David_T

Members-

Posts

6 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

JacquesCousteau reacted to a post in a topic:

Polaris by David_T - OcCre

JacquesCousteau reacted to a post in a topic:

Polaris by David_T - OcCre

-

Polaris by David_T - OcCre

David_T replied to David_T's topic in - Kit build logs for subjects built from 1801 - 1850

Thank you for the suggestions Snug Harbor. Unfortunately, events continued between my post and yours. 🙃 I read about that in another thread (apologies for not remembering where), but not confident enough in my creative side to attempt this. The deck has been attached to the false keel with the plank pattern suggested by OcCre. I also struggled to obtain a consistent peg hole size and alignment. I've made a note to create a template for the next project. While test fitting the deck, bending the deck revealed another place where the glue didn't hold. That was solved with a little bit of super glue. Unlike other's people's experience, I was surprised that the ribs fit into the deck cutouts with a soothing click. Glue and clamps were applied and I waited. Over the weekend, the battens (?) were glued in place at the bow and stern. Last night, the sanding began on the bow blocks. Comparing my bow profile to some other builds suggests I have the wrong profile. A test fit shows larger gap between the bow and plank that I think should there. It looks like I need to take more from the from the portion of the batten hidden by my finger. One deck plank at the bow was loose. I'll start sanding the stern when time permits and gauge my progress with planks. Regards, David -

chadwijm6 reacted to a post in a topic:

Polaris by Cenizas - OcCre - First Build

chadwijm6 reacted to a post in a topic:

Polaris by Cenizas - OcCre - First Build

-

Hello James; Looks like our projects are of similar vintages. Keep at it. David

- 10 replies

-

- OcCre

- First Build

-

(and 1 more)

Tagged with:

-

ibozev reacted to a post in a topic:

Polaris by David_T - OcCre

ibozev reacted to a post in a topic:

Polaris by David_T - OcCre

-

JacquesCousteau reacted to a post in a topic:

Polaris by David_T - OcCre

JacquesCousteau reacted to a post in a topic:

Polaris by David_T - OcCre

-

JacquesCousteau reacted to a post in a topic:

Polaris by David_T - OcCre

JacquesCousteau reacted to a post in a topic:

Polaris by David_T - OcCre

-

David_T started following Polaris by David_T - OcCre

-

Polaris by David_T - OcCre

David_T replied to David_T's topic in - Kit build logs for subjects built from 1801 - 1850

Finished gluing the deck boards to the boat last night. Started with a tube of Le Page's contact cement spread with a brush. It was too sticky and created a 'mask' that pulled away from the wood when removing the planks from the 'contact cement application jig' suggested by OcCre. After laying down the first side, I started on the next side but used a new can of LePage's contact cement. After laying down the glue, I realized I hadn't removed the planking material covering the mast hole. After all the planks were down, I used a wooden handle to press down on the planks. I was a too heavy handed - in the picture you can see the tool marks. While trimming the excess planks, I came across 4 or 5 places where the tips of the planks where attached to the deck plate. I used Lepage No clamp glue to attach them. (I would have used super glue, but none was found at my regular store when the contact cement was purchased.) This glue had a firmer consistency then the regular white glue. I had to do this over again, I would use this for the deck planking as I able to apply it precisely. After sanding the deck smooth, I notice a few places where the contact cement "mask" caused gaps between deck boards. I hope to fill those with gaps with saw dust of very fine super glue. Before calling it a night, drying fitting the masts and the deck to the skeleton didn't show any problems. The sandpaper I'm using is not bringing me joy - but it could be me and not the sandpaper. I've been using 320 grit which is much finer than I used to using and find the sheets wearing out quicker than expected. Some experimenting will be required with different girt and brands. Cheers, David -

ibozev reacted to a post in a topic:

Polaris by David_T - OcCre

ibozev reacted to a post in a topic:

Polaris by David_T - OcCre

-

ccoyle reacted to a post in a topic:

Polaris by David_T - OcCre

ccoyle reacted to a post in a topic:

Polaris by David_T - OcCre

-

SighingDutchman reacted to a post in a topic:

Polaris by David_T - OcCre

SighingDutchman reacted to a post in a topic:

Polaris by David_T - OcCre

-

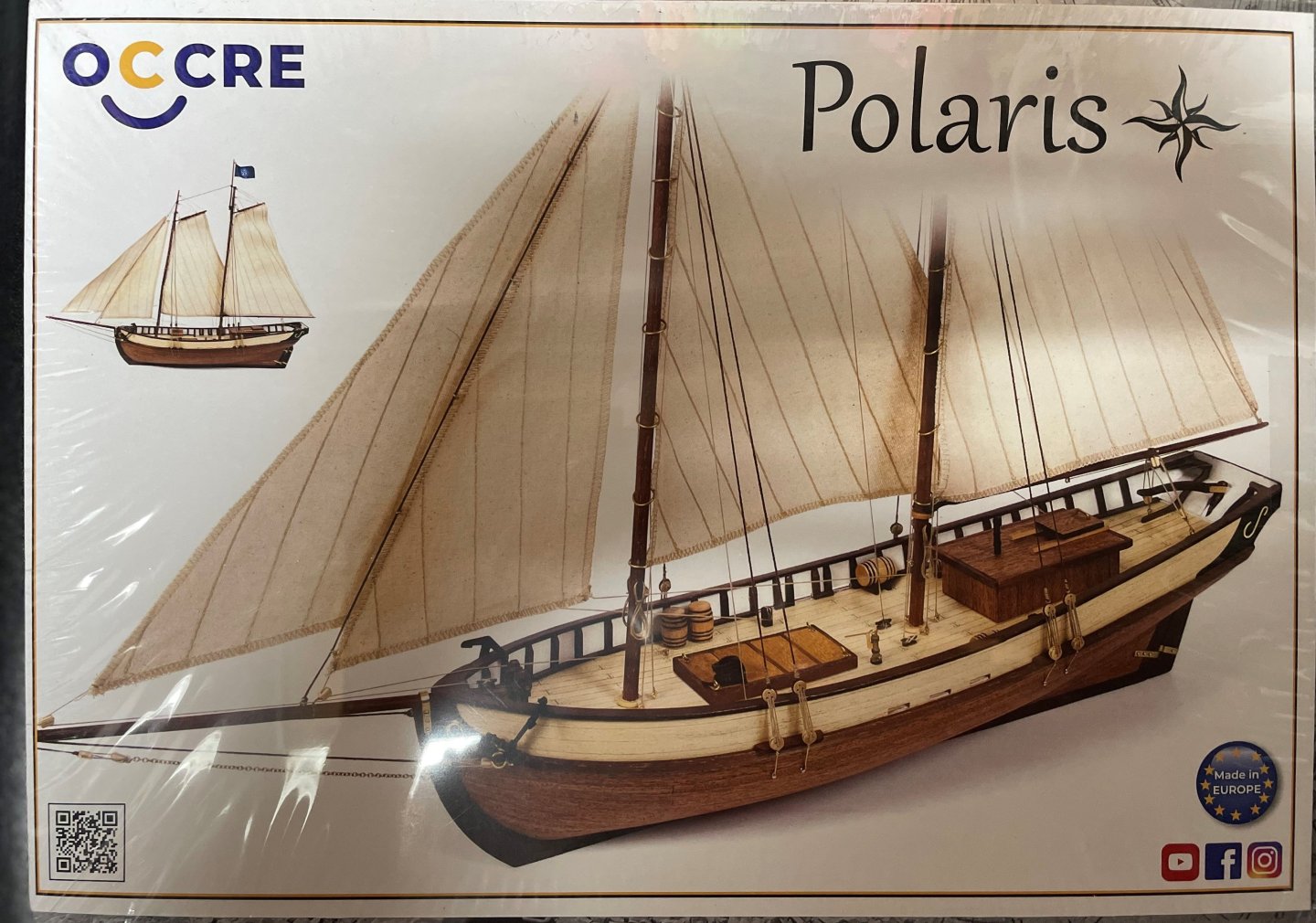

Hello; Over the weekend, I began work on OcCre's Polaris. I choose this model as it appear to a good kit for a beginner. There was one for sale in the area that I purchased last week. I have looked over amazing build logs of this ship that have been book marked for future reference. It seems the place to start is a picture of the box. The following weekend, I opened the box and checked that all the pieces were present and counted. The false keel had a very small bend in the middle but didn't seem to be a bad as others have shared. After gluing the ribs in place, I learned two things; use less glue and buy white glue. Not shown in the picture are the corner pieces I used to square the ribs to the feel. They are were to big to glue more than rib at a time. While waiting for each rib to dry, I managed to get the deck plates marked up with a 7 HB pencil and marked the center line on the deck plate. Sunday was a trip to store to buy wood glue that dry's clear and some contact cement. Comments and critiques are welcomed. David

-

KevinR reacted to a post in a topic:

Hello from Winnipeg

KevinR reacted to a post in a topic:

Hello from Winnipeg

-

SiriusVoyager reacted to a post in a topic:

Hello from Winnipeg

SiriusVoyager reacted to a post in a topic:

Hello from Winnipeg

-

Hello everyone; Last summer, I decide to try my hand at a wooden ship, again. My first experience ended in a failure, but I never gave up the dream of completing a wooden ship. I settled on trying my hand with Occre's Polaris. (Build log should start soon) Since joining MSW in November, I've been lurking around and learning. I have seen some lovely builds that have been bookmarked for reference. I have also looked at builds of ships and such that I had never considered building. It's with awe that I look at the talent and experience that was on display. I don't spend much time on social media sites, but this one has a friendly vibe. (Shout out the moderators and members) On the personal side, I'm an middle aged accountant that likes to read and visit with his family. The Admiral likes to scrapbook. Cheers, David

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.