-

Posts

75 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by J Snyder

-

Thanks Jim, this is a new hobby as I have gotten older and out of shape I can't do the more physical things I use to do. As I said in my intro I want to make a series of models of the sloop I helped build in the 1970s and this is good practice for that. I am debating whether to build the Model Shipways Lobster Smack or jump right in to working on the Gary Thomas. The kit teaches mold fairing and carvel planking which I have done full scale. I guess I will decide when I am nearer to completing the pram.

- 81 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

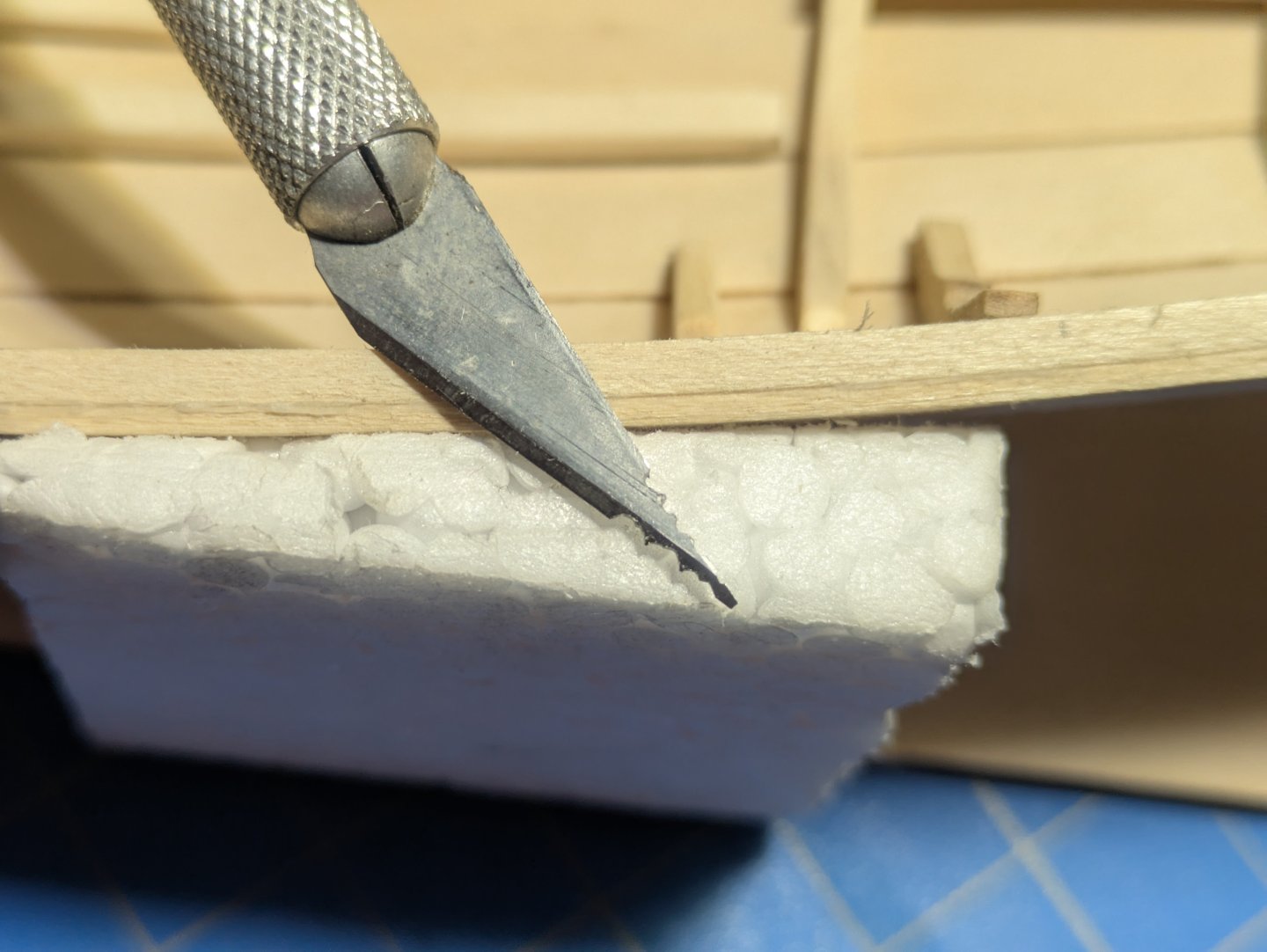

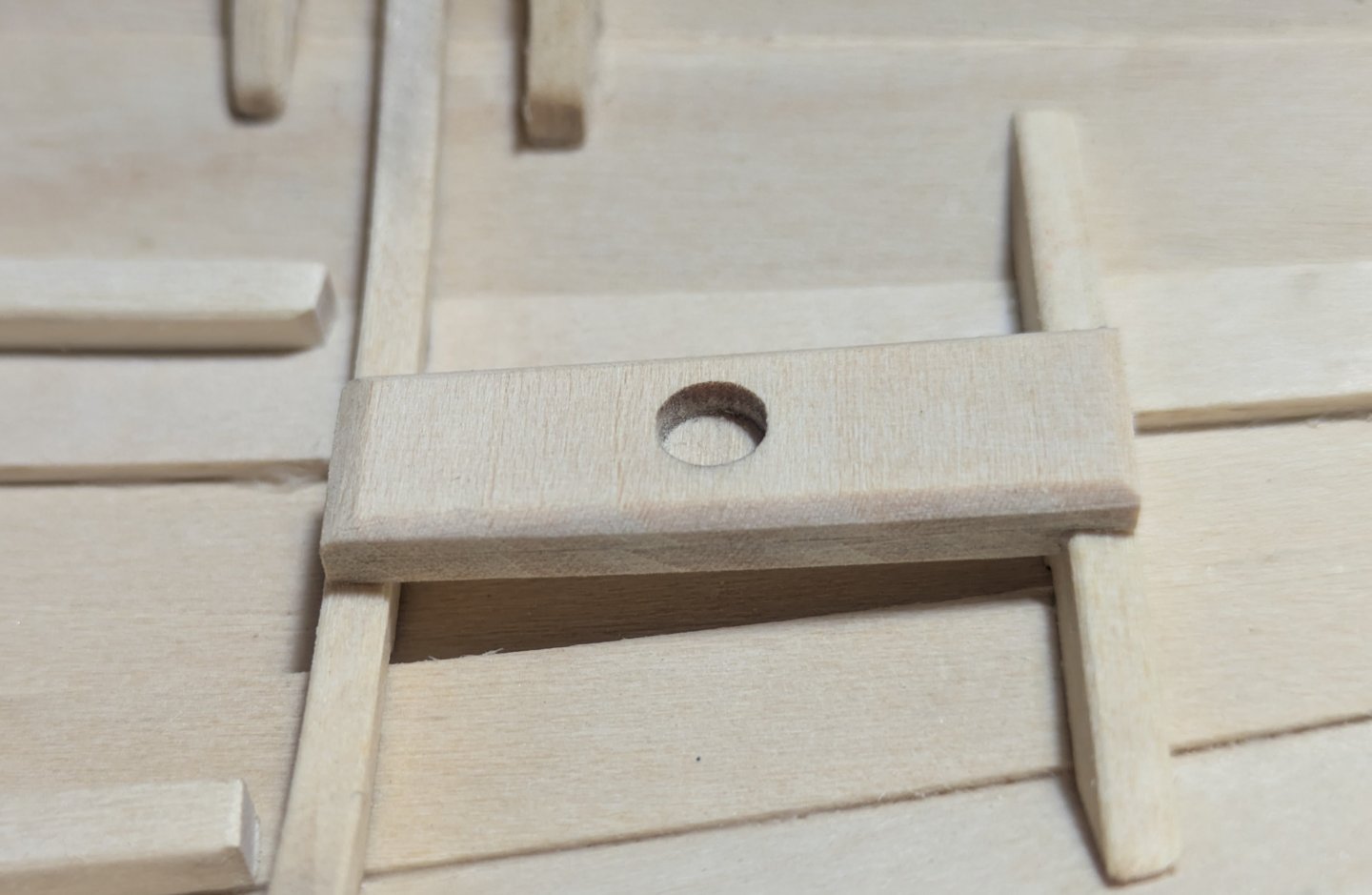

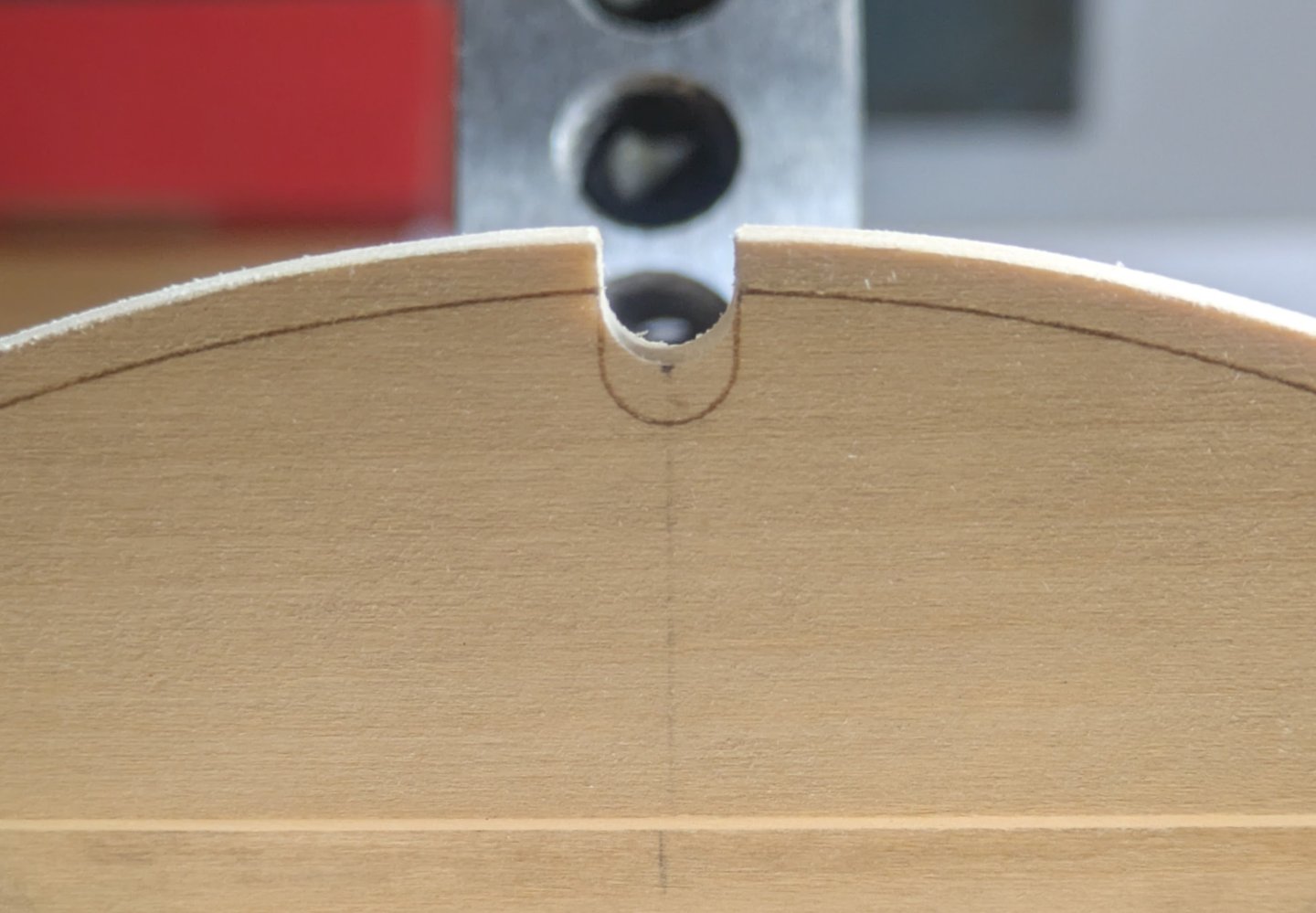

The directions say to drill a hole in the inwale then saw a slot for the chain plate. I drilled two holes then ground down an old blade and worked the wood out with it. The impromptu saw worked ok. I modified the placement of the mast step by notching the front to set better on the frame. I placed the rudder gudgeon pad not where the marks are but where the it is shown in the instructions. It's lower on the transom for better leverage. I see I forgot to fine sand it!

- 81 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

That hair straightener looks the ticket. I will look for one in the thrift stores. Thanks

- 81 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

Making slow progress on the inside of the pram. I installed the main frames perpendicular to the centerline by eye which I didn't like. So when I started on the seat and thwart frames I checked for square by measuring from the bow and stern transoms. As it turned out the eye was pretty good. I trimmed the transoms and filed the slot in the stern. I had a 3/8ths rattail file but it looked to big. I happen to have a 7/32nd (5.6mm) chain saw file that is the same size as the laser mark on the transom. I checked the thwarts to make sure the supports were the correct height. I went ahead and put three supports under the stern sheets you can see it in the back ground. I don't know how many are in the design if i were building the prototype that's what I would do. You can see I am gluing in the floor board cleats and am trying different ways of bending the wood. I bent the planks by soaking them in hot water for a short time then forming them and letting them dry. You can see the results of using my heat gun just to the upper left corner of the 1-2-3 block on the inwale. This time I tried putting the floor board cleats in boiling water then bending and letting them dry. I then remembered I had a Top Flite heat sealing iron so I tried that, the verdict is still out on that one. The heat gun is very hot, a blow-dryer is not hot enough, the heat sealing iron may not heat up enough. I will continue to experiment.

- 81 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks for all the recommendations. you are right there are numerus hobby / art supply stores here. The apple wood that I am collecting is for a future build.

- 81 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

For now I have no other basswood I need to get some. I have a neighbor that is a tree trimmer and brings a lot of wood that he splits into fire wood, He cut down a Apple tree and a Beech tree and gave me some. I cut it and am letting it air dry.

- 81 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks, I'm having a lot of fun and I like working out the challenges. I am going to start thinking about the colors I want. I don't like the red interior that is recommended.

- 81 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

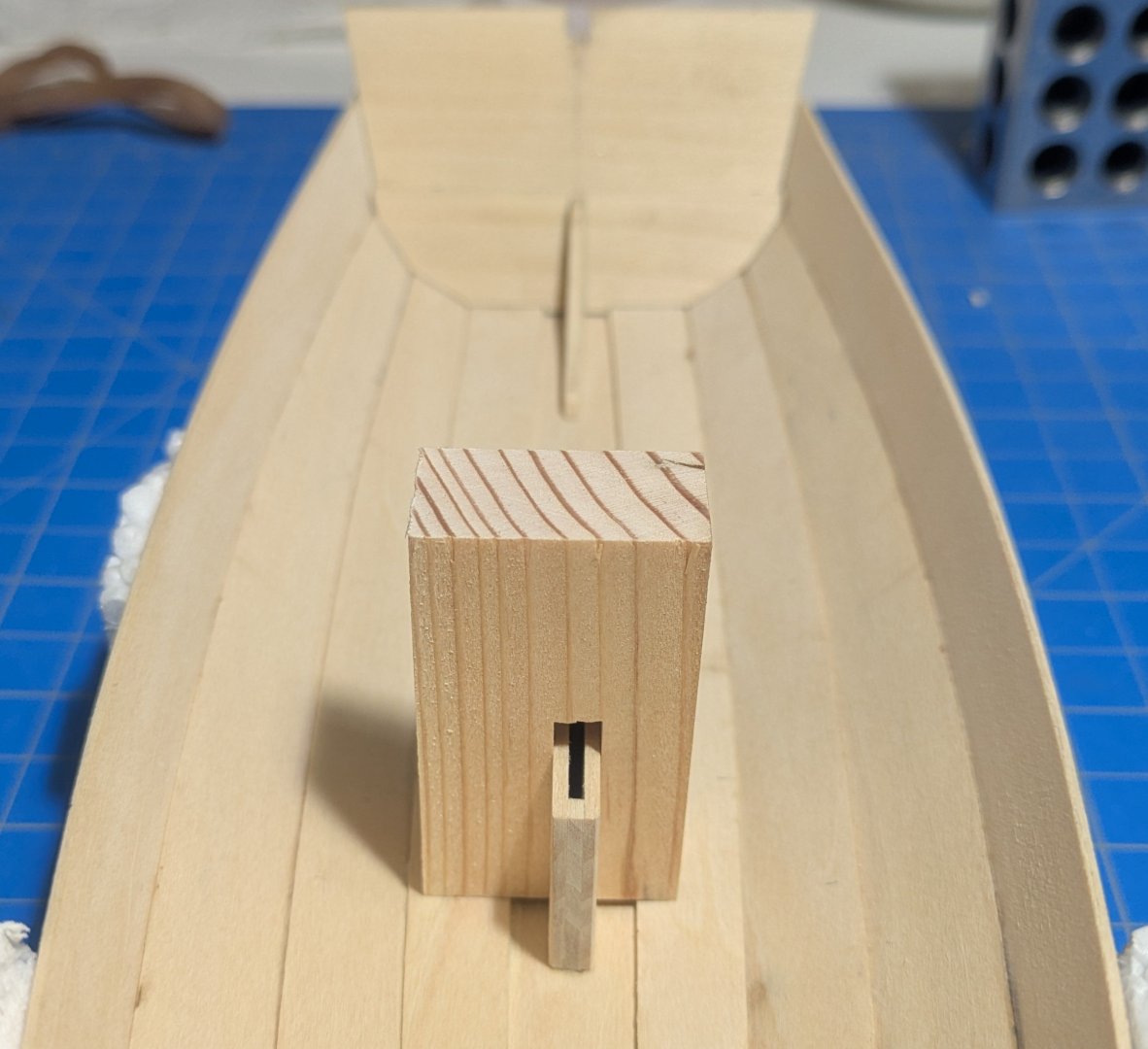

The three frames have been a challenge to get to fit with them vertical. As I mentioned the location of frame 3 behind the center board case uses the cutout in the keel as a reference or 37 1/4 scale inches from frame 2 center to center.

- 81 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

I beveled the outboard sides of the bilge keels. Then put the center board case together and as others have found the slot in the keel is longer the the case. I elected to set the case to the front and will put a filler piece at the back. I made another block to keep the case vertical. I checked the center board in the slot and it's a tight fit already without any paint! I will have to sand both later. Working on the frames. The distance from frame 2 and frame 3 is correct if you use the slot in the keel as the reference instead of the center board case.

- 81 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

The directions state "attach bilge keels along the inboard edge of the garboard strakes in the positions indicated" ? I scaled the overlap with the skeg using the non scale drawing on page 3 and estimated it at scale 6 1/2 inches. That's most of the outer hull done. Now the inside.

- 81 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

- 81 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

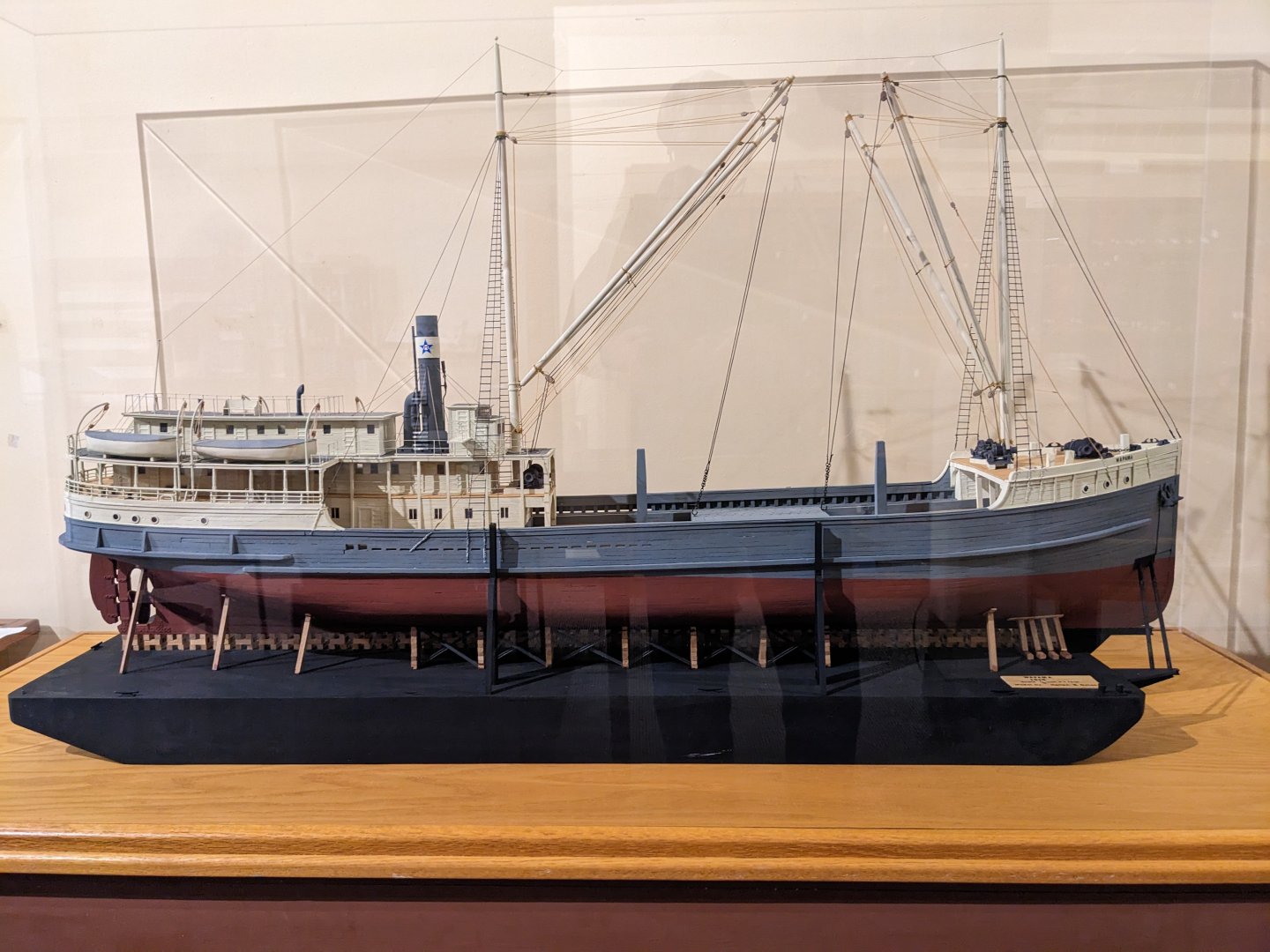

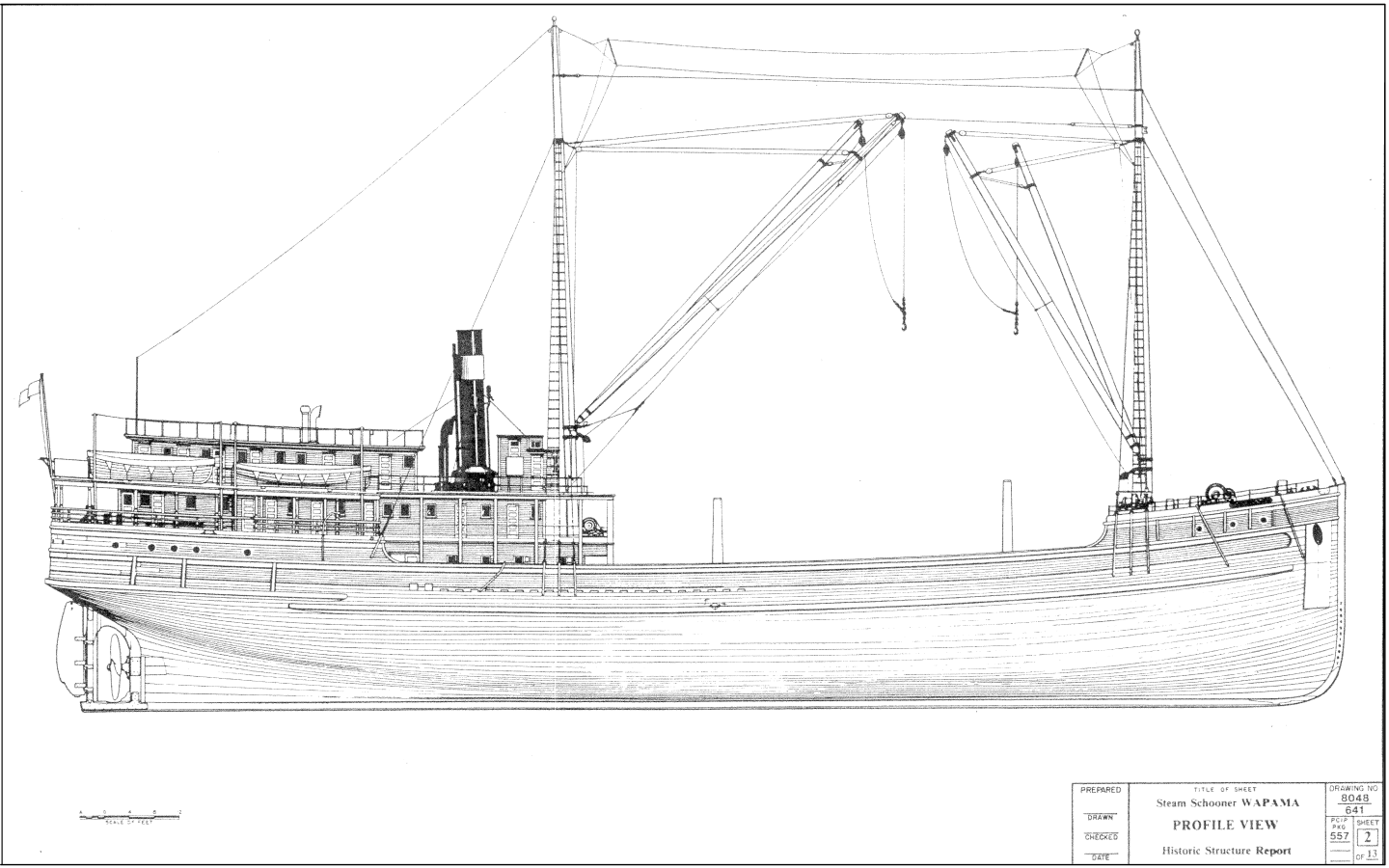

I have about 30 pictures of the Wapama. Including the engine and the prop on display. One of the life boats in storage. And some of the ship in service and when it was being deconstructed. I think some have never been published. I spent some time at the San Francisco maritime museum library going through their file of pictures. If you are interested I can see if I can figure out how to make my album available.

-

I thought I would show how I made it easier to slid the planks in and out when fitting them. I put some cutoffs as spacers under the rubber bands. I us clamps to hold the rubber band on the molds. After the plank is in position I move or remove the spacers. You can see the dowels I put through the molds thinking I would us them but my rubber bands were the wrong size.

- 81 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

Dream of building full size to reality of building models

J Snyder replied to J Snyder's topic in New member Introductions

Thanks for all the welcome. I worked for a small company Anderson Logging. We did work for Georgia-Pacific who owned the mill in Fort Bragg. They owned a lot of land also and logged federal land. I will read your log carefully! My idea is to build it sectioned from bow to stern at the rear side of the deck hatch to show the heavy construction, engine, and cabin interiors. I my never get to that big project but that is the goal. -

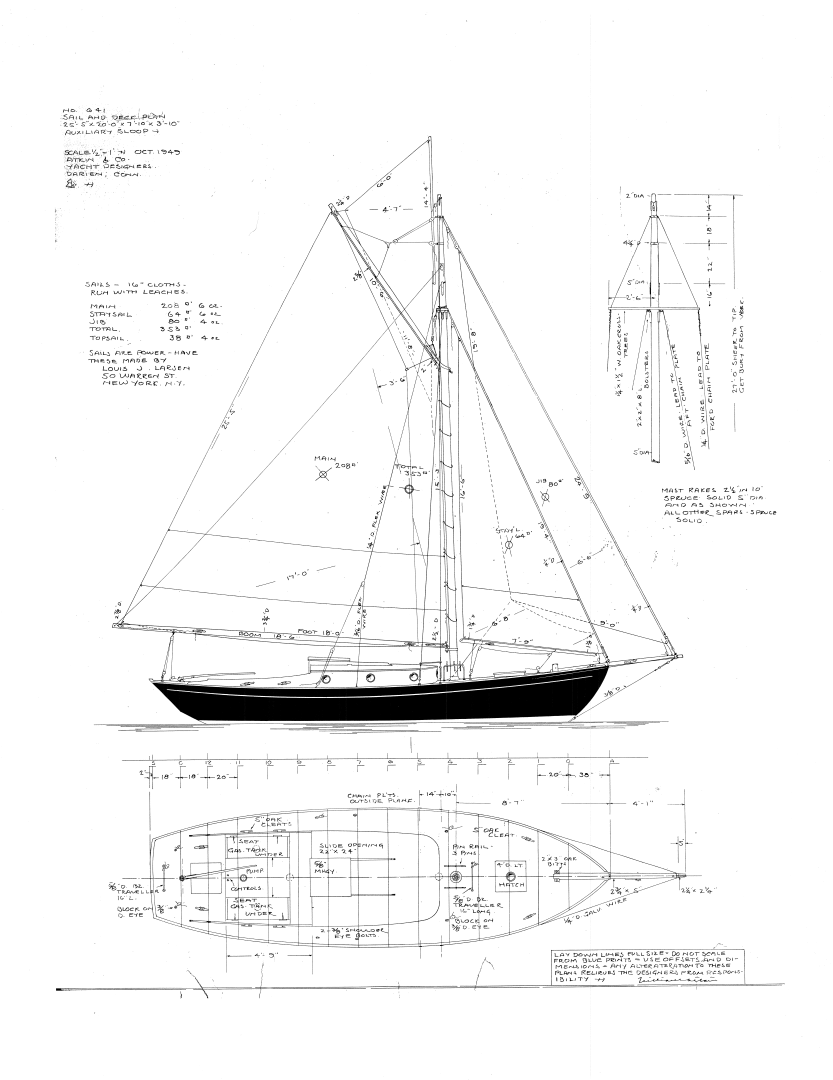

I would like to introduce myself. In 1976 I was a student at a local boat building school near Fort Bragg, CA. at Abalobadiah Creek. There were four student. Two worked on a 24ft. power launch. Another student and I worked on a William Atkin 25ft. sailboat called the Gary Thomas. I was able to stay on it till we sent it to southern Cal to be sold 14 months later. I would have loved after taking that boat building class to get into the boat building field but realizing I'm very slow and was a perfectionist. I knew I couldn't make money at it so I had to do something different and after commercial fishing with my dad for a while I decide to go into logging for a living. After all these years my plan is to make a series of models of the Gary Thomas starting with a POB and ending with a faithful model reproduction of the one I helped build. After the Gary Thomas builds I would like to work on a longitudinal Cutaway of the Lumber Schooner Wapama. A lot of plans but I have to start somewhere so I am starting on the Norwegian Sailing Pram.

-

I'm actually using an SLR with a 17-50 zoom! Just need a little "focus" on my part.

- 81 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

I am chasing the problem up the sides that the planks need slightly more curve and the bevels on the transoms need to be steeper. The bevels on the transoms being off don't bother me but the planks not having enough curve is a concern. In the second photo you can plainly see that the port plank (right side) is not as far over the garboard as it should be. And at the bow I had to ease both planks off to get the rest of the plank to lay properly. I don't want anyone to get the wrong impression, I am thoroughly enjoying this build and like the problem solving. I just got the sheer strakes of the bucket and they are drying so they are next.

- 81 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

Sorry about the blurry pictures. I am getting reacquainted with my camera. I had the same problem that many, the garboard planks were not curved enough. I first checked the transom bevels and cut them to fit better (the marked bevel line was to shallow) and I put in a slight bit more twist at the stern. This helped but I finally had to increase the curve of the plank by sanding 1/32nd out of the center tapering to nothing at the ends where the small "gains" are. This is where my use of the bucket could be a problem (maybe). I noticed that the port side plank was not fitting as well I sanded a little more of a curve (maybe 3/64ths) but still not fitting. I checked the mold frames, transoms nothing was asymmetrical. I did find that the port side garboard plank had a hard spot in it like an area near a knot that bent differently. So the problem is ether using the bucket or the hard spot or both. You can see in the last picture that the port garboard (right side of picture) is not where it should be right at the stern.

- 81 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

Enough of my rambling. Here are some pics For the transom supports I had to add paper shims in all areas to keep things from flopping around. At the stern I glued two scraps to stabilize the transom, this is not a good idea as the building board is not stiff enough if you use rubber bands. I had thought about mounting the board to a piece of 3/4 mdf but I didn't (sigh). The first issue I had was determining what were the transom knees they are not marked and there are nine possible knee like items on the laser cut sheet. This is the first thing the plans call for and is not a good way to start! One hour of head scratching and after removing a few knees and checking the angles I had them glued on. I put the bottom planks in some hot water then pre bent them over a large plastic bucket (more later) with a scrap of plastic laminate (Formica) over them for a few hours. After drying them the curve was nearly perfect but the beveling of the stern transom was to shallow so I cut beyond the marked lines in order to get the keel knee to set on the keel nicely. The stern transom must be checked for square as the first three planks are being glued as it still moved some.

- 81 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

I lived on (next to) the Noyo river 1.5 mi from the mouth for a few years growing up. the school at Abalobadiah Creek was just Dean Stephens home. We built the launch under a lean to attached to his barn and the sloop in the barn. The other students dug for a new outhouse and had the launch backbone already setup. I'm sorry I missed the work on the launch but happy I missed the outhouse work. We also helped turn butter and a few other household things. For the Sloop we used Balau for the backbone very hard dark brown and heavy. Difficult to work do to the interlocking grain, The adze and planes had to be used across the grain. The ribs were steam bent white oak and Port Orford Cedar was used for the planking.

- 81 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

Yes, every journey begins with a single step. I would have loved after taking that boat building class to get into the boat building field but realizing I'm very slow and I'm a perfectionist. I knew I couldn't make money at it so I had to do something different and after commercial fishing with my dad for a while I decide to go into logging for a living. I am enjoying working on the pram. Hopefully I can knock it out pretty fast and move on to either the lobster boat model or start on my scratch build.

- 81 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

I would like to introduce myself. In 1976 I was a student at a local boat building school near Fort Bragg, CA. at Abalobadiah Creek. There were four student. Two worked on a 24ft. power launch. Another student and I worked on a William Atkin 25ft. sailboat called the Gary Thomas. I was able to stay on it till we sent it to southern Cal to be sold 14 months later. After all these years my plan is to make a series of models of the Gary Thomas starting with a POB and ending with a faithful model reproduction of the one I helped build. After the Gary Thomas builds I would like to work on a longitudinal Cutaway of the Lumber Schooner Wapama. A lot of plans but I have to start somewhere so I am starting on the Norwegian Sailing Pram. I read over quite a few build logs to get an idea of the potential problems and I have found some already. I will post a few pictures tomorrow on my progress.

- 81 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.