cgiacoppo

NRG Member-

Posts

32 -

Joined

-

Last visited

About cgiacoppo

Recent Profile Visitors

-

yvesvidal reacted to a post in a topic:

CSS Virginia by cgiacoppo - BlueJacket Shipcrafters - Scale 1:192 - My son Michael's first wooden ship build

yvesvidal reacted to a post in a topic:

CSS Virginia by cgiacoppo - BlueJacket Shipcrafters - Scale 1:192 - My son Michael's first wooden ship build

-

yvesvidal reacted to a post in a topic:

CSS Virginia by cgiacoppo - BlueJacket Shipcrafters - Scale 1:192 - My son Michael's first wooden ship build

yvesvidal reacted to a post in a topic:

CSS Virginia by cgiacoppo - BlueJacket Shipcrafters - Scale 1:192 - My son Michael's first wooden ship build

-

yvesvidal reacted to a post in a topic:

CSS Virginia by cgiacoppo - BlueJacket Shipcrafters - Scale 1:192 - My son Michael's first wooden ship build

yvesvidal reacted to a post in a topic:

CSS Virginia by cgiacoppo - BlueJacket Shipcrafters - Scale 1:192 - My son Michael's first wooden ship build

-

yvesvidal reacted to a post in a topic:

CSS Virginia by cgiacoppo - BlueJacket Shipcrafters - Scale 1:192 - My son Michael's first wooden ship build

yvesvidal reacted to a post in a topic:

CSS Virginia by cgiacoppo - BlueJacket Shipcrafters - Scale 1:192 - My son Michael's first wooden ship build

-

yvesvidal reacted to a post in a topic:

CSS Virginia by cgiacoppo - BlueJacket Shipcrafters - Scale 1:192 - My son Michael's first wooden ship build

yvesvidal reacted to a post in a topic:

CSS Virginia by cgiacoppo - BlueJacket Shipcrafters - Scale 1:192 - My son Michael's first wooden ship build

-

robert952 reacted to a post in a topic:

CSS Virginia by cgiacoppo - BlueJacket Shipcrafters - Scale 1:192 - My son Michael's first wooden ship build

robert952 reacted to a post in a topic:

CSS Virginia by cgiacoppo - BlueJacket Shipcrafters - Scale 1:192 - My son Michael's first wooden ship build

-

robert952 reacted to a post in a topic:

CSS Virginia by cgiacoppo - BlueJacket Shipcrafters - Scale 1:192 - My son Michael's first wooden ship build

robert952 reacted to a post in a topic:

CSS Virginia by cgiacoppo - BlueJacket Shipcrafters - Scale 1:192 - My son Michael's first wooden ship build

-

robert952 reacted to a post in a topic:

CSS Virginia by cgiacoppo - BlueJacket Shipcrafters - Scale 1:192 - My son Michael's first wooden ship build

robert952 reacted to a post in a topic:

CSS Virginia by cgiacoppo - BlueJacket Shipcrafters - Scale 1:192 - My son Michael's first wooden ship build

-

robert952 reacted to a post in a topic:

CSS Virginia by cgiacoppo - BlueJacket Shipcrafters - Scale 1:192 - My son Michael's first wooden ship build

robert952 reacted to a post in a topic:

CSS Virginia by cgiacoppo - BlueJacket Shipcrafters - Scale 1:192 - My son Michael's first wooden ship build

-

GrandpaPhil reacted to a post in a topic:

CSS Virginia by cgiacoppo - BlueJacket Shipcrafters - Scale 1:192 - My son Michael's first wooden ship build

GrandpaPhil reacted to a post in a topic:

CSS Virginia by cgiacoppo - BlueJacket Shipcrafters - Scale 1:192 - My son Michael's first wooden ship build

-

It was difficult to get the chain back through the hole. I ended up tying a piece of thread to the chain and then the other end of the thread to a piece of thin wire that I was able to push through. Once the end of the wire emerged with the thread, I used the thread to pull the chain through.

- 37 replies

-

- first build

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

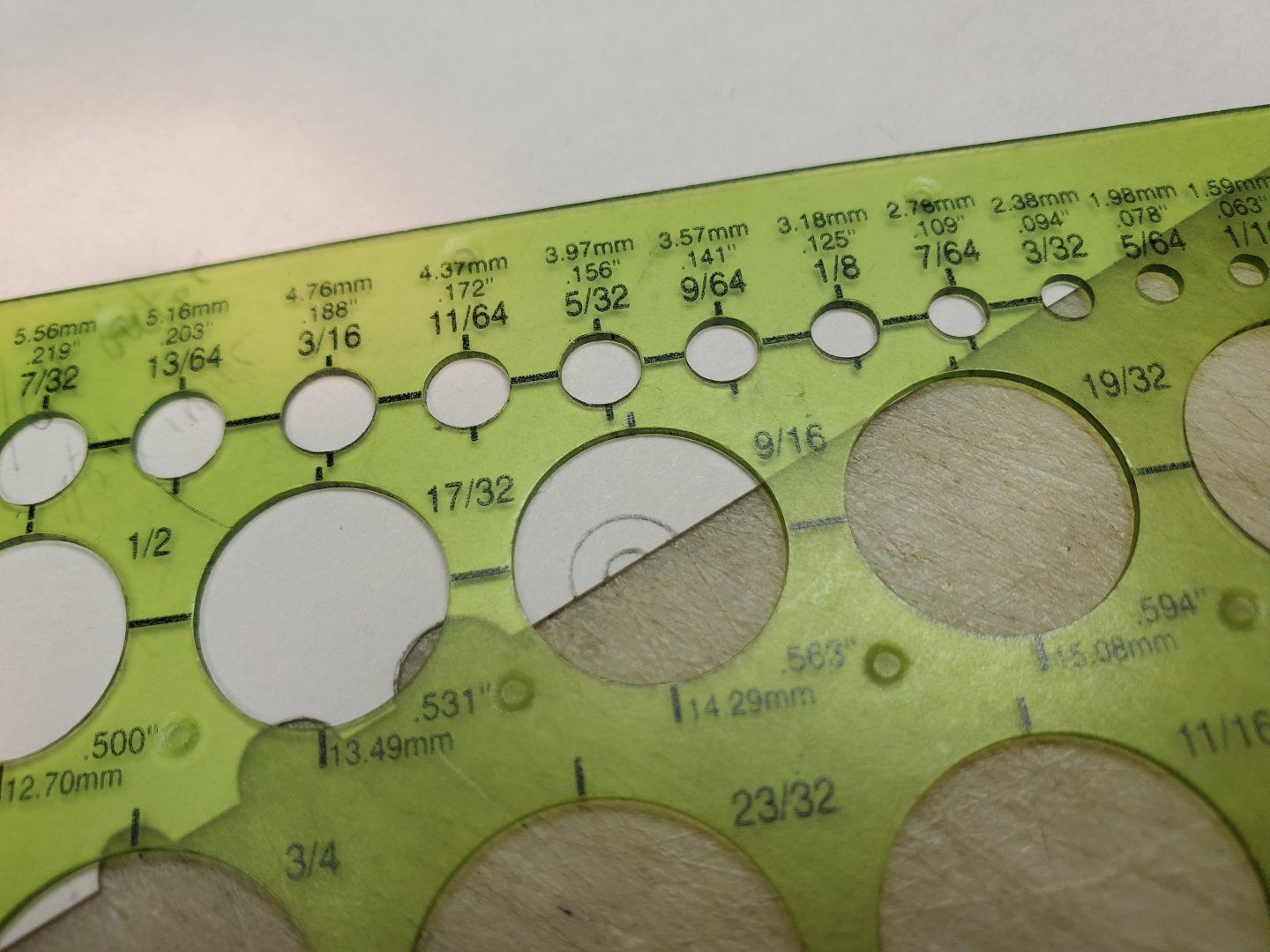

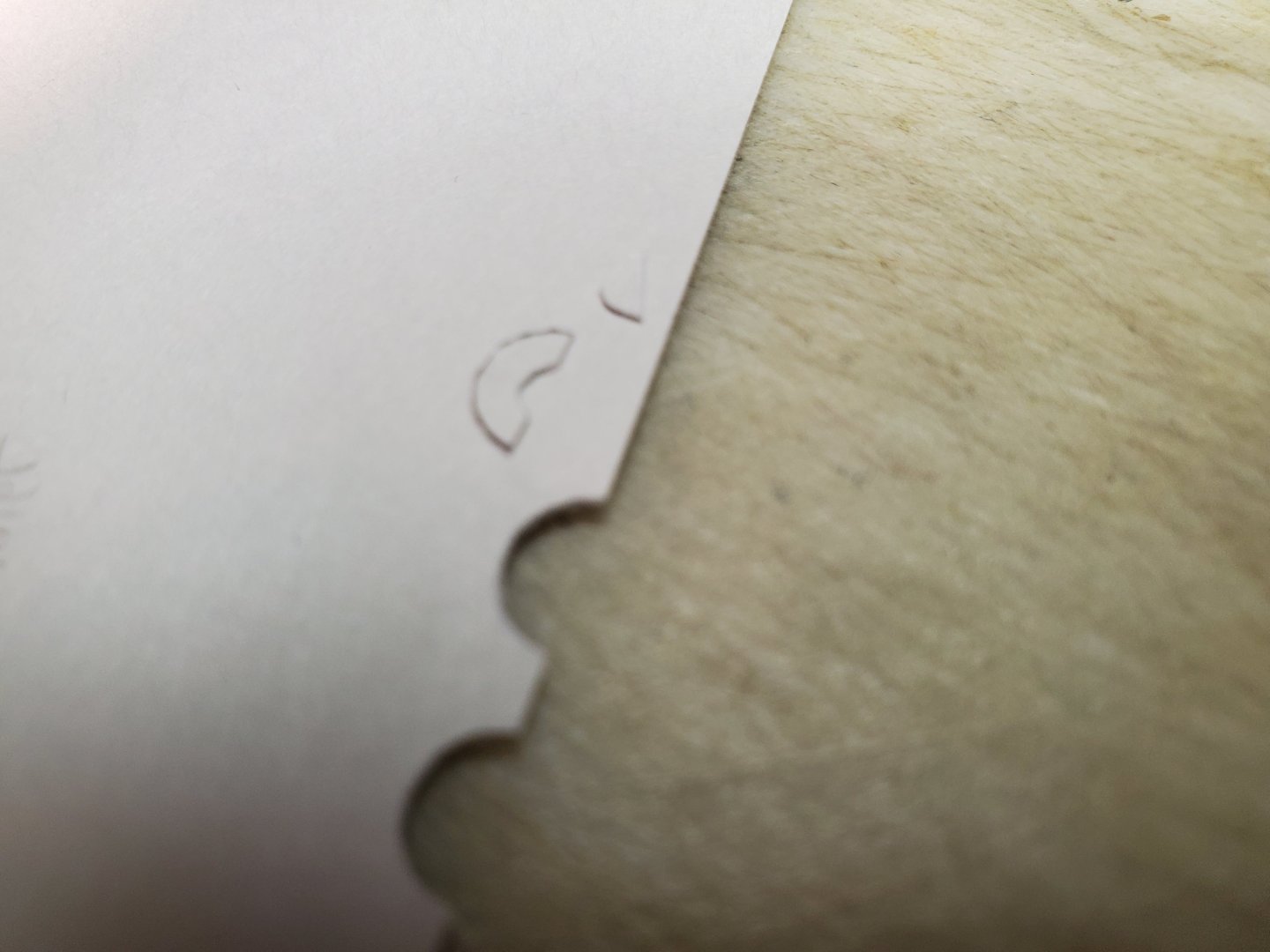

We now turned our attention to the holes where the rudder chains emerge from the hull. We previously used cardstock to create the armor plate rub rail and decided to create semi-circular openings out of the same card stock to give the holes a nice finished look.

- 37 replies

-

- first build

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

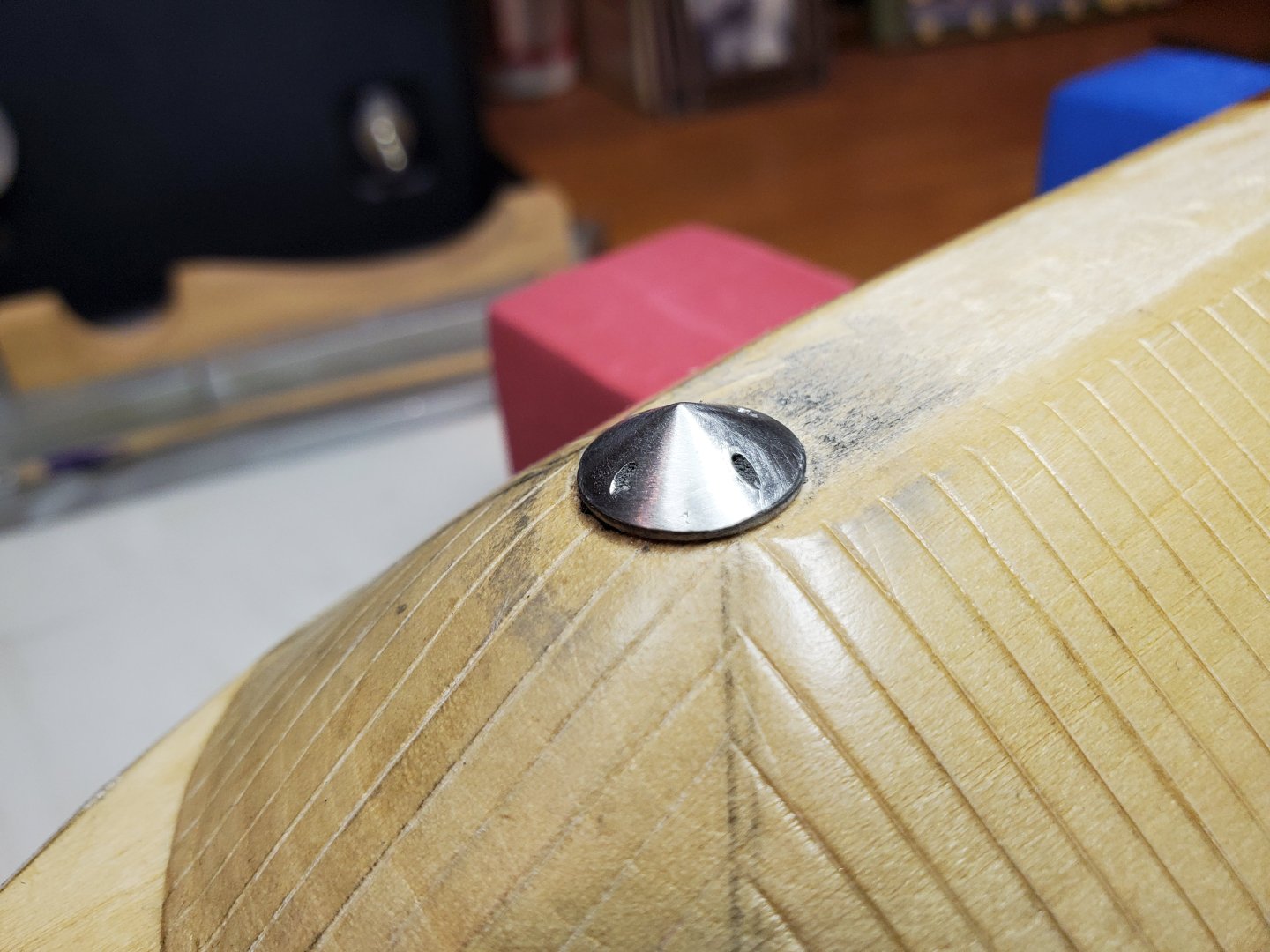

Setting aside the deck planking, we next attached the pilot turret. This is a metal piece so we used 2-part epoxy. The lookout ports on the turret were very slight indentations, so we drilled them out a bit to make them more realistic.

- 37 replies

-

- first build

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

- 37 replies

-

- first build

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

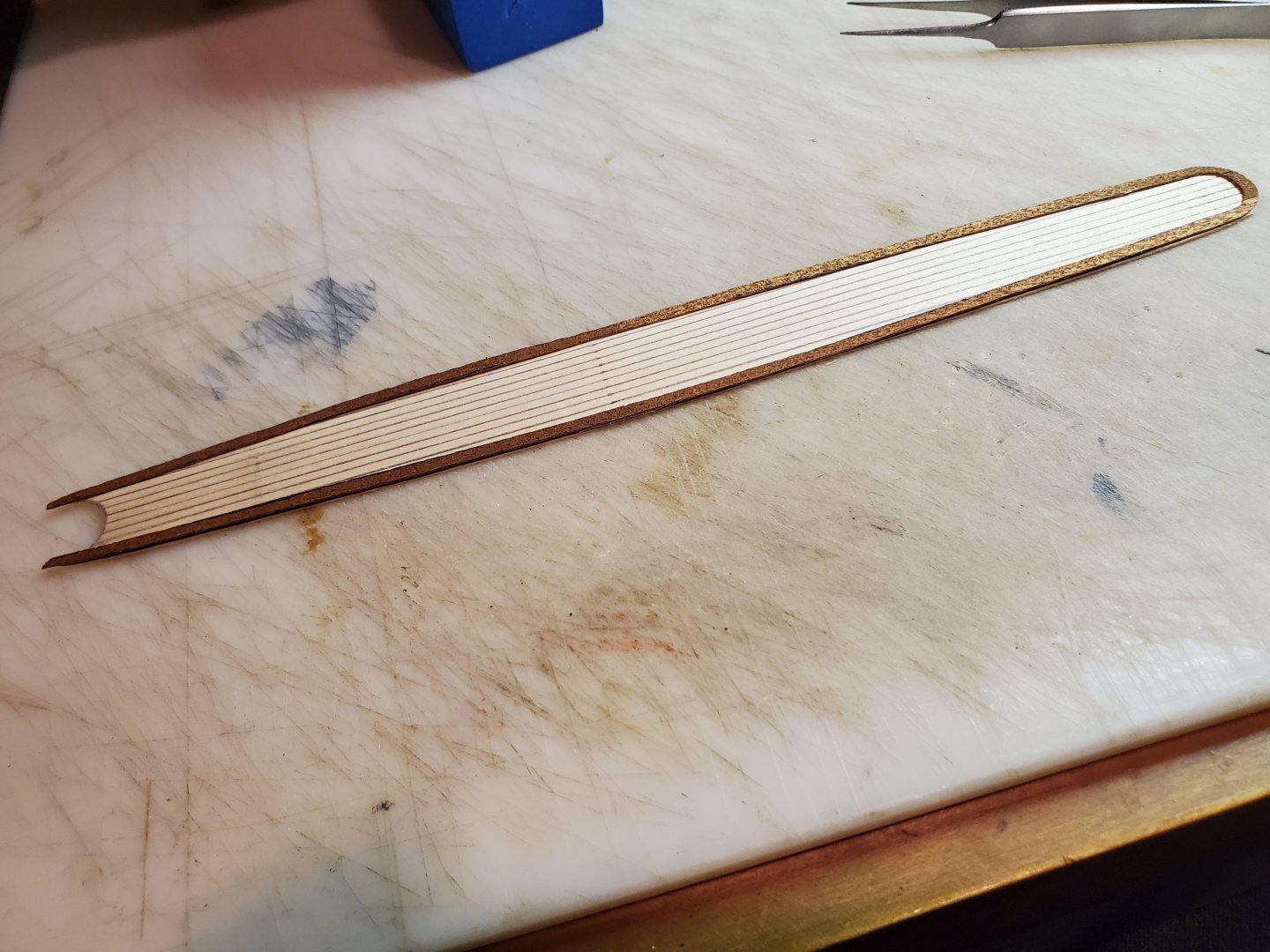

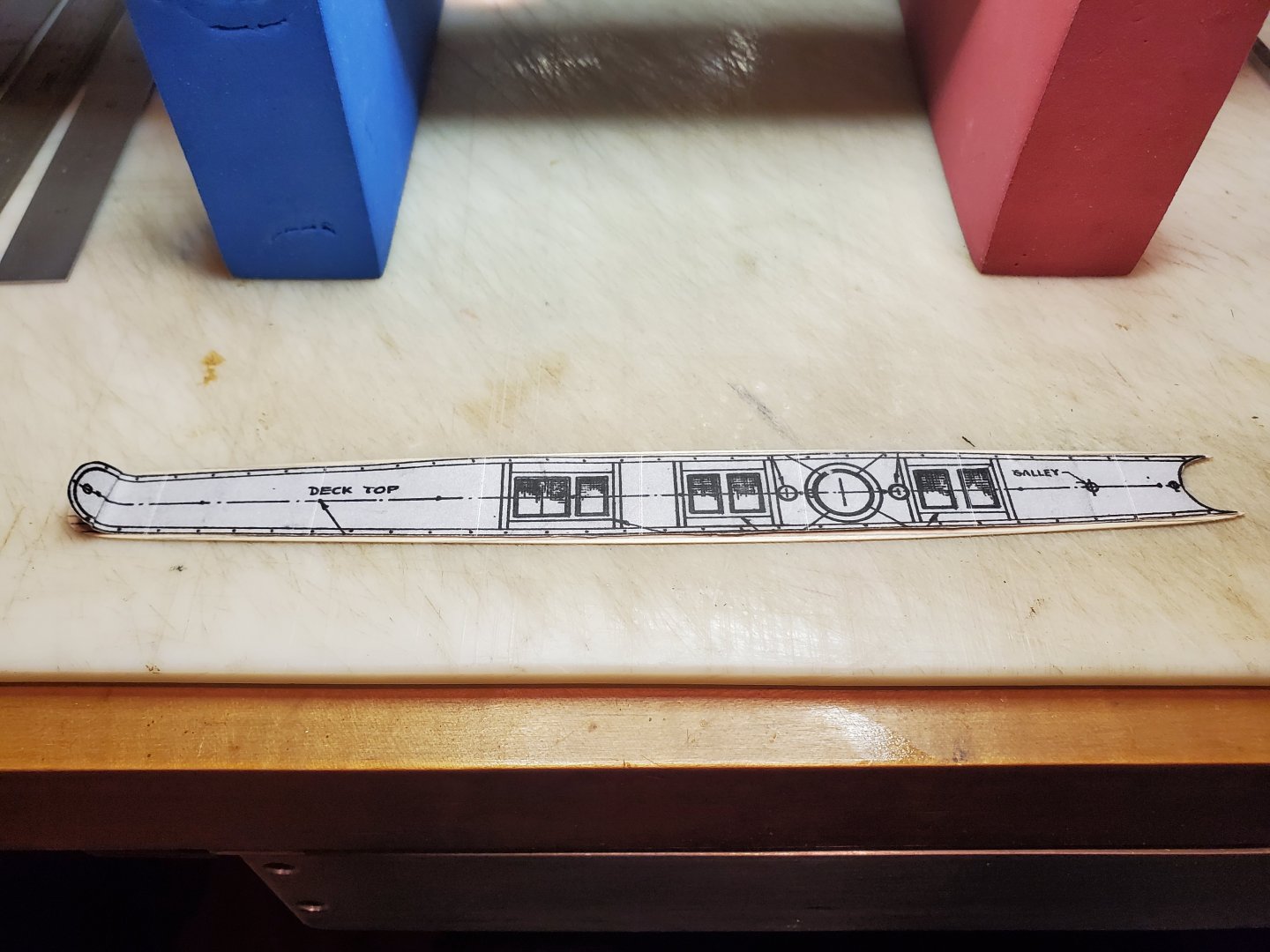

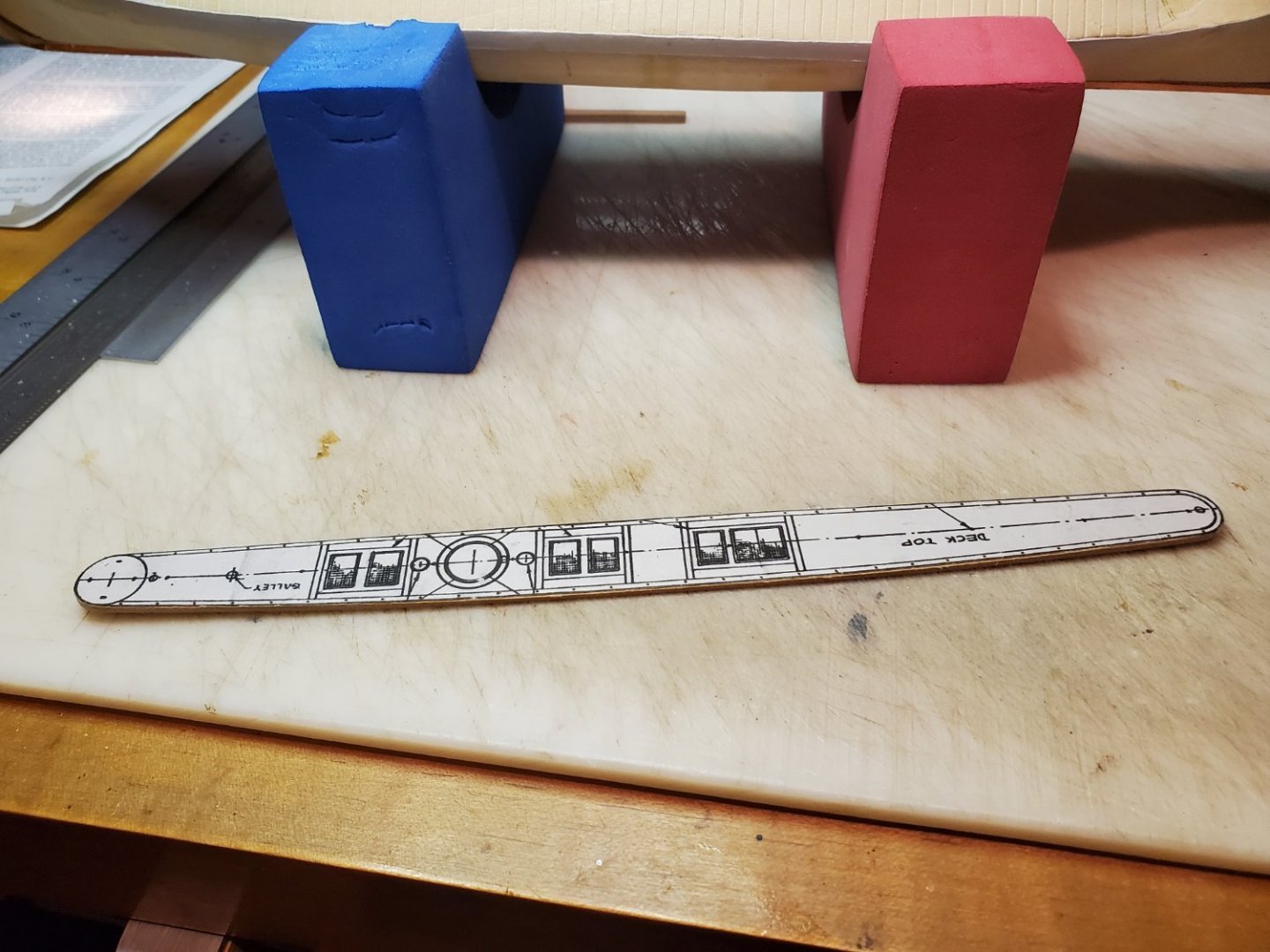

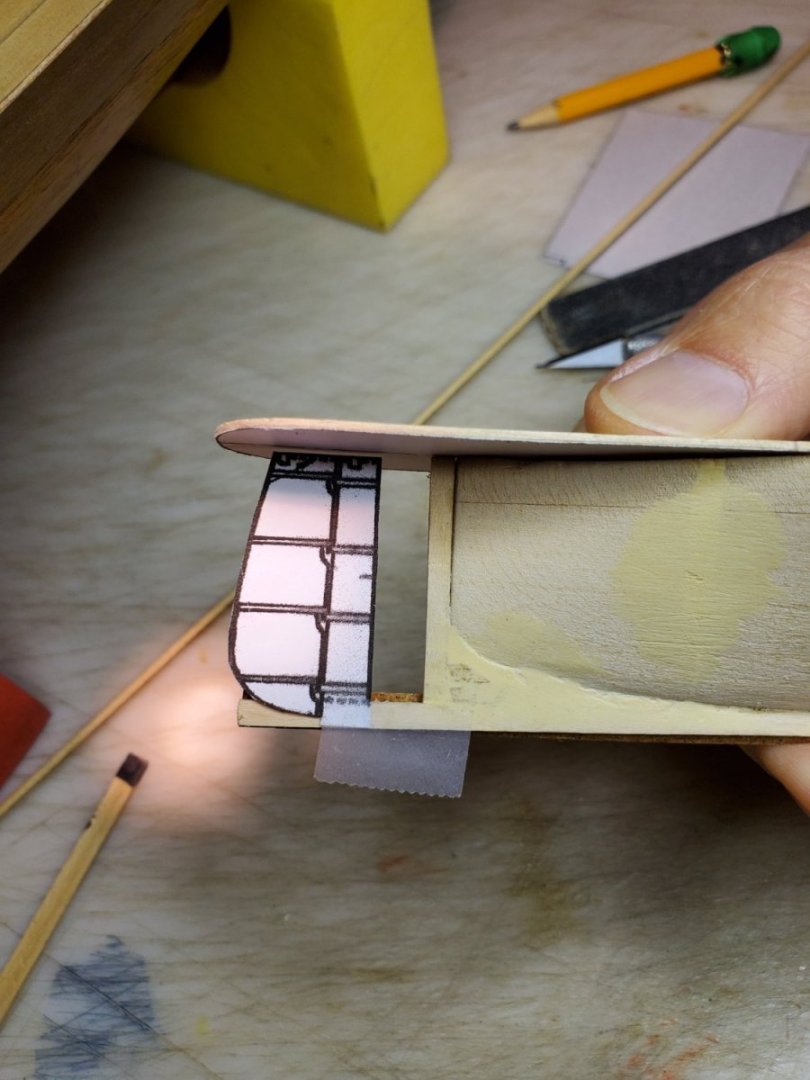

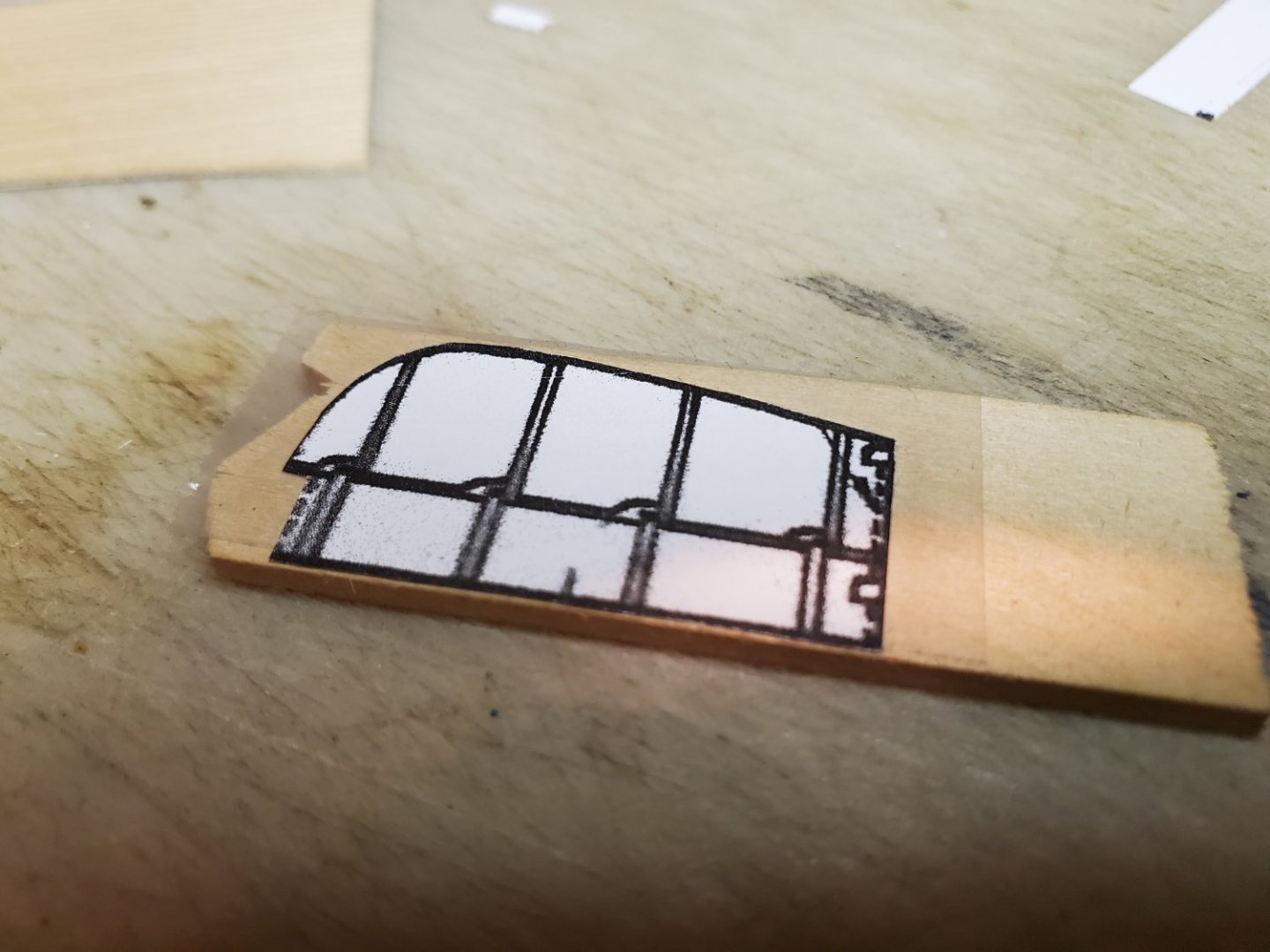

Once the decking was shaped to fit the top of the hull, we needed a margin plank. We photocopied the decking and used two-sided tape to attach strips of veneer to the edges of the copy so we could cut it out without damaging the planking.

- 37 replies

-

- first build

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

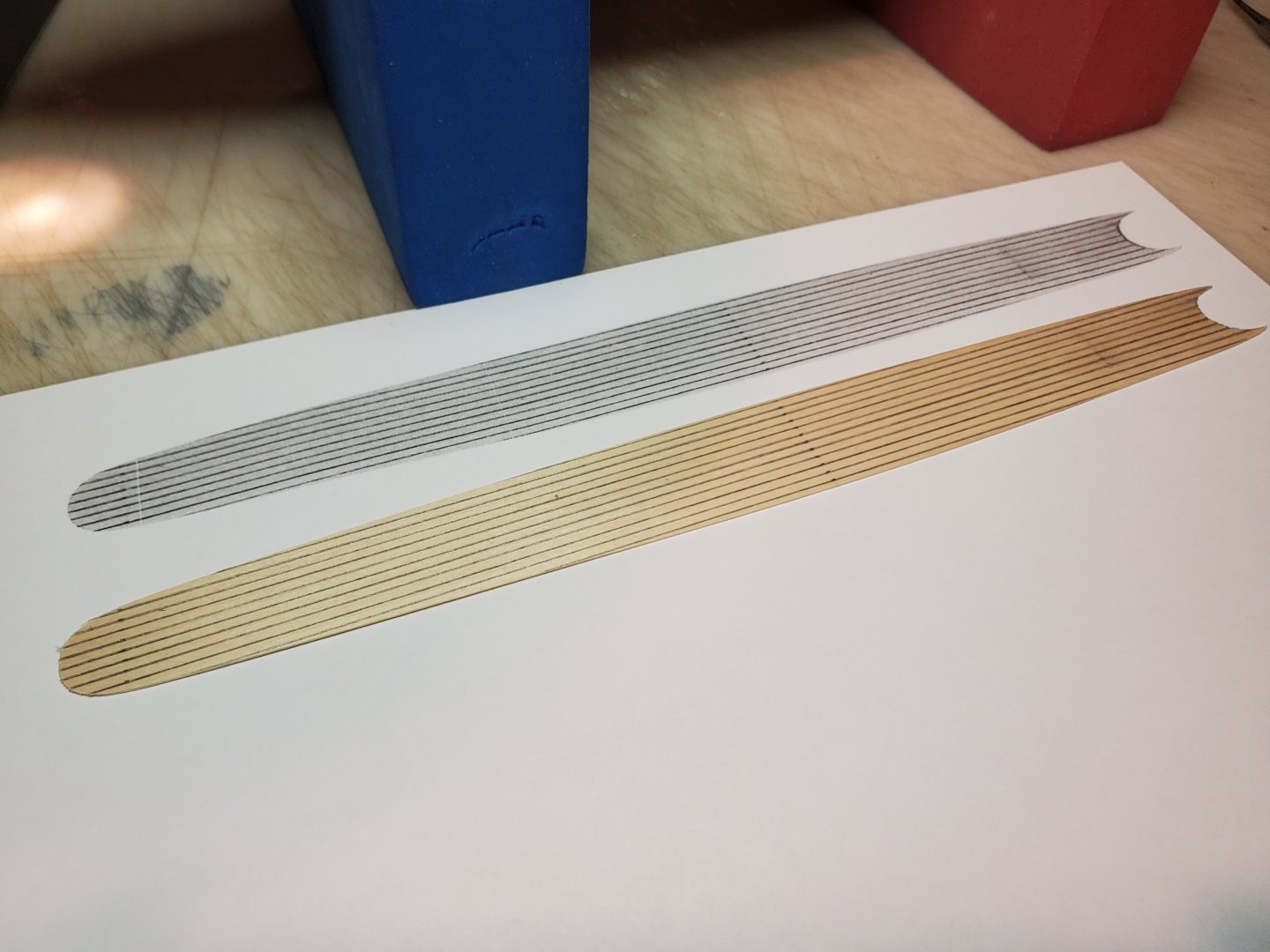

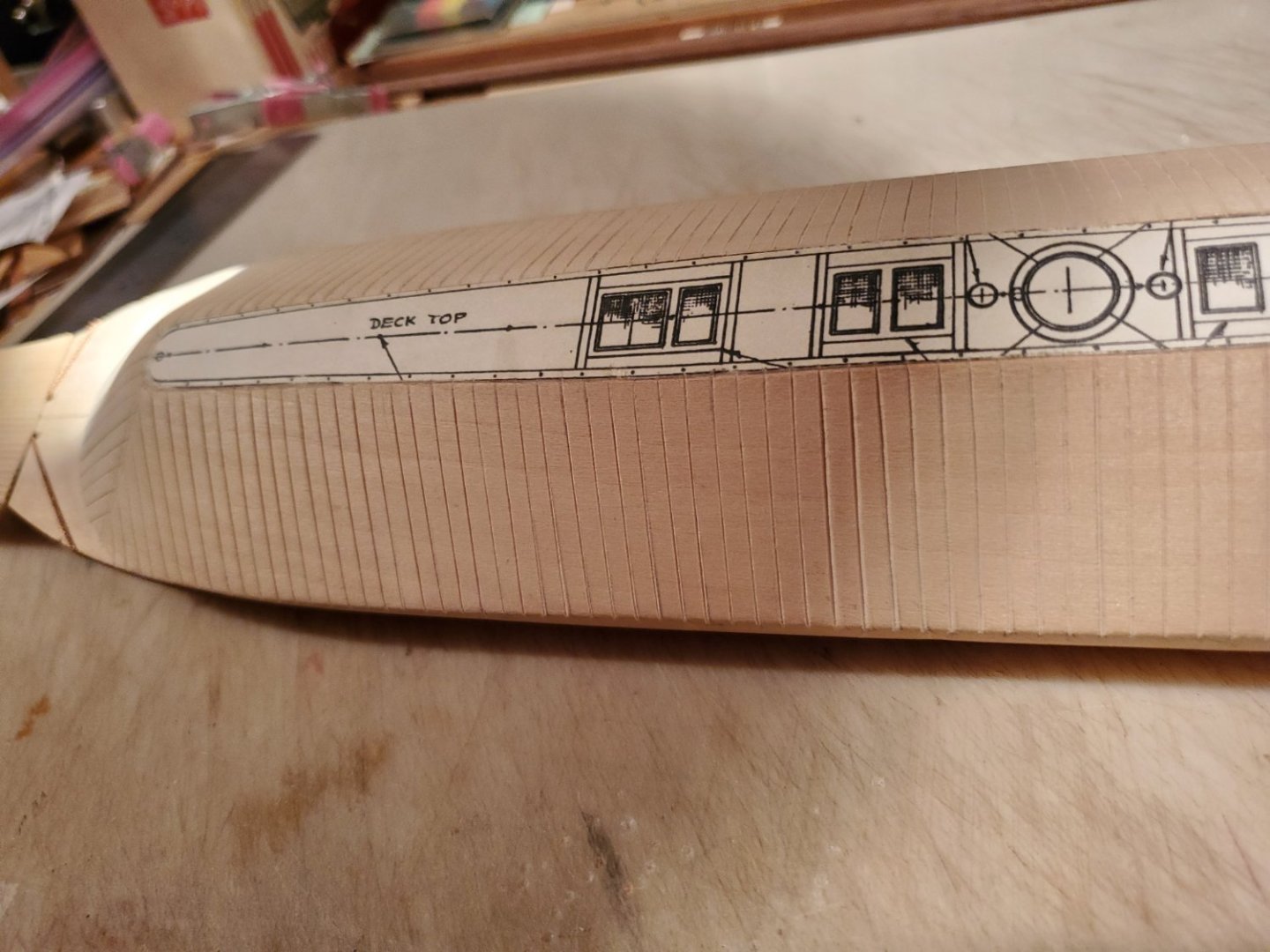

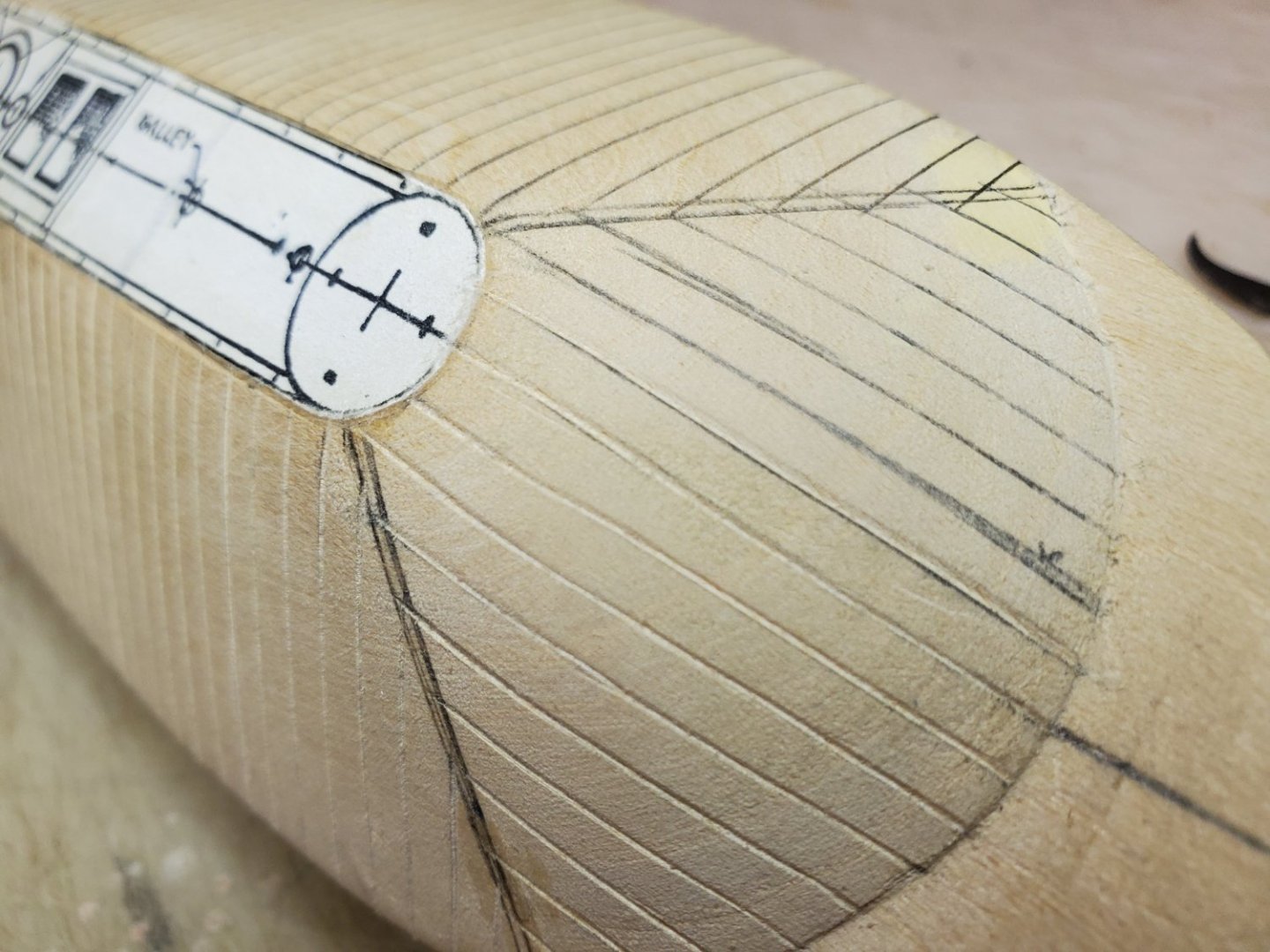

Thank you Robert Chenoweth and Phil for your tips. Well, we didn't like the way the last the last adjustment looked so we removed it. Unfortunately, I was a little over-vigorous with the sander and it distorted the top of the hull. My fault. I repaired it with some wood strips. The hope is this will mostly be hidden when we paint. Next we decided to plank the top of the hull using a thinner piece of pre-scribed veneer. I purchased such a piece but decided the plank lines were too close to each other. So we flipped it over, marked new plank lines with a pencil to simulate caulking, and then scored those lines with the back of a putty knife. We taped a copy of the plan over it to get the shape and cut it out. We sanded the back to make the veneer as thin as possible. Set on the model before final sanding.

- 37 replies

-

- first build

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

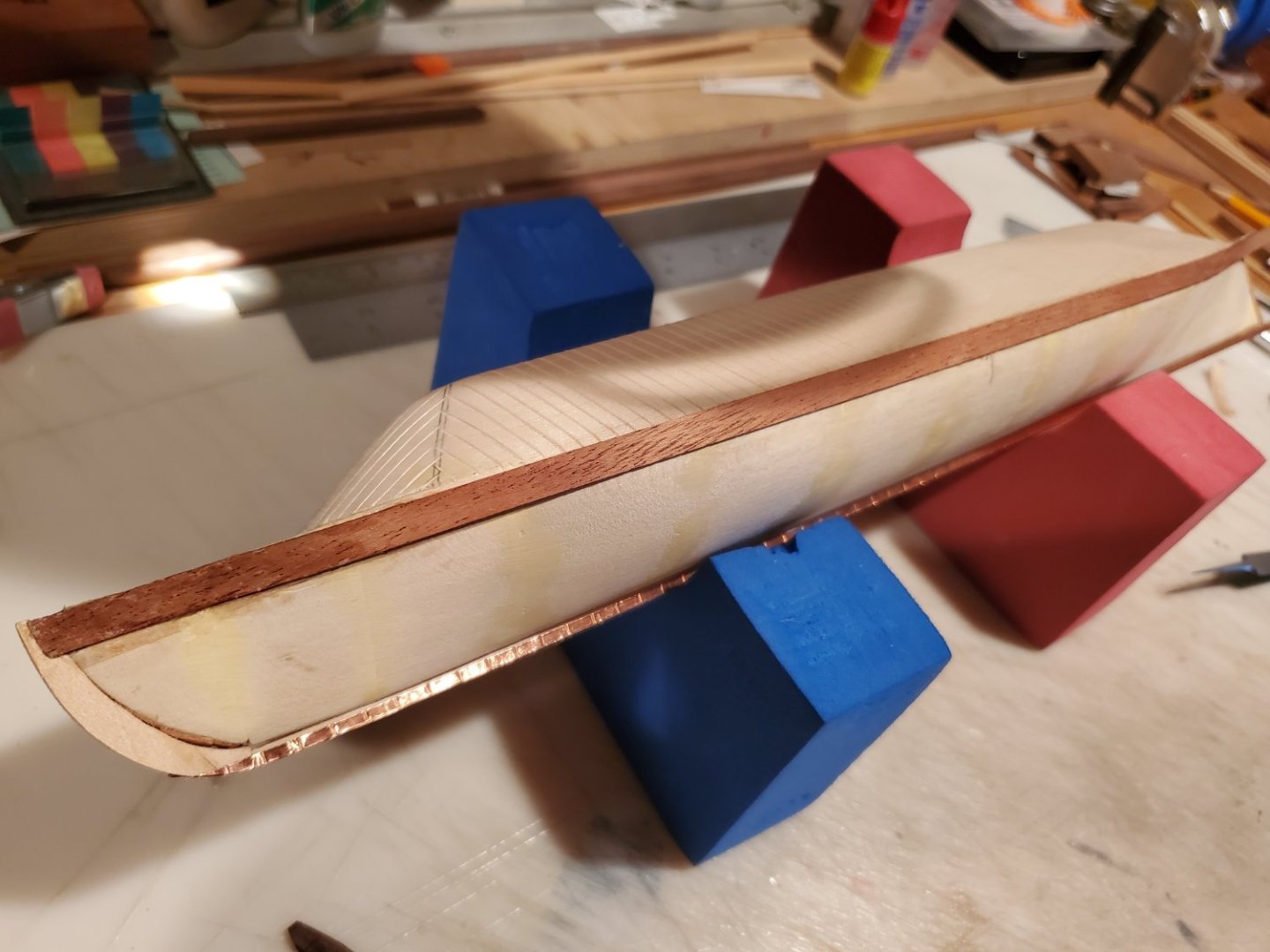

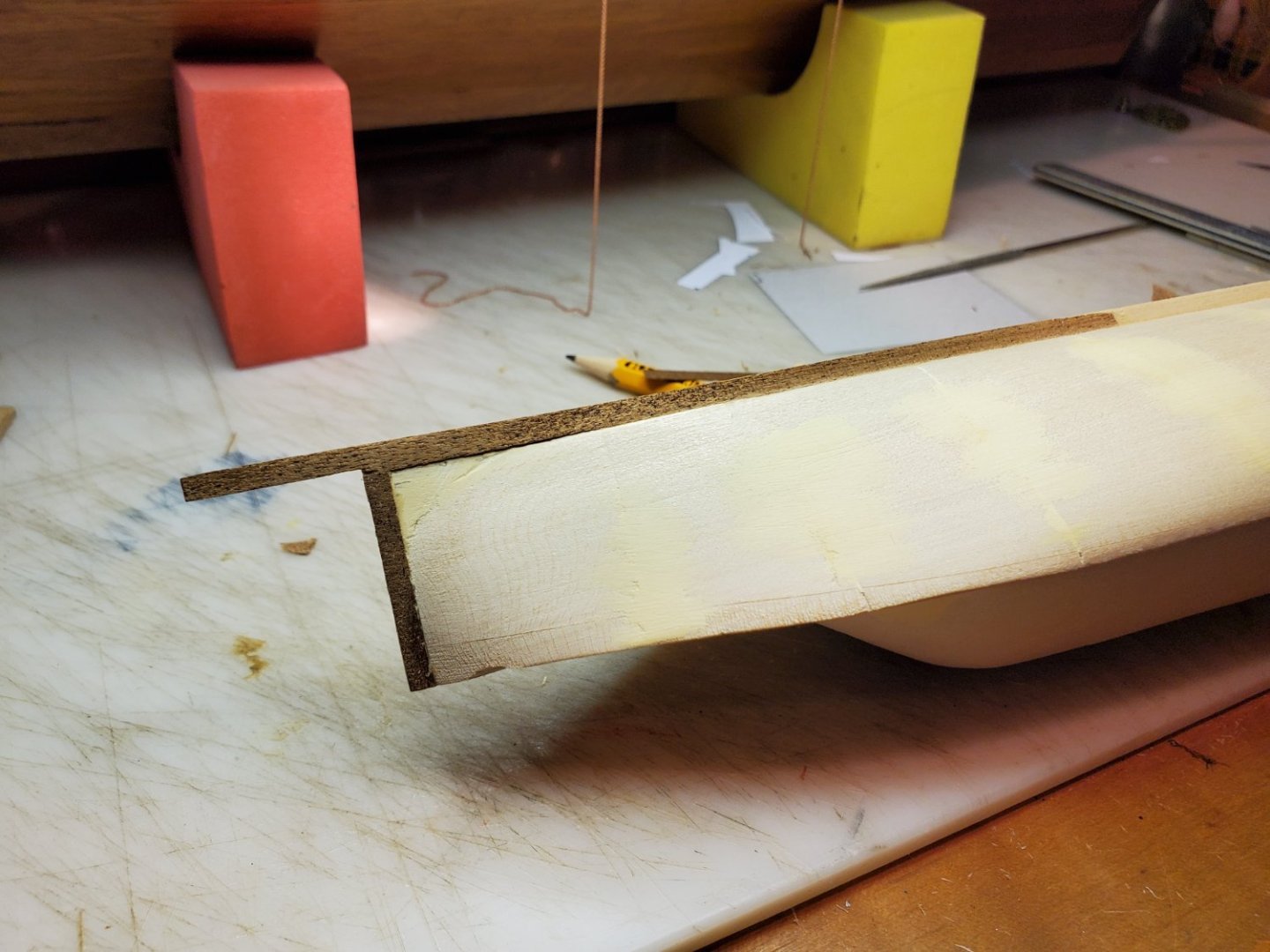

We cut out a thin piece of wood to serve as the top of the ship, in the hope of getting a sharp edge between the top and the sides. It has been glued and clamped in place. Once the glue dries, we'll remove the clamps and see if any patch work is needed to create a clean, sharp transition from the sides to the top.

- 37 replies

-

- first build

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Notice the copper plating along the keel in the previous 2 images. This is difficult at this scale, requiring a 1/16" strip of copper foil. The smallest we could find was 3/16" so I am slicing them in half (not easy!). At this scale, we decided to leave out the nail pattern. This was a test strip and we were pleased with the result. We will continue this once further progress on the model is made.

- 37 replies

-

- first build

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

The wooden strip turned out to be too inflexible and difficult to work with so we replaced it with a cardstock strip as suggested by the kit instructions.

- 37 replies

-

- first build

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

- 37 replies

-

- first build

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

- 37 replies

-

- first build

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Fantail installed. The chain used to move the rudder is temporarily in place to make sure we could install it with the deck in place.

- 37 replies

-

- first build

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

While Michael worked on the rudder, I used some leftover strips from another kit to straighten the keel and stern post.

- 37 replies

-

- first build

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

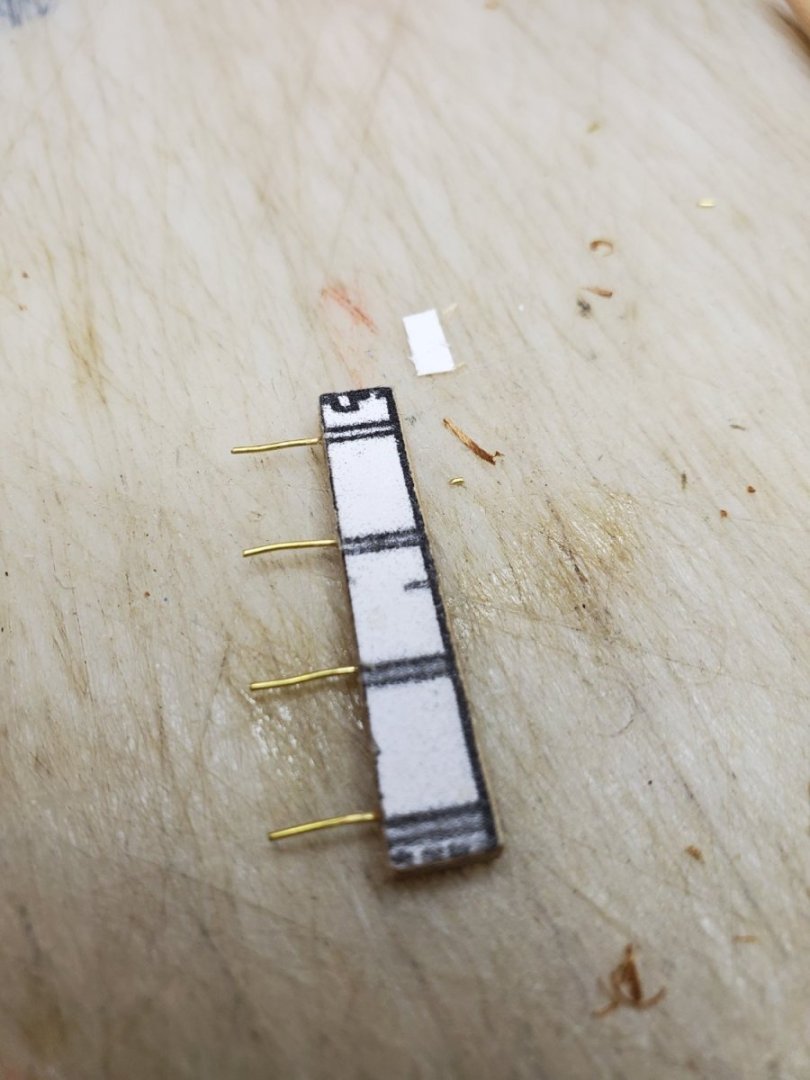

Pintles & gudgeons are not part of the kit. At 1/16 scale, we'll keep it simple. Hat tip to jre8655 and his post from 2013 - we will use a similar technique. Michael drilled holes with a #74 drill and glued in 4 pieces of brass wire. These will be used to connect the rudder to the post and should be concealed when complete.

- 37 replies

-

- first build

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

The new template fit perfectly and was attached to wood stock with two-sided tape and cut out, filed clean and then the post was separated from the rudder.

- 37 replies

-

- first build

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.