crooman

-

Posts

27 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by crooman

-

-

Finally getting back to the business of ship building!

I was looking for information how how to stiffen thread so as to be able to put the thread ends through the tiny holes in the various blocks.

Well,I read several people writing that solid beeswax was the answer. However I cannot locate a supplier this side of the atlantic.

I have found by chance that if you rub the thread along the surface of a dry bar of soap, it will stiffen the thread so that threading is quite quick and simple.

I hope this info may be of help to some one of my fellow ship builders.

Bob.

-

No Lou I did not as the blocks are the oblong ones with one hole and a groove on the outside.

Getting the thread to stay in position over the grooves was the trouble but I found the putting a tiny drop of wood glue on both ends made the thread

stay in place while i tightened it.

I will try to attach a close up photo.

Yes, the fireplace goes inside the ship!

Thanks for the tip about the threader- i will certainly use one if i can find one in the sewing box of She Who Must Be Obeyed !

Bob.

sorry the picture is so fuzzy.

-

-

Hi All fellow modellers.

It's been 6 weeks since I posted, but have been working away steadily on Cutty,

I find that threading the blocks on the masts to be a real pain, you know where,but again perseverance is the only answer.

Also as I had eye surgery 3 weeks ago hasn't helped.

Am including some up to date photos and would welcome any comments.

Hope its warmer wherever you are-its 8 degrees here in Dublin today.

Guess I will have to put a fireplace in the ship!!

Bob Crooman.

-

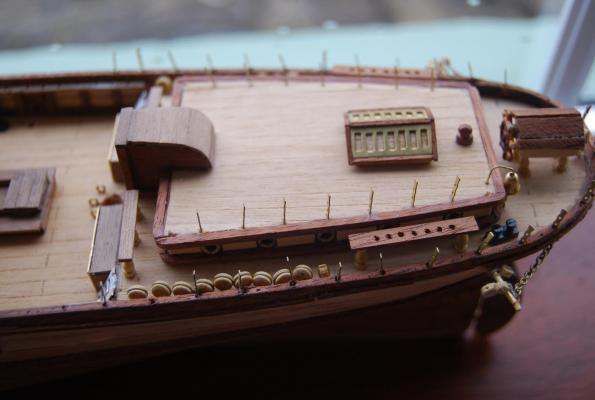

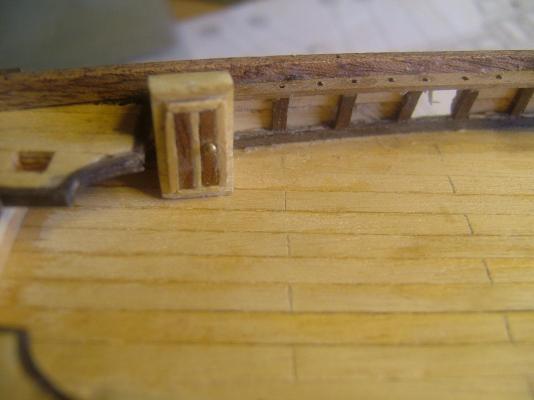

Well, three weeks have gone by since my last post. I have nearly finished the deck furniture but I am disappointed to see that the cabins have only got holes for portholes, whereas the earlier model I made had brass portholes fitted and the different coloured woods used were much more attractive than in this model.

However, I am trying to stick to the plans and perhaps whenever it is finished it wont look too bad.

Best wishes to you all.

Bob.

-

Bob,

The deck is now white,and mahogany before;

The capstan is now brass, not wooden and a different shape;

The handrails are very much inferior in quality and strength;

There are single and clump blocks on the outside of the hull, but none originally;

The windlass is completely different in construction;

There are no ladders to the foredeck in the original;

I think that's all I can see for the present!!.

Bob.

-

-

-

Nenad,

in reply to yours,

i have decided not to copper the hull or even paint it but instead leave it in the natural timber state.

So I am safe enough to have done what i have done.

In the meantime I am finding tying all these little knots with my old fingers a bit of a trial, however i will persist.

Crooman.

-

Lou,

I like it,but I will have to learn that song in 4 languages!

-

Still working away slowly and at the same time listening to Andre Rieu and his performance in Masstrict with Benny Neyman,who sadly died a few years ago .

My wife and I simply love his rendition of Ode to Maastrict..I hope to learn all the words and the music on my Bechstein piano [!] to sing and play on the occasion of our 50th wedding anniversary next year.

I just thought you all would want to know that !!!!!!!!!!!!!!!!!!!

Best wishes my fellow ship builders.

Crooman.

-

Thank you gentlemen for your kind comments.

Perhaps a well sanded down and varnished hull will be the best.

As for the red duster, I fully appreciate your delay in answering my plea !

I will investigate as you suggested Bob.

I think I will leave the figurehead till last as I would only knock it off !!!

Crooman.

-

No, I do not plan to second layer plank. I will be painting the hull black in part and coppeer in the rest so I hope the imperfections will not be visible-and there are lots of them!

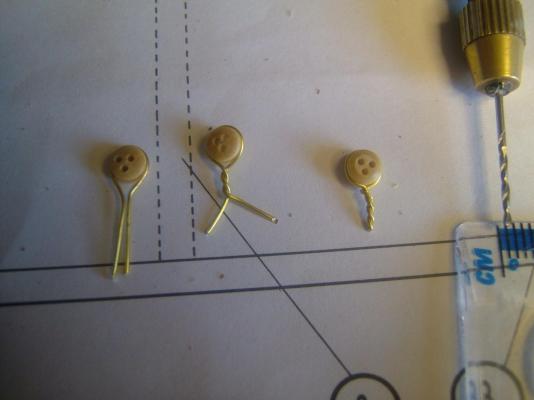

I have put on the deck latrines and am doing the single and clump blocks.

Your idea Nenad of using fine cord to tie them around is terrific and so realistic, but I do not have the patience for that and so am using wire as per the instructions.

So,a few more photos.

The rudder caused me a lot of trouble, breaking repeatedly, so it is not perfect-far from it.

I still have a lot of sanding down to do before I varnish and paint,but that can wait for the present.

Patience is the pre-requisite !!!

Crooman.

-

Giancarlo, this build is simply beautiful and your attention to detail is terrific.

Puts my own effort in the shade, but I will continue as best I can and some day you will see her sailing the pacific!!!

Crooman

-

So fellow modellers here is where i am at so far.

I had quite a bit of trouble bending the hull planks, many broke but I glued them back together again and sanded the joints so they look ok now.

I have not got the ends of the planks at the bow properly even, so I will have to cut them back and fit new pieces,glue and sand.

I must be running out of sand paper !

I found that the gallant rails are of such hard wood that it was very difficult to push the holding pins through them so I drilled tiny holes first and then it was easier to push the pins through.

Best wishes to you all.

Crooman

-

Nenad,

I hope this is helpful:

I use masking tape to hold the planks in place while the glue is drying, as I do not want to have the hull full of holes and anyway the tape is easier to use than the pins.

Below is a fish kettle I use to soften the planks.

I half fill it with boiling water and while the timbers are in it,2 at a time is all I do, I keep the water at a gentle boil for 15 minutes.

Then I take one out and move it back and forth over the hot soldering iron.It is important to keep it moving as the wood will scorch easily. However, if you heat the wood on the inside of the bend, then scorch marks will be next to the frames and will not be visible.

On the last model I made some years ago, I got a glass flask, rubber tubing and a 400mm long glass tube from a laboratory supplier.

Steam from the boiling water is passed through the glass tube in which I put the wood to be softened.

The main thing is to do the bending in easy stages.heat/bend;heat/bend and so on until you get the desired shape.

This is what it looks like now, so far.

-

-

-

Next is to score the planking ends on the deck planking with my craft knife`.

Then i am supposed to imitate the nail holes with a "burin" ??

Do they mean for me to Burn in the nail holes with a hot needle?

Crooman

-

-

I hope I am going about this the right way.

It is my first time to attempt a build log so if I am making mistakes I would welcome correction.

This, the Cutty Sark was given to me by my son more or less as you see it. I only have applied the planking veneers to the aft [?} deck and am now shaping and sanding the aft wedges.

Crooman

-

-

Thankyou for that crackers, but my model is by Constructo, a Spanish company.

I dont think Revell would be the same.

Crooman.

-

I hope I am putting this plea for help in the right place.

I have mislaid the plans booklet of the Constructo model of the Cutty Sark.

Can anyone tell me where I could get a copy please.

Thanking you all in advance,

Crooman

Cutty Sark 1869 by crooman - Constructo - scale 1:115 - Launched in Dumbarton, Scotland

in - Kit build logs for subjects built from 1851 - 1900

Posted

Hello to all fellow ship builders.

After many months of silence but having put in about 500 hours on Cutty,I am now nearing the finished model.

However can some one please tell me where I can buy 2 copies of the Red Duster-one for this model and one

for the model I made 10 years ago.

They would need to be to a scale of 1:115 and in cloth.

I do not have the skill to make them so would be happy to pay some kind soul to make them for me.

Many thanks,

Bob.