Search the Community

Showing results for tags 'non-ship review'.

-

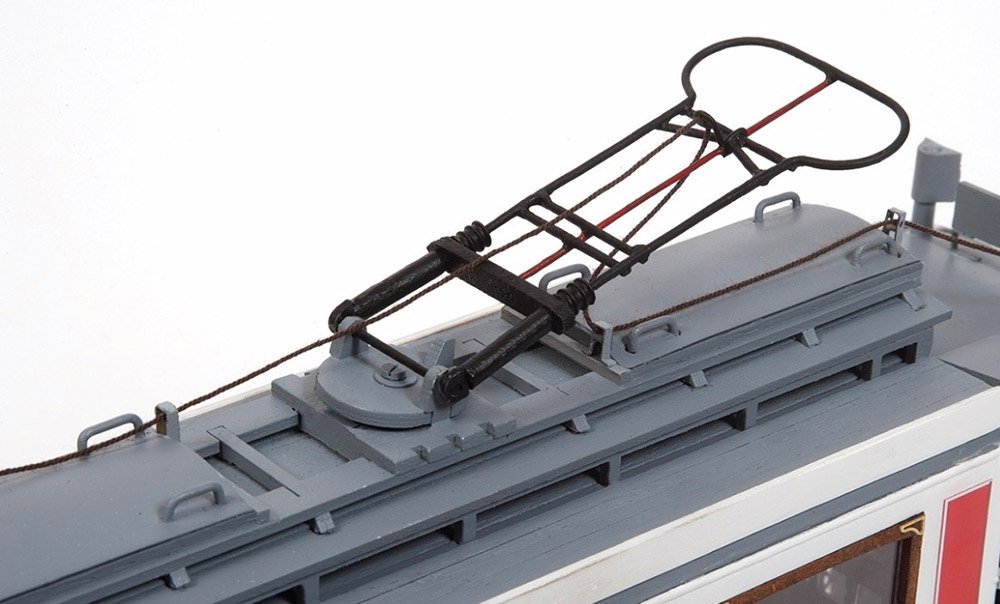

1:24 Istanbul tram OcCre Catalogue # 53010 Available from OcCre for €96,45 Istanbul, the former capital of the Ottoman Empire, once had a large tramway network on both the Asian and the European sides. It first started as a horse tram in 1860 and was gradually converted to an electric tram system starting in 1912. Many additional routes were added to the tram system, in progressive stages over time. The network reached its most widespread extent in 1956 with 108 million passengers being carried by 270 tram-cars, on 56 lines. However reflecting developments in many cities around the world during the 1960s, the tram service began to be closed down in 1956 and was completely stopped in 1966. The Authority thought to re-introduce heritage trams in Istanbul using the same type of rolling stock which was running in European part until 1962, and in the Asian part until 1966. The original Istanbul tram network was almost completely destroyed, including depots, termini, electric power stations, etc., except for some of the rolling stock which had been preserved in transport museums. Using old photographs, people's memories, and other sources, some rolling stock was built for the European side resembling pre-1962 European-side tram stock, including the size, shape, interior, colour scheme etc. The prototypes had originally been built in 1915. Around 1990, the Istiklal Caddesi became a pedestrian zone, and the tram was restored and revived in 1990, in the form of the Taksim-Tünel Nostalgia Tramway. After a 24-year absence, trams returned to Istanbul. The length of the line is 1.64 kilometres (1.02 mi) and there are 5 stops. The Istanbul nostalgic tramways are two heritage tramlines in the city of Istanbul, Turkey. The city has two completely separate heritage tram systems, one on the European side (the Taksim-Tünel Nostalgia Tramway, aka. T2 line), the other on the Asian side (T3 line, aka. the Kadıköy-Moda Nostalgia Tramway). The kit OcCre’s new Istanbul tram kit replicates one of those heritage trams mentioned in the passage above, and is packed into a slender, standard OcCre box, as per our Terror article that we published recently. A colour-printed wraparound label is affixed to this with tape, and a cut-out in the lid is designed to display the plastic tray of components within. Lifting the lid and removing the inserted component tray, we come to the main box and here you slice a few tape tags to open up the contents. All the timber parts are bundled with two sheets of photo-etch parts and are securely held together with a shrink wrap covering. This compact method of packaging ensures zero damage and all parts are pristine. Now we cut away the cellophane… This sheet of parts, all cleanly laser-cut, concerns the construction of the tram seating. Each seat is comprised of four parts, varying slightly, dependant on where in the tram it is installed. Note that no parts are engraved with numbers. Instead, you will need to refer to the printed parts plan that is a part of the assembly manual. Timber quality here is high, and all parts are only held in situ with small, easily cut tags. We now have an MDF sheet included. This one contains a number of parts for which removal of wood grain would have been a PITA, so this is a nice move. The largest part is the tram floor, with various slots and connecting tabs, roof side supports, roof end frames and roof support frames etc. Our next two plywood sheets are identical, containing frames, cabin ends and internal frameworks, more seat parts, door parts, bulkheads, etc. Each sheet contains over 30 parts, again, all cleanly cut in high-grade ply. Laser scorching is very low, and very localised, and char clean-up should be nice and easy. The next two sheets are also identical to each other, but instead of being produced from ply, these are also supplied as MDF. This is actually quite a savvy move as I mentioned, as a good number of these will go into building exterior areas of the tram, and of course, there will be no wood grain to remove. Here you can see the slab sides for the tram, more roof frames, boarding platform and chassis frames etc. A nice thick bundle of various size timber strip stock is included and bundled together with elastic bands. This material will form areas such as internal framing and the planked roof etc. Quality is very good, with only a little wispy material needing to be removed from some of the strip. That’s the last of the timber areas in this kit, as we now look at the two photo-etch sheets included here. The first one is made from brass, and includes the instantly obvious shutter gates, tram destination sign brackets, external window frame corner trims, etc. Etch quality is superb, with the removal tags being thin and narrow. The second PE sheet appears to be manufactured from some sort of nickel-alloy, and parts here include the boarding step housings, electric roof sheathing, cabin parts, ventilators, external footplates, and also hand rail mounting points. A number of lengths of thick brass wire are included for fashioning all manner of items, such as the trolley pole that catches the overhead electrical lines. Some of these items will need straight edges, so you’ll need to be careful when it comes to ensuring you straighten the wire suitably. I do think that some of these wire items will really lend themselves to being soldered, so if you are capable of that, it’s time to ready the hot iron! I admit that I didn’t really know how the exterior livery was going to be approached on this model, such as paint, decal etc., but OcCre have in fact included a nice, glossy sheet of self-adhesive panel stickers that should adhere nicely to the smooth MDF surfaces. These have the livery and text already in situ. You will need extreme care in applying these to ensure they line up perfectly, as I don’t know just how sticky they are. Printing quality is excellent, and this really will create the appearance of the tram you see in the photo at the start of this article. For the windows, a sheet of acetate is included, and for the internal ceiling, another printed sheet is included. This needs to be glued to the internal roof framework before fitting the various ceiling lights and ventilators etc. I do suggest you don’t use any glue which is too wet and would damage the thin paper sheet. Look at using a quality glue-stick instead. Now we can take a look at that neat plastic tray of components that we can see through the box lid. This is split into twelve compartments, with each holding either a singular type of item, or multiples of different elements. Many of the parts in here are made from cast white metal, such as leaf-spring suspension, interior lights, dampers, cabin components, wheels, couplings, lights, grab-rails etc. There are a small number of turned brass parts and screws in here too, as well as brass eyelets, washers, and a spool of rigging cord to simulate the electricity cable for the trolley pole. There is a small ply sheet too, with just four small parts for an external roof ventilation opening. As with the previous OcCre kit we looked at, the instructions for this release are all driven by clear colour photos of each stage, showing actual construction of the prototype model. This series of colour, foldedr A3 sheets goes through the building process in a clear and organised way. It’s also worth noting that the parts themselves are added to the mix in a sequential way, meaning it’s easy to trace where in construction a particular element is required. All stock timber sizes are also shown in dimensional form too, to ensure you use the correct material in the appropriate area. A set of written instructions is also included, referring to the specific photos. Conclusion This is certainly an unusual and well-executed little project from OcCre. There’s quite a lot of construction to be had here in both frame and PE, with a more than generous number of extra fittings thrown into the mix. A thoroughly detailed and nicely designed model of a famous heritage tram, and one that I image will be addictive to build. Just as well there’s a whole fleet of world heritage trams to choose from! Maybe we’ll look at a couple more soon. My sincere thanks to OcCre for the review sample seen here. To purchase directly, click the link at the top of this article.

-

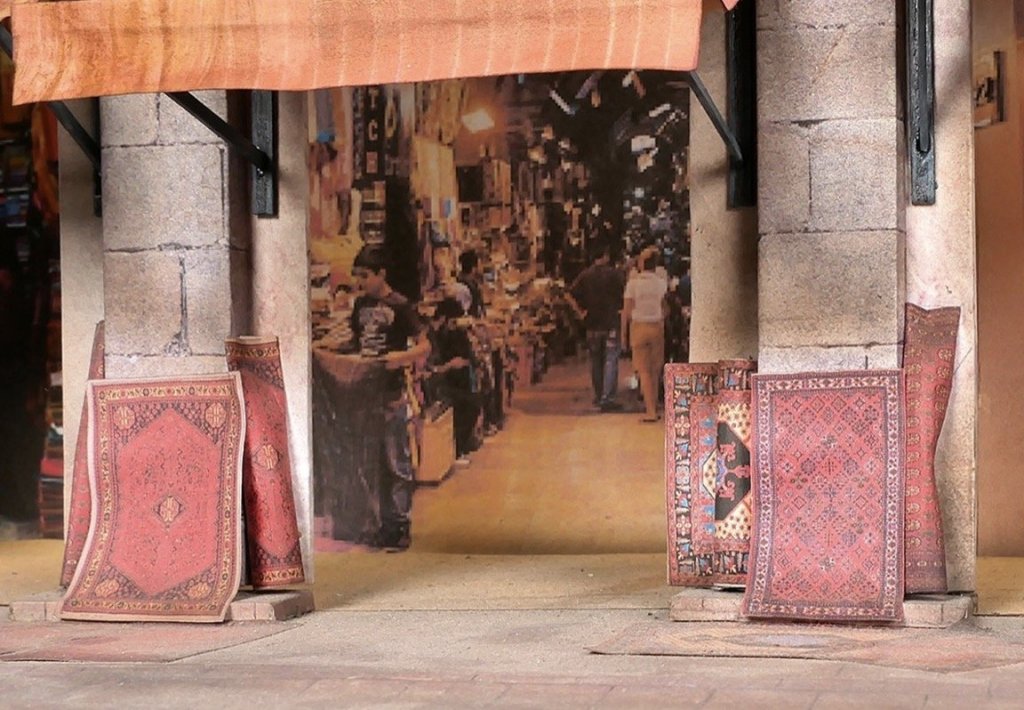

1:24 Istanbul Diorama OcCre Catalogue # 53010D Available from OcCre for €60,95 If you’ve recently taken a look at our Istanbul tram review, you might like this particular review article. Yes, of course you can display your tram on a shelf, or in a cabinet, but what about outside Istanbul’s Grand Bazaar? That’s exactly what this new product from OcCre allows us to do, and with relative ease of construction. This is what OcCre have as their website product description: “The diorama is a representation of the entrance to the Grand Bazaar of Istanbul, one of the largest in the world. Located inside the old “walled city", on the European side of Istanbul, between Nuruosmaniye, Mercan and Beyazıt, with more than 58 covered streets and 4,000 shops or stalls, every day the bazaar attracts between 250,000 and 400,000 visitors. The bazaar offers a wide range of products, in particular jewellers, precious metal workers, spice shops and carpet shops. The stalls tend to be grouped together by type, following the tradition of the ancient guilds. The bazaar includes two Bedestens, or domed stone-built structures, which are used for the storage of merchandise. The first of these was built in 1464, by order of Mehmet II, although it then had to be mostly rebuilt in 1864, following the earthquake. This fabulous diorama combines perfectly with the tram of Istanbul, joining the nostalgic line of Taksim-Tunnel with the Grand Bazaar, in an effort to group two large emblems of the city of Istanbul.” The kit The Istanbul diorama is packaged into quite a plain, shallow corrugated cardboard box, with a colour product label attached. There is also a reasonable amount of weight here too, so you know there’s plenty of building material afoot. Upon opening the box, it ca be seen that the multitude of sheet material is wrapped in a heat-sealed sleeve that needs to be cut away. As the sheets in here are various sizes, and the internal box has no compartmentalisation, this is a good way of ensuring that damage risk is minimised. There are also a number of printed sheets which are rolled up, some strip timber and brass wire. A catalogue and sheet pointing to the instructions, are also included. More on the latter in a moment. The numerous sheets are made from MDF and are very neatly laser-cut. You will note how some of the parts have dovetail connections too. In essence, the entire diorama is built up from a series of wall panels that have the Islamic arch shapes that attach to them to create a 3D relief, and this is sat upon a base which is built from sections, to incorporate the ruts along which the tram lines would run. Oddly enough, there is no actual brass section strip to recreate the tram line itself, but instead, timber strip, painted silver, it what’s prescribed. Using some metal strip could be a nice enhancement, but you would need to purchase that yourself, measured against the OcCre tram wheels for best fit. The idea behind this diorama is that anyone can typically build it, simply out of the box contents. To decorate the walls and floors etc. a series of colour-printed textures are provided, on A4 sheets. These include stone, marble and parquet styles, and these need to be cut out to suit the various structures, and then glued into position with a glue stick, for example. Using wet glues may cause the sheets to ripple and not adhere as flat as they should, although the instructions do actually show brushed PVA as being the glue of choice. Sheets of paper are also supplied to simulate the Bazaar interior, with crowds of people and stalls etc. When it comes to depicting the exterior details, more printed sheets are supplied, with such things as Turkish rugs, flags etc, and these can be draped over the display stands that sit outside the various stalls on the exterior of the Bazaar. These stalls also have printed awnings to shelter them from the Turkish sun. To recreate the road itself, then a series of strip card is supplied. This needs to be cut into brick-sized sections, and then plastered over the road in a staggered manner. You can of course then paint and infill between them and add some airbrushed staining to weather things realistically. Brass wire is supplied for all manner of things, such as the random-looking electrical cables that run along the outside walls. OcCre supply no instructions for this kit. Instead, they provide an online build guide which is very comprehensive, showing everything right down to measuring out specific dimensions for everything. This multi-part guide is excellent, with the facility to be able to download each part as a PDF. To check out the guide, head to this link: http://www.occremania.com/diorama-de-istanbul-parte-8-2/ Conclusion Dioramas aren’t usually my thing, but this looks very tempting, just to see if I can make a reasonable attempt at it and add some airbrush work to make it look a little more lived in. There’s certainly a nice quantity of building material here, and all nicely produced. Recreating the street surface will also be quite absorbing, as well as those kerb stones that are cut from the thick strip timber. My sincere thanks to OcCre for providing the review sample seen here. To purchase directly, click the link at the top of the article.

-

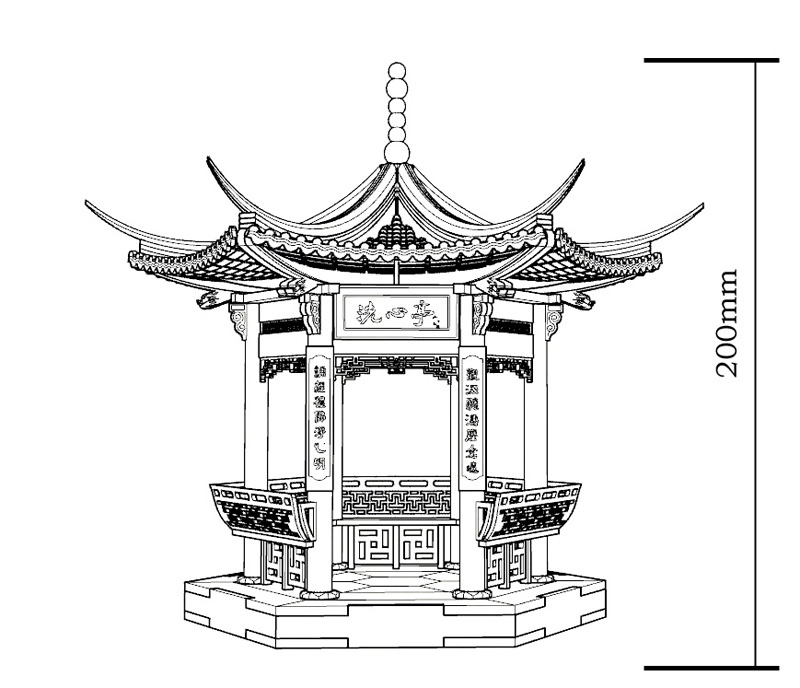

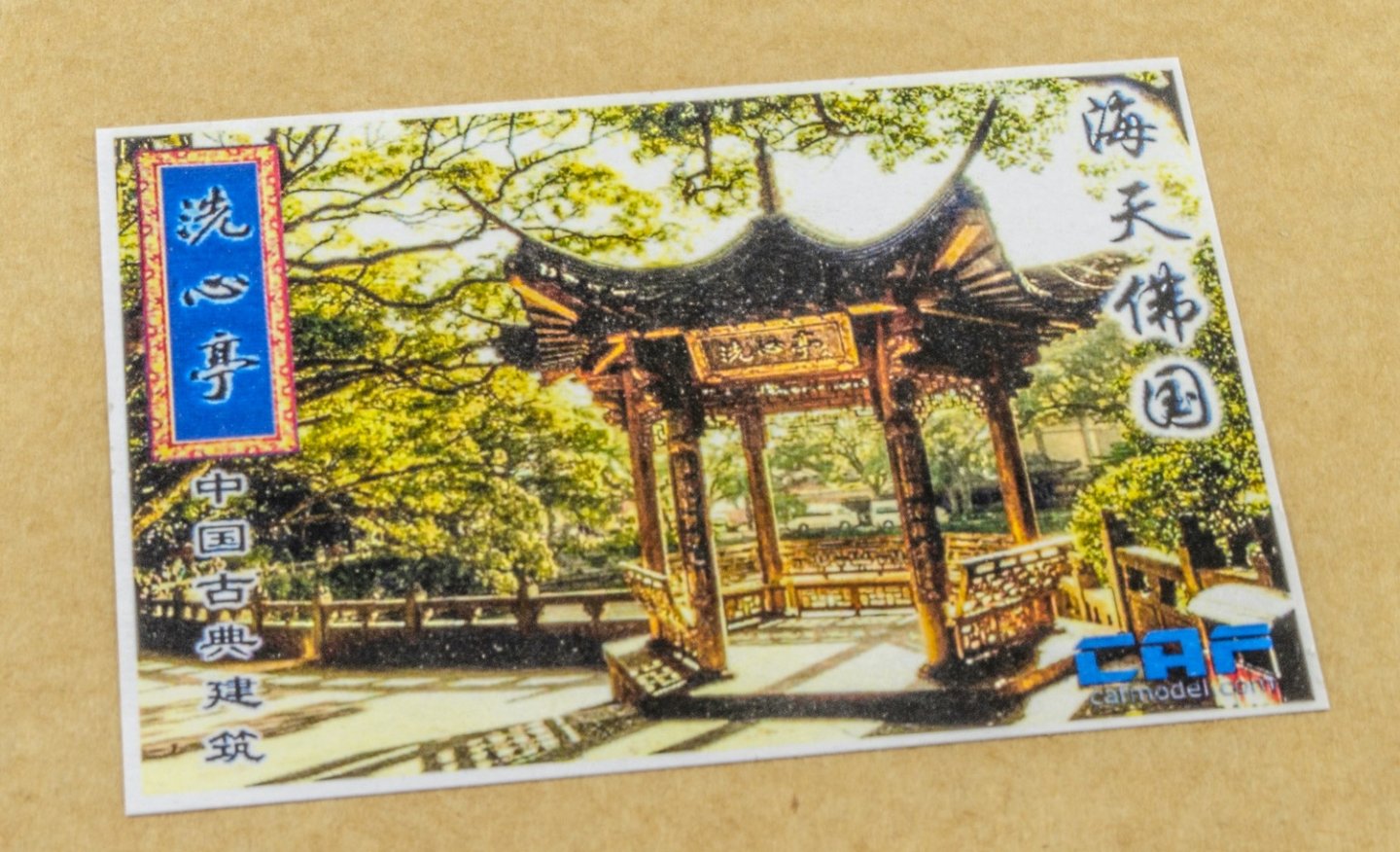

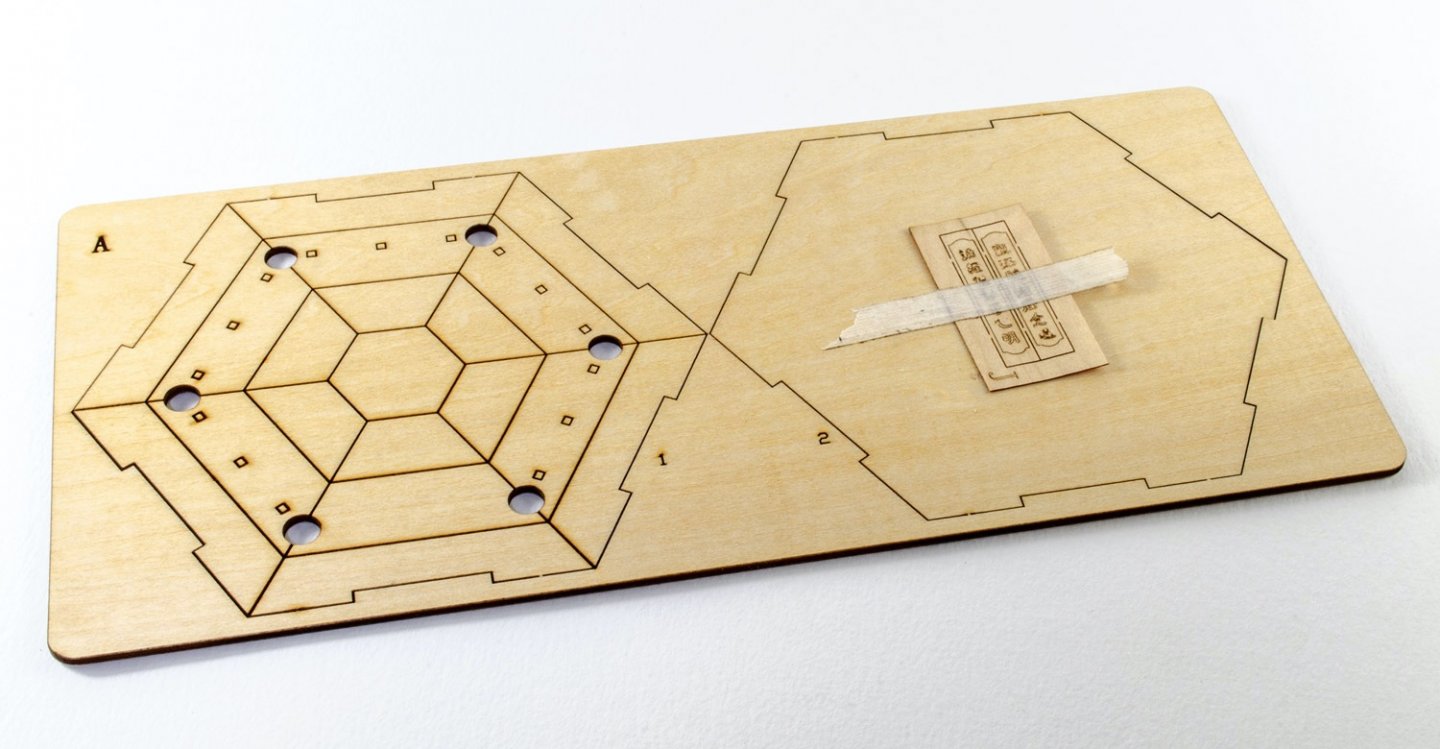

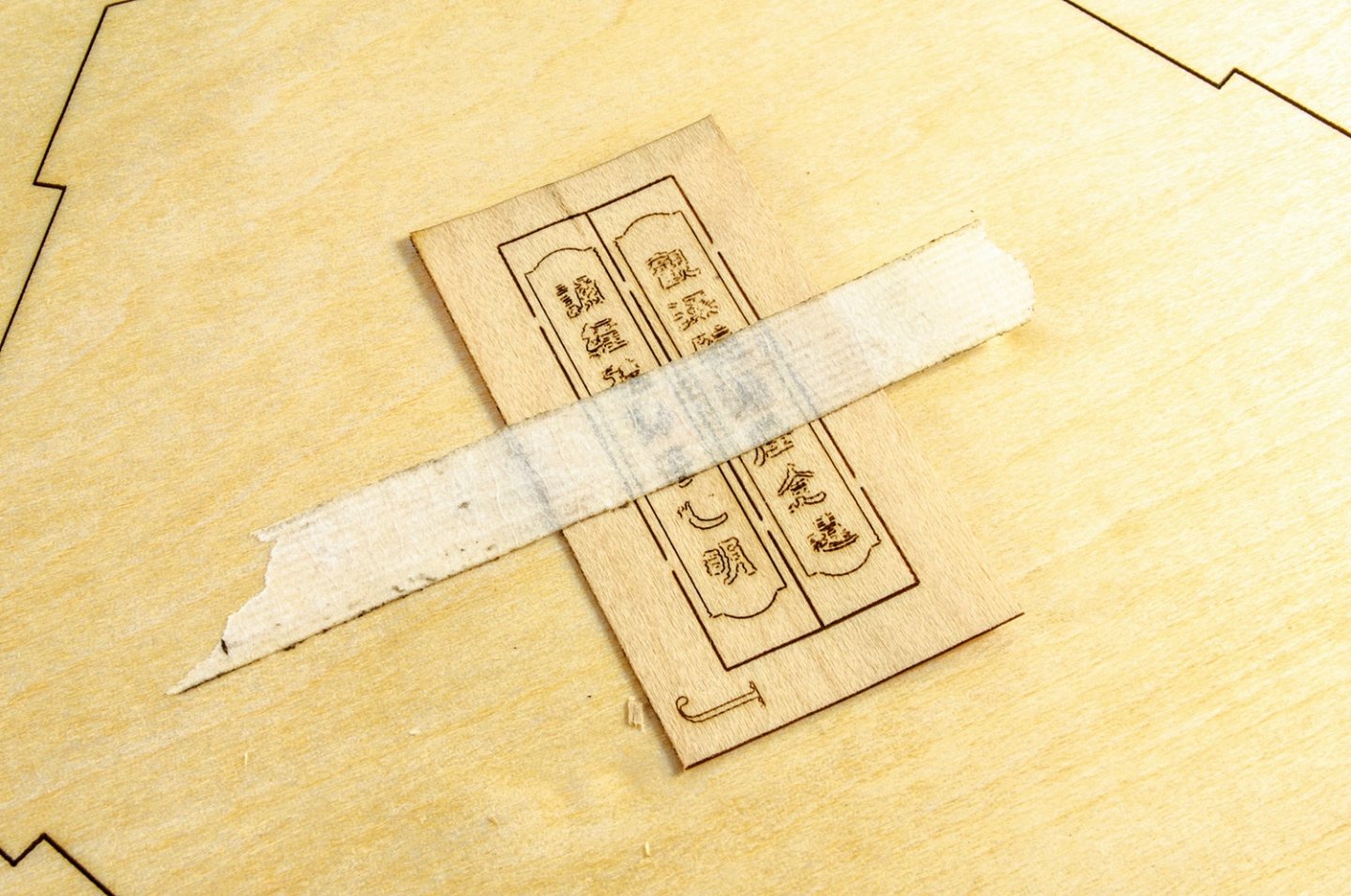

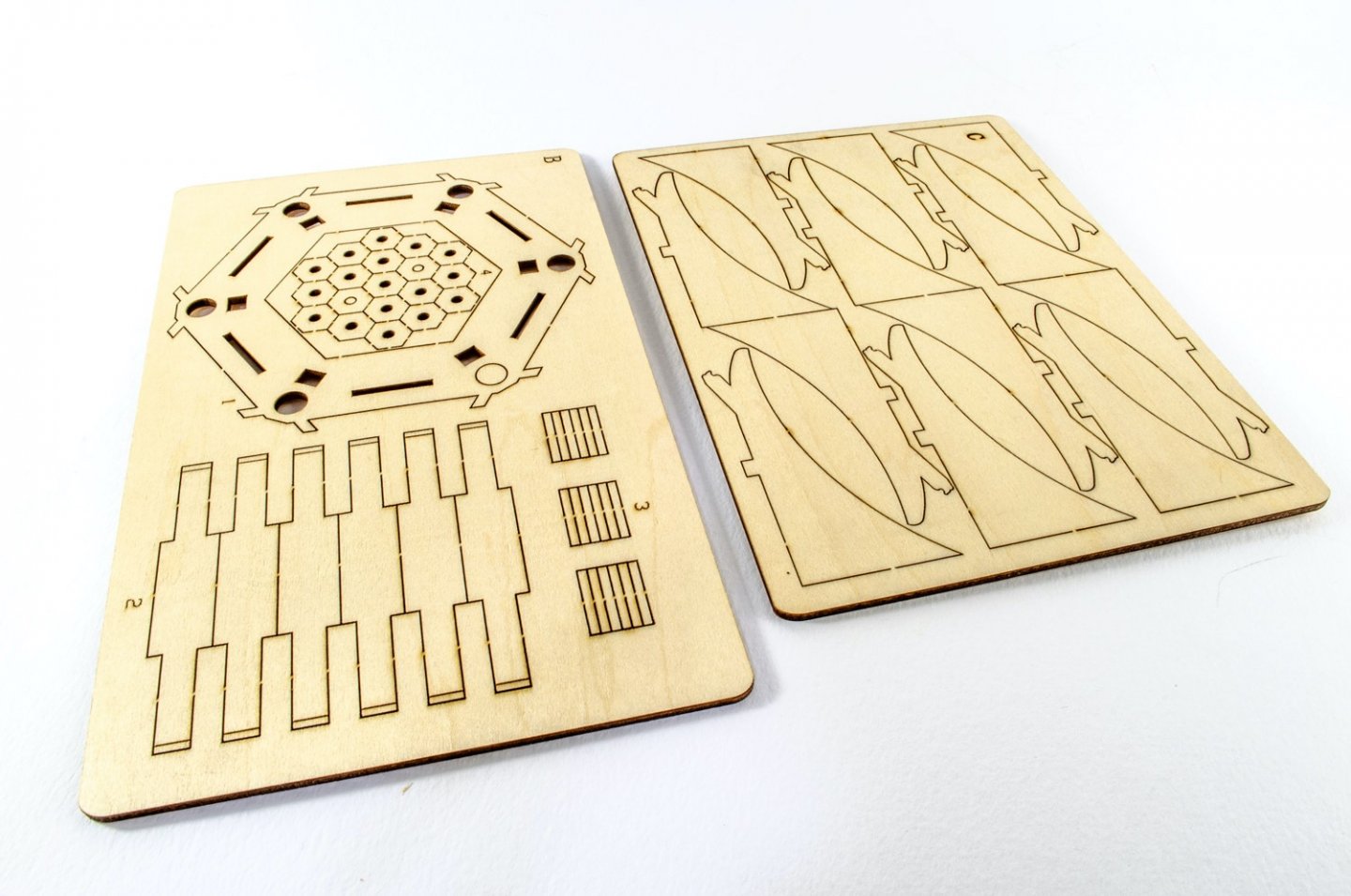

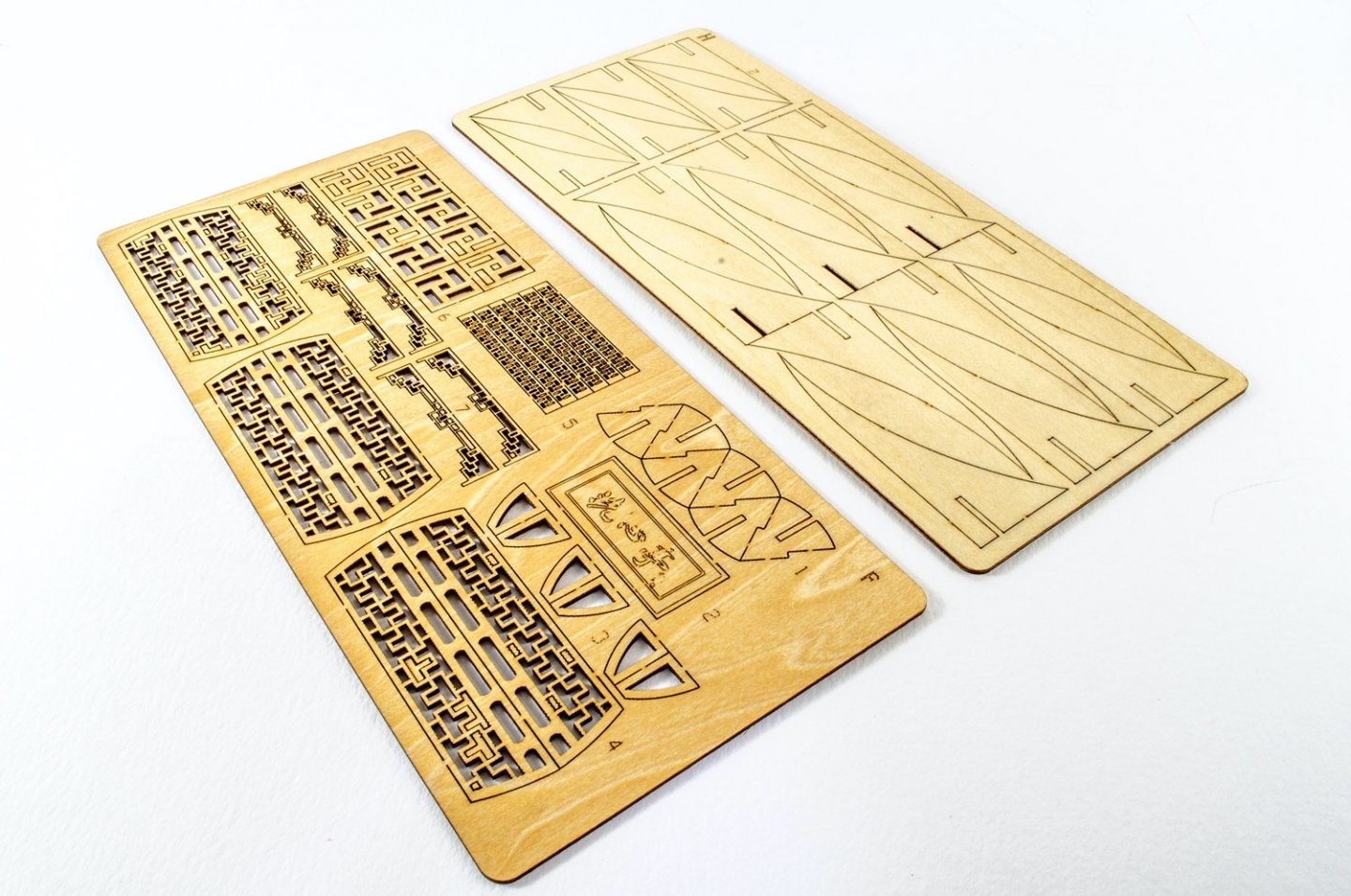

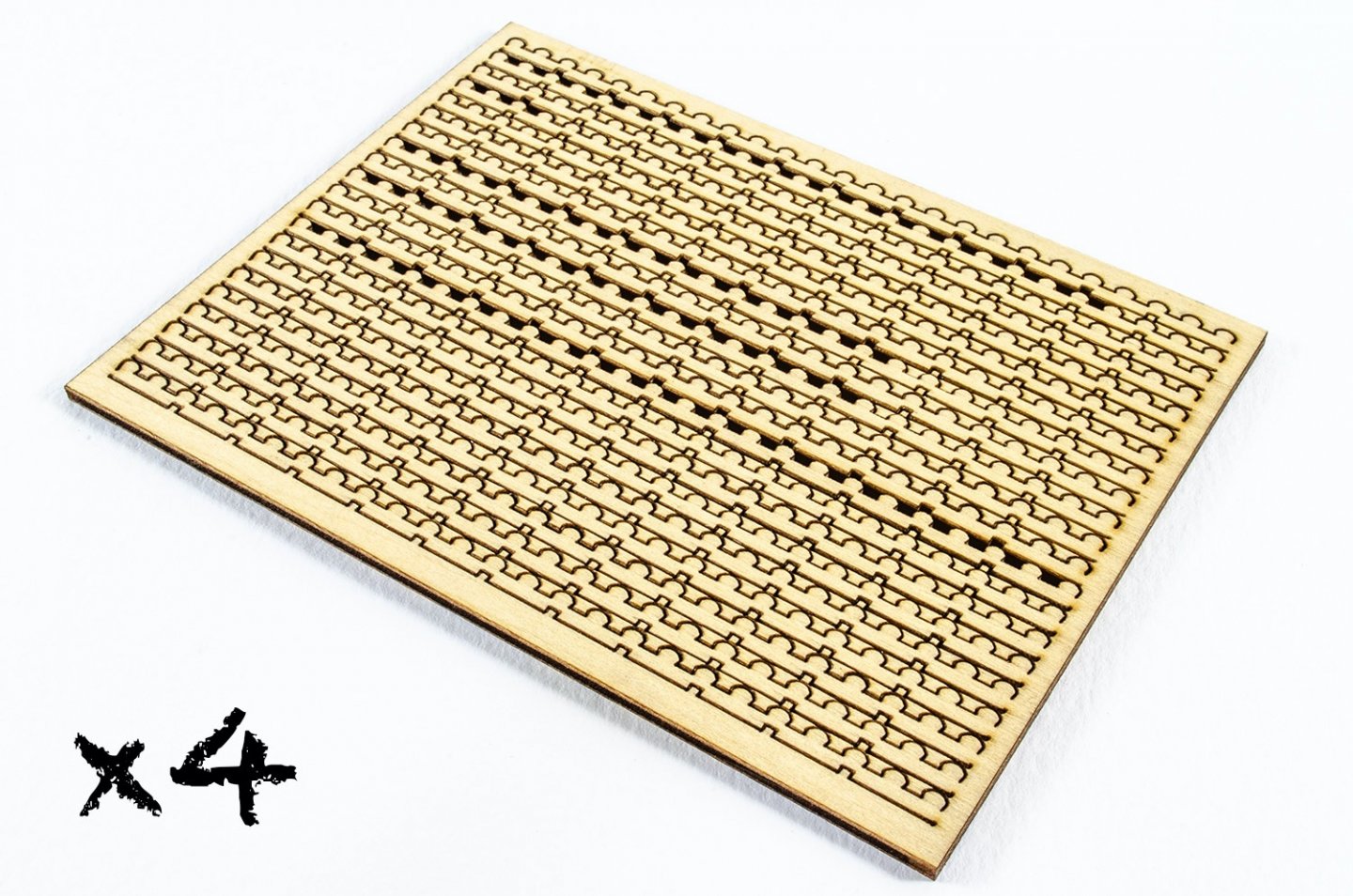

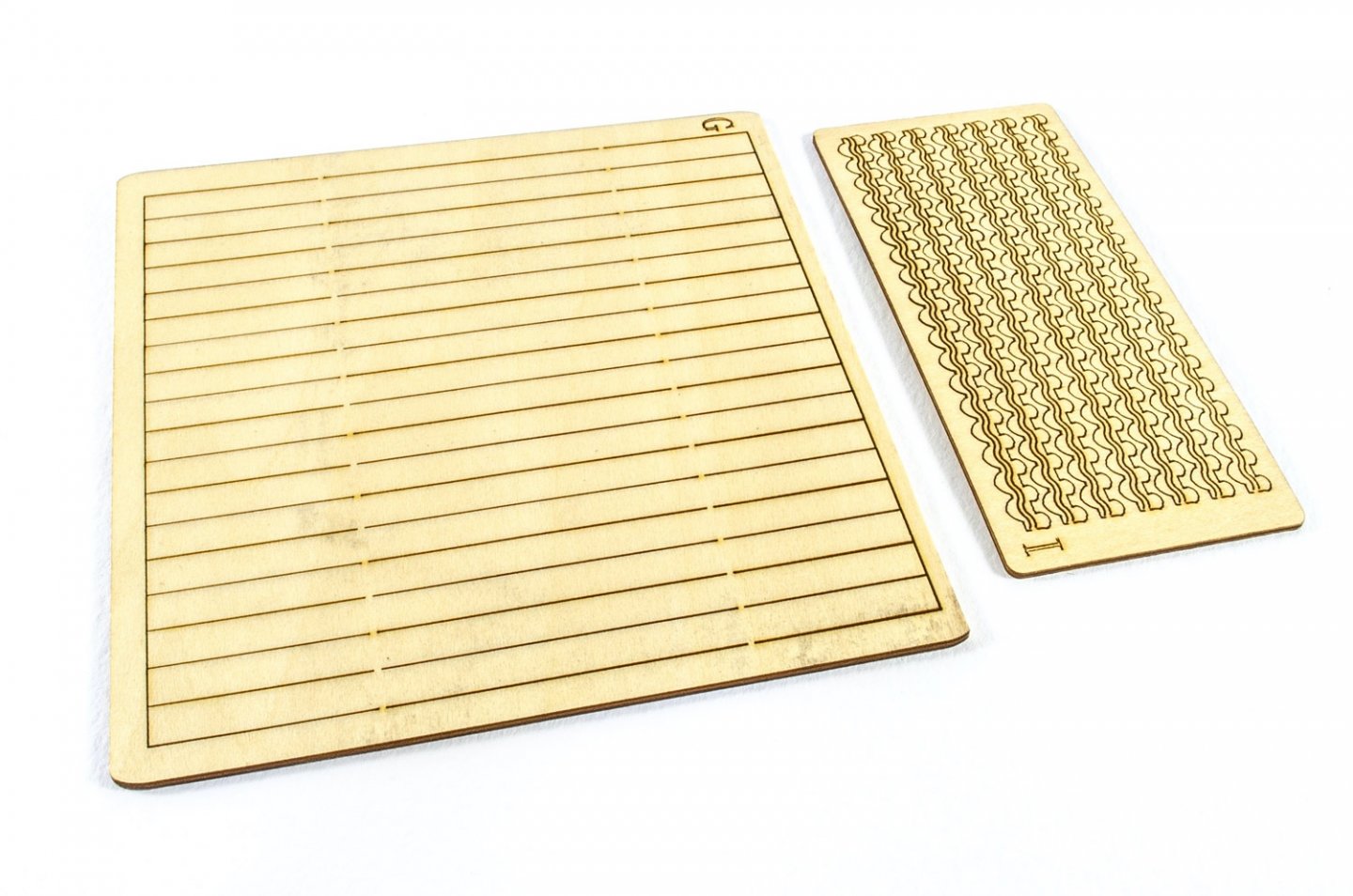

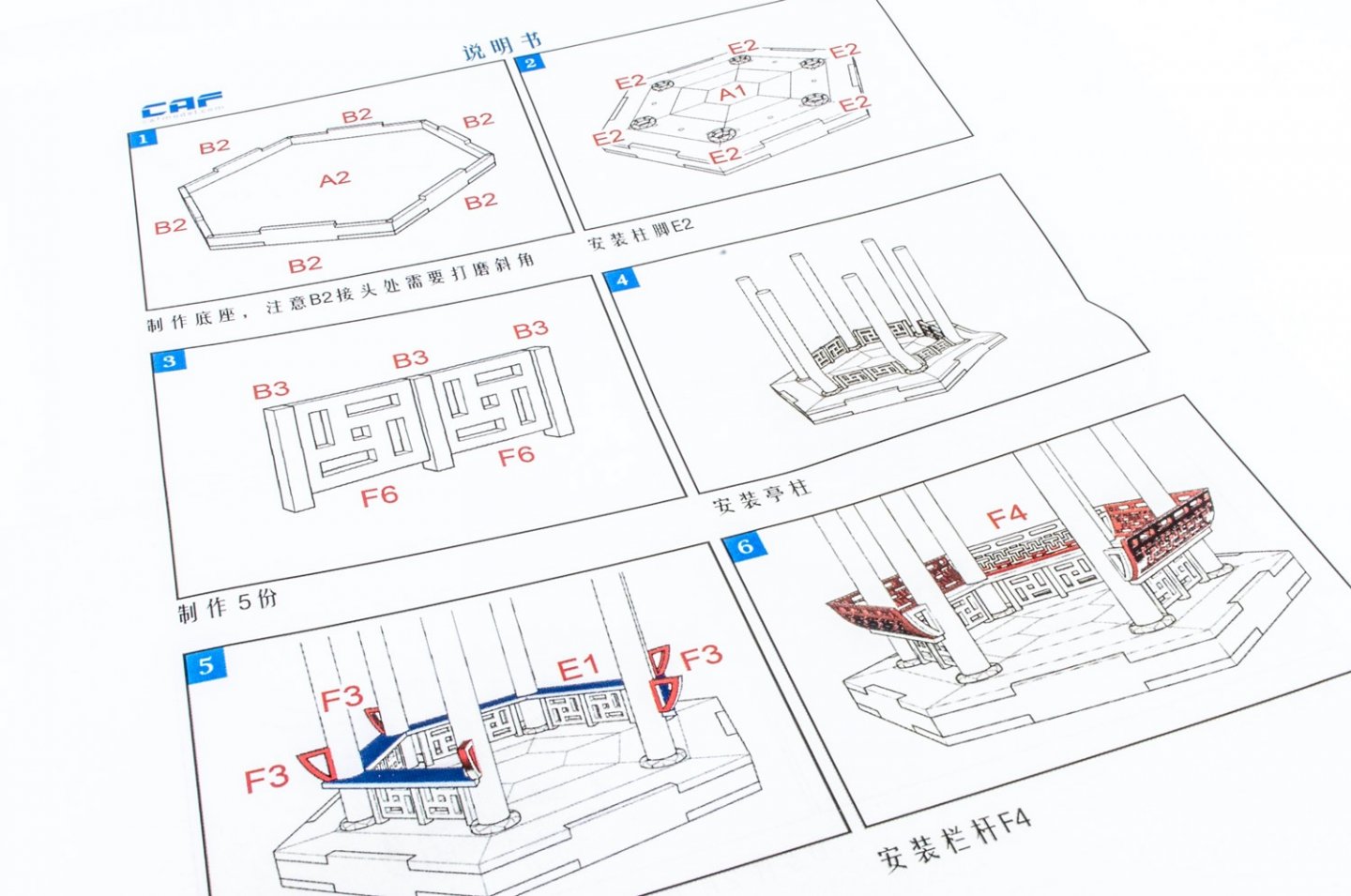

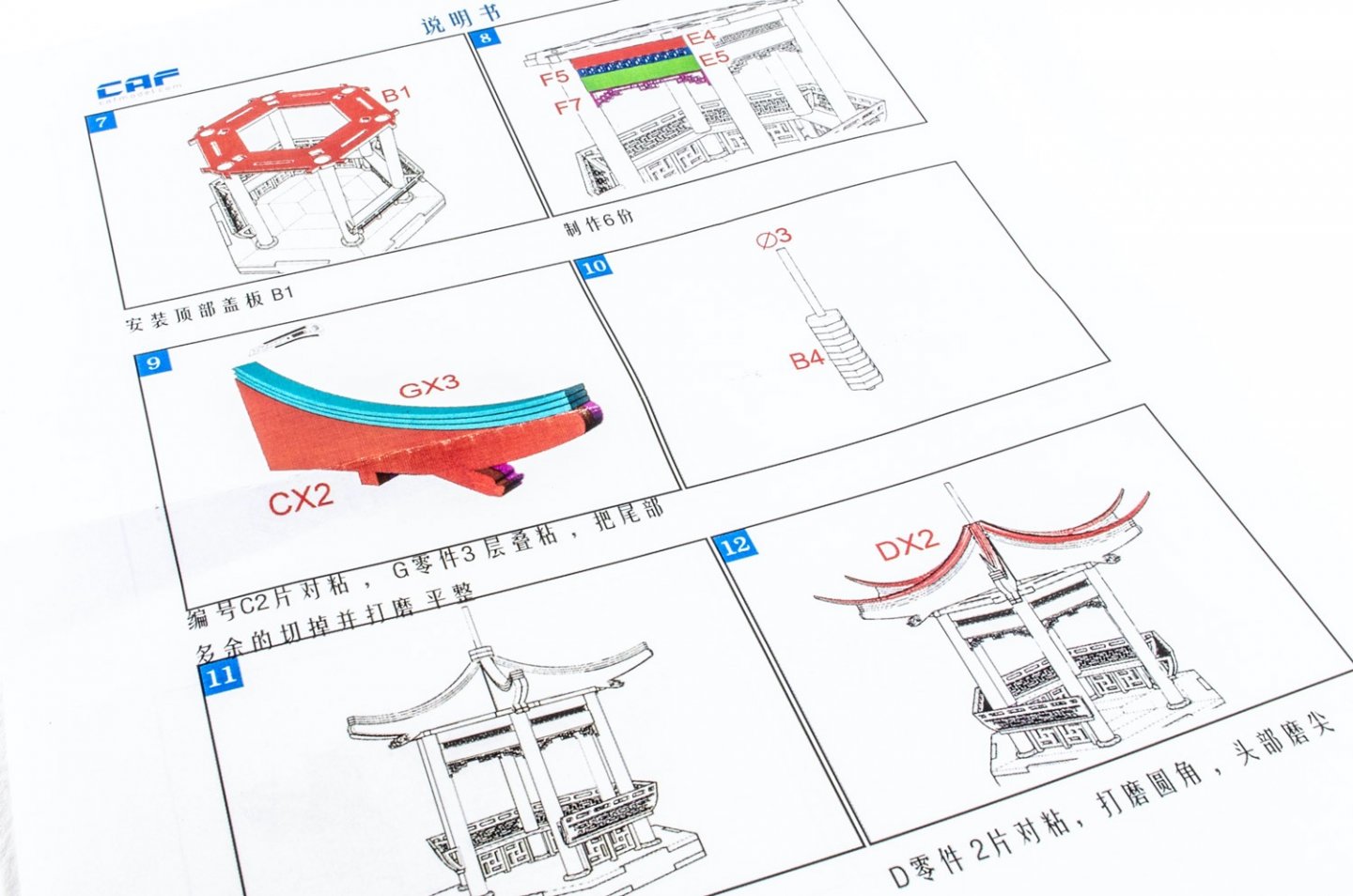

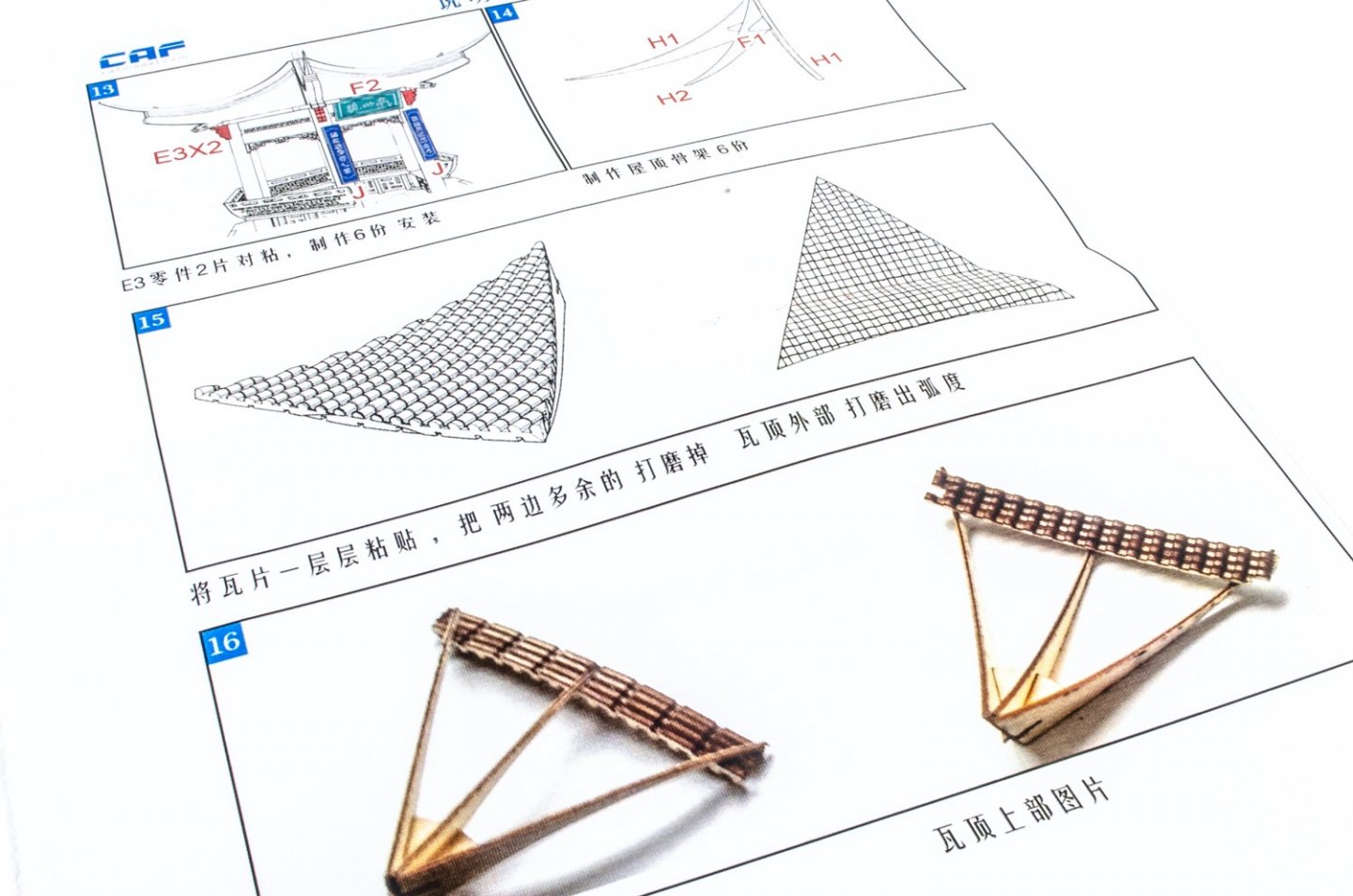

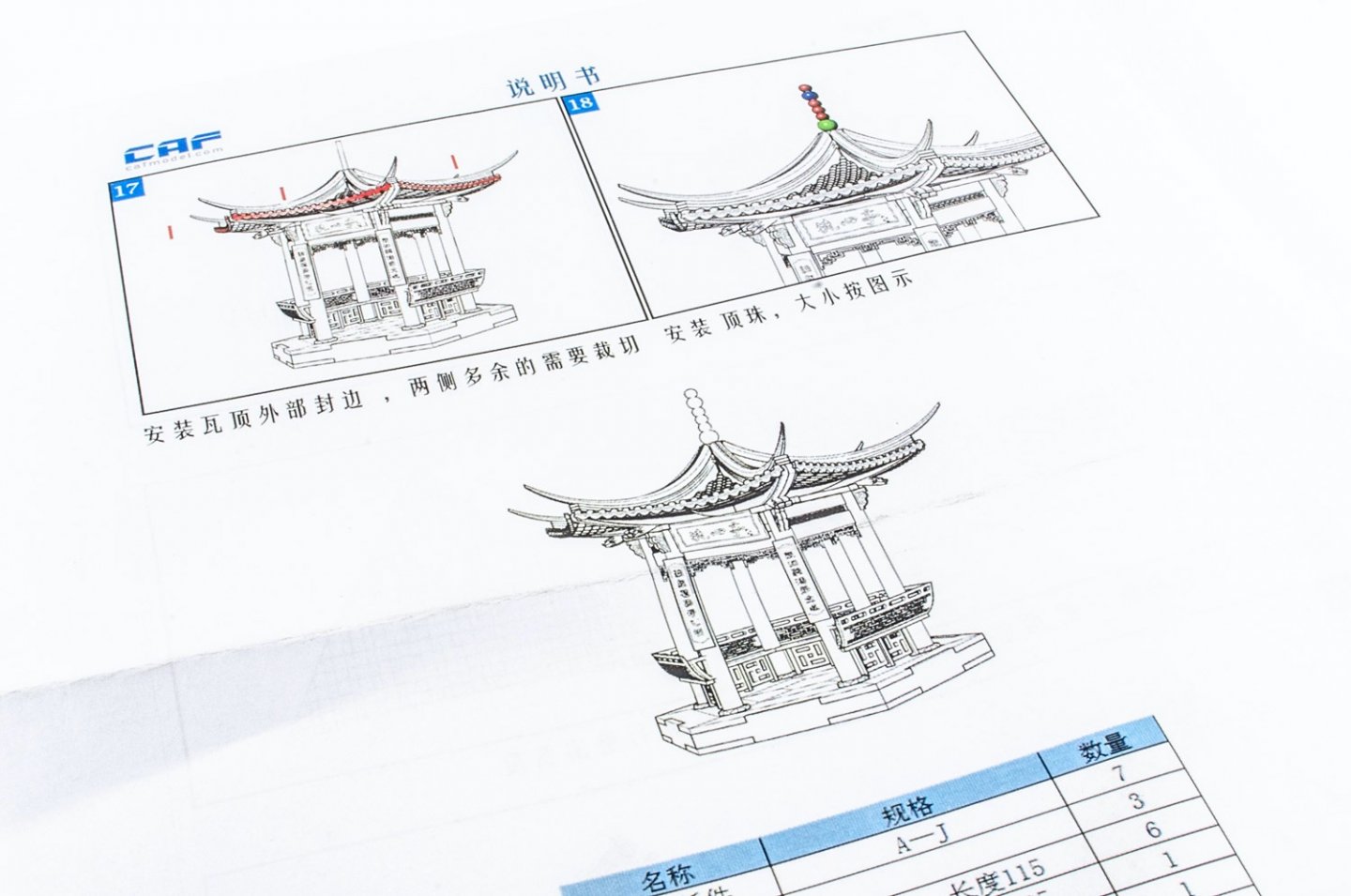

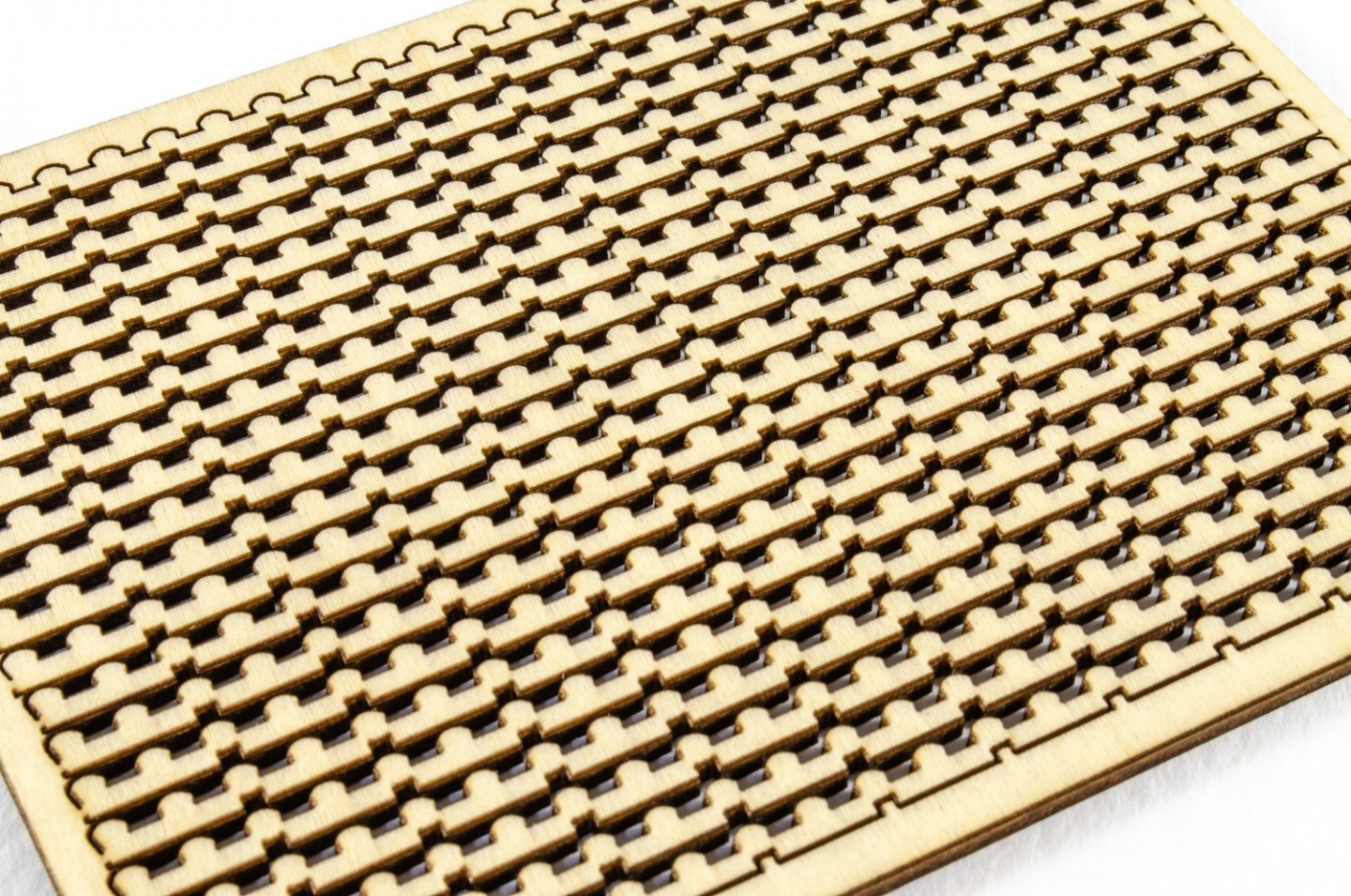

Ancient Chinese architecture XiXing Pavilion CAF Model Available from CAF Model for $32.00USD plus shipping The kit I love architecture from the Far East, having visited quite a lot of it when both times I've visited Japan. Some of the structures in old Kyoto are stunning, as they are in Osaka and Tokyo. I could lose myself in them for hours on end. Sometimes it's hard to believe some of these are around 1000yrs old. The same applies to China. I've always had a hankering to visit and see the cultural side of things. This little ancient Pavilion kit from XiXing (presumably in the Guangdong Province of China) is just the sort of thing that really appeals to me. I'm not sure of the actual scale, so here's a drawing of the completed model, with dimension: Th kit itself is packaged into a small box measuring 33xm x 17cm x 4cm. Inside, thirteen sheets of very nice quality, laser-cut/engraved ply, are sealed in a shrink wrap cellophane covering, along with a bag containing dowel and wooden balls, and two sheets of instructions. A small label is applied to the box lid to show what the box contains, and a piece of packing foam stops everything from rattling around in transit. Construction starts with the large hexagonal base. You can see the two principle parts for this here and that the wooden pillars will be easy to locate because of the pre-cut holes. That should remove probably the main cause of possible error in the main structure, especially as there are infill walls and benching that need to precisely sit between the pillars. All parts could possibly benefit from a light coat of varnish and a little sanding to protect them from paint soak if you decide to add some colour to your finished Pavilion. Tacked on top of the lower base are the signs, laser etched and cut in very thin veneer. These will wrap around the pillars on the entrance to the pavilion. On top of your pillars will sit the crown of the pavilion, before the roof is fitted. That is the other hexagonal part. This can be seen here, with the corresponding holes for the pillars tops. The hexagonal parts within it are for the 'spire' section, whilst the '3' parts are the infills between the wall sections which skirt the bottom of the pavilion. Between the base sections, you will need to add the side parts, seen here. There is an engraved line on them indicating the bevel needed where the walls meet. The other sheet contains the roof frame parts. The very ornate sheet shown here holds the parts for the wall sections, bench backs and the fancy trellis work that adorns the pavilion, just below the rood section. Most of the infill parts are gone, but there's just a few more I need to tap out lightly. More roof frames are seen on the other sheet. These two sheets contain the pillar bases, semi-hexagonal bench seating, decorative scrollwork, and infill panels around the top of the pillars. Again, another sheet contains some of the parts for that elaborate roof. One sheet here contains the beams which sit atop the four main roof frame sections. These will lie three-deep and need to be flushed to the ends of the frame sections. The other sheet here contains parts that finish off the edges of the tiled roof panels. Now, talking of tiled roof panels, these FOUR sheets hold the strips which, when assembled, create that characteristic roof finish you see own many ancient buildings in the Far East. There is some infill between these sheets which I removed, as you can see here: The last contents here are the dowels for the pillars and also the spire, plus the wooden balls which slide onto the spire in decreasing sizes. Instructions The Pavilion appears to be quite straightforward when it comes to the various stages, although I will use my phone translate app to make sure I don't miss any vital bit of information as I build. The instructions are printed on two sheets of A4 paper, double-sided, and also in colour to help identify the various components. Construction is completed over 18 stages, with all parts clearly numbered. Conclusion In all, this is a very nice, and also quite inexpensive kit from CAF, and it should provide many pleasant hours of construction. The photos of the finished build show the timbers painted in gold, with a grey roof and light grey base. Whilst the model can be left in bare timber, I do think a paint job would be the best option to highlight the details and male it more authentic. Sometimes, we all need a little side project, or perhaps a little something between our current shipyard work, and this little kit will certainly do that whilst sticking with wood and building something which looks beautiful when completed. Quality is excellent and the whole design looks nicely thought out. Finished Model My sincere thanks to Tom at CAF Model for sending this lovely little kit out for review on Model Ship World. To purchase, click the link at the top of the article.

-

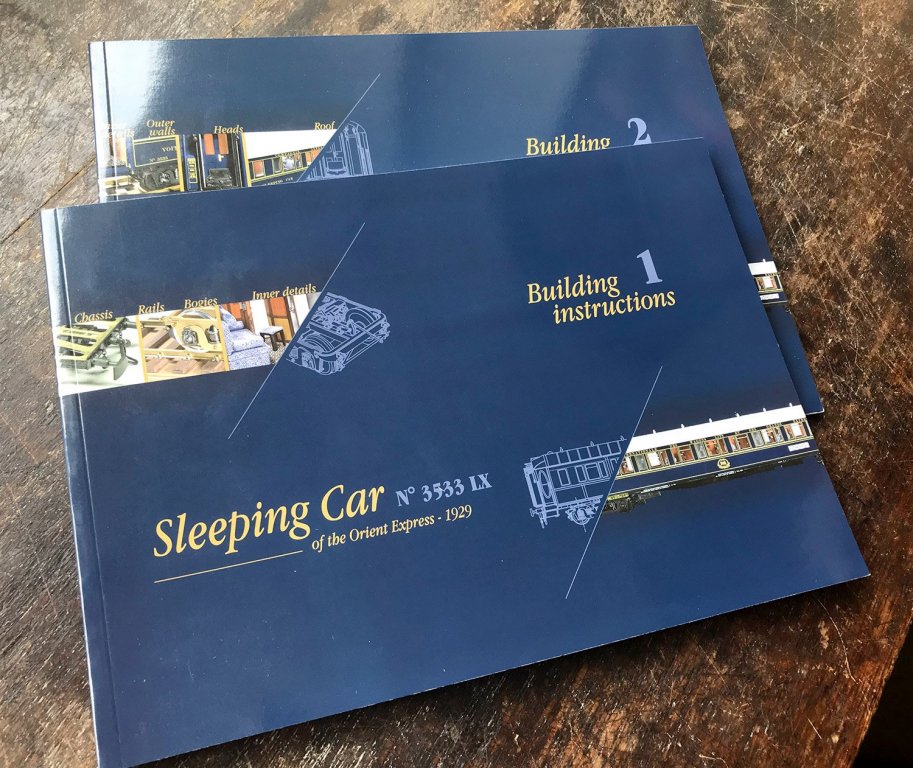

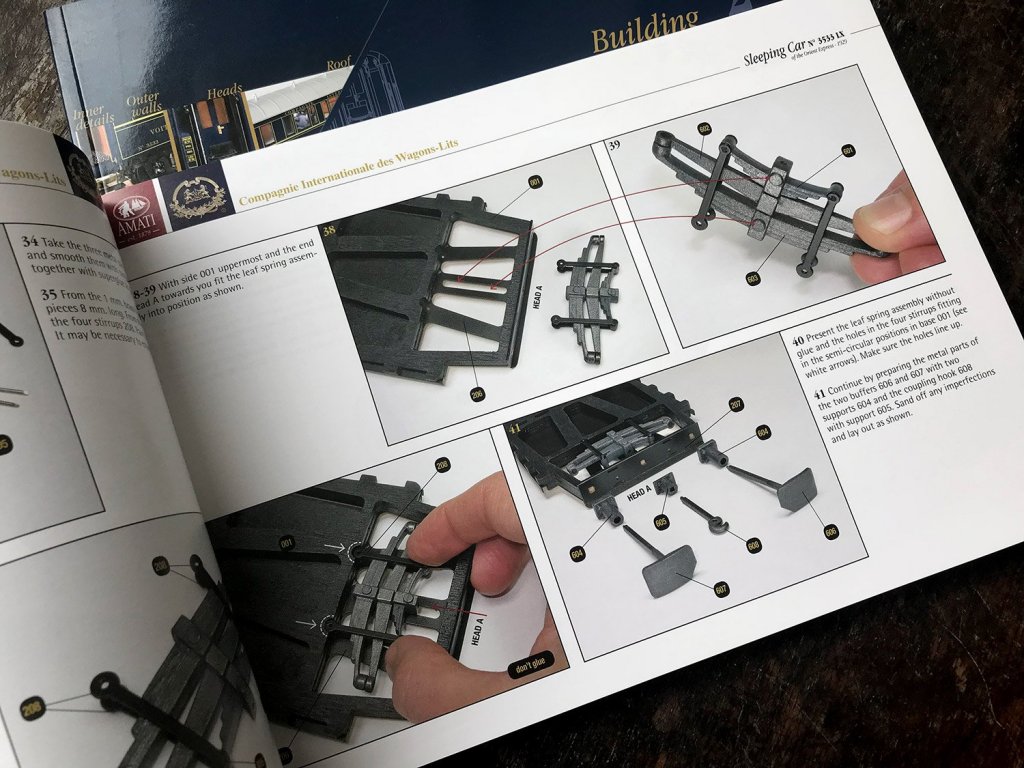

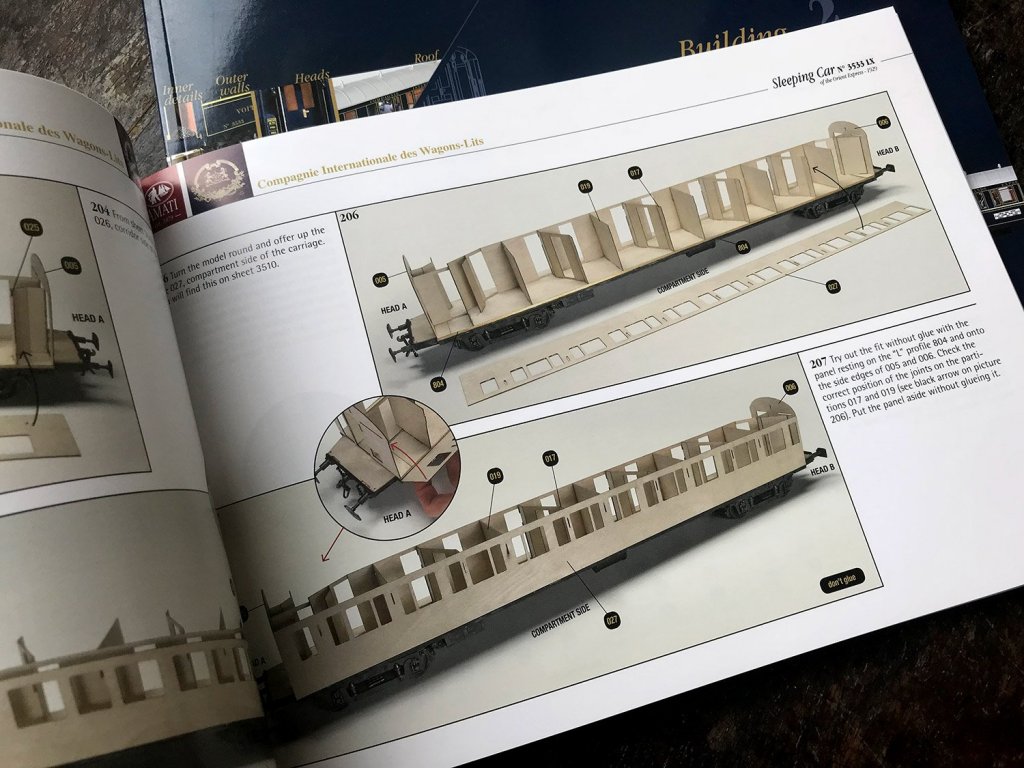

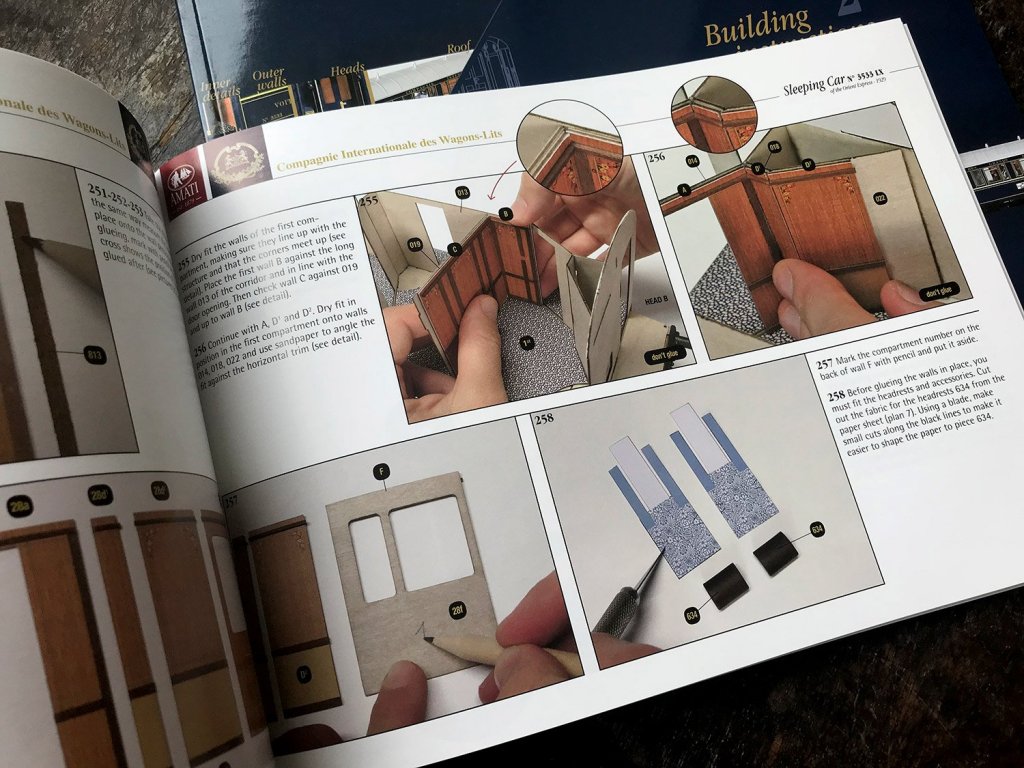

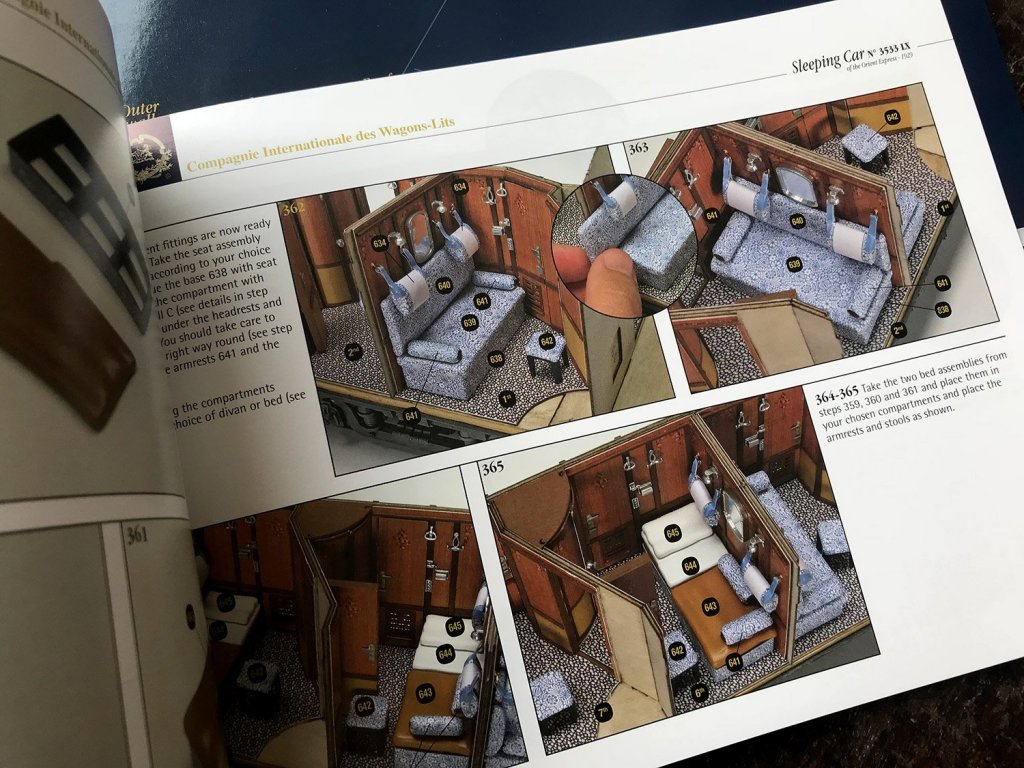

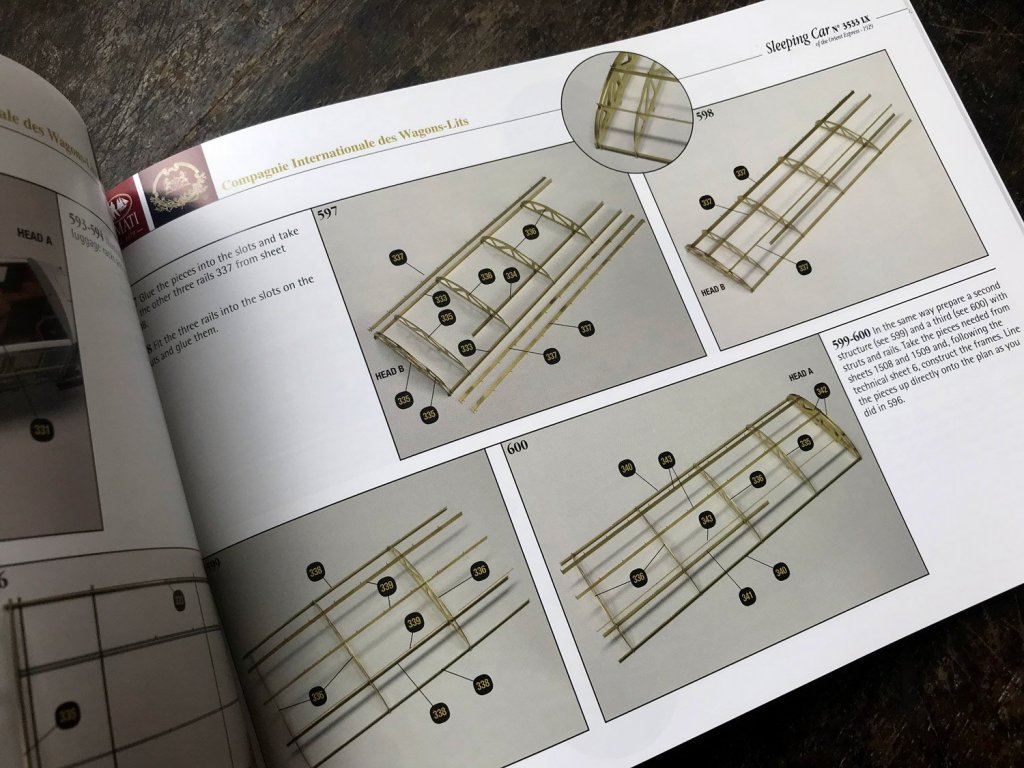

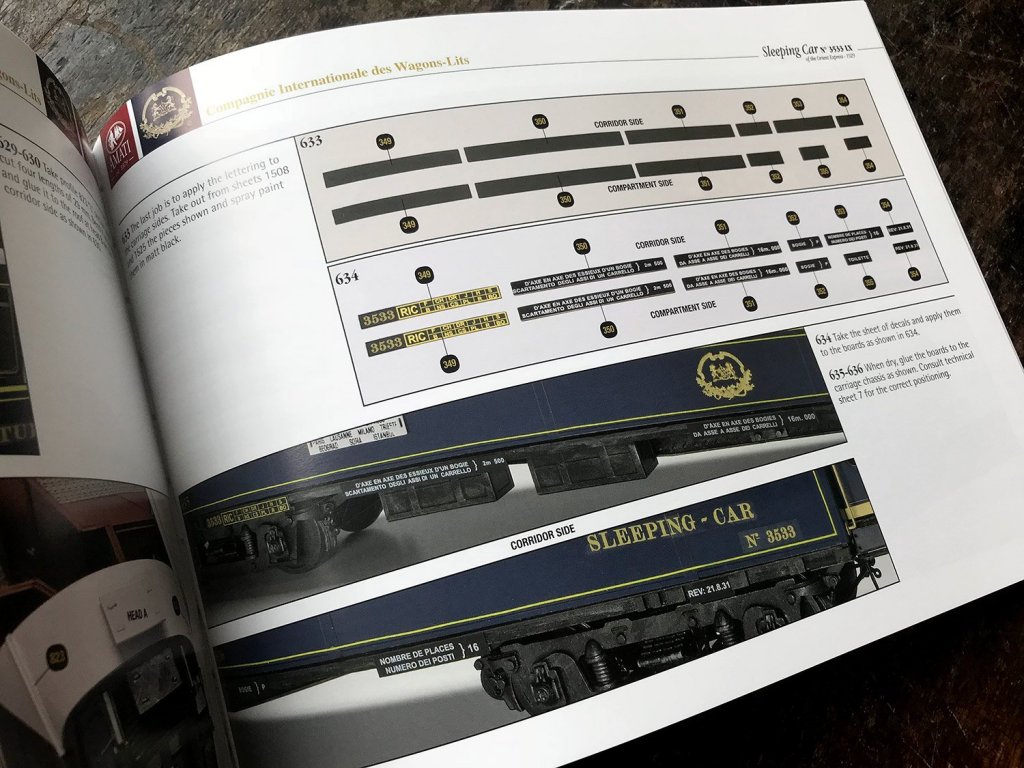

1/32 1929 Orient Express Sleeping Car No.3533 LX Amati Catalogue # 1714/01 Ok, I know this isn't a ship kit, but it is very much a wood and photo-etch model, and from Amati. I hope you enjoy! The Orient Expresswas a long-distance passenger train service created in 1883 by Compagnie Internationale des Wagons-Lits (CIWL). The route and rolling stock of the Orient Express changed many times. Several routes in the past concurrently used the Orient Express name, or slight variations. Although the original Orient Express was simply a normal international railway service, the name became synonymous with intrigue and luxury travel. The two city names most prominently associated with the Orient Express are Paris and Constantinople (Istanbul) the original endpoints of the timetabled service. The Orient Express was a showcase of luxury and comfort at a time when travelling was still rough and dangerous. On June 5, 1883, the first Express d'Orient left Paris for Vienna. Vienna remained the terminus until October 4, 1883. The train was officially renamed Orient Express in 1891. In 1889, the train's eastern terminus became Varna in Bulgaria, where passengers could take a ship to Constantinople. On June 1, 1889, the first direct train to Istanbul left Paris (Gare de l'Est). Istanbul remained its easternmost stop until May 19, 1977. 1929 Sleeping Car shown from 4.00minutes (new upholstery) The onset of World War I in 1914 saw Orient Express services suspended. They resumed at the end of hostilities in 1918, and in 1919 the opening of the Simplon Tunnel allowed the introduction of a more southerly route via Milan, Venice, and Trieste. The 1930s saw the Orient Express services at its most popular, with three parallel services running: the Orient Express, the Simplon Orient Express, and also the Arlberg Orient Express, which ran via Zürich and Innsbruck to Budapest, with sleeper cars running onwards from there to Bucharest and Athens. During this time, the Orient Express acquired its reputation for comfort and luxury, carrying sleeping-cars with permanent service and restaurant cars known for the quality of their cuisine. Royalty, nobles, diplomats, business people, and the bourgeoisie in general patronized it. Each of the Orient Express services also incorporated sleeping cars which had run from Calais to Paris, thus extending the service right from one edge of continental Europe to the other. The kit Amati had been publishing videos and photos of this then-upcoming kit on Facebook for a few months, and even though trains aren’t really my thing, this one looked intriguing with its 1920s/30s wooden opulence, so when Amati said they would ship one out to me to look at, that was very exciting. I knew this was going to me one large kit, but I had no idea! The model itself is 1/32 and the box is the same size as their1/72 HMS Vanguardthat I recently took a look at. Whilst the box doesn’t weigh as much as that kit, it’s certainly packed out with some heavy metal. The box lid itself is decorative, depicting the finished model and some period imagery. You will also note that this model has a section of track on which to display the sleeping car. Lifting off that large lid uncovers a complete box with a tabbed, lift up lid, adorned in the Amati logo as standard for these large releases. Chassis parts Inside the box, we have plastic trays full of parts, two smaller Amati boxes, a large thick plastic sleeve with paper/wood/metal components, and sleeves full of timber strip and brass section strip. There are also a series of folded plans and TWO perfect-bound, full colour instruction books which look sumptuous. Lifting all of these out uncovers two card covers that when removed, show a whole swathe of photo-etch brass and nickel-silver sheets, and a bag holding three sections for the base onto which the rail tracks and sleepers will mount. Amati’s 1/32 Orient Express Sleeping Car kit consists of: 1 x gloss card for carriage ceiling mouldings 1 x decal sheet for carriage signwriting and stencils 2 x gloss paper sheets with printed interior wood panelling and carpets. Also contains illustrations of exterior coach work for reference 2 x laser-cut ply sheets for the carriage chassis 5 x laser-cut ply sheets for all side and internal walls/construction of the carriage. 1 x tape of yellow self-adhesive trim of different widths 2 x white trays of cast and turned components, chain and wire. Parts include radiators, tissue dispensers, towel rails, wall mirrors, bottles and holders, soap racks, door handles, coat hooks, locks, eyelets, cabin lights, ventilation panels, electrical sockets, decorative cast exterior crest, spring-leaf shock absorbers, nuts, bolts, boiler, etc. 2 x boxes of components, contains parts such as sofa/bed carcasses and cushions, cores for the armrests and hanging headrests, rolling stock wheels and axles, sink units, stools, carriage entry tunnels, etc. 1 x pack of brass strut sections Various timber lengths of varying size and type 3 x MDF track base sections and stirrups 4 x sheets of photo-etch nickel-silver parts (internal main carriage wall panelling and hinges etc) 17 x sheets of photo etch brass parts (chassis, bogies, roof and roof sheathing, exyerior main carriage walls, etc. 1 x sheet of pre-cut acetate for windows 6 x parts and plans sheets 2 x full-colour instruction books Now, a little about the model itself. Whilst the Orient Express is known for its amazingly high standards, these sleeping cars only had a single WC for the whole carriage. Amati has created an entire, accurate interior to this model kit, of which the toilet and small boiler closet are also included. To be able to see all of these details, the lid, constructed from photo-etch and rolled brass, is removeable. White card inserts for she shaped interior ceilings are included, and this would provide an amazing opportunity to add some soft lighting which would set off each of the cabins. Each of those cabins is intricately detailed, and whilst have no per-cabin toilet facilities, each cabin does have facilities for passenger ablutions. These come in a stylish curved-door unit which contains sink and other things which you’d expect to see in this area, all intricately reproduced in this kit. The walls of the cabins are wooden panelled, and all of the cabin creature comforts are present, including seats, cushions for arms and head etc, and ceiling racks for storing luggage. Remember, these cabins were pretty compact as passengers spent the day in other areas of the train too. An access corridor runs alongside the cabins, and of course, these are fitted out with radiators etc. In all, an impressive piece of rail history that Amati has gone to pains to recreate here. The sleeping car is based on two lengths of laser-cut timber which sit atop each other to produce the main frame of the carriage. On the real thing, this would of course have been metal, so bear that in mind when building and ensure you seal any timber and rub down before filling, priming and painting in black. Added to the metal framework are lengths of heavy-gauge photo etch that create the authentic appearance of the carriage chassis. Other plates etc. are fitted out with miniature nuts and bolts. Brass section strips are also fitted to the entire length of the exterior frame, adding authenticity and some rigidity to the model. There is also a main bolt towards both front and rear of the carriage, onto which the moveable, wheeled bogies will mount. After all, your train won’t just roll in a straight line! The underside of the sleeping car is incredibly complex with some superbly engineered and cast leaf-spring suspension for the buffers, couplings, photo-etch battery housings, compressed air tank, etc. Assembling the rolling stock/bogies themselves is broken down into over EIGHTY separate stages in around 20 pages of the first construction manual. Of course, all of the parts for this are manufactured from either photo-etch, cast or turned parts, and a photo-etch bending tool really should be mandatory if you wish to tackle this model. After all, if you are willing to shell out 890€ for a kit, then it’s foolhardy not to progress with the required tools. For the base, Amati has supplied three parts on dovetailed MDF which is profiled for display purposes. The positions of the sleepers is also engraved onto the top. I have to say that the fit of these is so precise that virtually no joint can be seen when they are put together. If you flip them over, you’ll note that there is a pencil mark to show you which part is the best match. Two MDF splints are then to be glued into the underside channels. Now, I don’t think that MDF is a strange material for the base, as you may wish to paint this, but one omission, for me, is any material that can be used to infill between the buffers, such as the gravel/stones. This would have been a nice addition so as to hide the MDF. The tracks themselves are supplied as brass sections which need to be cut to length. As per the real thing, the tracks are attached to the sleepers by the correct hardware. I would use an assembled wheel/axle section to properly ensure that the tracks are equidistant at both ends, as well as traditional measuring. I would also look at either painting the tracks in an iron colour, or if you can immerse them in a shallow bath of burnishing fluid, then that would also fit the mark. With the base of the model now built, the time has come to assemble the carriage itself. This initially starts with the Head A and Head B bulkheads, followed by the fitting of the interior corridor wall. Onto this are fitted the interior compartment walls, creating the cabins. Please note that a lot of paper cutting will be required as the internal walls in their antique finishes, are printed matter and will need to be fixed to the pre-sealed internal plywood walls. This will also be enhanced with actual timber framing too. The printing of the wooden walls is very, very nice and should look as good as trying to emulate this using precious timbers. Besides, this approach means we all stand a level chance of success. Actual timber will be used to line the panels, adding to the realism. The carpets are also to be cut from paper. You will need to pick up some paper-crafting skills too as the numerous head rest and arm rest cores, sofa/bed chassis and stools, will need to be wrapped in the same matching paper and neatly fashioned around corners. There are some good techniques to be found online, such as dampening the paper to make it easier to mould around corners etc. Each cabin will also have its own wash locker, and these are constructed separately and then installed. As well as having all the mod-cons, for the 1920s, the doors on these will actually hinge open and closed. You won’t have this option for the cabin doors though, but these can be posed in any position using the nickel-silver etched parts. The main carriage exterior walls are sheathed in photo-etch brass which will be painted, and the trim/decals added. Internally, those same walls are plated with the nickel-silver panels. I don’t know the reasons for change in material from brass, but the panels are superbly produced. Remember, there’s no actual silver in those parts. Instead, it’s an alloy of zinc, copper and nickel. To construct the carriage’s roof, a series of photo-etch frames are interlinked with longerons that have raised pips. Once the basic frame is assembled, a series of individual brass panels are then rolled into shape and the holes in these used to lock over the raised pips of the longerons. Whilst you can use CA generally, I would suggest that the pip areas are soldered and filled before then being filed back flush to the roof. The roof is then painted white. Internally, the card mouldings are then shaped and sealed/sprayed white before decorative wooden edging is applied. Instruction manuals Two full-colour instruction manuals are included, showing the various stages using photographic images and clear text in English, with Italian also. Each step is very easy to understand, in the way that magazine part-works are designed to be straightforward. There’s nothing here that should catch any modeller out, meaning that the only thing you need to have some experience with is photo-etch. Each manual is landscape in format, and perfect-bound, as a novel would be etc. Paint references are used where necessary and supplied in FS codes. Plans A number of these sheets are simply for helping the user to identify the various PE parts and wood parts, with a couple of others showing the rail carriage in various plan formats. All line drawings are clear to understand shouldn’t provide the modeller with any issue. Decals A single sheet of waterslide decals is included for the exterior livery signwriting etc. Print quality looks excellent. It could be worthwhile trimming any of the clear carrier film as close to the actual decal as required. Conclusion This isn’t a cheap kit by any stretch of the imagination, but it is an epic one in every sense. The Orient Express kit is a sort of crossover between vehicle and doll’s house building, with some beautiful period features in the mix. It’s certainly a project that will command a lot of time from you in order to achieve the very best outcome. You really do have to be reasonably adept with photo-etch metal in bending, curving and folding, and although you don’t strictly need to, some elements would be better soldered than glued. A lot of attention to detail has been made here, from the kit detail itself, down to little things like the cut-out paper décor not lying across folds in the sheet paper. The instruction manuals are also a work of art and should be a cinch to follow. Projects like this are usually once in a lifetime, so if you fancy doing something pretty unusual, then this has certainly got to be a major contender. These kits are hot off the press, only having being released within the last 2 weeks, so get them whilst their fresh! My sincere thanks to Amati for sending this kit out for review on Model Ship World. To purchase, check your favourite Amati shop or online retailer. Tell them you saw the review here on MSW.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.