-

Posts

283 -

Joined

-

Last visited

About The Bitter End

- Birthday 07/23/1987

Contact Methods

-

Website URL

www.langdam.co.za

Profile Information

-

Gender

Male

-

Location

Koo Valley, Montagu, South Africa

-

Interests

Carpentry, blacksmithing, maritime history, agriculture, reading

Recent Profile Visitors

-

scrubbyj427 reacted to a post in a topic:

In which offense is taken (or, "hey! I resemble that remark")

scrubbyj427 reacted to a post in a topic:

In which offense is taken (or, "hey! I resemble that remark")

-

vvvjames reacted to a post in a topic:

In which offense is taken (or, "hey! I resemble that remark")

vvvjames reacted to a post in a topic:

In which offense is taken (or, "hey! I resemble that remark")

-

Keith Black reacted to a post in a topic:

In which offense is taken (or, "hey! I resemble that remark")

Keith Black reacted to a post in a topic:

In which offense is taken (or, "hey! I resemble that remark")

-

The Bitter End reacted to a post in a topic:

In which offense is taken (or, "hey! I resemble that remark")

The Bitter End reacted to a post in a topic:

In which offense is taken (or, "hey! I resemble that remark")

-

Bomber_County reacted to a post in a topic:

Planking precision and wood filler

Bomber_County reacted to a post in a topic:

Planking precision and wood filler

-

The Bitter End reacted to a post in a topic:

Constitution "Mystery Skylight"

The Bitter End reacted to a post in a topic:

Constitution "Mystery Skylight"

-

Mike Y reacted to a post in a topic:

Help with Fusion CAM for CNC

Mike Y reacted to a post in a topic:

Help with Fusion CAM for CNC

-

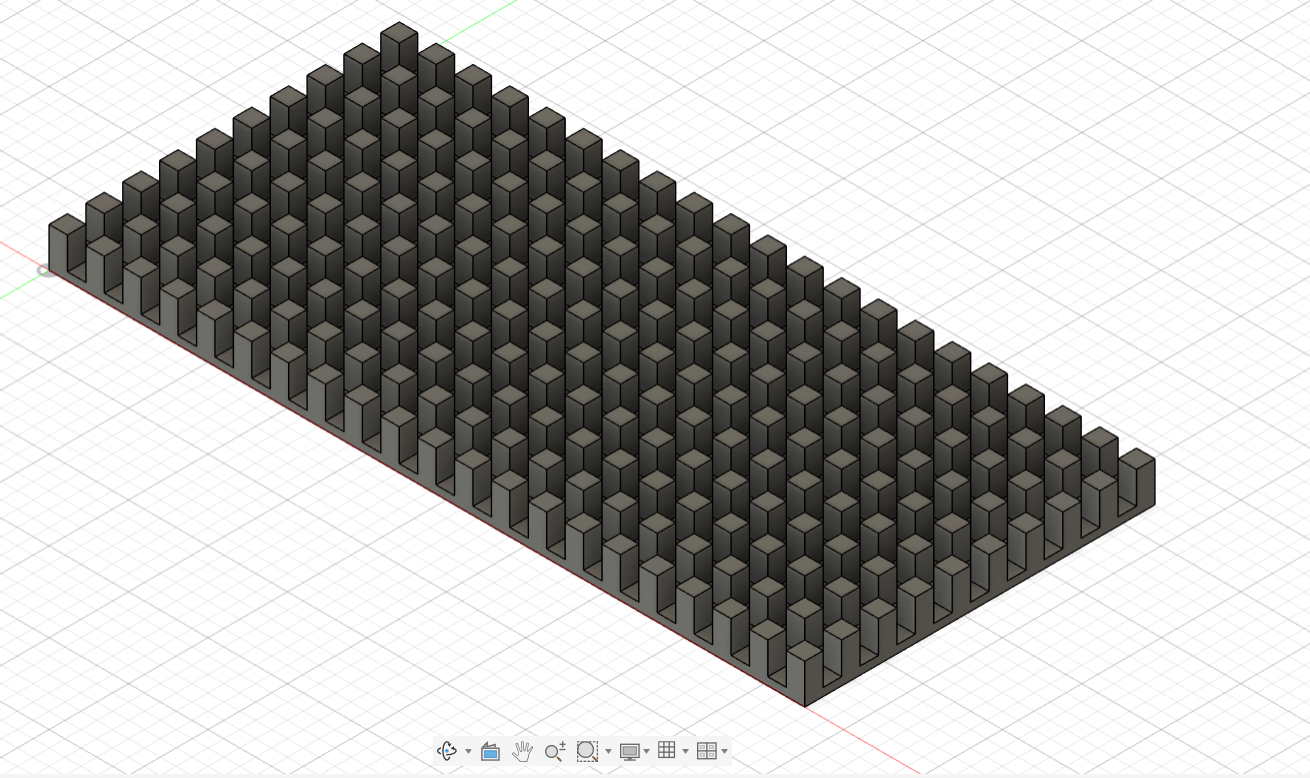

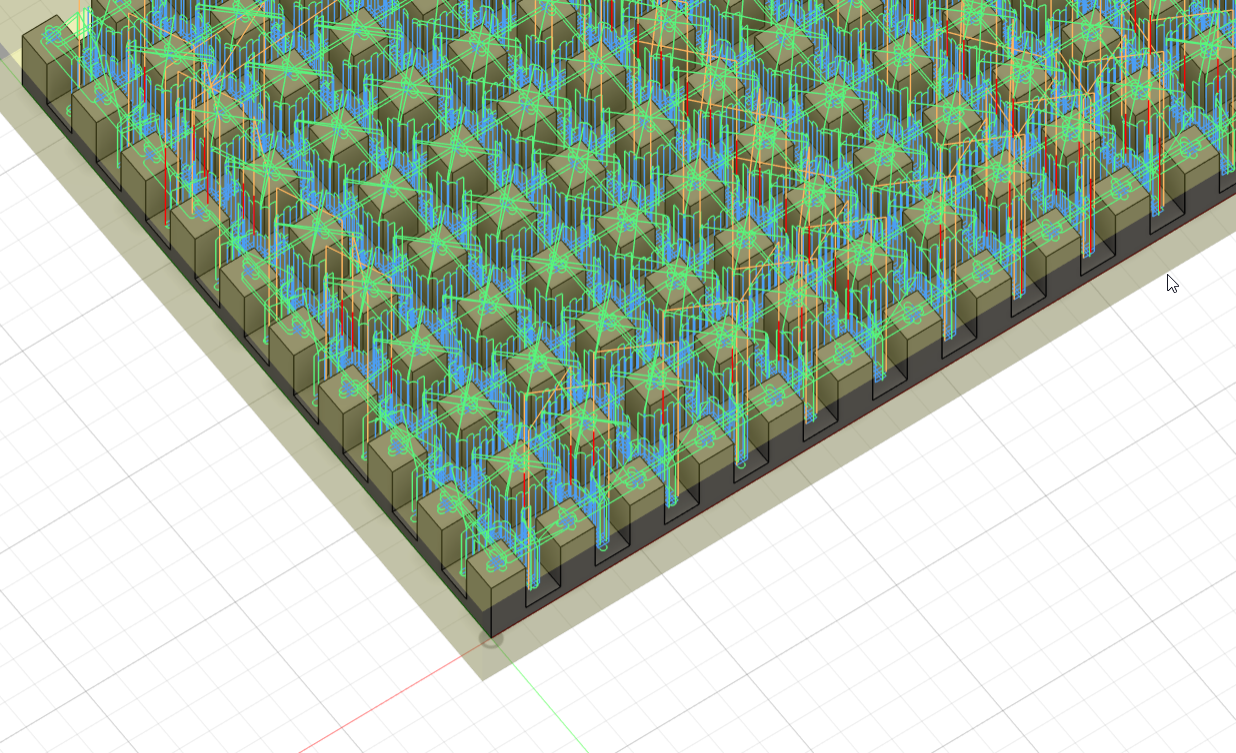

Good morning Everyone I recently got myself a desktop CNC in the hope of expanding my skill set in general, as well as perhaps creating certain parts for my current and future models. I am reasonably tech savvy and I have found Fusion to be fairly user friendly and I am enjoying the process of learning how to use the software. I have however hit one major hurdle and I was hoping that one of you ginfted individuals could help. I created this model for hatch coaming....(the grating running in the opposite direction will be slotted in later, this approach was taken from @mtbediz) My issue is that instead of a logical toolpath which simply runs up and down the X and Y axis to create these slots, cat creates the most absurd tool paths, which have also resulted in 4 broken end mills. Any advice on how to improve this, or even a suggestion on a course or resource to improve my skills, would be hugely appreciated, I have spent hours battling with this issue without any success. I am a complete newby so I'm hoping the solution is a simple one which I have just overlooked. Cheers Haiko

-

Russ2025 reacted to a post in a topic:

Fund raising

Russ2025 reacted to a post in a topic:

Fund raising

-

Fund raising

The Bitter End replied to Russ2025's topic in Using the MSW forum - **NO MODELING CONTENT IN THIS SUB-FORUM**

Absolutely, it certainly is. But I think it might help certain members if one could navigate directly to the donate page by clicking on the banner at the top of the page in the same way one navigates to the ship modelers handbook for example. -

Russ2025 reacted to a post in a topic:

Fund raising

Russ2025 reacted to a post in a topic:

Fund raising

-

Fund raising

The Bitter End replied to Russ2025's topic in Using the MSW forum - **NO MODELING CONTENT IN THIS SUB-FORUM**

Could someone perhaps tie a link directly to the donate banner at the top of the page? It might make it easier for some users and a fraction less friction always helps... -

The Bitter End reacted to a post in a topic:

USNA video, "Ships of 1812"

The Bitter End reacted to a post in a topic:

USNA video, "Ships of 1812"

-

Unegawahya reacted to a post in a topic:

USS Constitution by The Bitter End - Model Shipways - 1:76

Unegawahya reacted to a post in a topic:

USS Constitution by The Bitter End - Model Shipways - 1:76

-

Der Alte Rentner reacted to a post in a topic:

USS Constitution by The Bitter End - Model Shipways - 1:76

Der Alte Rentner reacted to a post in a topic:

USS Constitution by The Bitter End - Model Shipways - 1:76

-

Der Alte Rentner reacted to a post in a topic:

USS Constitution by The Bitter End - Model Shipways - 1:76

Der Alte Rentner reacted to a post in a topic:

USS Constitution by The Bitter End - Model Shipways - 1:76

-

Thanks for the help! it never ceases to amaze me just how much worse a photo can look than the real thing. You are spot on in this case, the effect is entirely more natural AND obvious on the real thing. Cheers Haiko

- 233 replies

-

- Model Shipways

- constitution

-

(and 5 more)

Tagged with:

-

Just a really quick one this morning. Thanks to the prompting and excellent presentation by @Thukydides I decided to take another run at the gun port painting. It has made a huge difference to the feel of the model and I am very grateful that I got that little push to improve my work in this way. I look forward to getting better at this ability and hopefully translating that skill onto the rest of the models paintwork. This simple upgrade was achieved by reading @Thukydides excellent presentation and applying what I learned in the form of 2 edge hilights, one of pure vallejo flat red and one of vallejo flat red mixed with vallejo yellow ochre followed by a glaze of watered down red to make a less hard gradient.

- 233 replies

-

- Model Shipways

- constitution

-

(and 5 more)

Tagged with:

-

Good Morning to you You are right about the shortcomings of the methodology and its definitely worth considering for the rest of this build as the handful of colour resources available will most likely be used over and over again. Thank you so much for sending me that information. I will climb into it immediately. I would like to use this opportunity to improve as many skills as possible so I am happy to spend some time learning how to improve my painting using your information as a resource. I also always endeavour for my work to look good from 1 ft away although I realuse that is more of a goal than a reality! I am in no rush to get this done so why not make each part as perfect as I can make it. This is my second build after my pegasus and I have realised that my joy in this hobby comes just as much from the process of learning as it does from the actual construction of the model. Please keep your comments coming on this build, I would like to make something special so your experience is very welcome. Cheers Haiko

- 233 replies

-

- Model Shipways

- constitution

-

(and 5 more)

Tagged with:

-

Good Morning My apologies for the delay, things have been rather crazy. Le time begin by thanking you for your detailed input here. You are absolutely correct on all of that. The nuance of the various colours is very hard to predict. Particularly when we are dealing with the number of variables which we find in the resources available. Intended perception, lighting, deterioration and infact the errors which the original artist may have made. I am quite obviously not an artist of any kind but even when trying to match a single colour in a single scenario with modern paints and tools it took me ages and its definitely not a perfect match. I would be really interested in seeing your presentation! Where can I find it? I have looked high and low for exactly that but find very little, most of the information I am getting is coming from miniature wargaming(warhammer mostly) but the scale is very different and a whole different set of rules apply. I was particularly interested in if I should be applying some of this technique to the pale(a large flat pack strip but I simply did not know how so I abandoned the Idea. Its not too late to change gun port colours so any info would be a huge help. Thanks again Haiko

- 233 replies

-

- Model Shipways

- constitution

-

(and 5 more)

Tagged with:

-

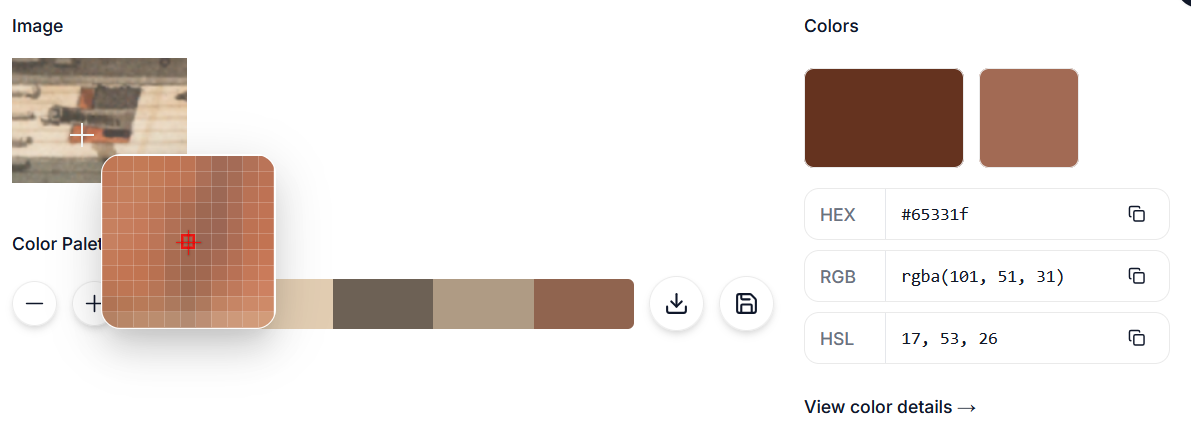

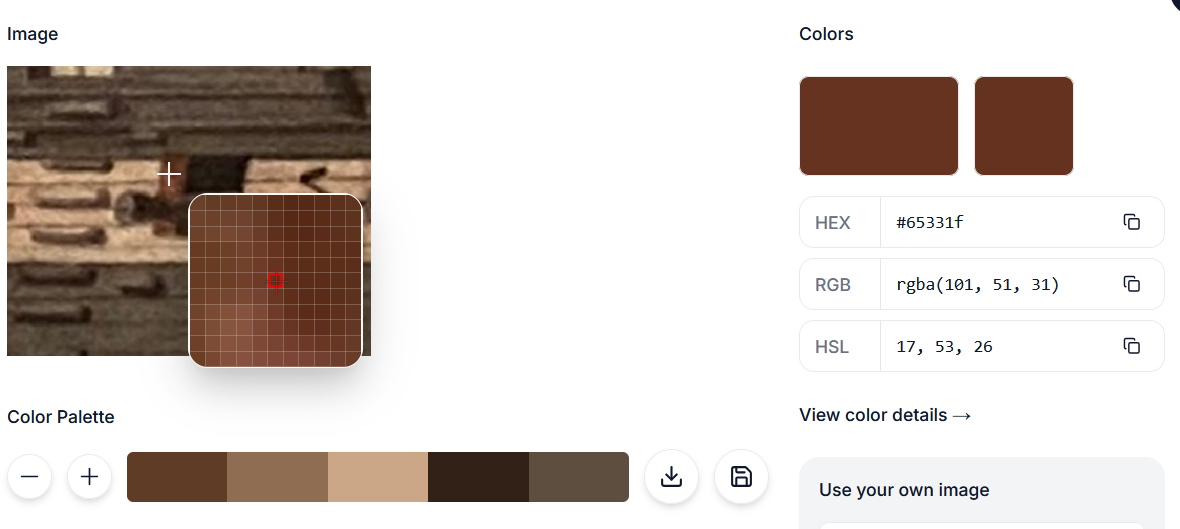

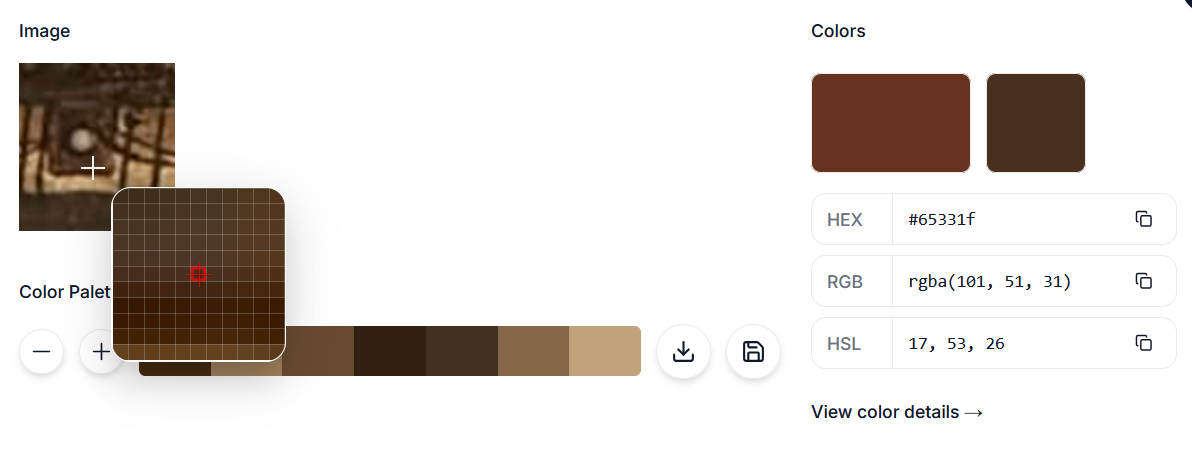

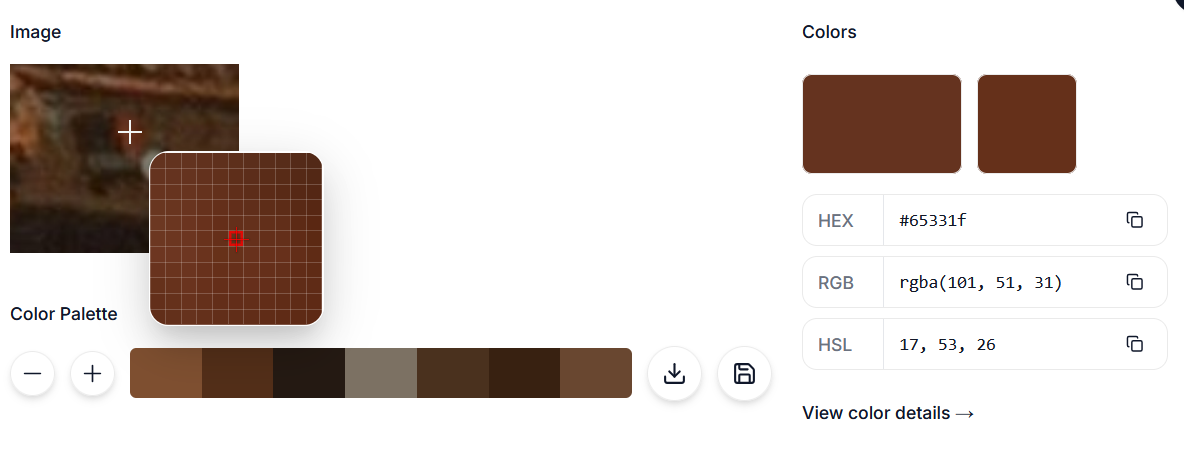

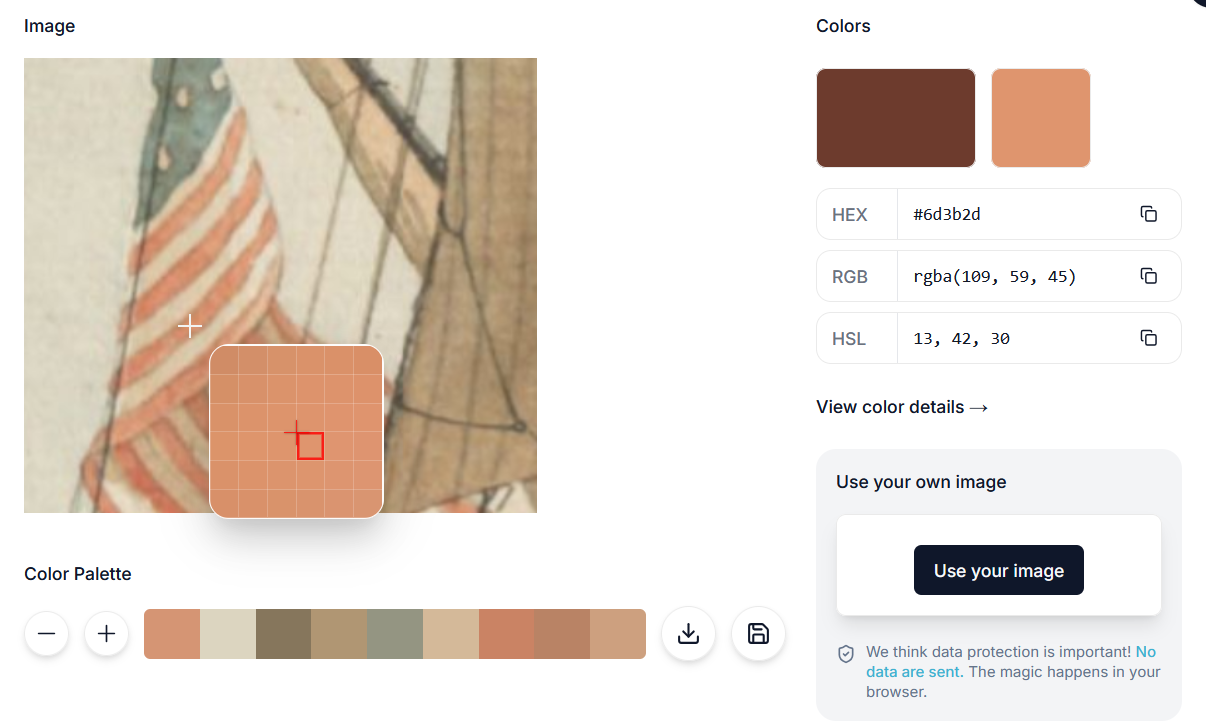

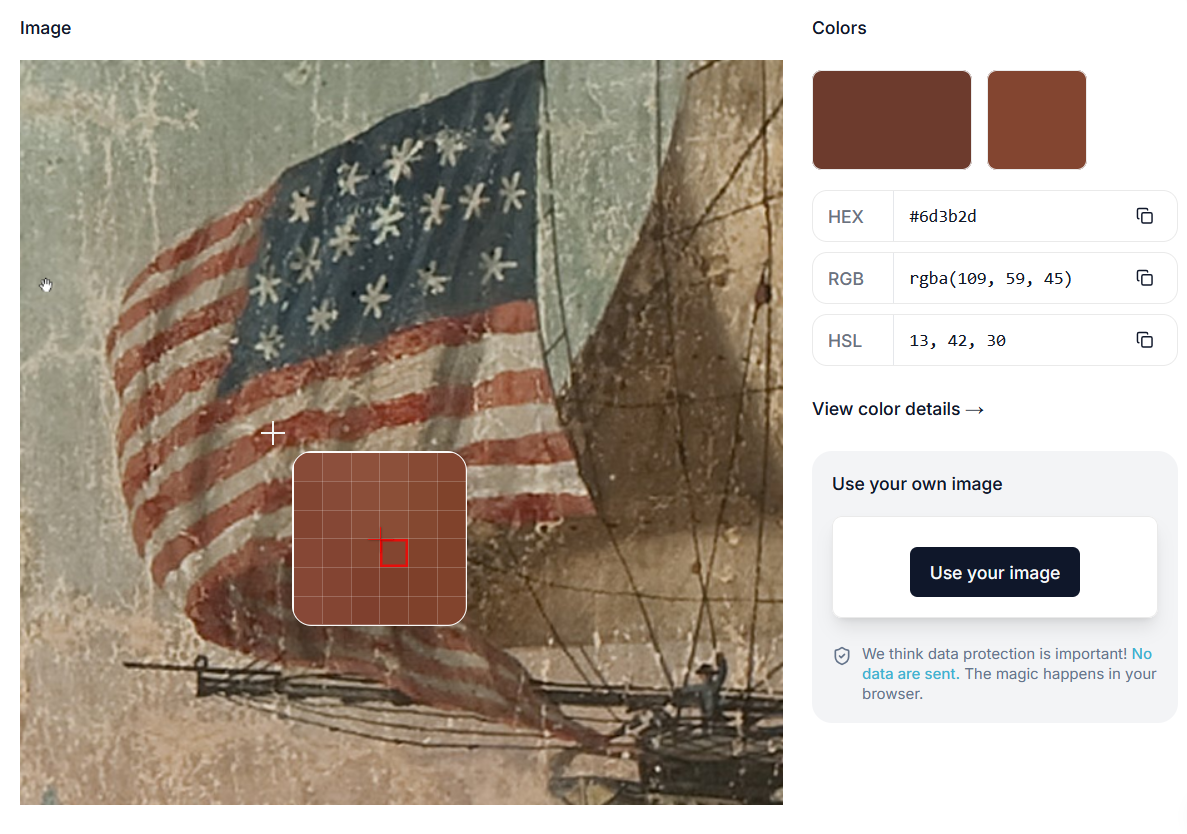

Hello everyone. Largely due to a very busy week, I didn't do a whole lot on Constitution except for some repairs to the gun deck(lessons learned will be shared in my spar deck post if I ever get there), a bit of tinkering on a stand to replace the pillow I'm currently using and a bit of research and execution on gun port painting. This was not the world's most complex process but it was a fairly agonising decision to make. Various rips records refer to "red" paint being part of the ship's supplies as mentioned in "Close up": Aug 1803 -- Paint pigments in ship's stores included 305# black, 3 cwt white lead, 3 cwt yellow, 50# green ("verdigris"), and 28# red ("vermilion"). [Receipt for John Osborn, 1 Aug 1803, Samuel Brown Papers, MHS.] 11 Jan 1804 -- Received 15 kegs of yellow ochre, 2 of red paint, 7 small ones of black paint, and 50 gallons of black varnish. [Ship's log, DNA.] This obviously does not tell us anything at all about where the paint was used or infact what exactly was meant by "red" It is fairly safe to assume that the colour that they are referring to is red ochre, a shade of red with a fair amount of brown in it. Below is an example of a building restored to its appearance at the time of the constitution launch showing just one of many shades of red ochre. This leaves us with 4 paintings by Roux and Corne to find evidence for the colour we need. My approach began by selecting a portion of each painting where the colour of the gun port lining can be seen and putting it into an online colour analysis. The smaller square of colour in the upper right corner indicates what the actual colour of the specific selected pixel is:(I realise the many flaws in this method but it gives us an indication....all rather brown After some discussion with good old Marcus we agreed that the colour shown on the painting may be wrong for 2 reasons. Firstly, the artist wished for the viewer to experience a certain colour, depending on lighting etc that may require use of a brown to show a reddish colour. In addition and arguably more importantly we don't know how paint colours deteriorated over the 200 odd years since these were painted. That then led me to the next step of the investigation: to pull the colour from the American flags which would all have been a fairly standardised bright red colour as can be seen in this example which flew on the Constitution around 1816 This resulted in surprisingly brown colour samples for something which is known to be red: This colour deterioration clearly showed that the colour of the gun port lining was meant to be closer to red than brown. The next logical step was to feed AI all the data I had from all the paintings and tell ChatGPT to do a colour correction for the gun ports based on the known colour deterioration of the flag. The result was surprisingly pleasing. Without any other prompting it gave me one value, HEX #A3050F: This seemed like the perfect balance between a modern and historical red. The application of this chosen colour was achieved as follows: 1. masked off the hull completely and applied a spray-painted layer of rustoleum matt black primer 2. Applied a thin coat of Vallejo "Red"(70.926) with a tiny tiny amount of Vallejo "Black"(70.950 and a drop of Vallejo "Cavalry brown"(70.982) with a single drop of paint retarder. Exact ratios are hard to describe but it's mostly red, a smidgen of black and a drop of brown) 3. I then applied another thin coat over this of "Red" with a small drop of Vallejo "Carmine Red"(70.908) 4. I finally finished this with a drybrushing of pure "carmine red to highlight the edges and to give the ports a bit more of a natural look. This recipe is by no means perfect but it worked for me. Now unless anyone has a warning of some sort for me I believe my next step is to begin the Quarter Galleries. Have a great evening Cheers Haiko

- 233 replies

-

- Model Shipways

- constitution

-

(and 5 more)

Tagged with:

-

The Bitter End reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

The Bitter End reacted to a post in a topic:

USS CONSTITUTION by Brian Falke - BlueJacket Shipcrafters - Scale 1:96

-

The Bitter End reacted to a post in a topic:

HMS Perseus by Thukydides - 1:64 - POB - Sphinx Class 6th Rate

The Bitter End reacted to a post in a topic:

HMS Perseus by Thukydides - 1:64 - POB - Sphinx Class 6th Rate

-

Marcus.K. started following The Bitter End

-

HI Ronald, thanks for your cheerleading, comments like that really help when the going gets tough The upper moulding wood was selected kind of by accident. I was making a table from South African Yellowwood which I happened to have in my workshop. When I finished the table I ended up with some very uniform, very thin offcut strips which I decided might come in handy on this build. lo and behold they worked perfectly for the upper edge of the transom. so short answer...South African yellow wood

- 233 replies

-

- Model Shipways

- constitution

-

(and 5 more)

Tagged with:

-

The Bitter End reacted to a post in a topic:

USS Constitution by The Bitter End - Model Shipways - 1:76

The Bitter End reacted to a post in a topic:

USS Constitution by The Bitter End - Model Shipways - 1:76

-

The Bitter End reacted to a post in a topic:

USS Constitution by The Bitter End - Model Shipways - 1:76

The Bitter End reacted to a post in a topic:

USS Constitution by The Bitter End - Model Shipways - 1:76

-

The Bitter End reacted to a post in a topic:

USS Constitution by The Bitter End - Model Shipways - 1:76

The Bitter End reacted to a post in a topic:

USS Constitution by The Bitter End - Model Shipways - 1:76

-

Just a quick one this evening, we are in the middle of our harvest and everything is insisting on breaking leaving very little time for the hobby. After living in denial for some time I realised that I would have to after all do some form of moulding on the transom(If this is the incorrect term please correct me). The only specific evidence for this which I can find is in the close up photo taken of the Isaac Hull Model by @Force9(thank you for these great photos they have been a huge help) here we can see some moulding around the Quarter gallery portions. Unfortunately the stern was closed in the 1812 configuration so there is no example of how the upper transom would have looked but I decided this was good enough for me to try and copy. As I am writing this I am beginning to wonder if this was a mistake but that ship has sailed...if you will To get this result I filed a profile into a sacrificial box cutter blade: After a trial or two to determine a suitable profile I cut this into the transom and went over it with some steel wool to smooth things out And painted it black as well as touching up the ochre.(The notches are to allow a tight fit under the bulkheads when pressed into place) Thats it for tonight...Tomorrow(hopefully) painting gun ports! Cheers Haiko

- 233 replies

-

- Model Shipways

- constitution

-

(and 5 more)

Tagged with:

-

Thank you, a bit of encouragement is always nice. The positioning is indeed a strange element and I also can't think of what else they could possibly be other than vents of some kind. It is of course, possible that they were angled as you suggested; this would solve the issue. I will definitely keep looking into this and if I find anything more concrete, I will be sure to pass it on. Cheers Haiko

- 233 replies

-

- Model Shipways

- constitution

-

(and 5 more)

Tagged with:

-

Oiling The hull - I realised that I failed to mention a pretty significant mistake from my initial application of Osmo Poly X and I felt that this warranted a repost incase someone made the same mistake as me. When they say mix the the product prior to application, what they mean is MIX THE PRODUCT PRIOR TO APPLICATION! I failed to do this with my first coat and the product came from a tin which had been standing in my workshop for some months. This resulted in a very unsatisfactory finish which i had to try to remove with Mineral spirits, I think I got most of it taken off and the final result was still ok but the mess to get this resolved was less than ideal. all that being said ..... back to the original post One of the best parts of the build. Oiling the hull. The hull was sanded back to 400 grit until all scratches were removed(kind of) and then given 2 very thin coats of Osmo Polyx Oil 3062 Clear Matt , this is a beautiful product. My only tips are to apply it with a soft scouring pad, to work in circular motions and to be very conservative with quantity. I also applied this over the paint which dried well and gave a lovely satin finish. I know I should really copper or paint this hull but the wood is special to me and I quite like this very unique effect, I hope you all do too and your feedback in welcomed. Cheers Haiko

- 233 replies

-

- Model Shipways

- constitution

-

(and 5 more)

Tagged with:

-

Good evening(or something to that effect) Thanks for taking the time to comment, the matter of the exact number of air vents is a bit of a question and the layout seen in the 1803 Corne painting is not without confusing elements. This is definitely something I will continue to look at. Your referenced drawings are great but I must say I did also think that their orientation relative to the deck beams was a little surprising. Unless perhaps they are showing cuts into the timber to accommodate internal ventilation as shown here: https://prints.rmg.co.uk/collections/ship-plans/products/ventilation-openings-for-three-deck-ships-of-war-j7328 A bit of a rummage around the archives brought up this equally confusing image. are these perhaps air vents?? And if they are then I would definitely say that this is a bit of an excessive amount! https://arkivalieronline.rigsarkivet.dk/da/billedviser?epid=17149179#207980,39521461 Either way, your input is appreciated and I hope that you continue to share your views. Cheers Haiko

- 233 replies

-

- Model Shipways

- constitution

-

(and 5 more)

Tagged with:

-

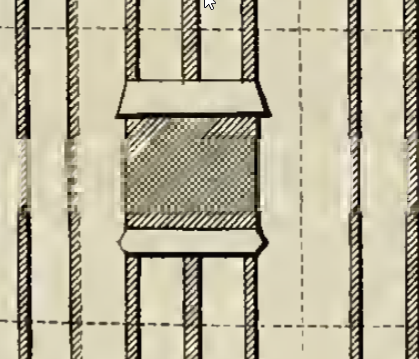

Gun Port Linings Gun port linings next, It would appear that the constitution didn not have fixed(Hinged) gun port lids at the time of launch but rather removable split lids. There is no indication of port lids at this point on any of the paintings or drawings of her or her sister ships in the early years of their existence. There may well have been port lids on the forward most ports and possibly coverings on the aft most ports but I will get into that detail at a later stage. For now our only concern is gun port linings. The only place where we can see these linings to any real degree is from the 1812 Isaac Hull model and Perhaps the Corne 1803 painting. In these two sources the ratio of lining to openings seems fairly consistent. If we assume an outer port opening of 3ft 3 inches as indicated in the 1794 body plan by Joshua Humphreys then we can deduct that the inner lining of the port is 4inches wide(1.3mm at scale). The only other piece of Evidence that was vaguely relevant is the orientation of the joints. This detail is purely academic as the ports will be painted but it is worth mentioning that David Steel shows the port linings to be the exposed frame section with 2 horizontal upper and lower sills mortoised into them. This means what would be visible to the viewer is 2 horizontal joints at the upper edge of the gun port and 2 miter joints at the lower edge of the gun port once planking has been installed. I bulk cut the 120 side to just slightly longer than their correct length, then bulk squared off one side of each plank and marked their correct length with pencil. I first installed the upper and lower sills and then squeezed the side sills in to seat them more tightly. I made sure that the edges were slightly too close to the outer planking and then tapped them to the correct depth using this little jig. Once all the sills were in i gave them a good buff with some steel wool and dragged a sausage of steel wool through each port to clean up the edges. I then made up a mix of wood glue and wood filler to make a gooey filler and used this to tidy up any little gaps between the outer and inner framing. This was applied with a small silicon sculpting tool. This is the almost final result, These ports will be painted in red ochre but that is a task for another day. Thats all for now. Next up is Quarter Galleries, an adventure on its own. Cheers Haiko

- 233 replies

-

- Model Shipways

- constitution

-

(and 5 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpeg.5d86b17d78477d3e2cfca4daa31dee09.jpeg)

.thumb.jpeg.e9400f8f48e0141bbca2548c73af157b.jpeg)

.jpeg.9d0a3dc4a2655058cbb891da980075d6.jpeg)