Steve20

NRG Member-

Posts

168 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Steve20

-

I could use some advice here. What’s the best method of cleaning in preparation for the poly? Air blowing and wiping down with a lint free cloth doesn’t seem to remove all the dust and I’ve read on the forums of people using thinners and damp cloths. Should I be using something like this to wipe down the Pear before applying the poly? Sorry if this question is a bit basic, but I’ve not used poly before.

-

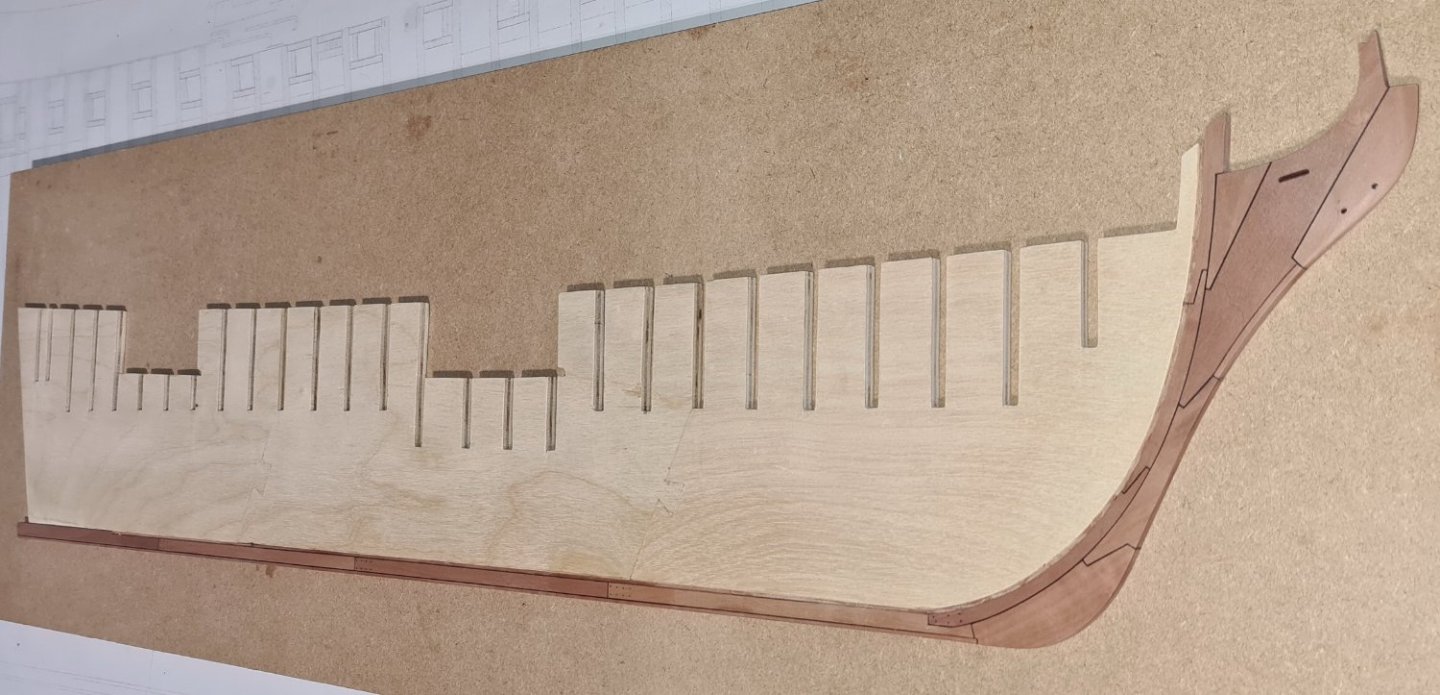

I’m back here after some time and am again making progress. I’ve cut the Castello and Pear into billets between 16”and 23” long, and as I’m going to use the Pear for Winchelsea, I’ve used Chucks materials lists for a take-off of the strips and sheets required and milled these in advance. Because the sycamore doesn’t work or look as good as the other wood, I’ve left this to one side for now.

-

Just to close this topic I’d like to add the following: Thanks to No Idea for the (UK based) Tuff Saws recommendation, I now have a good selection of excellent band saw blades which I am successfully using. However, I couldn’t find suitable slitting blades for the Proxxon FET table saw and I wasted quite a bit of money on blades that were not satisfactory. Also, I found that when milling strips with the FET it was difficult to achieve consistent accuracy, therefore, I accepted UK shipping and import charges and bought a Byrnes. Jim recommended the blades I needed (they were, of course, readily available) and I’m now milling wood easily and to fine tolerances. I wish I had bought the Byrnes in the first place. I also bought a Byrnes thicknesser and this solved my thicknessing problem. Using a sanding rather than the Proxxon DH40 cutting mechanism, the Byrnes didn’t tear the Pear like the DH40 did when the when the grain wasn’t in the right direction. Although I find the DH40 good for larger billets, the Byrnes is by far the better option for me. I find the milled Castello to be excellent and the Pear is pretty good also, but I’m not happy with the Sycamore and I doubt I will ever use it. I spent a week cutting all the Castello and Pear into billets and milled a large selection of various sized planking.

-

Hi Fred, I purchased the Byrnes Table Saw in March 2022 and with accessories the purchase price was $1,209. UPS shipping to the UK was $300 to give an invoice total of $1,509. Additionally, UPS invoiced me £221.52 for Import VAT and added a UPS Brokerage Charge of £11.50. I bought the Byrnes because I found the Proxxon FET to be limited in accuracy when milling wood and there are very few options for saw blades and accessories for the FET. I also bought the Byrnes Thicknesser at the same time and with a supply of abrasives, and a 6" wedge, the purchase price was $523. UPS shipping to the UK was $245 to give an invoice total of $768. Import VAT was £111.07 and UPS Brokerage Charge was again £11.50. Steve

-

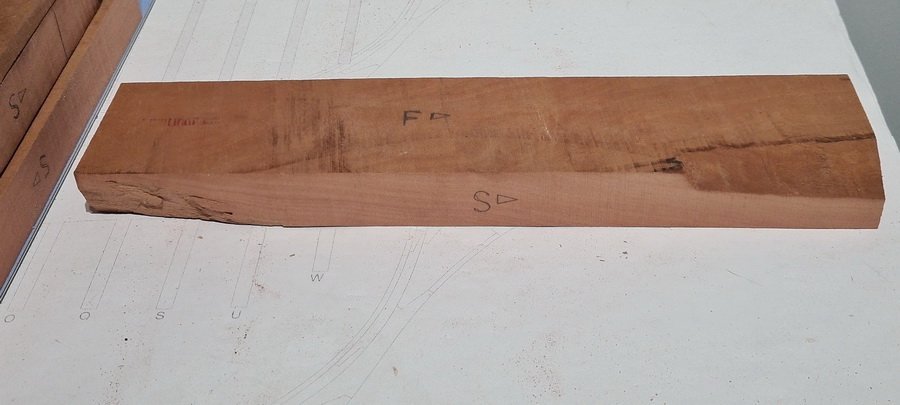

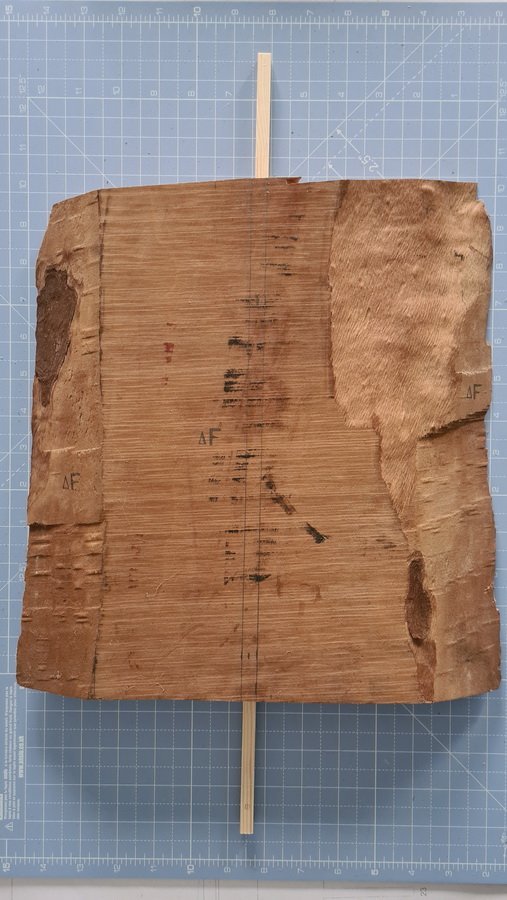

To avoid the thicknesser tearing the wood when it's fed against the grain, I’m marking grain direction with an elongated triangle - it's almost impossible to determine Pear grain direction when pieces become smaller. Also, with a view to milling planks later, I’m marking the Face with an ‘F’ and the Edge with an ‘S’ for Side. I don't use ‘E’ as it looks too much like an ‘F’.

-

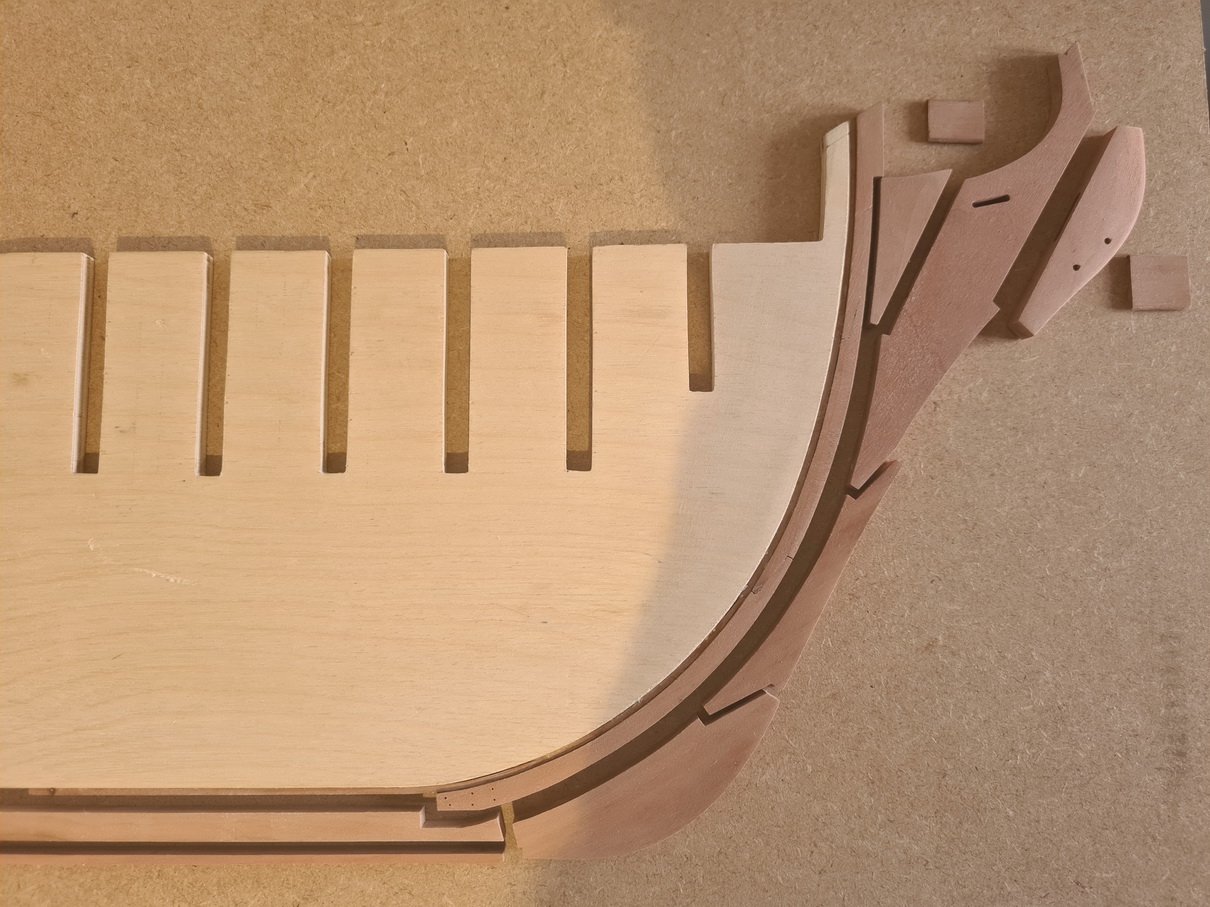

I then used the bandsaw to cut the Pear into billets less than 3 ¼” width as this is the maximum allowed by my Proxxon thicknesser. As the Pear does not have a straight edge, I thought the easiest way to do this would be to glue (Titebond) Pine strips to the underside of the cut timber and slot the strips in to the bandsaw mitre track. I used the thicknesser to size down the Pine and make it a close fit in the mitre tracking.

-

Now the way ahead is becoming clearer, I decided to cut the ½ ft3 Pear and ½ ft3 Sycamore into billets. I used a chop saw for this and cut the 4 pieces into 12 sections of varying lengths: Pear 2x20”2x16” & 2x13”, Sycamore 3x16” & 3x14”. While I was about it I cut half the 1 ½ ft3 Castillo Boxwood into smaller billets as well.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.