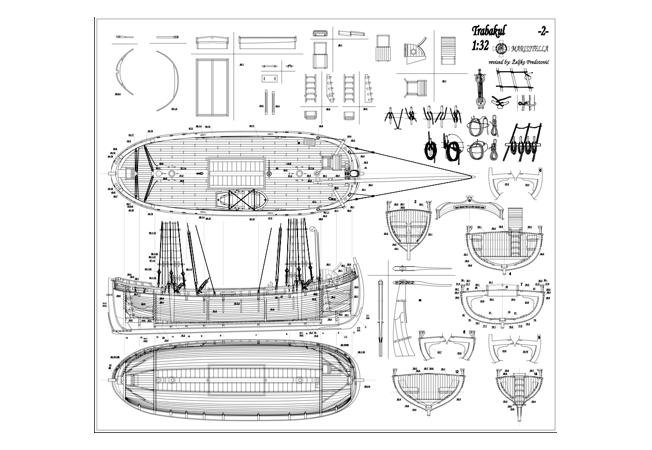

Good morning, Beginning the planking. The planks (serrette, verzene in old texts) are 7x1.5mm walnut strips placed on the frames (piana). Installation of the 2 acajou sheerstrakes (parascusola), 7x1.5mm strips. Beginning the planking of the bilge and cabin bulkheads. Beginning construction of the rear cabin (camera) deck for the captain (paron), which averages only 146 centimeters in height, while the crew enjoys a height of 123 centimeters at the bow! Beginning construction of the limewood bilge floor (paglioli) of 1.5x10mm. This floor is removable, allowing for the evacuation of bilge water. The kit plans are of high quality, as are the materials. The instructions should not be taken literally. Despite the scale, it is not easy to install the planking. Access between the frames for sanding and correcting is really tricky.

-

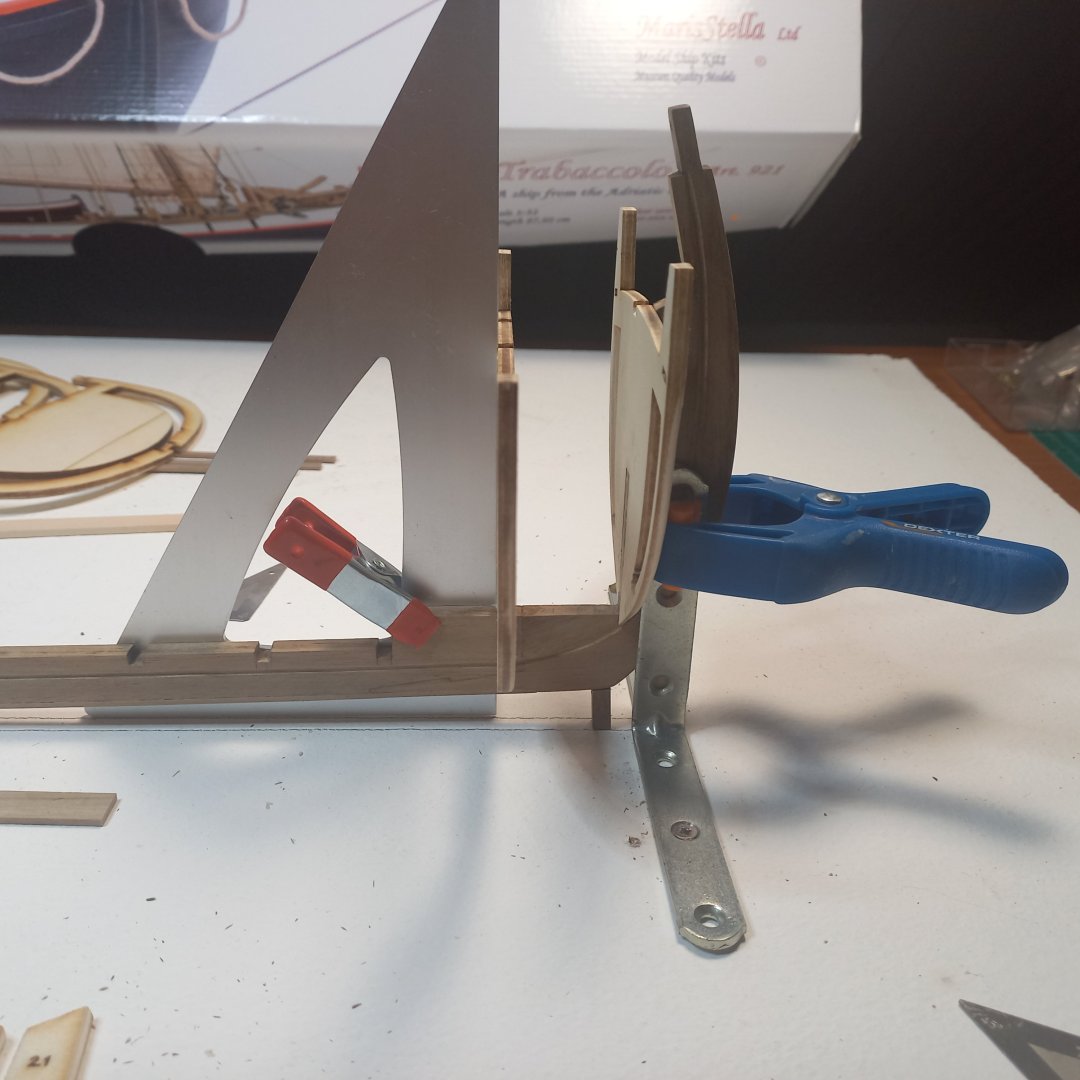

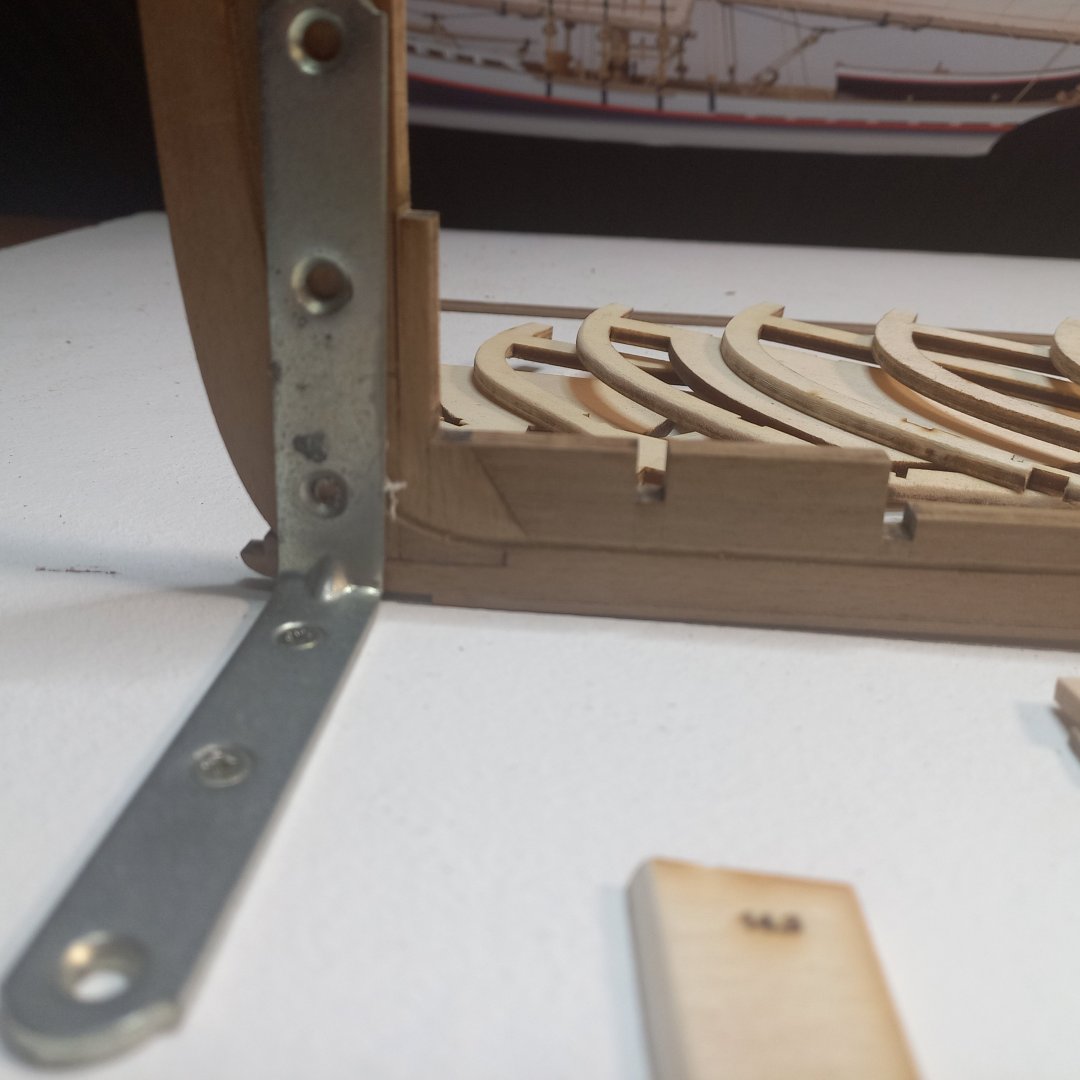

Hello, Reopening of the Squero with the creation of the 'keel clamp' -or - the 'work stand' 😉 'Usually, their construction did not take place in large shipyards, unless they were intended for the Navy, but rather in the various squeri, sometimes inside hangars, most often in the open air. In general, the term 'squero' today refers to a small shipyard, but in the 19th century, the definition was more precise, as this term designated areas located by the sea intended for shipbuilding and not exceeding 290 square meters; larger areas were rather defined as cantiere: 290 square meters was considered the minimum surface area necessary for the construction of boats of 200 tons of displacement. The main places housing squeri that were dedicated to the construction of these types of boats were: Molfetta, Manfredonia, Porto Civitanova, Pesaro, Cattolica, Rimini, Chioggia, Trieste, Piran, Rovinj, Rijeka, Cherso, Lussinpiccolo, Split, Korčula, and Dubrovnik.' M. Marzari Short film about the Squero di Cattolica: https://youtu.be/l5gKbJvICgc The frames (corbe) are not strictly perpendicular to the keel (colomba). There is a 1.5° angle. A photo from the book "Bateaux et Batellerie de Venise" by GB Rubin de Cervin

-

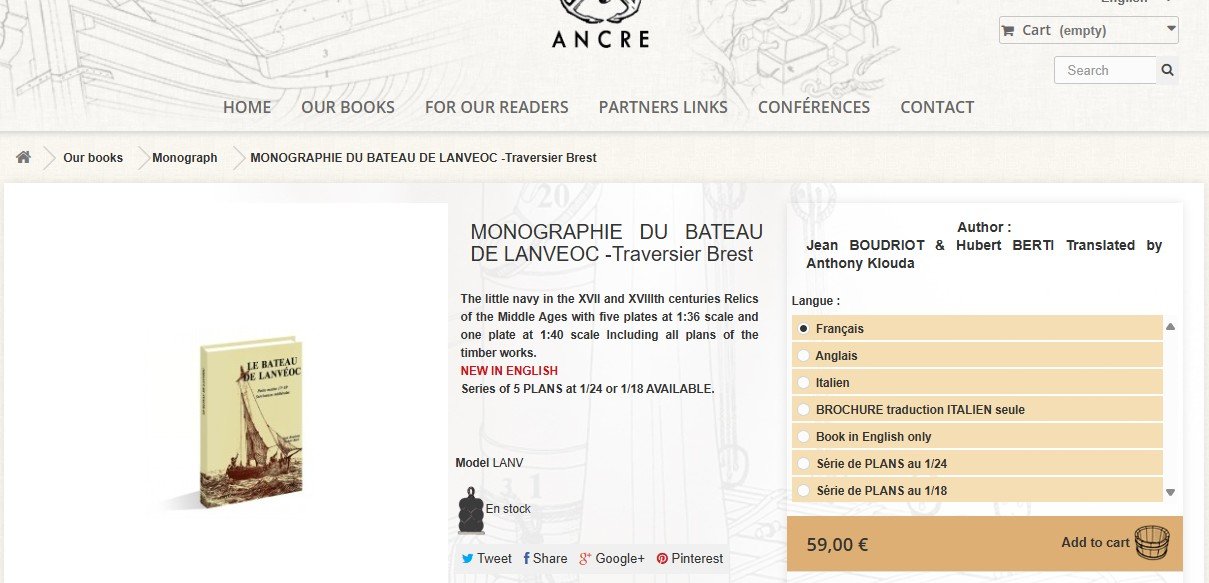

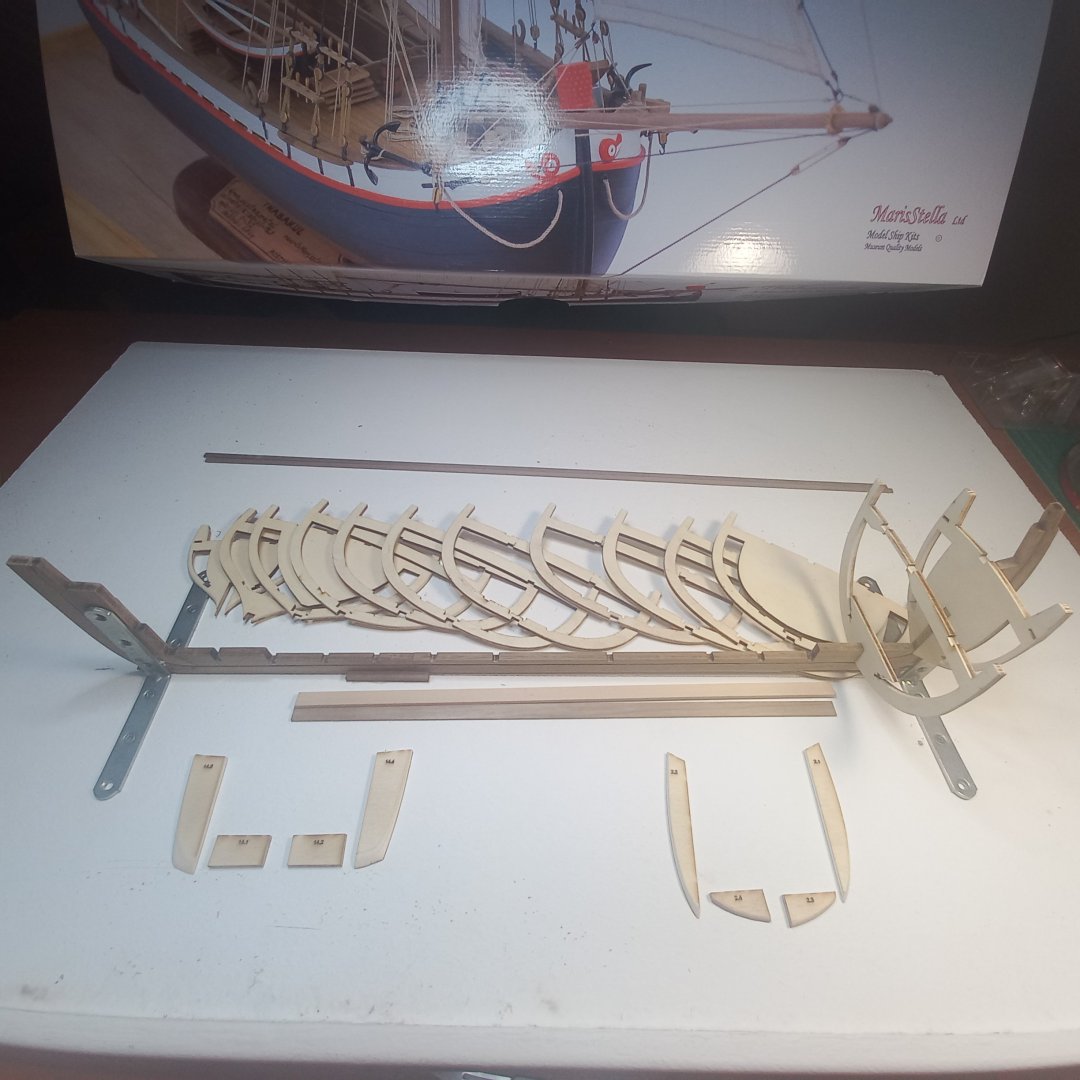

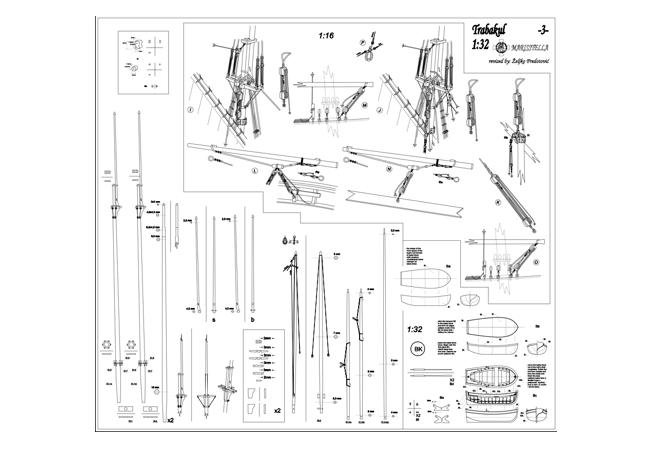

Hello, The box has arrived. 😀 Most of the pieces are walnut, the frames are plywood, and there's also balsa wood. It's laser-cut. There are 3 plans at a 1:32 scale, and the instructions are trilingual (English/Italian/Croatian). For Croatians, the Trabaccolo is called Trabakul. FYI, MariStella was founded in 2008 and is an association of 7 small businesses. It's located in Split, the regional capital of Dalmatia. The contact, Zoran, is very available. 😉 They've created a series of 1:32 scale Adriatic ships: Trabaccolo, Pelig, Brazzera, and Stilac. Some general info from a really interesting book (Trabaccoli e Pieleghi from Mario Marzari) : "The first step is to assemble the keel, called "colomba" or "Il primo" by the Venetians. The "colomba" was the main element, or rather the load-bearing axis of the structure, in addition to being the lower part of the hull: it was robust, heavy, and rectangular in section, with dimensions that could vary around 200 x 250 millimeters. This important structural element was composed of several pieces, closely joined together lengthwise, with scarf joints ("pallela"), to make the whole thing very solid. To build the keel, the best oak was used, and on both lateral faces of it, a rabbet ("battura") with an angular section was made, which then extended onto the stem and sternpost. These two lateral rabbets served to fit one of the edges of the first planks of the planking called "torelli" ". Keel, stem, sternpost, counter-sternpost, rabbet, transom, and counter-transom. I also create the rabbet, and it's easier to start in a flat position. It's best to use a flat surface, such as a piece of glass, to glue the different pieces. The drawing is placed under the glass to ensure proper alignment. Nest step : build a work stand (keel clamp). This is necessary to help support the keel and to keep it straight Let's go!

-

Good day, Following the Endurance expedition in the Weddell Sea with Sir Ernest Shackleton around 1915, and the HMS Granado, a British bomb vessel in 1756, I propose we embark on a new project together: building a Trabaccolo kit from the brand MarisStella. I hope to conclude this project with a visit to the Museo della Marineria in Cesenatico, Italy. The box has arrived. I'm thrilled! Most of the parts are made of walnut, the frames are plywood, and there's also some balsa wood. It's all laser-cut. There are three 1:32 scale plans included, and the instructions are trilingual (English/Italian/Croatian). In Croatian, a 'trabaccolo' is called a 'trabakul' For your information, MariStella was founded in 2008. It is an association of 7 small businesses. Located in Split, the regional capital of Dalmatia, the contact person, Zoran, is very available. They have created a series of Adriatic ships at 1:32 scale: Trabaccolo, Pelig, Brazzera, and Stilac. The first step is the construction of the keel, called by Venetians "colomba" or "Il primo"

-

Hello from France

François de Saint Nazaire replied to GRANADOS Philippe's topic in New member Introductions

Bienvenu Phillippe

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.c334ea1d4cfb12b6b3e2eb949f8f8dea.jpg)