-

Posts

40 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ollagynot

-

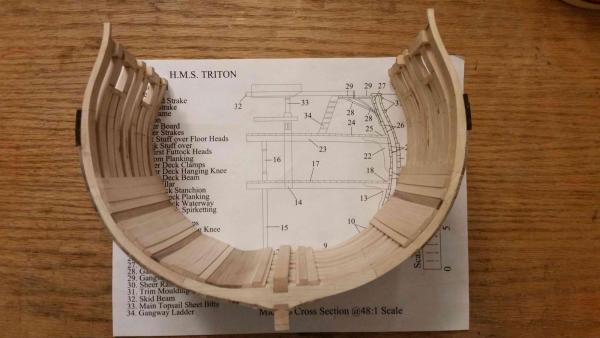

The outboard planking is now complete from the wales down, and the inboard planking is complete from the lower deck clamps down. I have chosen to leak a portion un-planked to expose the frames. Next I will be the treenails. I had cut the lower deck beams some time ago, I have them just "dry fit" in their spot in that last photo. Thanks for all the likes so far! Tony

-

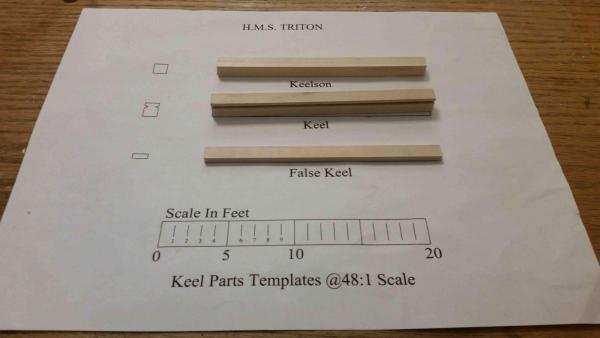

I have completed assembly and dry fit the keelson, a little fairing to be done. I am also looking into some different wood for the planking. I do not see pillars in the cross section plans, but I see pillars of varying numbers on other builds? I am curious where other builders got their ideas. Any additional info on the pillars, spacing/design would be appreciated. I would like to mill holes for them before installing the keelson. Thanks, Tony

-

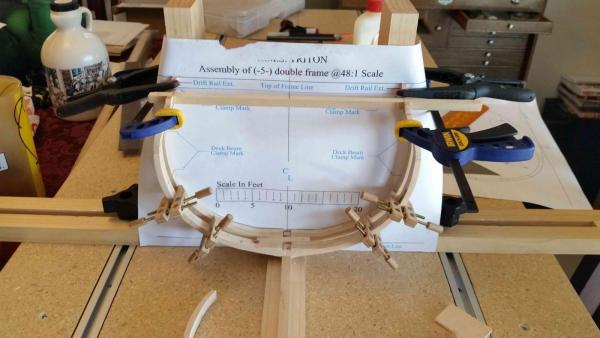

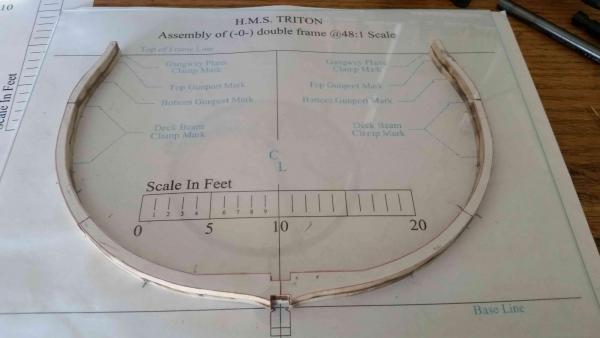

I finally finished the last of the frames today, now all nine of them are done! Moving on to cleaning up the notches for the keel and keelson. I am very happy with how they turned out. Most of the joints are pretty tight, only two or three that have a small gap. I am also happy with the wood choice (maple), the frames are surprisingly strong. I will also be looking for jig ideas in the other build logs before I begin assembling everything. Tony

-

USS Columbus 1819 by threebs - 1/72 scale

ollagynot replied to threebs's topic in - Build logs for subjects built 1801 - 1850

I saw your Columbus and Pennsylvania today at the fair. The Columbus is coming along very well and the Pennsylvania was beautiful. Tony

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.