Venti

Members-

Posts

60 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Venti

-

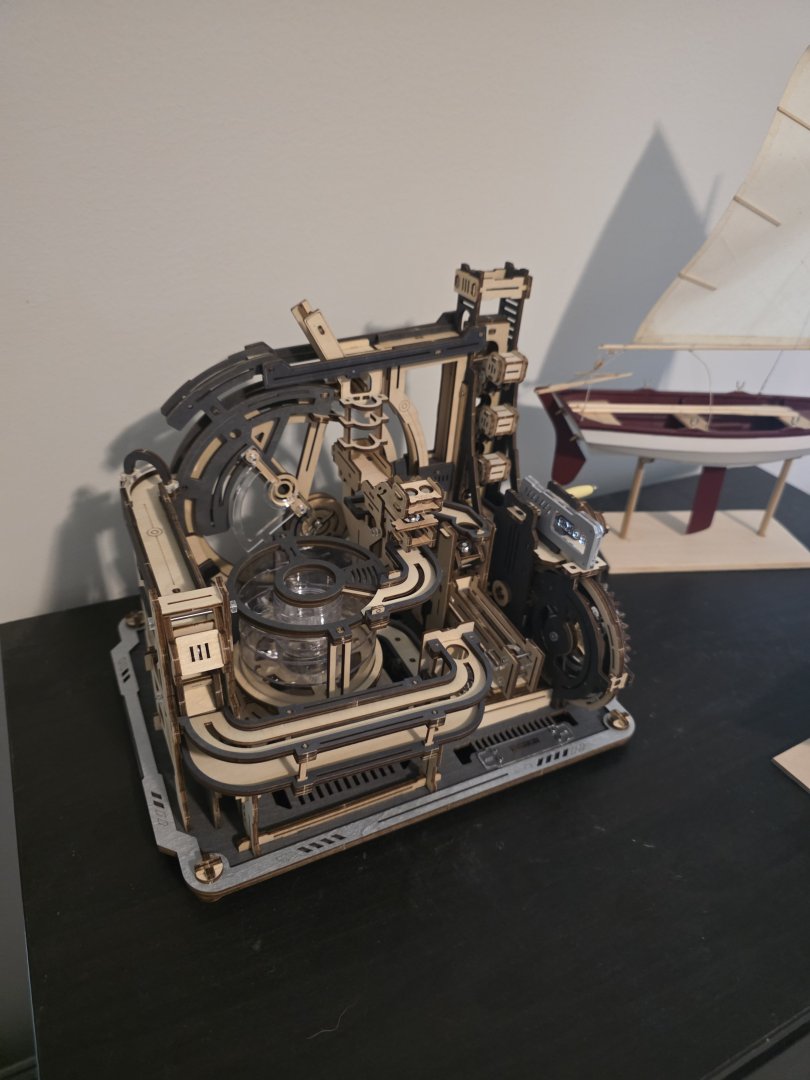

Doesn't feel like it's been as long as it has since I last posted.... But so much has happened since then. Bought a new house so I haven't been setup to work on this. A friend got me a marble run kit for Christmas, and it got me to get all my ship stuff out for it so now it's time to continue with the Smack! I need to get back into some other build logs/the instructions to refresh my memory of it all! I had done some of the fairing before I packed everything up, so I will make sure that all looks good and get ready for planking... Remember, I ordered Cherry wood strips to do the planking with! I think this will add a lot of challenge since it's a smaller boat, but I think it'll be great practice for the bigger ones when I get to them. I need to really refresh my memory how to plank with build logs and Chuck's guide.

-

Step 8: The Deck This step wasn't toooooo bad. Like the transom, I did not wet the top surface of the deck like the instructions say to. What I ended up doing was dry fitting them both as best I could to make sure they would come together in the center. Before gluing I looked at the tops of the frames to see how flat they were to each other and it wasn't good.... I had to sand a couple down as they were much higher than the 2 next to it and multiple were too low and would need shims to make the deck flat. I started by gluing one half down only on frames 4, 5 and 6. The instructions say to put glue on all of the frames... I'm very glad I didn't do that and started with the middle 3 only for two reasons. The frame at the transom still had a slight twist and I was able to use the deck to twist it back and glue it in place. The other reason is what I mentioned earlier, frames 1, 7, 8 and 9 all needed shims to make a nice looking curve of the deck. The first half of the deck went on without an issue; the edge of the deck lined up perfectly with the center of the spine. The second half went on mostly fine... The front section of the deck where it meets the other deck had a small gap in it somehow... I used some wood filler to fill it in along with the hole for the centerboard rod since I am not using it. The transom, somehow, was not perfectly lined up with the edge of the deck either. I suspect it was because this slight twist was there when I put frame 10 on and squared it to the other frames. Then when using the deck to get rid of the twist, the transom wasn't square anymore. Not a huge deal. I sanded it like the instructions say and it looks fine now! One concern I have is the fore edge of the cockpit does not line up perfectly with frame 6. I'm considering adding some wood filler to bring it all flush with each other. You can see this in the last picture of the last post for the cockpit seats. I have lots of sanding to do next for the fairing... it's my most dreaded step of the whole thing I think...

-

Step 7: Cockpit Seats Now I had a ton of fun with this step! I ended up not using the parts they supplied for the seats and ended up using some walnut strips to make my own. This was completely unplanned and only happened because Joe from Modeler's Sawmill accidentally sent me the wrong wood when I ordered some for the planking (he was great and corrected the issue before I even received the walnut planks). I ended up putting the supplied seat together just to make a stencil to plan my seats out. I used some spare pieces to hold all the planks together from underneath and just went for it! I glued the seat supports to the bottom of the seat and had to cut out some slots for the support planks underneath. **Note I had to sand the seat supports quite significantly in order for the seat to be level with the floor. I also used a piece of walnut for the back but didn't quite make it the same size as the supplied back. I have 5/16" wide strips and just used that for the back, cutting out a square slot at the same height as the spine. Lastly, I applied some wipe on poly and glued it in! I'm so happy with how it came out and really just confirms my eventual desire to do more scratch based builds. (Ignore the fact the deck is on in the last photo... I forgot to take one of the seat after i glued it in)

-

Step 6: Frame 10 and Transom The only thing I did differently than what the instructions say was I did not wet one side of the either piece. I found that I could hold them together well enough and keep the slight curve without it. (after the glue-pocalypse, I fear getting anything more wet than it needs to be). I glued the frame and transom to the spine and made sure it was lined up with the spine as best I could. It seemed that the top of the frame and transom were way taller than the spine but I don't think this is an issue as I just cut them down to be flush with it.

-

Step 5: The Bulkhead Frames I had been looking forward to this step for no particular reason other than it will start to look like a boat after haha. Unfortunately, it was a very long, very annoying step... The warp from the previous step was initially so frustrating that I almost stopped and ordered new/replacement parts... In my head if it was this warped, surely it will affect many many things later and make it look terrible... I ended up decided to just move on with it and see if I can straighten things up with the bulkheads. This was where another very frustrating discovery was made... the fit for ALL of the bulkheads to the spine was TERRIBLE... I had seen other logs having the same issue but still annoying the lack in quality for the bulkheads. Then when dry-fitting bulkhead 8 it was a little tight and I pushed too hard and broke the bottom of the spine where the keel goes.... I glued it back on and after these 3 things I had to call it a night as I was not in the right mindset to continue... When coming back the next day I started with bulkhead 4. The slot for the reinforcing piece had to be extended more than 3mm... I took lots of time to make sure these were square to the spine in hopes to keep everything good down the line... All of the other bulkheads fit to the spine was so bad that I had to find the center of the bulkhead and mark it so I could line it up with the spine and then also shim each side of the spine between the bulkhead and spine... I'm new to building ships in general and this is my first one with bulkheads but this seems like a fairly critical step to have this poor of a fit... After slogging through this taking WAY too much time (I think) on this step it is done... The bow from before isn't even noticeable now, thankfully and the bulkheads all look square! I ended up going for a faux planked cockpit floor and staining it with a light oak color. Unfortunately, this brought out the grain of the basswood and kind of gives away it's fake haha.

-

Step 4: Reinforcing Pieces This step was very straightforward (if you had correctly marked wood sheets showing you where they go). A big thing to note that the instructions don't really say is that bulkhead 4 will slot onto the B-pair of pieces. One of my spines had the laser etch of where B should but it didn't help much as the reinforcing piece was much wider than the spot lasered... I ended up getting out the two bulkhead halves and using them to know where to put the B pieces. C and D I just tried to line up with the slots and the bottom of the spine since they are used for the planking later. After I got them all glued on, I let it sit overnight like how it is in the picture which was a HUGE mistake... I didn't think about it and was very frustrated after the glue-cident but all that glue on the wood make the wood wet and without doing anything special the spine had a pretty severe bow in it... Looking at it from the front it looked like a parenthesis - ) . VERY frustrating and unfortunately I did not notice until starting the bulkheads...

-

Steps 1-3: The Central Spine These steps were pretty straight forward. I took extra time to make sure the slots and top of the spine lined up to try and prevent any issues later! This went well and didn't have any issues. Almost glued in a spacer but caught it in time haha. I also took a lot of extra time letting glue dry while I had my 1-2-3 blocks pressing them together to try to prevent any warping and it did great. I decided to fix the centerboard in. Partially because I didn't want to test my luck with another moving part and mostly because when I was dry fitting it, the curved slot in the spine did not line up with the hole for the brass rod... I sanded the centerboard and rounded the fore edges and glued it in in a mostly down position. Lastly, I went to glue the other half of the spine on... I had been using a cheap squeeze bottle with a fairly precise nozzle for the first time. So I wouldn't have to squeeze some out into a little cup and apply with a brush. it worked great for the first half but when putting glue down, I guess I squeezed it too hard and popped the lid off and my white glue POURED out right onto the wood... It was a disaster... I cleaned up the model as fast as I could and finished putting glue on where it was needed and put on the other spine... It ended up being very slightly shifted back but considering the situation I was pretty happy with it... p.s. I guess I didn't get a picture with the other spine half on but it doesn't show much more than this picture!

-

Sooooo I couldn't wait any longer... I've been trying to hold off on starting this until we sold the house but it's going much slower than we hoped so here we are... I'm going to be trying to split up posts by steps and try to have an index at the top so that if someone reading this in the future can go to specific steps if needed. I decided to upgrade my shipyard with some 3d printed tool holders! so far it's been great! Not having to go into a drawer for EVERYTHING is very nice. I need to get some drawers made but having some printer issues 😭.

-

How does it deal with two or more objects touching each other? It's going to depend on how good the "template" is for the thing being counted. I just downloaded CountThis and tried it a bit. They have a bunch of prebuilt templates for random things. I tried the "similar items outstanding from background" one with the picture Chuck posted of the thimbles and it counted them all plus an extra invisible one 🤣 but that template is "experimental". I then got some ibuprofen out and used the pill counter template and it did perfect. I even had some on the sides to try to trick it. Picture result below. The experiment template didn't do very well and clumped them together. That said, this app was the first I saw and tried. It doesn't seem like it will let you create your own template but I'm sure theres a more open source one out there somewhere.

-

Unfortunately it says "Borrow Unavailable" at the moment. I assume someone else is borrowing it now and I'll keep checking on it. But I saw a picture on someone else's build log and I'm not sure it'll be all that helpful. I think I've decided to forgo the pre-shaped planks given in this kit. I want to get extra practice lining off the hull and bending/shaping the planks the "real" way. Is this a bad idea for this ship? Not sure if they give the pre-shaped planks because it's a learning kit and/or because it's small and difficult to plank. The garboard seems it might be a little difficult but otherwise I don't foresee anything too bad. With this I need some help choosing the size of strips to use for this. The planks given in the kit are 1/32" thick so that seems like it should be the thickness. The width of the planks are kind of all over the place... around 3/16" wide with sheer strake at 3/8". Once again my wood sheets are not labeled correctly and did not come with a parts sheet to identify parts so I will contact ModelExpo and try to get that.

-

Just finished the Pram which was a ton of fun but I am much more excited to start this one! This style of planking seems much more enjoyable to me and is what I've seen done the most on bigger ships. I think I'm going to order some black synthetic rope and some sheave blocks as a little upgrade from what the kit has. For a few days I'll probably be reading instructions and build logs again to be better prepared but I might not be able to help myself and get started 😅 Table of Contents: Appendix 1: Part Sheet Appendix 2: Shipyard Update Steps 1-3: The Central Spine Step 4: Reinforcing Pieces Step 5: The Bulkhead Frames Step 6: Frame 10 and Transom Step 7: Cockpit Seats Step 8: Deck

-

Thank you all! I think I've decided on going with Syren as well. Mostly because I would also like to get some better sheave blocks and ropesofscale doesn't have those haha That makes perfect sense! Good! You're so close and it looks amazing!

- 55 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 2 more)

Tagged with:

-

Whelp, a big day today. Just finished everything up!! Started with getting the back stays. With the fore stay done I used a rubberband to hold the mast back and to help it from moving. I then used a knot that can be easily tightened and holds under tension (knot 1472 is closest I could find quickly. Instead of both ends doing the same knot, just doing one with the loose end of the back stay). Once this is done, it's incredibly simple to tighten both sides equally. This also made it easy to lash the loop under tension. After this was done, it was just a couple more things. Hoisting the sail and main sheet. This was pretty simple but tying them off on the small cleats was annoying. Not sure if it is because the quality of the cordage or bad technique haha. I was following Trevor's masterclass on belaying to a cleat here: I ended up just doing a loose coil of the sheet on the floorboards. I just imagine it is used often and wouldn't be in a fancy pinwheel. Not sure how it would actually be stored while in use. All in all, I had a ton of fun building this and have learned so much. I just couldn't stop working on it in all of my free time 🤣 I've got the smack instructions out and have started reading them and I've already ready many a build log on it. Look forward to starting a new log and thanks everyone for the comments and likes on this one!

- 55 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 2 more)

Tagged with:

-

I did not think about the material making that much of a difference, but that makes sense. Maybe I'll look at getting new cordage for the smack as it seems a good bit more complicated and I could use any help I can get. I'll look around, but if anyone has suggestions on which supplier has good quality stuff, let me know! I will look through the many MSW sponsors. Ah yes, this one looks much nicer than stacked overhand knots! Excellent explanation, thank you! I suppose it's like calling the mast the "wood" 🤣

- 55 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 2 more)

Tagged with:

-

Trevor, thanks again for some of your knowledge! I feel I will never stop learning new things with this new hobby haha. Got a little more done last night! I thought I was going to finish her up, but I got a headache and stopped for the night. I finally got the backstay plates on the mast (I was waiting to get a better idea of the angle they would be at before gluing them on). I would love to find a way to glue the extremely short nails in while still letting the plates swing freely. I got the Halyard and Downhaul attached. The travel done. Almost forgot to put the block on there before... but remembered last minute. And I got the forestay done... Saw lots of issues people were having with this part so it took me a very long time to make sure I got it right. I'm not really sure the intended way to make a loop for this is. (I should probably go read Trevor's log again because it likely says 😆) but I just went with the one loop knot I'm familiar with... Number 290 in Ashley's book of knots. I'm also having trouble with the other knots needed... the instructions call for half hitches (#48 in the book) and I end up doing two (#54). It doesn't seem to tighten up very well which isn't an issue for this since I'm gluing them in place anyways but would love some insight on what some better knots for this would be. With this, is there a good knot for stopping the rope from going through holes? Like for the Downhaul line or Traveler? I usually just do 1 or 2 overhand knots (#46)

- 55 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 2 more)

Tagged with:

-

Good morning, all! I have just recently started making lots of sawdust and I have started planning a long list of ships to do haha. I love the look of the Winchelsea and would love to build it, but I just wanted to ask about where she sits from a difficulty standpoint. I have only really read through one build log (Trussben's) and he made it look easy, but I suspect that speaks more to his skill than the build being easy 🤣 I am almost done building the Pram, then I plan to build the Lobster Smack and then plan to get the Vanguard Sherbourne. Not sure if that's enough experience to dive into building a Winnie or if I should do something a little bigger (been looking at either Vanguard HM Brig Harpy, HM Brig Sloop Flirt, or HMS Speedy). Thanks!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.