-

Posts

150 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Oliver1973

-

ancre La Belle 1684 by Oliver1973 - 1/36

Oliver1973 replied to Oliver1973's topic in - Build logs for subjects built 1501 - 1750

-

ancre La Belle 1684 by Oliver1973 - 1/36

Oliver1973 replied to Oliver1973's topic in - Build logs for subjects built 1501 - 1750

-

ancre La Belle 1684 by Oliver1973 - 1/36

Oliver1973 replied to Oliver1973's topic in - Build logs for subjects built 1501 - 1750

-

ancre La Belle 1684 by Oliver1973 - 1/36

Oliver1973 replied to Oliver1973's topic in - Build logs for subjects built 1501 - 1750

-

ancre La Belle 1684 by Oliver1973 - 1/36

Oliver1973 replied to Oliver1973's topic in - Build logs for subjects built 1501 - 1750

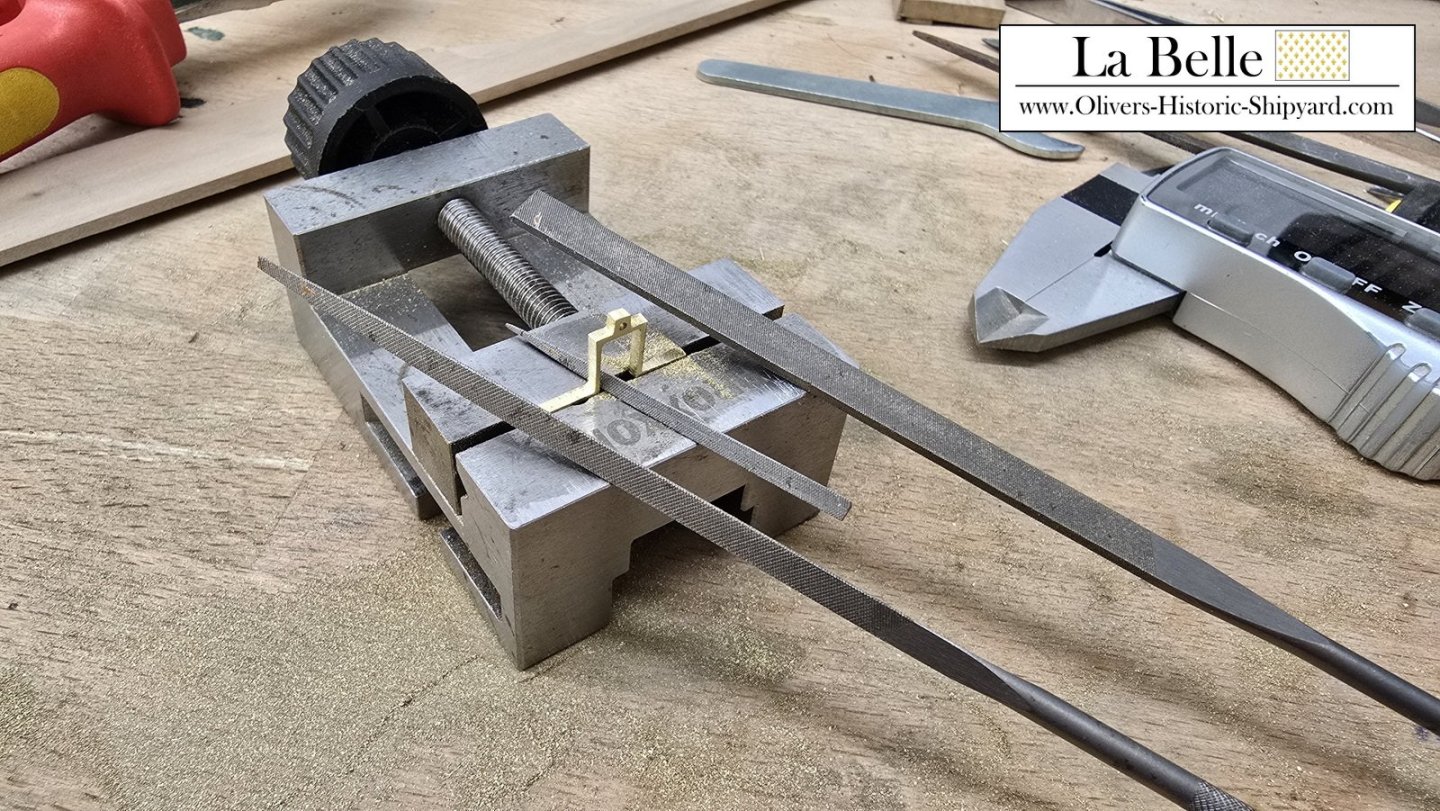

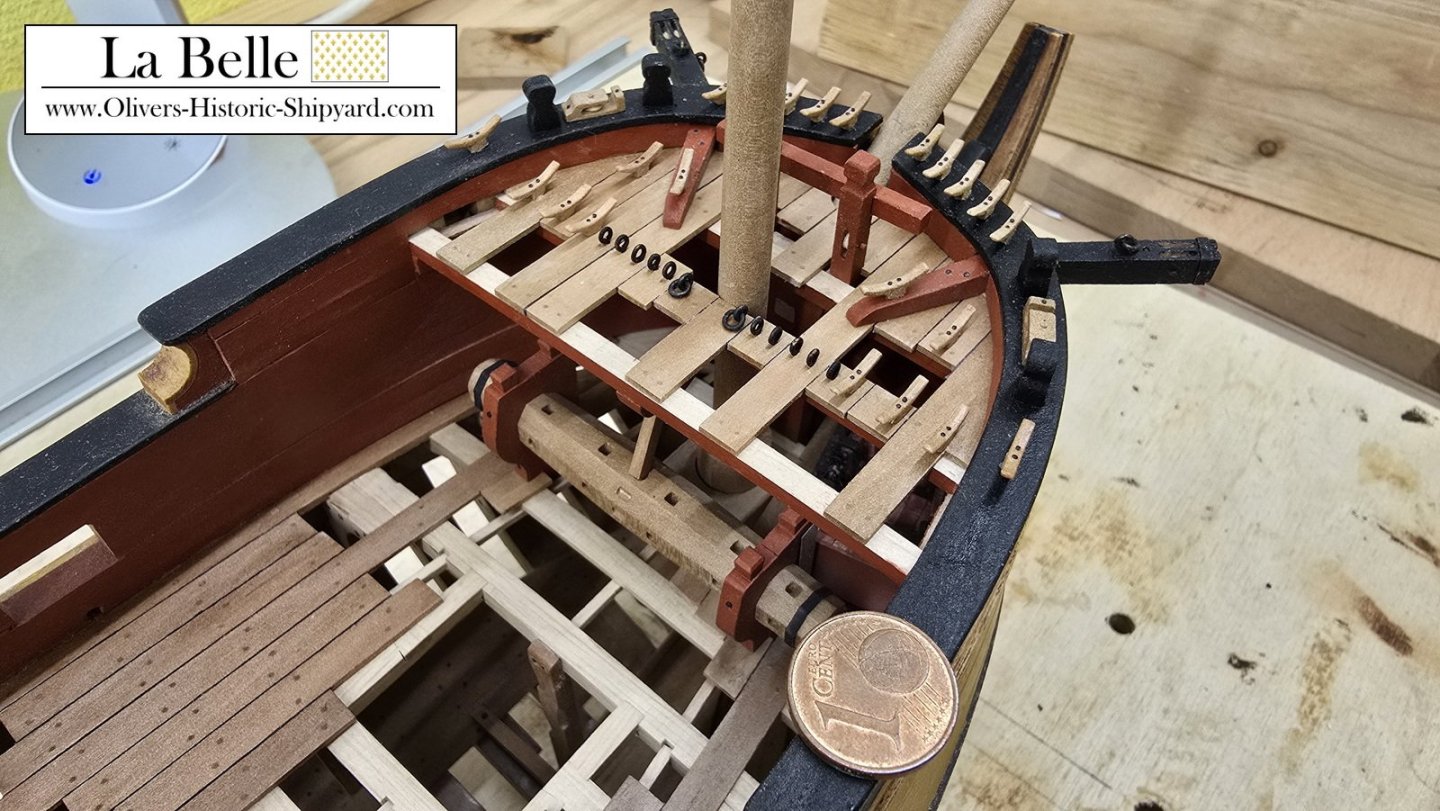

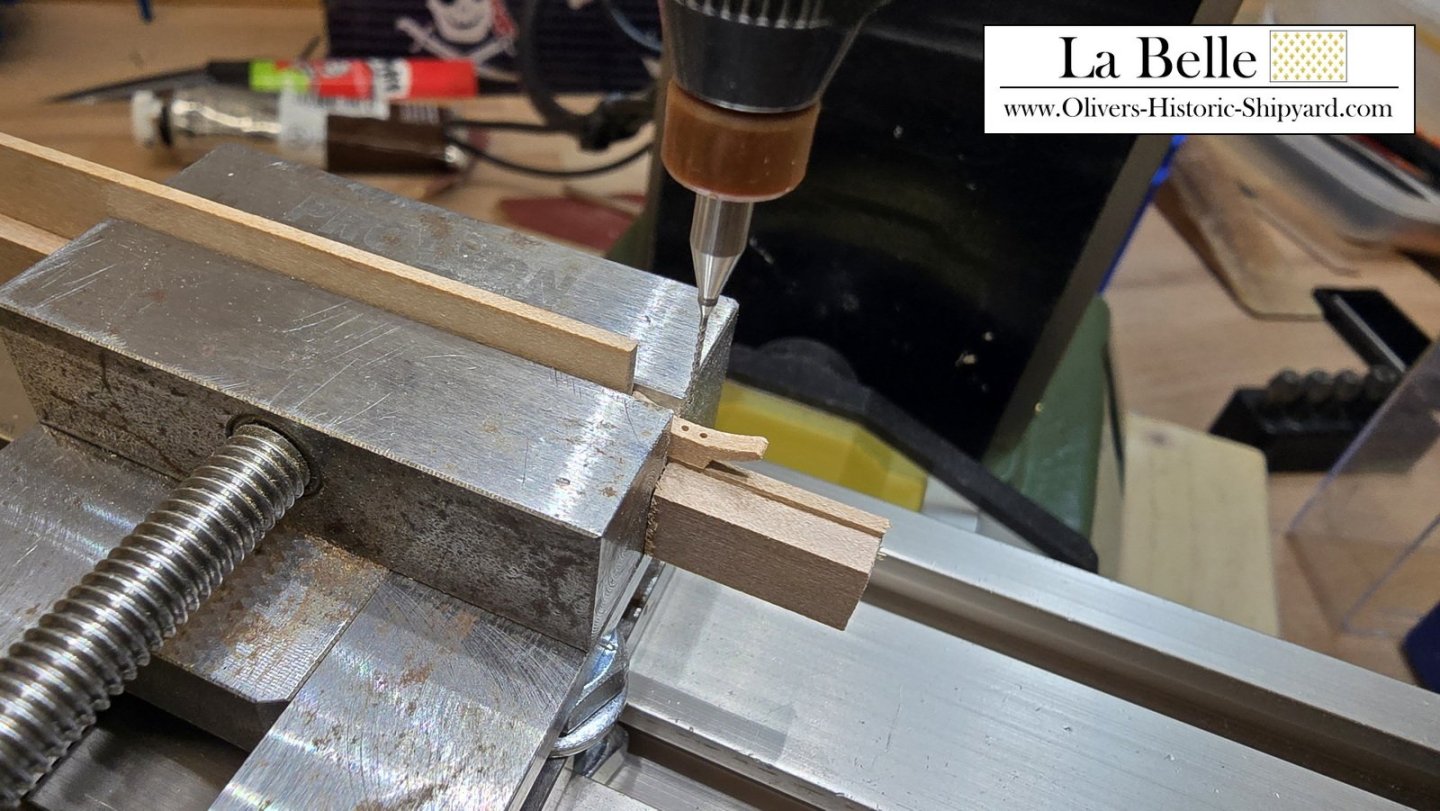

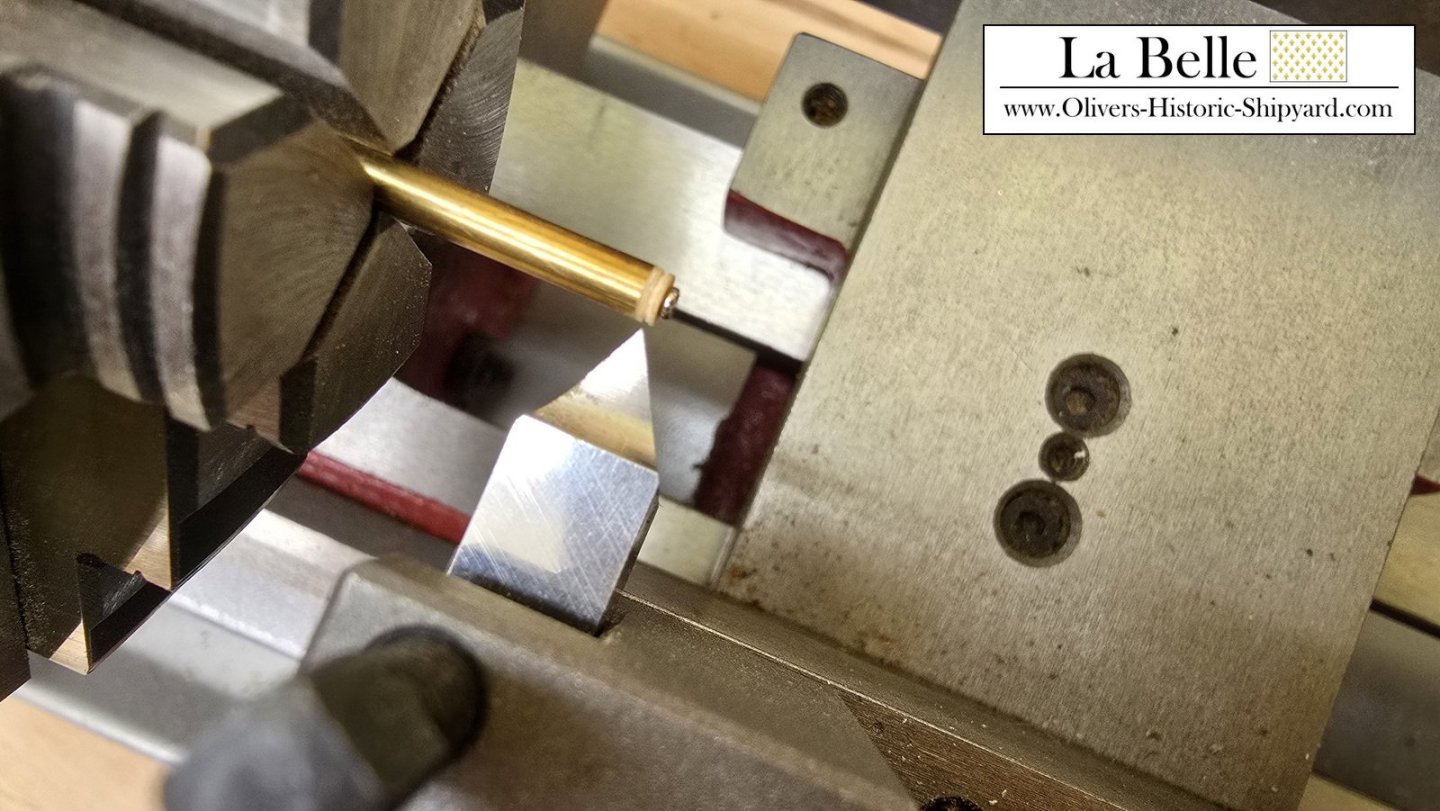

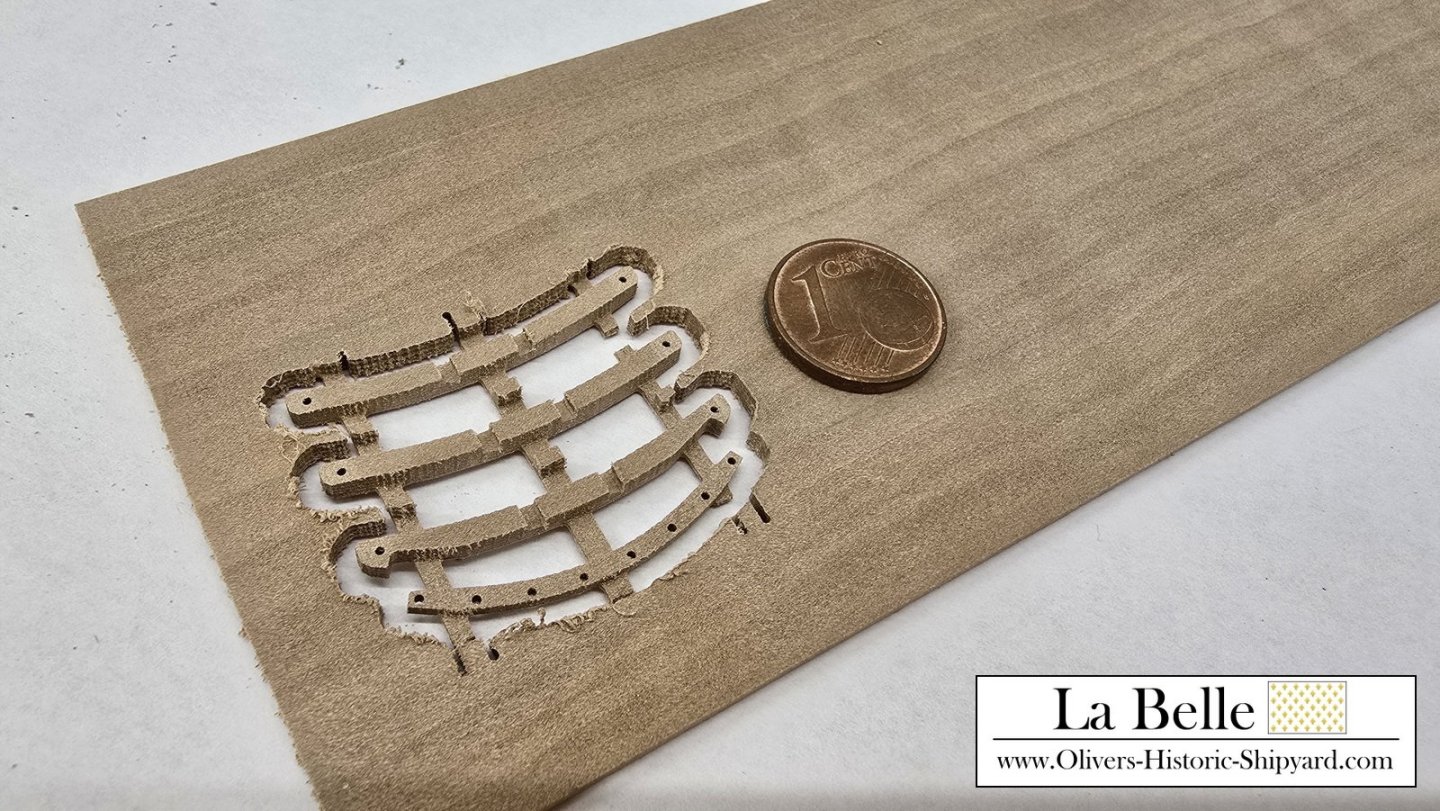

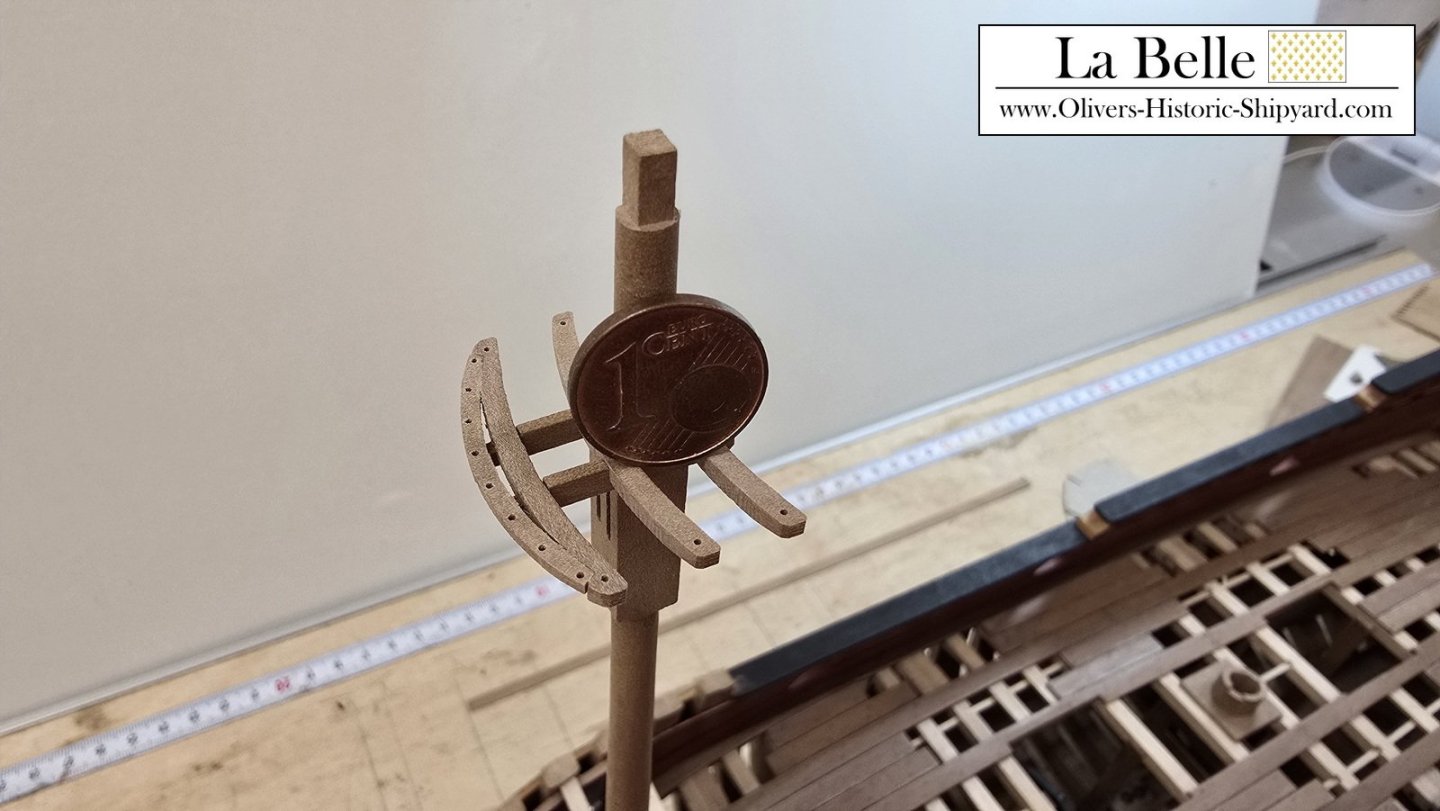

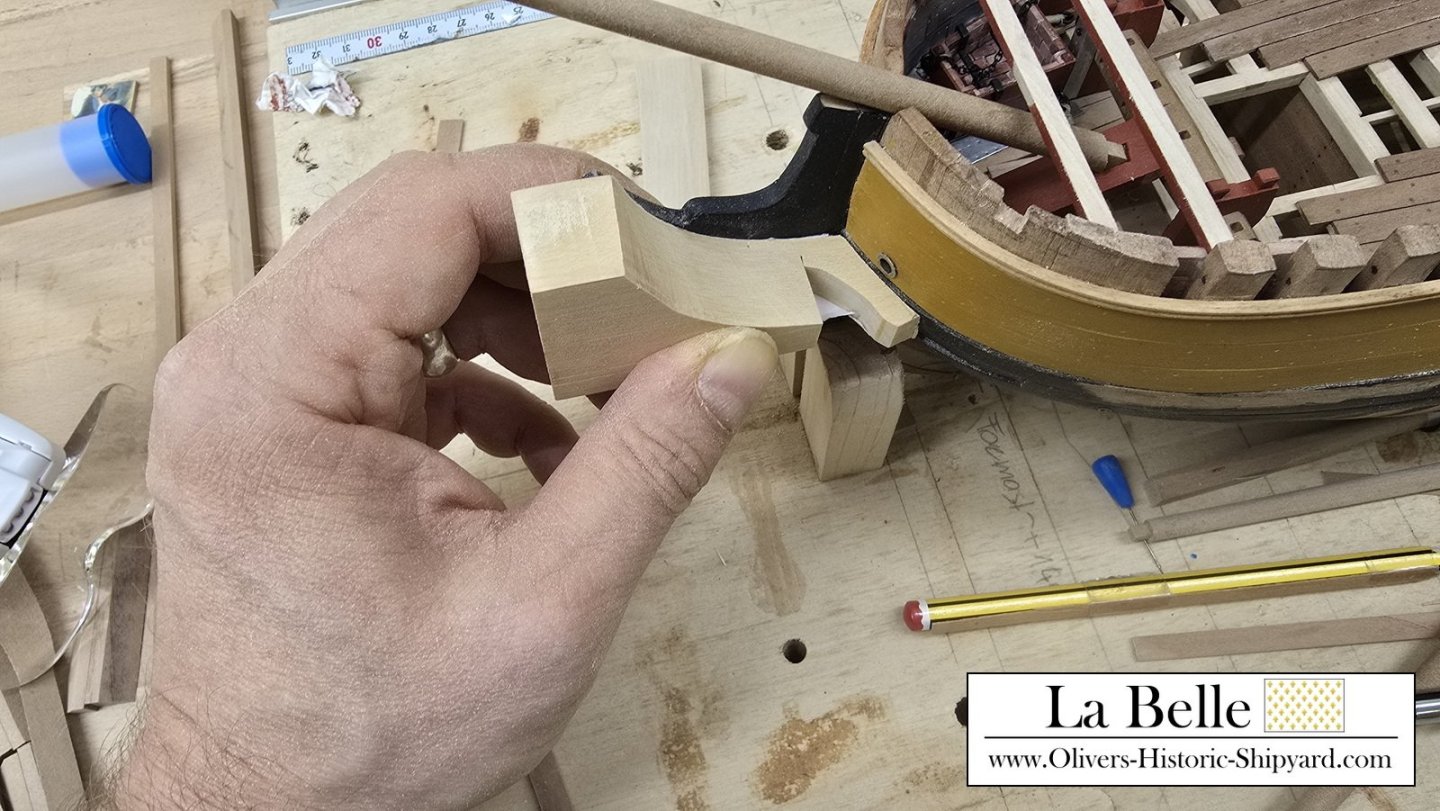

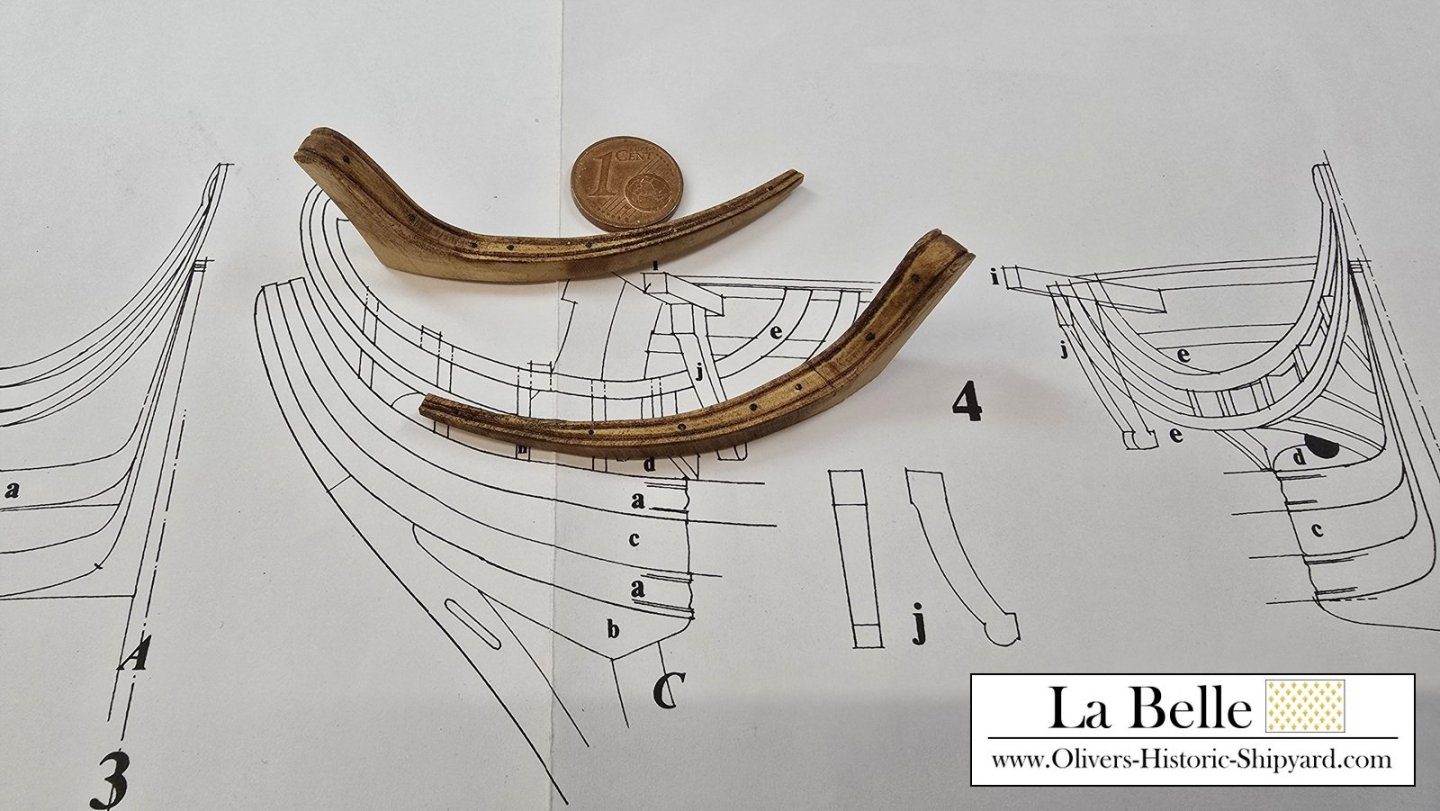

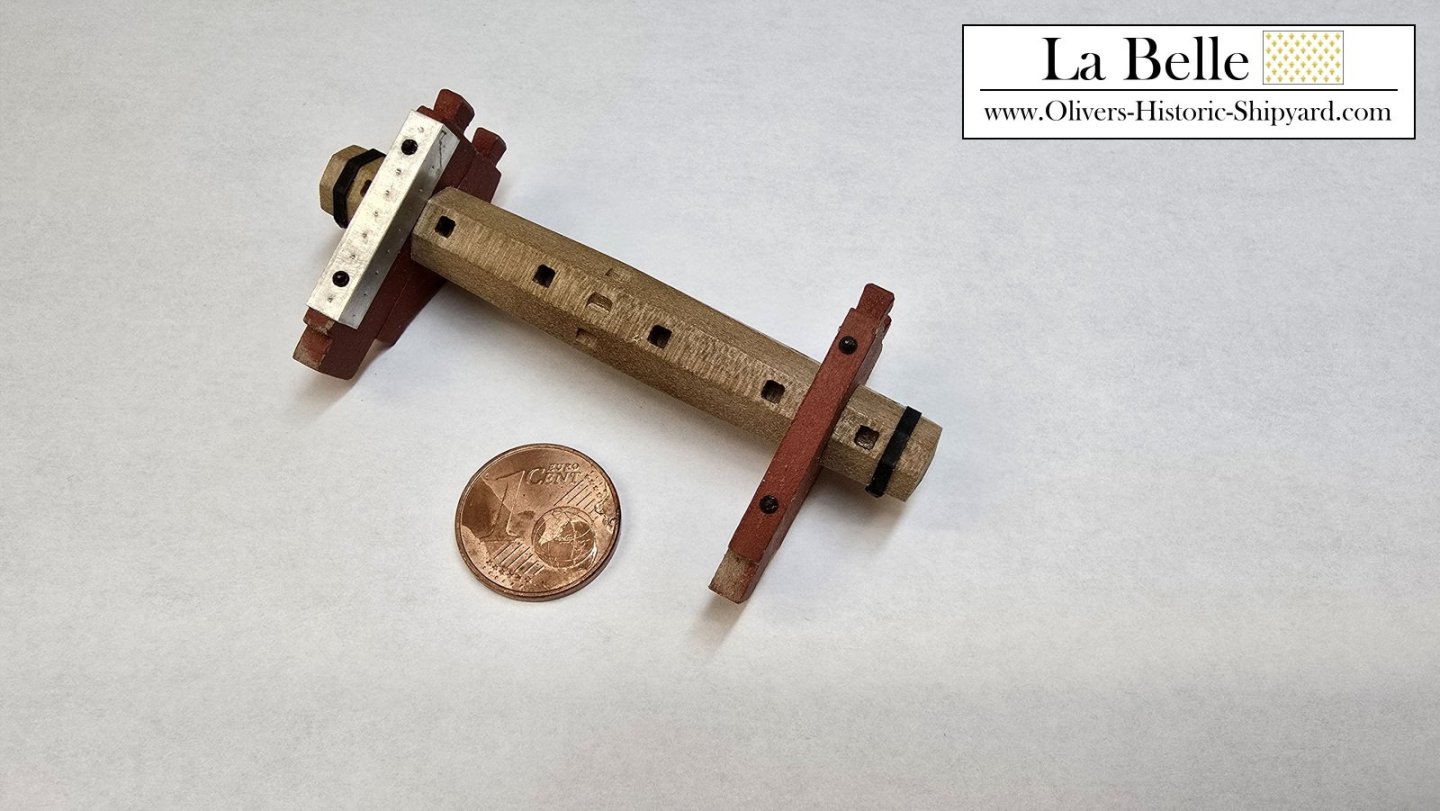

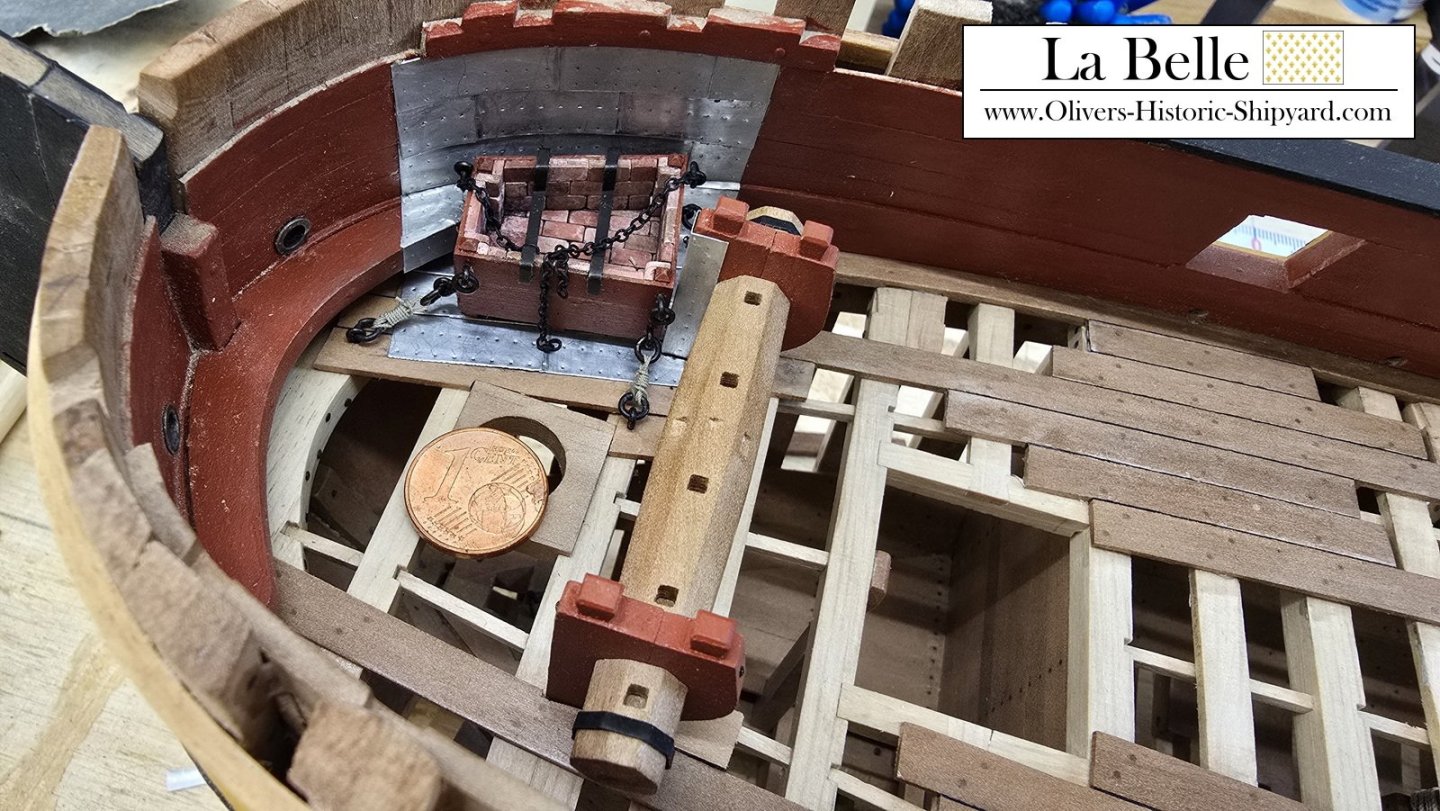

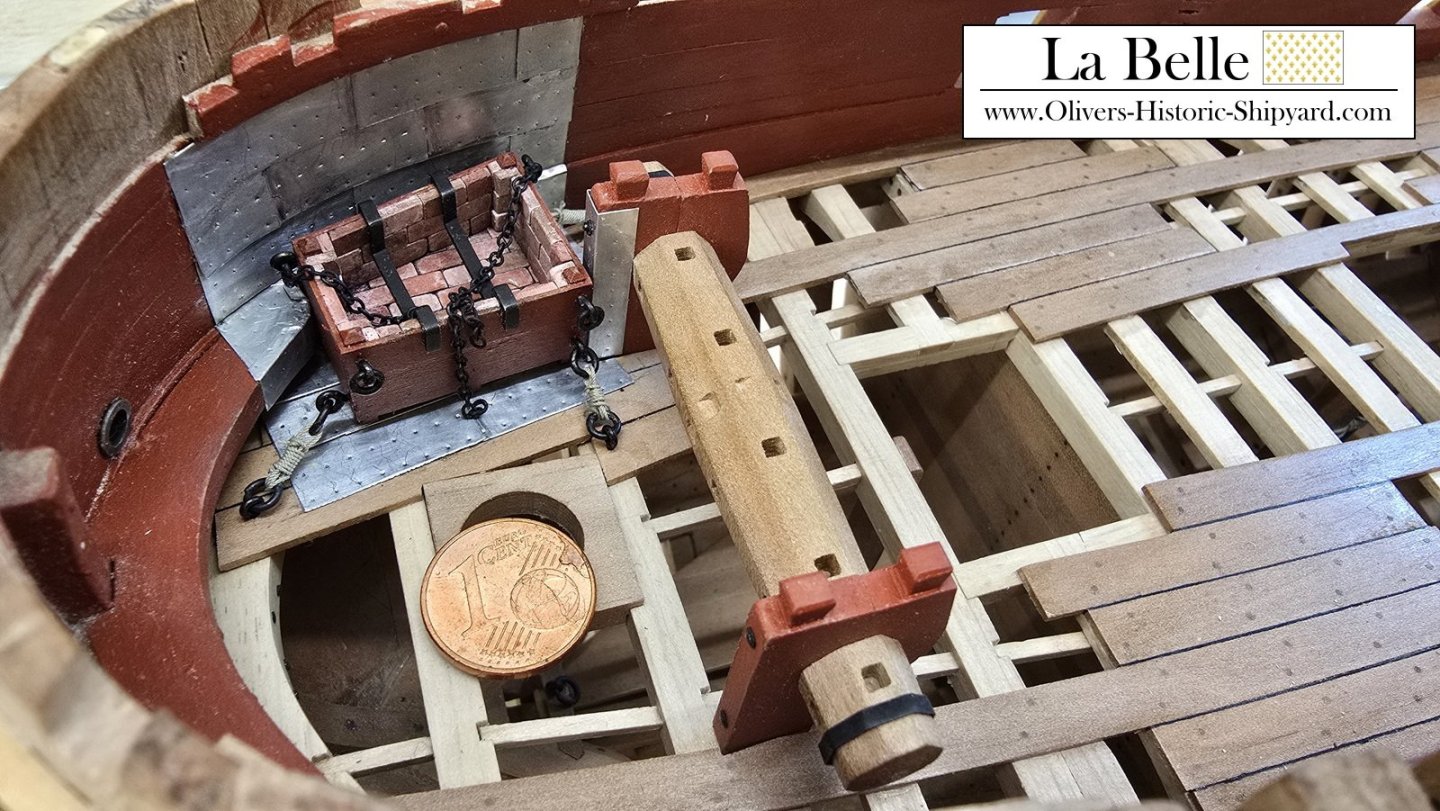

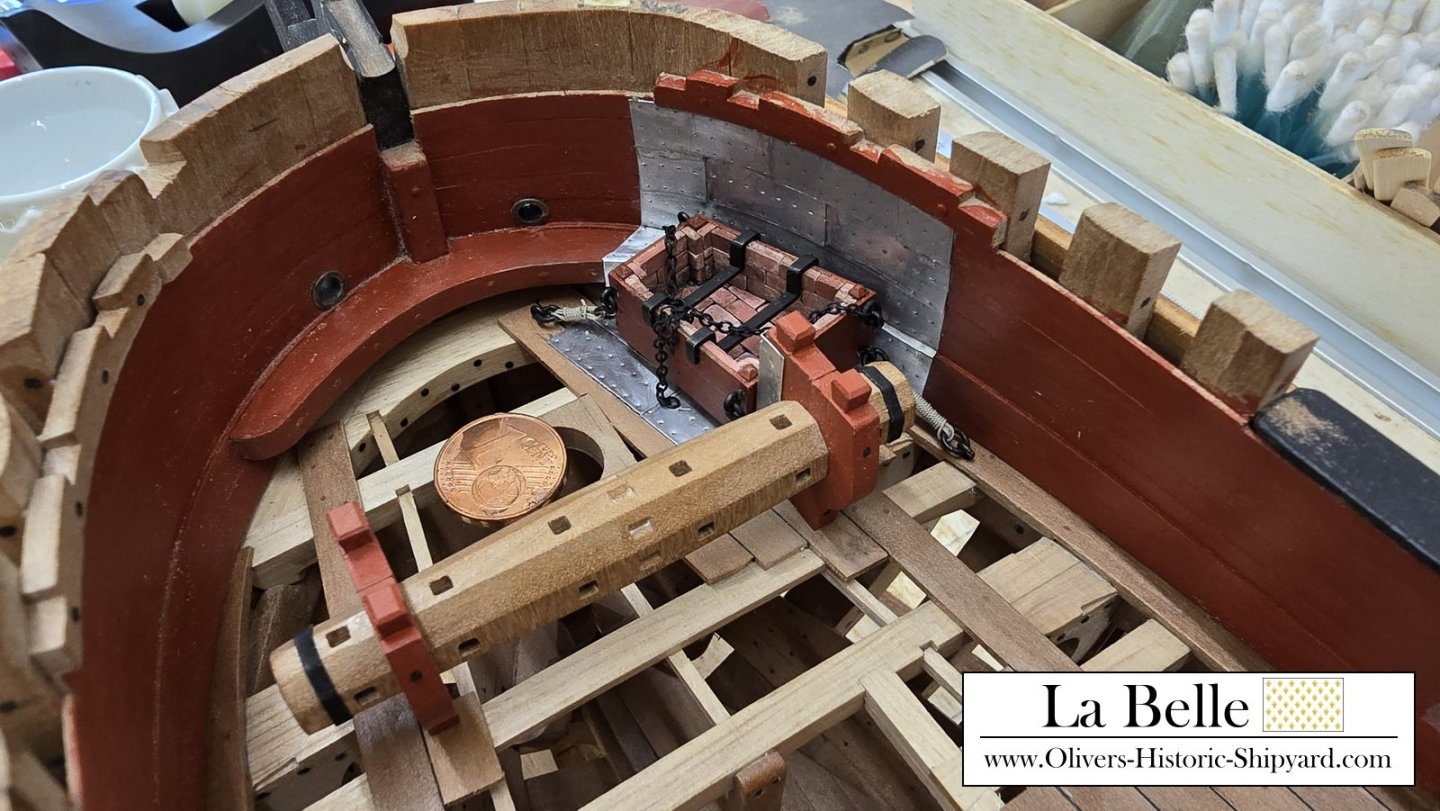

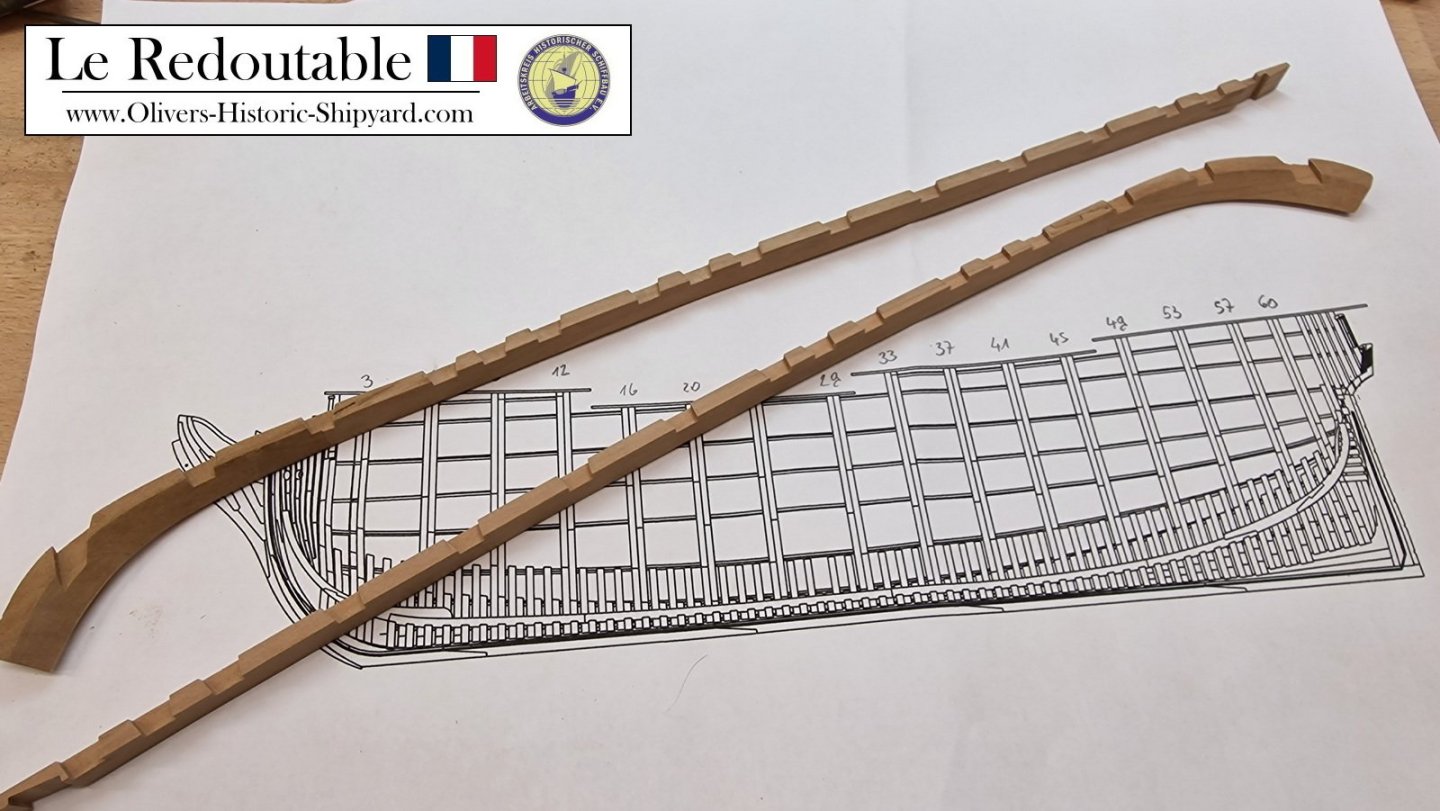

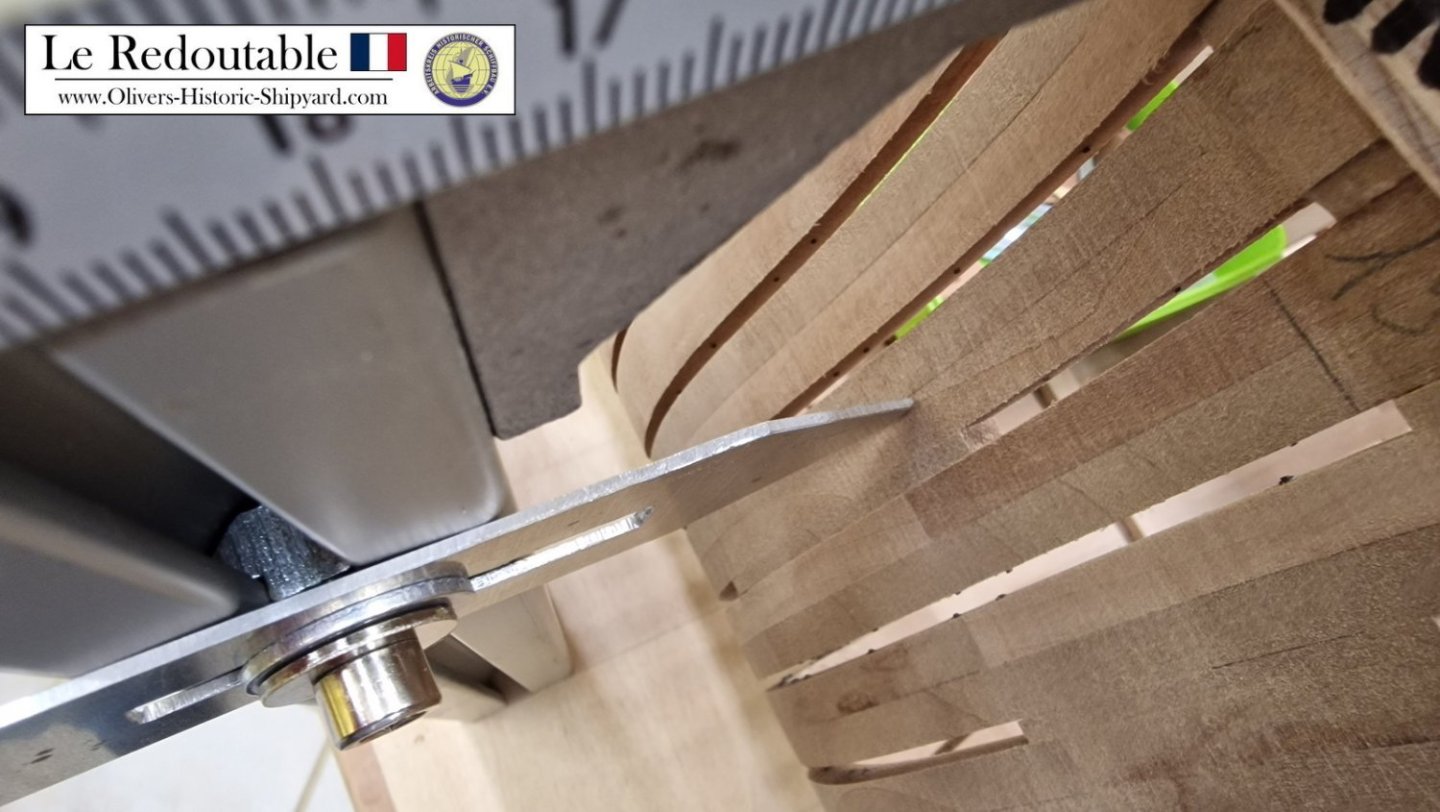

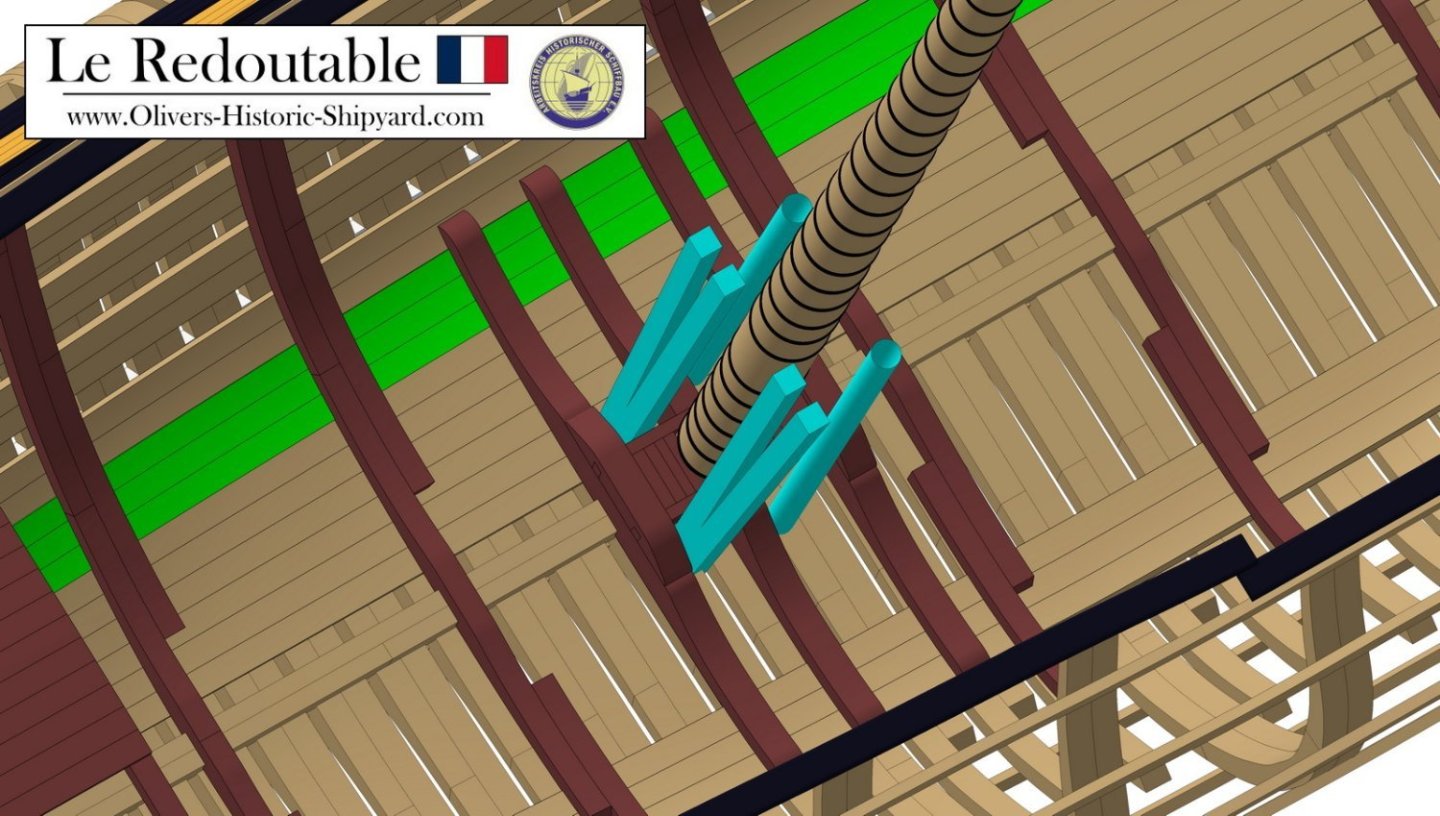

The cleats correspond geometrically to the small cleats on the wreck. As I don't trust glued cleats, I will also secure them with a bolt. The 3mm rollers will be installed in the crane beams, mast cradles and the fixed snatch blocks on the railing. According to the wreck, La Belle only had wooden sheaves and axles. Before installation, the parts are cleaned again, the cleats rounded, etc. -

ancre La Belle 1684 by Oliver1973 - 1/36

Oliver1973 replied to Oliver1973's topic in - Build logs for subjects built 1501 - 1750

-

ancre La Belle 1684 by Oliver1973 - 1/36

Oliver1973 replied to Oliver1973's topic in - Build logs for subjects built 1501 - 1750

-

ancre La Belle 1684 by Oliver1973 - 1/36

Oliver1973 replied to Oliver1973's topic in - Build logs for subjects built 1501 - 1750

-

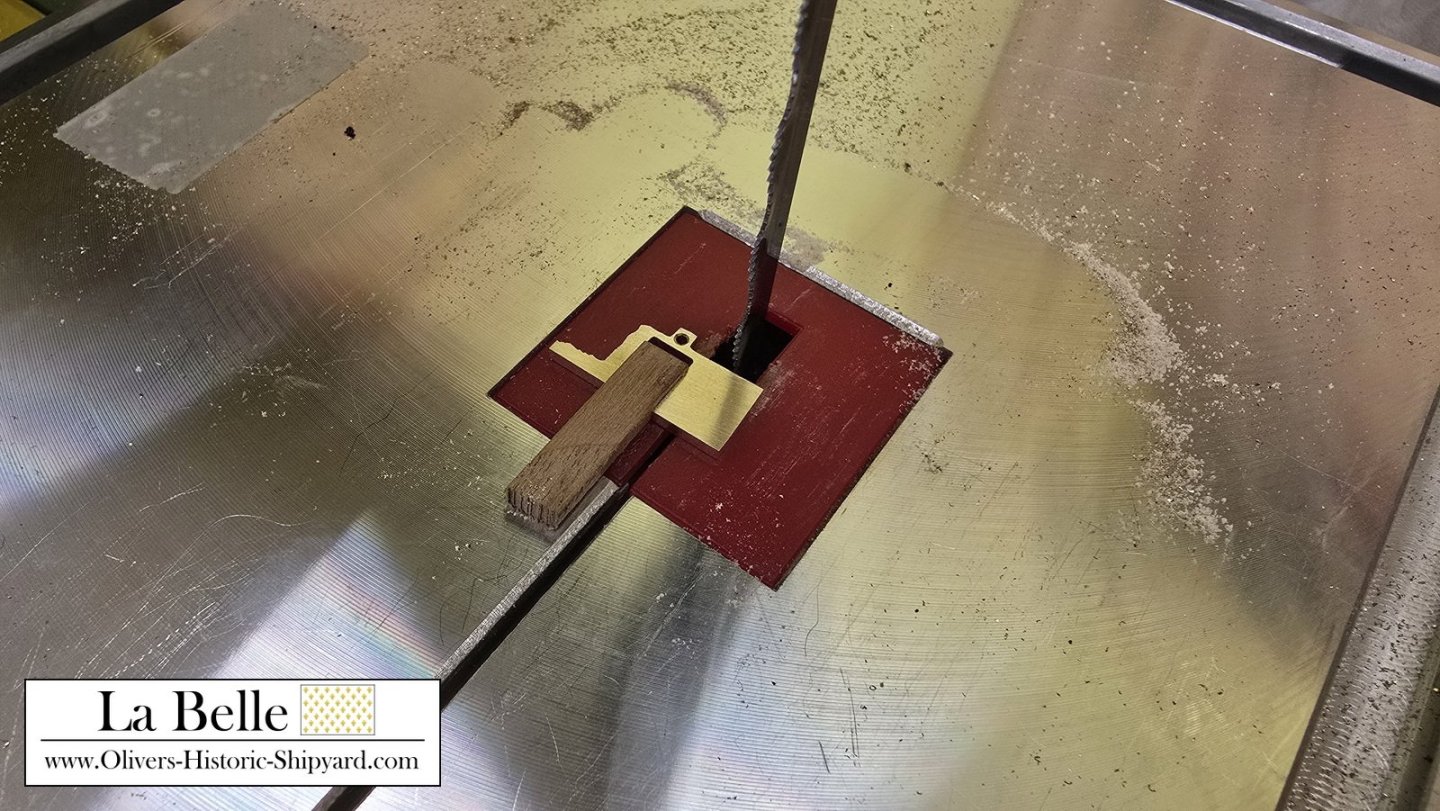

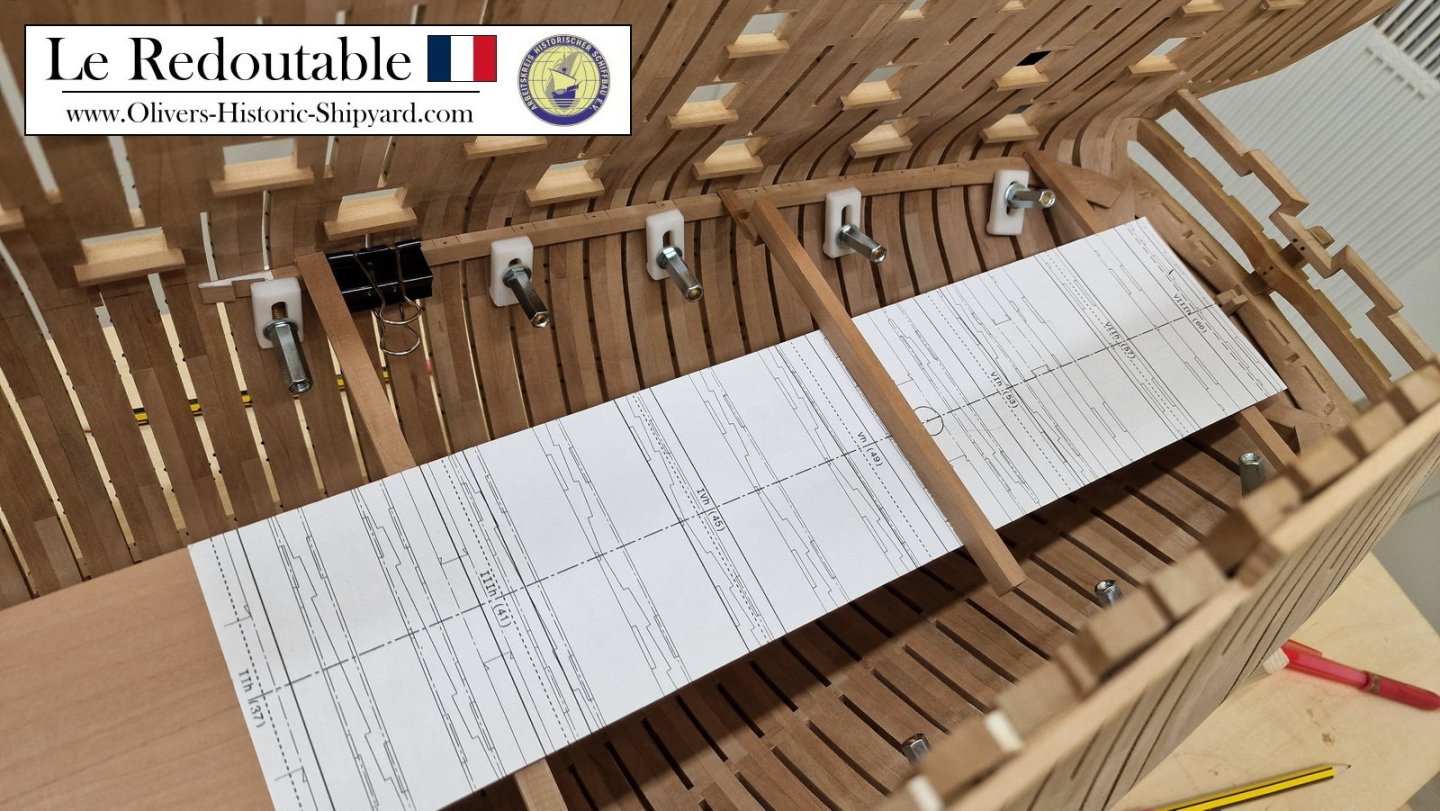

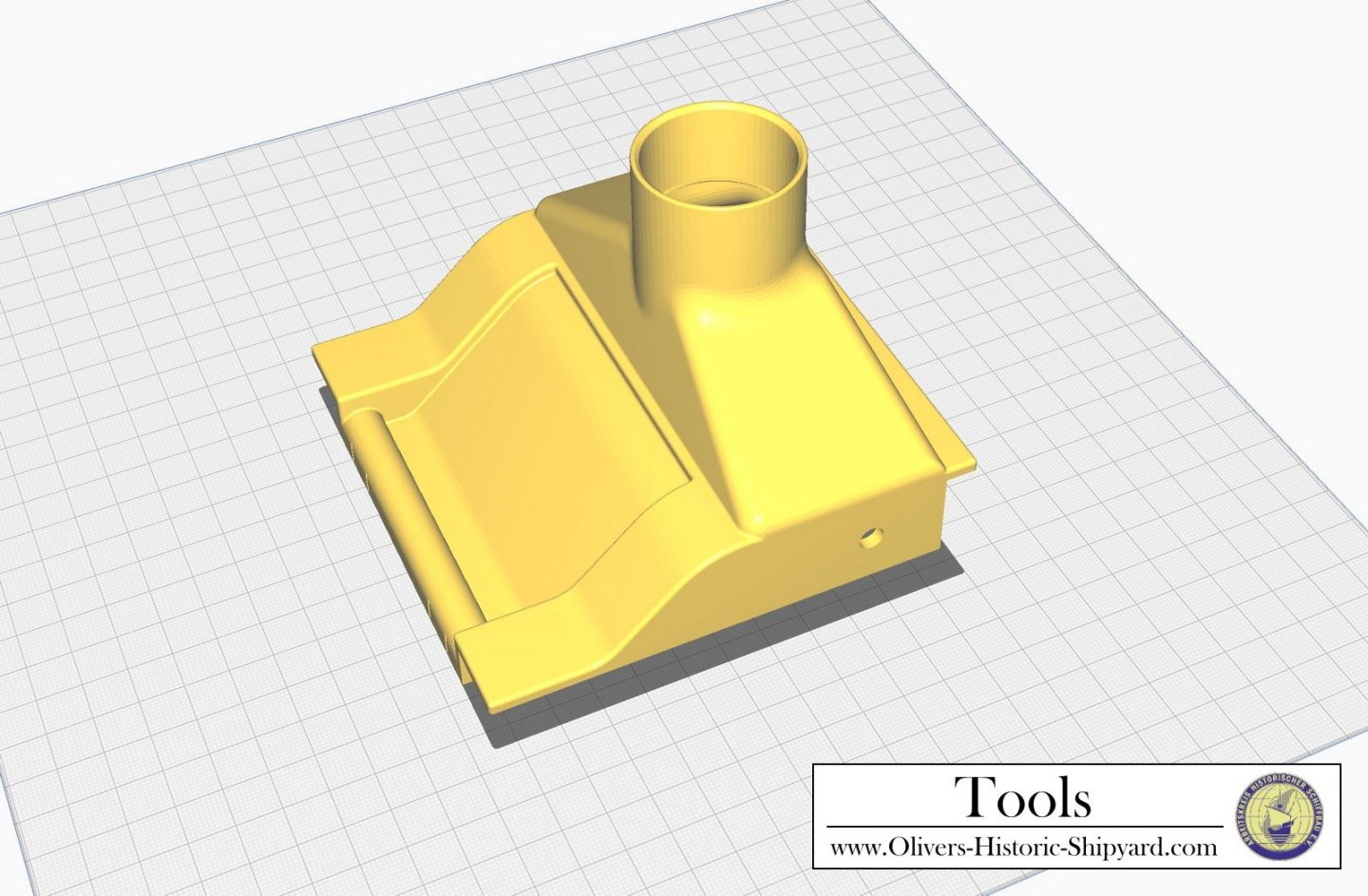

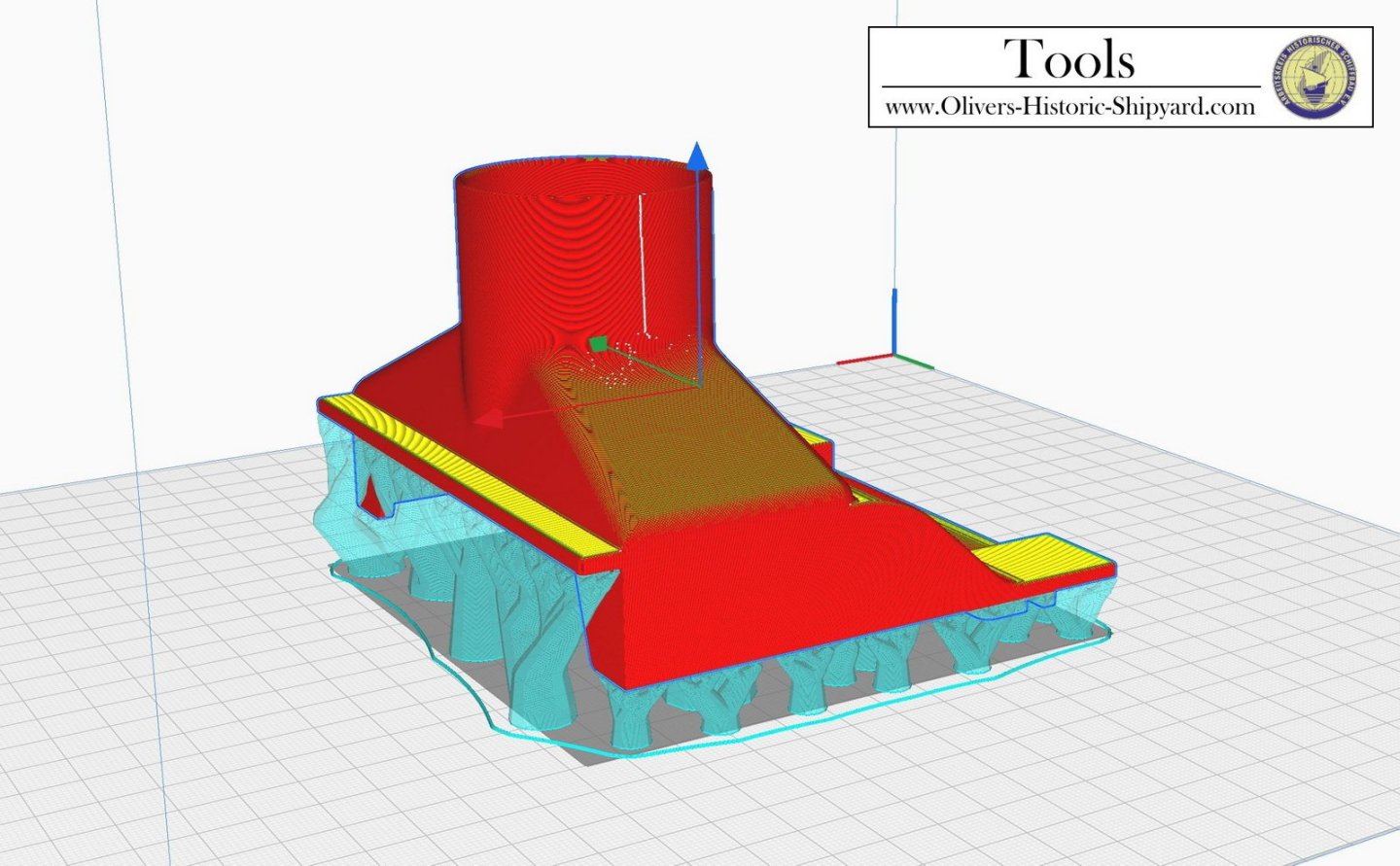

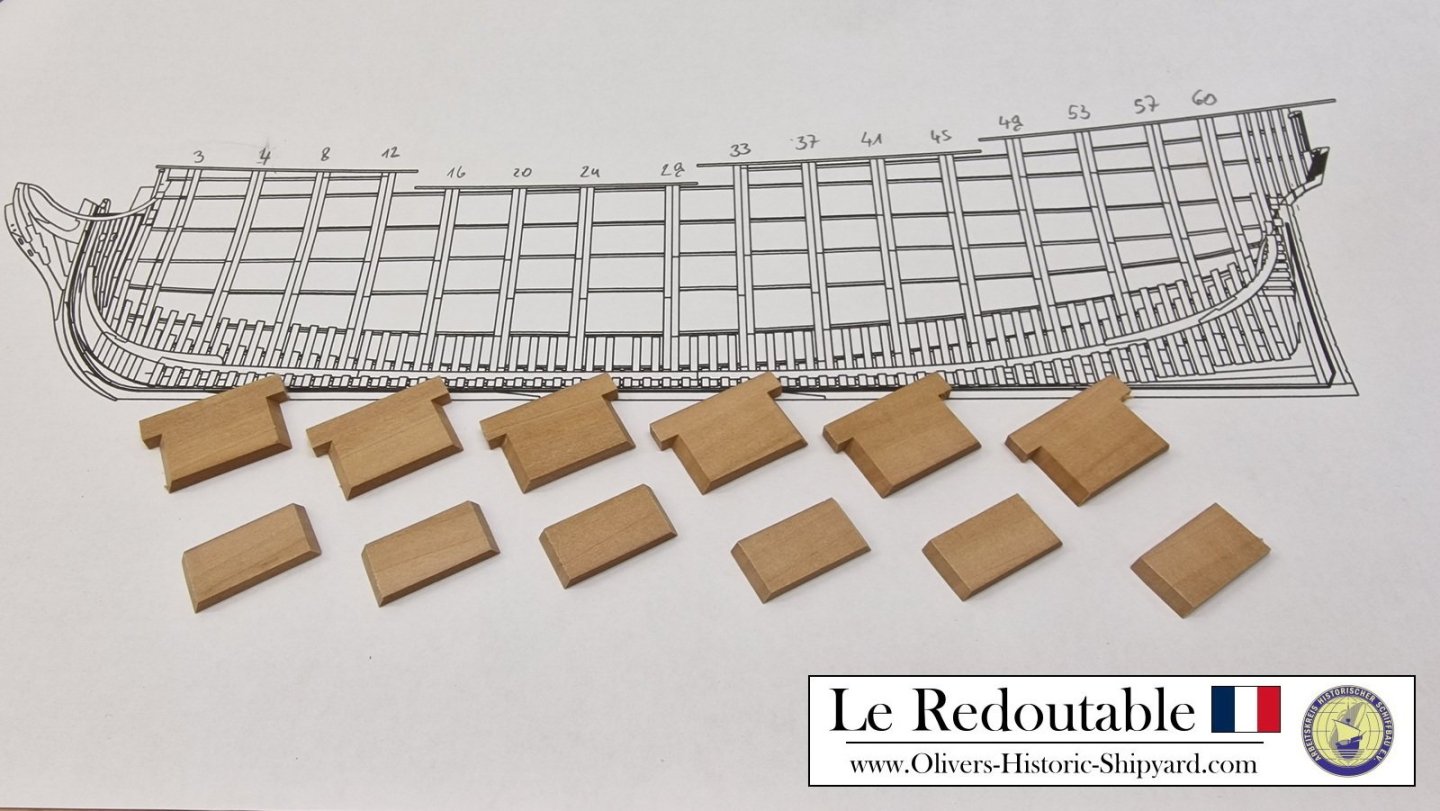

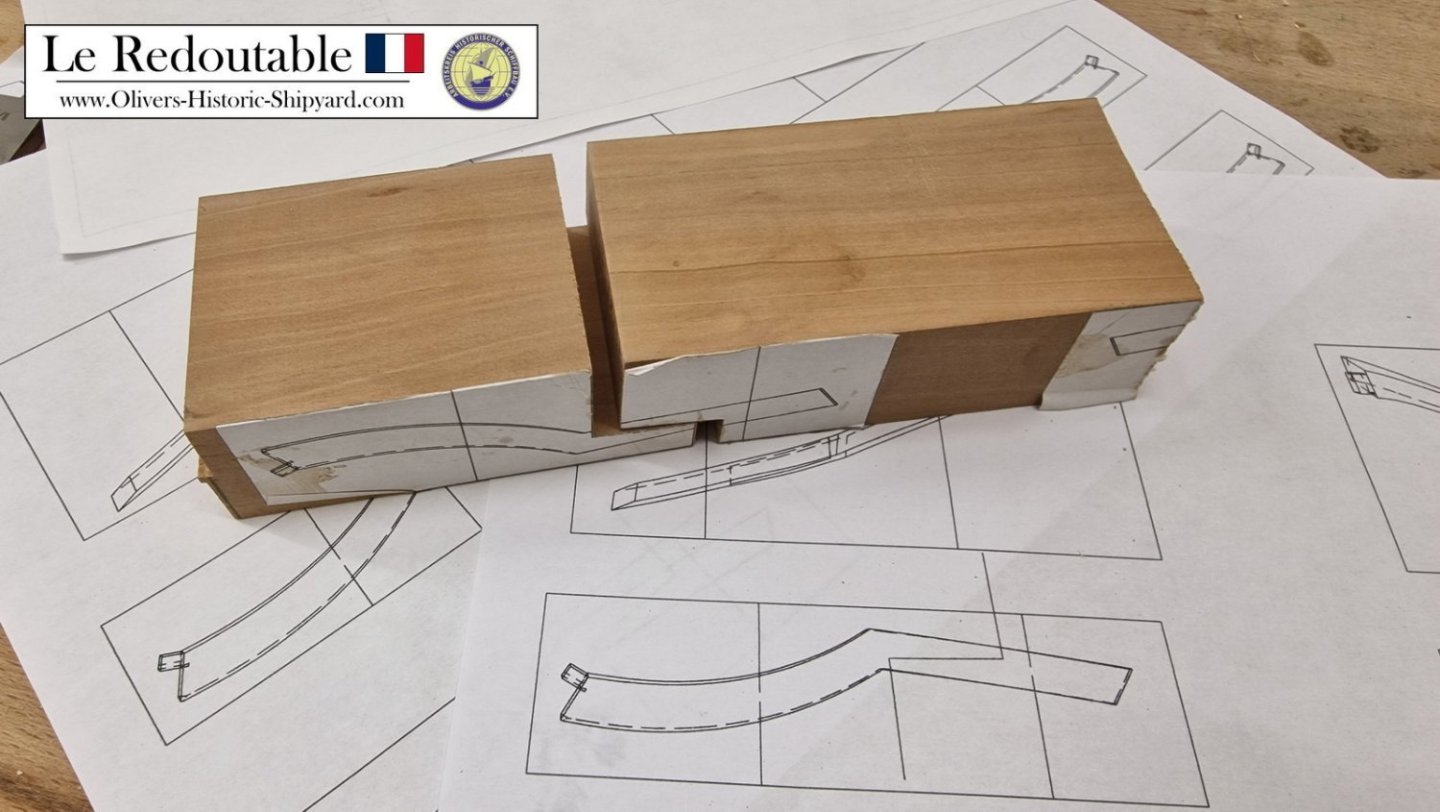

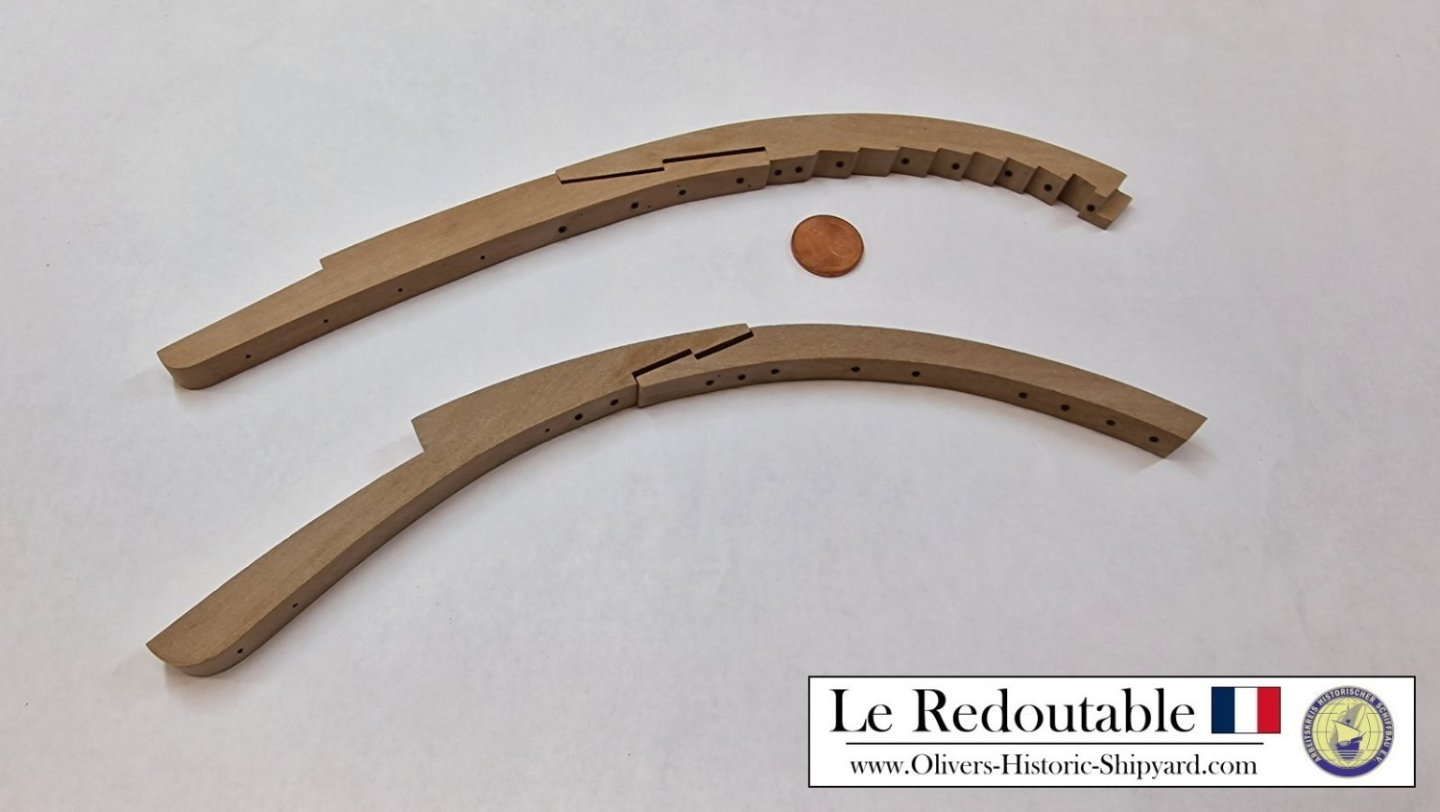

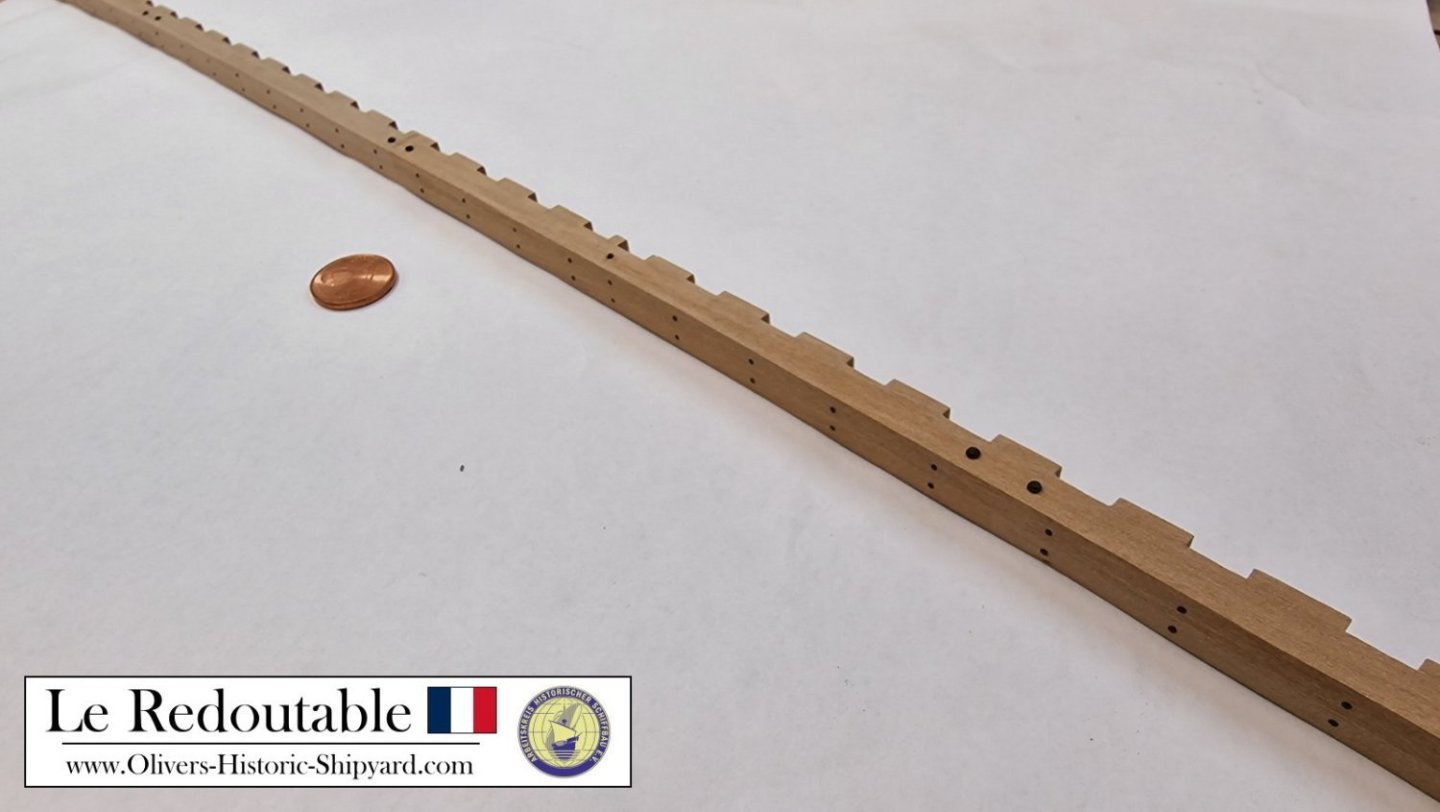

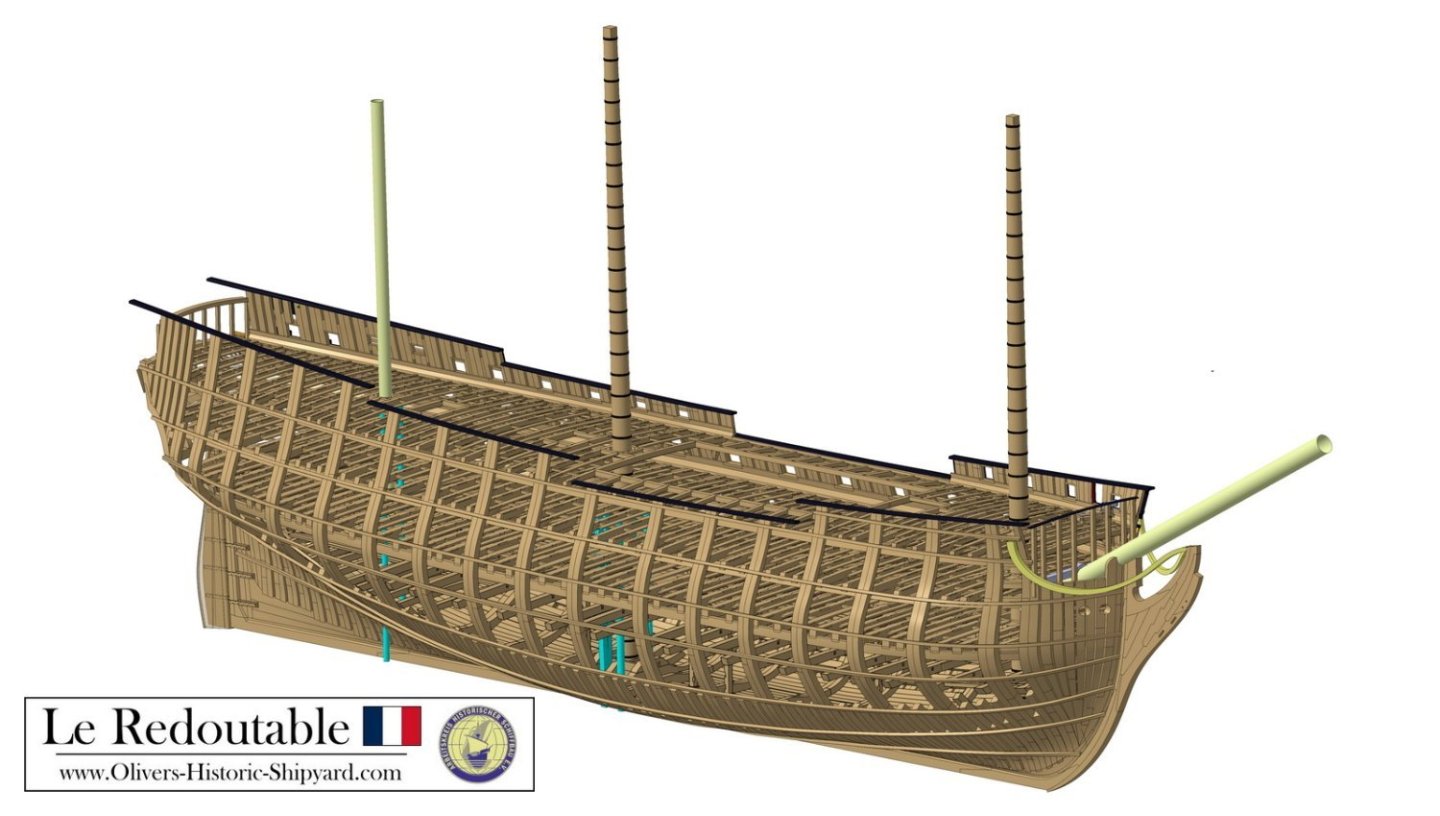

I spent the last days before the well-deserved summer holiday making new clamps. Unfortunately, due to the narrow frame spacing incl. bolt heads, I could no longer use my clamps from the La Belle. So new ones were needed. With the focus on subsequent projects, I oversized them a lot. I could now also build a Valmy in 1/48 with them (actually a nice project). I will also make new clamps for the bow area. But there I will copy the La Belle principle 1:1, because they worked great there. I will show this in detail when it is ready.

-

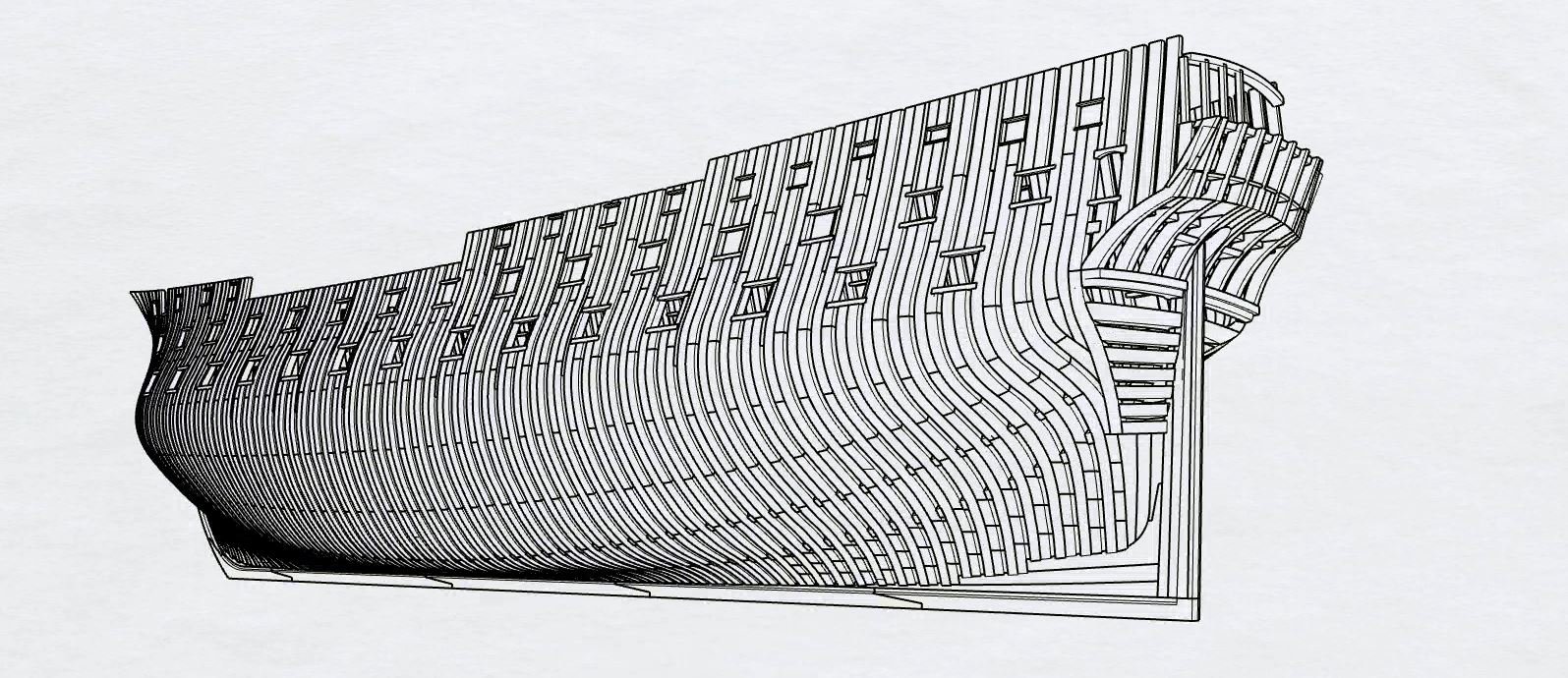

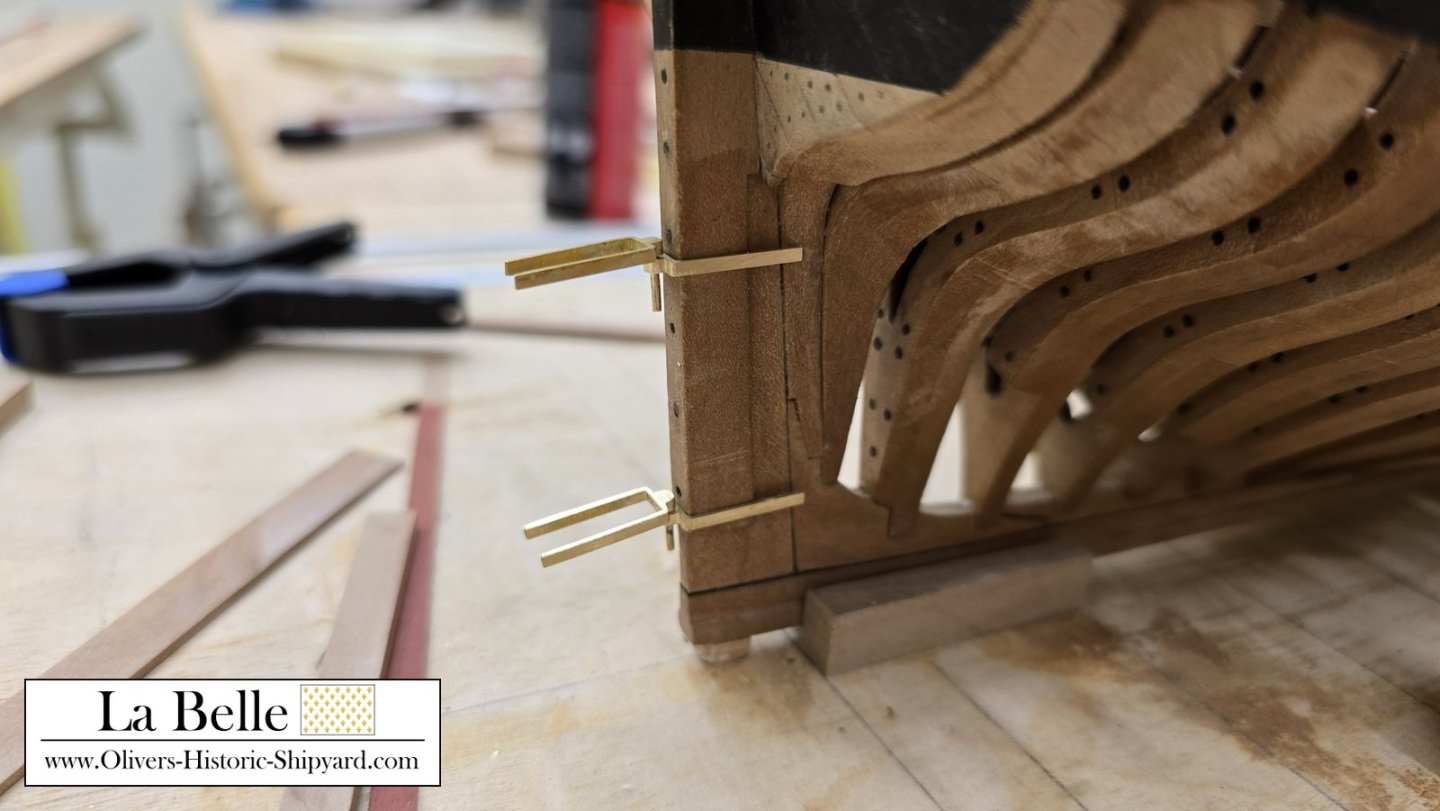

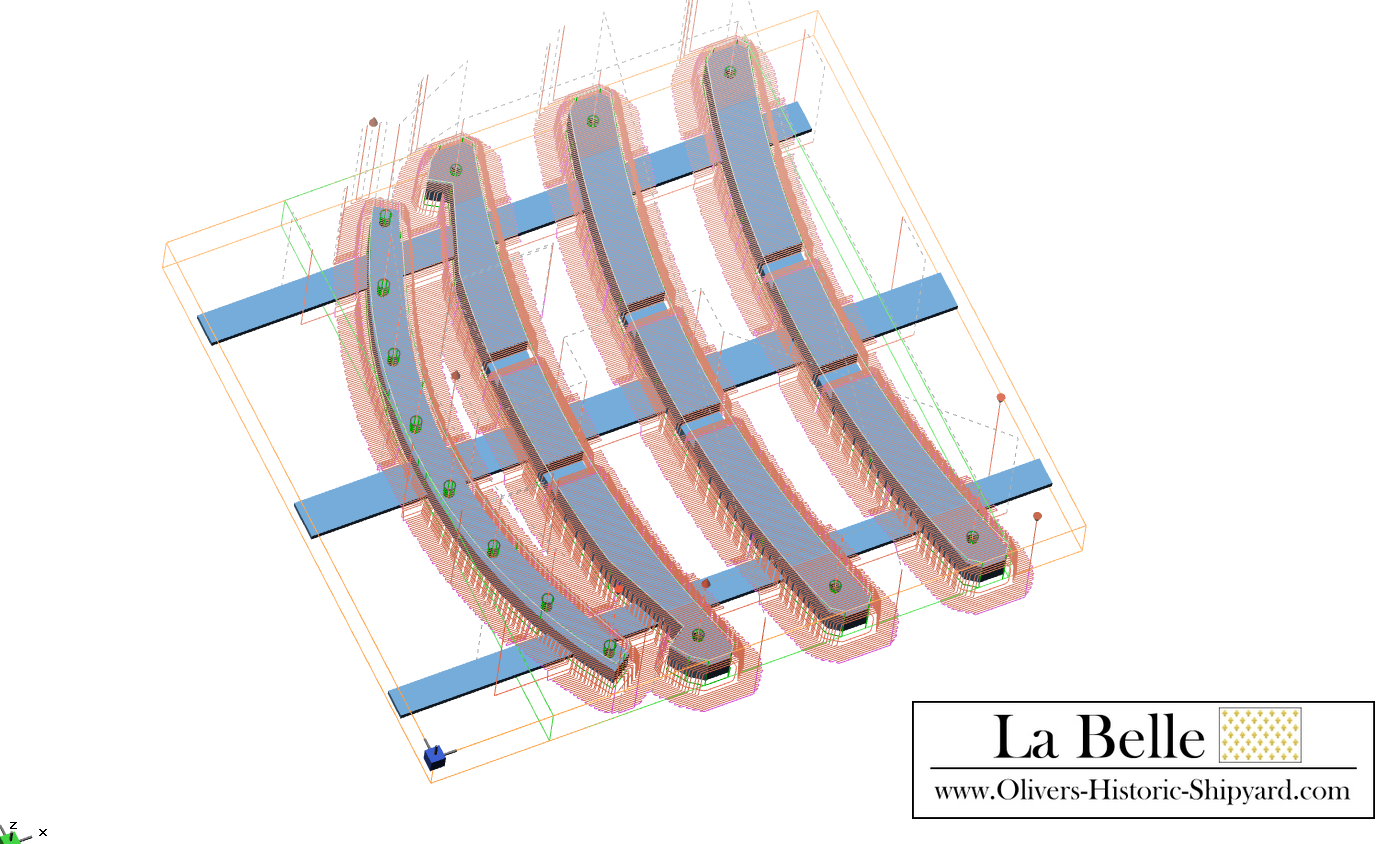

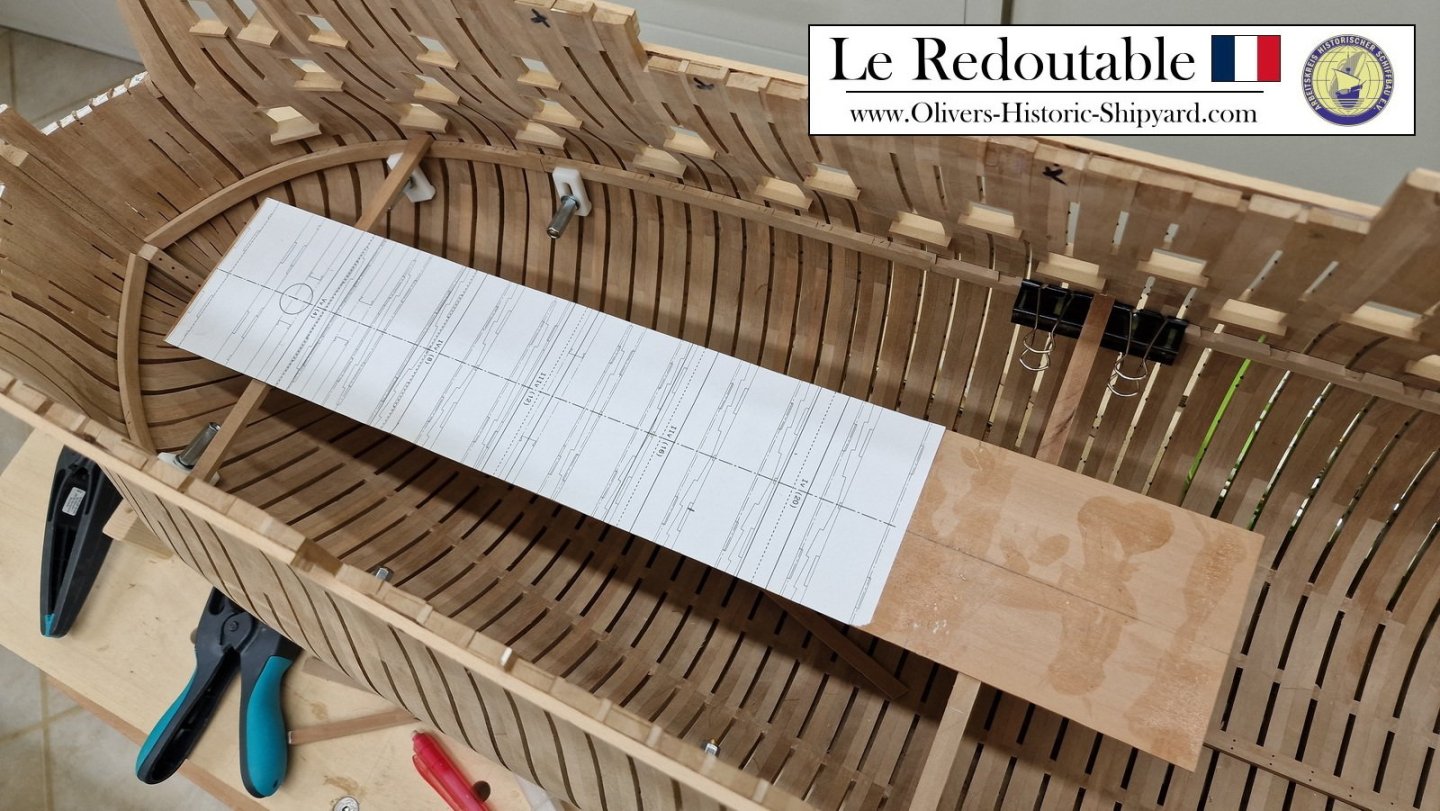

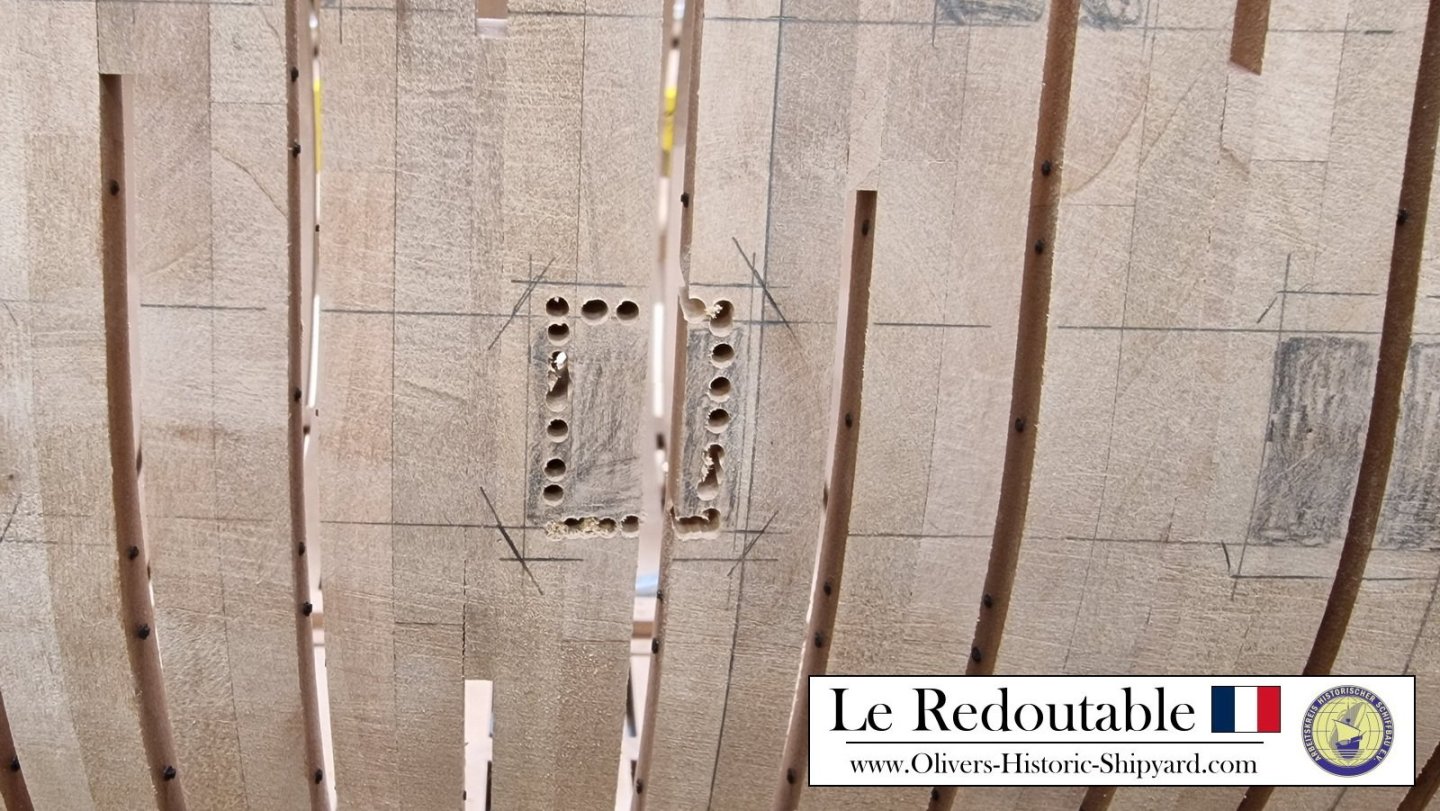

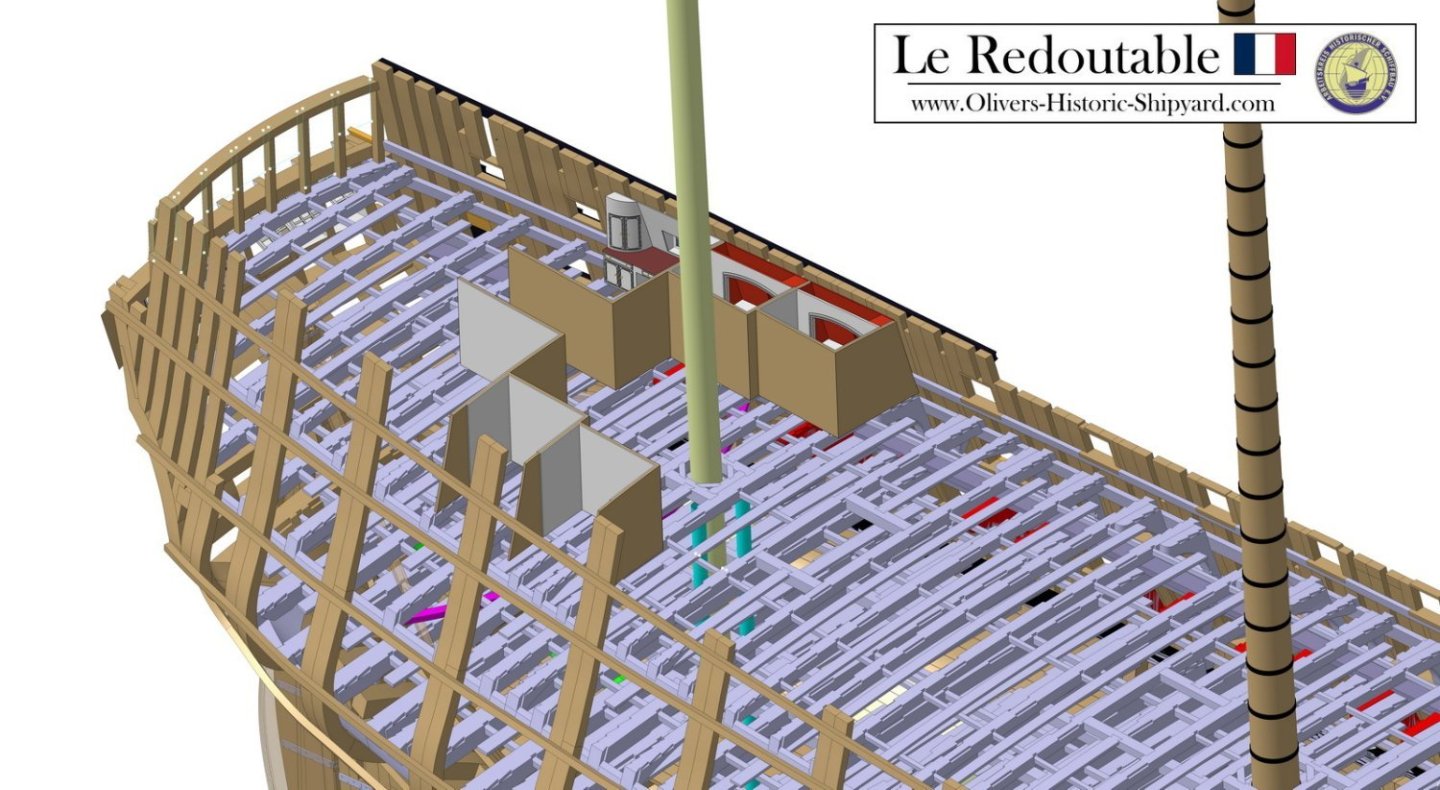

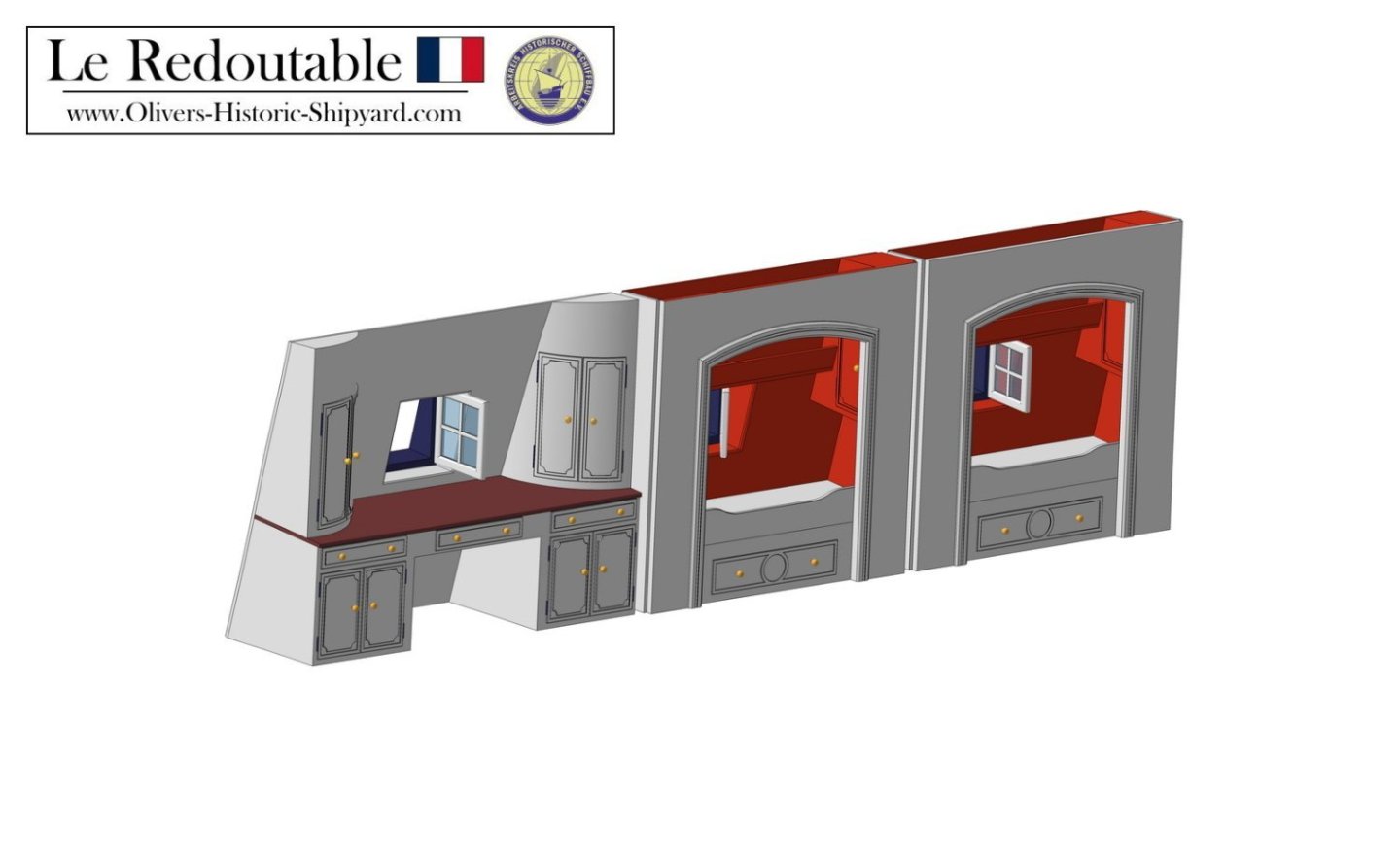

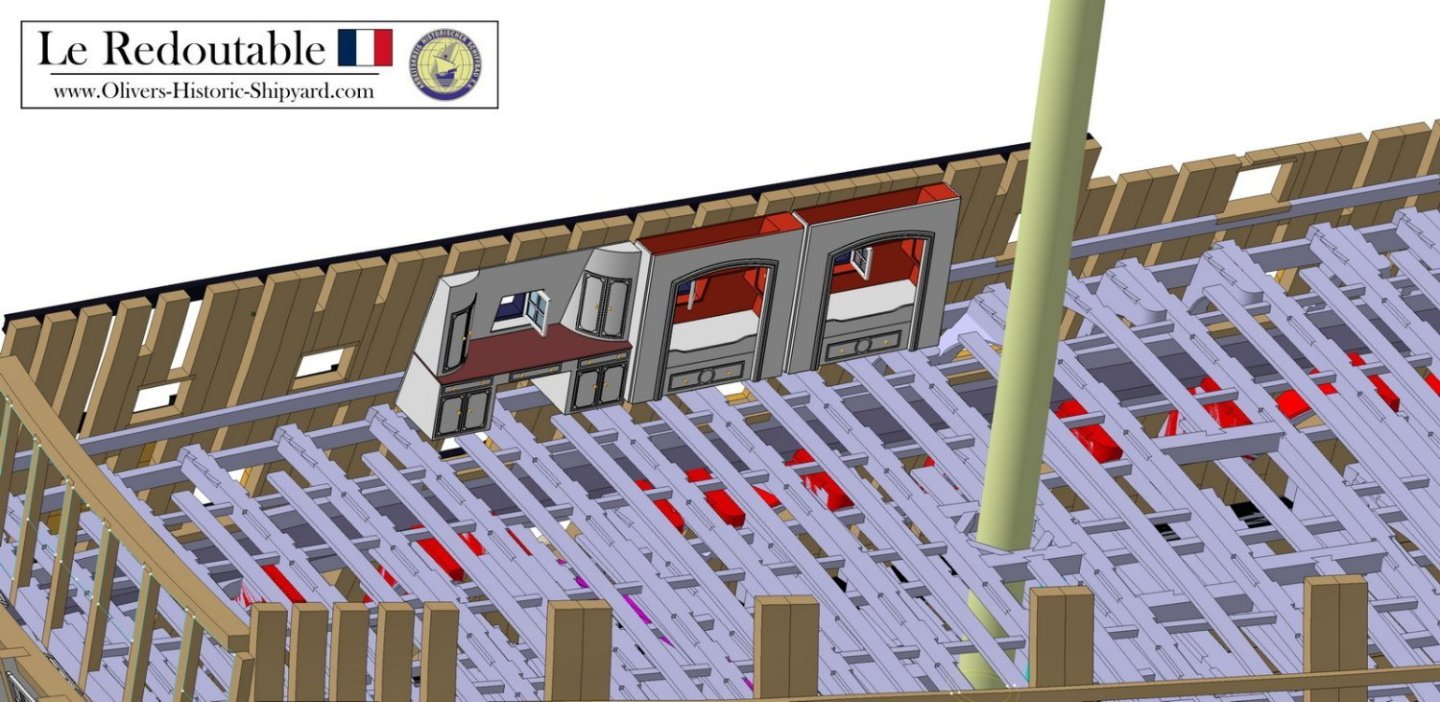

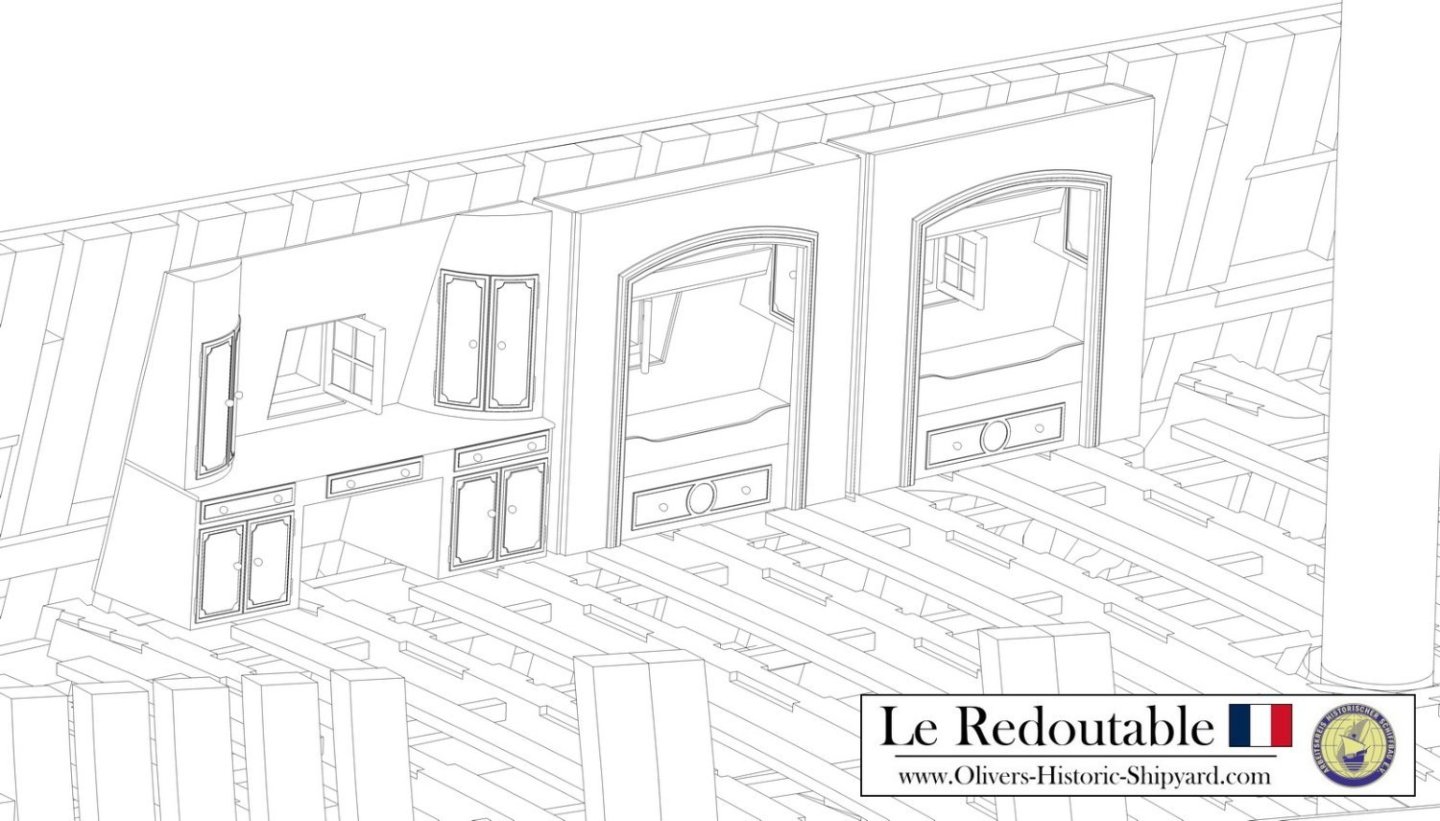

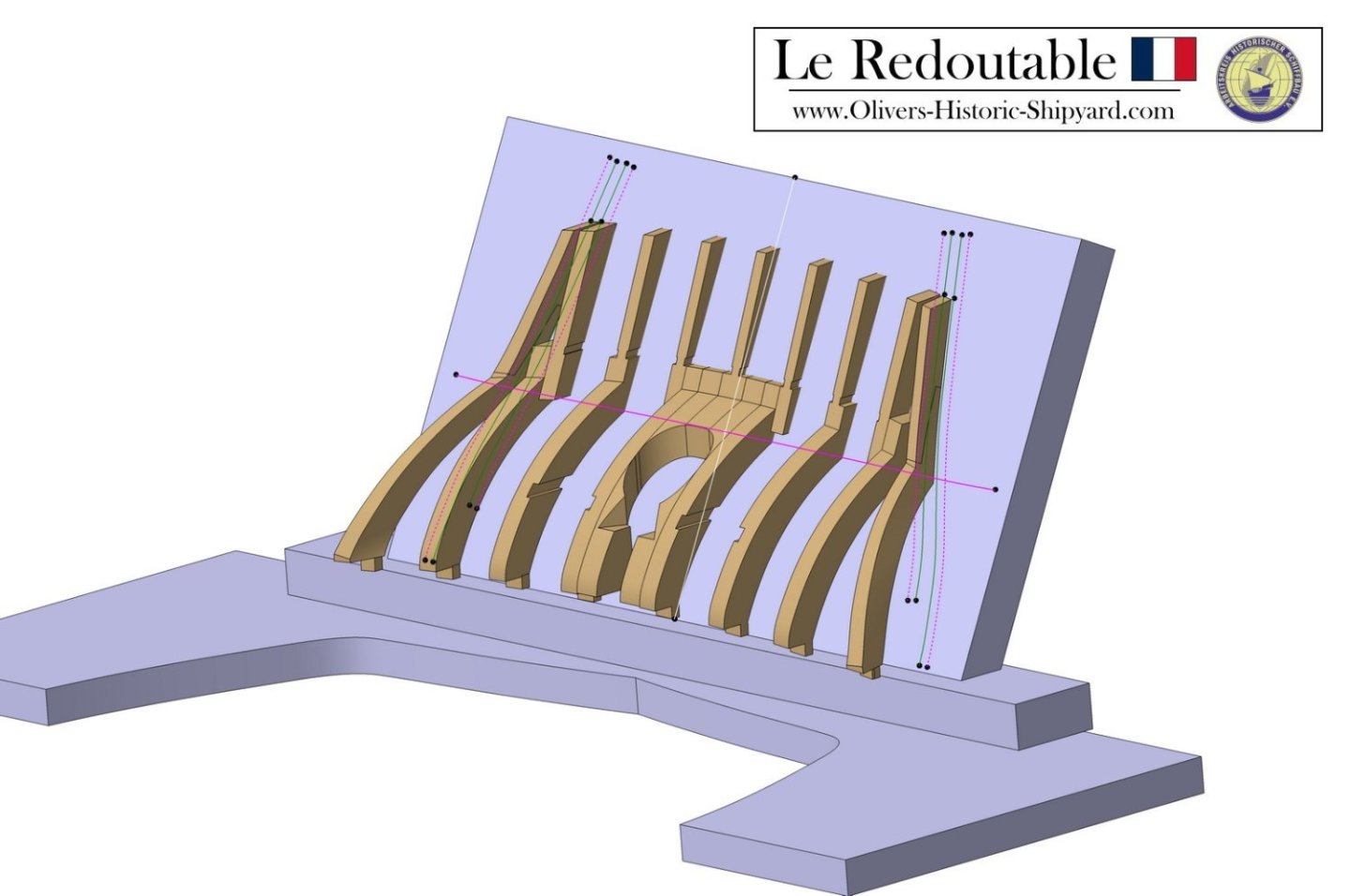

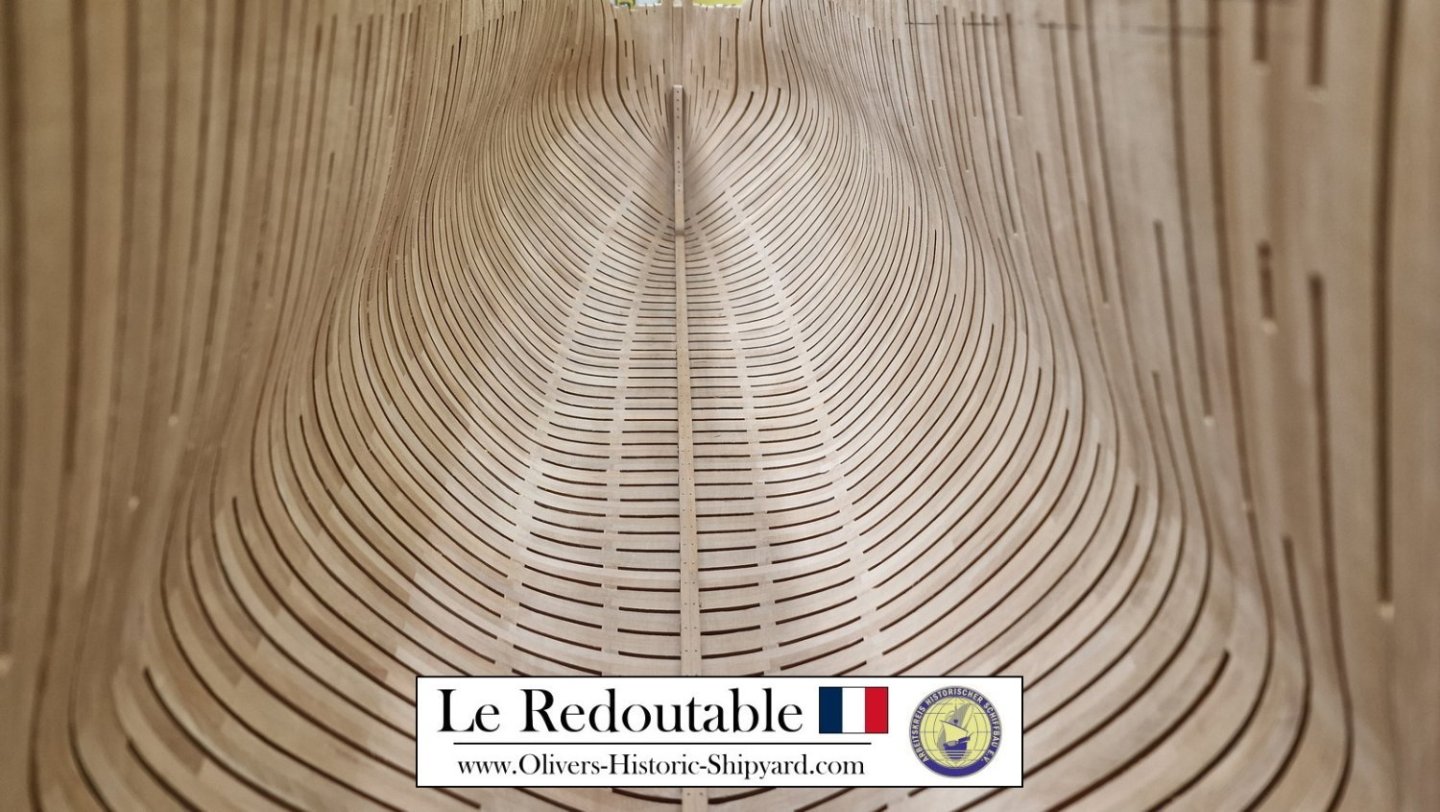

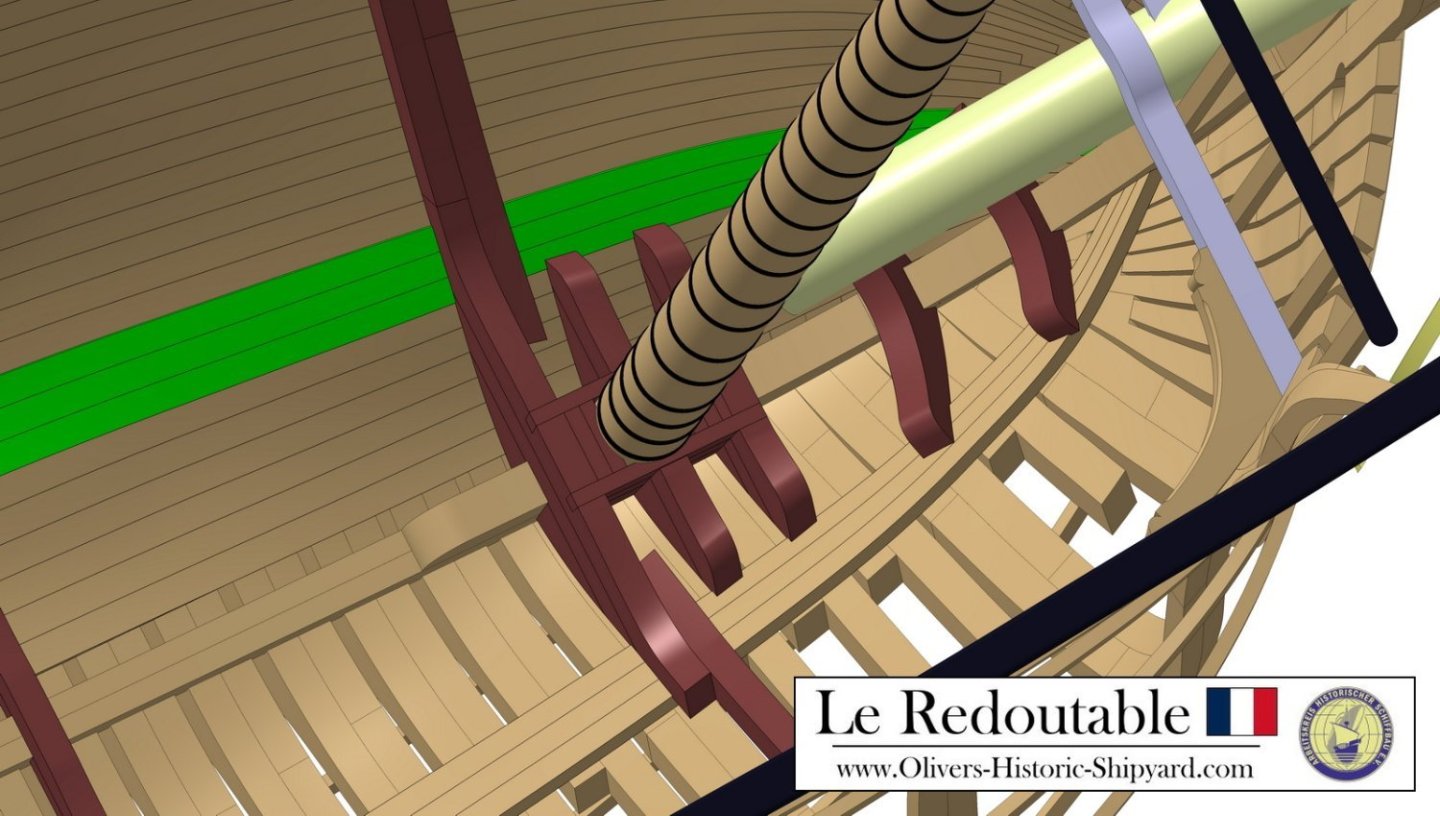

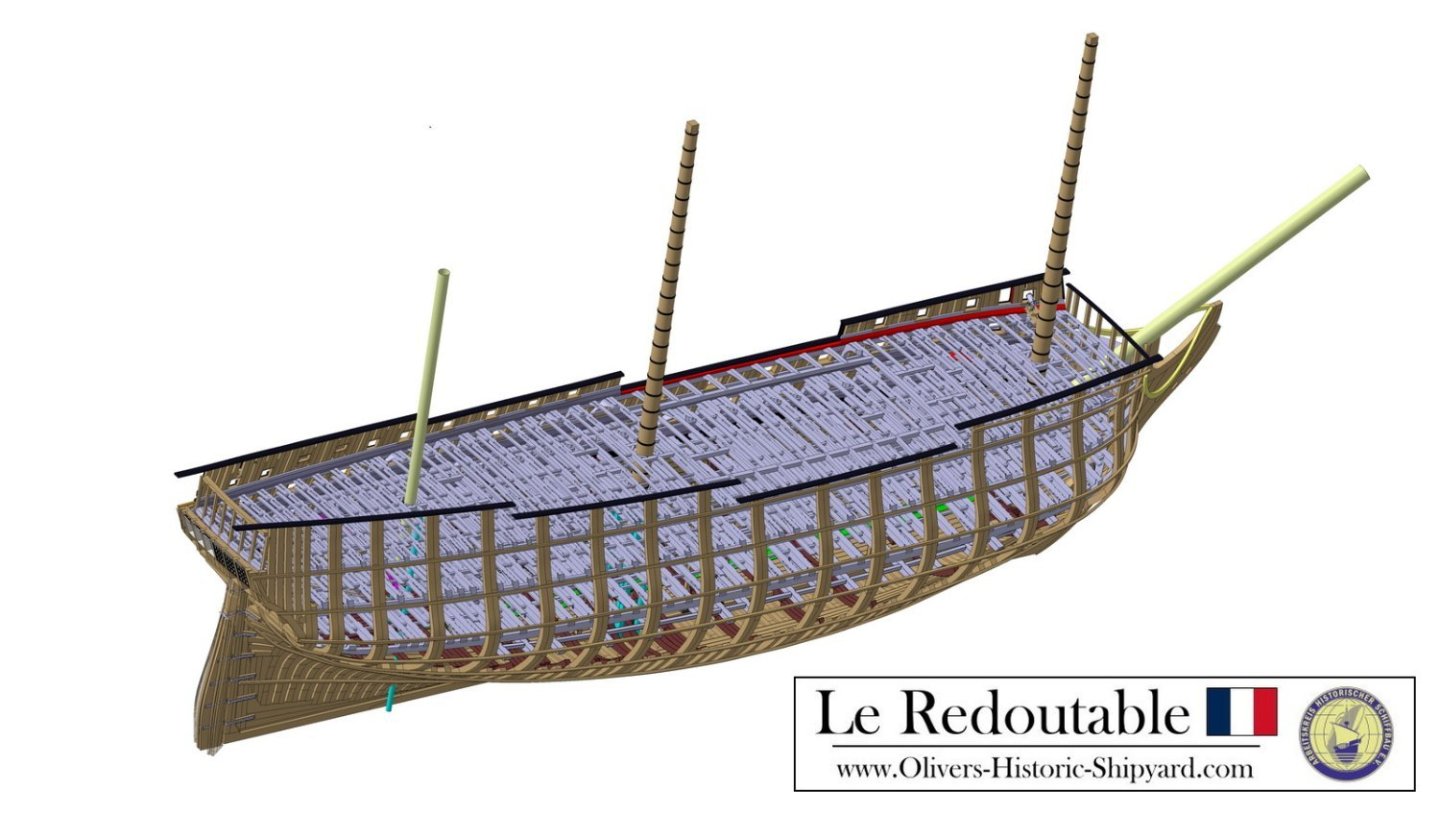

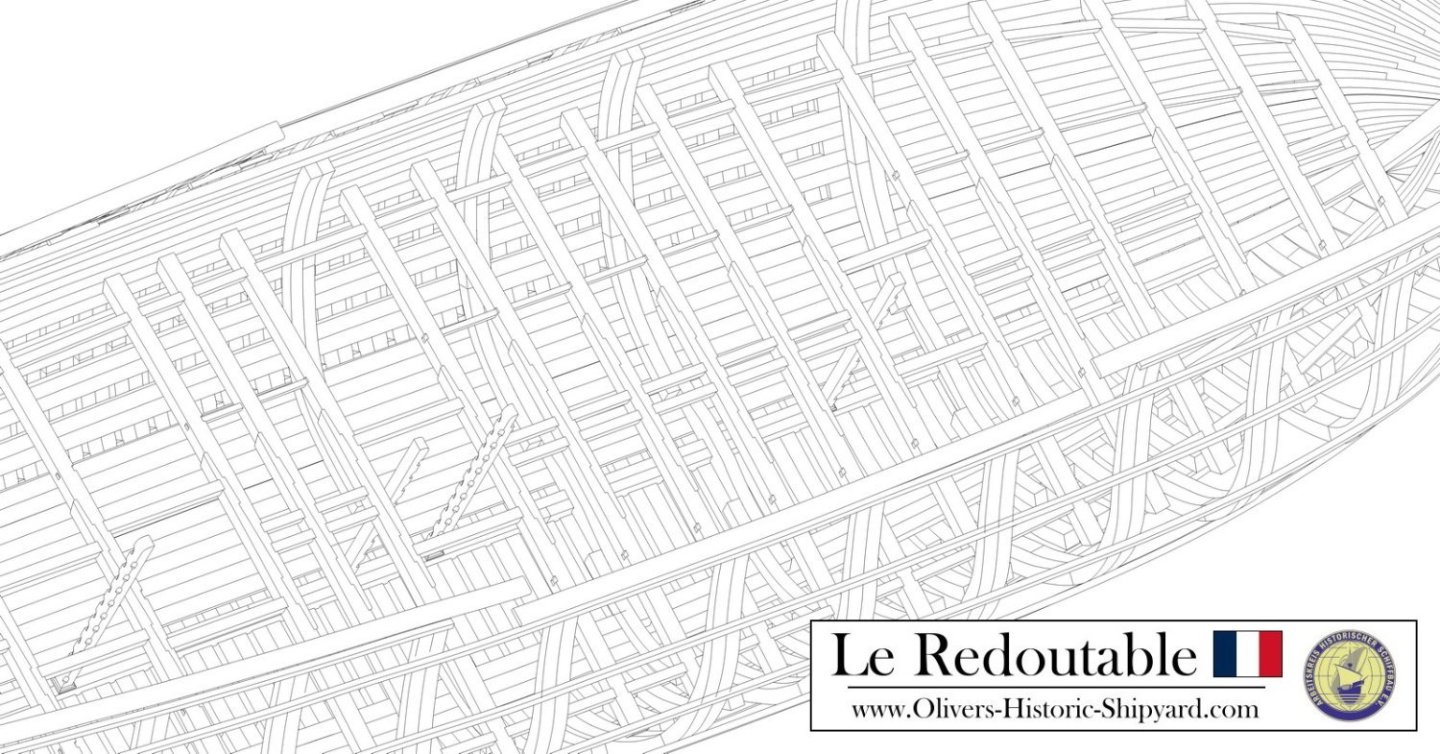

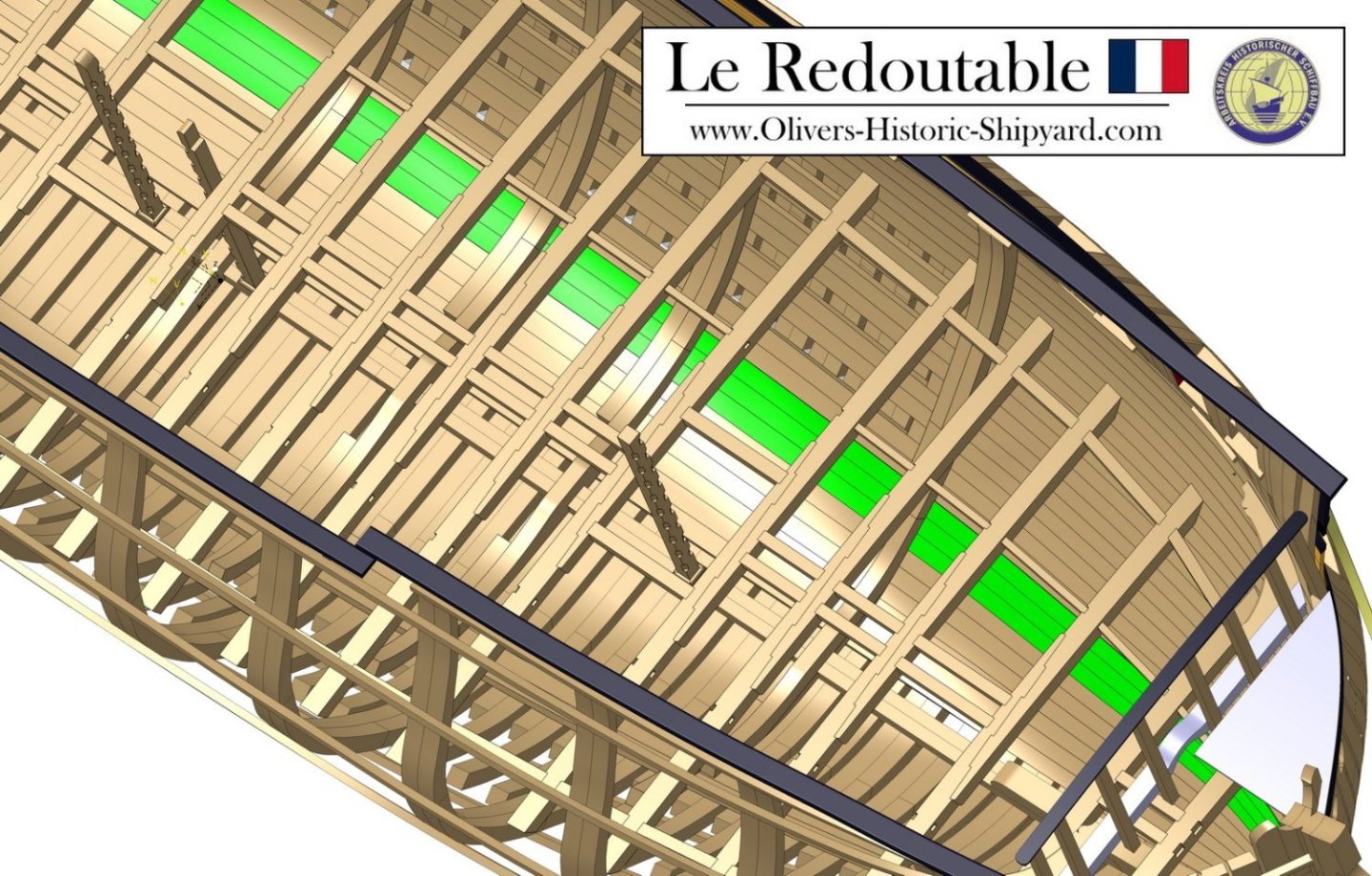

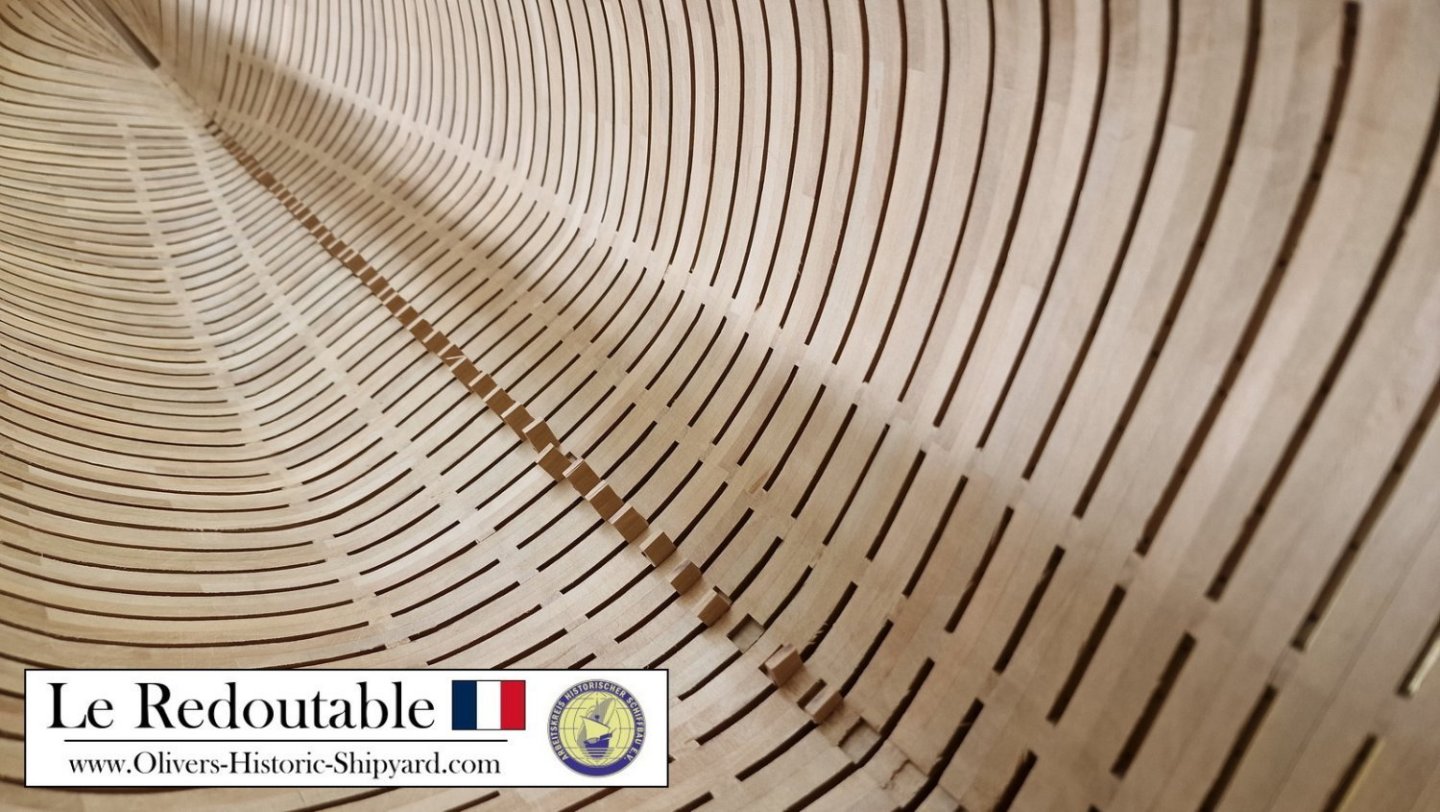

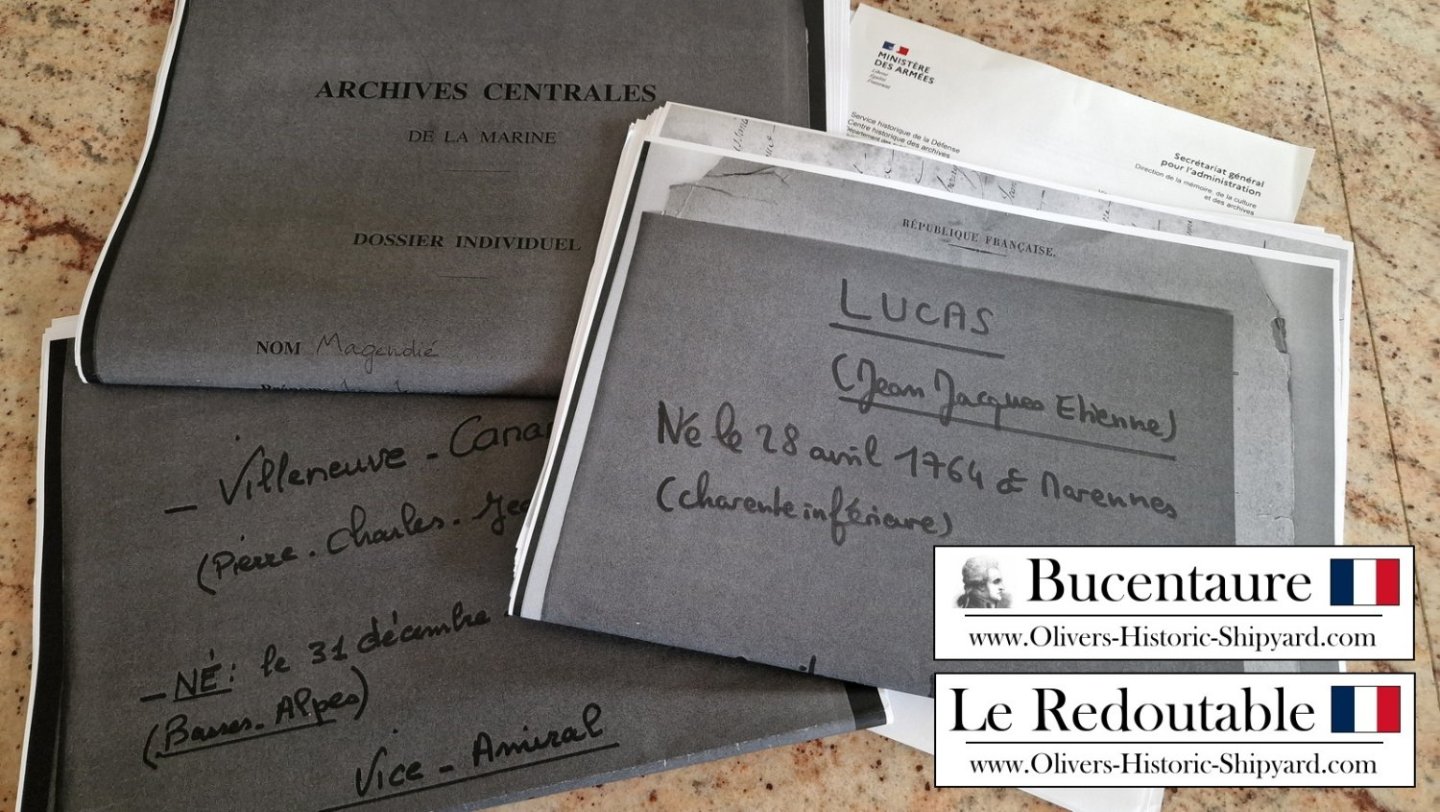

After a sabbatical year, the work on Redoutable continues. I replaced my big tablesaw for a bandsaw and i did some modifications in my lightsystem to get more light in the middle of the ship. On the CAD i added a lot of deckdetails, now i work on the riders to check the points on the keelson. On the model i added 58 fillingpieces with drainingholes. Every one is a individual part for a individual place. I shaped the portside and starbordside of the innerhull, the starboardside looks very good, the portside maybe 85%. Next step will be the keelson.

-

ancre La Belle 1684 by Oliver1973 - 1/36

Oliver1973 replied to Oliver1973's topic in - Build logs for subjects built 1501 - 1750

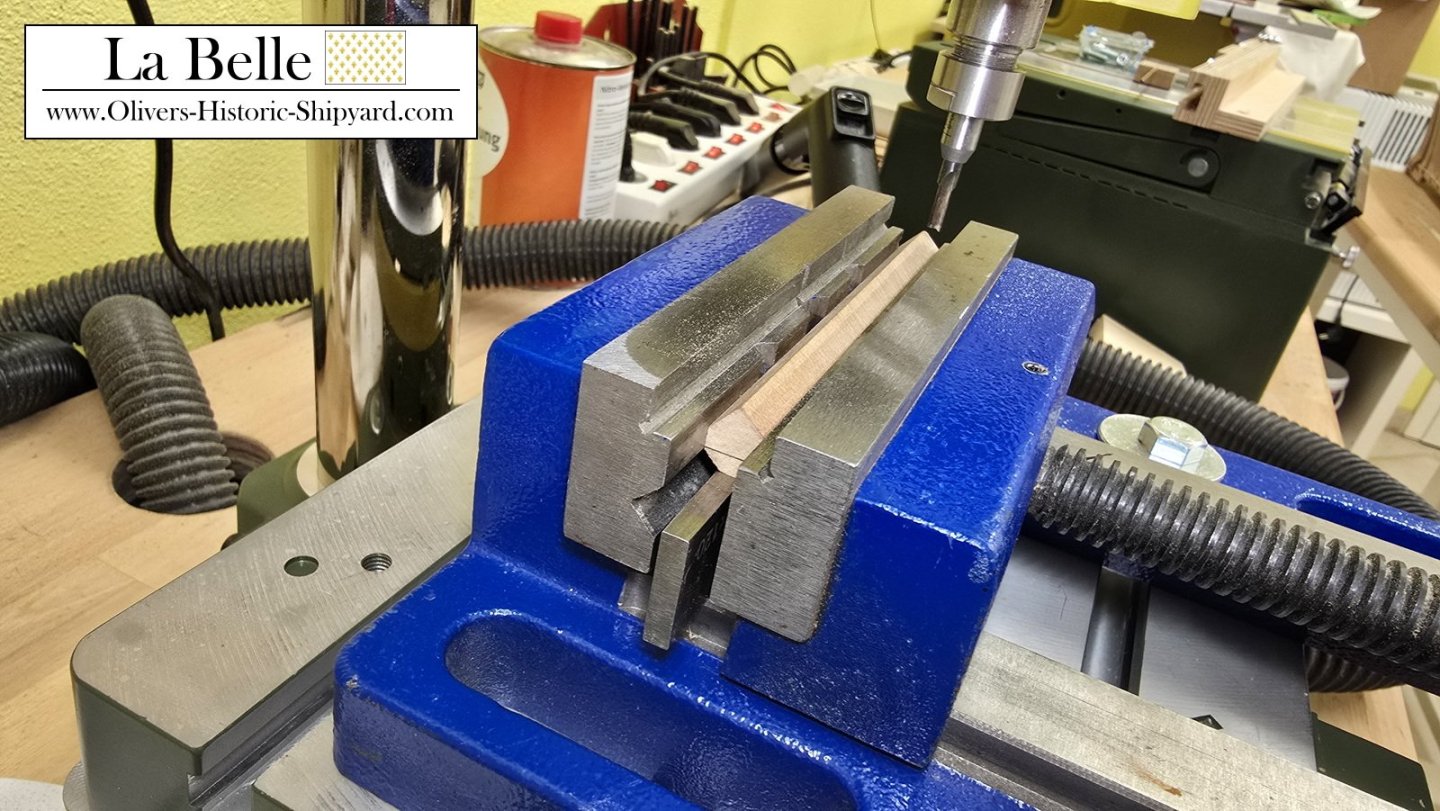

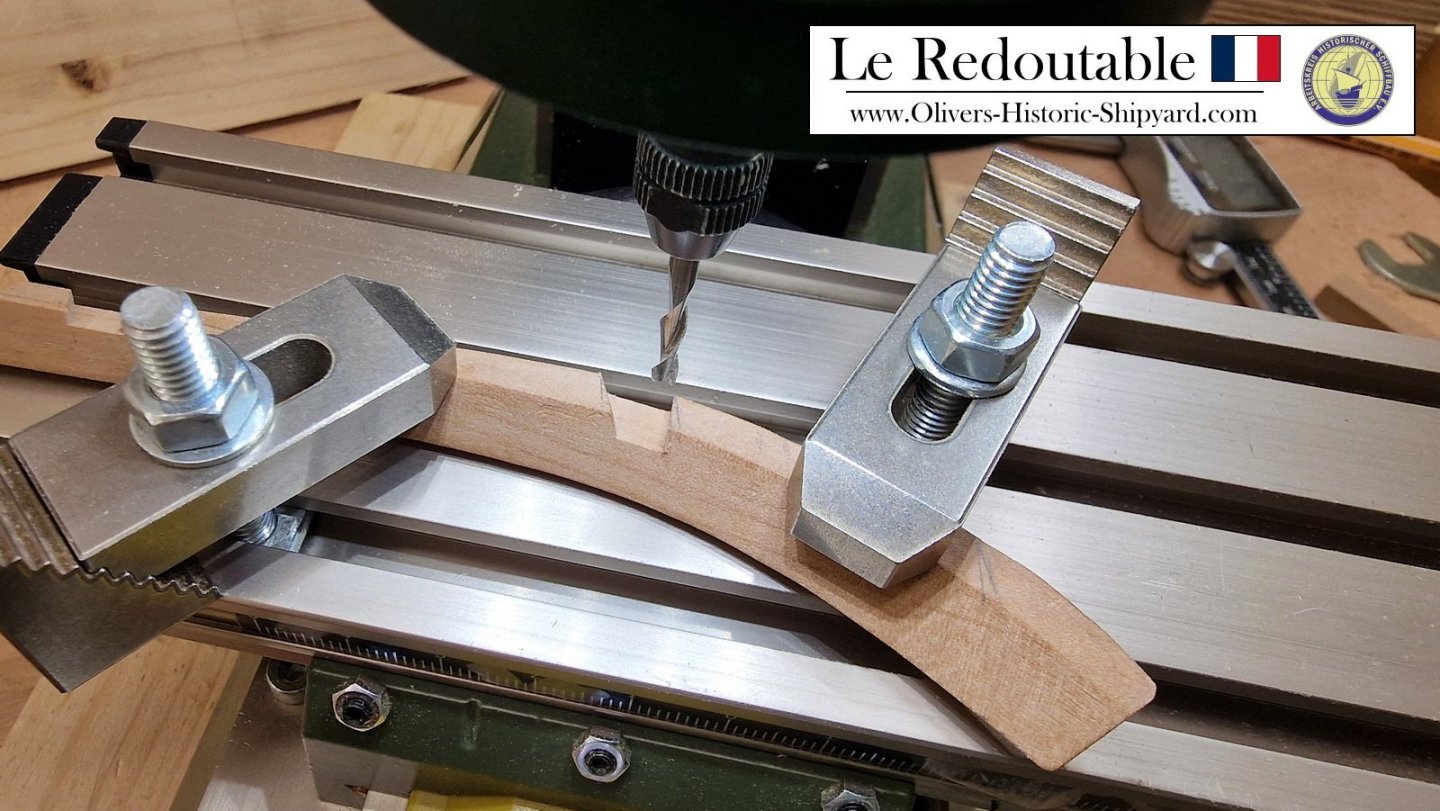

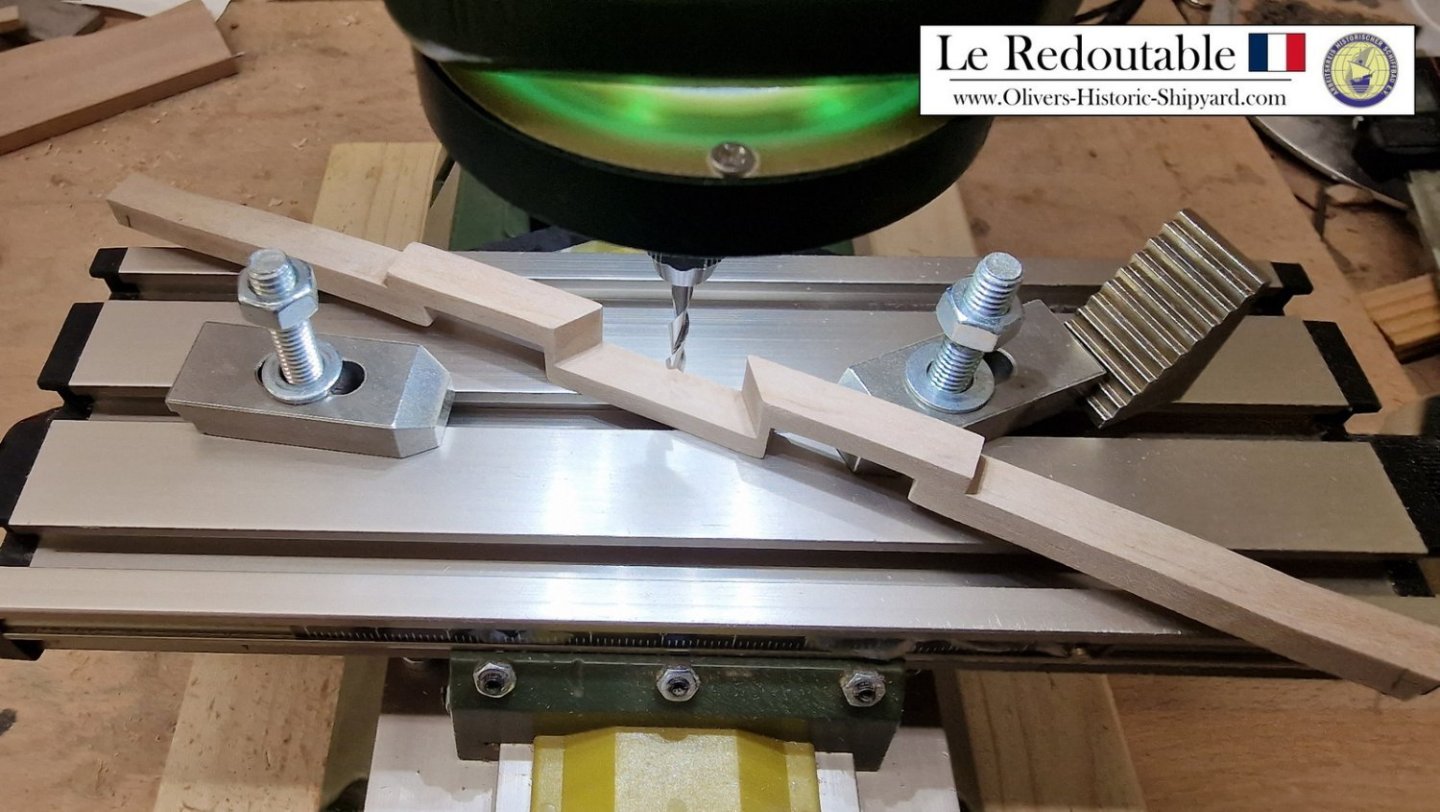

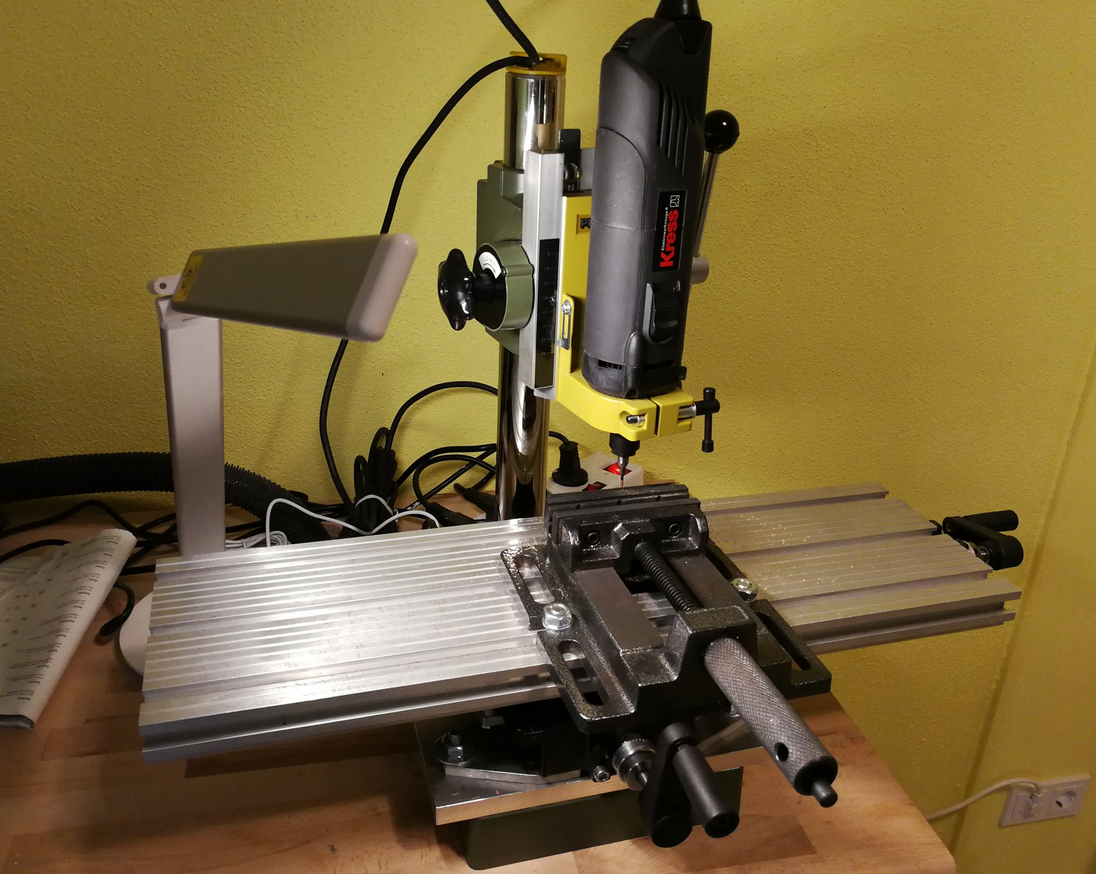

@Kranck Sorry, i was offline from the shipbuilding for a time. I use this milling machine. Its a self-made combination because in my eyes there is no milling machine in the market for our type of work. The MF70 is a very good machine, but with limitations. But for small parts it´s a good choice. The same is with the Unimat. If you work on bigger projects, you will run as well in limitations.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.