Phil B

Members-

Posts

61 -

Joined

-

Last visited

About Phil B

- Birthday 03/04/1961

Profile Information

-

Gender

Male

-

Location

Landis, NC

-

Interests

Exploring, camping, model railroading and ship modeling

Recent Profile Visitors

-

gsdpic reacted to a post in a topic:

Seguin by Phil B - BlueJacket Shipcrafters - 1:48

gsdpic reacted to a post in a topic:

Seguin by Phil B - BlueJacket Shipcrafters - 1:48

-

rvchima reacted to a post in a topic:

Seguin by Phil B - BlueJacket Shipcrafters - 1:48

rvchima reacted to a post in a topic:

Seguin by Phil B - BlueJacket Shipcrafters - 1:48

-

rvchima reacted to a post in a topic:

Seguin by Phil B - BlueJacket Shipcrafters - 1:48

rvchima reacted to a post in a topic:

Seguin by Phil B - BlueJacket Shipcrafters - 1:48

-

ccoyle reacted to a post in a topic:

Seguin by Phil B - BlueJacket Shipcrafters - 1:48

ccoyle reacted to a post in a topic:

Seguin by Phil B - BlueJacket Shipcrafters - 1:48

-

Here's a few more pics of the Seguin. While waiting for parts I mounted it on the oak base I made. The front pedestal is a little taller than the one in the back. I did it that way because the sheer makes it look like the stern is either to high or the bow to low if you use the same size pedestals. I added a length of Pactra gold trim tape at the waterline. Little brass pins worked for door knobs. Stay warm. Phil (In freezing cold NC)

- 50 replies

-

schooner reacted to a post in a topic:

Seguin by Phil B - BlueJacket Shipcrafters - 1:48

schooner reacted to a post in a topic:

Seguin by Phil B - BlueJacket Shipcrafters - 1:48

-

Taking a little break from the Seguin build (Big day coming et al). Gave me a good excuse to tidy up the work table. Took the opportunity to order some additional items. Decided to put scribed boards on the top deck rathers than just painting the bass wood. Also ordered nice brass stanchions from Harbor models. Have a wonderful holiday everyone. Phil

- 50 replies

-

rvchima reacted to a post in a topic:

Seguin by Phil B - BlueJacket Shipcrafters - 1:48

rvchima reacted to a post in a topic:

Seguin by Phil B - BlueJacket Shipcrafters - 1:48

-

Hey Rod, Thanks for the compliment and support😁. We were at the NCTM just a couple of weeks ago. We took all the kids to the Polar Express. Me with the 🤓 Phil

- 50 replies

-

rvchima reacted to a post in a topic:

Seguin by Phil B - BlueJacket Shipcrafters - 1:48

rvchima reacted to a post in a topic:

Seguin by Phil B - BlueJacket Shipcrafters - 1:48

-

rvchima reacted to a post in a topic:

Seguin by Phil B - BlueJacket Shipcrafters - 1:48

rvchima reacted to a post in a topic:

Seguin by Phil B - BlueJacket Shipcrafters - 1:48

-

rvchima reacted to a post in a topic:

Seguin by Phil B - BlueJacket Shipcrafters - 1:48

rvchima reacted to a post in a topic:

Seguin by Phil B - BlueJacket Shipcrafters - 1:48

-

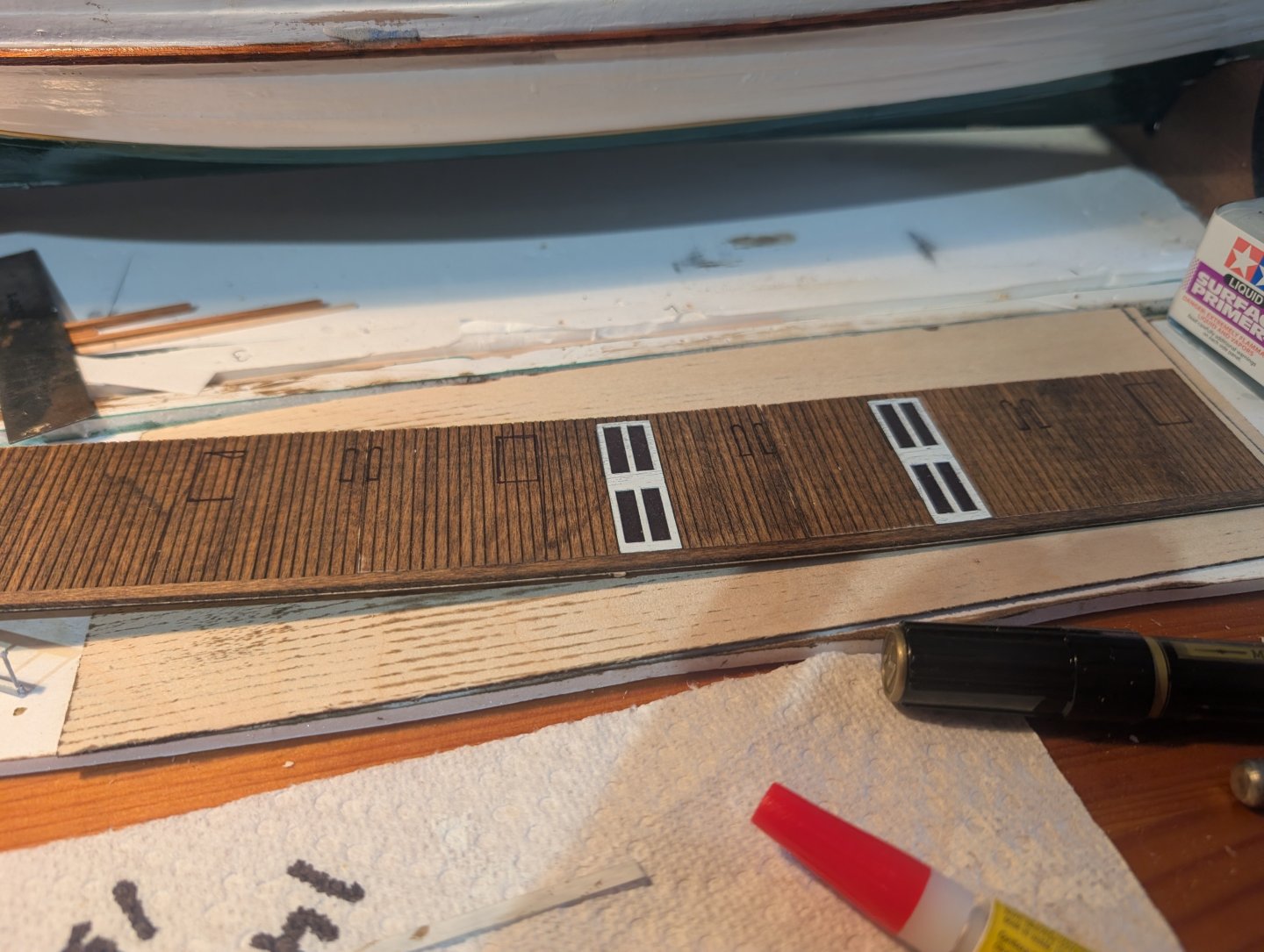

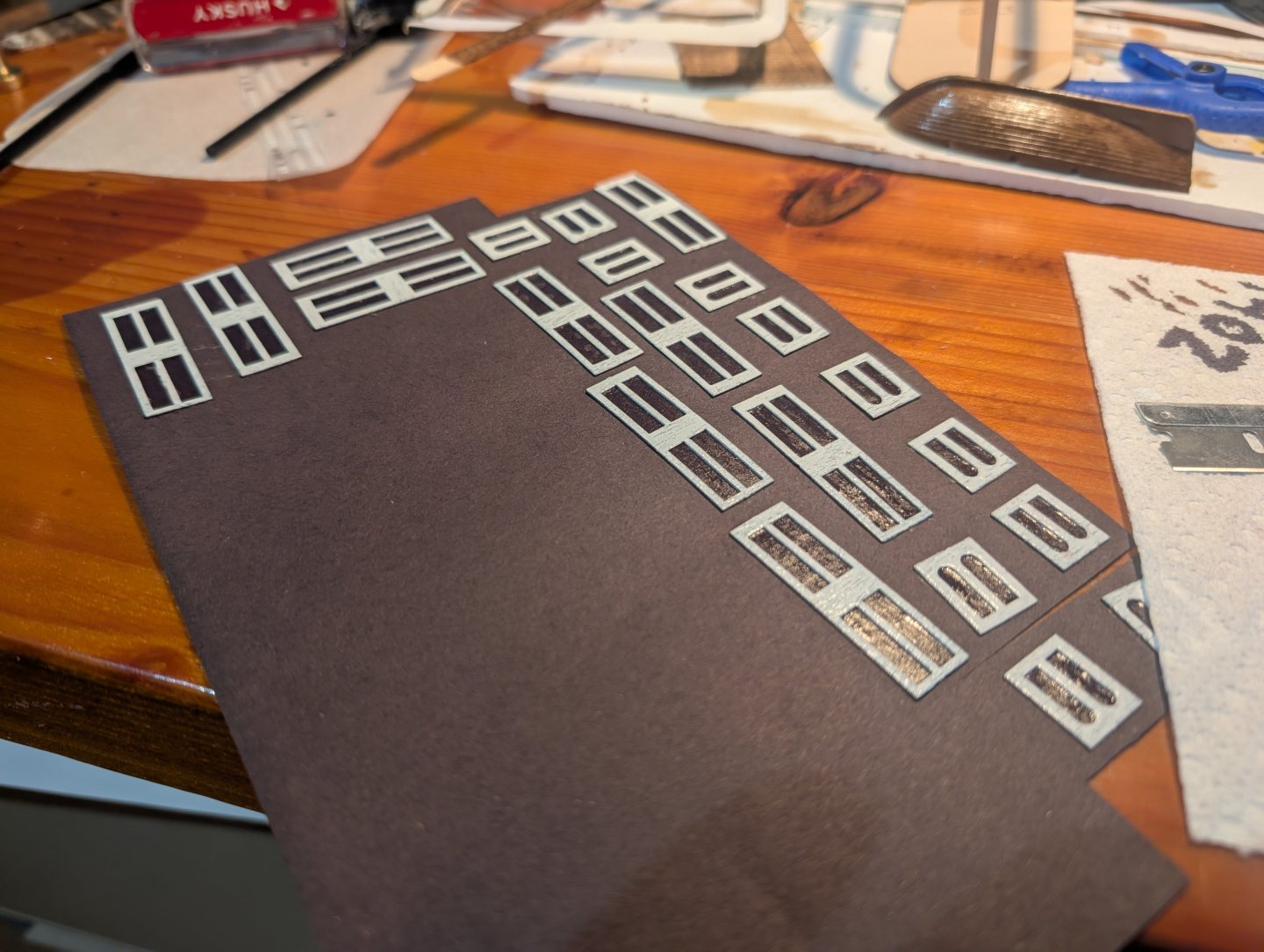

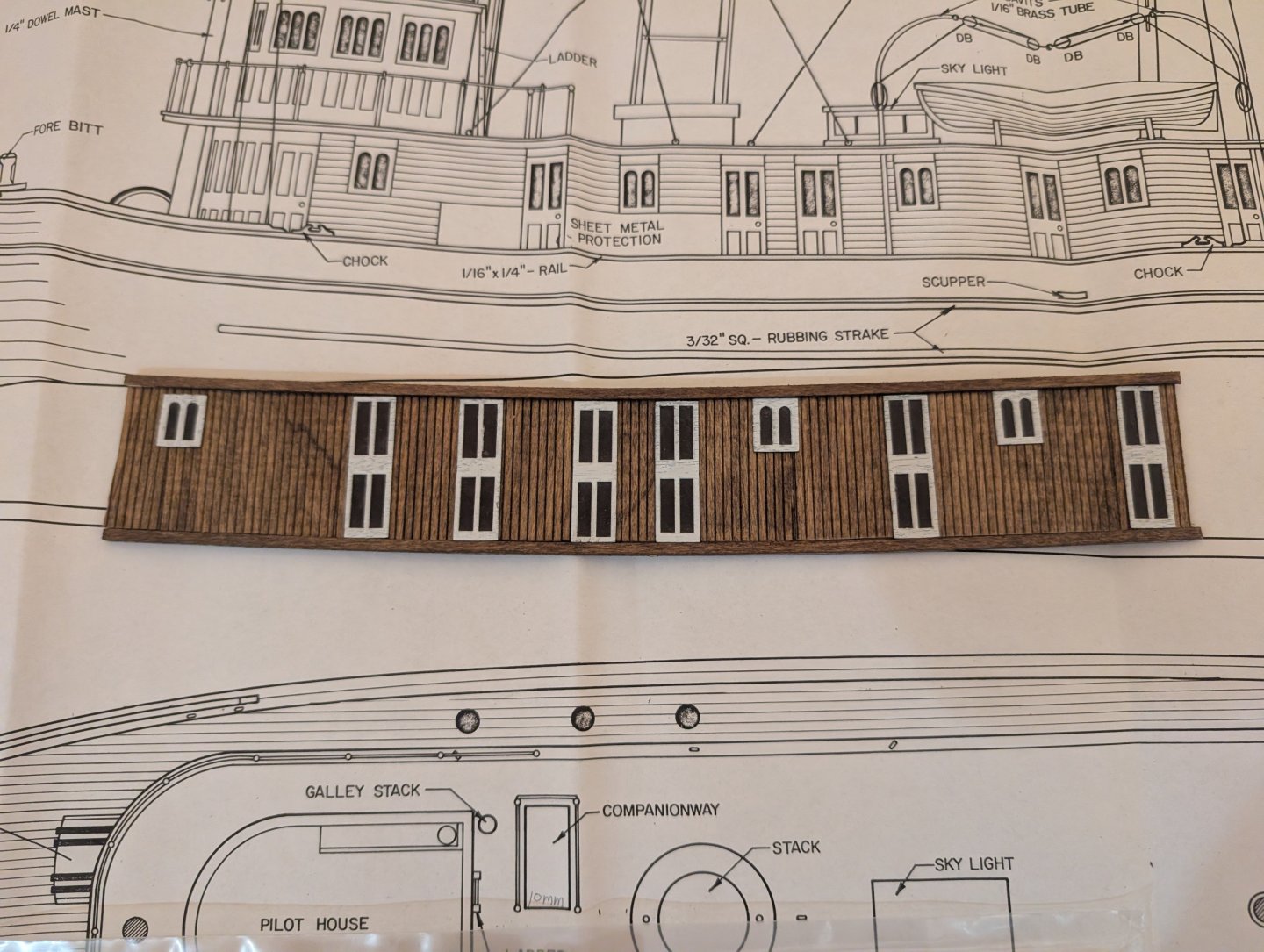

As a scratch builder/kit basher ( which is code for can not follow directions) I have taken a few liberties with the Seguin build. Installing the siding horizontally around the windows and doors on the deck house was more effort than I was willing to put in to it. Not only that, I knew the results would be dubious at best. So instead i installed the siding vertically, covering the laser cut window openings. I glued black paper to the backside of the doors and windows. When I needed a window or door I just cut them off the paper and glued them to the bulkhead. I know its probably not historically accurate, but at least it got done. (Thanks to John with his helpful editing instructions) Phil

- 50 replies

-

Phil B reacted to a post in a topic:

Seguin by Phil B - BlueJacket Shipcrafters - 1:48

Phil B reacted to a post in a topic:

Seguin by Phil B - BlueJacket Shipcrafters - 1:48

-

Question for you guys that are following along with my build here. How do I do a post where I include multiple photos and then have text after each photo?

- 50 replies

-

Hey Rod, I've seen the layout. I was there a couple years ago, very nice indeed! When I lived in Florida I had a 7/8 scale garden railroad, 2/3 larger than g scale. I scratched built all of my rolling stock. A big difference, building trains using your full size table saw 😆. We spent New Year's s Eve in Asheville a couple of years ago and spent a day at the Biltmore. We'll have to try to do that again and go see the garden railroad at the arboretum. If we do, I'll give you a heads up. Phil

- 50 replies

-

rvchima reacted to a post in a topic:

Seguin by Phil B - BlueJacket Shipcrafters - 1:48

rvchima reacted to a post in a topic:

Seguin by Phil B - BlueJacket Shipcrafters - 1:48

-

Started working on the transom. I was happy with the way the stern rail came out although I did have to cut it down a few mm. Started the vertical planking which I'm a bit iffy on but with sanding and cosmetics it should look alright.

- 50 replies

-

- 50 replies

-

To make the 80 or so Frameheads I made a little jig to speed up the cutting and keep the pieces consistent

- 50 replies

-

- 50 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.