KarenM

Members-

Posts

215 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by KarenM

-

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

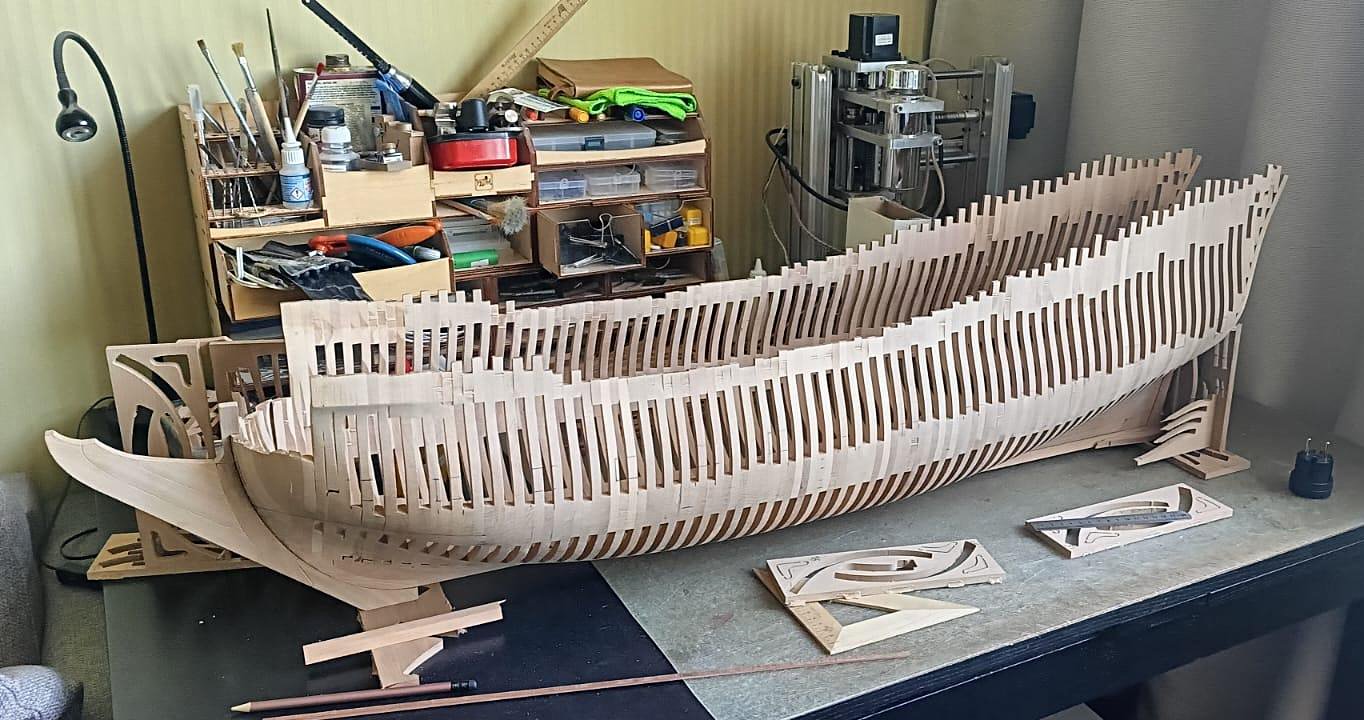

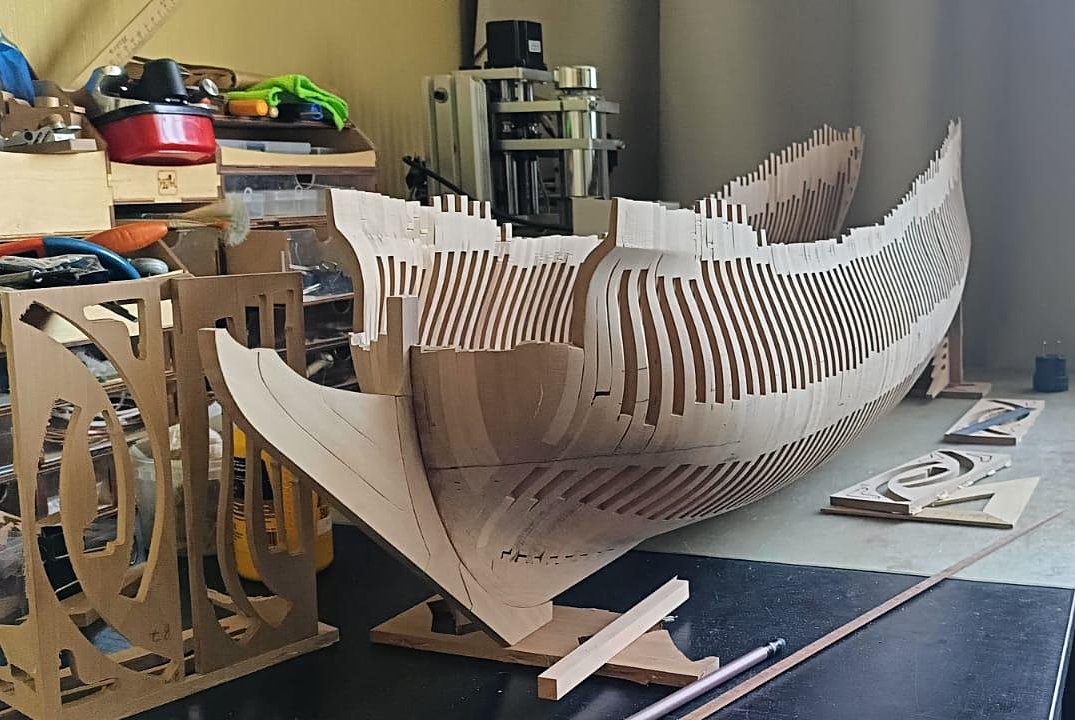

I place the slats close to each other. There is no distance between them. The slats have angles of 45 degrees, not 90. Maybe that is why it seems that there is a distance between them. -

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

-

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

-

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

-

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

-

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

Started to cover the body with slats -

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

In the evening I glue the strip, in the morning I break it off. And so on 2 times. I still couldn't get an even and correct line. -

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

-

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

On Aliexpress 003.mp4 -

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

-

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

This is the second option, I didn’t like the first option. -

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

-

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

-

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

-

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

-

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

Our modelers make their own tools for modelers. Some very successful tools are put into production and sold to others. There are also branded tools, but they still have to be modified. For example, all Prokson machines are modified. We make stops and guides ourselves. -

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

I know about this plane. Mine is of the same quality as Veritas. -

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

-

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

-

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

The ship's hull is assembled and sanded. Now I'll start cutting out the gun ports and finishing the stern. -

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

He made this mini plane for all the modellers I know. -

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

A friend of mine makes such a tool to order. It is very convenient for them to process the hull of a ship. -

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

-

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

I make the minimum distance and then manually adjust it to fit the bow of the ship. -

HMS RESOLUTION 1667 by KarenM - 1:48

KarenM replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.