-

Posts

50 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Ship_Right

-

Well it's been a while since I posted. It is now January 2026, and I am finally back in the shipyard. I wasn't really looking forward to this next job. I had created the davit arms, and then wasn't sure about my approach to installing them. And there are eight of them ... As is often the case, once I started working on them it didn't take me as long as I thought it would. As others have pointed out, the straight davits supplied in the kit are not what appear on sketches of the actual ship. As I read it, the curved davits were installed as part of the refit prior to Erebus heading for the Arctic - but I'm of the opinion that she also carried straight davits that could be installed or removed as needed. I have simply installed four pairs of davits towards the stern as you can see on the attached photos.

- 74 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

-

Just to reassure everyone who visits this build log: I've been away from the shipyard for a few weeks (except for spray painting some metal parts with etching primer, ready for a coat of paint) to complete some home projects that needed my attention, plus a week at "the cottage", a place we rent every year at Sauble Beach where the ice cream is delicious and the sunsets over Lake Huron are legendary. Davit construction will resume in due course, but it may be another month or two before I have anything to show. Thanks for checking in ...

- 74 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

-

Thanks everyone for all your comments and likes. On the subject of curved davits .... Here's how I am making curved davits without laminating. Took me a while to get them to the point where the results were acceptable. I have no 2 x 2 material, but lots of spare 2 x 5 limewood so I cut strips of 2 x 2 off the 2 x 5. I made a form in the shape that conforms to the drawings in Matthew Betts book, with clamps bent from aluminum electrical wire holders. Soaked the pieces for 24 hours before working them, and applied the heat from the outside of the curve. Lack of patience is the enemy ... I also created a form for completed pieces because they needed to be held in shape while they cooled and dried. This allowed me to make two a day. Before removing them I marked the start and end points and the point where I wanted the mounting pin. I had a fairly high reject rate, especially at first, with the wood giving way at the apex of the curve. Might have got away with this once painted but I decided to persevere - the attempts for perfection getting in the way of production as usual. Here is one of the early ones with its pivot pin inserted. I will post photos of them installed once I get them on the ship.

- 74 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

-

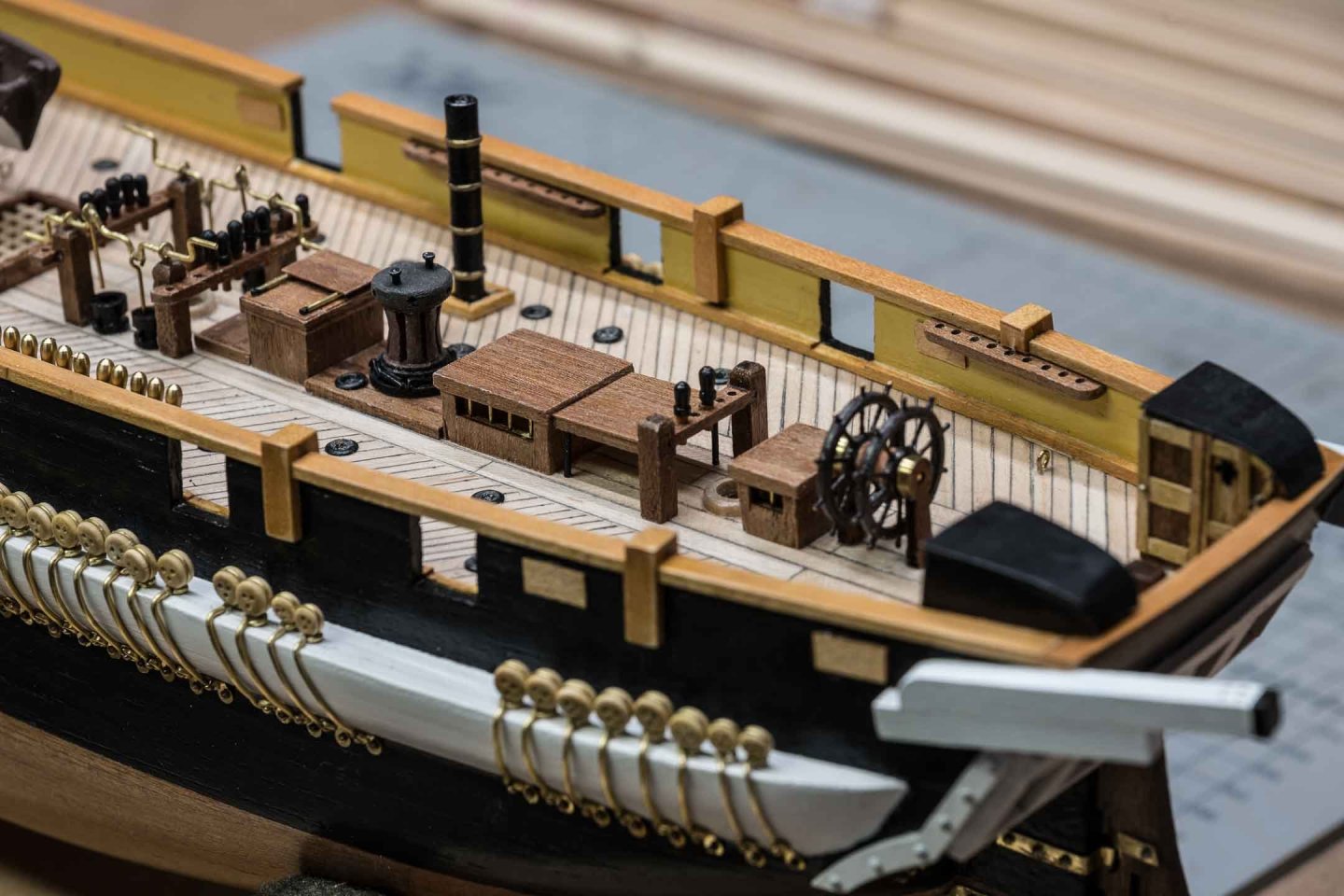

Thanks everyone for all your comments. Nothing new to report until now. There must be a better way to do the chain plates! After the first 20 I thought I should be getting good at making the brass wire parts ... but not so. It's interesting that the pictures in the OcCre instructions (and I have come to realize that they are pictures, not the photos that they appear to be) show loops at each end of the brass wire on some pictures, and no loops at the bottom end in others. Doesn't show an alternate method of fastening them though - just pins. I couldn't get them straight, consistent lengths to the bends. Ah well if I ever build another one I will invent a new approach 😬 This photo shows my version of the capstan, and the Caldercraft 10-spoke wheels installed (but not yet cabled to the rudder). On this - as on all the metal components - I am having difficulty making paint stick, even with metal primer applied. It seems ok , but if I rub my finger over it it flakes off. Is this because water-based acrylic paints are just not as sticky as the ones that fume off and give you headaches? Oh for the good old days .... I did find some brass belaying pins at a "local" supplier (Montreal - only 500 km away). I had already ordered 10 mm ones before the discussion above suggested 8mm might be more appropriate, but these ones do fit in the holes I have already drilled. They are made by Dekam in Italy, distributed in Canada by UDISCO - found them on eBay. Size is not 100% consistent but it looks like any given batch is the same.

- 74 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

-

Do you know what the correct size is Keith? I found some 10 mm brass ones, the OcCre ones are 10 mm long. My best guess from the plans is 6 - 8 mm, but I don't know how accurate the drawings are for something that small.

- 74 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

-

I had never looked at your Terror build, Keith, just the Erebus - Wow! So much good information and tips. Had I looked at it earlier in my build I probably would not have understood a lot of it, and since this is my first ship build I would likely have been overwhelmed! Your capstan looks great, and is along the lines of what I was thinking of attempting. Where did you get your silver-coloured belaying pins - or are they from the kit but painted that way? Just a follow up on the stern davits - as you can see in the photos I went with straight davits, no tapering, no joins. I'm happy with the result, it looks mechanically correct to me.

- 74 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

-

I am working through all the deck furniture components. Most have gone well, but bending the pump handles gave me some trouble. The piece that drops from the handle into the pump is too short at the location that is at top dead centre. I am not trying to modify these, just going with the kit. I did purchase two Caldercraft 10-spoke wheels which I have assembled and am just about to paint. They are not yet installed so don't show up on the attached photos. I am trying to decide what to do about the capstan. Looking at the ship drawings I believe the height of the one supplied is about right, but the diameter is small and the top is shaped improperly. I won't go too far with this, but I am wondering whether I can just beef up the top, and possibly use 2x3's instead of 2x2's for the barrel to give it a little more diameter. I have just finished planning where to put the bottoms of the chain plates so the angles are correct - OcCre keeps it a secret. I worked it out by scale drawing the plates with respect to the tops of the masts, following down where the shrouds will go when they are rigged. We'll see how the installation goes ...

- 74 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

-

Kudos to OcCre! I contacted them through their website regarding the missing Sapelli strips, and on their instruction filled out an on-line warranty form. I received 3 replacement strips by Canada Post within two weeks. This was an amazing response, for which I have thanked them. (In fact I may only have been short one strip, because their list of materials had an error in the length of one of the components.)

- 74 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

-

This makes more sense to me than putting a joint in them Keith.

- 74 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

-

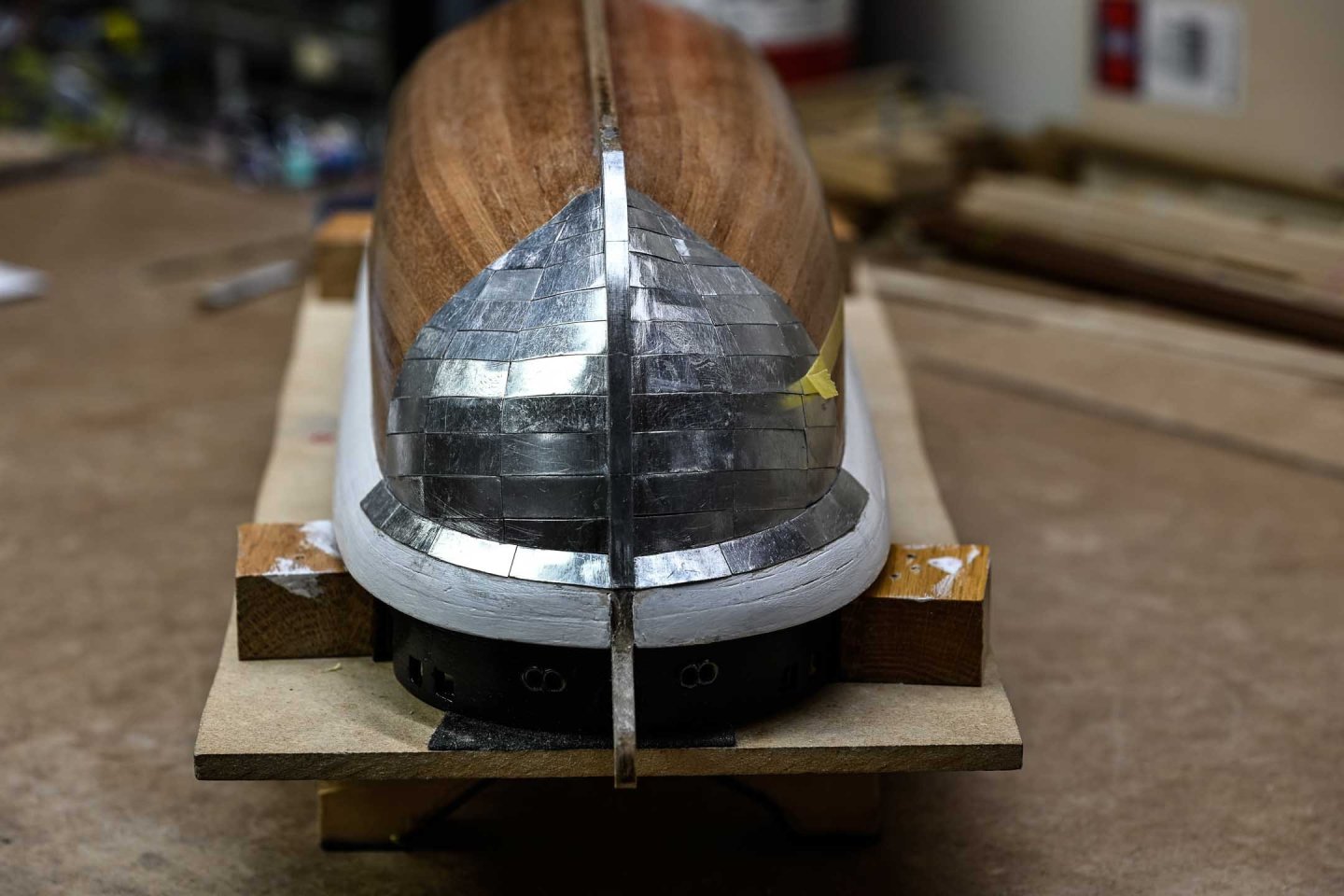

Thank you for your praise Jon. I didn't find the aluminum too difficult in the end - I made a jig to make marking the pieces for cutting a little faster. I did make a mistake with the layout. The pieces closest to the bow should have been shorter (I made them "full length") which left some tiny triangles further aft. Not a big deal. The glue worked out ok as far as I can tell - nothing's fallen off yet!

- 74 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

-

Another decision to be made - the stern davits ... The kit calls for a compound angle so the davits point almost horizontally away from the stern, and parallel to the ship's fore-aft axis. I found drawings in the original ship plans section in Matthew's book that show them as straight in all directions. This means they point towards the ship's fore-aft axis, and point slightly skyward. This makes sense from a structural point of view, because not having joints in them gives them more strength. I can't see any reason to make them change direction - but perhaps there is some reason from a sea-going point of view? I'm getting conflicting signals from all the different sources (even some of the pictures of the models in Matthew's book suggest both simple and compound joints, but the camera angles distort things too. My impulse at the moment is to go with the simple, straight davits...

- 74 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

-

Just ran into a problem: There is not enough 2x4 Sapelli wood in the kit to make all the parts that call for it. I only have one length of Sapelli 2x4x400 mm. The parts list calls for a total of 822 mm. Have written to OcCre to see what they can do about it - I've never seen Sapelli wood in my local hobby stores in Canada, otherwise I would just buy some and swallow the extra cost.

- 74 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

-

Today I arrived at a point where I believe the hull to be finished. From now on, the work is for deck fittings, davits, pumps, etc etc. It's an arbitrary milestone but gives me a sense of satisfaction. The "ironwork" around the rudder drove me crazy and I think there is a fair amount of skin from my glued fingers and thumbs still buried in the varnish. I was also disappointed that the rudder movement is so limited. On my model the pintels are very slightly off-centre, and the rudder will only turn in one direction - and not very far at that. The model design is a limiting factor here. There are 12 panels glued to the inside and outside of the hull towards the stern whose purpose I have yet to discover. I have not found a reference in Betts' book. The kit calls for 5 of them, and when I questioned OcCre they agreed it should call for 12 - three each on the deck side and the outside, port and starbord. Anyone know what they are? When I asked OcCre where to place them, they gave me a vertical dimension (2mm below the taff rails) but said to estimate the horizontal placement from the drawings. So I did. Of course, Murphy was on hand, and when I came to install the 4 pillars on the bulwarks two of them interfered. I was able to pry them off with minimal damage and install the pillars in the proper places.

- 74 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

-

Reinforcement complete, and I painted the hull black down to the waterline. The reinforcement is a matt black, while the rest is satin. Not as much difference as I would have liked, and you can't really tell from the photo. Still - time to move along.

- 74 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

-

Well the Aluminum Black experiment is over. After I had let it sit overnight, I rubbed my finger across the surface and most of the black finish rubbed off. Possible that a varnish over the top would have worked, but I decided that I preferred to have a more durable base. I did find a bottle of "Metal Primer" at a local store (who had previously told me they didn't have any 🙂), so now I am brushing that on and painting. Will post photos when finished.

- 74 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

-

Completed the aluminum bow reinforcement pieces today. Now grappling with the question of how to colour them black. Aluminum is notoriously bad at accepting paint, and the old primers (zinc chromate) are not available because they were so toxic. The most readily available self-etching primer is in spray form only, and I am reluctant to spend the time I would need to to mask the whole ship while I spray the reinforcement. There is a brush-on "metal primer" listed in most hobby stores - but every hobby store in the city is out of stock. I am testing Aluminum Black - does anyone have any experience with it? I might have to varnish over the blackened aluminum to protect it - but I don't know how well the varnish is going to stick. An alternative may be to spray some of the self-etching primer into a jar and then paint it on. Thoughts and advice from this knowledgeable community would be most welcome!

- 74 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

-

Thanks Keith - proceeding with the aluminum bow reinforcement using (thick) CA glue - seems to be working so far, one side completed today.

- 74 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

-

A question about glue for the aluminum bow reinforcement ... What kind of glue have people used for this? Does CA glue work ok? Or PVA? I haven't been using contact cement, don't like the smell - but there is a water-based contact cement available, not suitable for veneer so I didn't use it for second planking. Any advice would be appreciated.

- 74 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

-

Thanks everyone for your likes and comments. Quite a lot of progress since I last posted; The planking is complete... ... and the windows installed. I put some clear plastic behind the frames to have some reflectivity. The OcCre instructions are sadly lacking, not just for the transom/stern post mismatch as I mentioned earlier, but for the dimensions of the parts for the windows. Lots of head-scratching but I think the final result is ok. I spent a couple of days building the deck houses, using Matt Betts' book diagrams - put them into photoshop, then printed them off to scale, made it easy to fabricate the parts. They're shown here temporarily in place for the photo. Next I will turn the ship over to install the bow reinforcement, so no deck furniture or protrusions while she is sitting on her wales. Also will wait before installing the tafrails.

- 74 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

-

I spent a couple of hours at the reference library leafing through the James Lees rigging book. I scanned the chart of mast and spar dimensions so I now have a ready reference for finally selecting the mast and yard sizes. Tapering these remains a bit of a mystery to me - even when I found references to the amount of taper, I couldn't find any explanation of how to apply them. I find many of these books to be lacking in explanation - even Matthew Betts book - expecting the reader to know the terminology. Just my personal rant 🙂

- 74 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

-

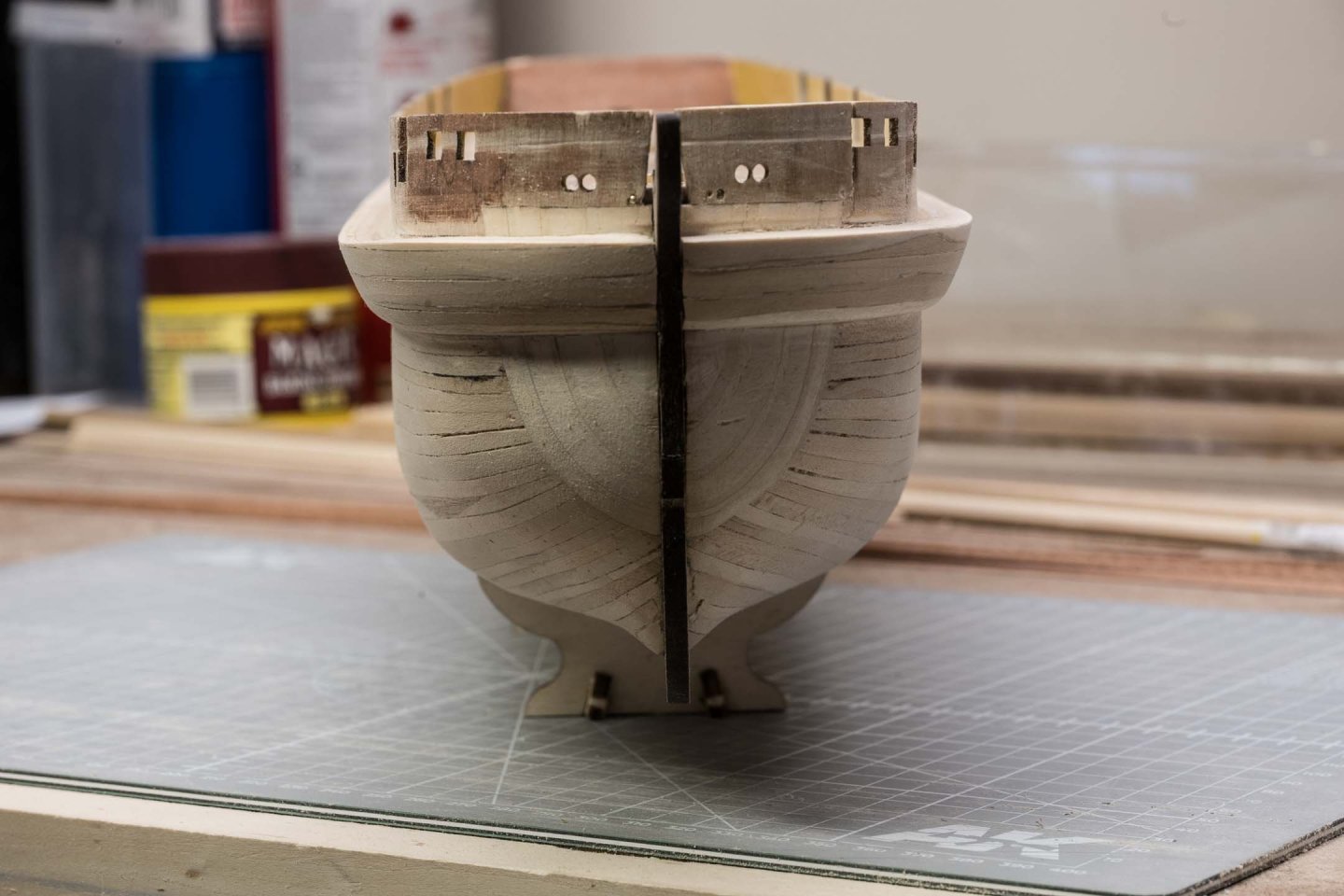

Second layer planking has been in progress for a while now - and I think can see the end! Being very careful to try to use only full length planks through the whole process. I use a spreadsheet to calculate the required plank widths at 5 cm intervals along the hull. After I have installed a few planks, I recheck all the dimensions and adjust accordingly. Details of how to finish the transom, with the stern post installation, were sadly incomplete in the OcCre kit instructions. I have done the best I can with the help of others' build logs. The Stern Post did not fit on my build - I had to sand it to shape and hope it works out when I fit the rudder. It puzzles me as to why, having supplied a nice piece of oak for the stern post, OcCre then requires the builder to sandwich it between two pieces of plywood; then sand the plywood down, exposing the glue between the plys (is that the plural of ply?) which don't absorb stain. I will end up planking the stern post for this reason alone. Despite my earlier comments, the keel turned out to be just 2mm short. I suspect I didn't quite adjust the pieces properly when I modified the kit position of the bowsprit. I inserted to 2mm pieces of oak between two of the keel pieces at one of the joints. Not perfect but it works for me.

- 74 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

-

I've just finished installing and sanding the Ice Buffers. I had some problems lining them up so the port and starboard buffers were at equal height at the bow. I was also daunted by the amount of sanding required, so with much trepidation used my recently acquired Dremel to help. I was very careful, and am happy with the results. The picture here has the keel pieces temporarily taped in. I have a problem with the keel, because the keel seems to be about 5-10 mm short, and the part that the rudder will attach to doesn't quite fit properly. Not sure yet how I will line it all up. I have enough of the Oak sprue to make a fill-in piece if that's what it takes, but the alignment at the stern is going to be critical for the rudder to fit properly. Will attach photos when I am closer to finalizing that part. I have just located a copy of Lees' Masting and Rigging at our reference library (snowstorms permitting), so will be spending some time there next week to fully understand what they say about rigging, and how all the different spar sizes fit together.

- 74 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

-

So the bowsprit should be 7.6mm dia, ditto the foremast. My foremast is 7mm, but my bowsprit is only 6. I'll have to revisit these.

- 74 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

-

I will celebrate appropriately in the tradition, with Canadian Rye!

- 74 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.