-

Posts

407 -

Joined

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Bitao

-

Thank you for your attention. Actually, I'm just as confused as you are. But GEMA's drawing was in many ways incoherent, my English was poor, and I didn't have much information to use, so I had to refer to the winner's work, and in order to do that, it took me a lot more time to work out the details. I don't think it's going to affect the drainage down there, because the deck is very curved.

-

So you can't just like it and not have any problems. Ha Ha! It works like this: the greatest use of the metal platform is to be able to adjust the angle of the hull at any time, such as in the laying of slats, while the wooden platform is relatively fixed, a stable, continuous support operation. Besides, the metal table is big and heavy, and the space in the house is very limited. My tools are scattered in different rooms, sometimes for convenience.

-

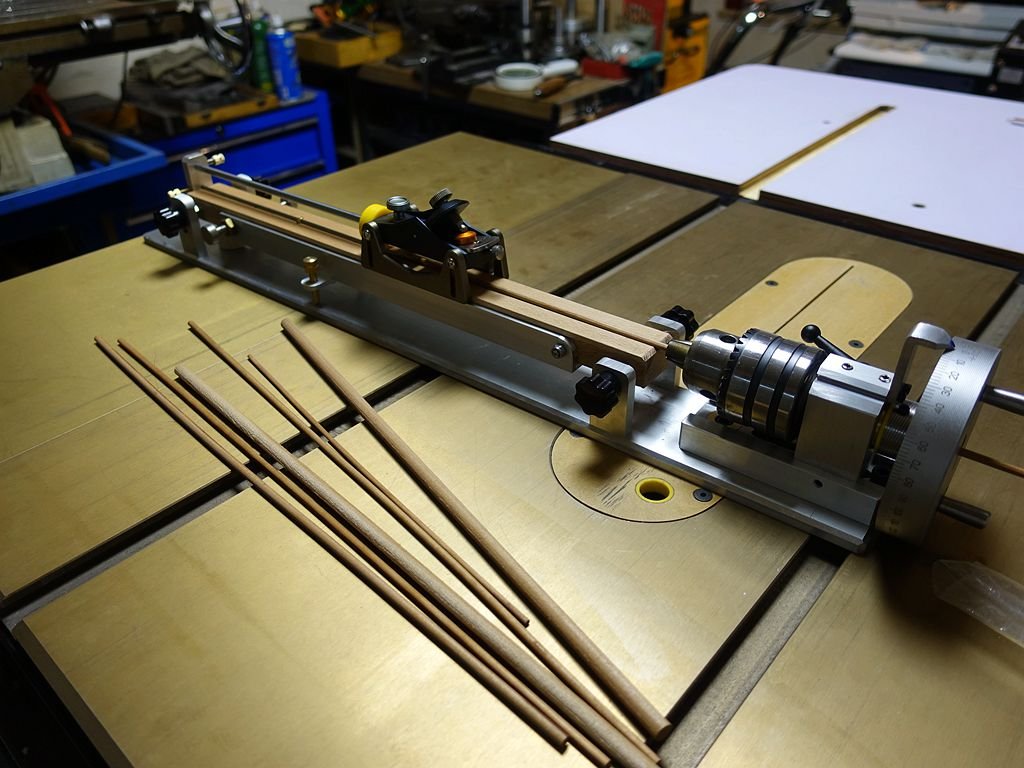

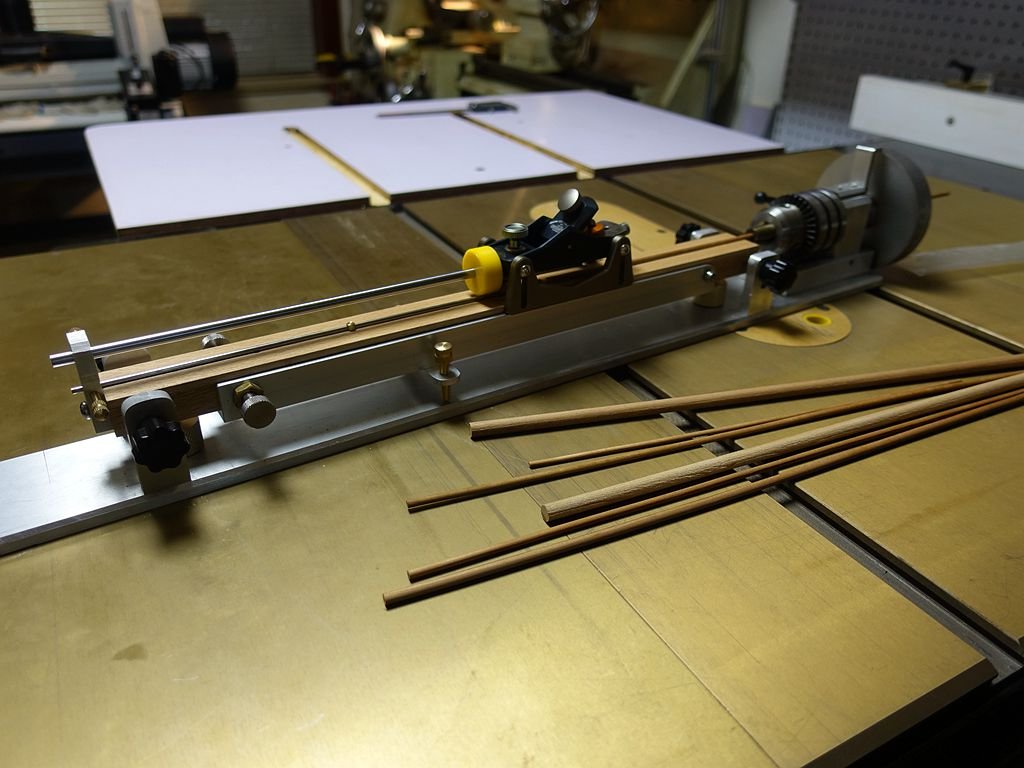

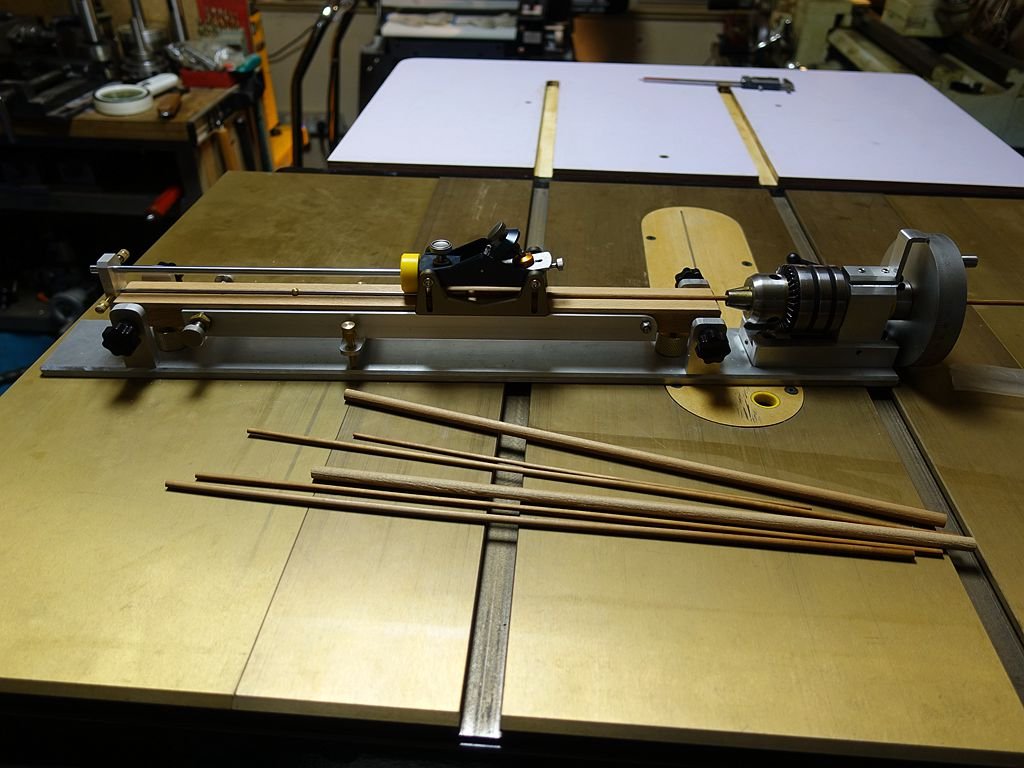

Thank you for your attention and discussion. I won't answer all the questions because there's too much space. Make a brief description here: 1 The yellow cylinder is the limit slider. In order to prevent the production of manual planing force in the sliding process, and many parts need to be processed are effective stroke, under which there is a "thimble" needed to process parts, to prevent parts from offset processing. The left and right sides of the base are respectively provided with two adjusting screws for adjusting the tilt angle of the base slide block. 3 The idea is based on a hand planer, the model listed in No. 6 upstairs is not suitable; the Planer itself has two side panels that can be used to adjust height and push-pull time limits; 4 usually thin and long parts are machined, although it can be easily accomplished with accessories on a lathe, machining Polyhedra without power heads and indexing devices is extremely difficult, even if there are no accessories on the milling machine. And some deformations are uncontrollable, so using this design in special cases is a conservative approach.

-

Specially designed for the processing of slender masts. The base can be angled to achieve the desired taper. The dividing head can adjust the number of Polyhedra as needed, and can also be used to planing and cutting cylinder by hand.

-

Use for making rope cake. Different specifications of diameter and center hole, height, just to replace the head can be.

-

I don't think there's anything for sale. I'll just have to make it myself. It's about meeting my own needs, and it's also about demonstrating my own design philosophy. Because I have a bigger milling machine, the only dividing head has been bought by a friend of mine. . .

-

-

The first is used to bind pulleys and hand-wound wires. The second type is specifically designed for clamping small parts of the welding。

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.