MarkBseau

Members-

Posts

50 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by MarkBseau

-

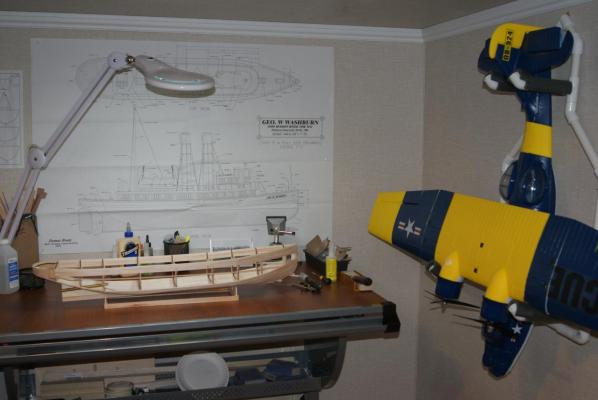

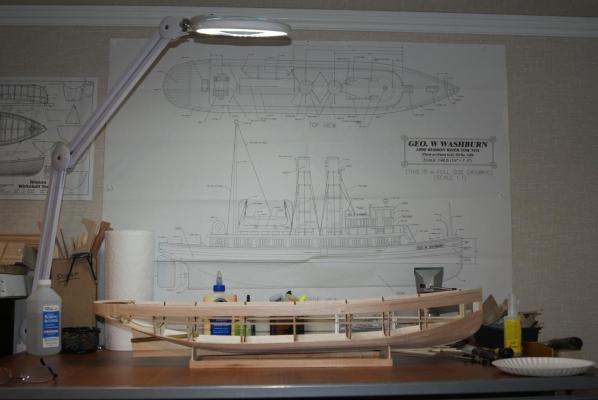

Photos are a little hap-hazard here, I'll have to figure out how to better order them, and how to comment before/after an image... Anyway - at the stage that these were taken, I'd made a couple of my mistakes, but not all of them yet! Was doing alright for a while and had everything straight and square. Then at some point I think I left things for one night with one plank on a side without gluing the same plank on the other side, and (that's what I'm choosing as the culprit, anyway) suddenly I realized that my stem was no longer straight. (Curses!) Am going to live with it this time, I'm way beyond doing anything about that. You can see this in a couple of the middle photos. I'll get some more pix up tomorrow (have to recharge the camera battery) showing where I am now. I'm planked and awaiting my fiberglass supplies. With those pictures, I'll have a couple questions for the experts on where I went wrong.

- 30 replies

-

- george w washburn

- dumas

-

(and 1 more)

Tagged with:

-

- 30 replies

-

- george w washburn

- dumas

-

(and 1 more)

Tagged with:

-

I've really hesitated to start a build log... At first it was simply because I'd started building without taking any photos for a while, so I figured it was just too late to start a log. But later, because of all the fantastic work I've seen in other builds - you folks are some real artists! - I'm embarrased to show my efforts. But I've browsed enough now to know that a build log is definitely the way to go, there is so much experience and help out there, it's silly to waste it. So I'll upload what photos I do have to this point on my first ship build, and hope that you guys can help me keep my head above water from here on. Or actually I will later tonight when I'm home. This is just a start while I'm eating lunch at the office...

- 30 replies

-

- george w washburn

- dumas

-

(and 1 more)

Tagged with:

-

Thanks for the tips & advice, I appreciate it. So it sounds like you perhaps had some stair-casing on those upper planks as well? I will be fiberglassing the boat also, so I know I shouldn't worry much about it at this point; I pretty much just wondered if I was going wrong... No build log yet, but I see what you mean about all the tips, I was just looking through your current build of the Niagra. That's been some project! Certainly looks great, though, very impressive. You comments bring on another kind of question - how did you happen to come across the info that the Washburn's hull was steel? Is there a good database for such info, or did you just do a lot of searching somewhere on the net? Maybe right here in the NRG?

-

The plans & instructions from Duma (which are pretty explicit) say that they show "exactly" how each plank was put on this hull, on their prototype. The planking material for this is 1/8" x 1/2" balsa. My hull is framed correctly. The first 3 or 4 full-width planks (from topside) curve upward toward the bow a good deal. In fact, the 1st plank rises fully 3/4", which can be measured even on the full-scale plan. They show no spiling in these first few planks, they describe them as needing no trimming at all, they just bend along that curve. I just don't see that as possible, without a really big "clinker" effect. (Actually the very first plank is a 1/4" width one, which is no problem bending to that curve.) In looking at a Washburn build in these forums (see Larry's), it almost looks to me like he doesn't have the upward curvature at the bow that I've got. In fact, looking at a couple specific photos, it looks like no curve upward at all. Could that be the case? I'm going to send Larry a message about this - but in case he doesn't remember solving this, or isn't available, I'd love to hear from anyone else who might have done this build, or otherwise might have some insight. I'd like to try to build this "as described", and learn how to deal with this sort of problem, but then wonder if I should just put some kind of stealer there instead. Thanks, Mark

-

Thanks, all. I now have two of those planking books (authors Dressell and Roberts) on my desk, and they look like they're going to be very useful indeed. Next best thing to an in-person demonstration. I especially like the look of Jim Roberts book, I think for me it's going to answer a lot. I have a lot of studying to do...

- 14 replies

-

Good to hear Nigel, as I'm sure I haven't even scratched the surface, yet, thanks. Aha ModelExpo, there it is! Thank you Russ. Seems a shame to pay a minimum shipping for just one small book, guess I'll just have to buy something else... So many tools, so little time...

- 14 replies

-

Thank you, folks. Yes, have been reading the tutorials here on MSW, that's where my questions begin... Does anyone know where I might find the Roberts book (or brochure)? I haven't seen any search results for that one. The D.Dressell book is already on order!

- 14 replies

-

I'm trying to absorb the tutorials about planking, and having trouble wrapping my head around of couple of the concepts. For starters - With a kit, you're probably given planking material - let's say it's a narrow width of about 1/4 inch. If you're working a hull where almost every plank needs to be curved in order to lay flat on the bulkheads, doesn't that render much, if not all, that material useless? I can't really believe that's the case, yet it seems to me that you'd have to cut most planks by hand out of a much wider sheet of lumber. What am I missing? I'm certainly not arguing with experienced builders; I'm just having a hard time understanding it. Does anyone know of a YouTube video where these concepts are demonstrated? I've seen a couple that "talk" about spiling, but don't show much of value. Also - what, exactly, is the point of lining out the hull (dividing it into 4 or 5 bands to be worked). Some authors go into, after this, a discussion of calculating the number of planks, for a given plank-width, in each band, but to what purpose? Isn't it just going to be whatever it's going to be? Is there a reason to have each band have the same number of planks? There must be more to this than just divide-and-conquer, but I'm not seeing it. Thanks, Mark

- 14 replies

-

Thanks for the replies. Russ asked what model I was dealing with - for one, I have Dumas' G. W. Washburn waiting for me to get some more experience with simple stuff first. It doesn't seem to mention single or double-planking, and that's one reason I asked the question (wondering if it was just a "given" that we double-plank). So it sounds like when double is called for, it might be a different wood (or perhaps different widths?) used? It also seems like you would completely ignore the pattern of planks in the 1st layer when doing the 2nd, is that right? Sorry for being completely ignorant, but - er. well - I am...

-

Why are some models double-planked, some not? Is this for historic accuracy, or to get a better finish? I can well imagine wooden sailing ships being double-planked for strength - for that matter, might some have more than that? Is it assumed that you'll double-plank a hull when the instructions don't say anything about it? Or will a kit always supply enough wood for a second planking and discuss it when that's supposed to happen?

-

Larry, I happened upon your build log of the Washburn - it's beautiful. I have this on the shelf and want to build it, and I have a couple questions for you: I have no idea what it's called, but that 'beard' of rope that you put on the bow - it just looks so authentic - there must be a term for that, do you know what it's called, and do you have any links or articles about it? Saw the photos of you building it, looks like you learned a lot about its construction. Also - did you rig this boat up for R/C, or have any experience with that? I'm wondering how you get after those components after it's built - is it designed so that the cabin area is removable? Thanks, Mark

-

Thanks cDogg, Allan and Joe. I've been busy at work for a couple days and so didn't get around to responding right away. I'm now getting a real appreciation for all the experience and knowledge is 'out there', it's mind-boggling. I hadn't even seen the term spiling yet, even though I was aware of the process... Joe - when I get some time in the evening, I'm going to send you a few more questions about your description above. (Just warning...) Thanks, Mark

-

Thanks Nigel, Geoff, and Joe. I just looked at photos of your work, and it is impressive indeed! I'm not sure what awards the ranks under your names (Captain, Commodore, Sub Lieut.), but they appear to be well deserved. (The 'Officer Cadet' under mine seems fairly fraudulent at this point...). I will study those tutorials, but at this point they seem to go into way more skill levels than I thought I'd need for this build. Joe - This boat being your first build, I am very impressed! Beautiful job. Your detailed comments bring up a couple follow-up questions. So I take it that if you can twist these small planks (not bend, which is easy - but twist them along their length), they can be made to conform without shaping them? Since they are so small, I'm thinking that their edges don't really need to be beveled, is that right? But I didn't realize that they can be wet/soaked without affecting the CA glue - is that the case? If the plank is somewhat wet, especially with a foreign substance, it will still glue? Also - Since you certainly don't want to glue the plank to the (temporary) forms, how do you make it conform to that shape (the twist)? Do you somehow clamp it in place and glue down only a small portion of the plank at a time? Even if that's the case, I'm not sure how to physically do that. Or does it make more sense to ignore the advice and just glue them to the forms and worry about cutting those out later? Mark

-

Hello all, I hope I can explain my stumbling here (wow, this was supposed to be the easy stuff...). I'm brand new to this, to state the obvious. But I wanted to try my hand at some building and started with Midwest's Boston Whitehall Tender, plank-on-frames. (Another one of those things I've wanted to do since I was about 10 yrs old; now I'm getting to it in my second childhood.) The instructions and illustrations don't describe any shaping of the hull planks, and only show full planks extending from the stem to the transom, until you get to all the way down to the keel and have to start shaping to fit. (The only photos of the finished boat don't show much detail of problem areas.) But with the curves and changes in the lines from bow to stern, I just don't see how that can be. And I've pretty much made a mess of it about half way down toward the keel, because the planks want to "step" down, and I know that's not right. If I wanted to quint my eyes real hard and pretend, I could sand to the outside of the hull (to onion-skin thickness in some spots) to a nice finish, but the inside would still be a mess. What am I missing here? What I really want to do is start over, but I can't even really envision any different result.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.