-

Posts

543 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by 6ohiocav

-

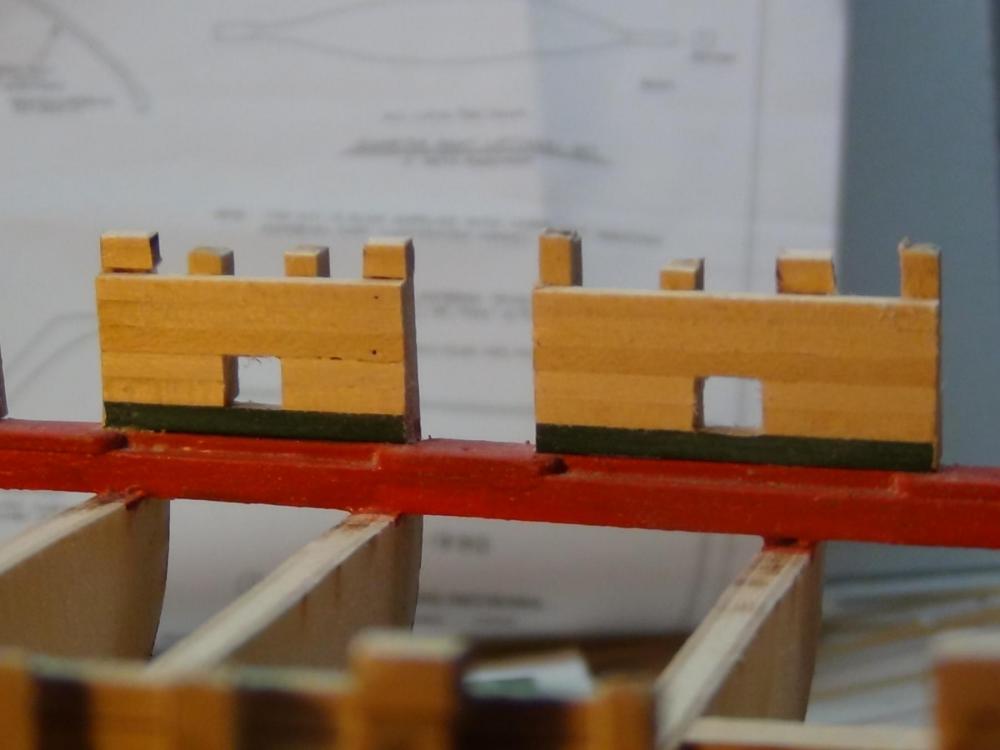

I am switching between work that I did over the winter months and current work. In February and March, I worked on the masts and yards. The Bowsprit was quite the challenge. I did not take many pictures, and I am working on recreating some of the techniques I used for later posts. For now, I worked on the chock rail and catheads over the weekend. Since I am swapping out all non painted parts from the basswood to cherry, I had to recreate my own rails and catheads. I milled some cherry strips, traced from the laser cut pattern, cut the parts carefully on the bandsaw, and sanded to a fine finish. I cut the sheaves in the catheads very carefully with multiple drill holes and finished with an exacto knife. As usual, I broke one, and had to start over. I am going pretty close to a 3 to 2 clip. It always seems to take at least 3 tries to get 2 right. Here are some photos.

- 648 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

- 648 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

With the deck complete, time for some deck furniture. That starts with the carronades and long guns. I painted all of the platforms and carriages. then built a jig from the laser cut sheet to drill the holes for the rings. I again used one of my very small diamond tipped cutters for the dremel. I just put a measured hole in the jig and used it for the platforms. I drilled one hole and then flipped the platform over and drilled the hole on the other side I also used the same jig to cut the notch for the buckled ring on the back of the carriage and the notch on each side for another set of rings. I placed some photos to show how I made the rings. I basically drilled a series of 20 holes in one of the kit supplied brass strips, inserted 20 rings, and then cut each off of the main strip. It made it easier to handle such small pieces. I then blackened all of the parts with Birchwood Brass Black ( a great product and another great tip lifted from this forum). For the rounded metal straps on the nose of the platform, I started with a 24 gauge black wire, made a tight circle, pounded it flat with a hammer, and then cut small sections to fit on the front of the platforms. I then blackened that as well. I painted the gun barrels with the kit supplied black paint. I have an Iwata double action air brush that puts down a great finish. I used bass wood strips for the quions. I cut the small triangles and put a small hole with a push pin in the back, and inserted the tip of a touthpick for the handle.

- 648 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

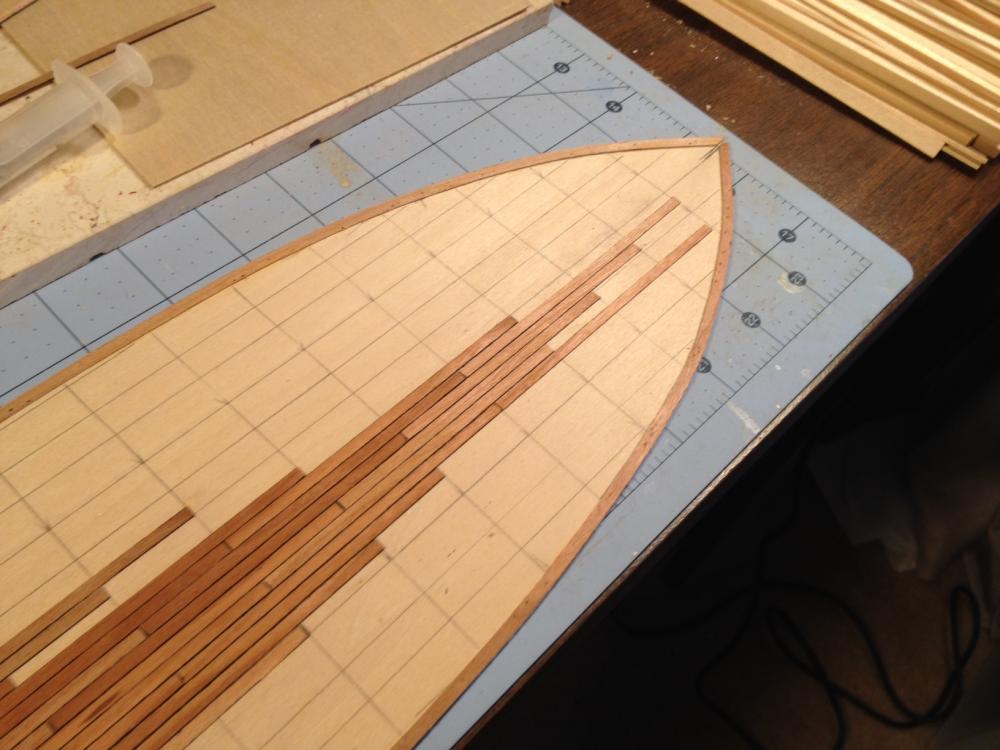

I next moved on to the deck. I decided to use 1/8 wide cherry veneer strips on a 1/16 thick sheet of birch plywood. I cut out the picture of the deck from the plans and used it to trace an image onto the plywood. I then cut it out on the jig saw. After a little bit of sanding, it fit good enough. With the plywood set on the ship, I took strips of the veneer and glued them down around the perimeter. This assured a perfect fit against the waterway. Once the perimeter strips dried, I removed the plywood from the ship and went back to the bench. I decided to use 4 inch strips on 1 inch centers. I marked the 1 inch lines and then ran a series of lines long way to act as guides. I cut a pile of 4 inch strips and used a black sharpie to line the edges. On the hardwood cherry, the black ink penetrated just enough to simulate caulking. I then started glueing them down using yellow wood glue. I was able to move at a pretty good pace and loved the look of the cherry. I was able to do the entire deck in an afternoon. Once it dried, I punched nail holes with a puch pin and blackend the holes with a sharp No. 2 pencil. A good but gentle sanding (the veneer is paper thin) completed the process. Using the veneer on birch plywood and laying the planks OFF the ship was a good decision. I recommend it.

- 648 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

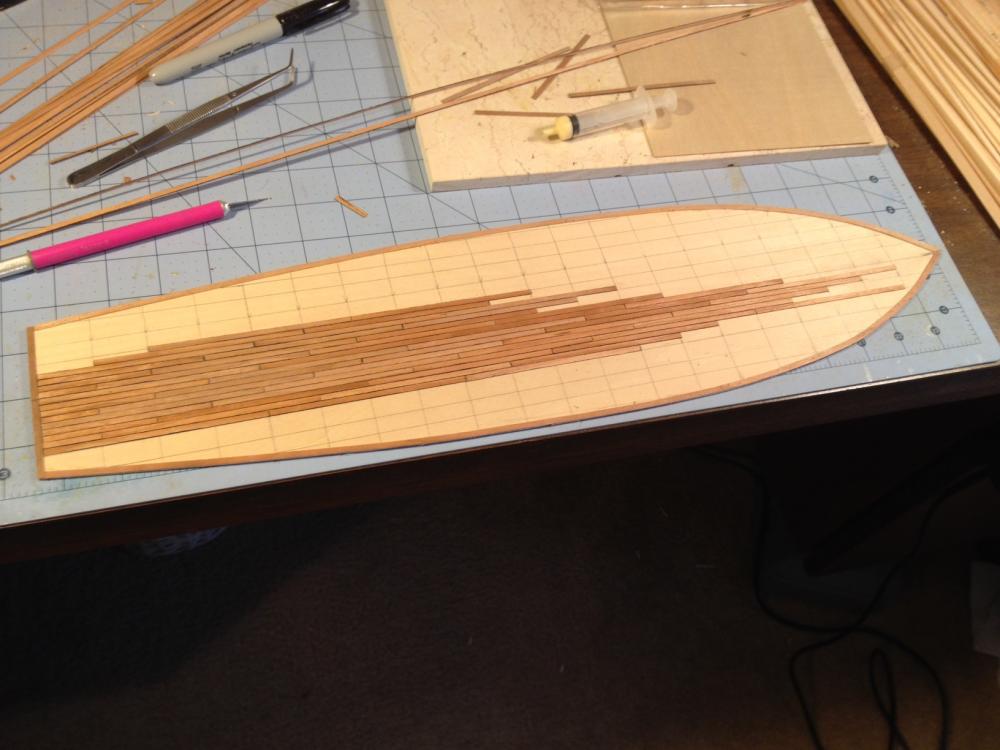

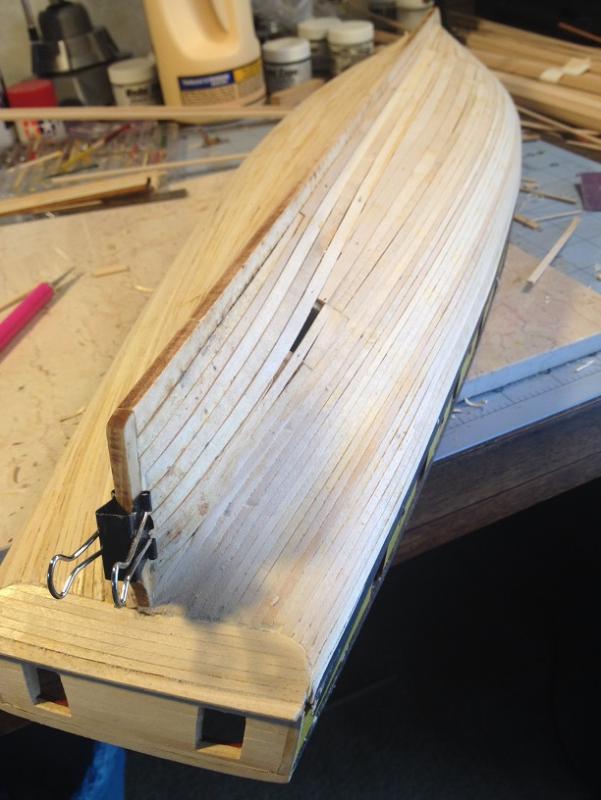

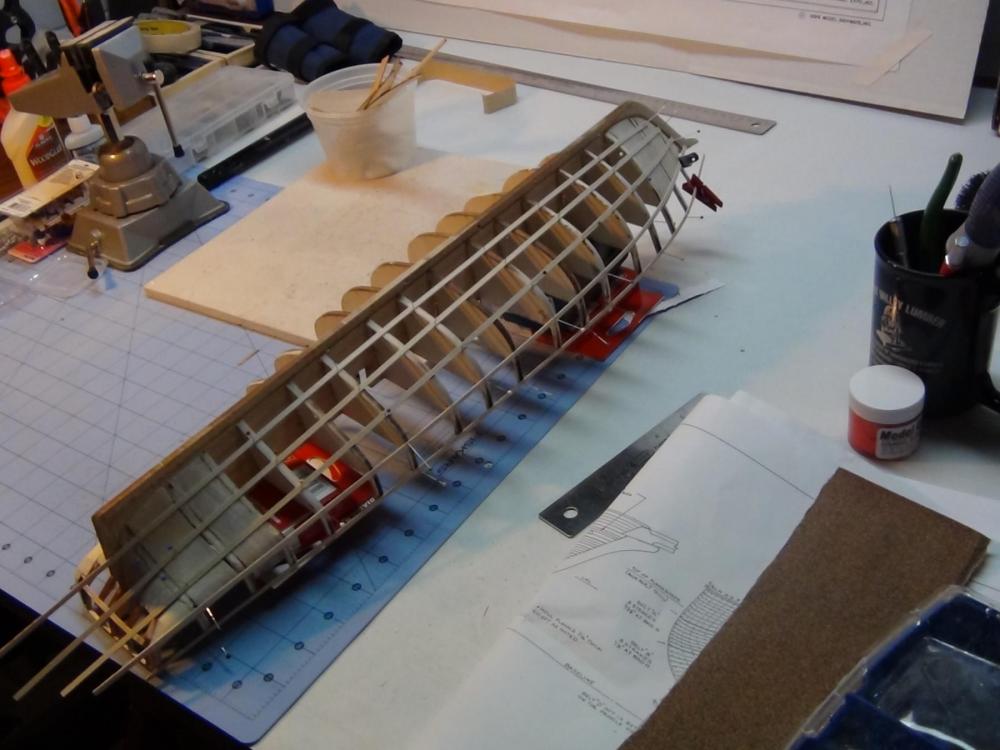

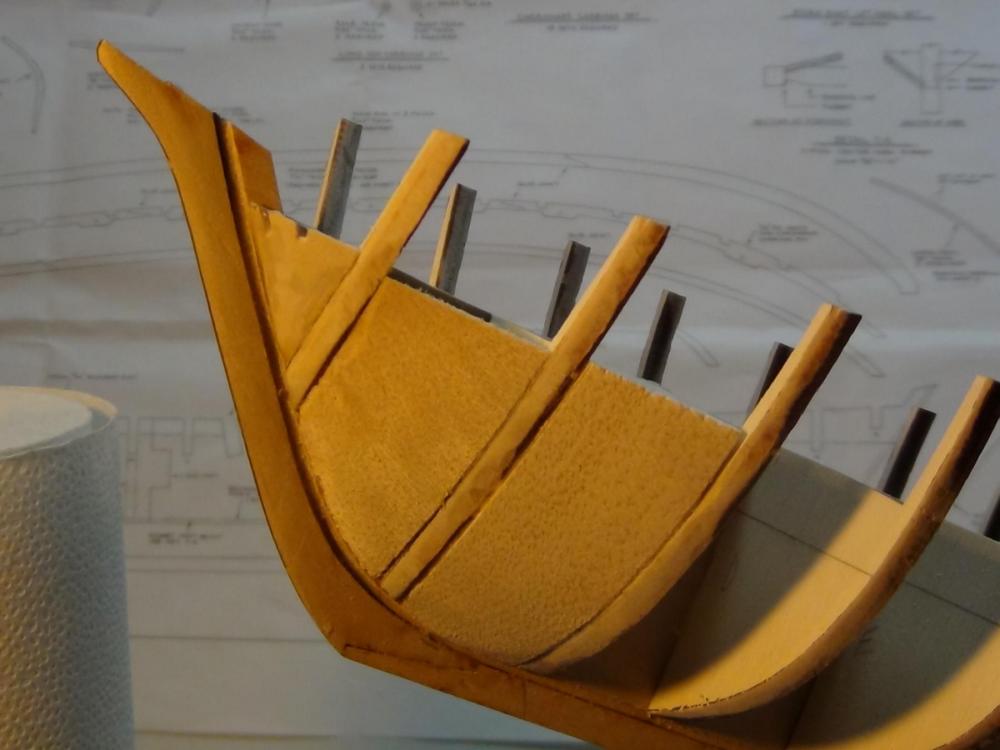

And that finally brings me to 2016. When i picked up this project again, after being dormant for years, and realized my build log was gone in the crash, I figured I would simply plug away and gave up the idea of starting the log all over again. Therefore, as I get closer to the present, the next few posts will cover alot of work but with only a few pictures. First up, the overwhelming project of planking the hull. It ended up being the typical, think about the daunting hurdle for weeks, read everything I could get my hands on, nervously glue on the first strake, then get totally consumed with finishing. In the end, after I laid the last strake (which I did take a picture of for posterity), I sat back and had one of those "did I actually do this" moments. Since the hull is painted (allowing all of the gaps to be filled and sanded), and single planked, I opted to simply lay the strakes in the recommended bands from the kit plans. I did not taper many strakes, and heavily relied on steelers when necessary. It was a good exercise. When the time comes for a future build requiring a double planked hull where the paint and filler crutches are unavailable to cover up the work, I should be ready.

- 648 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

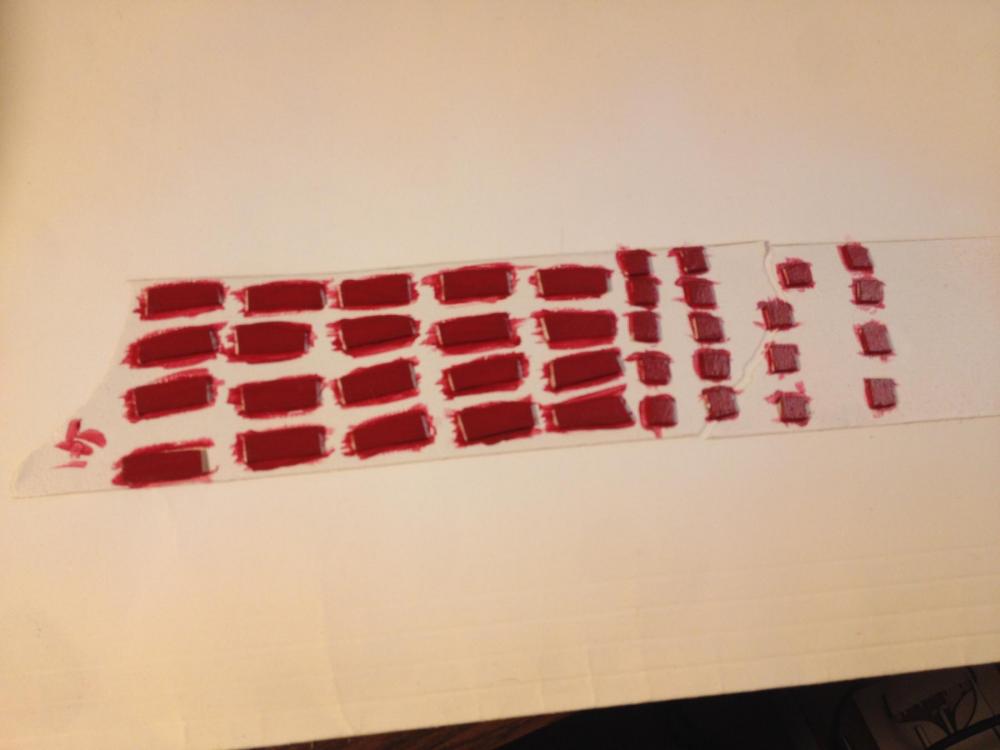

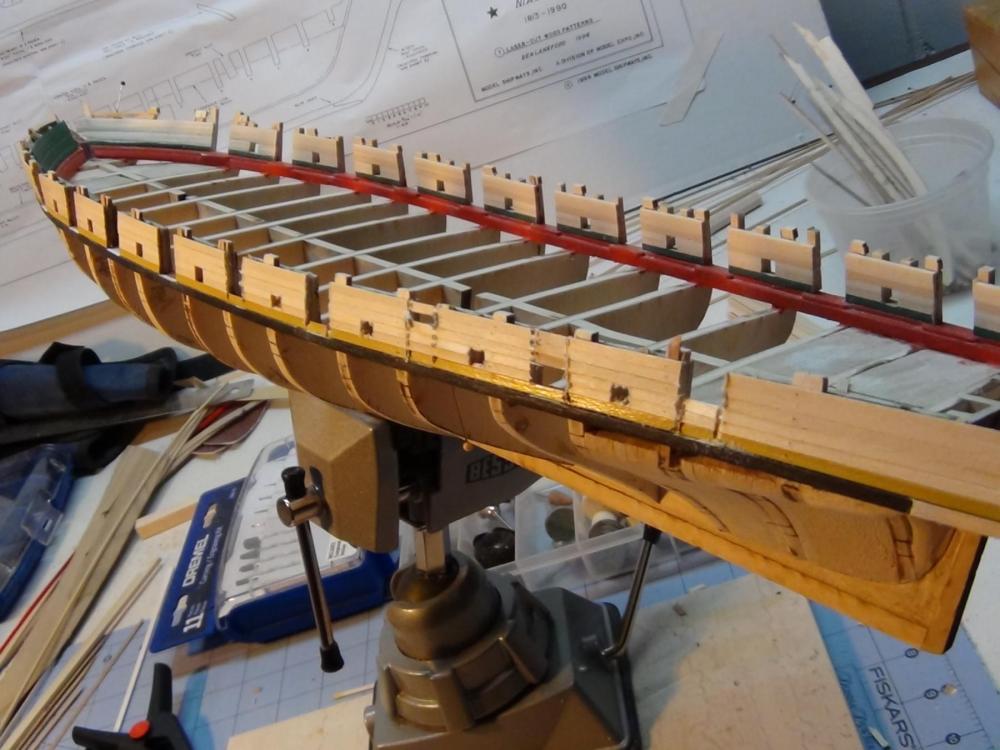

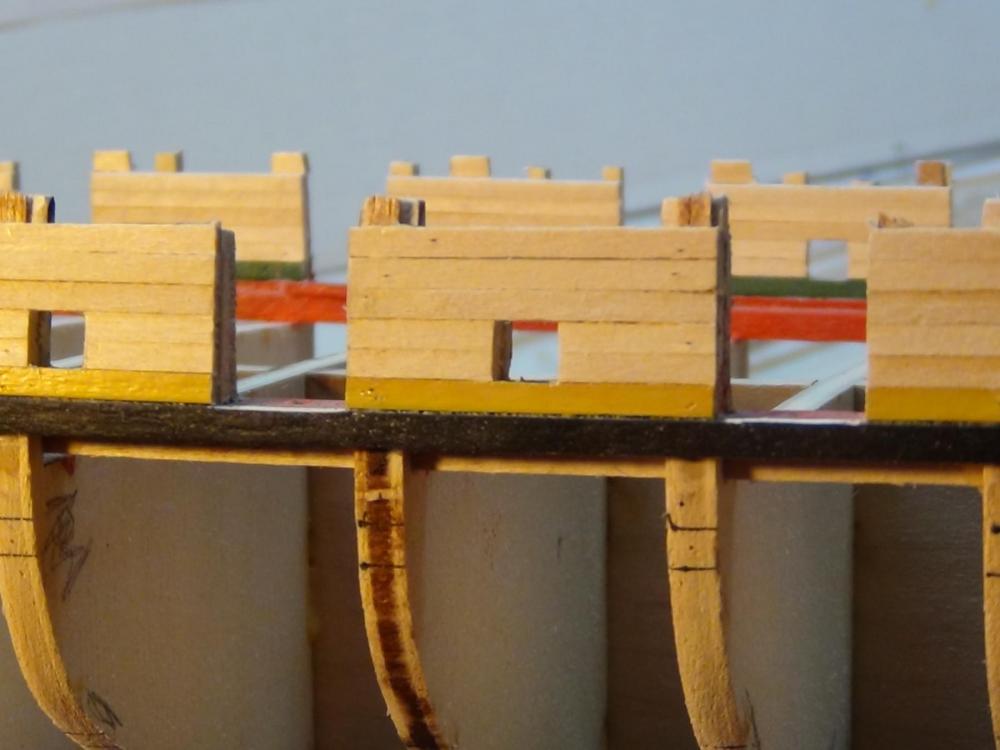

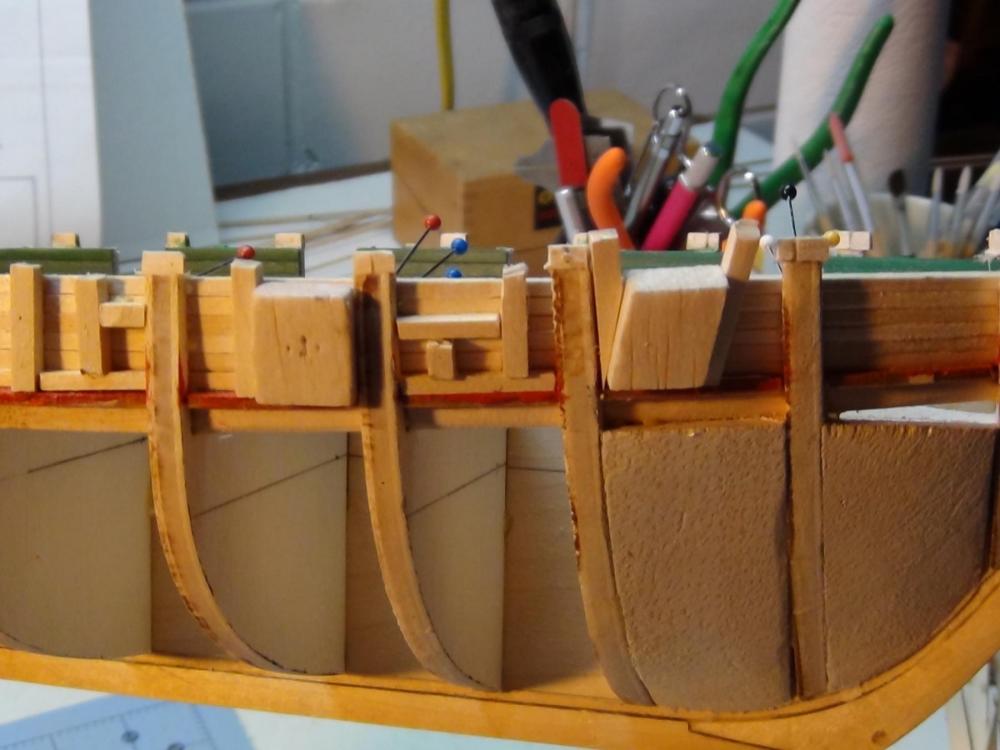

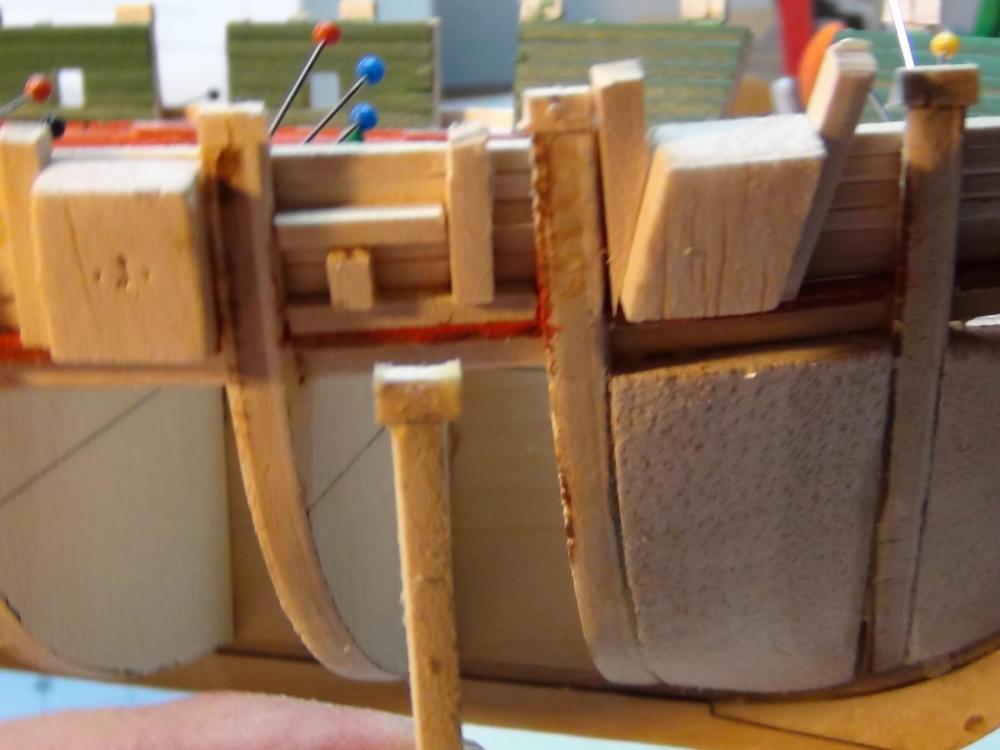

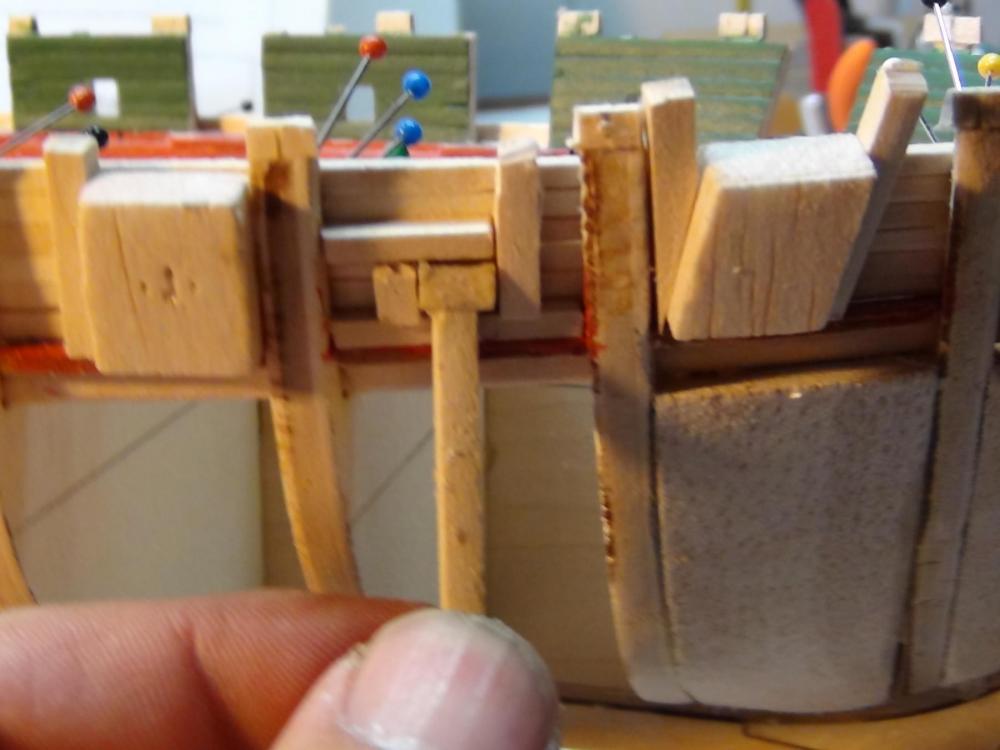

Next step was to finish painting the bulwarks, inside and out, and then line the gunports and sweeps with strip wood. I opted to size each lining seperately, number them to keep them straight, and then prime and paint them with the gun red before installing. It took a week of tedious work. In the end, i did not like the finish, and to make matters worse, i marred and chipped the painted surface during the installation and clamping..... SO..... I ended up doing what I tried to avoid. I had to sand the finished and painted bulwarks, inside and out (a daunting task) to make the linings flush with the walls, and repaint the whole thing over again, by hand. In the end, i would have been much better off installing the linings BEFORE I painted. Lesson learned.

- 648 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks John and Mark for checking in. Wow, someone is actually looking at all this. John, thanks for the photo link. I have actually viewed your shots on many occasions, as you have graciously posted them on the other Niagara logs. I took some photos myself in 2011 but they are not nearly as good as yours. Your photo collection is a fantastic resource. Mark, I did not take any pictures of the damage caused by the table collapse. I have however posted the last photo that i took of the ship before the accident, and I suspect, this is the position of the ship in the vice when the table gave way. You will note that it is sitting in a vice with the stern pointing down. I used a marble tile to suction the bottom of the vice to. That extra weight at the very end of the table, along with the humidity and heat swings in the shop probably caused the hand crank to loosen just enough for the front of the table to give way. Three of the stern posts broke completely off together with all of the framing and the back portion of the keel cracked. The only bad thing was that I had a hard time finding all of the pieces among the huge pile of you know what. Everything that was on that table was in a single pile on the floor. In the end, it could have been a lot worse but at the time however, it was enough to take the wind out of my sails. I is good to have it back. Darrell

- 648 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

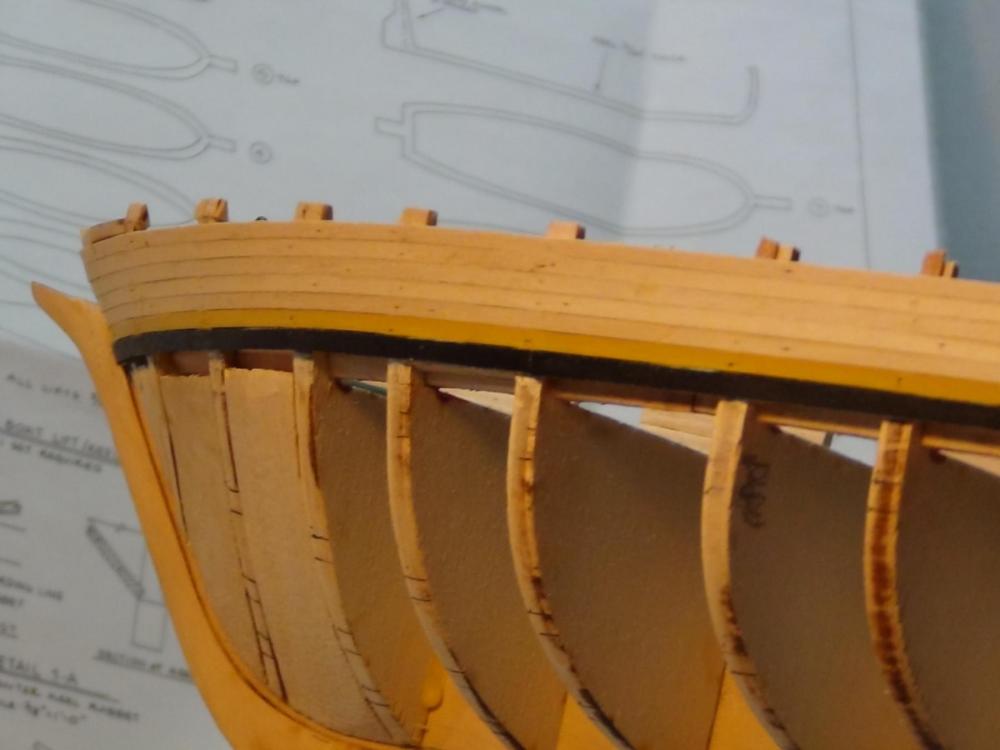

Time to start planking the bulworks. And this brought me face to face with paint issues. Consistent with my decision to prepaint strakes with different colors that abutted each other before installation, I had to decide what colors to use. In my previous post, you will note that I prepainted the waterway and planksheer with the Model Export Gun Red Paint that I ordered with the kit. As others have noted, the red paint is nearly orange-too bright for my eye. In order to darken it, I mixed in a few drops of black. That did not work. Just a few drops of black turned it a muddy gray. scratch 1/3 of my red paint. In the second batch, I only put in 1 drop and got something that I liked. I then repainted the waterway and planksheer. The green provide by Model Expo for the inner bulwarks was fine. No need to do any mixing. The yellow was a whole different issue. I have pictures of the original ship and the outer bulwarks are a dark yellow. The paint kit does not provide anything even close. I searched my local hobby shop and purchased at least 6 different yellow paints before deciding on a Model Master acrylic "Yellow Zink Chromate" The other decision I made was to glue all of the strakes onto the bulwarks from port to stern and then go back and cut out the gun ports and sweeps. I used a diamond tipped cutting bit for the dremel for the rough work and a flat file for finishing. I had a small mini file that fit perfectly inside the small sweeps that helped clean them up. Before I did all of this, I soaked all of the strakes and pinned them to the bulkheads over night to dry to fix the bends. Then I painted the whale strake flat black for the bottom, the first strake above that with the yellow for the outside. Then painted the first strake with green for the inside. Overall, I was very satisfied with the result.

- 648 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

On to the gun ports and sweeps. I noticed that every gun port and some of the sweeps had at least one side affixed to a bulkhead top. So, I created wooden blocks in the shape of the square gun port, a trapazoid shaped one for the front port, and a small block for the sweep. I laid the block against the designated bulkhead and built the port around it. This method assured that the ports would be square and consistently sized. I did the same with the sweeps block. This tedious job, which as I look back on it took days to complete, was made easier with the block jigs.

- 648 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

As I am "recreating" a build log that was started nearly 4 years ago, with only pictures and no narrative, I have to rely on my less than true memory. As I moved on to the waterway and planksheer, it was at about this time that I made some critical decisions that affected the build then and now. 1. I decided I did not like the bass wood for anything other than planking the hull and bulwarks. It is too soft and does not keep an edge. I marveled at the work by the experts with some of the exotic woods they came across. I have an abundance of seasoned cherry from trees I cut down on the farm and decided to use it for everything I could. 2. I decided to use cherry veneer strips for the deck. I had a tube of 1/8 inch wide cherry veneer strips in the shop. I had viewed many bass wood planked decks that looked beautiful when laid, but less so when finished with stain and sealer. Bass wood is simply too soft, and like any such wood, trying to get a true stained finish to look good was too much of a challenge for me. Even using pre stain sealers does not necessarily prevent a blotchy finish. My veneer strips however were extremely thin, so I decided to glue them to a thin sheet of birch plywood. While I decided to do this simply because of the aesthetics, I found laying the deck on a sheet of plywood "off the ship" was easy. I did add some height to the deck that I had to adjust for, but overall, a good decision. 3. I decided that every place where a two pieces with different paint colors met, I would paint them in advance, so that I would avoid masking and painting. I thought that would save me time and allow a better look. This would end up being just a so-so decision. When I first laid the pieces down, they looked great and I did not have to do any masking. However, what I did not take into consideration was how many nicks and dents would occur as the build continued. Also, I cannot understand how the dust on my desk can be so darned destructive. I must have corrosive dust here in Ohio, since it can mar the driest painted surface. In the end, the re-sanding and repainting to repair this damage probably did not save me any time. And adding more layers of paint on a surface than I wanted to also affected the look. Here are some photos of the waterway and planksheer. By the way, future Niagara builders beware. The planksheer does not fit well. It does not extend out far enough to lay flush with the outer bulkheads. Nearly every Niagara builder has noted this. I did as well. Since I had painted it in advance, it took additional time to sand off the edge and glue on extension pieces. Here are some photos of the waterway and planksheer installation.

- 648 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

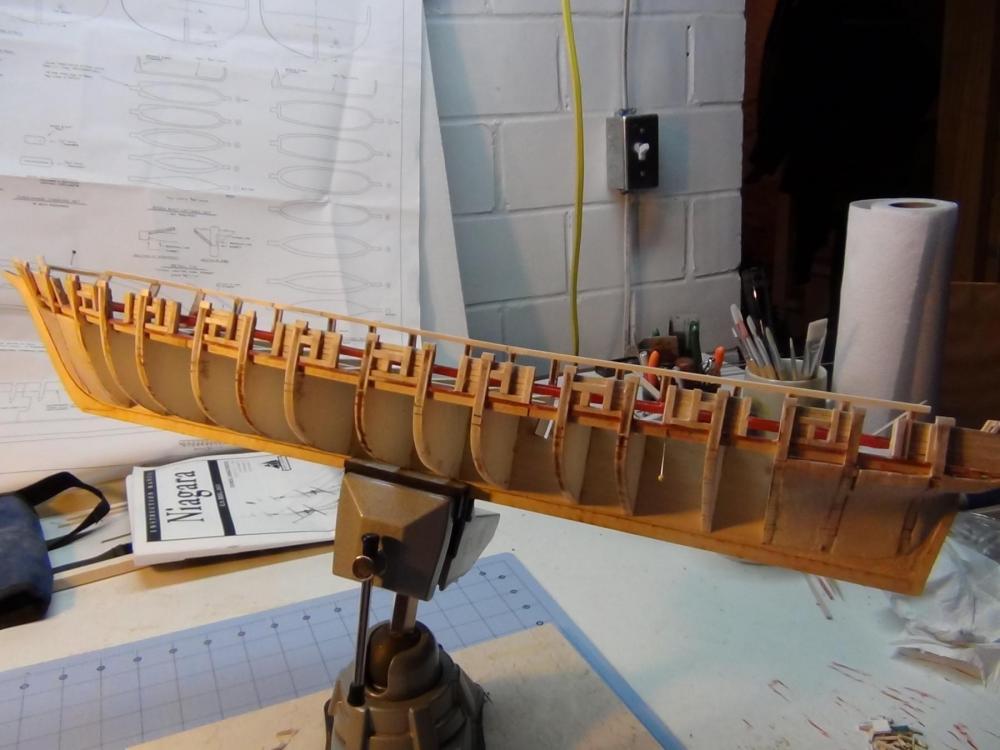

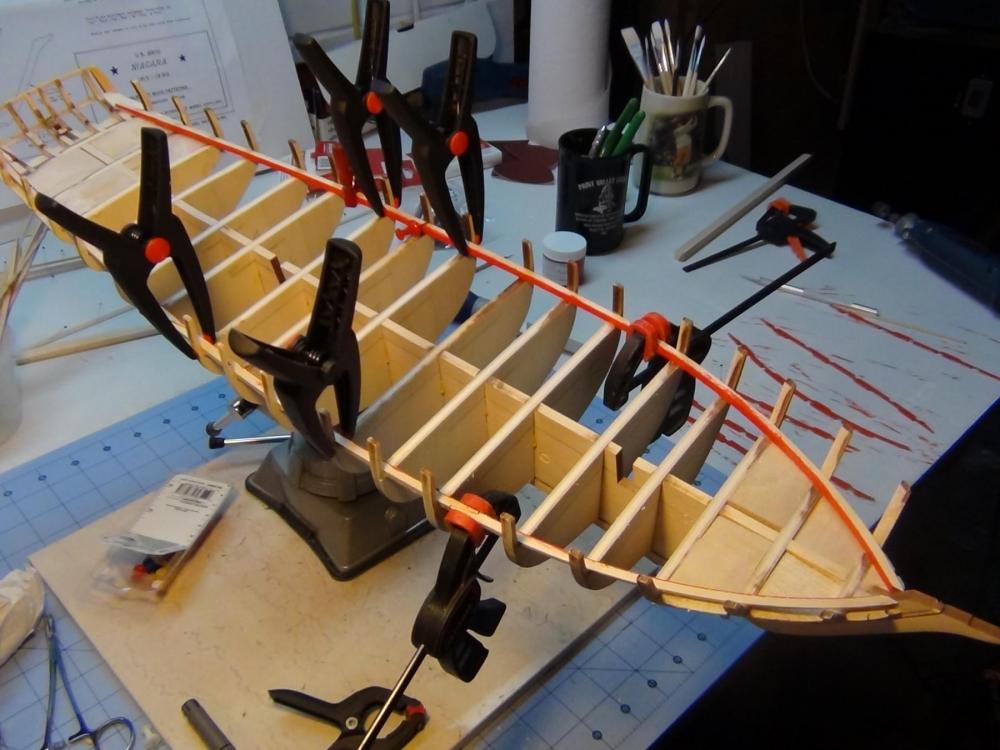

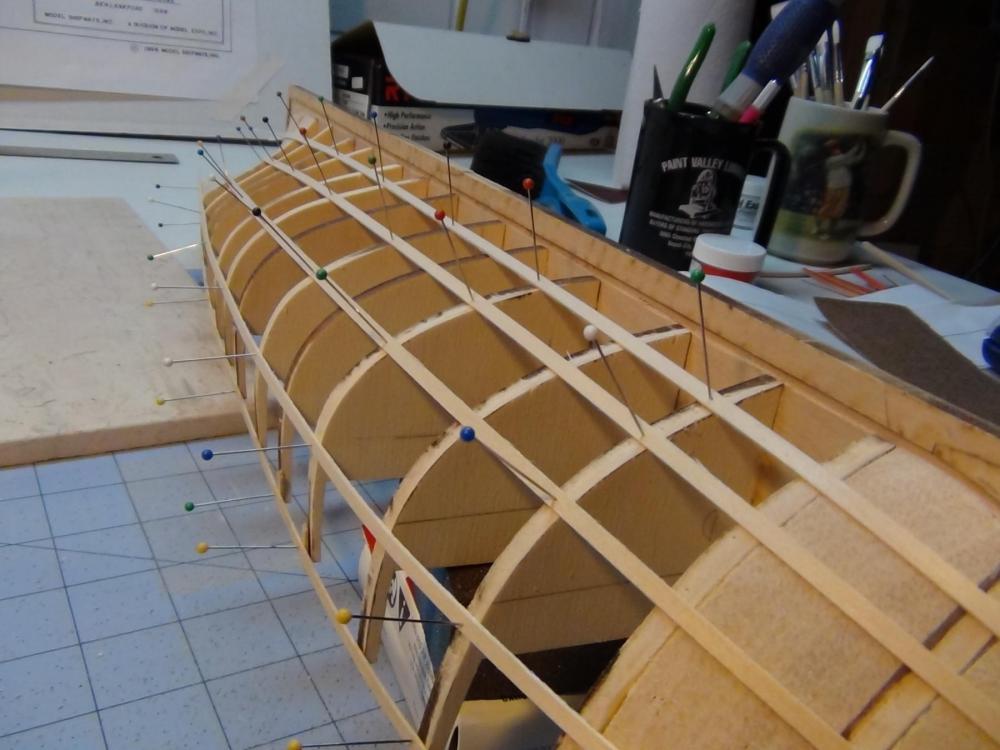

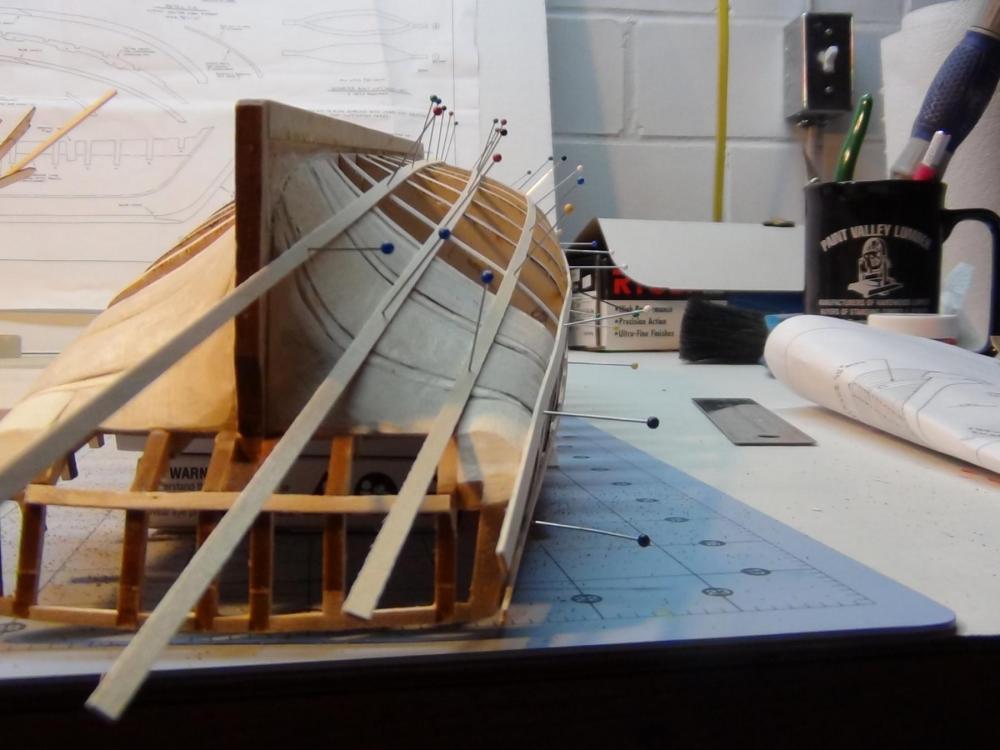

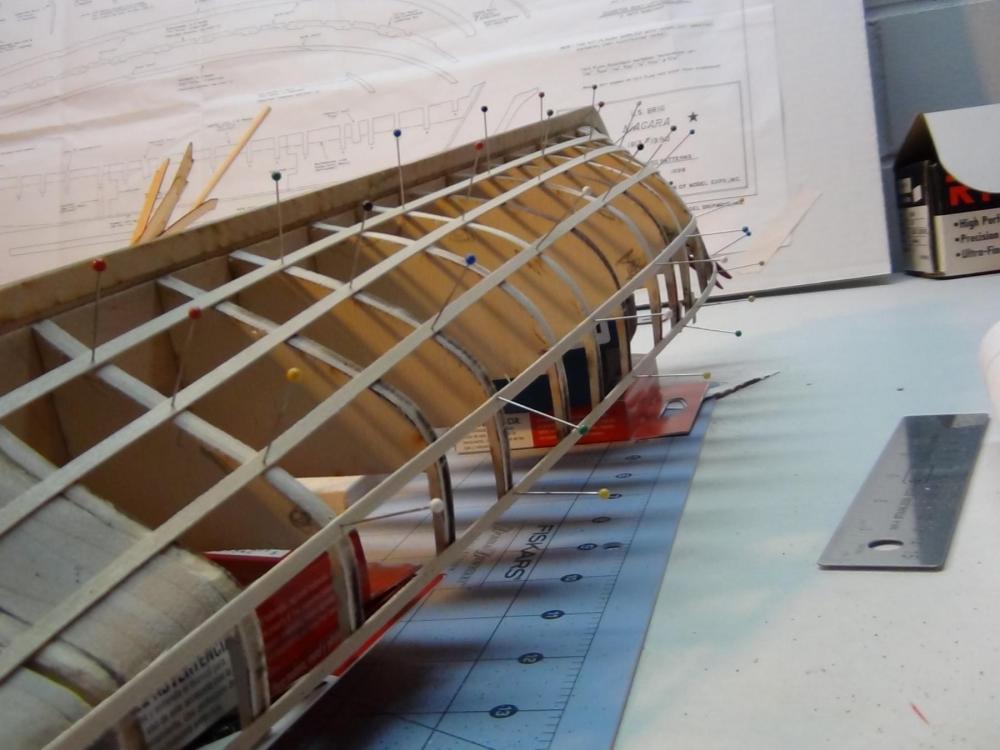

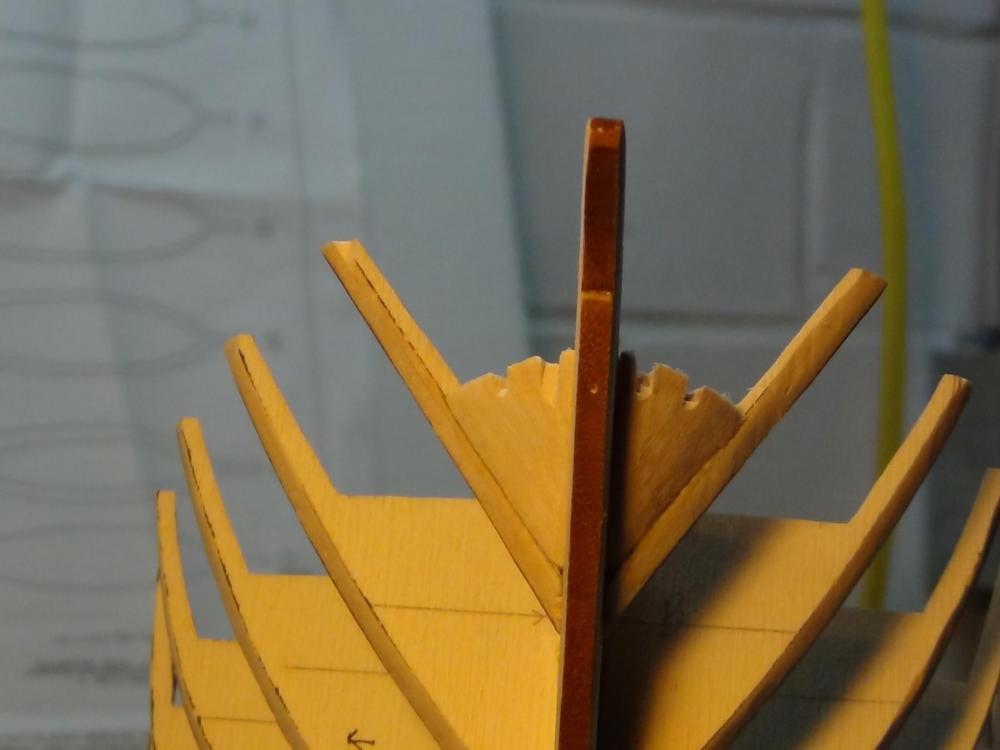

Time to fair the hull. I would have never even thought of doing this at this time. However, repeated suggestions on this forum emphasized how important this is when it comes time to plank the hull. They were right. The balsa filler blocks made it easy to pin some strakes to the hull at the kit supplied band marks. From there, I marked the high and low spots on the bulkheads and added splints or filed them down. There was some work to be done, but overall, the kit supplied bulkheads weren't too bad. I also added the required bevels on the fore and aft bulkheads. Overall, a pretty easy process. Here are some photos of the finished product.

- 648 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

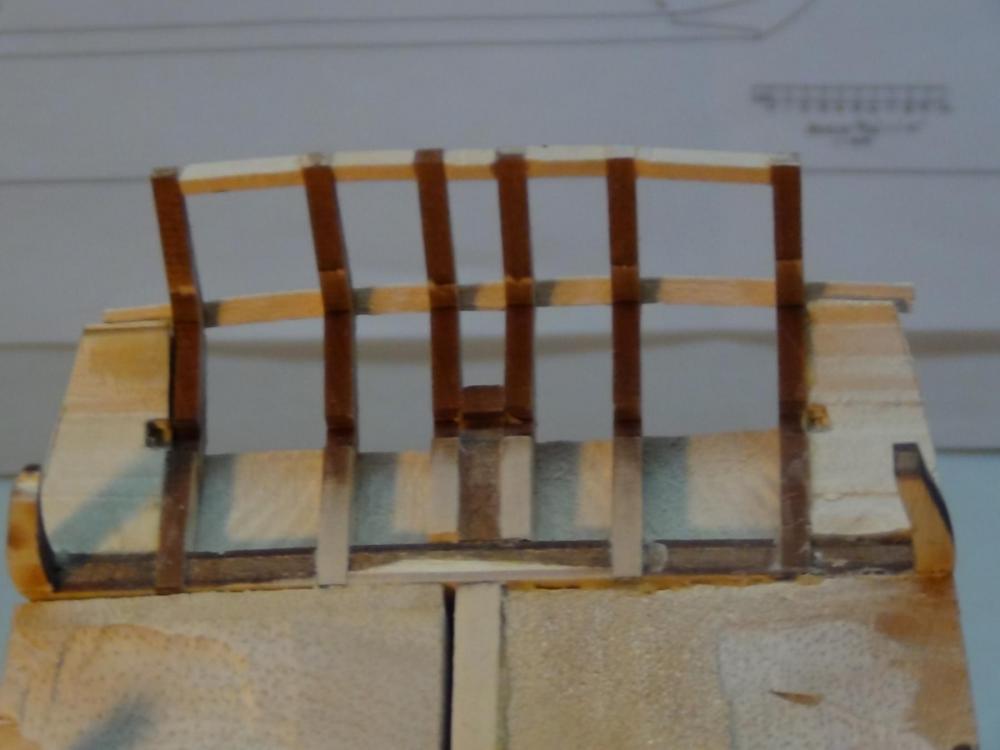

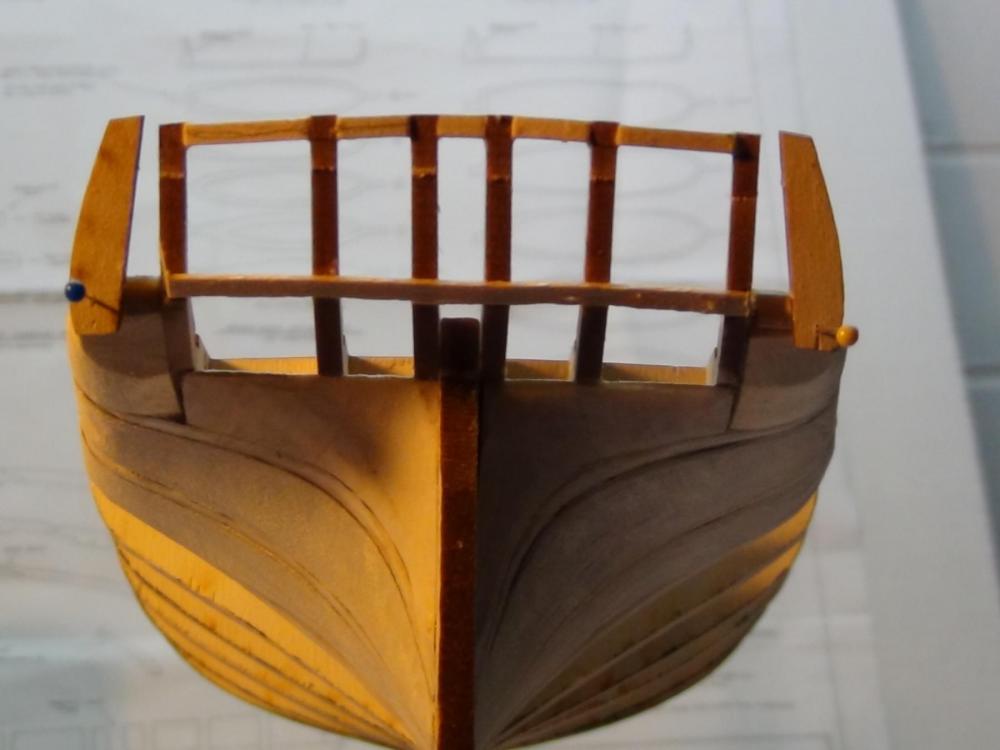

I then built the stern frames and added filler blocks. The stern frames went up pretty easily. The kit supplied blocks however were a challenge, especially the "corner fill blocks." They are small with complex shapes, and since they are prominently positioned on the outside corner of the stern, must be done right. The plans provide two dimensional -to scale- pictures, so I cut them out, and traced them to a small block of bass wood. I carefully cut those on a jig saw, and when mounted, was able to file them to size. As I found in nearly all of this build, I screwed up the first set, but did better on the second set. Practice makes perfect, or nearly so. I also added additional blocks as I did at the bow. Some photos.

- 648 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

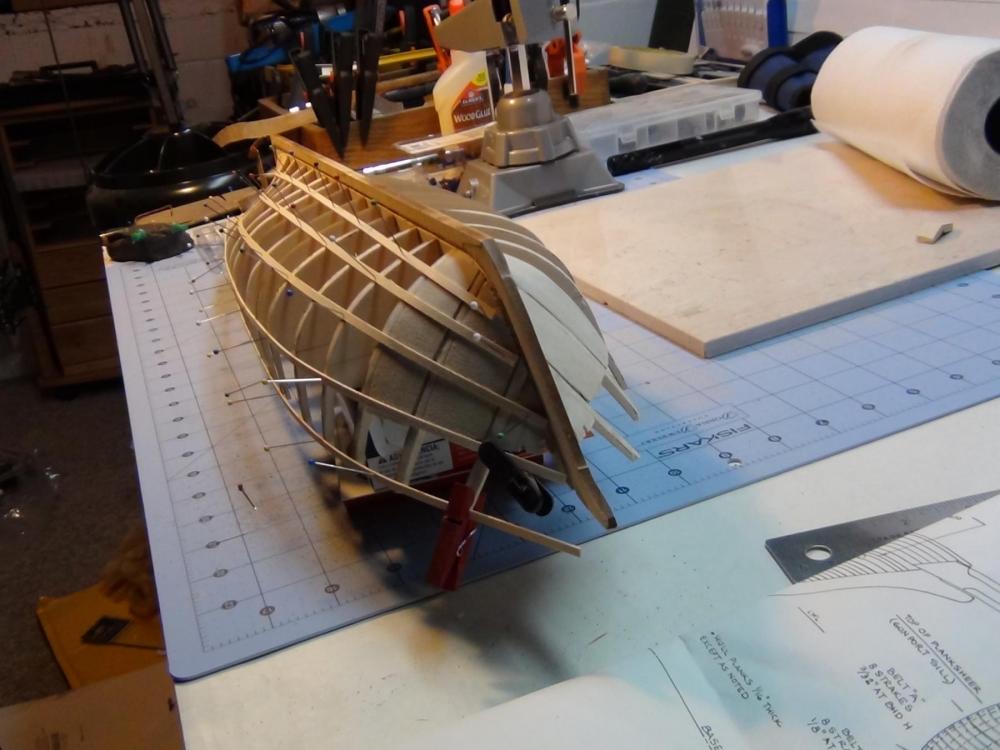

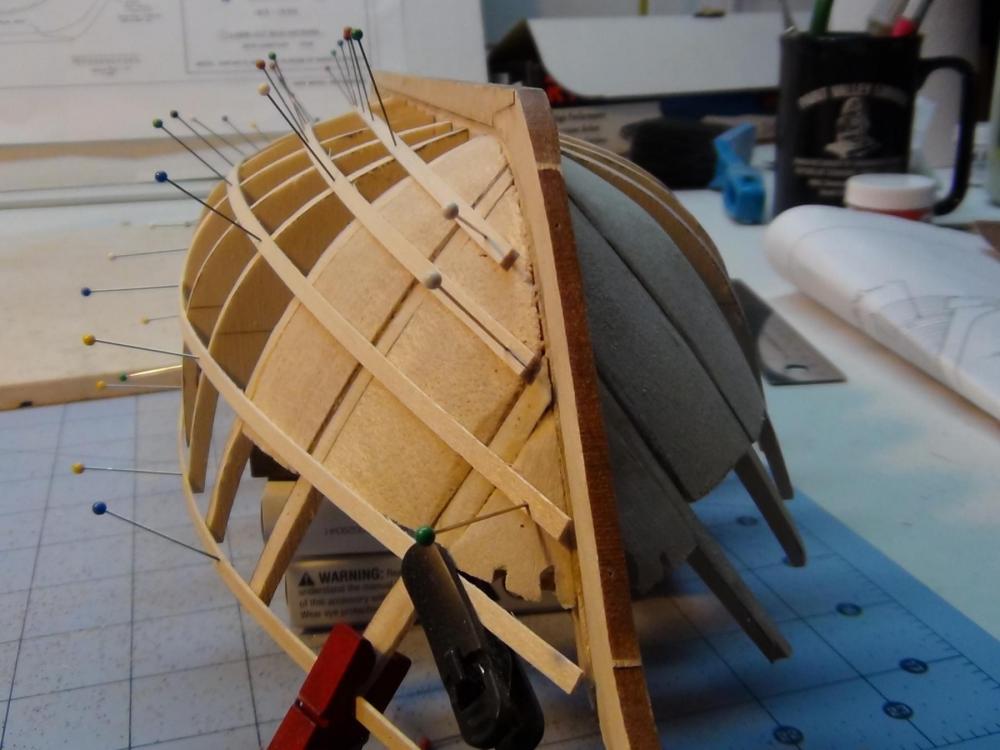

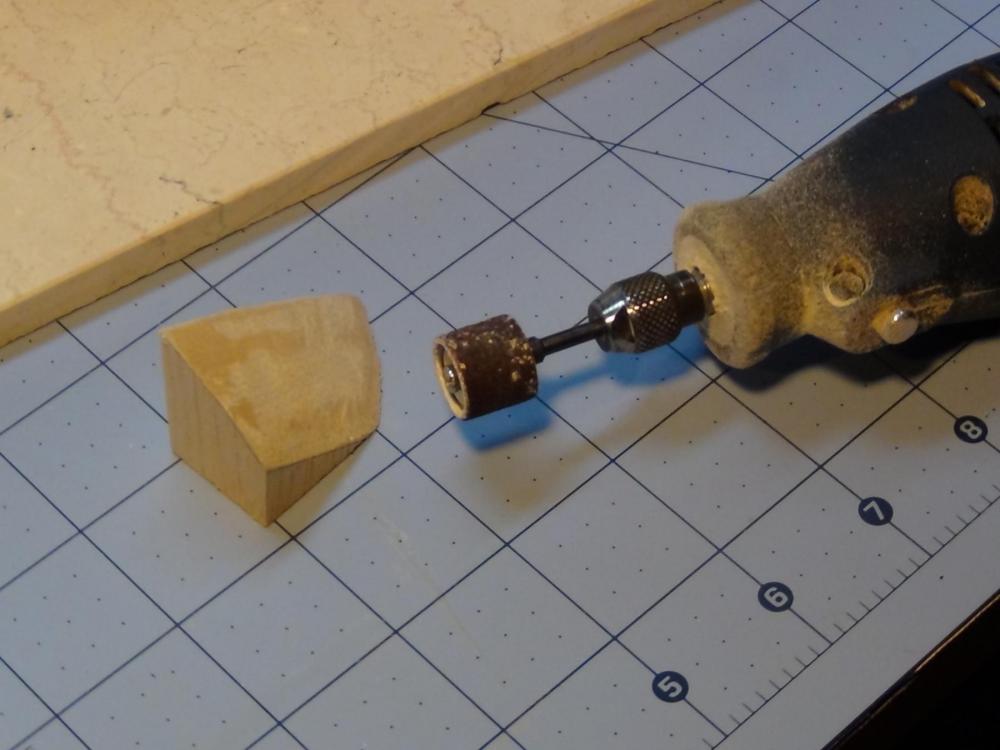

Well Here goes. After I put the frame together, I worked on the kit supplied filler blocks at the bow and stern. I picked up a tip on this forum that I should add additional blocks. That was good advice. When it came time to plank, it provided a firm base to secure the curved planks. I used balsa wood. It was easy to cut on the band saw, and easy to file down to size. I used my dremel drum sander for rough work, and a flat file for finish. Getting them to the right shape was a concern, but I found that once they were mounted to the ship, the frames acted as good guides for filing. It was not as daunting as I thought it would be. Here are a few shots of the bow.

- 648 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

- 648 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

I sheepishly reenter the water with my fellow Niagara shipwrights. I have been "lost at sea" for the last three years after my Niagara build (and as I later found my build log) took a raking broadside in a work bench accident causing damage to its stern and keel. More on that later, But I start with a short introduction. I am an amateur woodworker in Northeastern Ohio with a keen interest in military history. I am a true landsman, with no sailing experience. I built styrene models as a kid, including Revel's Cutty Sark, and gained an interest in building ship models, albeit in plastic. In the late 80's after graduating from college, and with a misguided motion that I would have plenty of free time, I purchased a POB kit, the La Toulonnaise. My unsuccessful efforts to negotiate the poorly translated, and nearly non-existent instruction manual, coupled with my lack of proper tools and modeling skills, doomed the project from the start. I kept that unfinished kit (I hit a road block at the construction of the stern fillers) for many years. I now regret that I must have thrown that kit away during one of my many moves and life changes. I sure wish I had it today. In 2011, I rediscovered my interest in wooden ship building after a visit to a tall ships event on Lake Erie where I toured the Niagara. That fall, Model Shipway put the kit on sale, and alas. I found myself back at it. There was one big difference however, While surfing the Model Shipway site, I came upon the link to this Forum. This was a real game changer. I found build logs from expert modelers like Bahama Diver and others that were building the Niagara. While the Model Shipways Niagara has a pretty good instruction manual, the color pictures on this site and the ability to ask stupid questions gave me the confidence to forge ahead. I started my build and the build log in January 2012. I completed the framing and bulwarks (and got past the dreaded stern fillers) by May of 2012. Then disaster! My bench table, an antique drafting table with a swivel top, somehow gave way, and my Niagara in its stern vice, and all of the material, tools and everything you can imagine we carry on our benches, was dumped onto the concrete floor. The fall crushed the stern fillers (of course) and broke off half of the keel. Surprisingly, there was no other damage, but the mess was extreme. I had just enough energy to clean up the mess, but not enough to continue the build. Fast forward to today. I was in Boston in December and had the privilege to see the Constitution in dry dock. What an experience. The inspiration of witnessing such a beauty gave me the initiative to take my Niagara out of ordinary and get it back to the shipyard. Of course, I attempted to access my build log, and discovered my ship was not the only thing that took a raking broadside. It was gone by way of the big crash (the administrators need to use live oak to build their hard drives). Since all of my photos were on an old computer that is long gone, I thought the log was a lost cause. I have been hard at work since January. I fixed the damage, finished the bulwarks, planked the hull and the deck, built the guns and most of the deck furniture, and just about finished the masts and yards. Here are some photos (forgive the poor quality) of where I am. Nothing is glued down, and is set in place just for the photos. I wasn’t going to post a log, but guilt and finally some luck pushed me otherwise. Over the holiday, I got my camera out for a family picnic and lo and behold, the shots of my build log were still on the camera disc. Since I spend so much time getting tips and help from others logs, I felt compelled to give back. Over the next several weeks, I will be adding the old pictures and recreating the narrative (that is truly gone). And as I go forward, will humbly place myself along side my fellow Niagara builders for the end run.

- 648 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.