Picard

-

Posts

6 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Picard

-

-

17 hours ago, Chuck Seiler said:

While definitely NOT an expert in planking (I struggle on a regular basis) I see some areas that might be helpful.

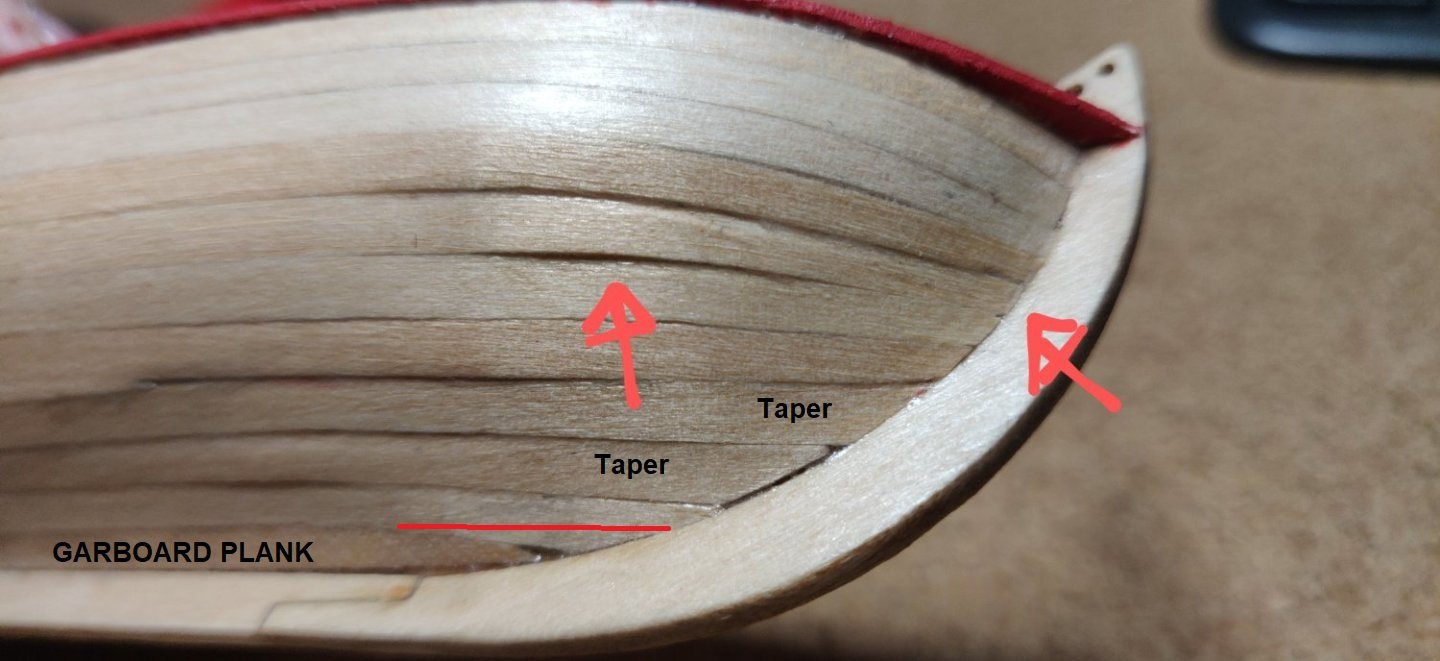

I believe your garboard strake does not go far enough forward and bends down. I always have problems with the garbord, but getting it right is one key to proper planking. Continuing it as indicated gives a better angle for the next plank and sets up a better distance for follow-on planks. This allows the follow-on planks to be tapered to fit the hull, whether spiled or edge-bent.

Actually the instructions said: "The garboard plank should start just ahead of the scarph joint at the bow. Don’t start it too far forward because your planks will need to taper too much in order to fit ten strips.".

I did not taper the plank above the garboard, thinking it wasn't necessary, but i was wrong.

Thanks!

-

18 hours ago, allanyed said:

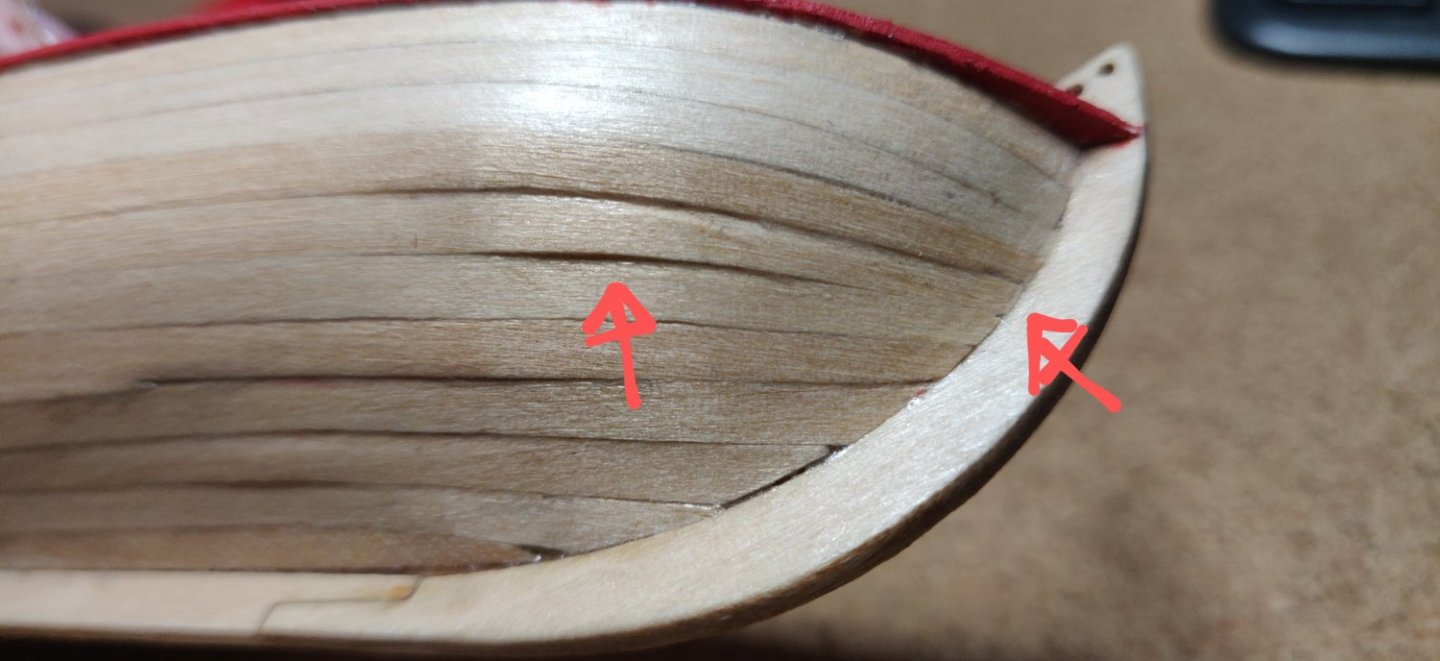

Did you bevel the frames before planking? If so, it looks like the plank above the one with the left red arrow is not seated completely against the bulkhead. I have found that soaking the plank thoroughly then clamping it to the frames without glue works well. Be sure the clamps have soft faces or put a piece of cardboard or soft wood between the wet plank and face of the clamp to prevent denting the plank. Then, heat it with a hot air gun for a minute or two. (Her hair dryer will work, but there are consequences if you get caught.) Once done you can remove the plank and it will hold the shape. Then you can glue it in place with finger pressure, no clamps. This will help assure the plank is seated well. Be sure it is completely dry as it will be expanded while wet, then shrink once dry.

Yes, i bevel the frames (and the plank as well) but maybe not so well. I did an edge bending on the planks, but i'll consider your approach next time, it could be useful.

18 hours ago, allanyed said:Alternatively, spile the planks. There is an excellent tutorial on here in the MSW articles data base by David Antscherl on how to do this. I find this a much better way to shape the planks for harder wood species. If your build is a kit, you will have to get sheet stock as you cannot use strip wood to spile a plank.

Allan

I excluded the spiling right now, it seems too hard to handle for my skills. Maybe it'll be an option in the future.

Thanks a lot!

-

Hi,

i'm trying to improve my planking technique (like everyone) and i have a couple of question for you.

This is a picture of my last WIP: the 18th century longboat. It's very fun to build and i tried to apply the Chuck Passaro method.

The arrows show 2 problems i encountered here, and in my last build as well.

- The fissures between the plank, you any suggestion to reduce this kind of gap? Maybe i didn't sand the bulkhead properly? Or it could be a tapering issue?

- The plank on bow have different size and are not very realistic. How do you taper the edge of the plank to obtain an uniform size?

Thanks in advance for your reply!

Simo

-

-

Hi,

I'm glad to join this community. I'm an italian modeller with some experience with plastic models and only one wood ship completed: the America's Cup Endeavour. Now i decided to improve my skills, starting again with the Amati Lady Nelson.I think i'll start a building log very soon, i'm sure i can get many useful tips.

Bye

- mtaylor and Fernando E

-

2

2

Planking improvement

in Building, Framing, Planking and plating a ships hull and deck

Posted

Hi,

first of all, thank you for reply.

You got a point: is easier just to glue the piece thinking “one plank less”. Just today i told myself that i can improve only with time and patience. Maybe repeating a job if i’m not satisfied of it. I’ll keep in mind this suggestion.

Talking about the plano bevel, this was the first time i did. So i have to pratice and better understand the technique.

Ad majora