-

Posts

81 -

Joined

-

Last visited

About Zack Soderquist

Profile Information

-

Gender

Male

-

Location

Fargo, ND

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

SighingDutchman reacted to a post in a topic:

CA glue nozzles or tips

SighingDutchman reacted to a post in a topic:

CA glue nozzles or tips

-

Vlax reacted to a post in a topic:

Norwegian Sailing Pram by Zack Soderquist - Model Shipways - Scale 1:12

Vlax reacted to a post in a topic:

Norwegian Sailing Pram by Zack Soderquist - Model Shipways - Scale 1:12

-

kuya reacted to a post in a topic:

Norwegian Sailing Pram by Zack Soderquist - Model Shipways - Scale 1:12

kuya reacted to a post in a topic:

Norwegian Sailing Pram by Zack Soderquist - Model Shipways - Scale 1:12

-

Ryland Craze reacted to a post in a topic:

Norwegian Sailing Pram by Zack Soderquist - Model Shipways - Scale 1:12

Ryland Craze reacted to a post in a topic:

Norwegian Sailing Pram by Zack Soderquist - Model Shipways - Scale 1:12

-

Ryland Craze reacted to a post in a topic:

Norwegian Sailing Pram by Zack Soderquist - Model Shipways - Scale 1:12

Ryland Craze reacted to a post in a topic:

Norwegian Sailing Pram by Zack Soderquist - Model Shipways - Scale 1:12

-

Ryland Craze reacted to a post in a topic:

Norwegian Sailing Pram by Zack Soderquist - Model Shipways - Scale 1:12

Ryland Craze reacted to a post in a topic:

Norwegian Sailing Pram by Zack Soderquist - Model Shipways - Scale 1:12

-

Ryland Craze reacted to a post in a topic:

Norwegian Sailing Pram by Zack Soderquist - Model Shipways - Scale 1:12

Ryland Craze reacted to a post in a topic:

Norwegian Sailing Pram by Zack Soderquist - Model Shipways - Scale 1:12

-

Ryland Craze reacted to a post in a topic:

Norwegian Sailing Pram by Zack Soderquist - Model Shipways - Scale 1:12

Ryland Craze reacted to a post in a topic:

Norwegian Sailing Pram by Zack Soderquist - Model Shipways - Scale 1:12

-

Ryland Craze reacted to a post in a topic:

Norwegian Sailing Pram by Zack Soderquist - Model Shipways - Scale 1:12

Ryland Craze reacted to a post in a topic:

Norwegian Sailing Pram by Zack Soderquist - Model Shipways - Scale 1:12

-

WizardOfOs reacted to a post in a topic:

Norwegian Sailing Pram by Zack Soderquist - Model Shipways - Scale 1:12

WizardOfOs reacted to a post in a topic:

Norwegian Sailing Pram by Zack Soderquist - Model Shipways - Scale 1:12

-

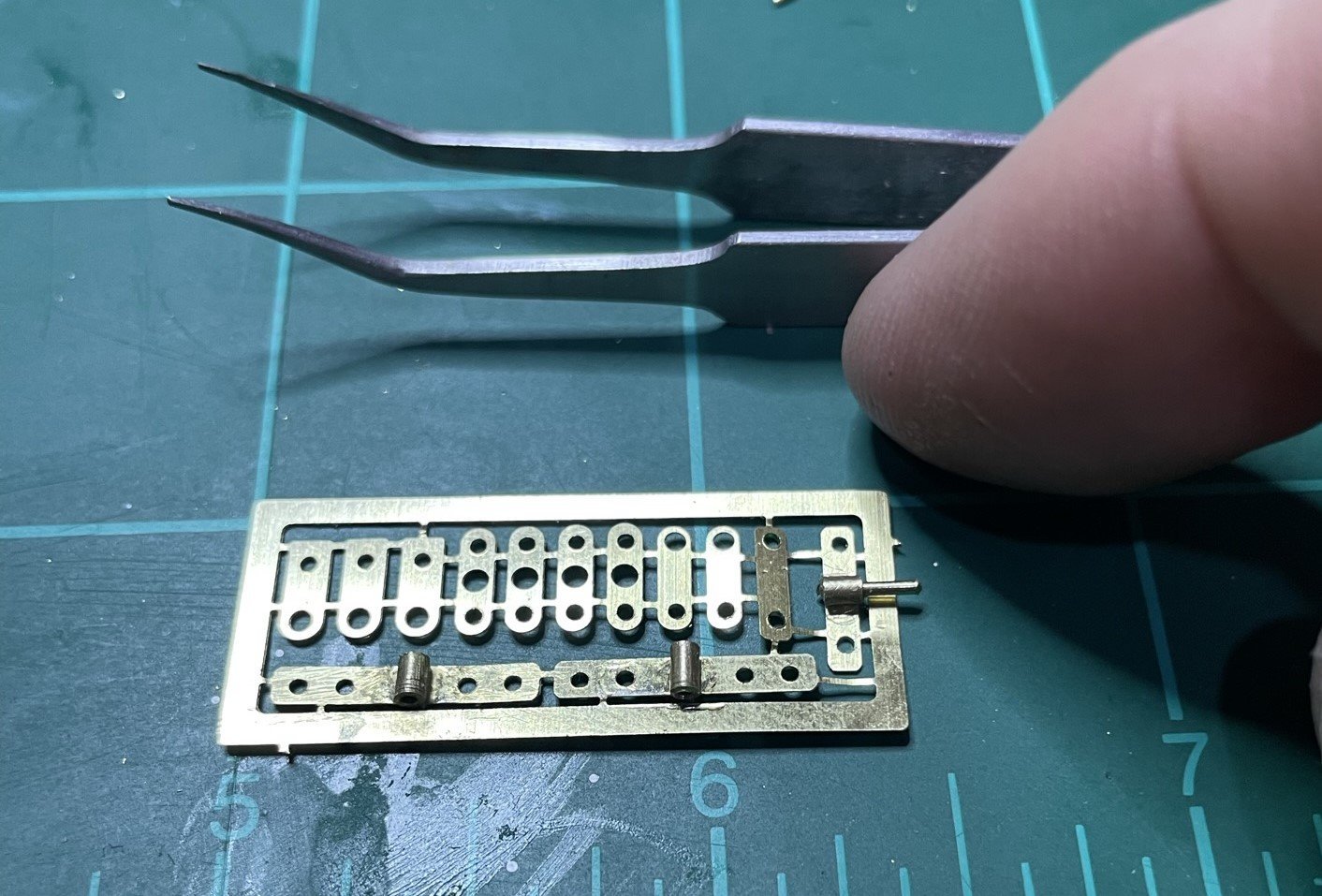

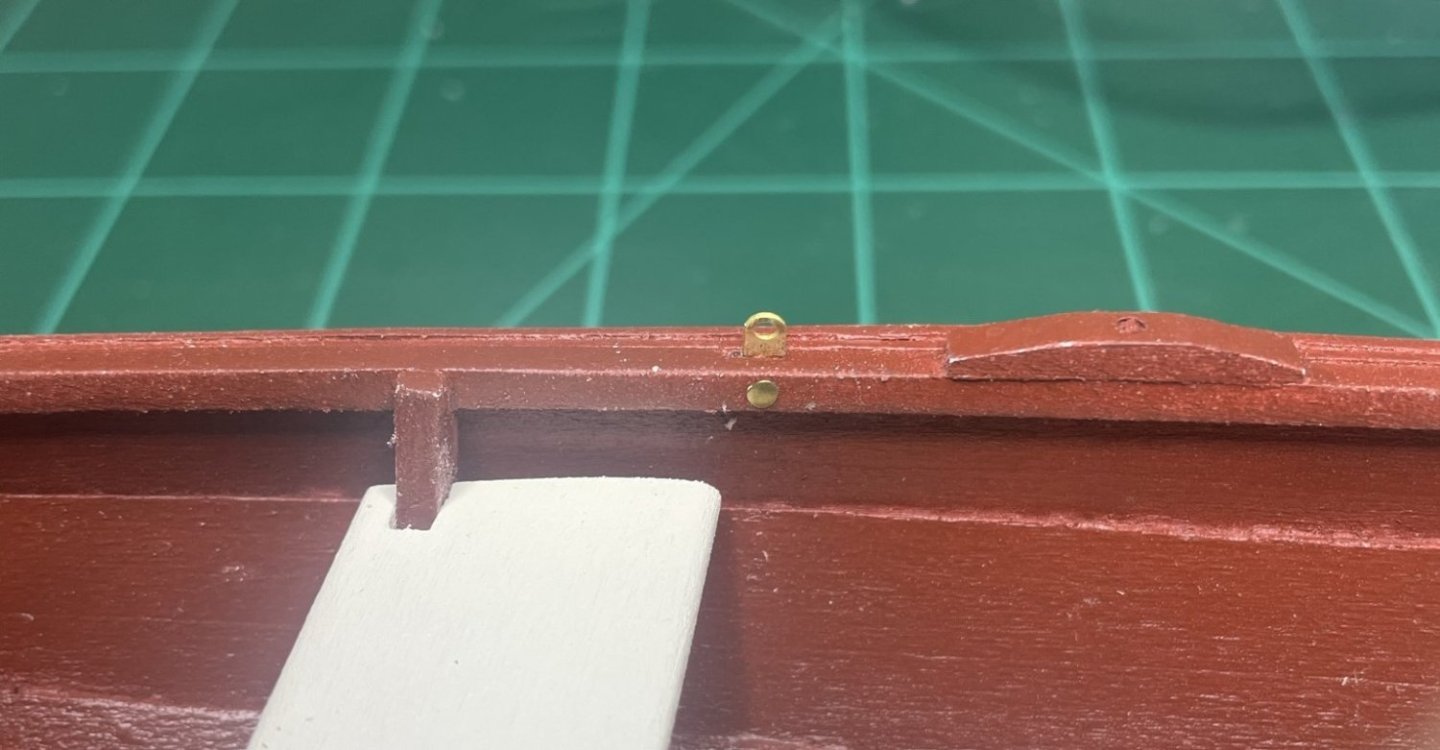

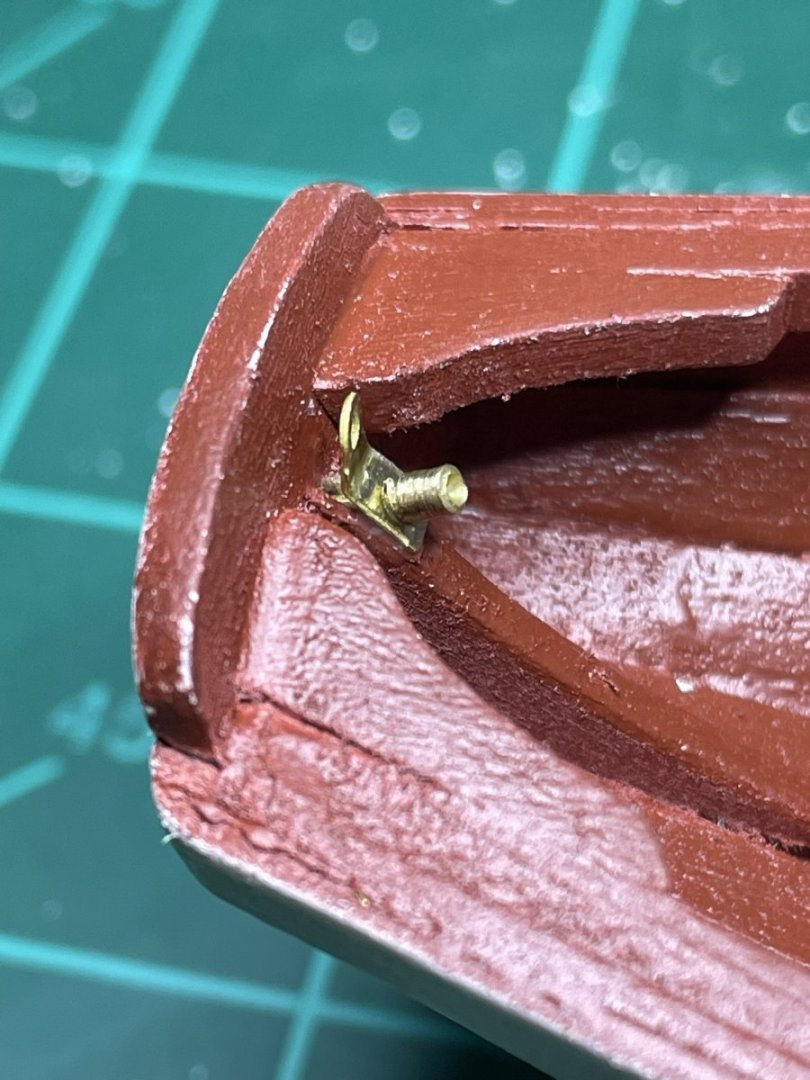

Step 39 Pintles. Ok.. now I officially HATE working with these stupid tiny pieces of brass and tiny brass nails that go flying everywhere. Ugg The brass straps they provided after bending around the tubing were way too short to wrap around and secure to the rudder. My kit had an extra phote-etched sheet so I used the extra four hold straps and size wise it worked out much better. I had the extra hole but it was a concession I made. This picture was before cleaning up and touching up the paint. Also, I did the notches way wrong and now realized they should have been more shallow and wider to accommodate the brass strap. However, the pintles are already so close I don't know that recessing them closer to the rudder would have been a good idea. I may fill in and paint the notches. Undecided at this point.

-

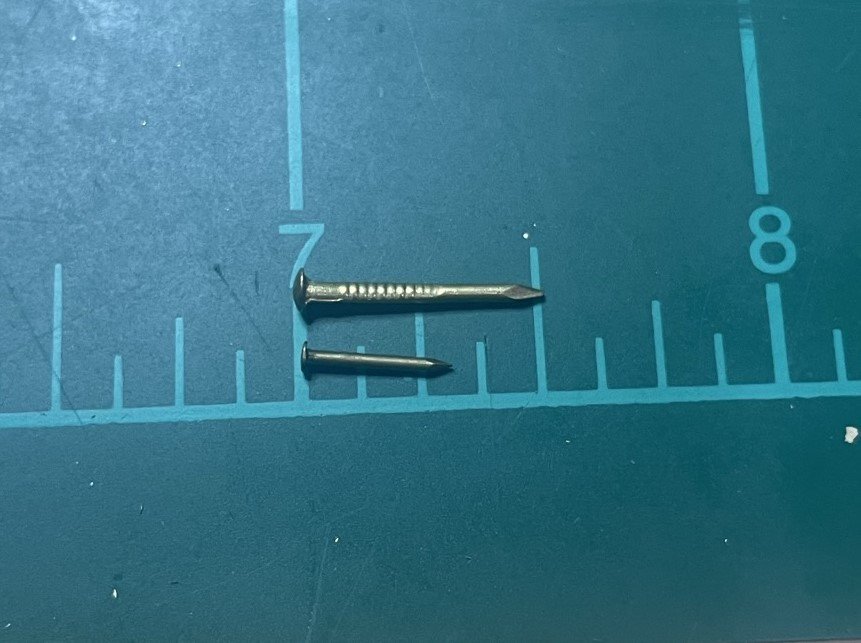

Step 37 stay plates So I was not happy with the nails they provided. Way too big and didn't look right so I went back to those small nails from my abandoned Rattlesnake build. The top nail below is the one provided with the kit. The lower one is the Rattlesnake nail. Part number for these nails is MS0940 The smaller nails looked much better

-

Step 36 Metal fittings: eyebolt in the bow. This was pretty straight forward too but the eyebolt went flying and I couldn't find it so I requested a replacement from Model Expo. The part was free but they charged me $5 for shipping on a part they could put in an envelope and throw a stamp on it. Oh.. and then the next day, I found the dang eyebolt. Go figure. I am using CA glue to attach the brass to the boat. Even with a applicator tip, it was putting out too much glue so I switched to using my little pink glue cups and a glue applicator I got from Micro Mark (I think) awhile back. Also, I really like the Starbond Oderless Thin CA glue.

-

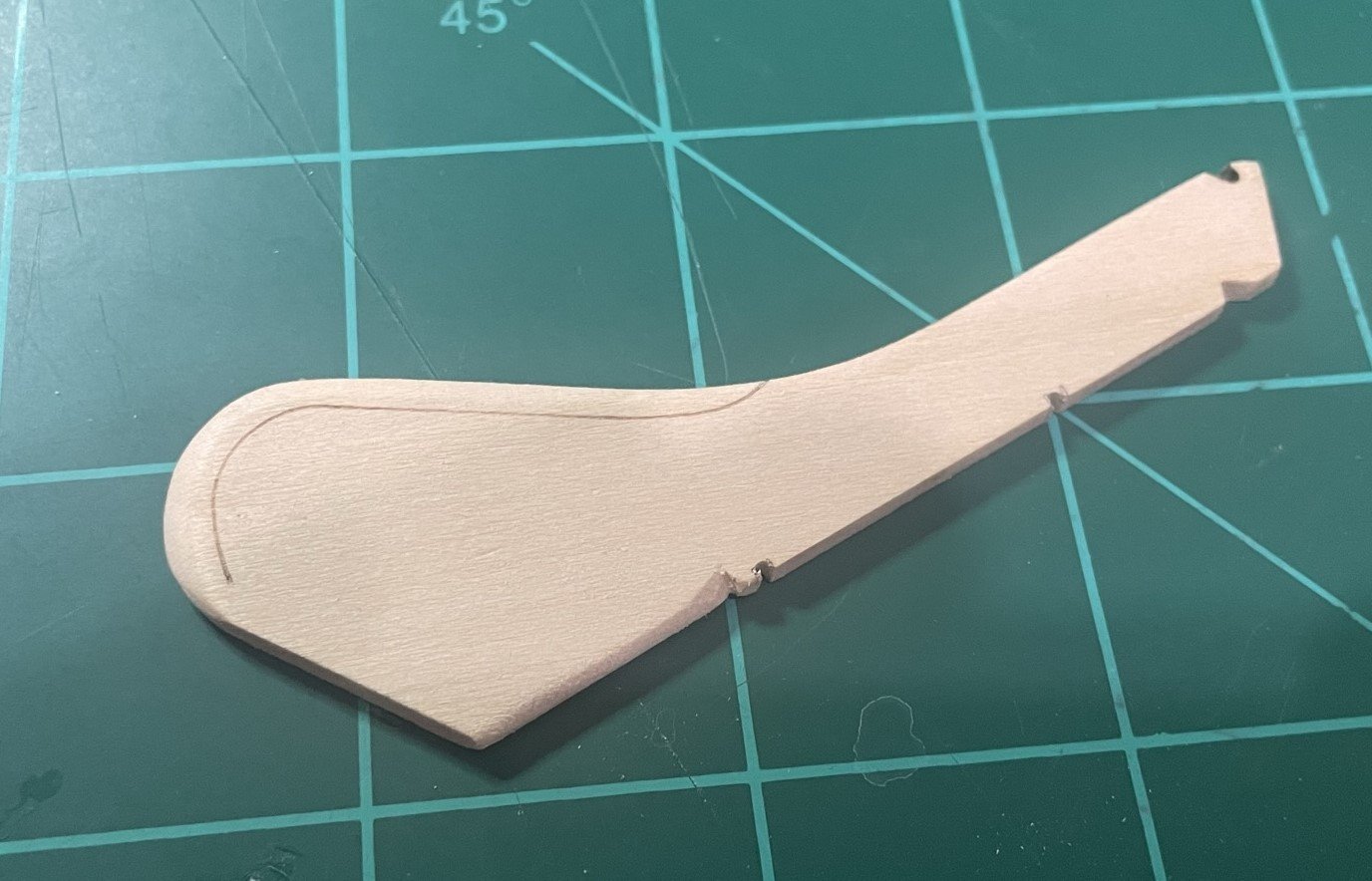

Step 35 tiller assembly The tiller assembly was pretty straightforward. I struggled a bit with mushrooming the 1/16" brass rod for the rivet took awhile but finally got it done. The tiller extension was problematic. First, I went with the 1/32" brass rod because the 1/16" seem too big for the piece of wood. I was unable to get this to mushroom even after annealing it. It ending up splitting the wood on the extension. I had some tiny brass nails from an abandoned build of the Rattlesnake so I used one of those so it looked better on the top. Since the wood on the extension was already split making it extra fragile and I wasn't even going to try to mushroom the other side of the nail, I just glued it into place and made in non-functional. I also used 1/32" brass rod for the tiller extension handle and not the 1/16" rod per the instructions.

-

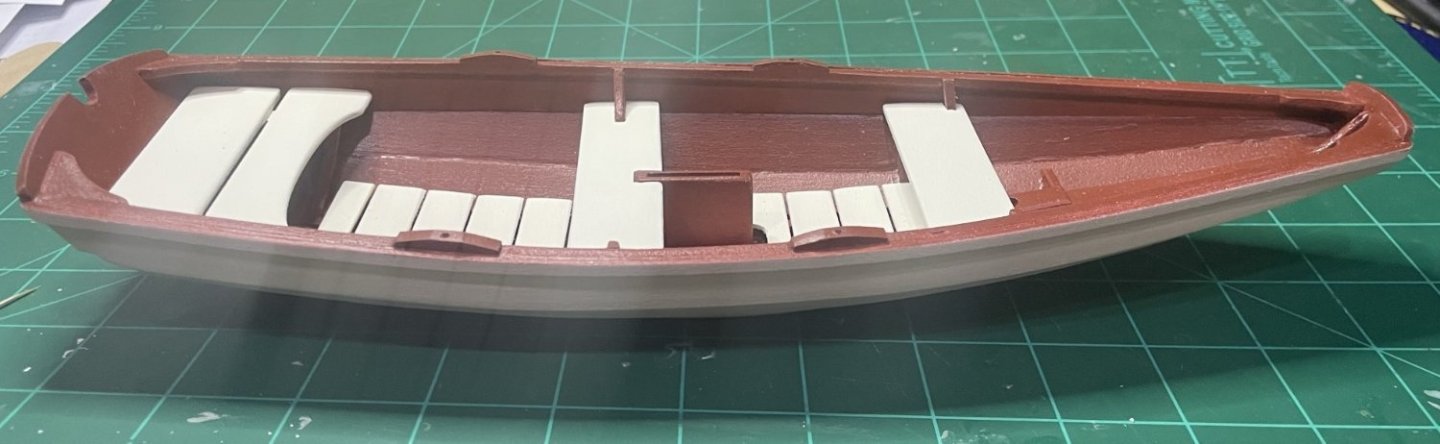

Step 34 Floor Boards When attaching the stern side floor boards, I started with board 9. To ensure I got equal spacing around the dagger board trunk (front and sides). Then I spaced the rest off of that one. Also, boards' 1 and 12 I had to trim down a little and touch up the paint on the cut edge after installing all of them with equal spacing.

-

ccoyle & WizardOfOs: Thank you for the feedback. Much appreciated! I looked at your build WizardOfOs and I like the look. I will be going for a similar paint scheme. To give an update on the progress, I have completed the painting of the hull and will be begin working on the floor boards and painting them and the thwarts prior to assembly. I will post some progress photos soon.

-

I'm considering painting the seats, masts, etc that might normally be stained. I'm considering painting it warm white similar to the exterior hull. My question, not being a boat expert, would it be uncommon to paint the masts? Anything else that might be uncommon to paint? Current plan on paint is to go with the same paint scheme as the instructions. Warm white (MS-4832) exterior, Hull Copper Red (MS-4814) interior.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.