Dave Wood

Members-

Posts

93 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Dave Wood

-

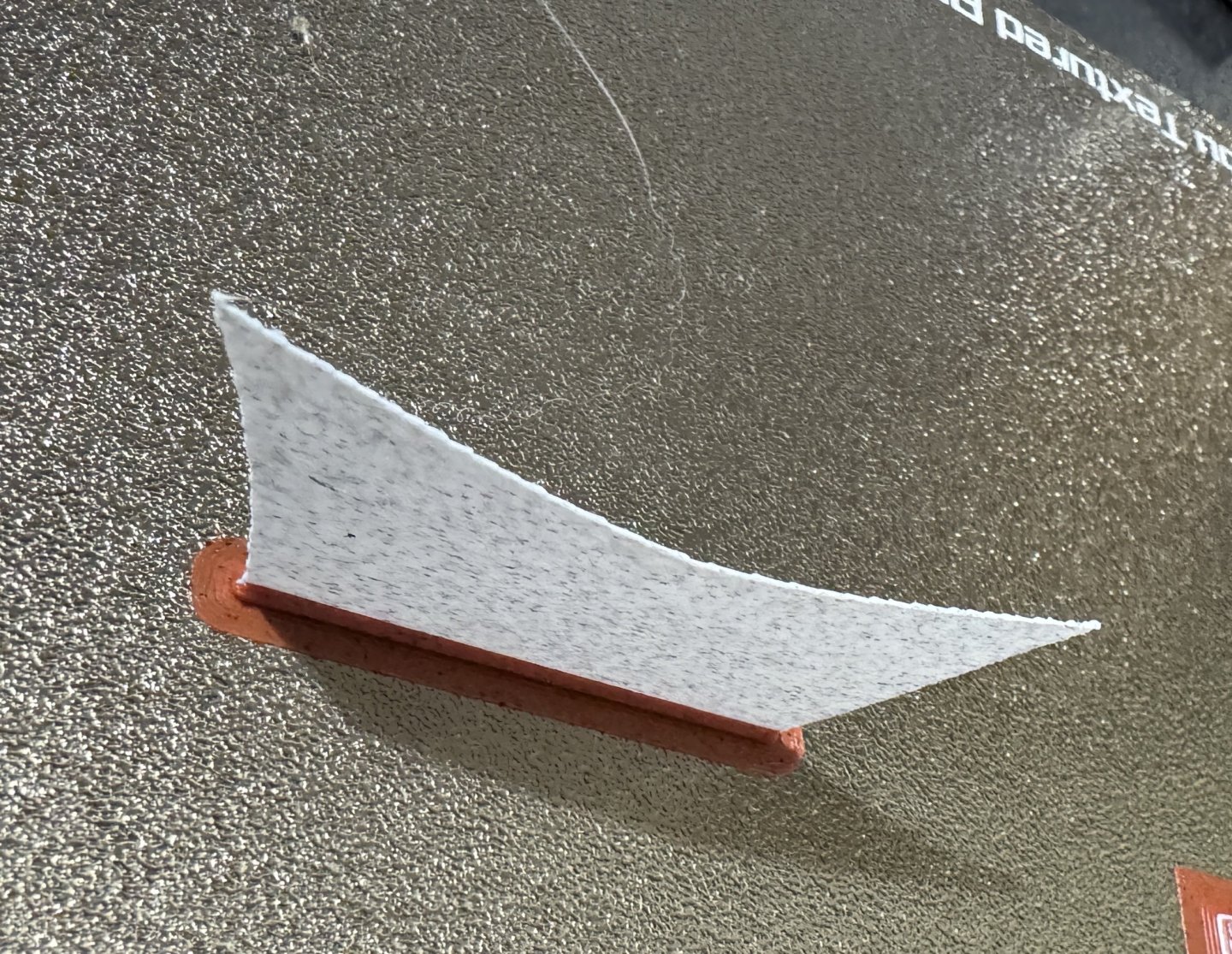

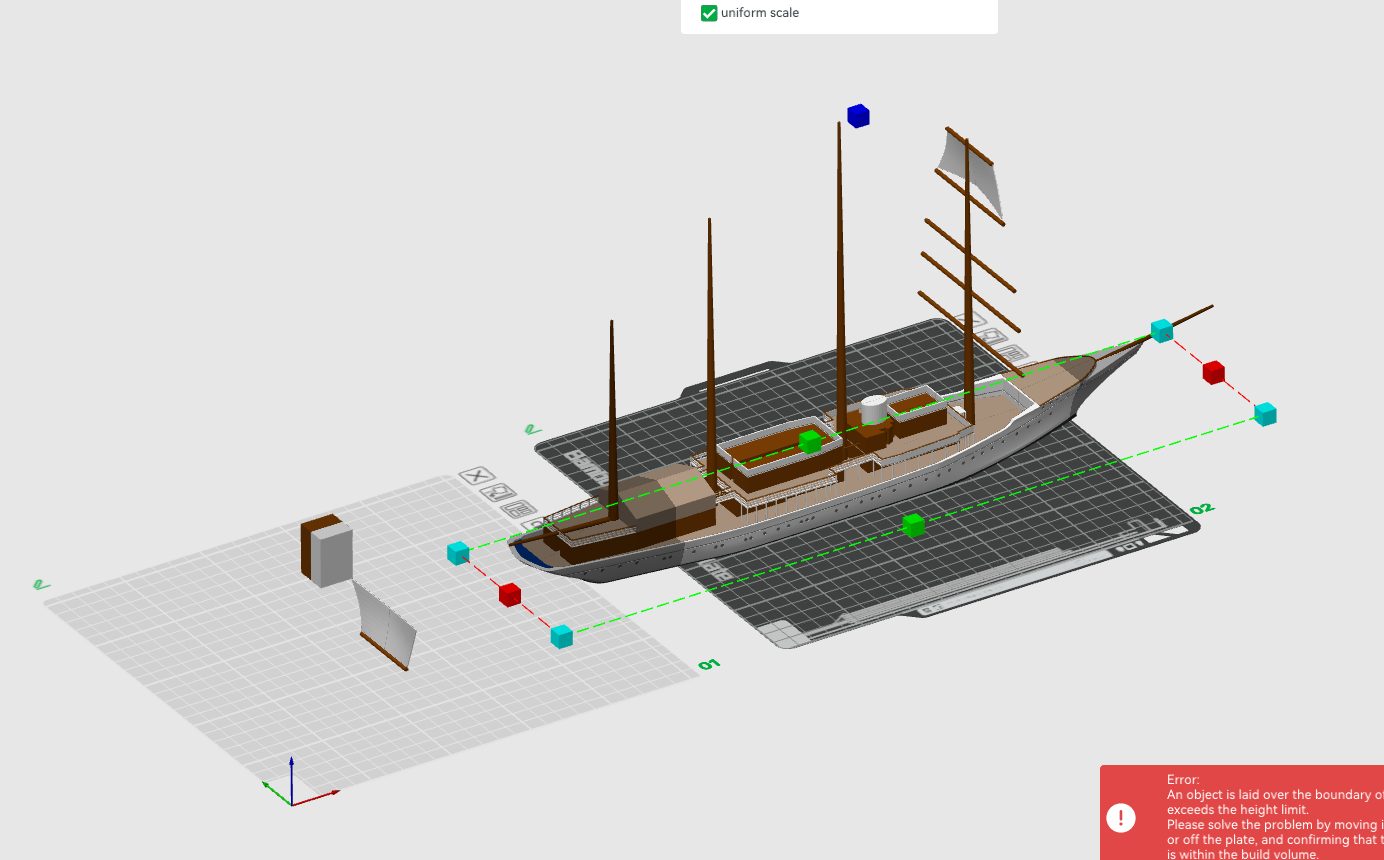

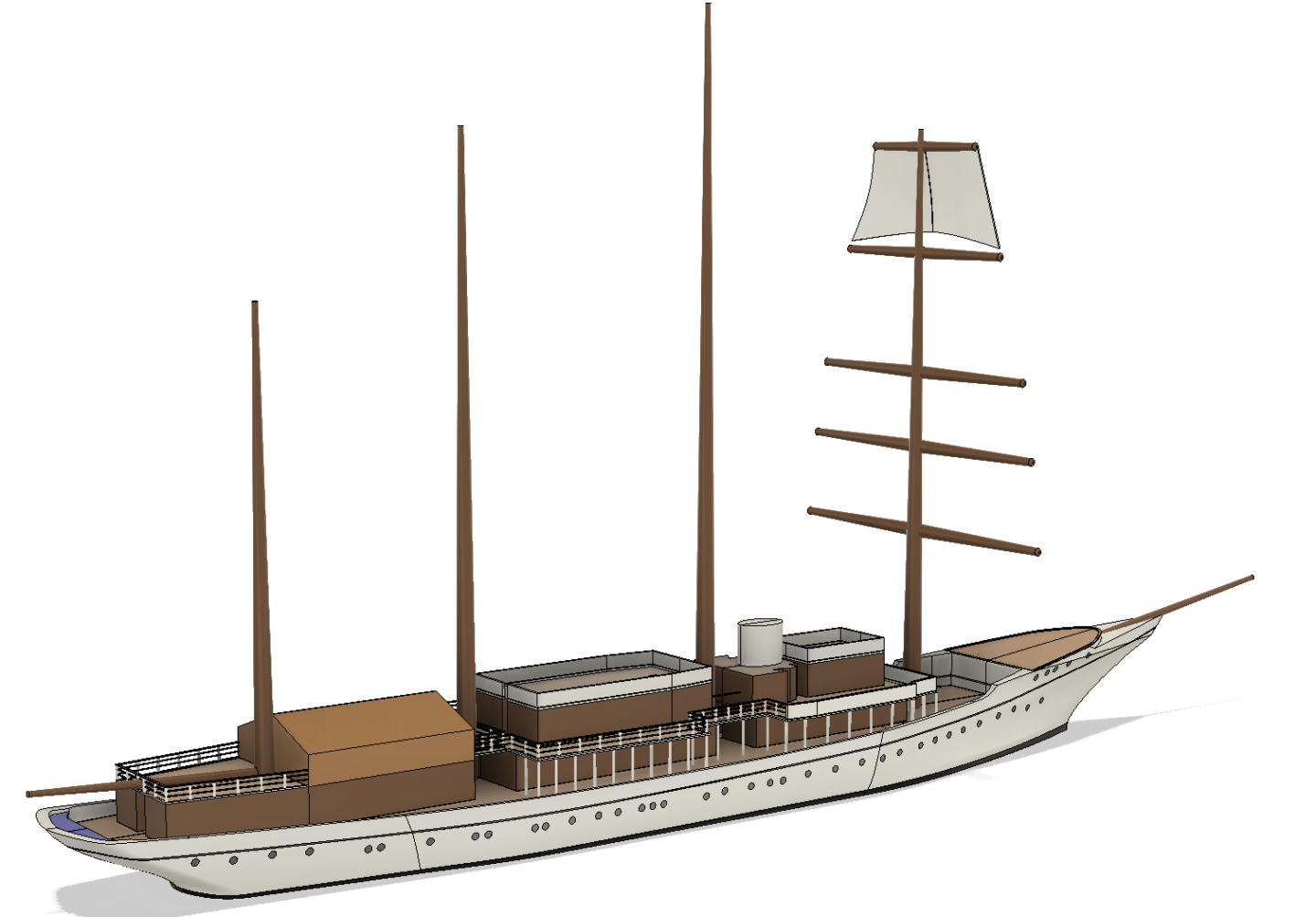

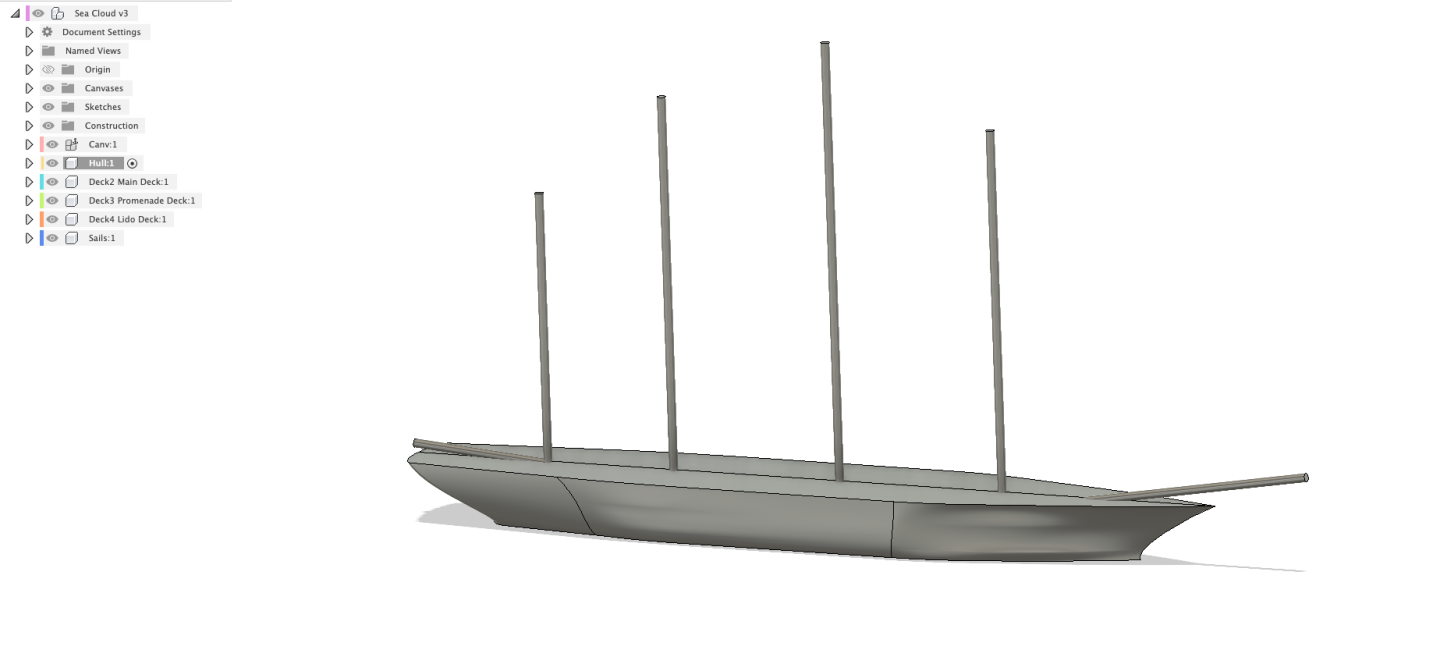

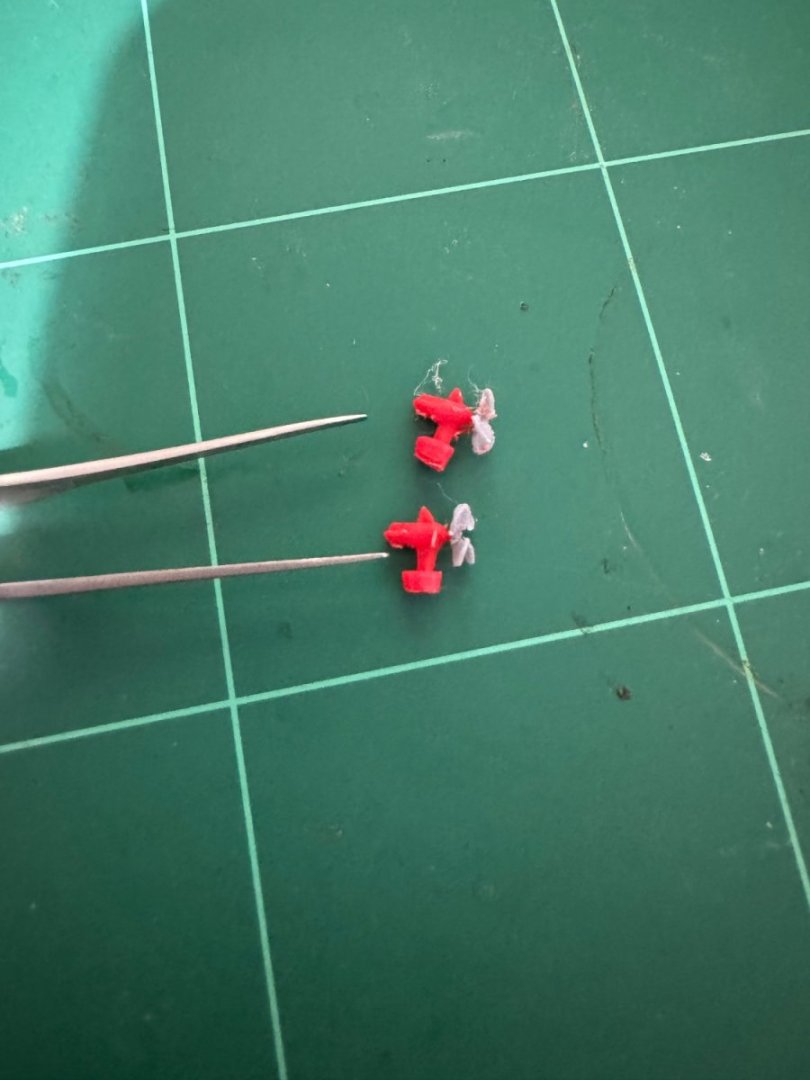

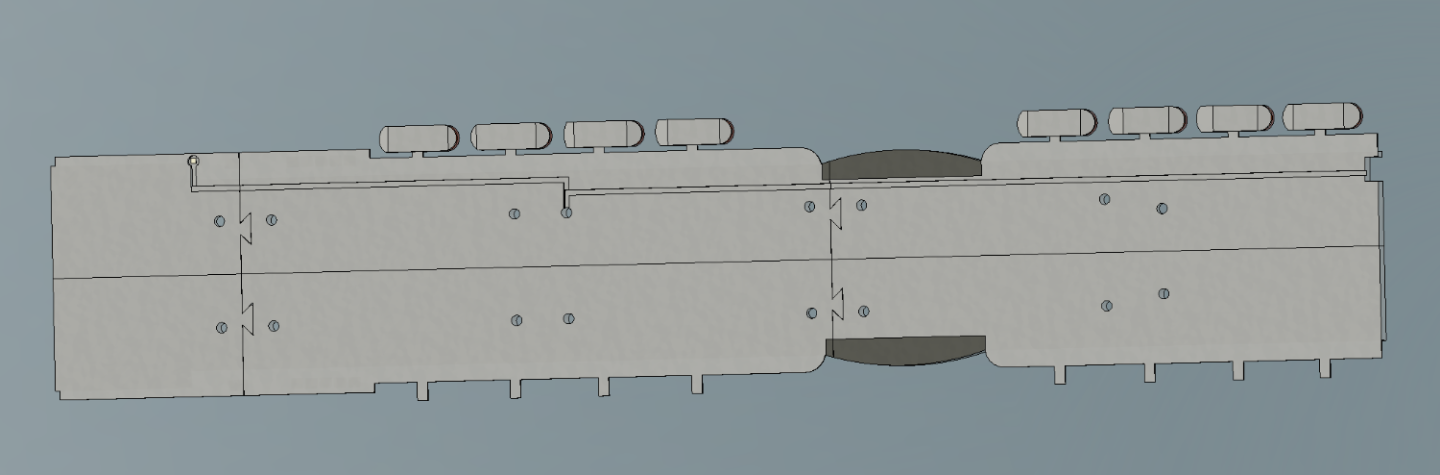

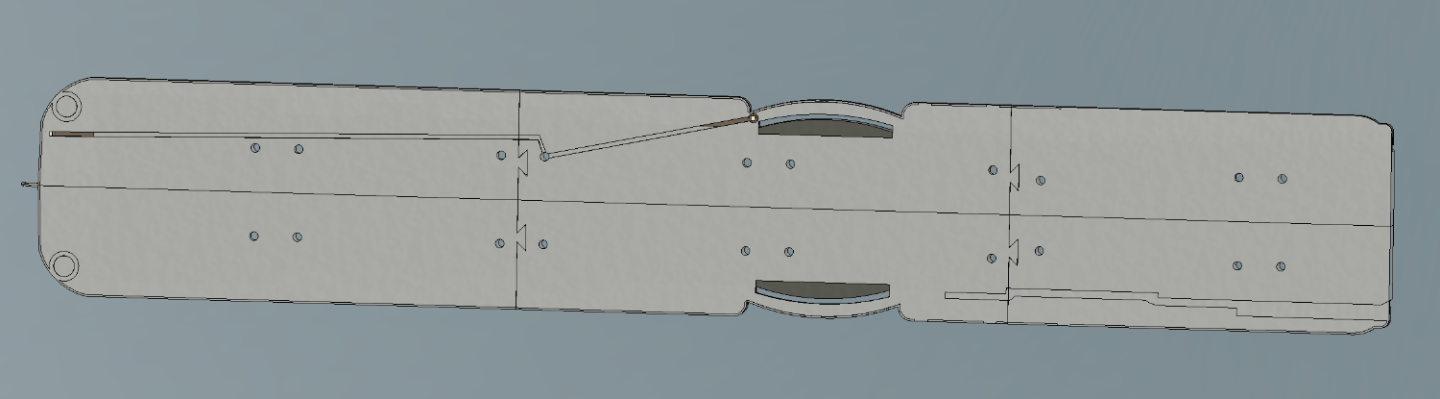

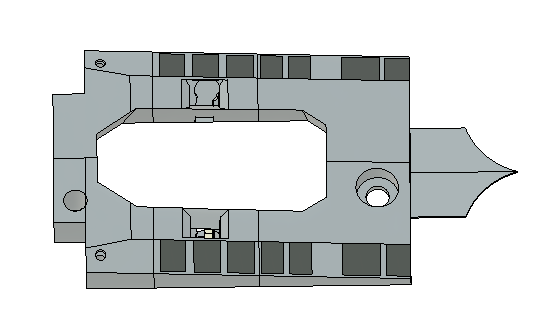

Tried a test print of the little sail at the top of the front mast to see if it would be practical at 1:250 scale. Came out pretty well. Illustration of the size of the ship at 1:250 scale compared to build plate - so should only need to split it once in the middle. Lots more detail to add - especially the ropes, windows, doors and deck furniture.

-

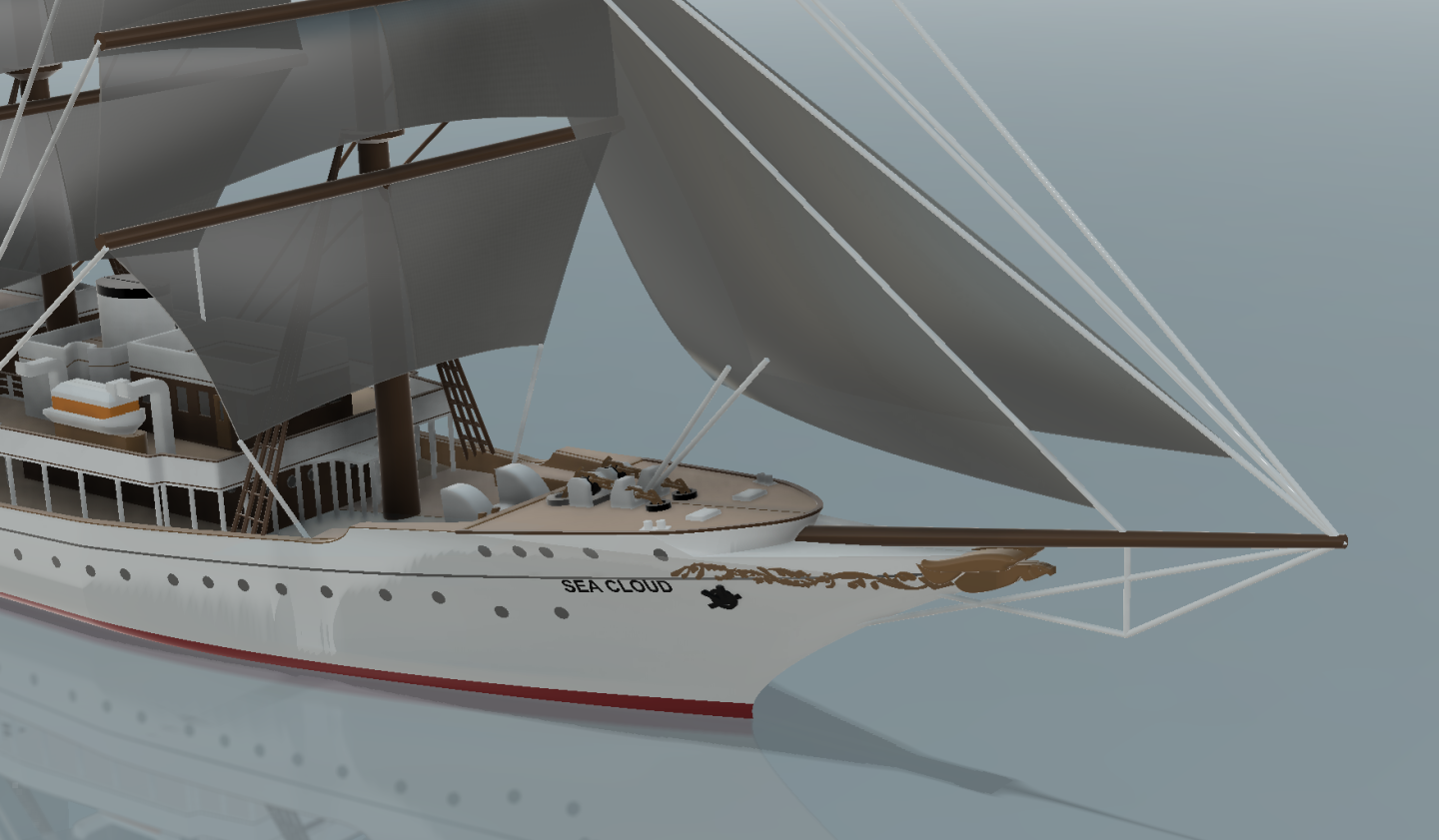

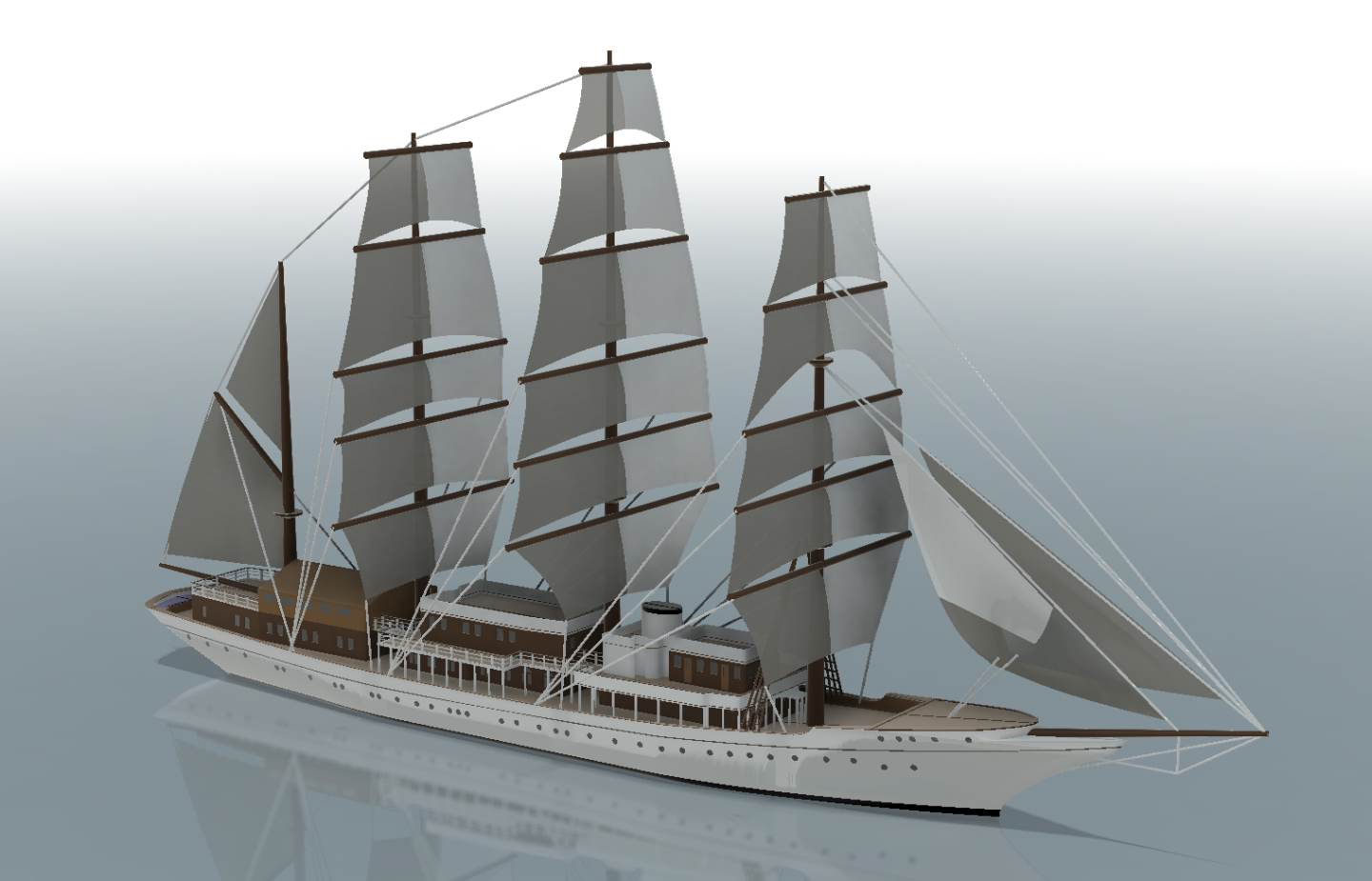

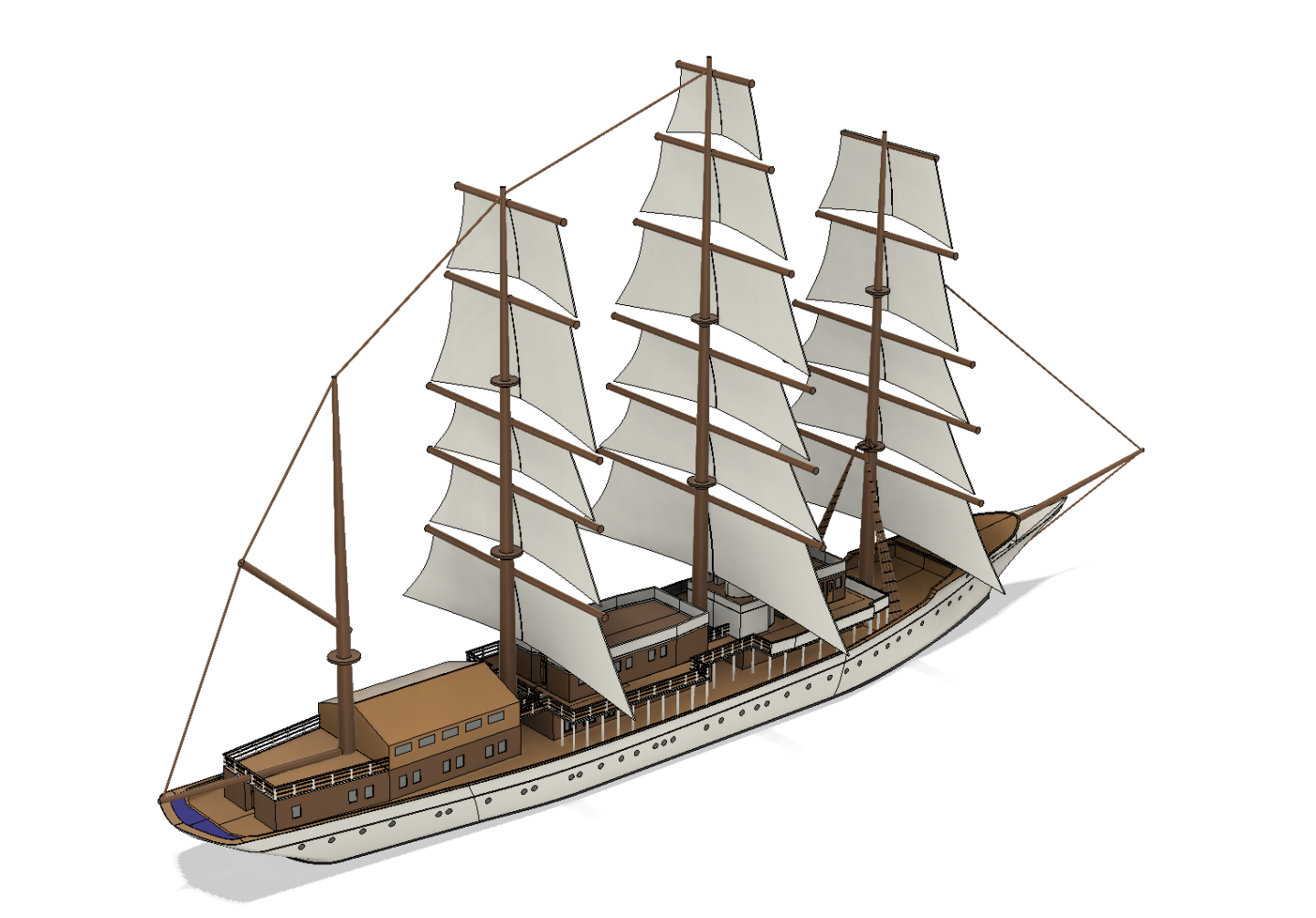

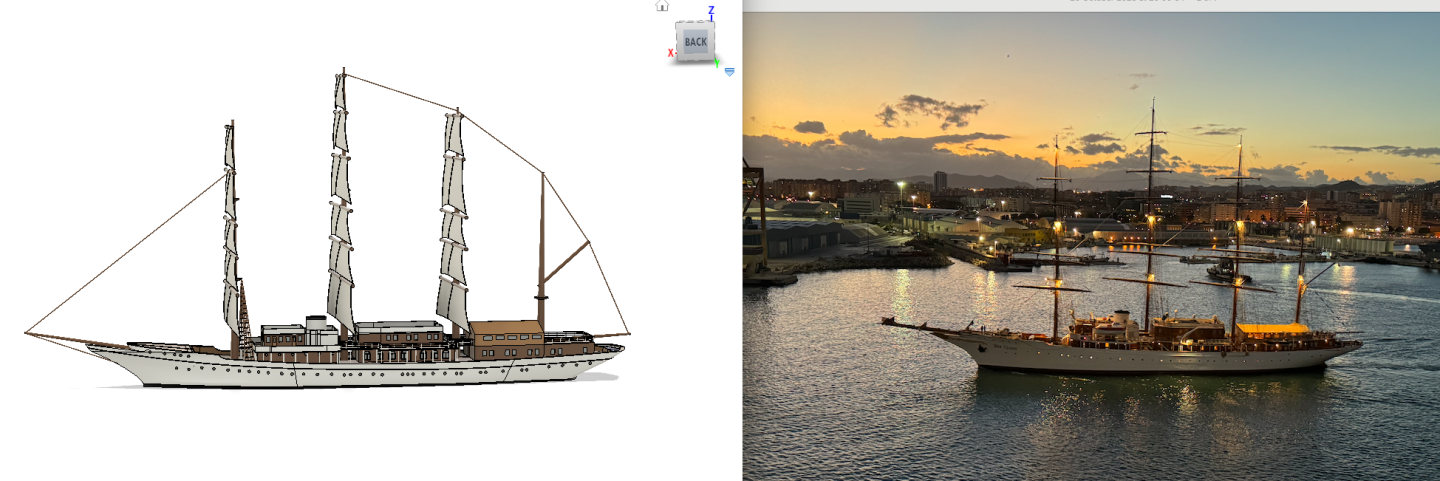

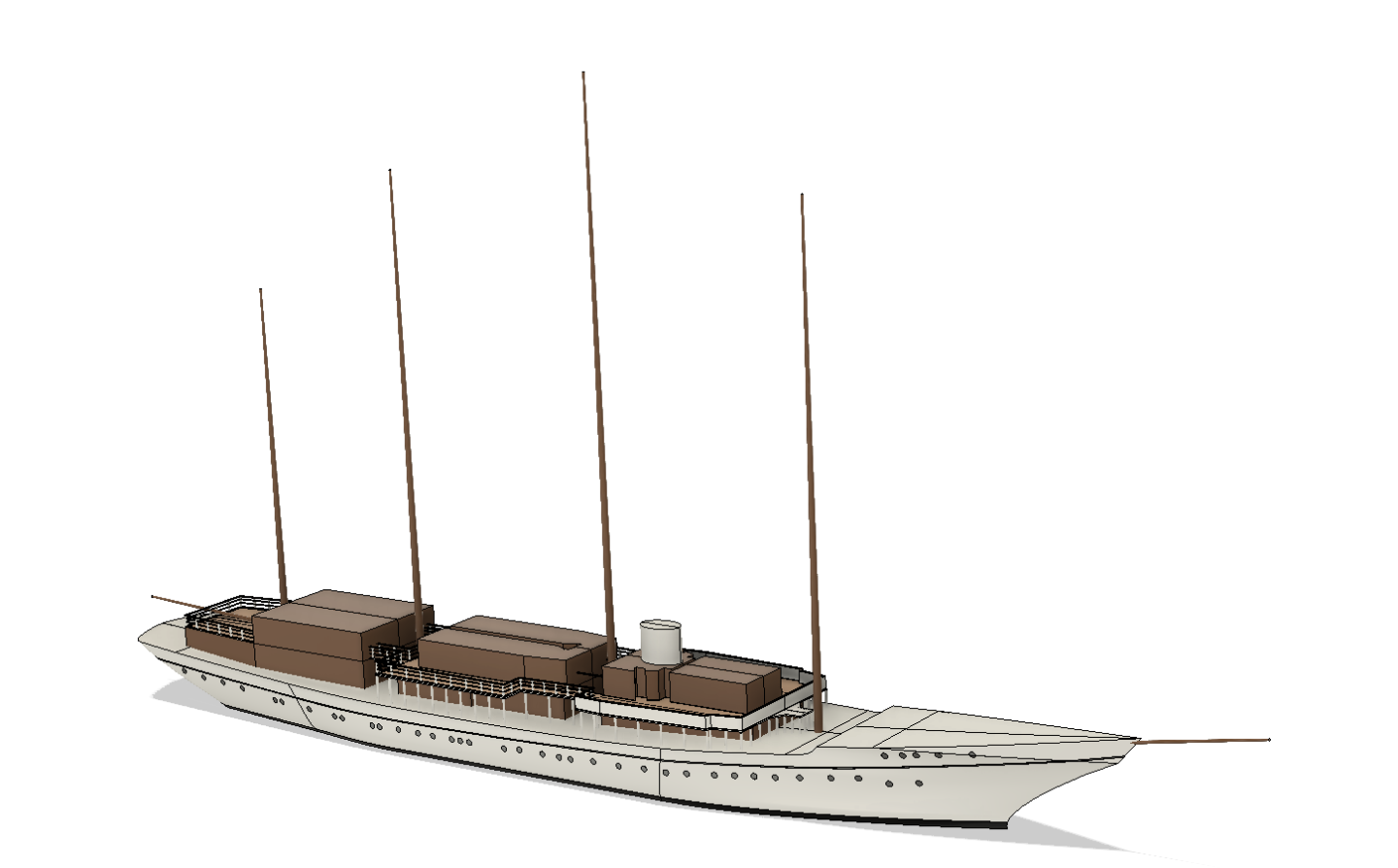

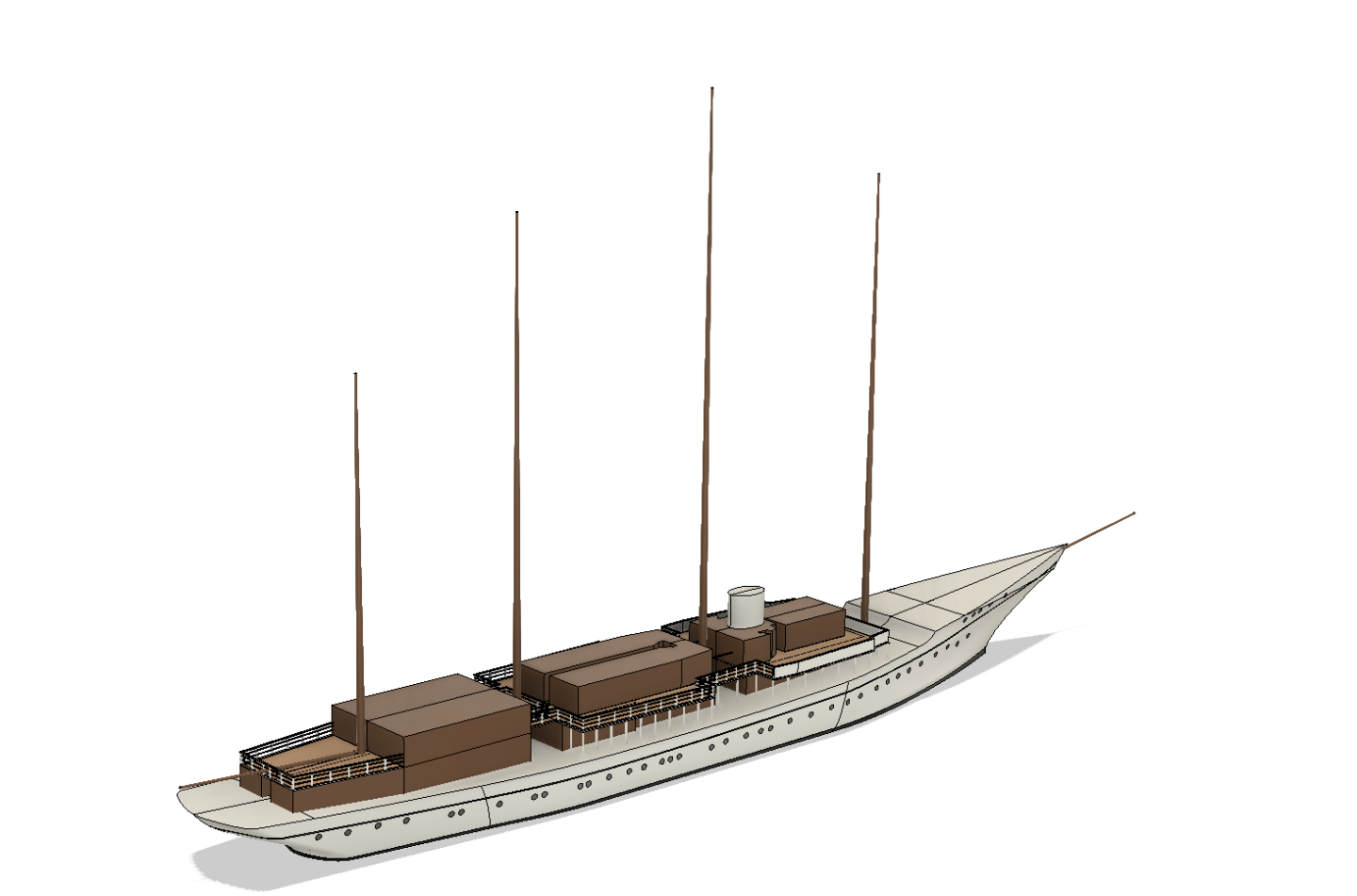

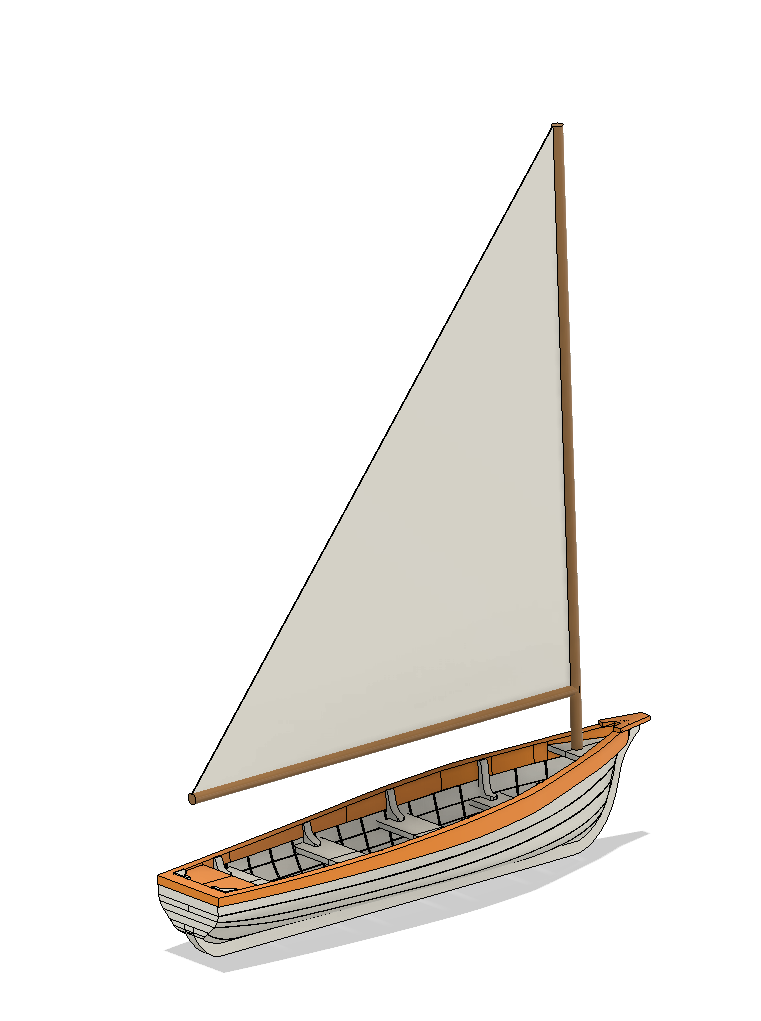

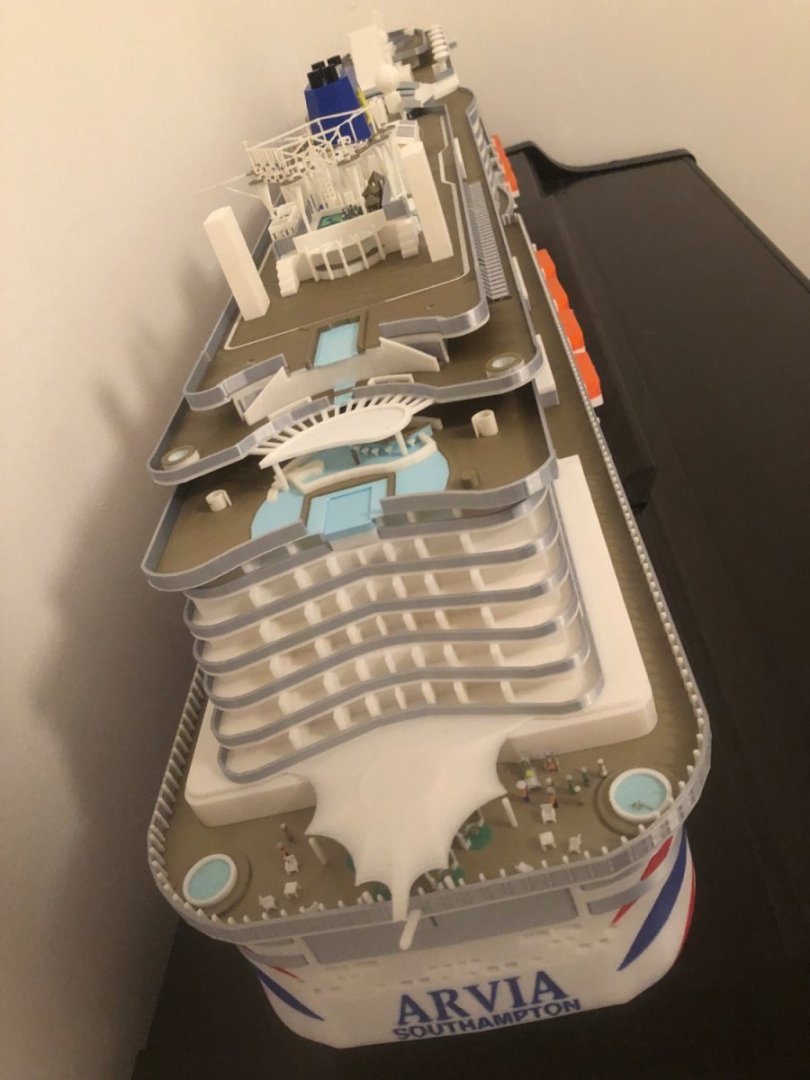

I have started today on a 3d model for 3d printing of Sea Cloud - this 1931 ship is pictured by me last year in Malaga and Cadiz. (from P&O Cruises Azura). The design will be done in Autodesk Fusion 360 and then printed multi colour on a 3d printer. This will be my first sailed ship and previous cruise ship models I have produced are all more recent ships. First prototype picture of a test ship with sail attached too. Background info on the ship here - with pictures of the ship in full sail and details of its fairly long history. https://www.seacloud.com/en/sea-cloud/ My most recent conventional cruise ship model is here - this is a 1:500 version of Cunard Queen Victoria. This ship is about 300m long and the model about 60cm long - vs Sea Cloud being 109m long - so the 1:250 Sea Cloud model will be about 2/3 of the length of this model or about 42cm. Might decide to increase the scale a bit if the detail proves challenging to model/print at 1:250.

-

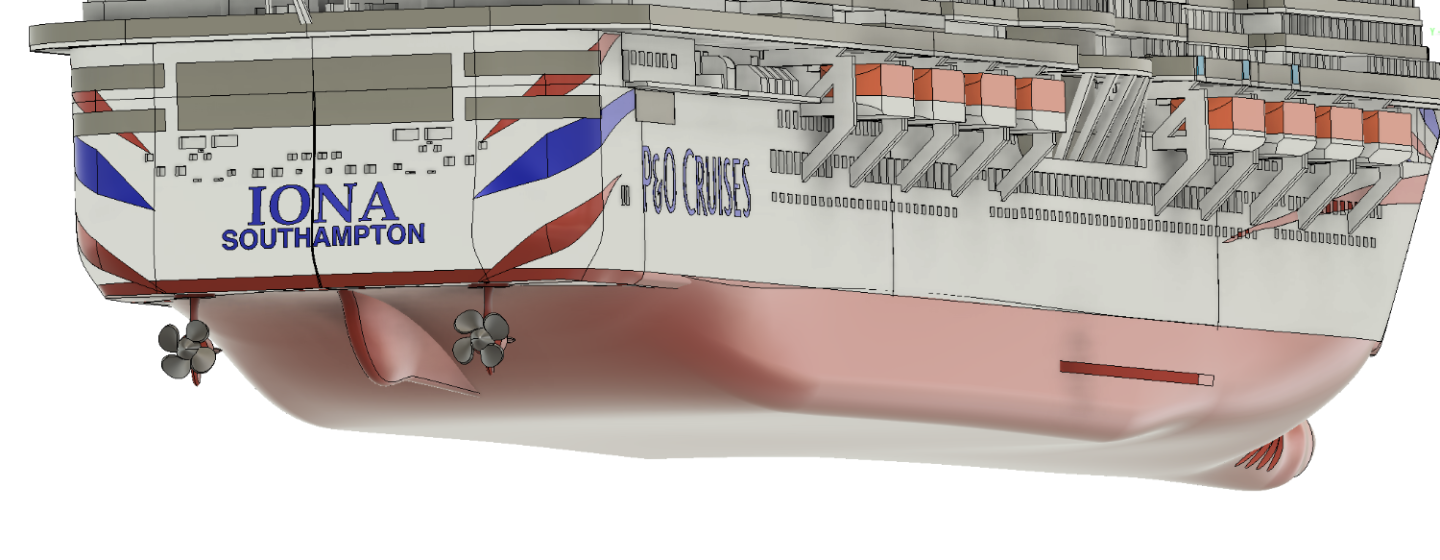

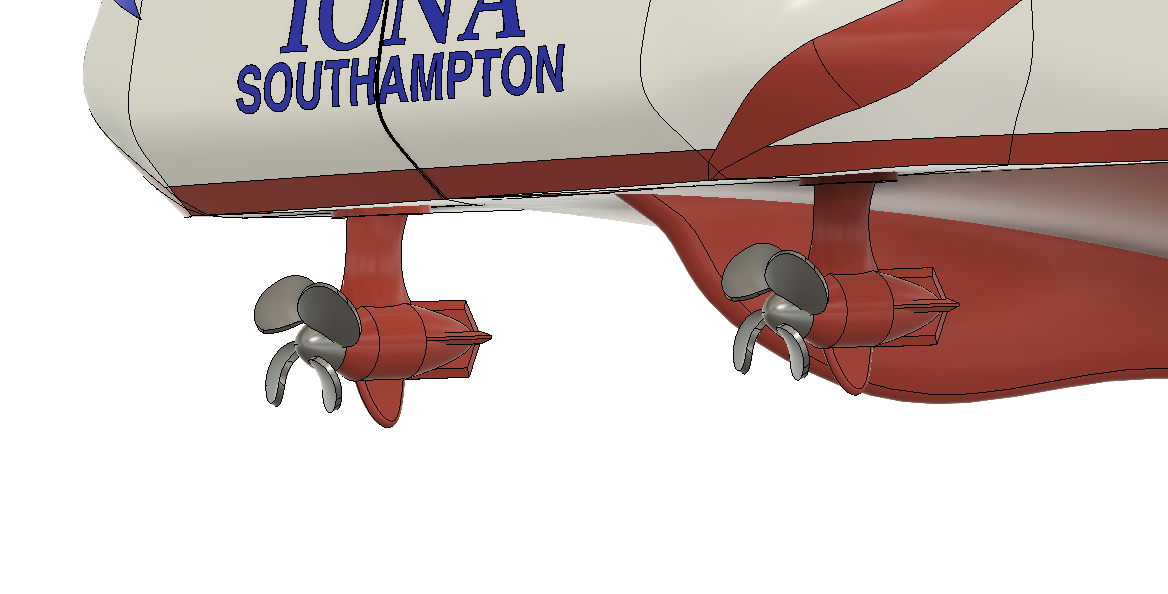

Good progress made today on printing the underwater hull. One of the biggest problems is that the Azipods are so small - but managed to get them to work - prints a little bit stringy - but I think I can clean them up. 1:1000 version (which is 1/4 of the size of the big ship in this thread) now more or less complete - just need to do a final reporting tomorrow with the bow thruster props and stabilisers too.

-

Great thanks for the feedback and you are correct I thought those signs on the side mean't there were thrusters there, so will remove them. Plus will also angle the fins down a bit. Also I think I need to change the direction of the propellors too on one of the azipods and two of the remaining thrusters.

-

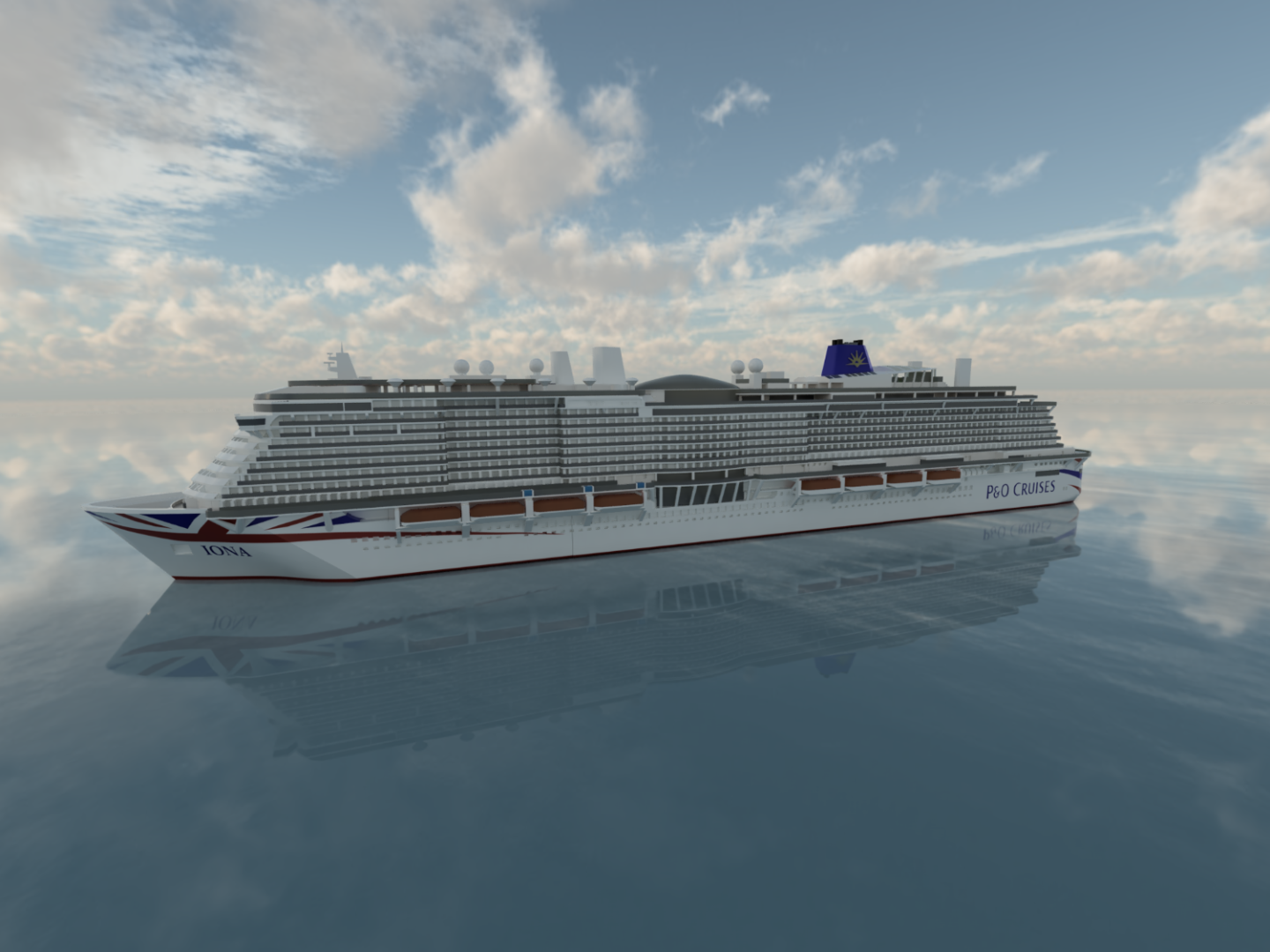

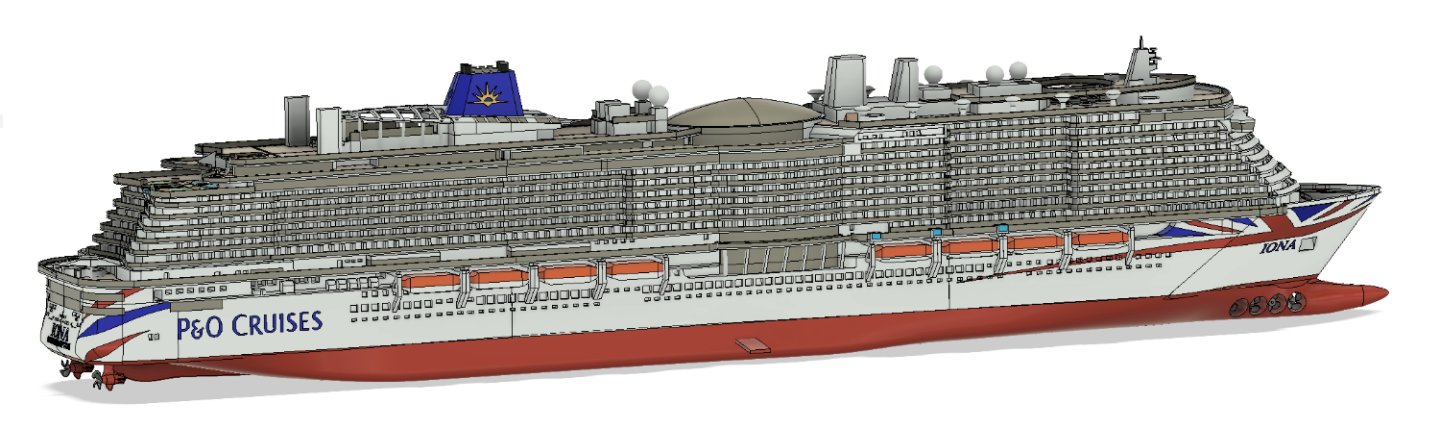

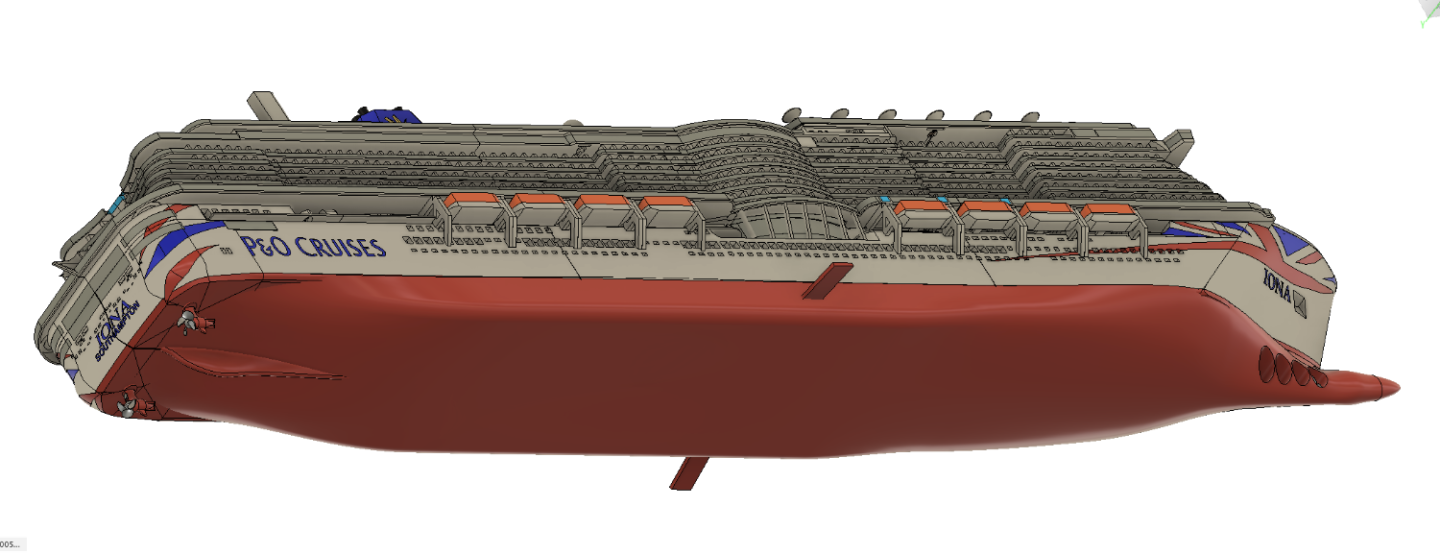

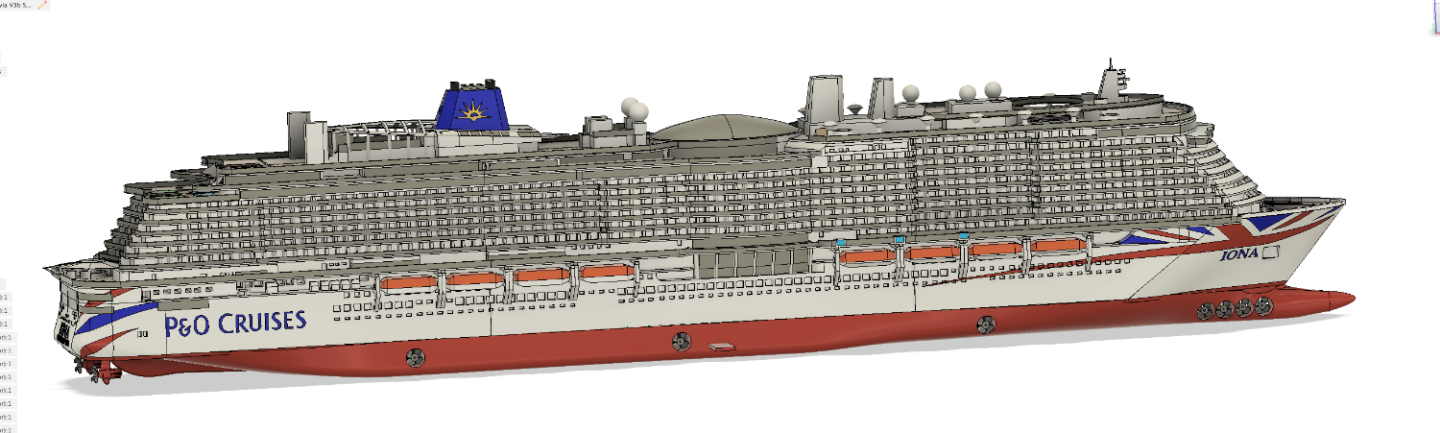

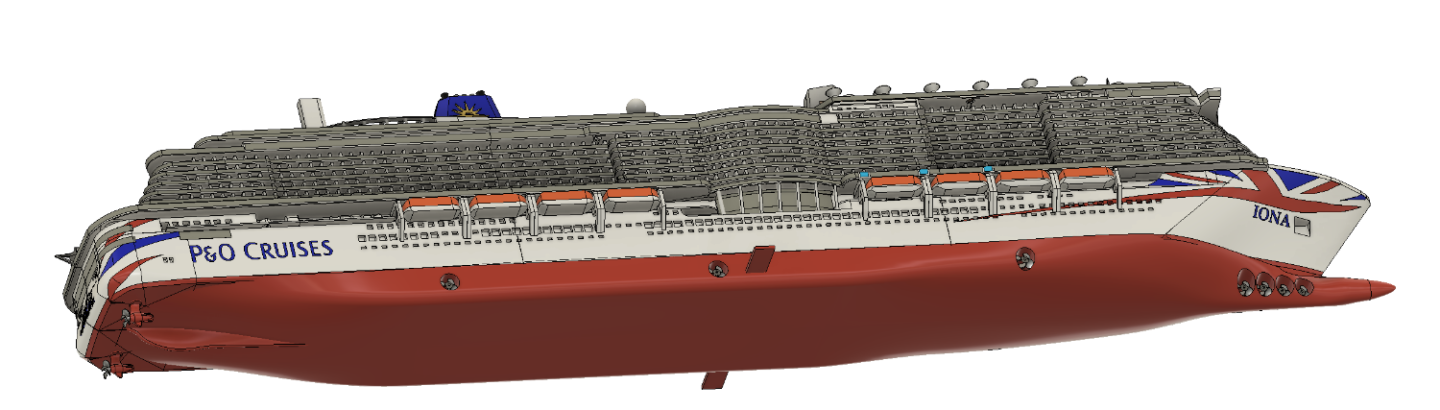

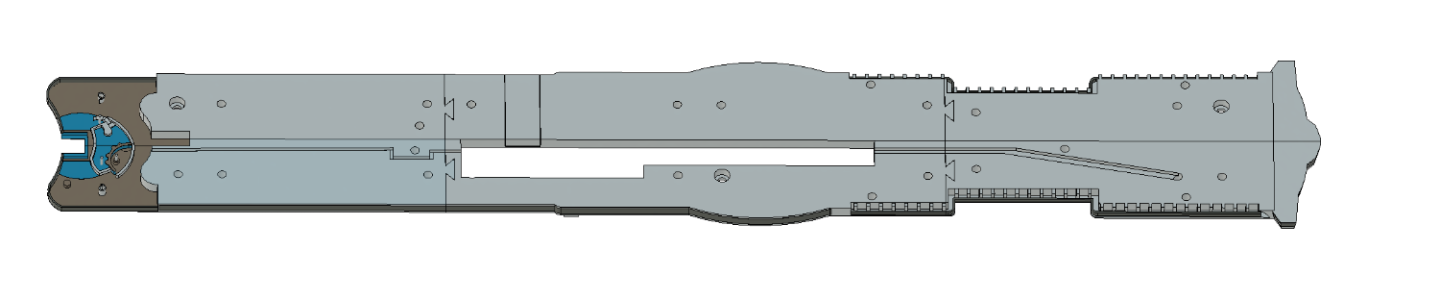

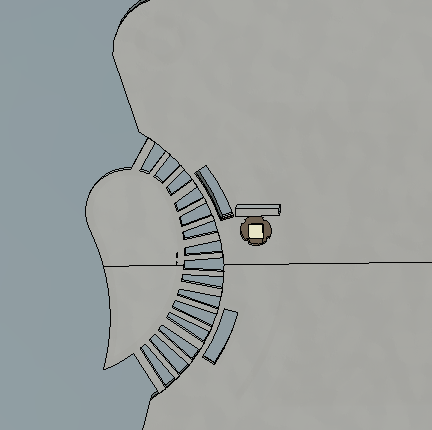

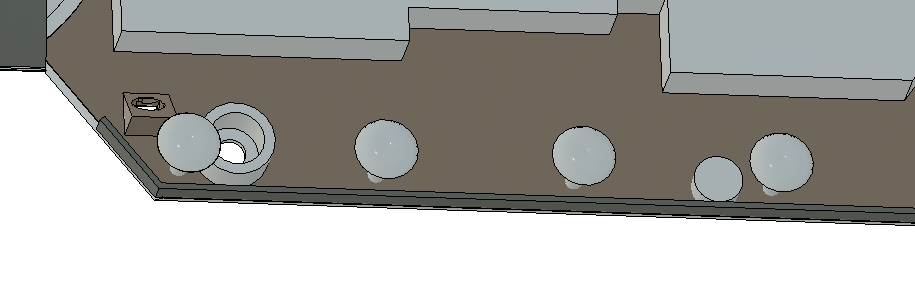

Finally got round to modelling the underwater parts of Arvia - presented in this pictures underneath Iona - as I assume the two sisters are probably identical under the water. Not sure if I have got the proportions correct, shapes quite right, or whether I have missed any bits. Will probably just apply these additions to my 1:1000 versions initially. Got the shapes from various photos on Cruise Critic and YouTube. May contact yard as suggested a few months ago - with this pictures to see if they are willing to help with better pictures or plans.

-

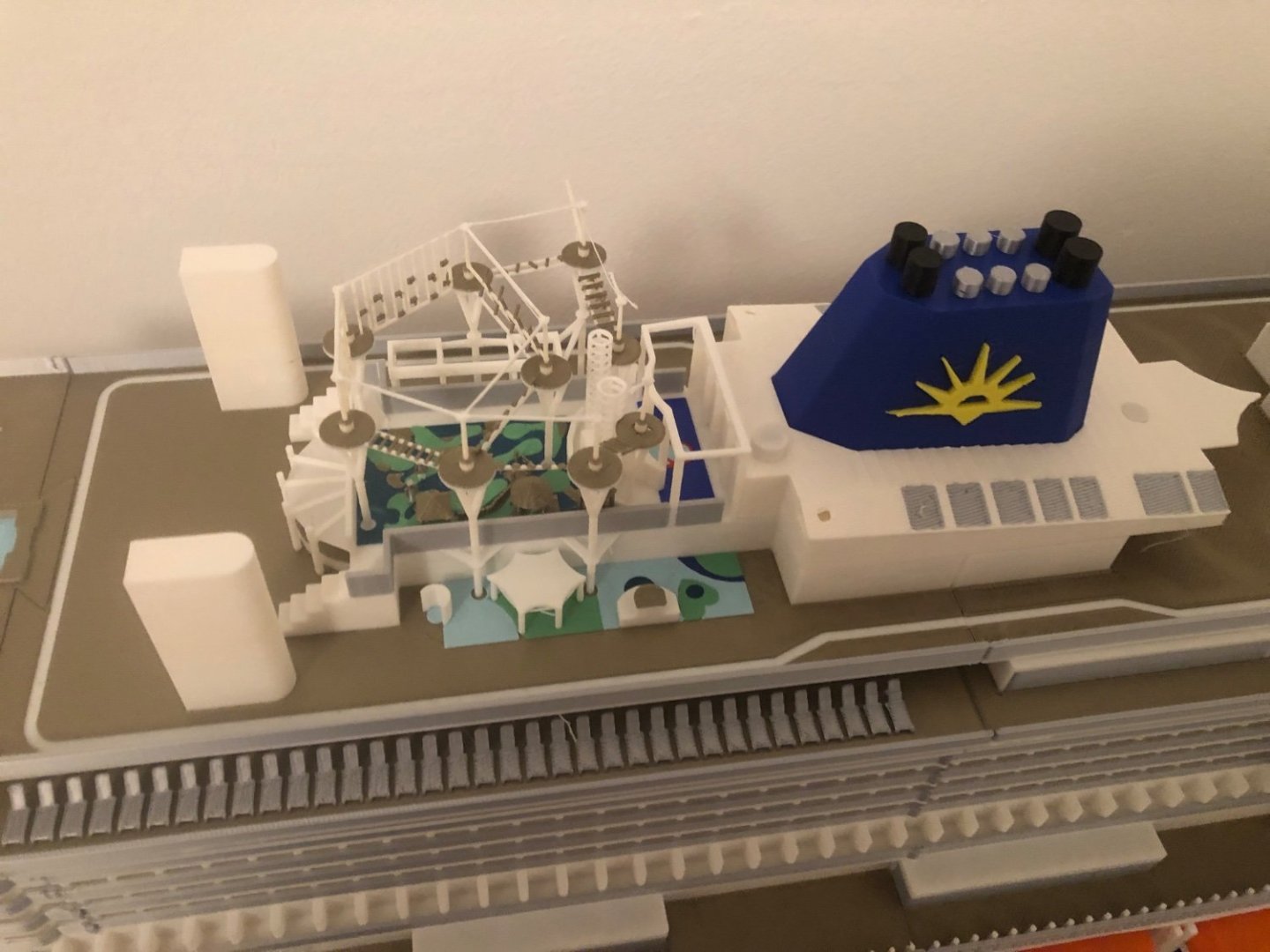

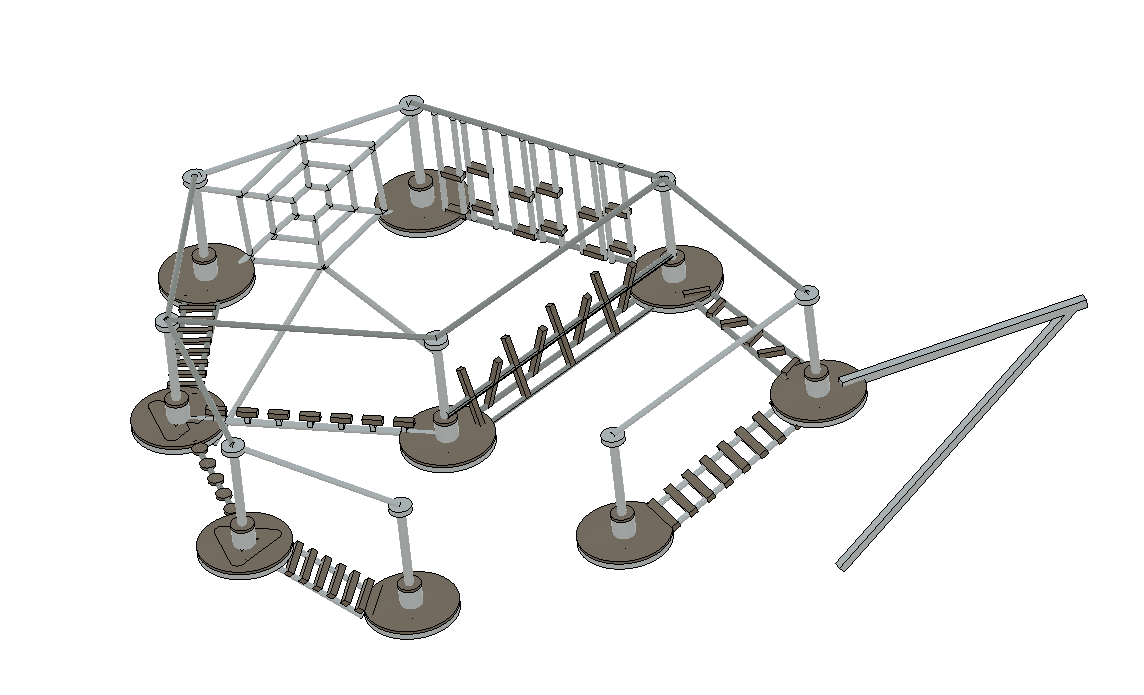

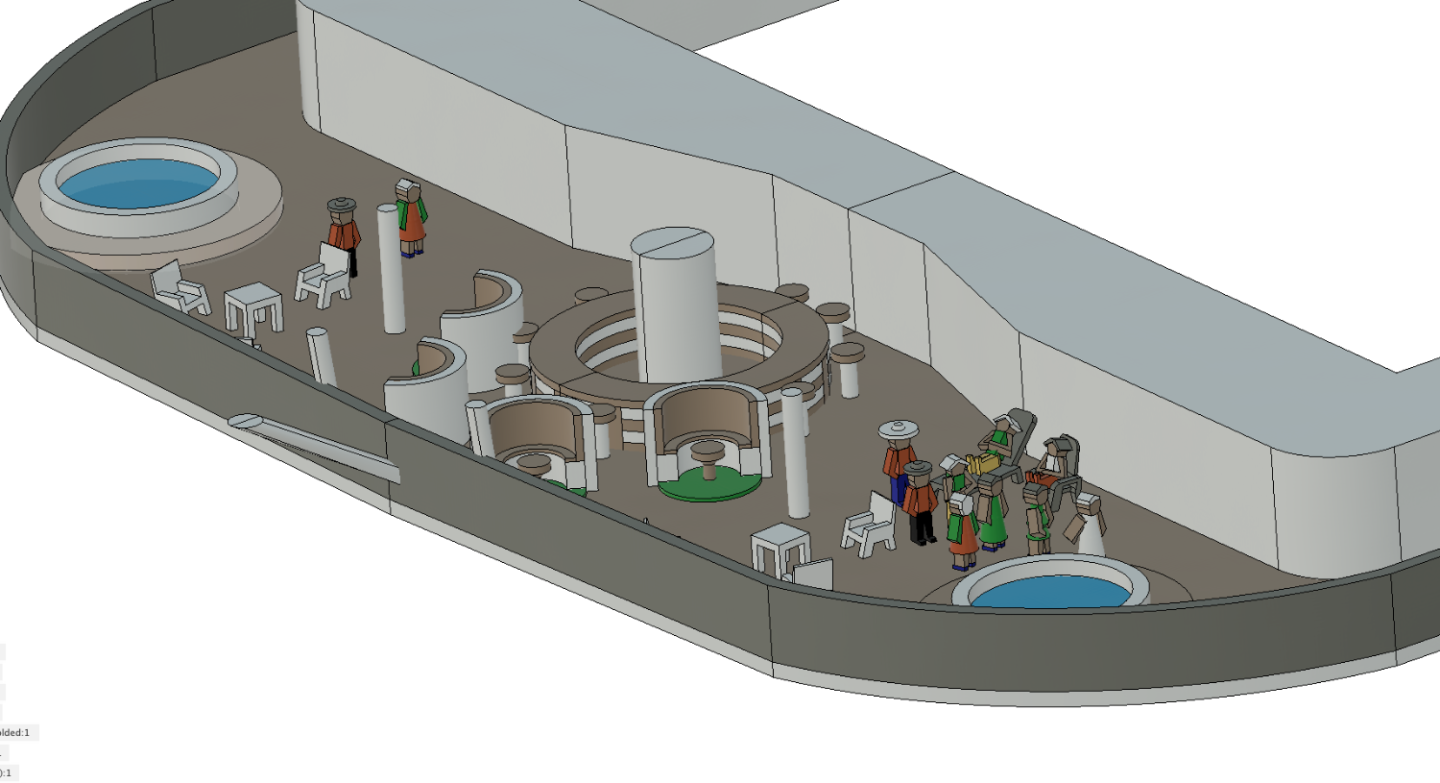

Just discovered this fantastic thread on Cruise Community. Arvia Construction wish I'd found it earlier - but will be very useful for later below waterline additions. Plus I think I will also try and break the 1:1000 version into real sections as they were delivered - might try making a video that intersperses the parts being delivered and then being built up one by one. Deck build up continuing to progress nicely - also interesting to see the difference in scale between this 1:250 model and the 1:1000 P&O Cruises Ventura model that I am also working on. Its a slightly smaller ship - but looks tiny compared to Ariva 250. Next stage is to Model more detail into Deck16 before I can print it- particularly the swim up bar at the back.

-

Sorry about that - mine didn't seem to appear at first, but it is now coming up in the 'Overview section' - just beneath 'content view behavour'

-

Haha - Given the lack of interest in the 1:500 models I published - probably won't bother releasing 1:250 models any time soon. Plus this will probably be the only one I do myself as printing it is taking weeks to print the 100+ plates, plus I don't have the space for too many. I am however going to opposite direction - currently prototyping a 1:1000 version of Ventura that you can print on a single plate. About 6 hrs printing time single colour and about 20hrs multi colour.

-

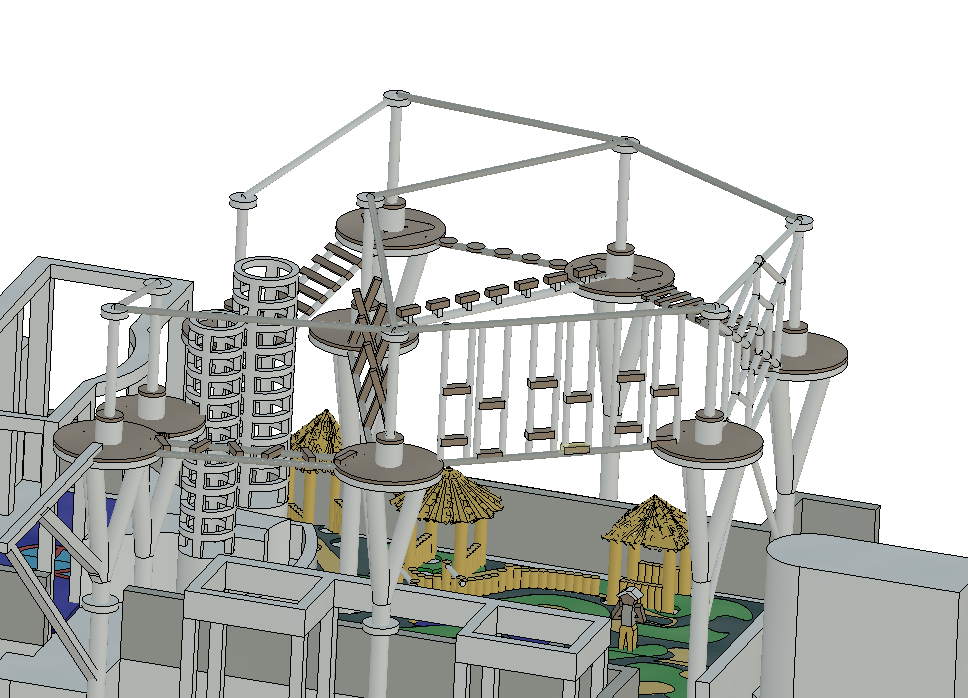

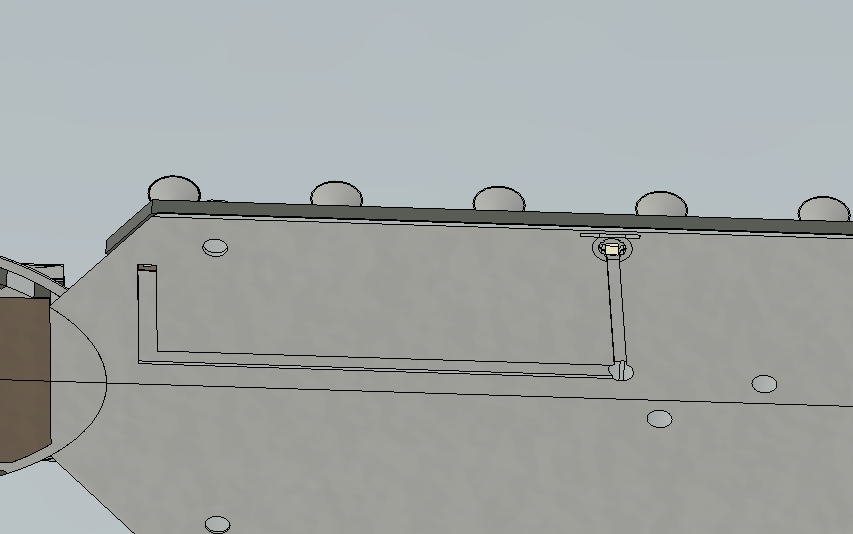

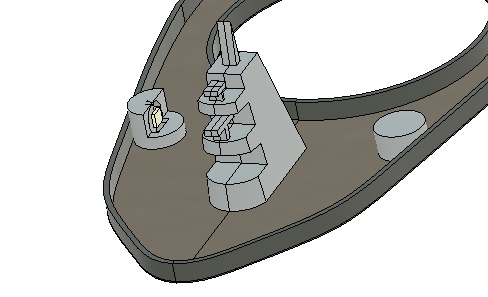

Now up to deck 11, with deck 12-15 ready to print (Luckily the middle 4 sections of deck 10-15 are all identical). Had some challenges with Fusion 360 - particularly relating to changing my deck section joining method over from 'tight dovetails' to mostly 'springy T slot' (other than the centre joint with is a 'loose dovetail' to allow for dissassembly. Quite pleased with furniture demo on Promenade deck, and example person in controversial 'Balcony Mini Suite'. Will likely also create a 1:1250 version of Arvia model too - as _CNPICs on printables has printed my Iona 1:500 model single colour in one go at 1:1250 and it came out surprisingly well. Iona 1:1250 print.

-

From a distance and with my eye sight deck8 stern print looking pretty good. Could perhaps refine the tiny models a little bit or maybe use a different filament for the arms - its PLA Metal. Still quite pleased with the results. Back section took about 8 hrs to print. Back section of deck 8 printed on 0.4mm nozzle, rest of ship so far all printed on 0.6mm Nozzle.

-

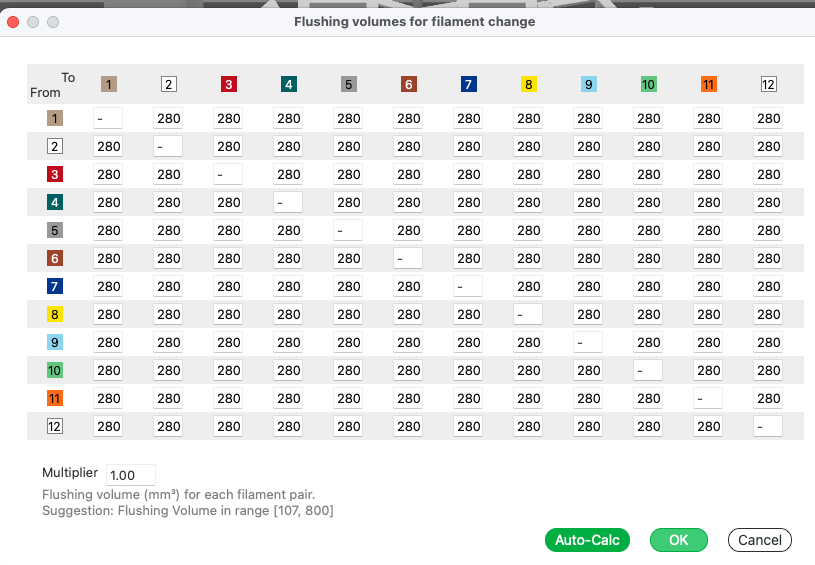

Quite a few changes to design required to incorporate wiring for LED lighting. Lessons learned. 1. Don't leave floors too thin when adding in cable runs - otherwise reprints will be required 2. Making the internals of the ship more hollow would make it much easier to add things like lighting for other future models. 3. Doing cable runs below decks is easier to manage than above - as wires can be taped in place before decks are bolted down 4. Allow inter deck holes to be big enough to accommodate shrink wrapped extensions to smaller wires 5. Make designs for LED holders more generic - to allow for changes to lights - and add ons such as individually addressable LEDs. 6. Consider having the collection point for the wiring at the bottom rather than near the top - so it is easier to handle wiring without having to worry about hiding it. 7. Check that cable routes are efficient and won't result in the need for extensions. 7. Consider adding wireless inter deck wiring interconnects like these in future designs - to make putting the model together, taking it apart and maintenance. Changes made to design to incorporate wiring + LED holders Deck7. - New channels and LED Holder Deck8 - new channels Deck16 - with space to wiring hub Deck17 - LED holder Deck18 Deck19 Funnel

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.