-

Posts

8,557 -

Joined

-

Last visited

About ccoyle

- Birthday 08/15/1963

Profile Information

-

Gender

Male

-

Location

Greer, South Carolina

-

Interests

model building, hunting, fishing, reading, genealogy

Recent Profile Visitors

-

Dave_E reacted to a post in a topic:

Curtiss P-40K Kittyhawk Mk III by realworkingsailor - Special Hobby - 1/72

Dave_E reacted to a post in a topic:

Curtiss P-40K Kittyhawk Mk III by realworkingsailor - Special Hobby - 1/72

-

Dave_E reacted to a post in a topic:

Hawker Hurricane Mk. I by ccoyle - Halinski - 1/33 - CARD

Dave_E reacted to a post in a topic:

Hawker Hurricane Mk. I by ccoyle - Halinski - 1/33 - CARD

-

Dave_E reacted to a post in a topic:

Hawker Hurricane Mk. I by ccoyle - Halinski - 1/33 - CARD

Dave_E reacted to a post in a topic:

Hawker Hurricane Mk. I by ccoyle - Halinski - 1/33 - CARD

-

GrandpaPhil reacted to a post in a topic:

Herzogin Cecilie 1902 by Jim Lad - Four Masted Barque

GrandpaPhil reacted to a post in a topic:

Herzogin Cecilie 1902 by Jim Lad - Four Masted Barque

-

scrubbyj427 reacted to a post in a topic:

HMS Sphynx 1775 by Alex M - Scale 1/48 - English 20-Gun Frigate

scrubbyj427 reacted to a post in a topic:

HMS Sphynx 1775 by Alex M - Scale 1/48 - English 20-Gun Frigate

-

ccoyle reacted to a post in a topic:

Curtiss P-40K Kittyhawk Mk III by realworkingsailor - Special Hobby - 1/72

ccoyle reacted to a post in a topic:

Curtiss P-40K Kittyhawk Mk III by realworkingsailor - Special Hobby - 1/72

-

GrandpaPhil reacted to a post in a topic:

Hawker Hurricane Mk. I by ccoyle - Halinski - 1/33 - CARD

GrandpaPhil reacted to a post in a topic:

Hawker Hurricane Mk. I by ccoyle - Halinski - 1/33 - CARD

-

GrandpaPhil reacted to a post in a topic:

Hawker Hurricane Mk. I by ccoyle - Halinski - 1/33 - CARD

GrandpaPhil reacted to a post in a topic:

Hawker Hurricane Mk. I by ccoyle - Halinski - 1/33 - CARD

-

wvdhee reacted to a post in a topic:

Hawker Hurricane Mk. I by ccoyle - Halinski - 1/33 - CARD

wvdhee reacted to a post in a topic:

Hawker Hurricane Mk. I by ccoyle - Halinski - 1/33 - CARD

-

ccoyle reacted to a post in a topic:

Roar Ege by Scottish Guy - Billing Boats - 1:25

ccoyle reacted to a post in a topic:

Roar Ege by Scottish Guy - Billing Boats - 1:25

-

Old Collingwood reacted to a post in a topic:

Curtiss P-40K Kittyhawk Mk III by realworkingsailor - Special Hobby - 1/72

Old Collingwood reacted to a post in a topic:

Curtiss P-40K Kittyhawk Mk III by realworkingsailor - Special Hobby - 1/72

-

ccoyle reacted to a post in a topic:

LA VENUS 1782 by giampieroricci - FINISHED - Scale 1:96 - French Frigate

ccoyle reacted to a post in a topic:

LA VENUS 1782 by giampieroricci - FINISHED - Scale 1:96 - French Frigate

-

Canute reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Canute reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

ccoyle reacted to a post in a topic:

US Brig Oneida 1809 by rlb - The Lumberyard - 1:48 scale - POF - Lake Ontario Warship

ccoyle reacted to a post in a topic:

US Brig Oneida 1809 by rlb - The Lumberyard - 1:48 scale - POF - Lake Ontario Warship

-

ccoyle reacted to a post in a topic:

AEG G.IV - Creature of the Night by DocRob - Wingnut Wings - 1/32

ccoyle reacted to a post in a topic:

AEG G.IV - Creature of the Night by DocRob - Wingnut Wings - 1/32

-

ccoyle reacted to a post in a topic:

Le Cerf by Moxis - FINISHED - 1/48 scale - French cutter

ccoyle reacted to a post in a topic:

Le Cerf by Moxis - FINISHED - 1/48 scale - French cutter

-

ccoyle reacted to a post in a topic:

Xebec by mij - FINISHED - 1:60 scale

ccoyle reacted to a post in a topic:

Xebec by mij - FINISHED - 1:60 scale

-

ccoyle reacted to a post in a topic:

HMS Dragon 1760 by Siggi52 - FINISHED - Scale 1:48 - English 74-Gun ship

ccoyle reacted to a post in a topic:

HMS Dragon 1760 by Siggi52 - FINISHED - Scale 1:48 - English 74-Gun ship

-

ccoyle reacted to a post in a topic:

HMS Beagle by brunnels - OcCre - 1:60 - first build

ccoyle reacted to a post in a topic:

HMS Beagle by brunnels - OcCre - 1:60 - first build

-

Researching family military history in the various records can be very rewarding. When I began doing genealogy work years ago, no one in my immediate family had any knowledge of our family's service prior to WW2. Through unit roll calls and a variety of other sources, I was able to piece together my 2x-great grandfather's service in the Palmetto Sharpshooters during the 'Late Unpleasantness'. I was very surprised to learn that the PSS were a highly regarded unit within the Confederate armed forces and fought in many of its bloodiest engagements, including Second Manassas, the Peninsula Campaign, Antietam, and The Wilderness. I'm sure my ancestor could have recounted many harrowing tales, but sadly I have no evidence suggesting he ever left any written accounts. Good luck on both your projects!

-

I already feel a connection to this ship. John Dolbeer invented the steam donkey in Eureka, California, in 1881 for use in Humboldt County's redwood forests. Dolbeer was a partner in the Dolbeer and Carson Lumber Company. The now-defunct company's timber holdings were sold off long ago. I had the good fortune to work on some of them back in my fish habitat restoration days. William Carson had a home built, the Carson Mansion, which is one of the most famous and most photographed examples of Victorian architecture. The site of Carson & Dolbeer's main mill in Eureka is now occupied by a community center and boardwalk.

-

Happy birthday? 😬 Hope everything heals up quickly!

- 97 replies

-

- Cutty Sark

- plastic

-

(and 3 more)

Tagged with:

-

Hawker Hurricane Mk. I by ccoyle - Halinski - 1/33 - CARD

ccoyle replied to ccoyle's topic in Non-ship/categorised builds

-

Hawker Hurricane Mk. I by ccoyle - Halinski - 1/33 - CARD

ccoyle replied to ccoyle's topic in Non-ship/categorised builds

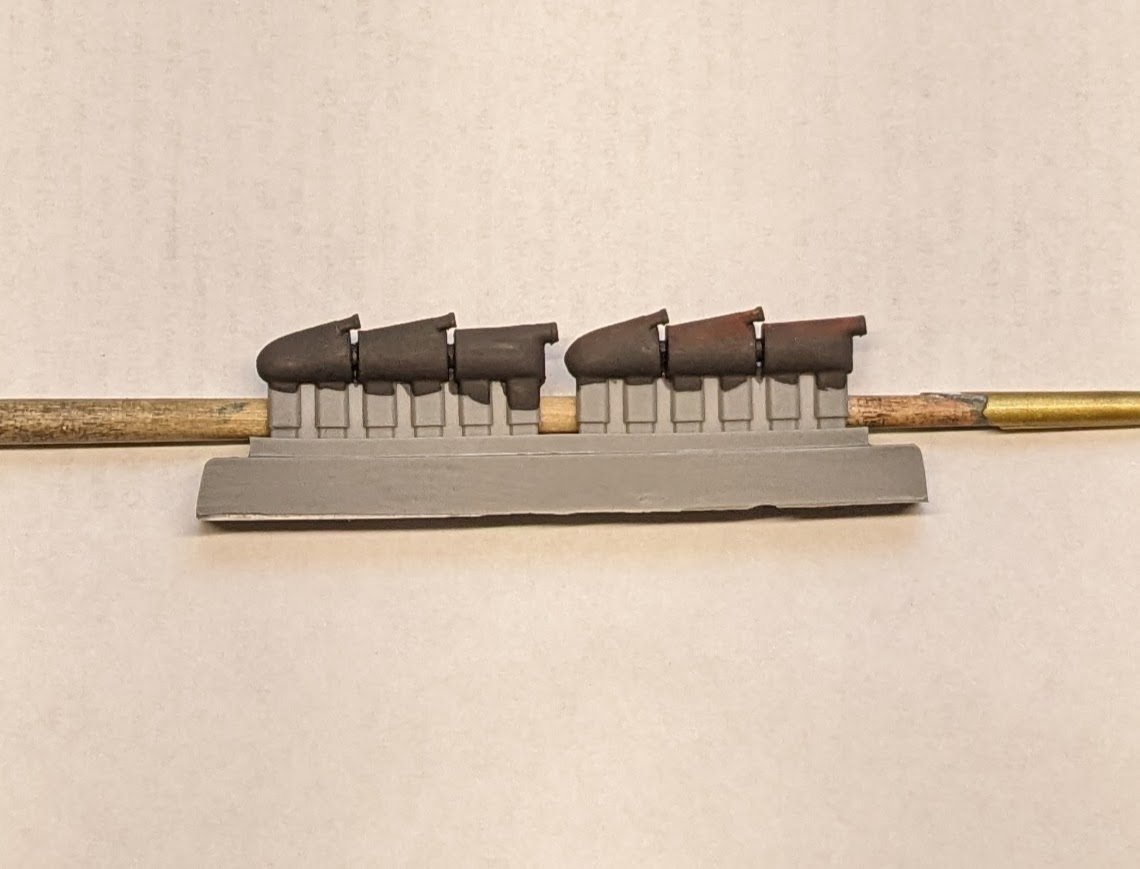

The resin exhaust stubs arrived today. It turns out that Squadron.com is down the road a bit from me in Ellijay, Georgia, where my Granny Coyle's family was originally from -- small world. I gave the exhausts a bath in soap and water, just in case there was any residual releasing agent, then painted them a suitably dingy shade of brown. After that dried, I tried my hand at grunging them up a bit. The forward stack should be the least corroded, for obvious reasons. Here's how the first set turned out (right), compared to the still un-grunged second set (left). As per usual, the cellphone cam image washes things out a bit. I don't want to over-do the effect. BTW, there is a negligible difference in size between the 1/33 scale paper parts and their 1/32 scale replacements. I will need to do some cutting into the fuselage to fit the new stacks -- shouldn't be too arduous (fingers crossed). -

Outstanding! I think I may need to pry the padlock off my wallet!

- 9 replies

-

- Speeljacht

- card

-

(and 1 more)

Tagged with:

-

@0Seahorse Tomek, do you have a target release date for this kit? I know a guy who might be very interested in purchasing a copy! 😉

- 9 replies

-

- Speeljacht

- card

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.