-

Posts

38 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by DWright

-

Thanks Dave! Too kind lad. At the start I was dubious about starting a "build log", but now I know that it has many virtues. It keeps me motivated to do much better, and I get the best advice available. At 72 I was searching for something that was a challenge, other than golf and flyfishing, and landing on an old hobby. I'm so thankful to the folks that started this blog/site as it has been a Godsend. I think I can, with help, get through rigging! DW

-

Floyd, Thanks for the kind words, and you captured my sentiments to a tee. I sort of looked at this effort as learning how to ride a bike with training wheels. Since the completion of the hull planking, revealing the graceful lines of the schooner, I've had a change of heart . It's truly a beautiful ship and I'm beginning to appreciate its design, grace and class. In some other post on this site you have alluded to a meeting of folks here in the Northwest. I live on Lake Coeur d'Alene, ID and would very much like to attend a get-together of fellow modelers to expand my knowledge, and hopefully talants. I'm beginning to see that practice doesn't necessarly make perfect, but it definitely does make better! Cheers, Darrel

-

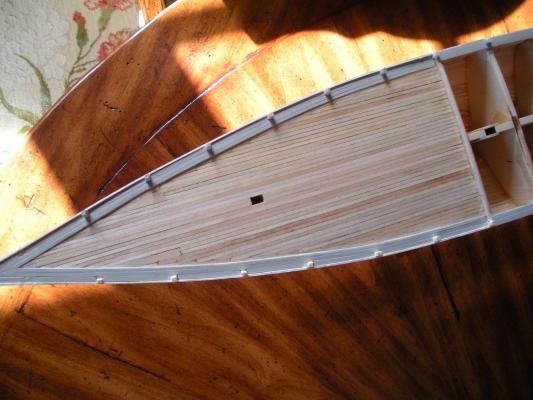

Log #4 The next step in the process is the foredeck planking. One of the previous logs had suggested that if he had to do it over again he’d seriously consider sheathing the deck with very thin ply (1/64 inch) to facilitate the planking effort. I second that motion! I probably didn’t prep the bulkheads and keel properly and as a result realized some uneven planks that needed scraping to bring even with the other planks. A close look at the foredeck pictures will reveal that plank nibbing was not initially my strong suit. It took me about 10 nibs to begin to understand the process, but it rendered a few rather poor efforts. The unsupported nibbing strike presented a few problems as I cracked it once requiring a slight remodel. The next event will be the quarter deck planking, but first I must figure out how the stern/transom assembly is to be handled. The plans and instructions are a little vague and even Bob Hunt practicum doesn’t really spell it out. Any comments or suggestions would be appreciated. Darrel

-

Dave, I'd like to second all of the congratulatory comments on the completion of an absolutely beautiful model. I recently posted a build log of my first endeavour in to this new hobby, which happens to be the same Model Shipways Bluenose. I'm at quarter deck planking, and after seeing your fine work will definitely have to up my game! I look forward to the photos Floyd has requested. Darrel

- 43 replies

-

- bluenose

- model shipways

-

(and 2 more)

Tagged with:

-

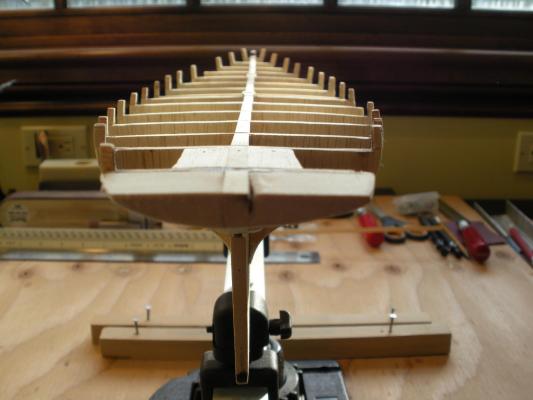

Post 3. The photos below show the completed hull planking. I would say the keys to producing a good planking job begins with fairing the bulkheads adequately, and secondly, like any other phase of ship modeling, take your time. The couple of time I hurried resulted in a “remodel”. I used Zap-A-Gap CA glue and glued the planks spanning two bulkheads at a time, and edge glued all planks. Where possible, I tried to use the edge of my Exacto knife blade to hold the plank in place while the glue set. This kept me from gluing myself to the Bluenose. Since I planned to rough sand the hull as I went, I soon discovered that scrapping the planks and high spots, with a #22 Exacto blade worked much better. Scrapping produced a nice sharp line and brought all of the planks even. After planking and rough scraping/sanding I applied Elmer’s wood filler to the entire hull. I used the filler as it comes from the contained, and in retrospect, I will next time thin the filler with water to achieve a more workable product and a more even coat. I let the hull stand for 24 hours before I began sanding. Using #80 grit sandpaper I rough sanded the entire hull. I then finished the sanding with 120 grit sandpaper. Total time to sand and fine sand, about 3 to 4 hours. Darrel

-

I'm adding three post on one date to bring the log current. Log Entry #2 Planking is now nearing completion and in most respects is acceptable. However, I did not adequately trim the last few strikes at the bow and consequently had to resort to stealers at both the bow and stern. (Mistake #4) I suggest using three or four pieces of planking held up against the area that remains to be planked when installing the last five or six strikes. This will give an idea of how much must be trimmed from the last few strikes to accommodate a comfortable fit, and eliminate the use of stealers or partial planks at the bow. Darrel

-

Post #1 My name is Darrel Wright and I'm in the process of rekindling an old hobby I put down some 57 years ago. To initiate this effort I've selected to model Model Shipways' Schooner Bluenose (1:64) because of its sleek and simplified hull affording simplified planking, which I look forward to, and an uncomplicated rigging scheme, which I'm somewhat intimidated by. I realize the Bluenose is a rather blasé model, having been modeled and logged perhaps hundreds if not thousands of times. However, I plan to write this log as a beginner for beginners, highlighting all accomplishments and pitfalls in an attempt to aid all who wish to embark upon the hobby. I'm starting a little late with the log as I'm just about ready to commence the hull planking operation. I will attempt to briefly articulate the steps taken to date that have brought me to the planking effort. Upon receipt of my kit from Model Expo, as instructed, I inventoried each item in the kit and found that one "open chock" and one bag of 12 "single blocks" were missing. I have contacted Model Expo for replacements, which should be forthcoming. Next I read virtually the entire instruction manual and reviewed the six sheet plan set. Additionally, I purchased and have reviewed the rather comprehensive practicum from Bob Hunt. Now to construction. Firstly, I removed the three pieces of the keel from their billet and sanded clean the billet residue. I then dry-fit the keel and noticed a slight imperfection at the bottom line of the assembled pieces. I concluded these minor imperfections could best be taken care of after assembly with a clean-up sanding. Using a very straight piece of partical board as a work surface, covered with waxed paper, I applied white carpenter's glue to all edges to be joined, and then tightly fit the assembly on the board. I then covered the keel again with waxed paper and laid a heavy 2" X 10" board on top to let the assembled keel set over night. Upon retrieving the keel the next morning I began the delineation of the bearding and rabbit lines. I had made full size copies of the plan sheet that contained the keel. I precisely cut out the keel at the top line and the rabbit line. I then placed and taped the template to the keel, and then, with the aid of an architectural French curve, (more about that later) drew in the rabbit line on both sides of the keel. The next step was to cut the template along the bearding line and repeat the same procedure to effect the location of the bearding line on both sides. At this point, as recommended, I glued scrap pieces of wood at the two keel join points for extra strength. Ah, the rabbit cut! My goal here was to effect a cut along the rabbit line no greater than a 1/16th of an inch deep so as not to cut through the keel when both rabbit lines were installed. Using a tip provided by another member of this blog, I placed a piece of masking tape up 1/16th on an inch from the tip of my exacto knife blade, and at the approximated angle of my cut. Again, using architectural French curves for alignment, I successfully made the rabbits cuts without disaster. Note: I later learned from someone on this site to use ship's curves as opposed to architectural French curves. Much, much easier! I have subsequently purchased a set of ship's curves on Amazon.com for $22.00 US. Creating the rabbit via chiseling is a somewhat tedious process, and most definitely a learning experience. The right angle, the right depth while keeping it aligned with the bearding line all come into play. I've noticed in some photos (even the Model Shipways promotional photos) a slight bulging of the planking at the "deadwood" where it dies into the sternpost. I assume this line should be adequately faired so as to render a smooth transition into the stern post. On my model I removed a fair amount of deadwood between the bearding line and rabbit in order to create this smooth look. With the keel prepped it was time to fit and install the bulkheads. Again, I cleaned them up, and then placed them on the respective plan to check for correctness. All seemed reasonable well with respect to size and shape, and thus I began to fit them onto the keel. With the exception of three bulkheads all fit quite well, standing at the desired 90 degree angle to the keel. I deftly mended the slots on the three tight fitting bulkheads and proceeded to glue and install them. For this installation I used Zap-medium CA glue, and in retrospect I would suggest using glue with a longer cure time to permit any adjustments prior to setup. (Mistake #1) I got quite lucky as all bulkheads came about as close to 90 degrees as possible thanks to Model Shipways accurate laser cuts. Now to what I, and virtually all experienced modelers, consider one of the most important aspects of ship modeling, the fairing of the ship. I vaguely remember, from my youth, not understanding the importance of this critical operation and thus wound up with lumpy, bumpy hulls. This time, though I may have occasionally "over worked" the wood, I was determined to have every plank sit fully and naturally on each bulkhead in all locations. I suggest using a piece of planking as a batten to constantly run up and down the bulkheads to insure compliance in all locations. In my zeal to properly fair the ship I snapped off the very fragile stern piece at the rudder post. (Mistake #2) After several attempts to just glue it back together (not enough wood surface to do so) I fashioned some support timbers and devised clamping system to reinstall it with the correct alignment both vertically and horizontally. Live and learn. Also note the three missing bulwark stations. (Mistake #3) These were not victims of overzealous fairing, but departed due to the trimming of the stanchions to 1/8th inch as called for. Take note that the bulkhead plywood is very fragile and crumbles when cut. I believe I can span the missing stanchions location with the bulwark planks and replace these stanchions when the false stanchions are installed. I'm now at the point of installing the waterways and commencing the planking operation. I've elected to do something that may not be proper procedure. Because I desire as crisp a model as I'm able to fashion, I have elected to prepaint the waterways, bulkhead stanchions and the inside of the bulwark planks so that I don't have to 'cut-in" the white and grey paint after completing the installation. I fully realize I will have touch up, but that's preferred to trying to cut-in paint, in a tiny hard to access location with, these aging, aching and shaky old hand. I've enclosed some pictures for your review. Darrel

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.