Dave Wood

Members-

Posts

93 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Dave Wood

-

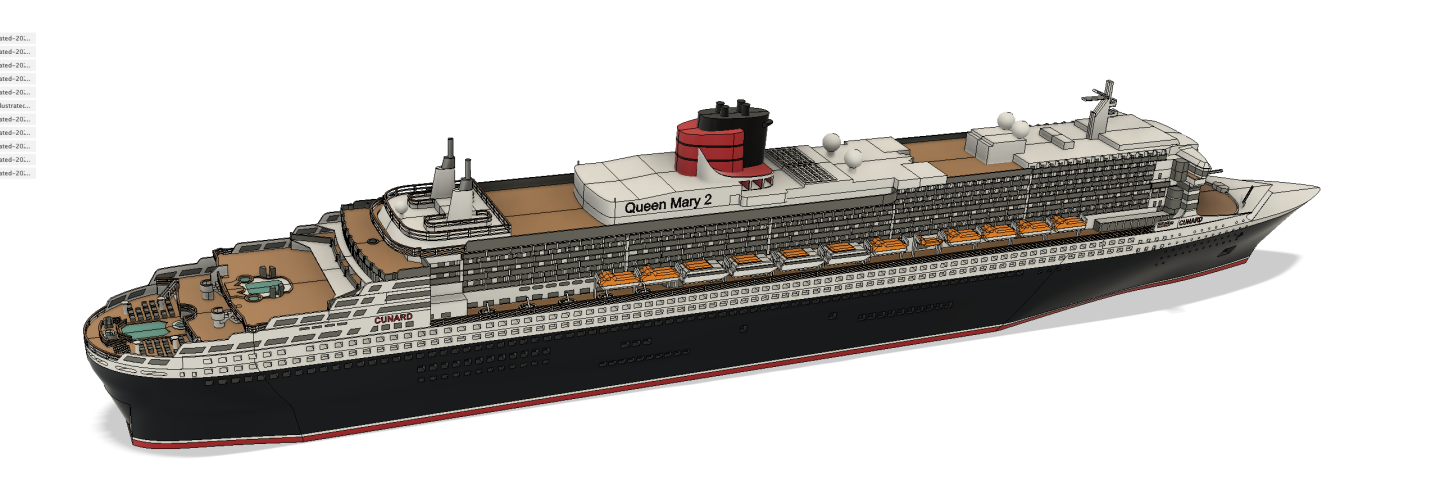

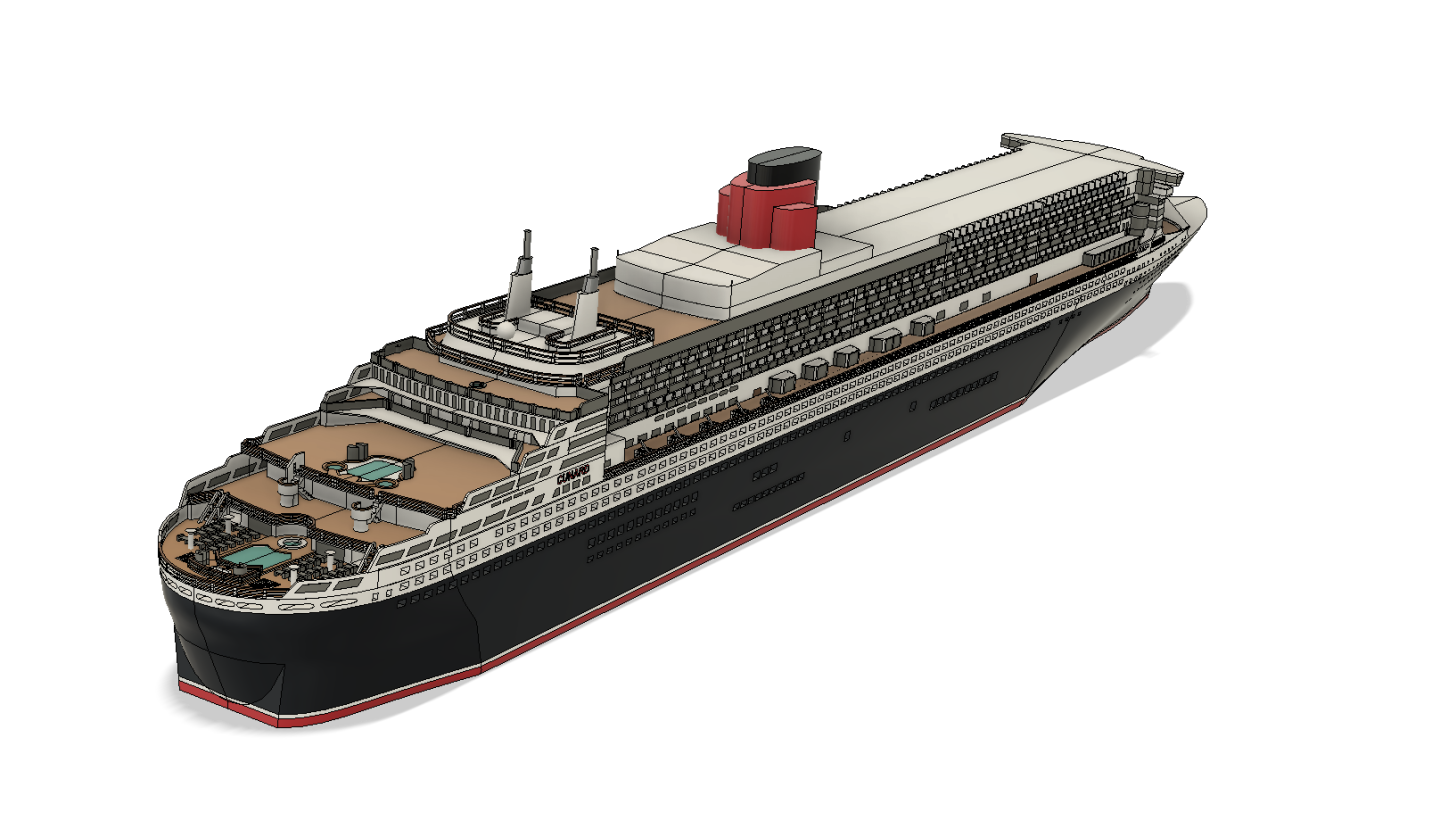

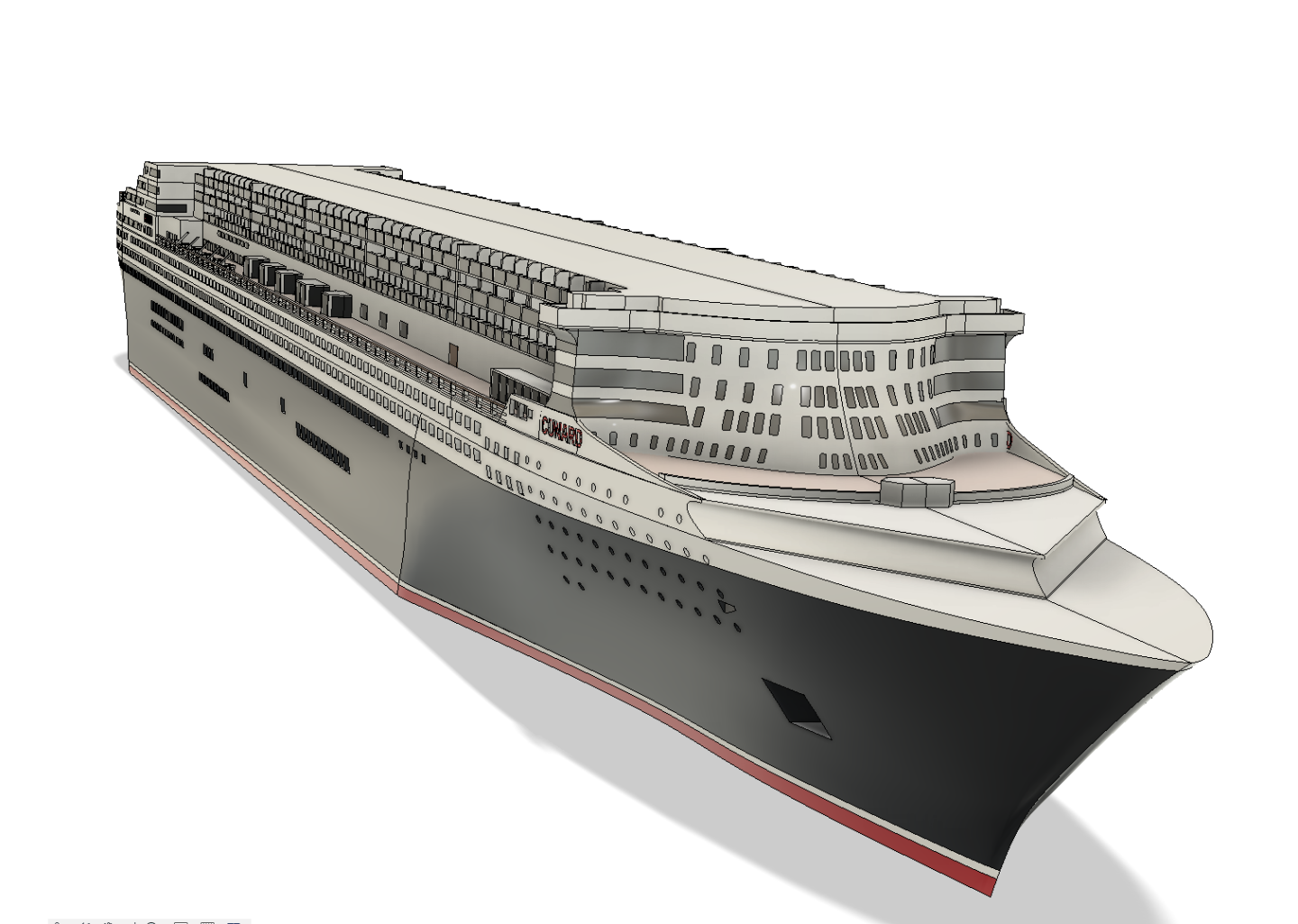

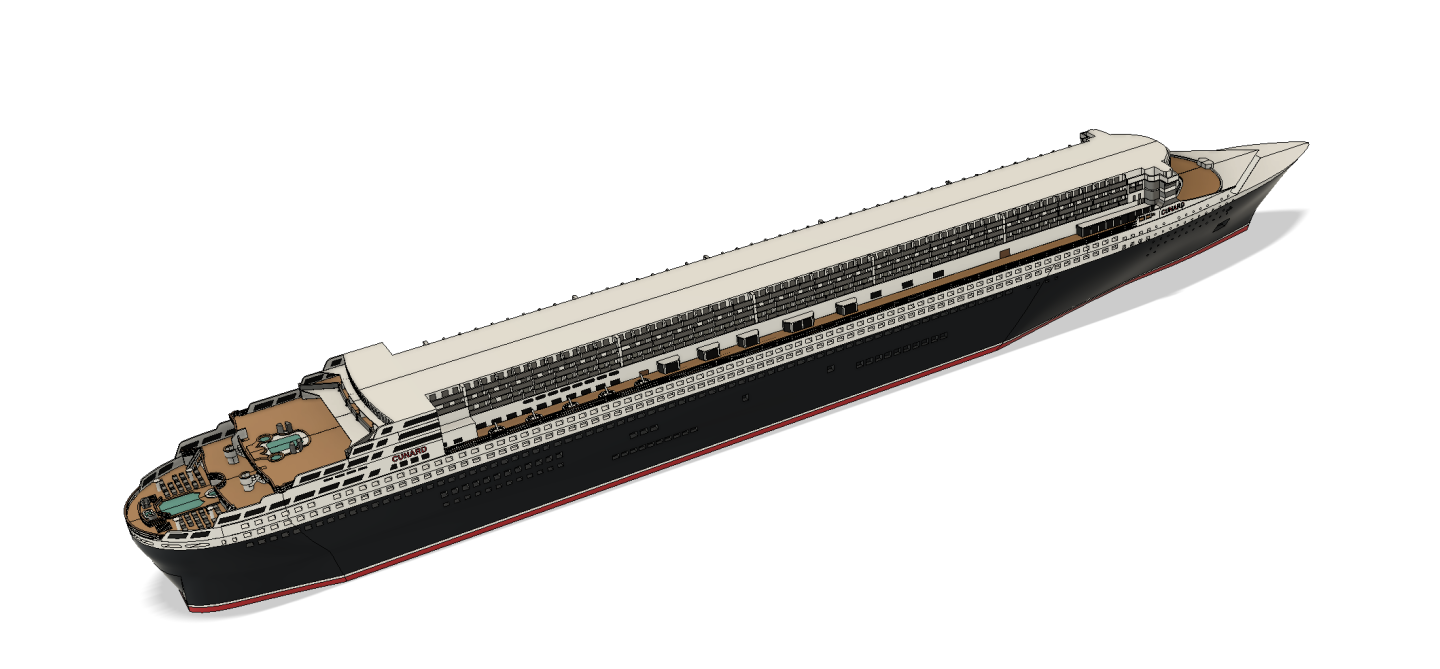

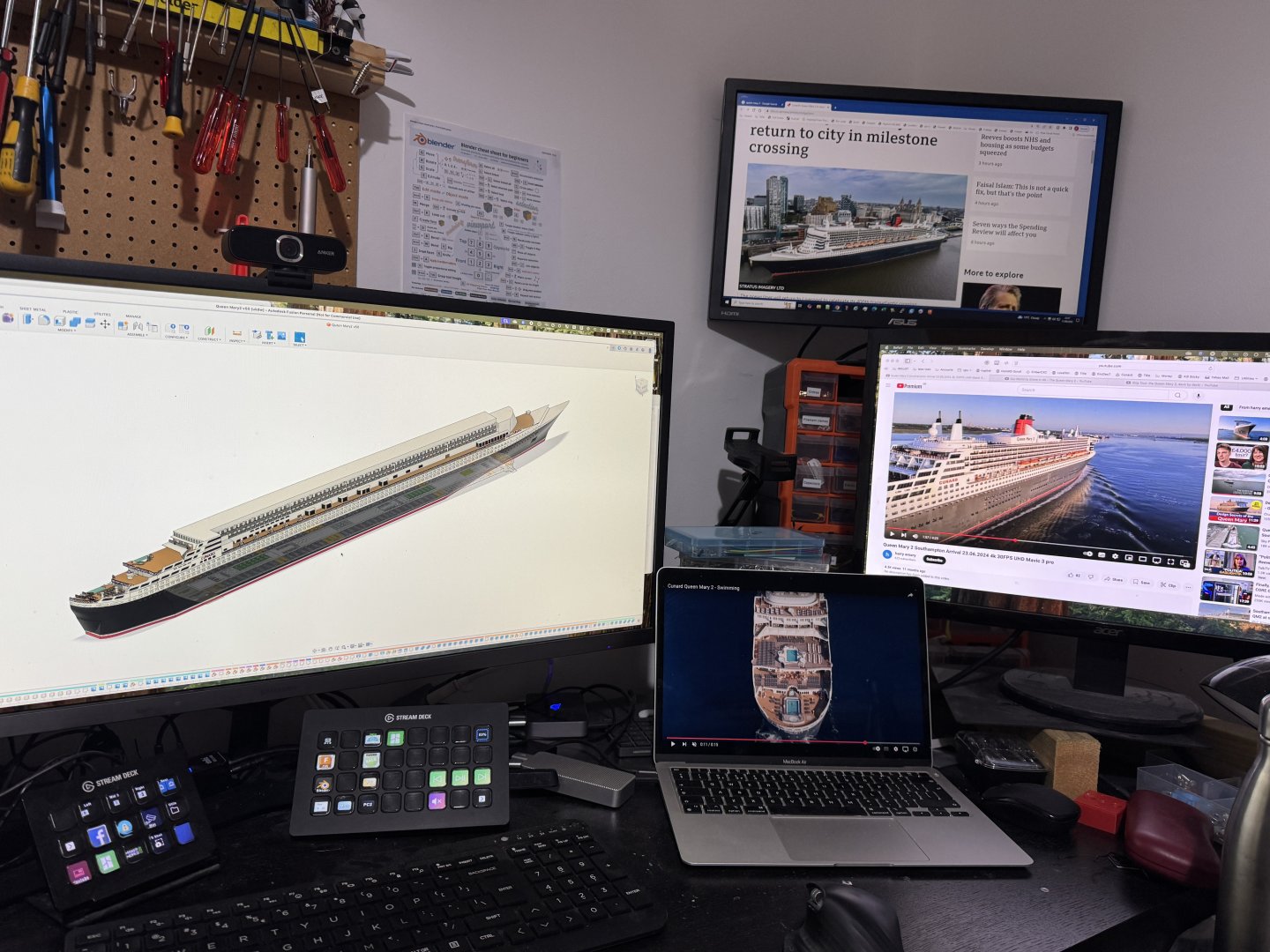

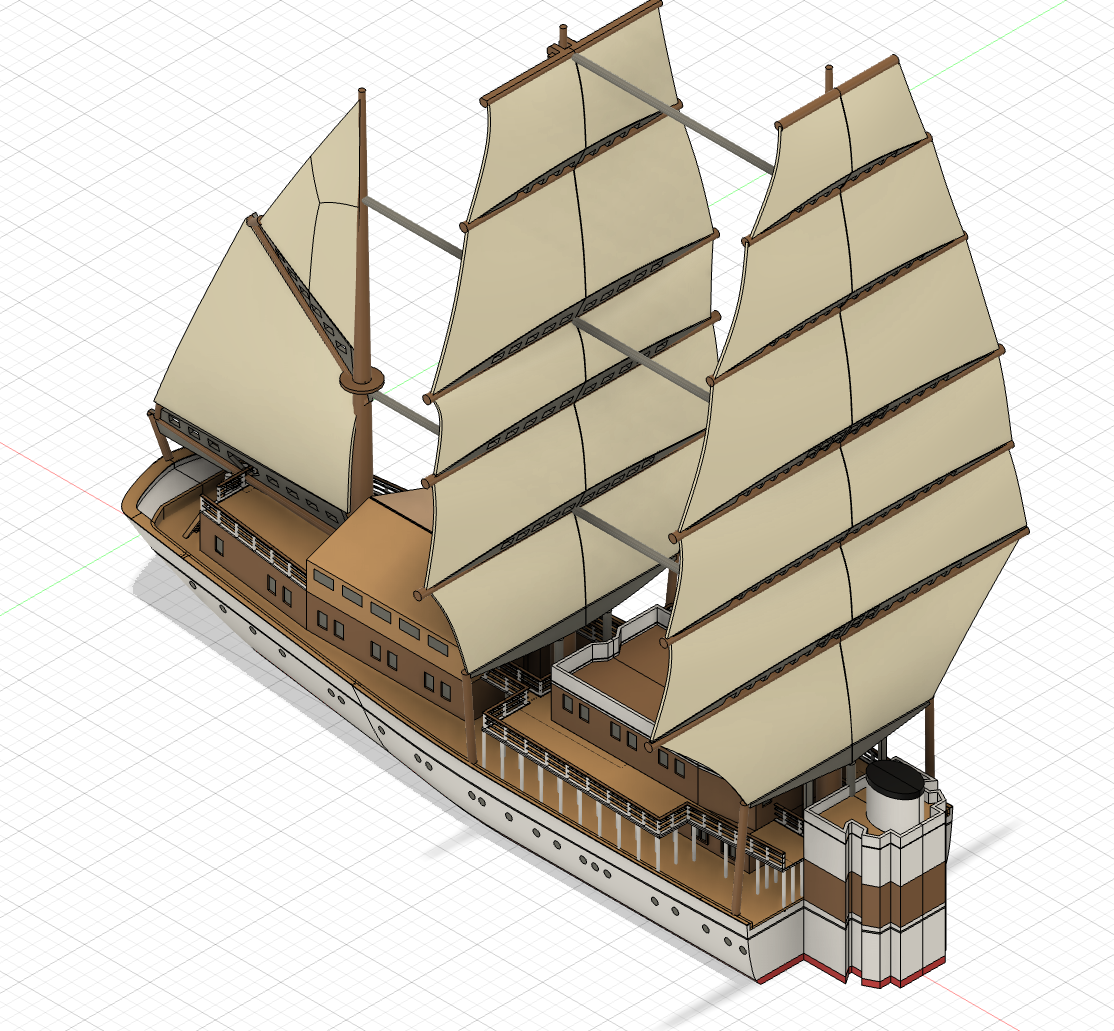

More details added - plus short video showing how the decks appear in Fusion 360.

- 34 replies

-

- Queen Mary 2

- 3d printed

-

(and 1 more)

Tagged with:

-

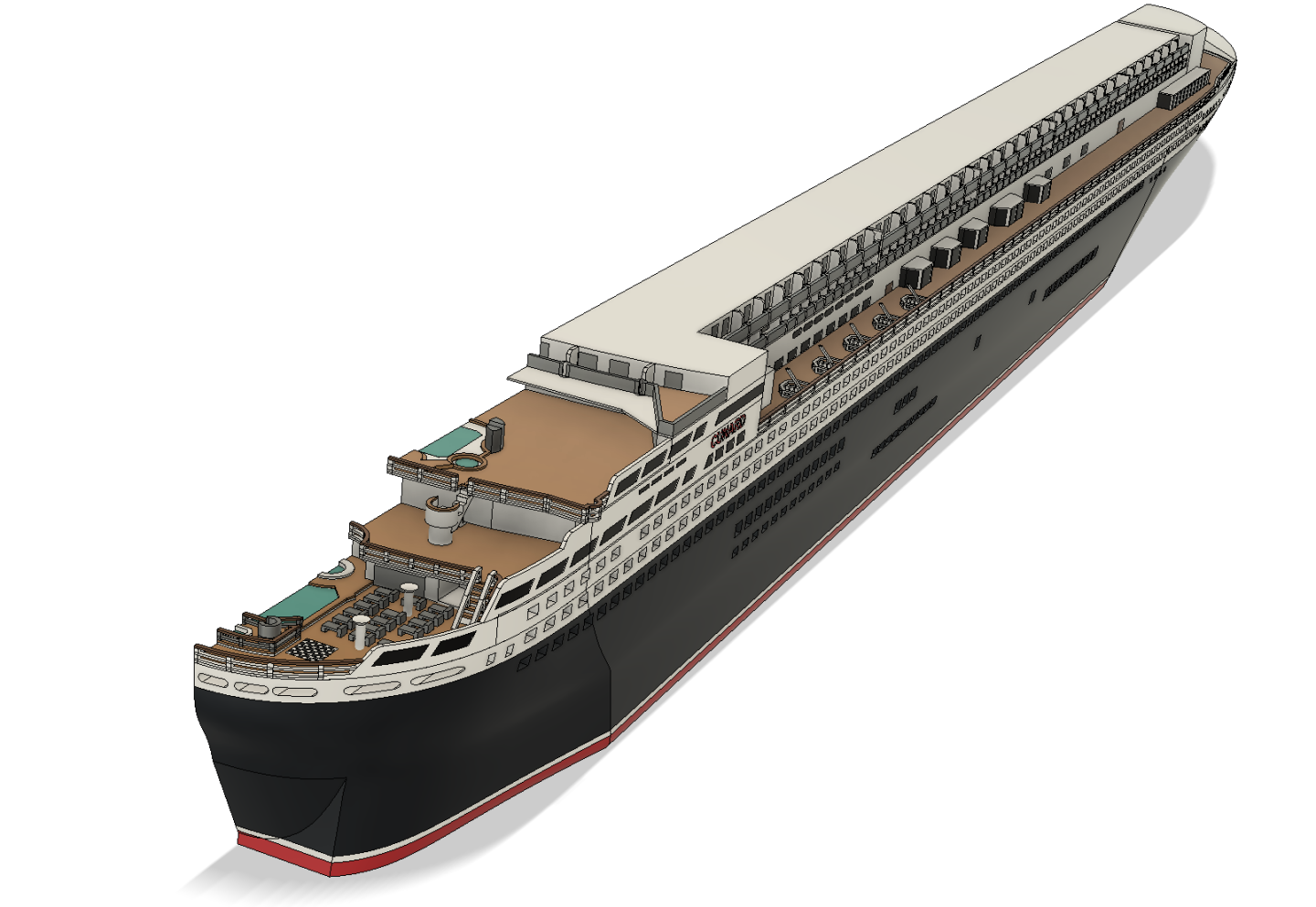

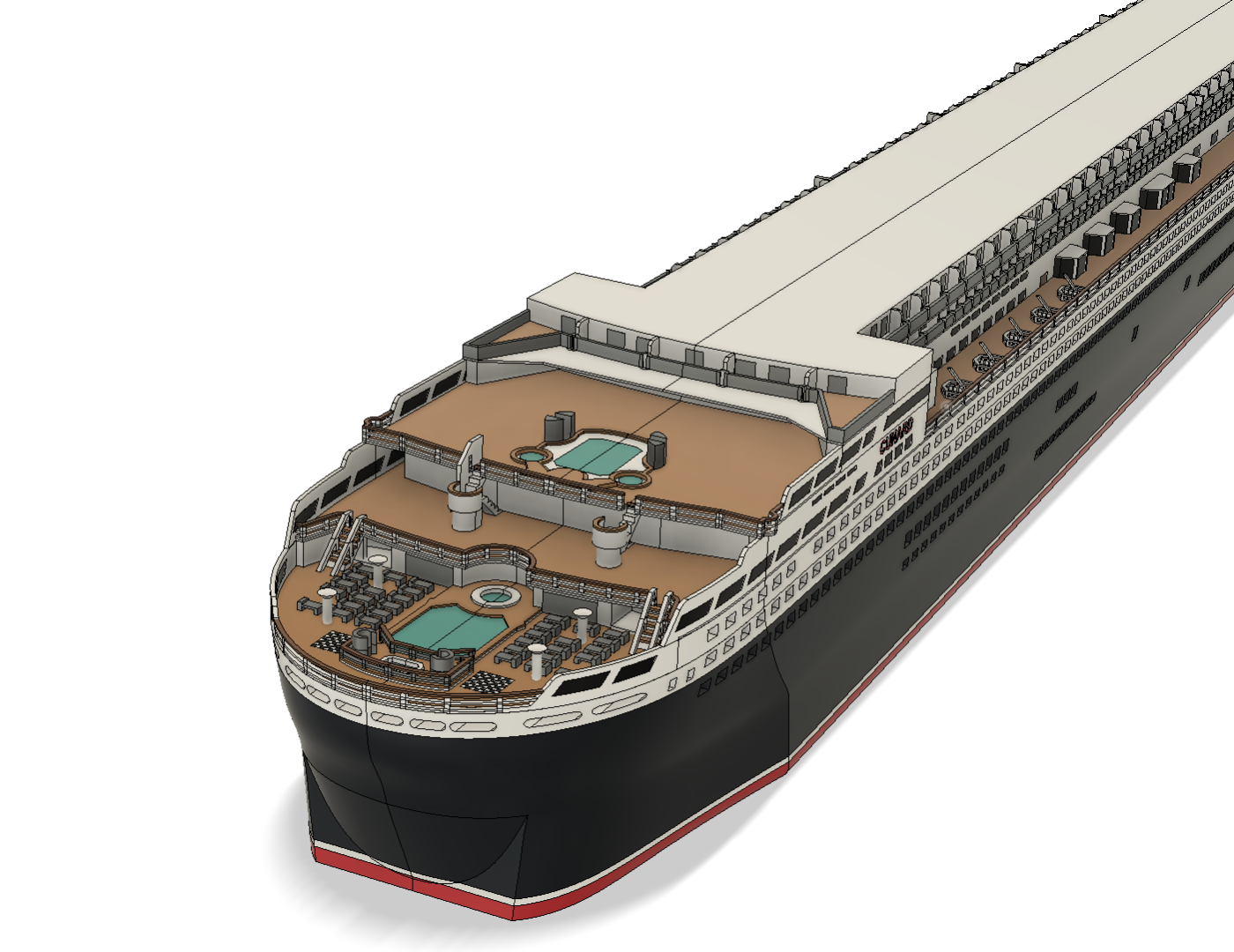

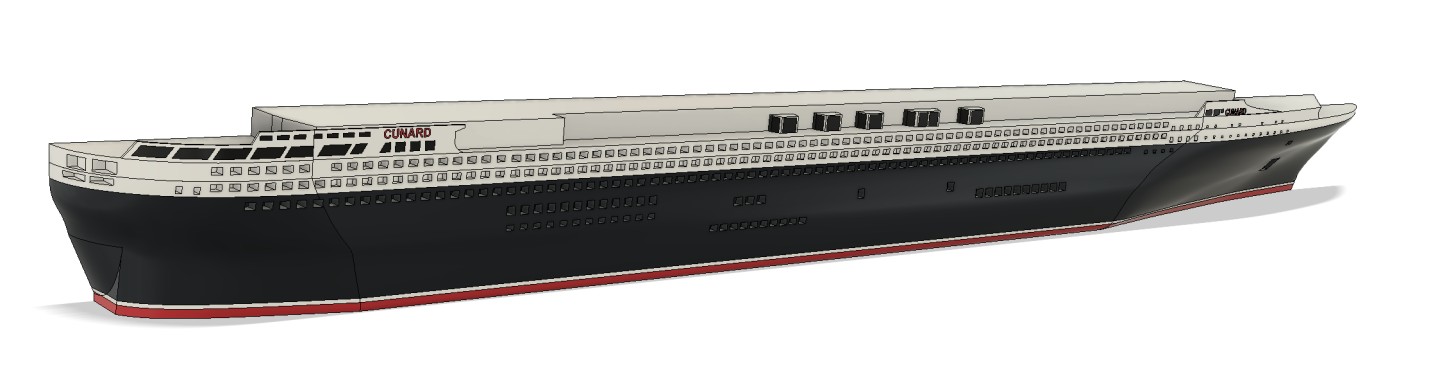

Further refinements made - see here for 360 degree render.

- 34 replies

-

- Queen Mary 2

- 3d printed

-

(and 1 more)

Tagged with:

-

- 34 replies

-

- Queen Mary 2

- 3d printed

-

(and 1 more)

Tagged with:

-

- 34 replies

-

- Queen Mary 2

- 3d printed

-

(and 1 more)

Tagged with:

-

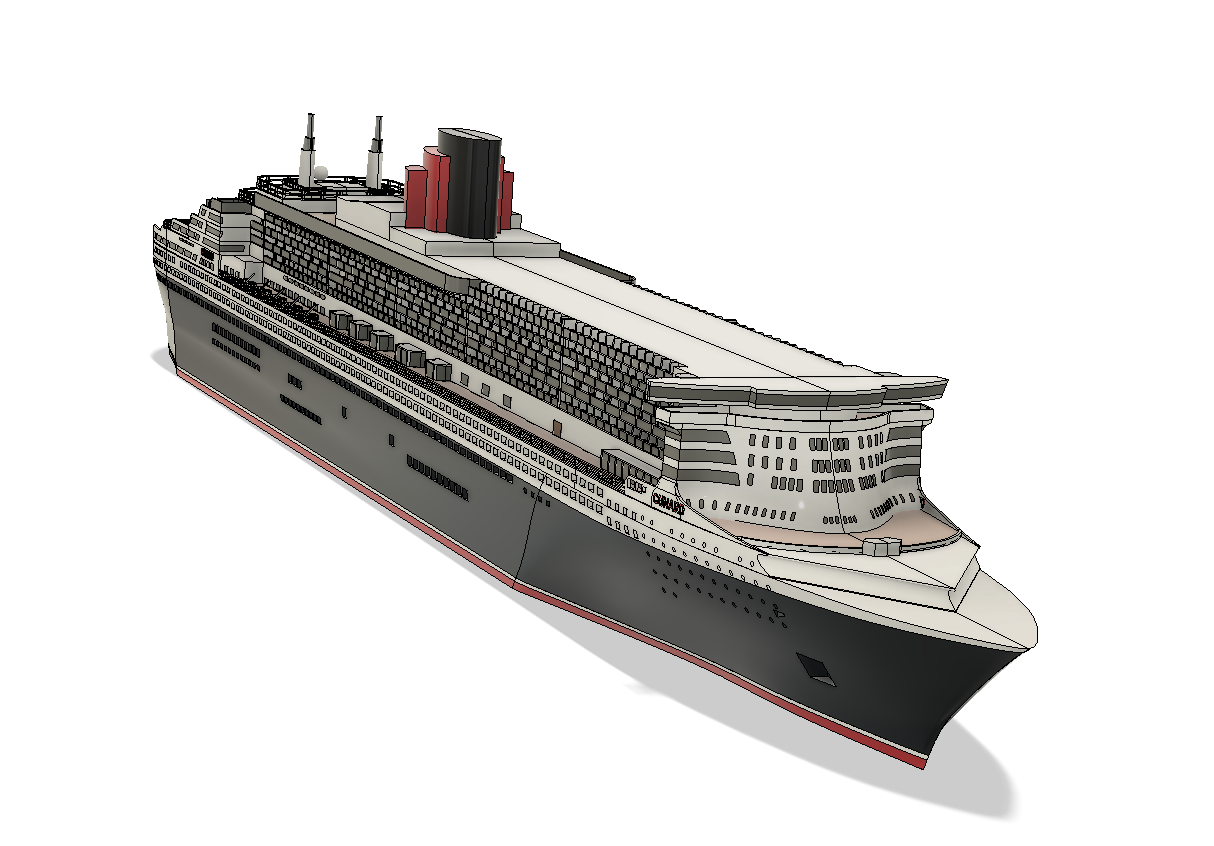

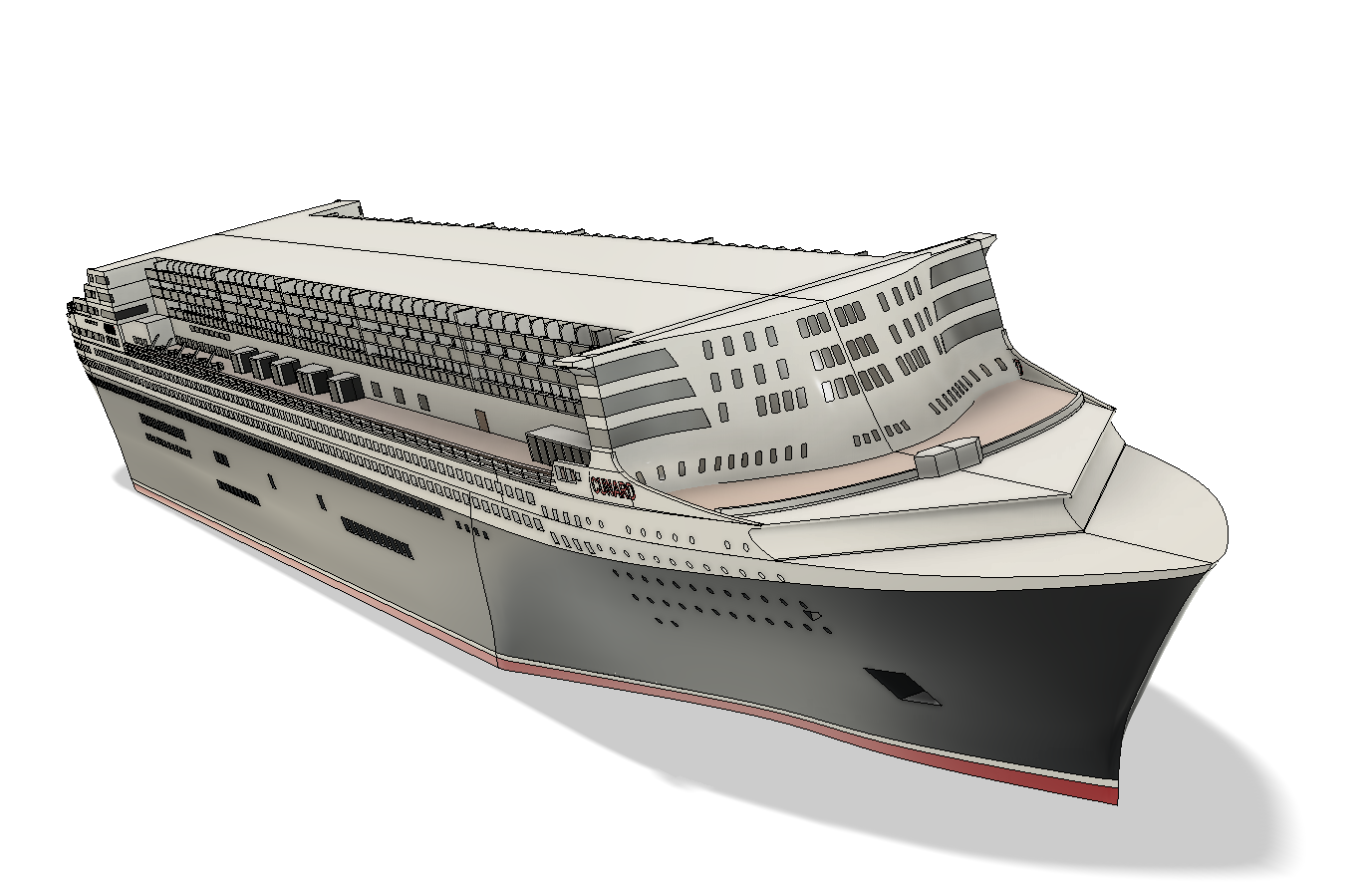

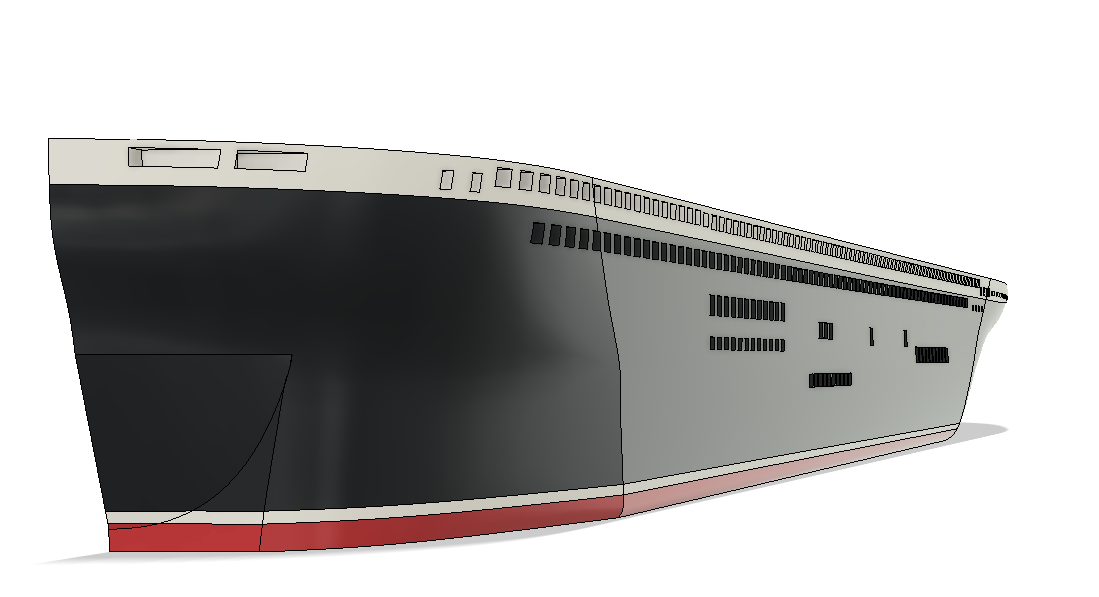

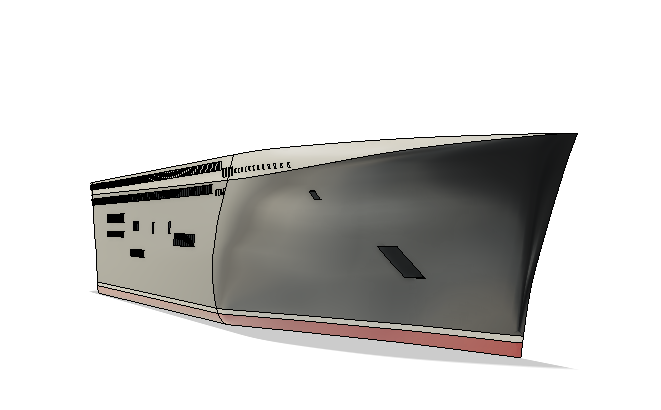

Found I had got the decks confused at the front - had put the observation deck in one too low - so windows were all wrong too. Now corrected.

- 34 replies

-

- Queen Mary 2

- 3d printed

-

(and 1 more)

Tagged with:

-

- 34 replies

-

- Queen Mary 2

- 3d printed

-

(and 1 more)

Tagged with:

-

- 34 replies

-

- Queen Mary 2

- 3d printed

-

(and 1 more)

Tagged with:

-

- 34 replies

-

- Queen Mary 2

- 3d printed

-

(and 1 more)

Tagged with:

-

- 34 replies

-

- Queen Mary 2

- 3d printed

-

(and 1 more)

Tagged with:

-

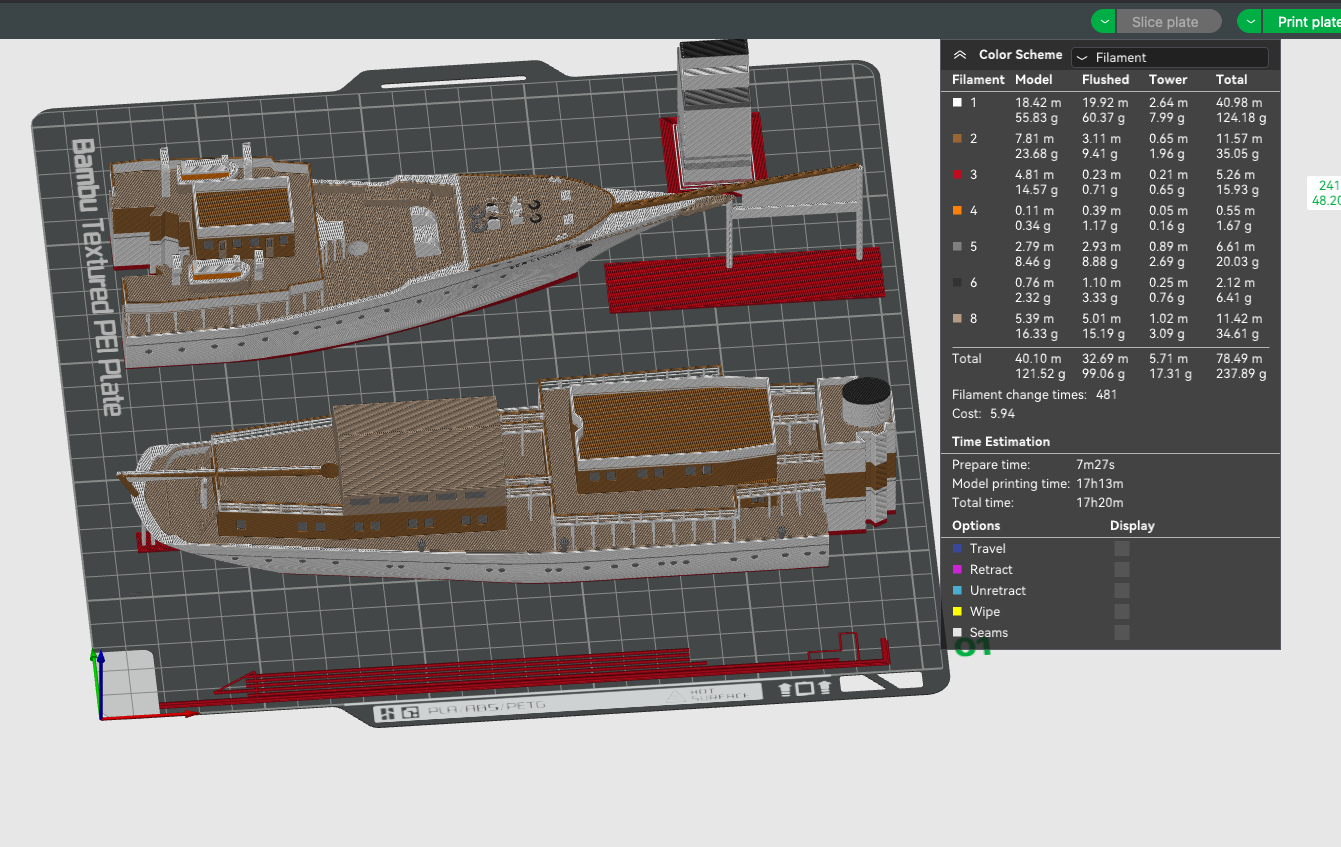

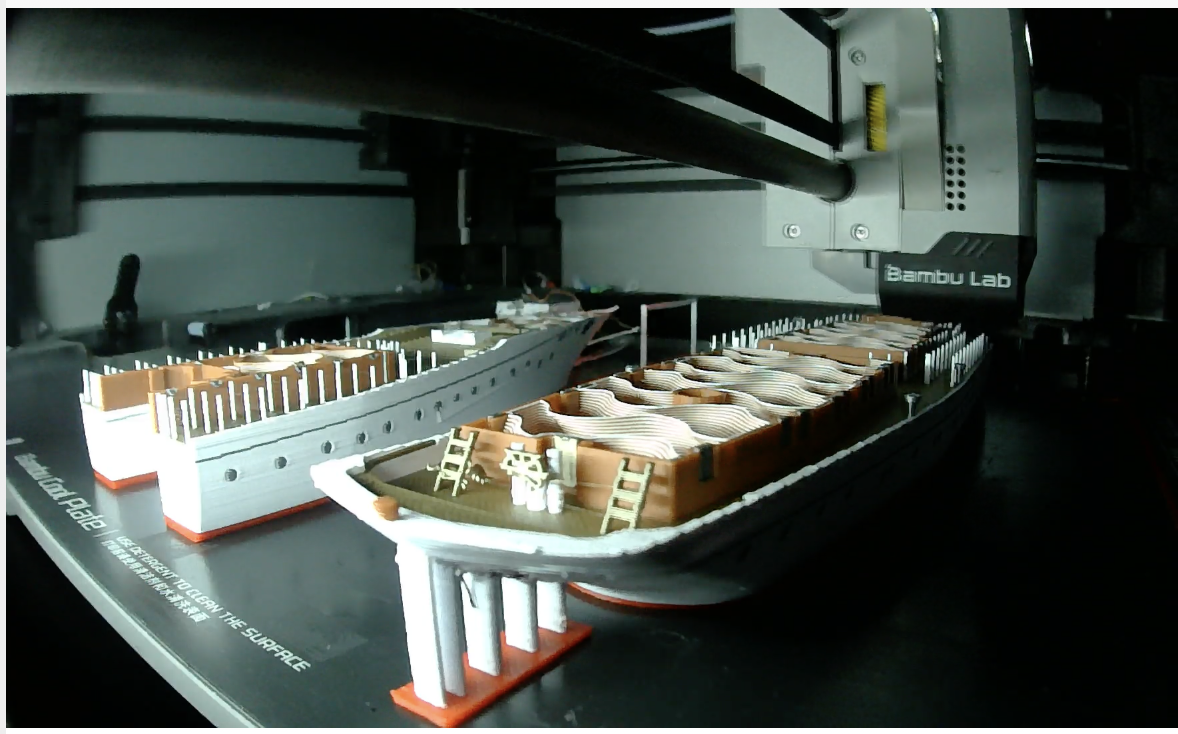

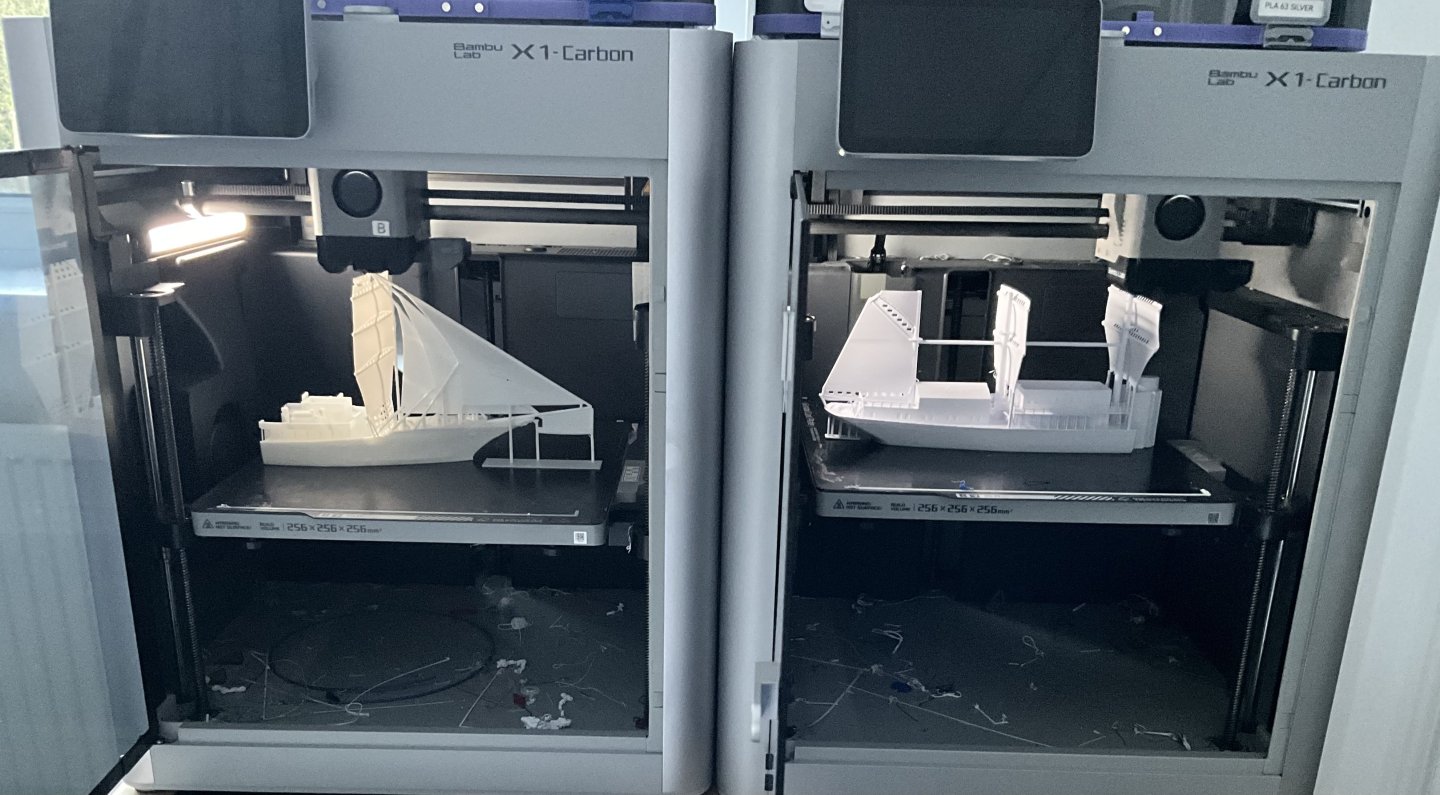

Made a start yesterday on QM2 Multi Colour 3d printed model - will design it for 1:500 initially, then scale down to 1:1000 Modelling from deck plans from Cunard site and various photos, using Fusion 360. Will then Muti colour 3d print on a BambuLab X1C or H2D. Hull shape needs a bit of work. Will mirror it once a few more decks are done.

- 34 replies

-

- Queen Mary 2

- 3d printed

-

(and 1 more)

Tagged with:

-

Has been wrestling with what to do about the ropes - whether to 3d print them etc. - Decided in the first instance to try making them out of copper wire led strings - The wires are doubled up and are about 0.25mm diameter - with the led's about 100mm apart. Should like quite good hopefully. Example render attached. Day time Night time

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.