-

Posts

407 -

Joined

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Bitao

-

Hello. The pursuit of better is my model not to give up the concept. I have developed or copied and improved things without selling a lot of assistive tools. After all, I have been doing this for more than 20 years. I wouldn't go to a manufacturer for these things, because mass produced things aren't guaranteed, and only the designer can understand the parts of the structure that need to be precisely controlled.

-

Hello. I like to develop and make my own tools. In order to make the model more accurate and efficient,. Of course, it's not for sale. Few people in the country can buy what I make for their own use. After all, I'm a model enthusiast, not a businessman.

-

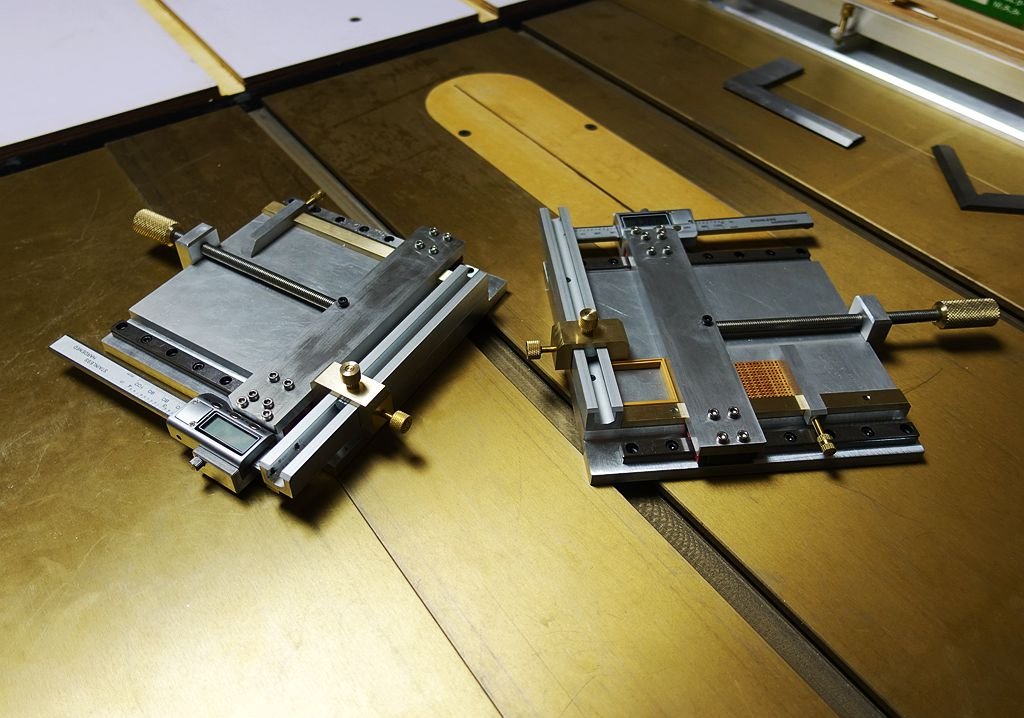

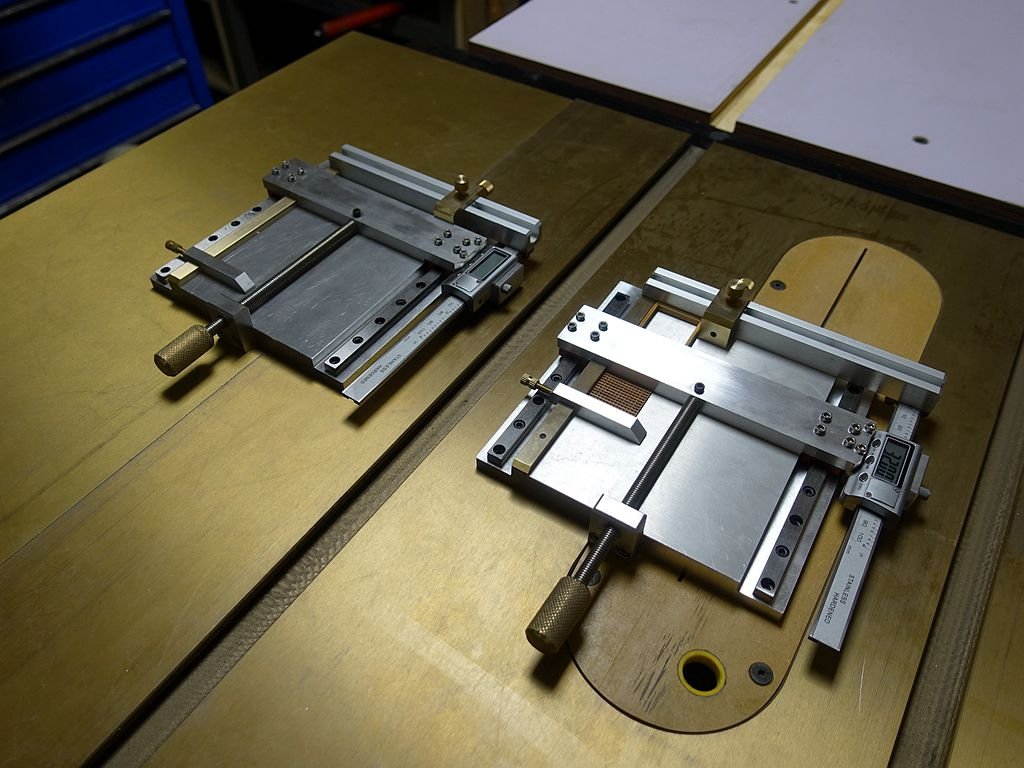

Five versions of the rectangular positioner have been designed and manufactured; the last one can be used in the plane machining of the milling machine with adjustable angles, especially the slotting of various angles of the Keel, the ribs and the crossbeam. At the same time, it can also be used as a precise positioning of rectangular assembly. The metal material can avoid the overflow of glue which makes the workpiece difficult to separate. The material is high hardness aluminum alloy (6061) and brass (H59) .

-

I have two sand bar machines for grinding curves. However, there is a common problem: The gasket uneven caused when grinding the end of the workpiece can not ensure that vertical. In particular, smaller parts are more prominent; and the spacer between the gasket and the sand column is often too large to cause small parts often involved. So the use of their own aluminum and brass turning, to ensure that the deviation control in the minimum range.

-

I've been working since the middle of last September. I usually have enough time, so I have enough patience to finish it. No less than 10 hours a day. Except for machining, most of the parts are done by hand. I am very concerned about the cleanliness of the work environment, not only to reduce the dust caused by the processing bias, but also to accurately find the tools I need.

-

《DIY tools for personal use》Sand disc

Bitao replied to Bitao's topic in Modeling tools and Workshop Equipment

Hi Kris, The diameter of this sand table is 150. As a high precision grinding tool, the more the joints, the greater the deviation; in the effective range of grinding, whether horizontal or vertical, the role and stroke is the same. So I through the table on the backrest design angle adjustment to achieve the "tilt" function. It's much more stable on the countertop. Because of the need to polish the metal parts, the motor has a power of 750w; the weight is about more than 30 kg. -

《DIY tools for personal use》Sand disc

Bitao replied to Bitao's topic in Modeling tools and Workshop Equipment

Hi Moab. By changing the frequency speed, the basic loss of torque output, than the usual current speed is much more stable. The cost per unit must be much higher than the cost of mass production. . . -

Self-made sand disk . Three-phase motor frequency control, can achieve accurate grinding, chamfering, low speed does not affect the torque output, ultra-low noise night operation. The table surface of the two-axis slide rail can be moved and polished, and can also be locked at any angle. The sandpaper can be quickly changed by hand by turning two nuts on the dust-collecting cover. High precision machining ensures minimal deviation and in some cases can be used as an alternative tool for milling small parts.

-

Thank you for your attention. Many of the unpublished tools in this image were created by me. I mainly use the lathe processing, milling processing way production. I also like to make any part of my model in these ways; after this piece is finished, I'll post another post about my various diy tools. Have a nice life!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.