-

Posts

5,964 -

Joined

-

Last visited

About James H

- Birthday 02/26/1970

Contact Methods

-

Website URL

www.modelshipworld.com

Profile Information

-

Gender

Male

-

Location

Anderton, Lancashire, UK

-

Interests

Foreign food, travel in general, modelling in timber and plastics, photography and guitar playing.

-

Carleroo reacted to a post in a topic:

1:25 Drakkar ‘Oseberg’ - Ships of Pavel Nikitin

Carleroo reacted to a post in a topic:

1:25 Drakkar ‘Oseberg’ - Ships of Pavel Nikitin

-

Kit review 1:25 Drakkar ‘Oseberg’ - Ships of Pavel Nikitin

James H replied to James H's topic in REVIEWS: Model kits

No concerns at all with the kit. So far, it's built up very nicely. All those plank strakes have fitted as they should, and the materials are very, very good. Vanguard Models has these in stock at the moment: https://vanguardmodels.co.uk/products/the-viking-ship-oseberg-version-3-ships-of-pavel-nikitin -

James H reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

James H reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

-

Which ship kit? OcCre Endurance or Terror

James H replied to tony1745's topic in Wood ship model kits

We have both kits reviewed here: -

James H reacted to a post in a topic:

Mitsubishi A6M5a Rei-sen by ccoyle - FINISHED - Halinski/Kartonowy Arsenal - 1/33 - CARD - Allied code name "Zeke"

James H reacted to a post in a topic:

Mitsubishi A6M5a Rei-sen by ccoyle - FINISHED - Halinski/Kartonowy Arsenal - 1/33 - CARD - Allied code name "Zeke"

-

Mobile Phone Repair Clamps

James H replied to Paul Le Wol's topic in Modeling tools and Workshop Equipment

Just bought a set of 4 from Amazon UK for £5.99. They look real useful so thanks for that tip! -

James H reacted to a post in a topic:

Mobile Phone Repair Clamps

James H reacted to a post in a topic:

Mobile Phone Repair Clamps

-

To those who HAVE posted, the issue is with the content provider, not the journal. It would seem to be intermittent. For example, I've logged in first time, with no delay. When an issue is made 'subscription only', it's one click which does this for the entire membership, so it's not an individual thing I need to do for each single member. Please be patient with this as we simply can't control any issues with the content provider.

-

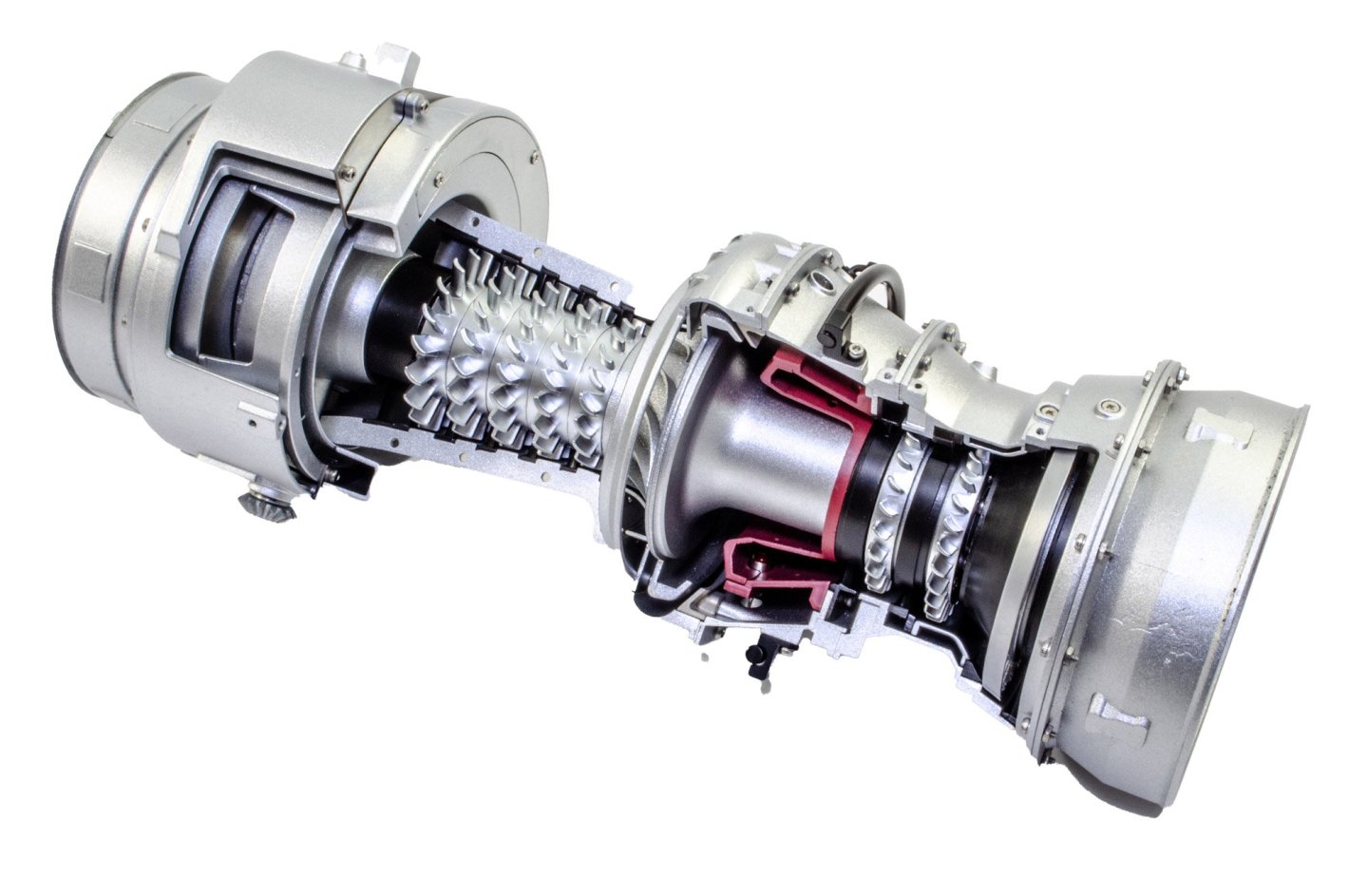

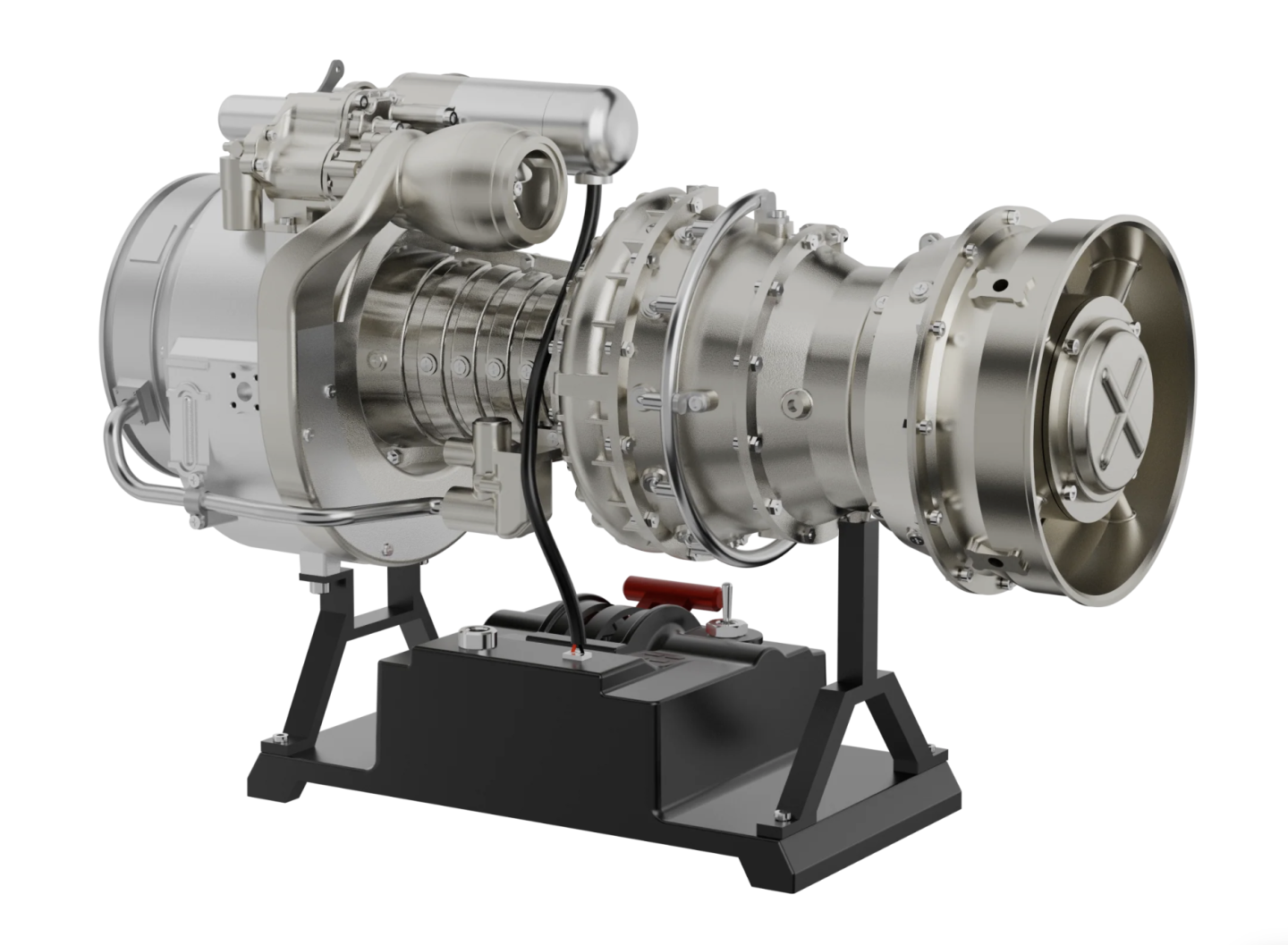

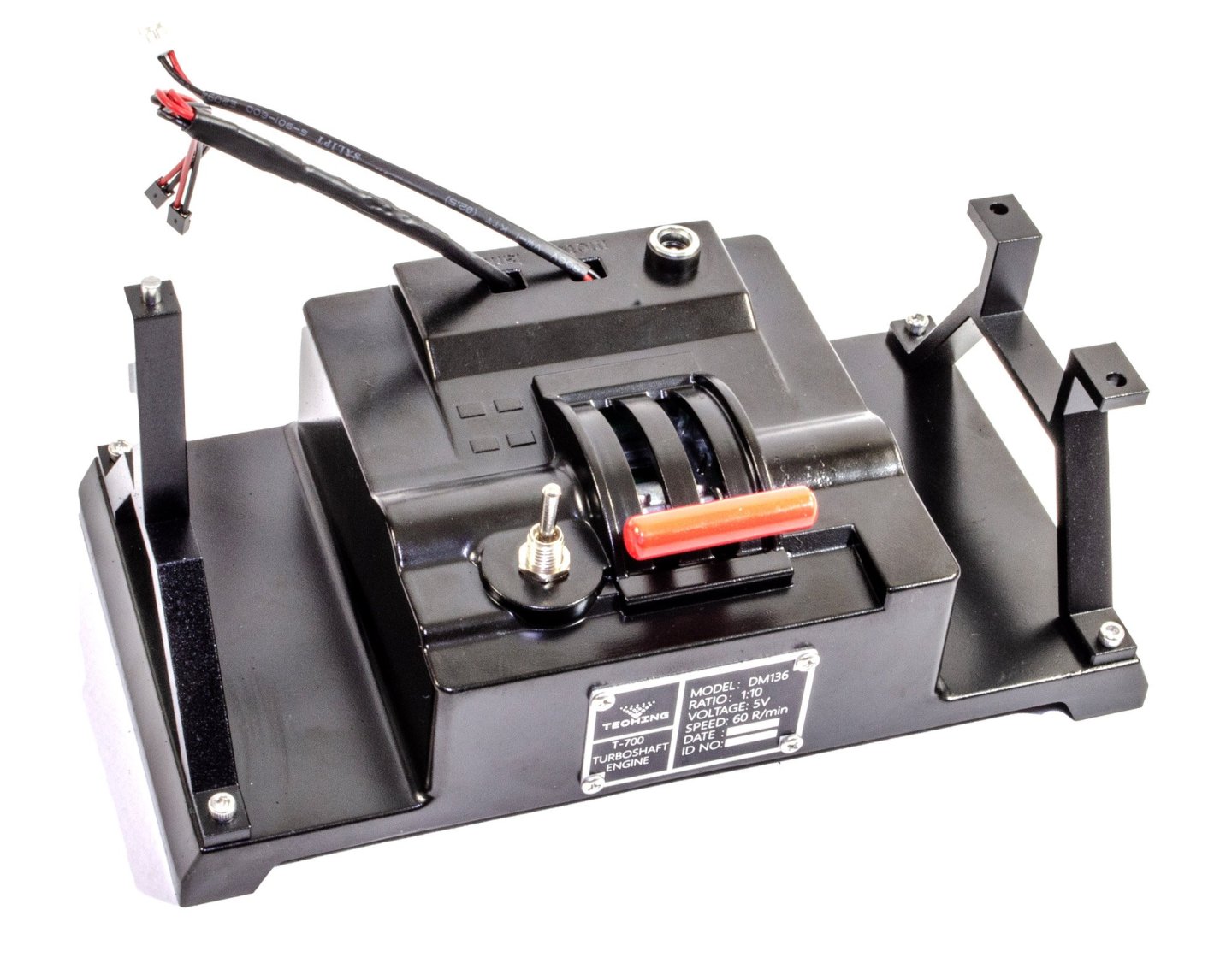

Conclusion Out of all the engines I've built so far, this is by far one of the easiest in terms of design and accessibility for the various fasteners that inevitably go into awkward places. I do think I'd have liked the LEDs to have been a little brighter, but they do show up well in subdued light. If helicopters are your thing, then this is most definitely one to add to the collection, especially anyone who liked the Black Hawk. Great kit, easy assembly, and very rewarding. My sincere thanks to EngineDIY for the sample you see here on MSW. To buy direct, click the link at the top of the article.

-

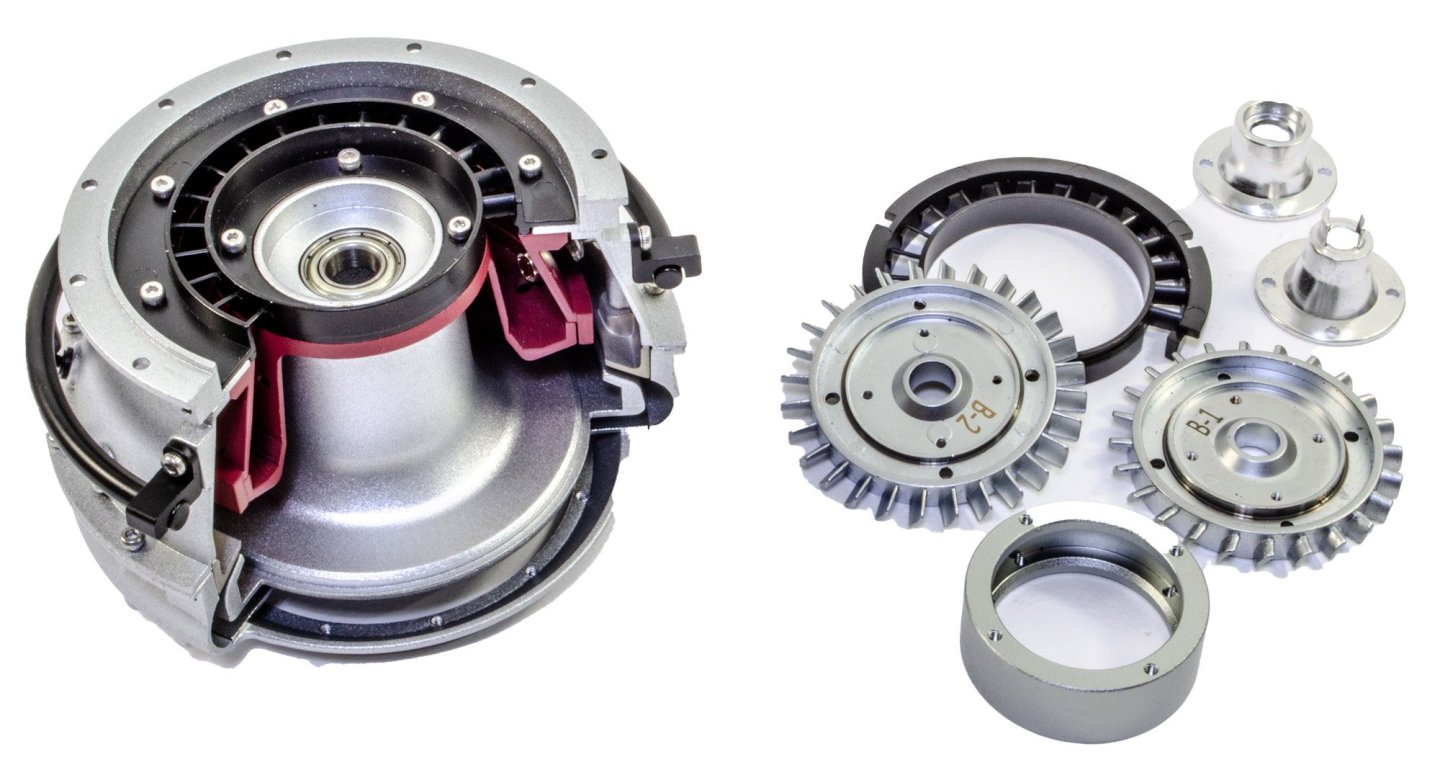

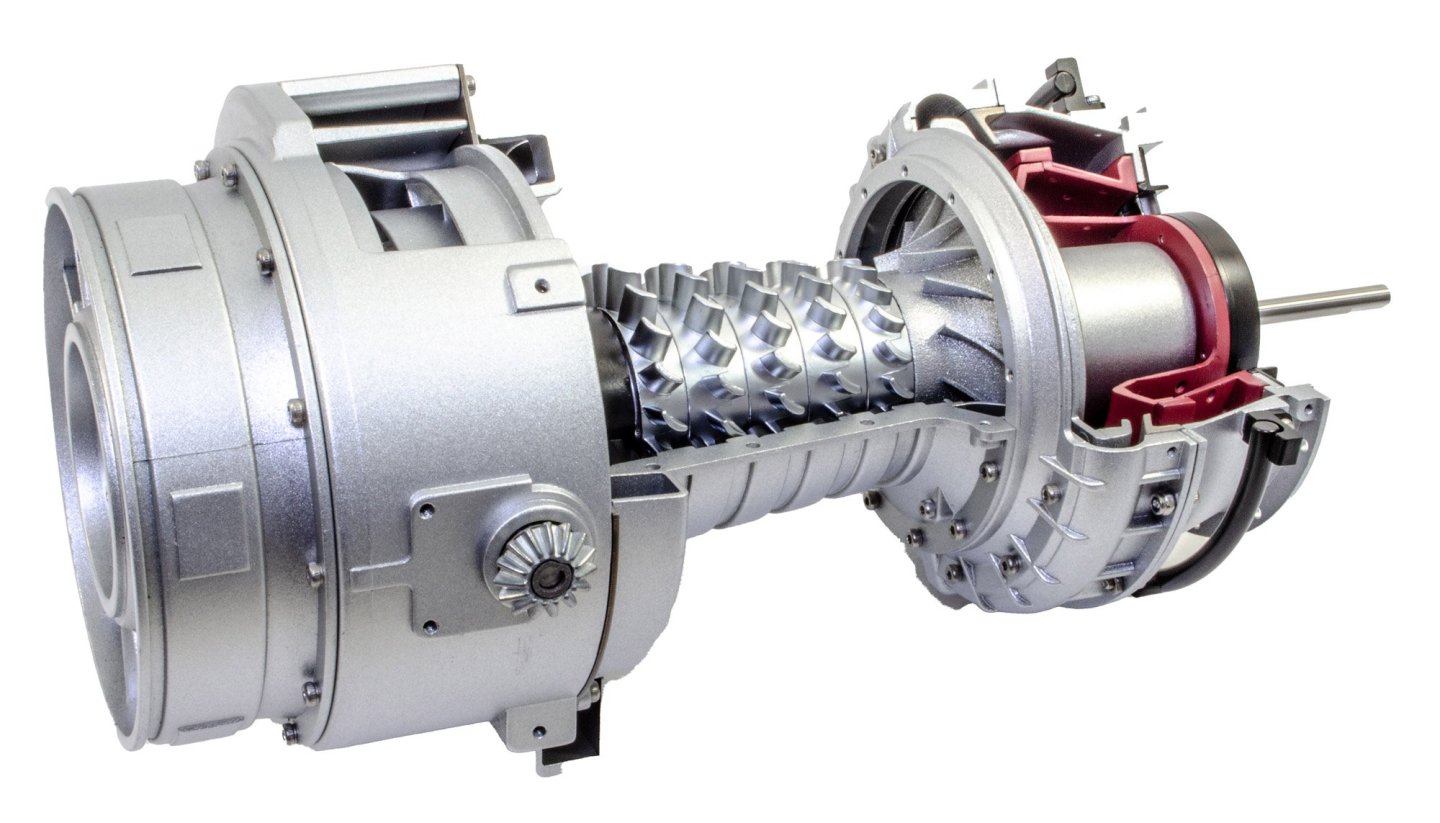

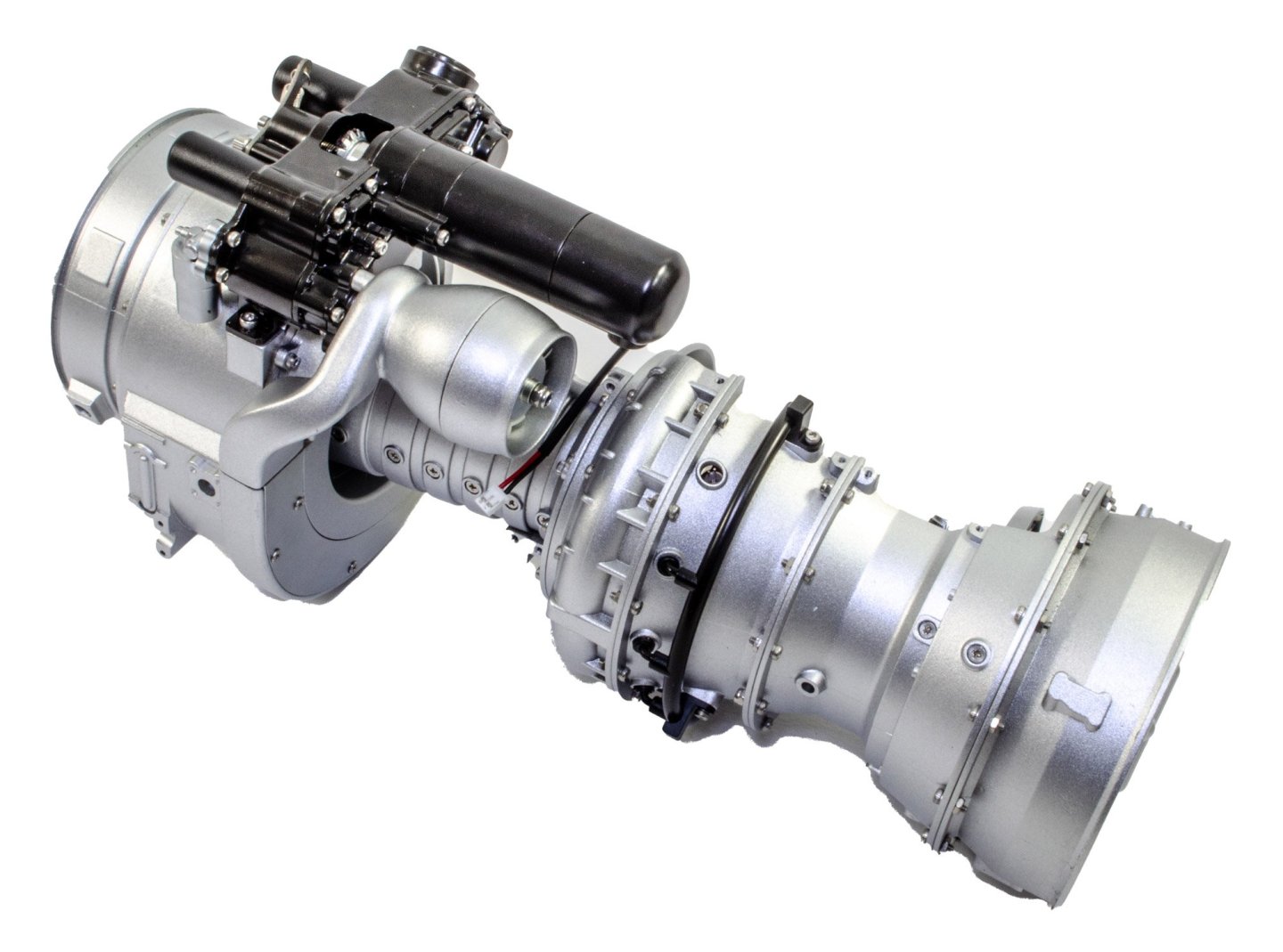

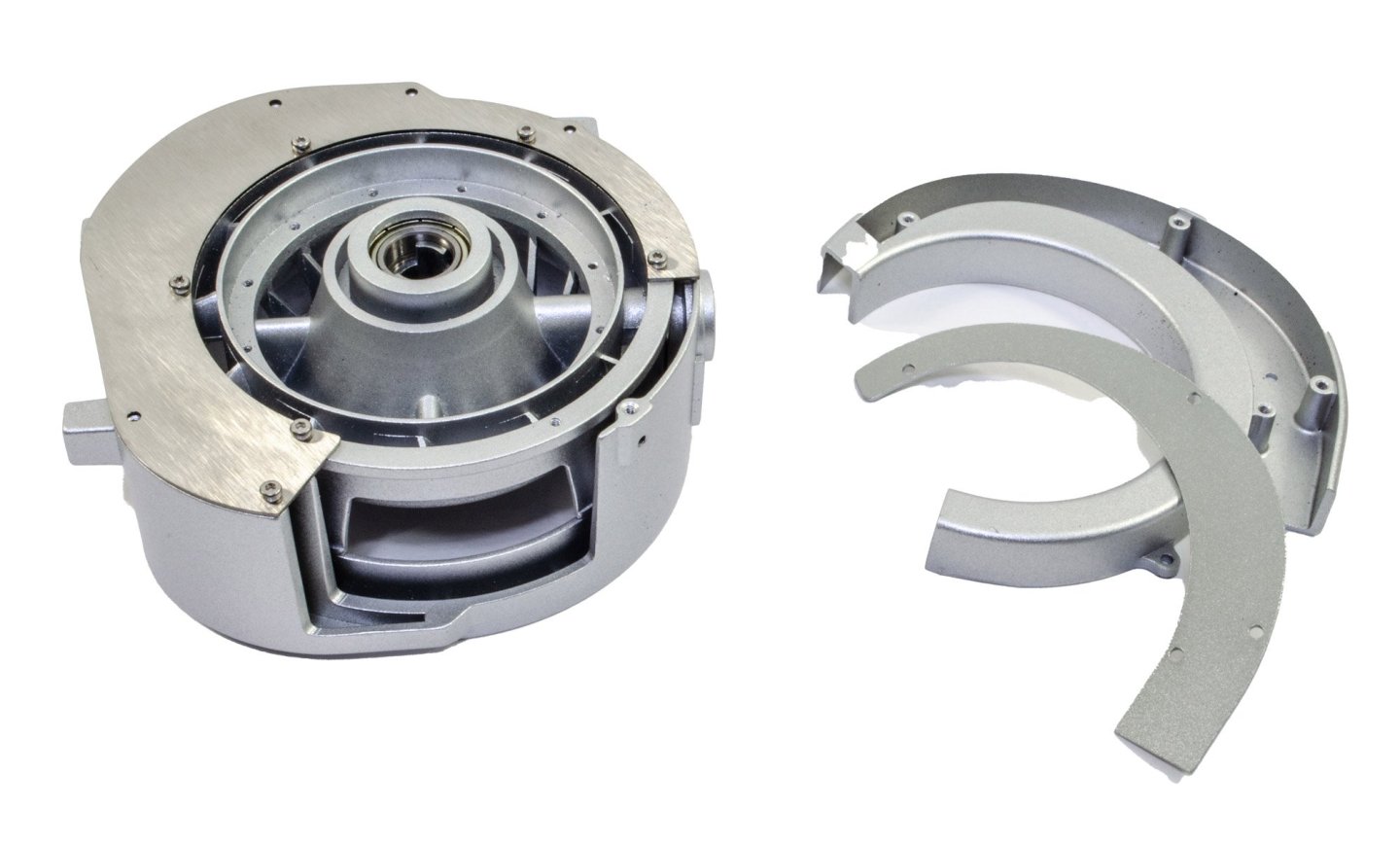

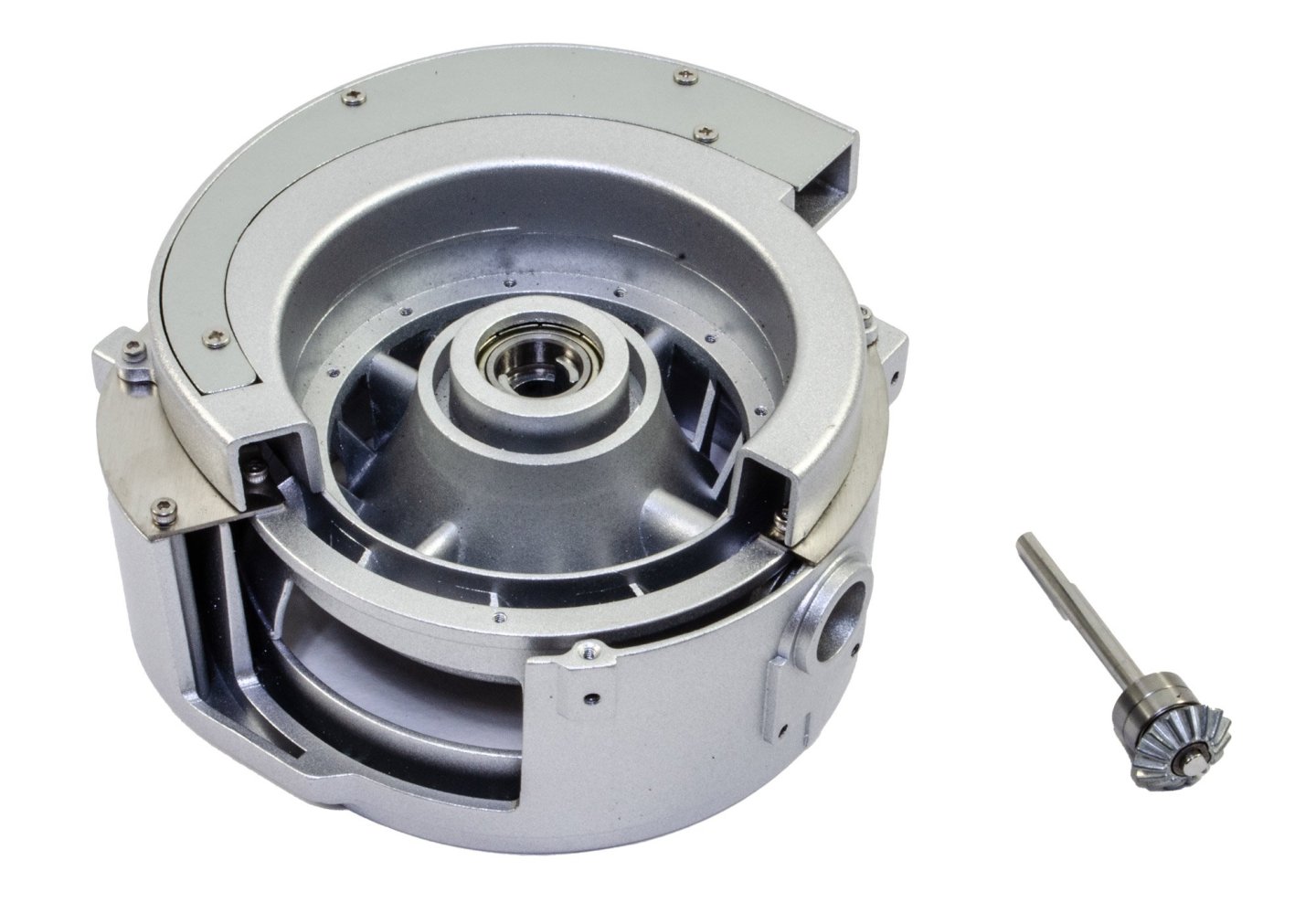

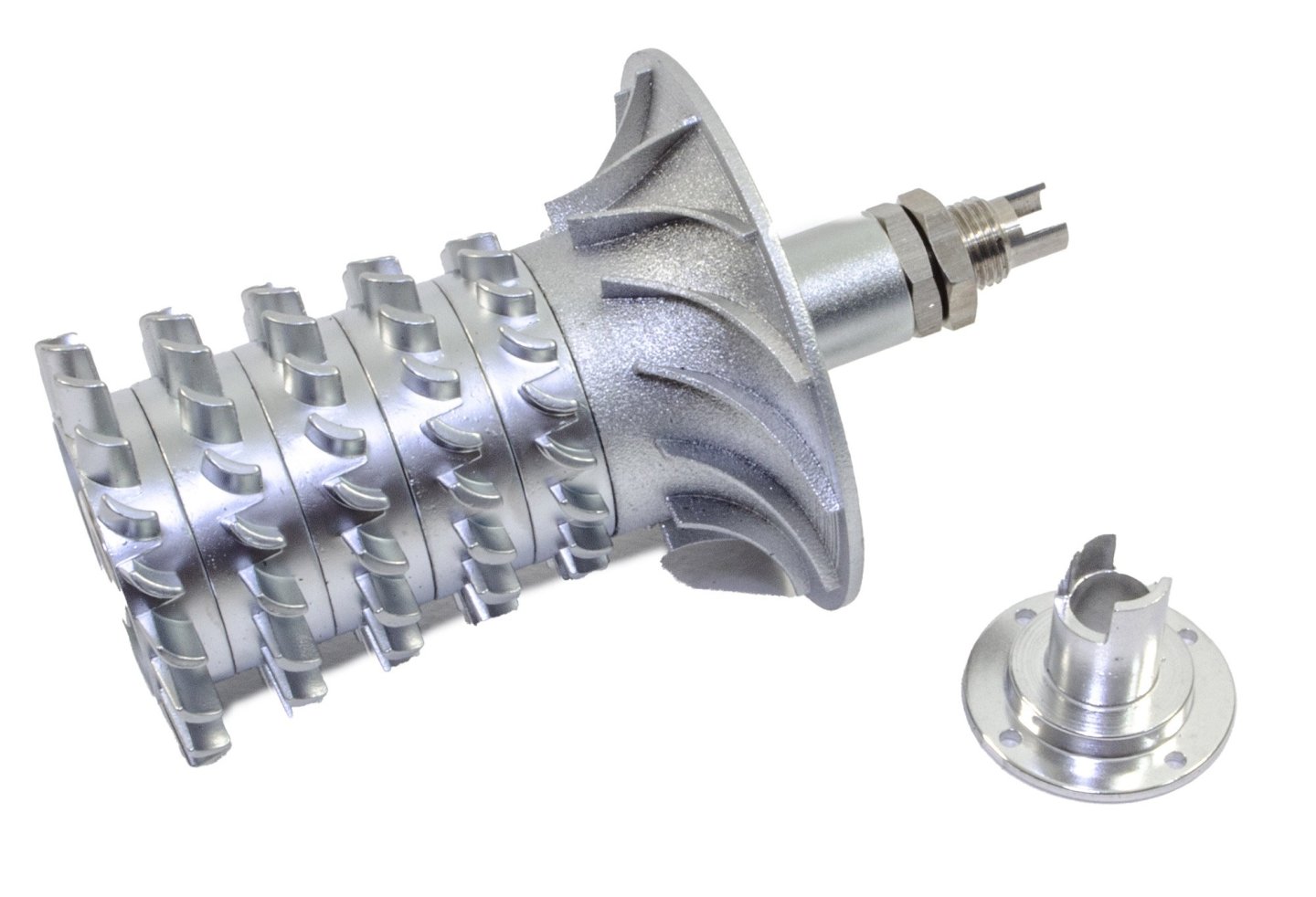

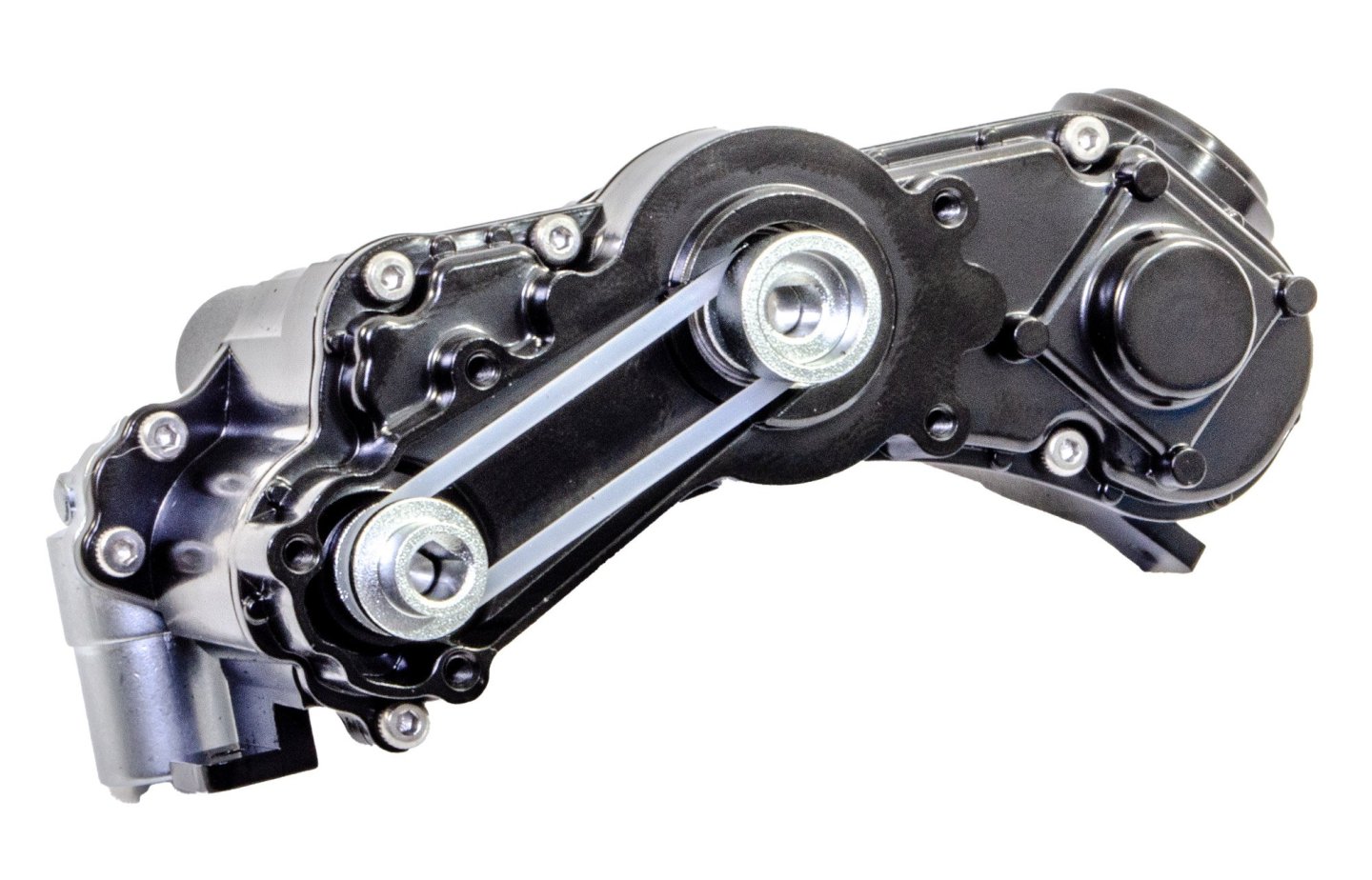

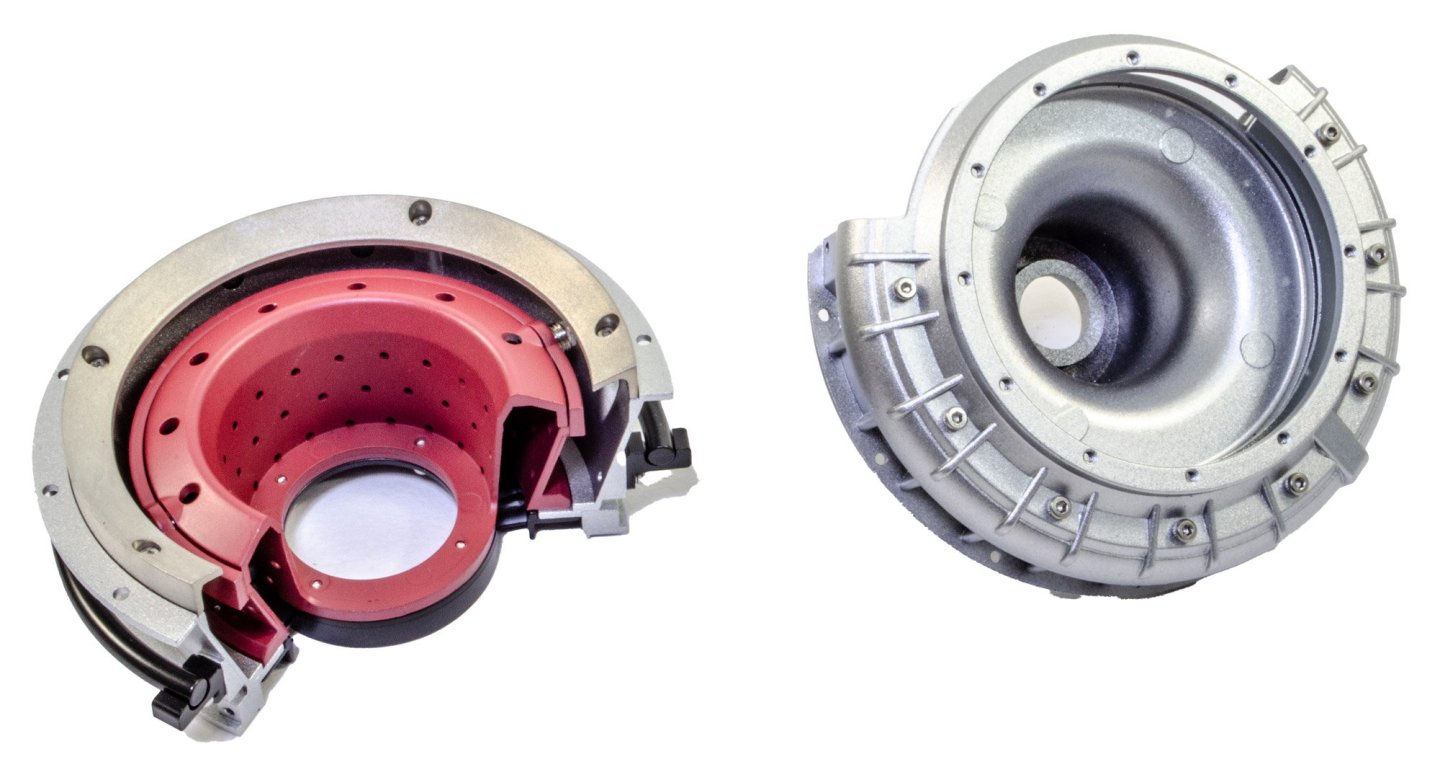

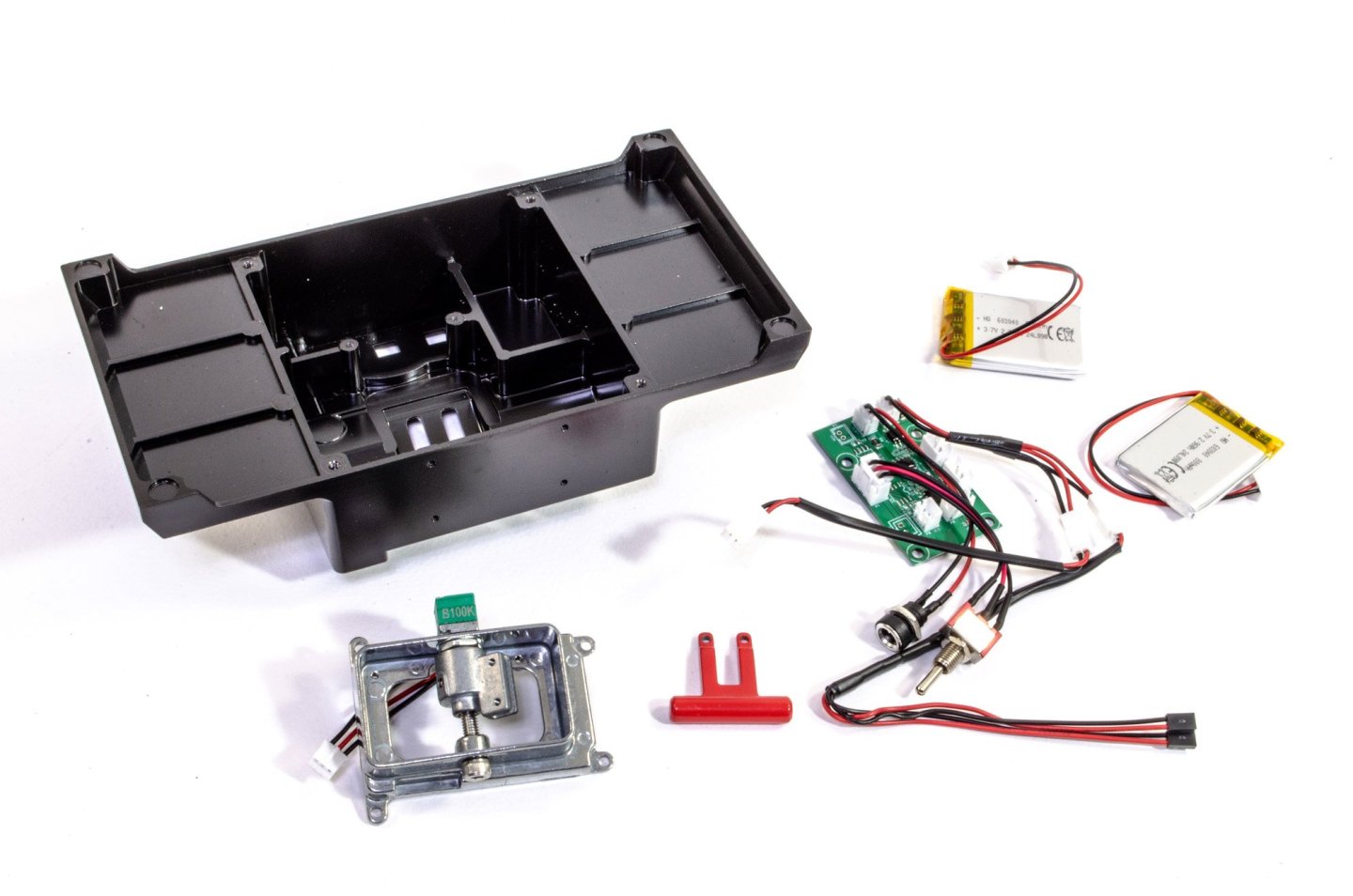

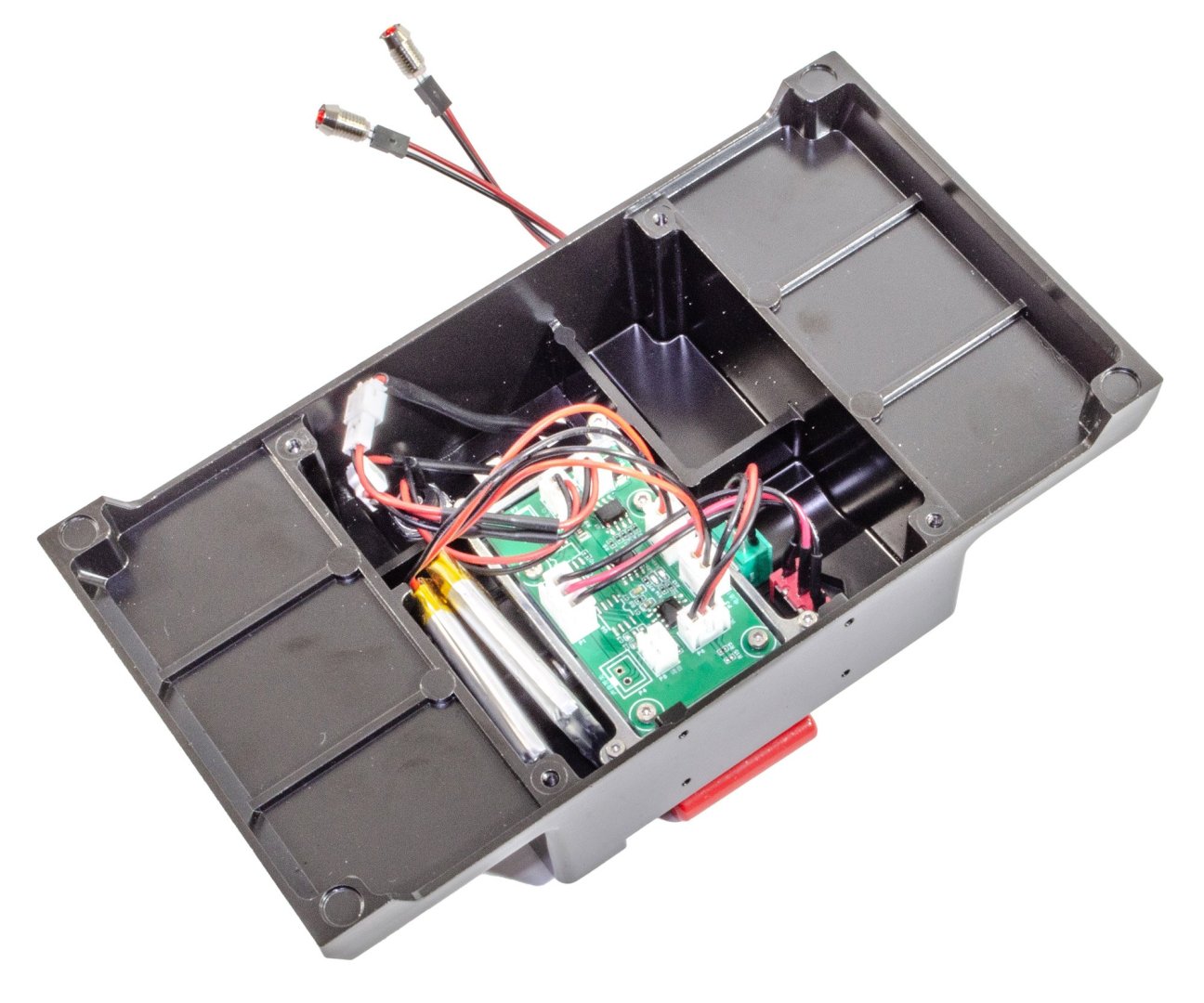

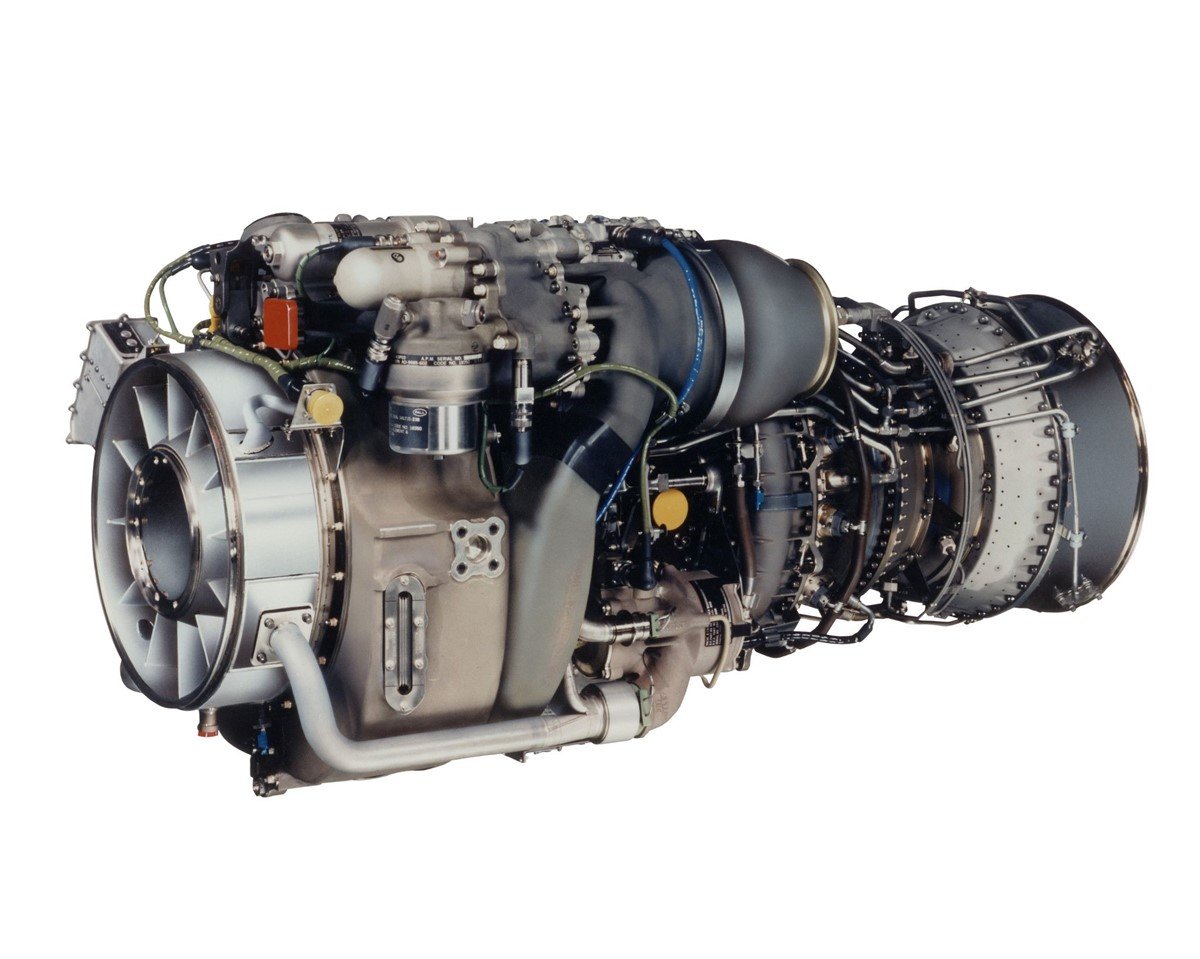

T-700 Turboshaft Engine - Teching EngineDIY Available from EngineDIY for $499.99USD The General Electric T700 family are turboshaft and turboprop engines in the 1,500–3,000 shp (1,100–2,200 kW) class. The T700 was initially bench-tested in 1973, passed military qualification in 1976, and went into production in 1978. The initial "T700-GE-700" is an un-geared free-turbine turboshaft, with a five-stage axial / one-stage centrifugal mixed-flow compressor, featuring one-piece "blisk" axial stages, with the inlet guide vanes and first two stator stages variable; an annular combustion chamber with central fuel injection to improve combustion and reduce smoke; a two-stage compressor turbine; and a two-stage free power turbine with tip-shrouded blades. The engine is designed for high reliability, featuring an inlet particle separator designed to spin out dirt, sand, and dust. The T700-GE-700 is rated at 1,622 shp (1,210 kW) intermediate power. The T700-GE-700 was followed by improved and uprated Army engine variants for the UH-60 Black Hawk and the AH-64 Apache helicopters, as well as marinized naval engine variants for the SH-60 Seahawk derivative of the Black Hawk, the SH-2G Seasprite, and the Bell AH-1W Supercobra. T700s are also used on Italian and commercial variants of the Agusta-Westland EH101/AW101 helicopter, and Italian variants of the NHIndustries NH90 helicopter. These are all twin-engine machines, except for the three-engined EH101. Abridged from Wikipedia The kit This kit is beautifully presented in a tough box with numerous images of the finished engine. This one is rated at 4 star with regard to complexity, and contains around 470 parts, inclusive of the various bolts, nuts and washers. Not quite sure how the star rating works, but this one was very straightforward to build, so all is good! Under the lid, the first thing you see is a nice, full colour, 88 page manual, with every stage presented in colour CAD format and easy to understand text. A full colour parts index is also included, although that's more for checking individual parts, which the main instructions do very well anyway. The parts trays are protected under a thin sheet of clear acrylic. Three parts trays are included, in semi-rigid foam, holding the parts securely in place. The first try shown underneath, also has two containers which contain all of the screws, bearings, specialised fittings, nuts, etc. The parts are clearly identified from a list in each lid. Building the base As with many of these aero engines, the T-700 requires a base unit from where it will be controlled. Unlike the others though, the modeller gets to build this one from components. Here you see the cast shell, control board, dual lithium batteries, the speed controller and also the various port connections. Also seen here are some tools supplied to start work on this kit. The base unit is very straightforward and it's seems very unlikely that anyone could go wrong with this assembly. When the components are fitted, a small plate holds everything in situ. Engine construction From here, I'll merely show the various assemblies being constructed, and you can follow along. Where appropriate, I've used lithium grease for things like gears. The bearings don't need any lubricant.

-

James H reacted to a post in a topic:

Santìsima Trinidad by Kevin - Artesanía Latina - 1/84 - started June 2025

James H reacted to a post in a topic:

Santìsima Trinidad by Kevin - Artesanía Latina - 1/84 - started June 2025

-

Need help with building a Strap for topgallant shrouds

James H replied to Y.T.'s topic in Masting, rigging and sails

Pruned. Please keep on topic. -

Vanguard MDF

James H replied to hornet's topic in Building, Framing, Planking and plating a ships hull and deck

Nope. Not one single issue out of more than a dozen I’ve built.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpeg.fc5d633a7b34428fcf19419a73d56d55.jpeg)