johnhoward

NRG Member-

Posts

162 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by johnhoward

-

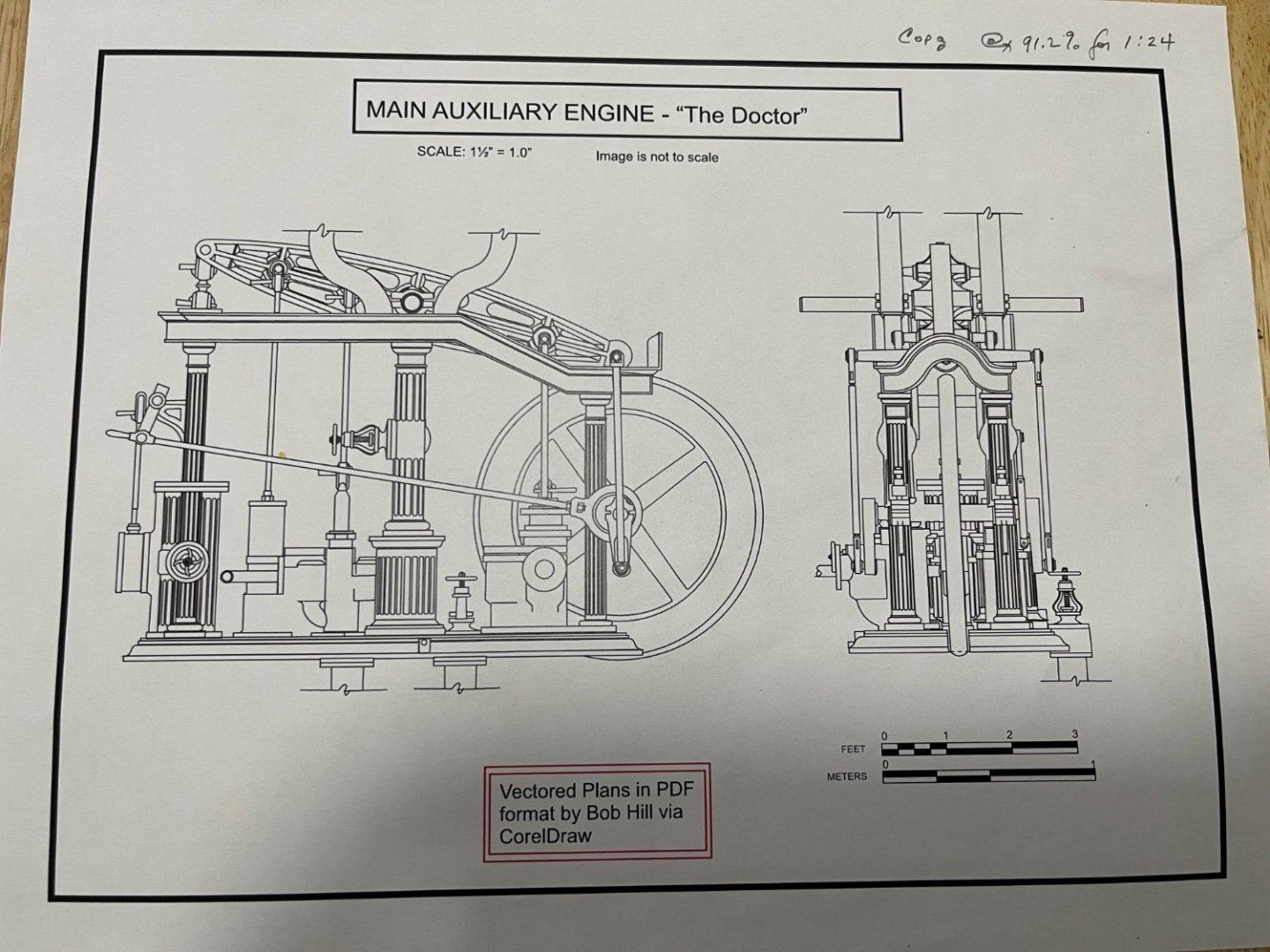

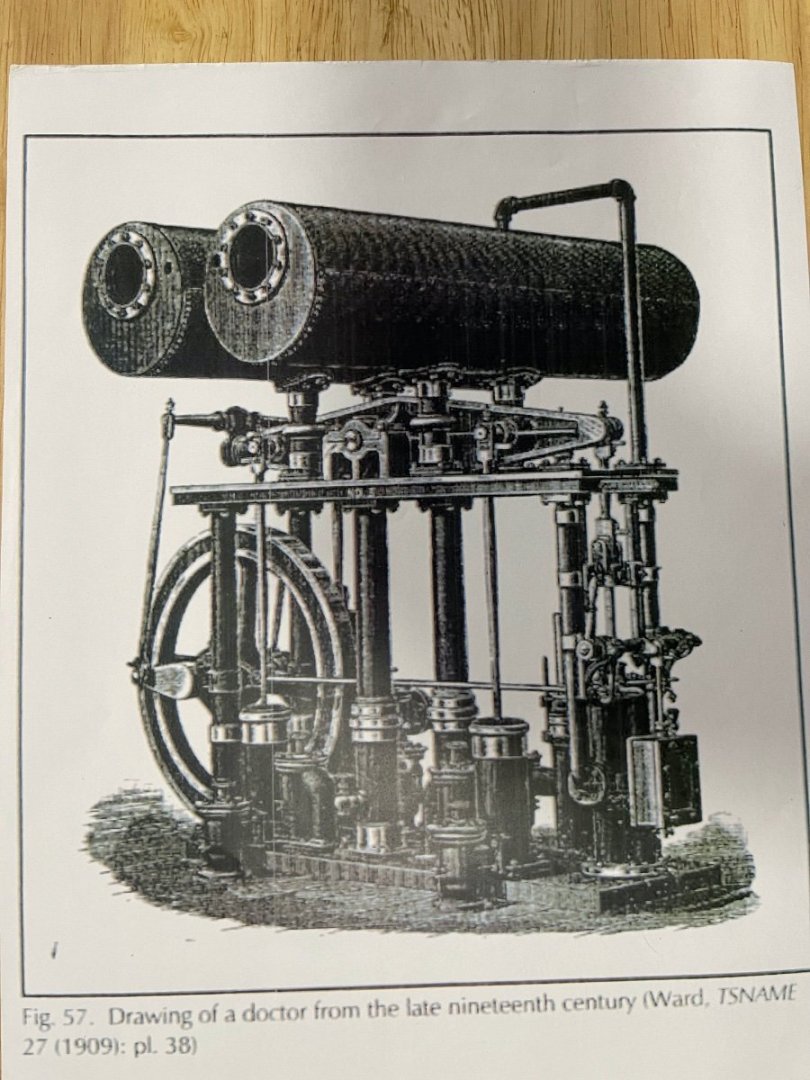

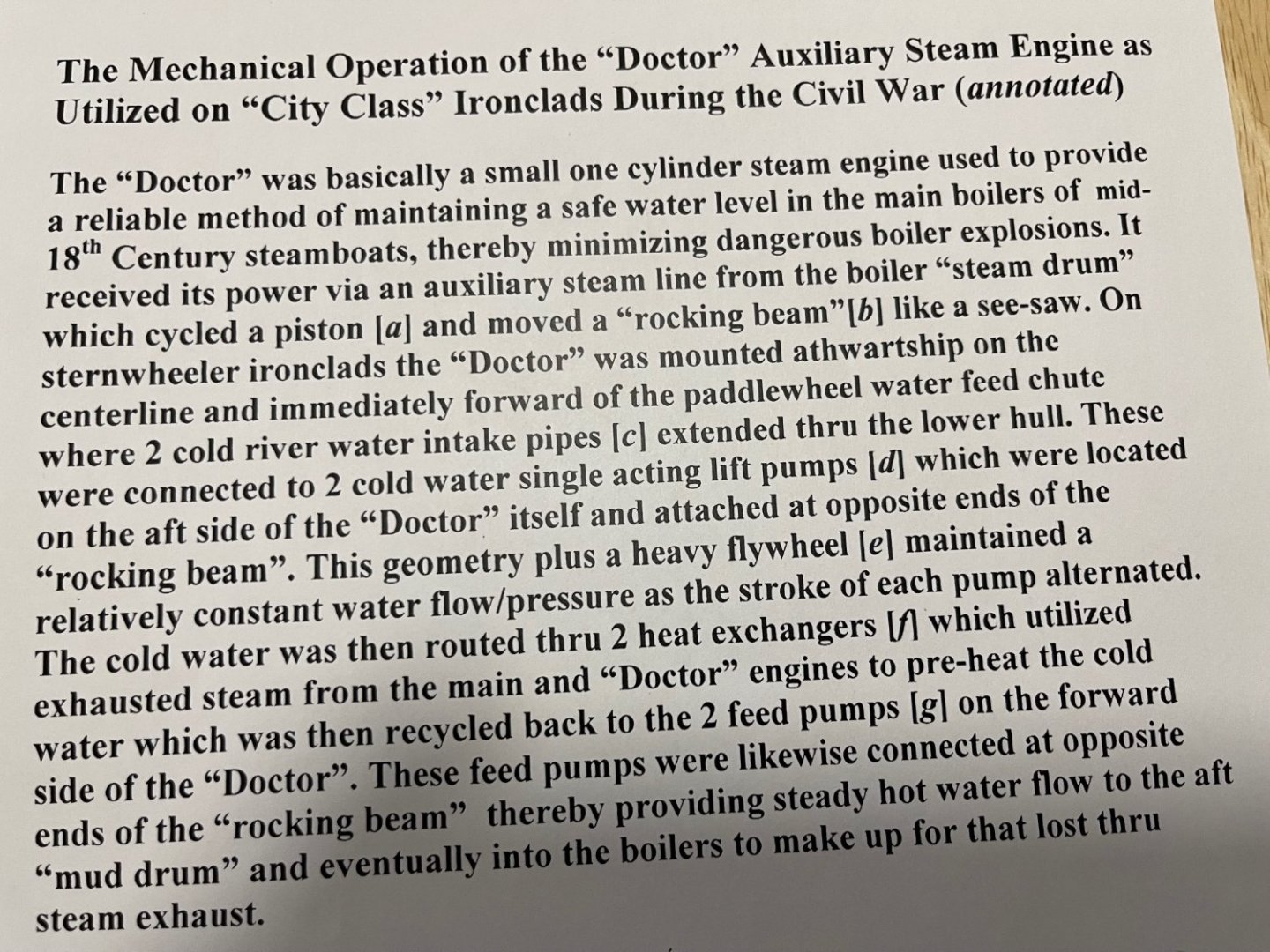

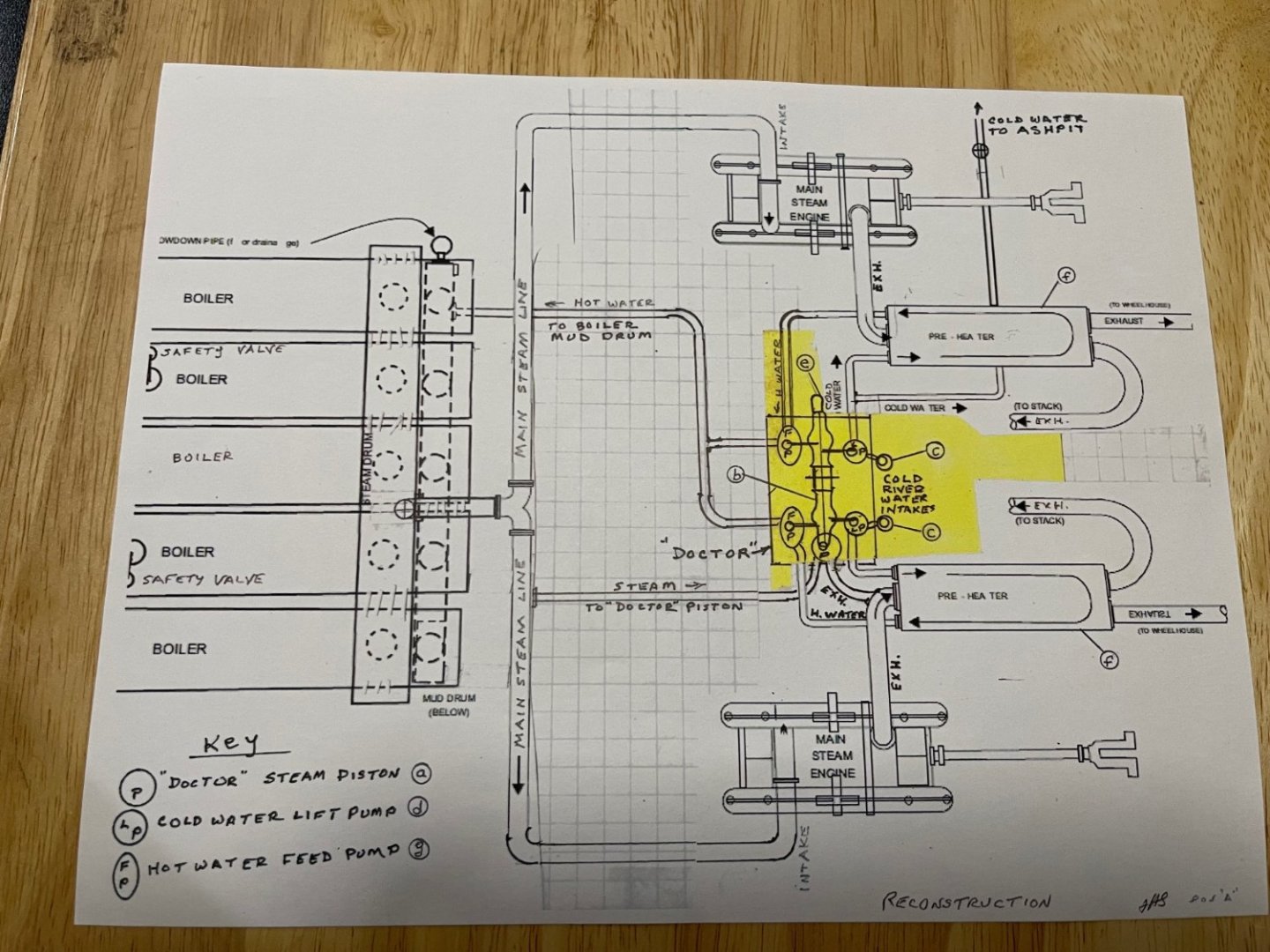

Hi again Pat, The difference between a "Doctor" and a "Donkey" is that a "Doctor" does not produce steam itself since it doesn't have its own firebox & boiler whereas a "Donkey Engine" does, and creates its own steam. The "Doctor" got its name because it automatically reduced the high number of accidental steamboat boiler explosions which resulted from low water levels in their boilers. The schematic drawing reflects corrections to the NPS version for "Doctors", highlighted in yellow, as used on "City Class Ironclads". JOHNHOWARD

-

Tim, The two large tanks above the "Doctor" Auxiliary Steam Engine are not "condensing tanks", but are "pre-heaters" for river intake water, utilizing main engine exhaust gases, before pumping it into the mud drums and eventually into the boilers to maintain safe water levels. The main engine exhaust gases from the pre-heaters are then either routed to the wheelhouse to prevent paddlewheel freezing in the winter, or back to the main exhaust smokestacks. JOHNHOWARD

-

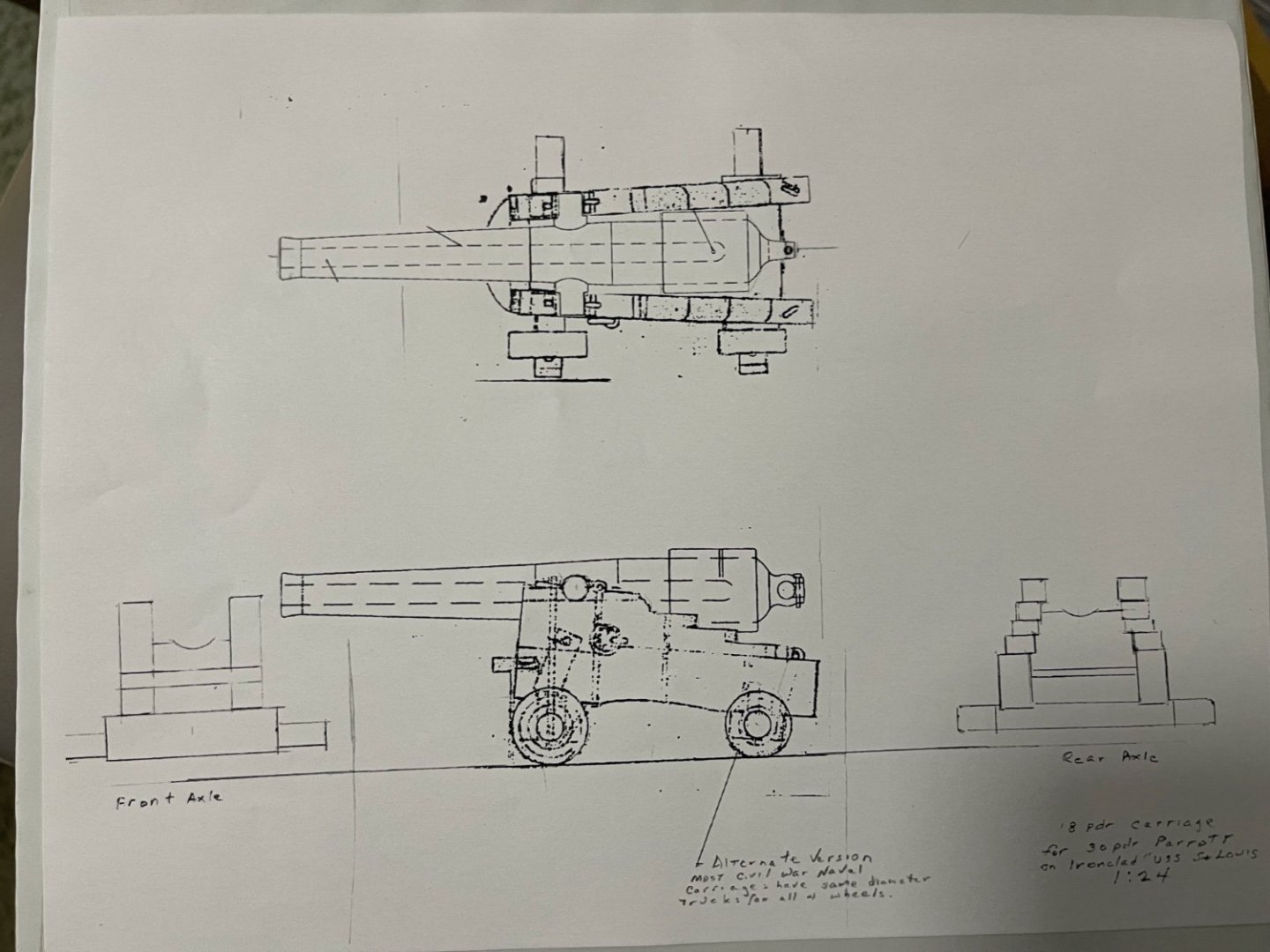

Tim, Regarding the caption requiring a "special fit" for Bill's 32 pounder carriage, I believe he is referring to his 30-Pounder Parrott Rifle barrel which requires a standard 18 pounder Naval Carriage and an elevating screw-jack rather than the 32 pounder (or small) carriage and wedge type quoin as incorrectly depicted on the Doug Ashleys NPS drawing. Great job on the photos. JOHNHOWARD

-

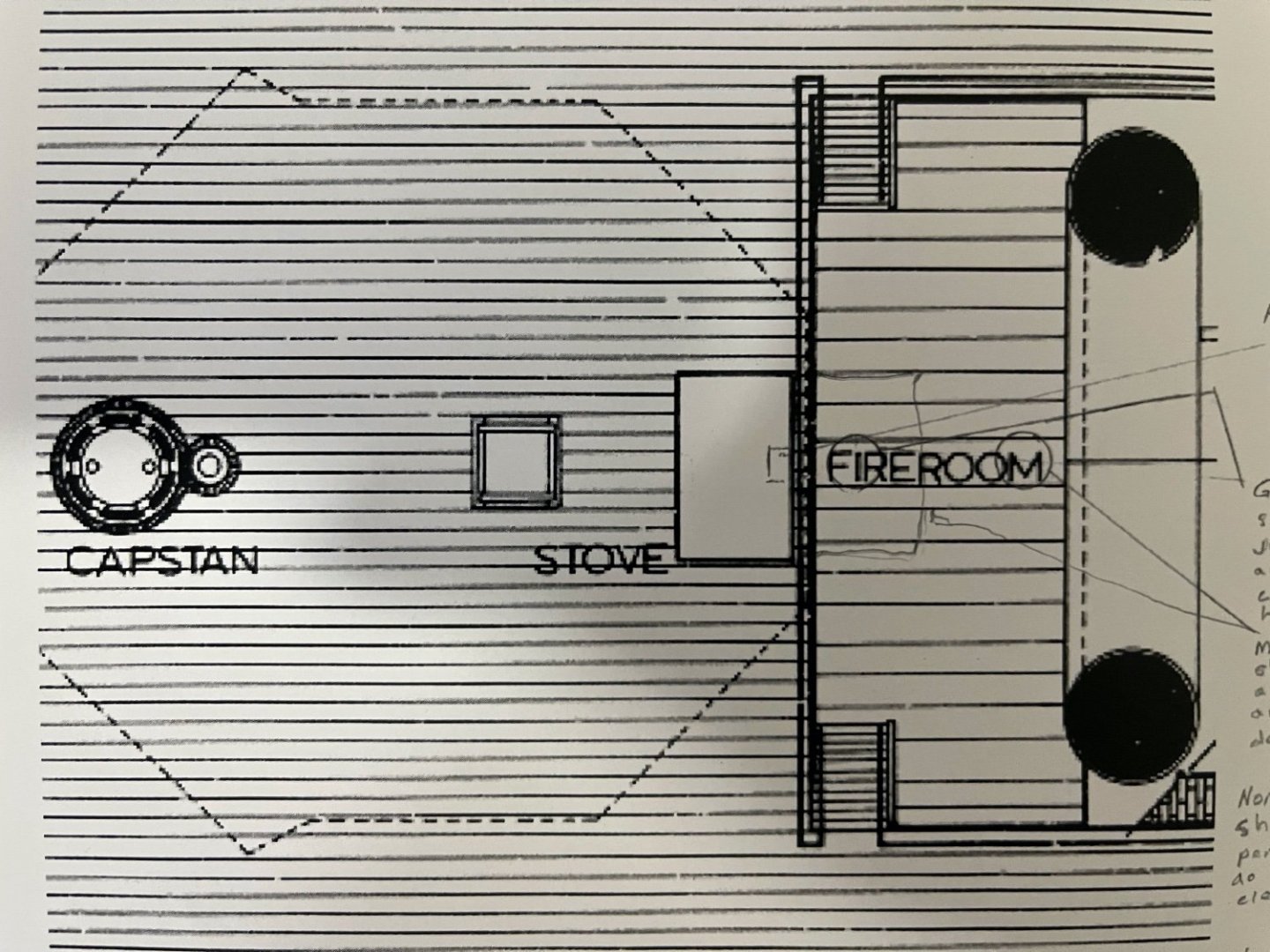

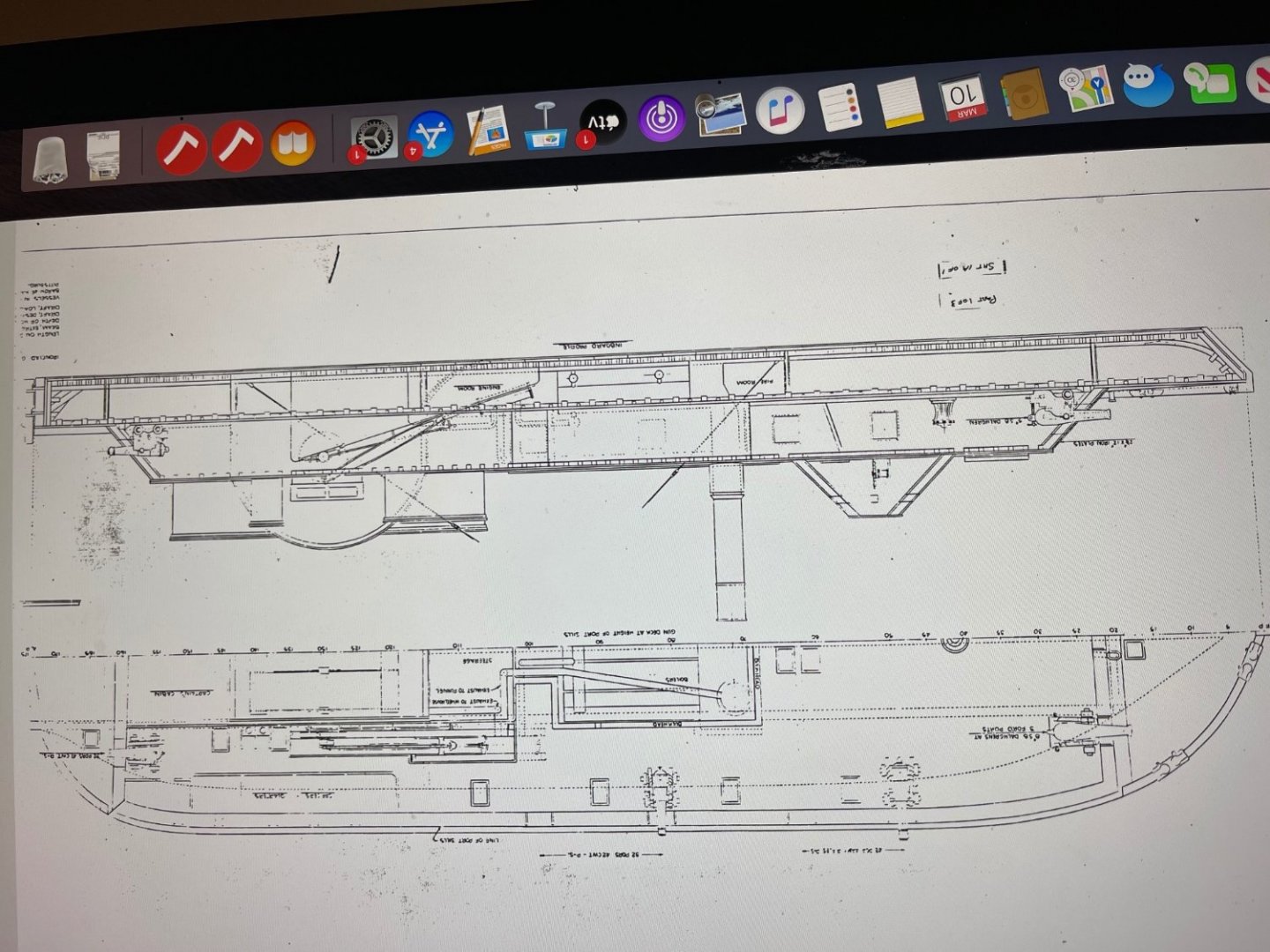

Brian & Pat, Thanks for all the help. I'm pretty sure that the aft ventilation funnels were intended to service the engine room. I think we had to relocate them from Ashley's drawing because they went directly into a wall or doorway on the gun deck. This is not too surprising because he probably only had old photos to determine funnel locations since the Hurricane deck didn't survive the USS Cairo recovery. The next mystery I'm going to reinvestigate is the Auxiliary Steam Engine and PTO Shaft , depicted on Ashley's HSR Sheet 28 drawing, and located in the chine, and which I suspect was used, as we modeled it on our USS St. Louis, to power the capstan. It may also have powered high pressure water pumps, which were specified in the HSR, but which I have never located. In 2014, I questioned Elizabeth Joyner, USS Cairo Museum Curator, about this Auxiliary Steam Engine, and she recalled that :"they actually found it in the wreckage, but lost it during recovery",so Ashley's drawing records it "as location Unknown", and his drawing of it seems to come from the US National Archives, but I was never able to confirm this. I think Ashley's drawing is probably reliable because the outline he shows of the chine is unique to the "City Class" ironclads. I have never seen this on any other USS Cairo models but it would be hidden below the gun deck and behind upper and lower chine armor plates. We'll need some help on this one! JOHNHOWARD

-

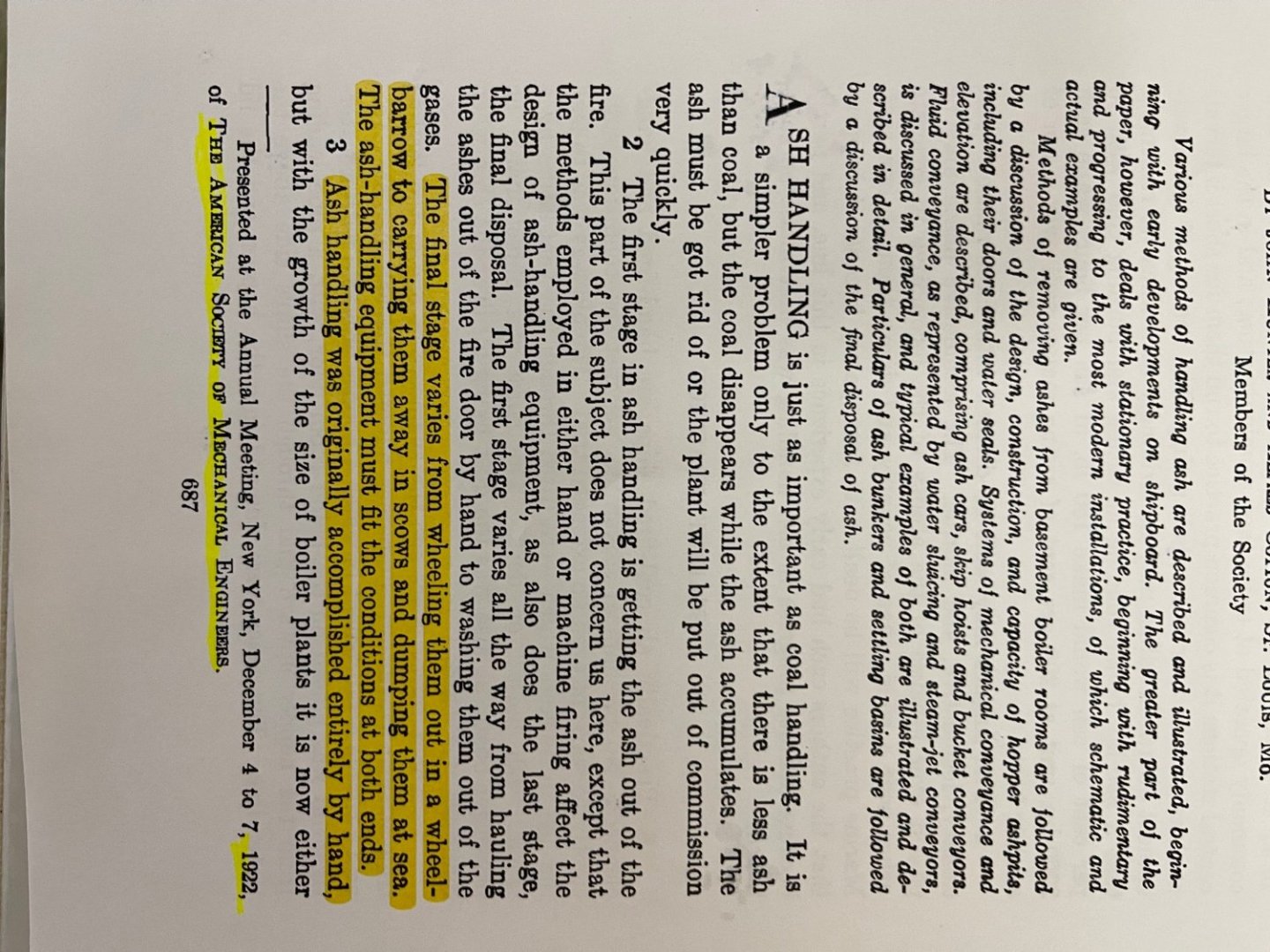

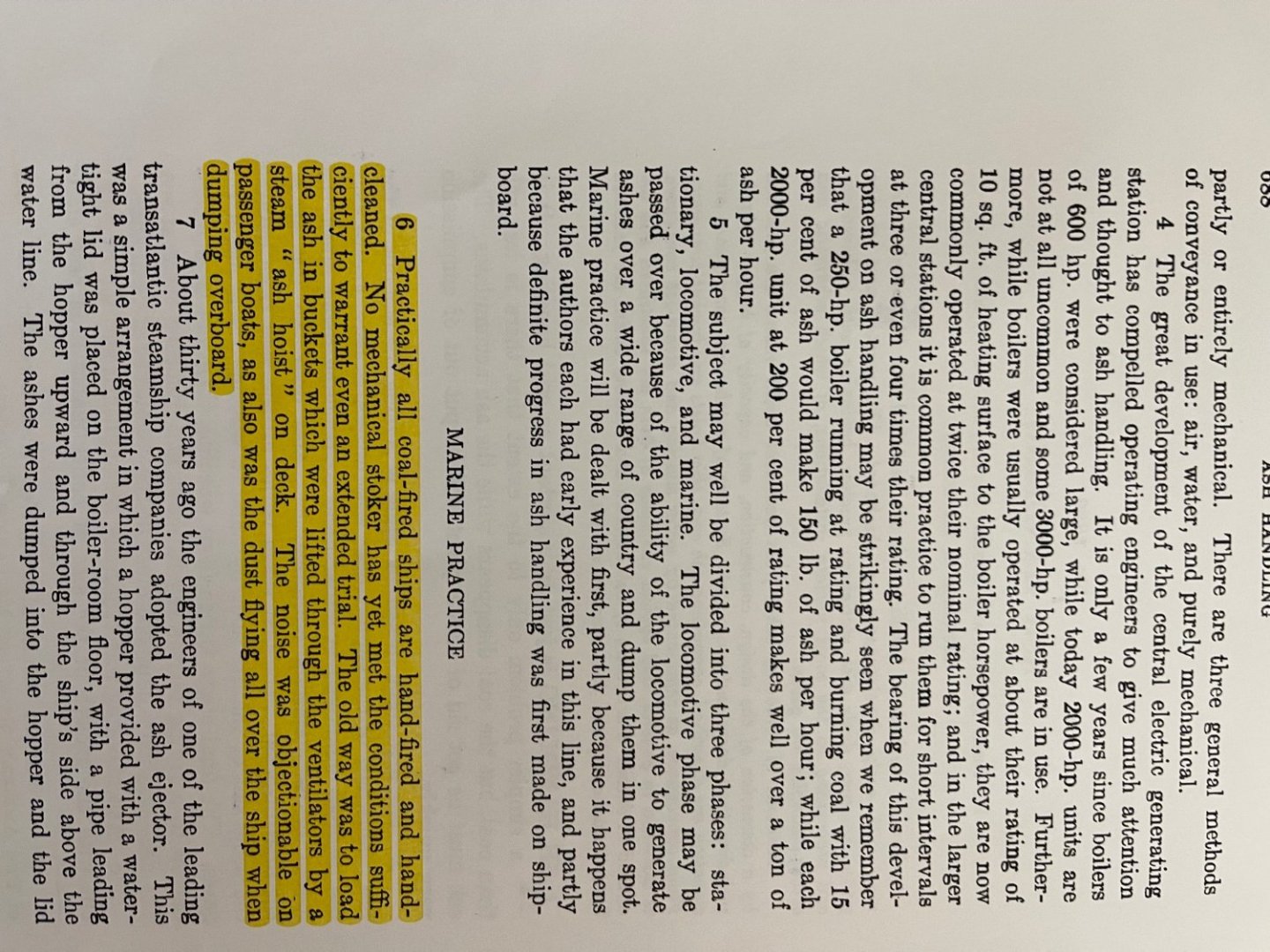

"Slag & Ash Removal on Coal Fired Ironclads" with Firerooms Located Deep in their Hull such as the USS Cairo and USS St. Louis For those of us who have been following our search for an answer to this question since about 2017, I think Pat has really "Nailed it" by finding the attached document: "No 1866" entitled "ASH HANDLING" which was presented at the Annual Meeting, New York, December 4 to 7, 1922 of "The American Society 0f Mechanical Engineers." (Specifically refer to the sections highlighted in yellow and in particular: Paragraph 6 under MARINE PRACTICE.) I am extremely indebted to "Pat" for his excellent research effort in finding this document and all the numerous others he has provided regarding "coaling operations" in the late 19th Century, which after a more thorough review, may change some of the earlier modeling decisions we reached on coaling the "USS St. Louis" Ironclad. . However,I am now totally convinced that the attached document fully confirms the method of "slag & ash removal via a bucket hoisted thru the ventilation funnels in the fire-room, onto the Hurricane Deck, transportation to the lee side deck edge via wheelbarrow and down over the upper casement armor plating in a metal chute, into the river." (This was referred to as the "OLD WAY" in paragraph 6.) Thanks again, Pat, JOHNHOWARD

-

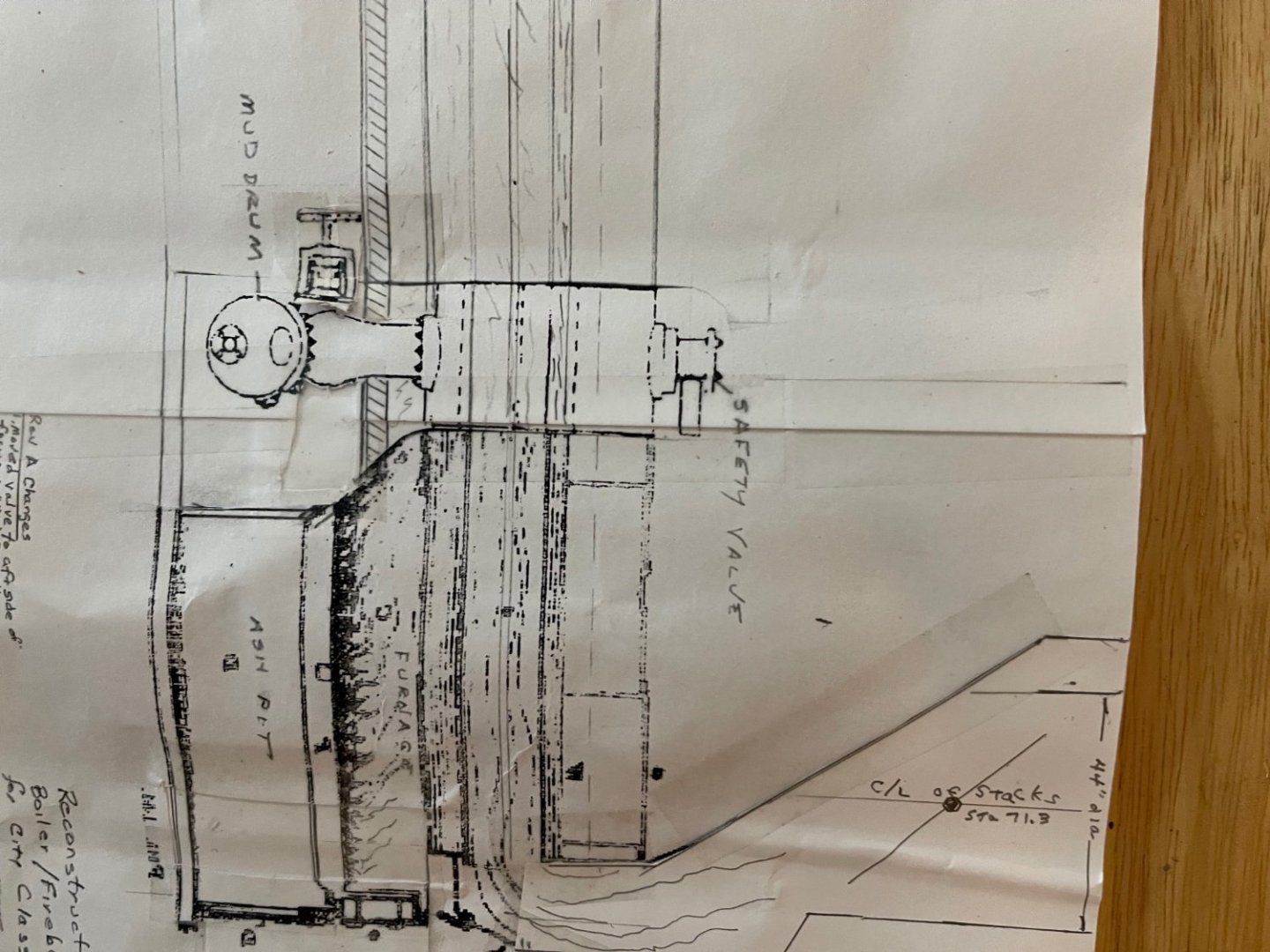

Thanks to all that have responded to this topic. Now we have a whole new set of issues to address but I don't see any "show stoppers", yet. On the issue of unlimited water supply, my research of the City Class Ironclads reveals only one major river water intake source as being thru the keel into "The Doctor", which is powered by a very small steam piston, and which primarily serves to maintain boiler water safety level among other minor utility purposes (See Photos with Posting #220). Water from "The Doctor" was pumped directly into the Mud Drums below the boilers. The only other pumps I found were manually operated and used to remove bilge water. Where should I look to find a more powerful steam driven water pump? I have found several definitions for the "Steamboat Coal" size then in use, but apparently this is rather small like we could use on a Bar-B-Que grill. Would this size coal still fuse into larger slag? or would it remain ash? The Fire-Room is relatively very small, yet it has practically exclusive use of 2 of the 4 ventilation funnels on board an ironclad. Temporarily removing the upper curved "bell" shaped section of one funnel would reduce the ventilator air draw or inflow, if the ironclad was in motion but it wouldn't totally disrupt ventilation. The bulk of boiler heat is constantly expelled thru the large iron grating on the centerline of the Hurricane Deck, directly aft of the smokestacks. The Fire-Room was completely surrounded at the hull floor level by the fire boxes on the aft side and coal-bins on the other 3 sides. Working here would be a living hell. Admittedly, contemporary photographs are very frustratingly poor proof, but there was a significant amount of the original USS Cairo" original fabric" recovered, especially in the lower hull section which was buried in mud for 100 years with many small metal components. Unfortunately, very little of the Hurricane deck survived and original reconstructions are sometimes unreliable. So far, we haven't identified any new slag & ash removal technology which was definitely in use in 1861, that is also compatible with the ironclad configuration, except possibly the manual hoist and bucket. Once we can get the bucket of slag and ash onto the hurricane deck, we can use a wheelbarrow and a portable metal chute to safely dispose it over the down-wind side casement. This equipment would probably have been stored in the Hurricane Deck House forward of the paddle wheel house where the ship's bell and other equipment was found by recovery divers. A lot of speculation? However, when you think about it, with any photographs, we have a tremendous amount of material for modeling these ironclads compared to any pre Civil War ships. JOHNHOWARD

-

Brian, I think I have found the solution to our ash and slag removal and it's so simple I can't believe we didn't think of it before! They didn't need a hatch in the Hurricane deck for this activity because they already had two perfectly safe ventilation funnels that protruded thru the Fire-Room ceiling [actually the Hurricane Deck]. All they had to do was temporarily remove the upper funnel section and drop a line with a hook from a portable winch to pull up a bucket of ash & slag and dump it over the Hurricane deck edge or into some other container. The two ventilation funnels protrude thru the Fire-Room ceiling near the two ladders near the forward wall on Ashley's NPS drawing. We chose to put this ladder on the forward wall so it doesn't block the doors to the coal bins on the port and starboard sides. Many contemporary photos show these ventilation funnels, which have at least 2 sections, raised, lowered or removed all together. I think their best option would be simply to remove the upper section which would leave a shorter straight section of ducting to transverse the past gun deck into the fire room. This would be the duct seen protruding thru the boiler room wall in Captain Walke's sketch, posted earlier. If you line up the smokestacks in these photos, the funnel location works out perfectly. JOHNHOWARD

-

Roger, (Regarding your Post #222) We totally agree with your assessment on ash # slag disposal. (See my Post #202) The problem on the City Class Ironclads is that the only exit we have found from the Fire-Room in the hold, is up a vertical wall-mounted ladder, thru a horizontal doorway, out onto the gun deck, and thru an open gun port in either the forward or side casements. This is potentially a very dangerous path with a bucket of slag and ash where a single spark and gun-powder residue on the deck could spell disaster. As we indicated in Posting #202, our current theory is the use of a hoisting winch & cable thru a hatch on the unarmed Hurricane Deck, which is actually also the Fire-Room ceiling, to lift a bucket of slag & ash directly from the Fire-Room floor and then over the side thru the Hammock Rails. The only problem with this idea is that , so far, we have only positively identified one such hatch on the Hurricane Deck and it inside of the pilot house for the captain, navigator & steersman. Such a hatch would be aft of the pilothouse, roughly between the smoke stacks, if it exists. JOHNHOWARD

-

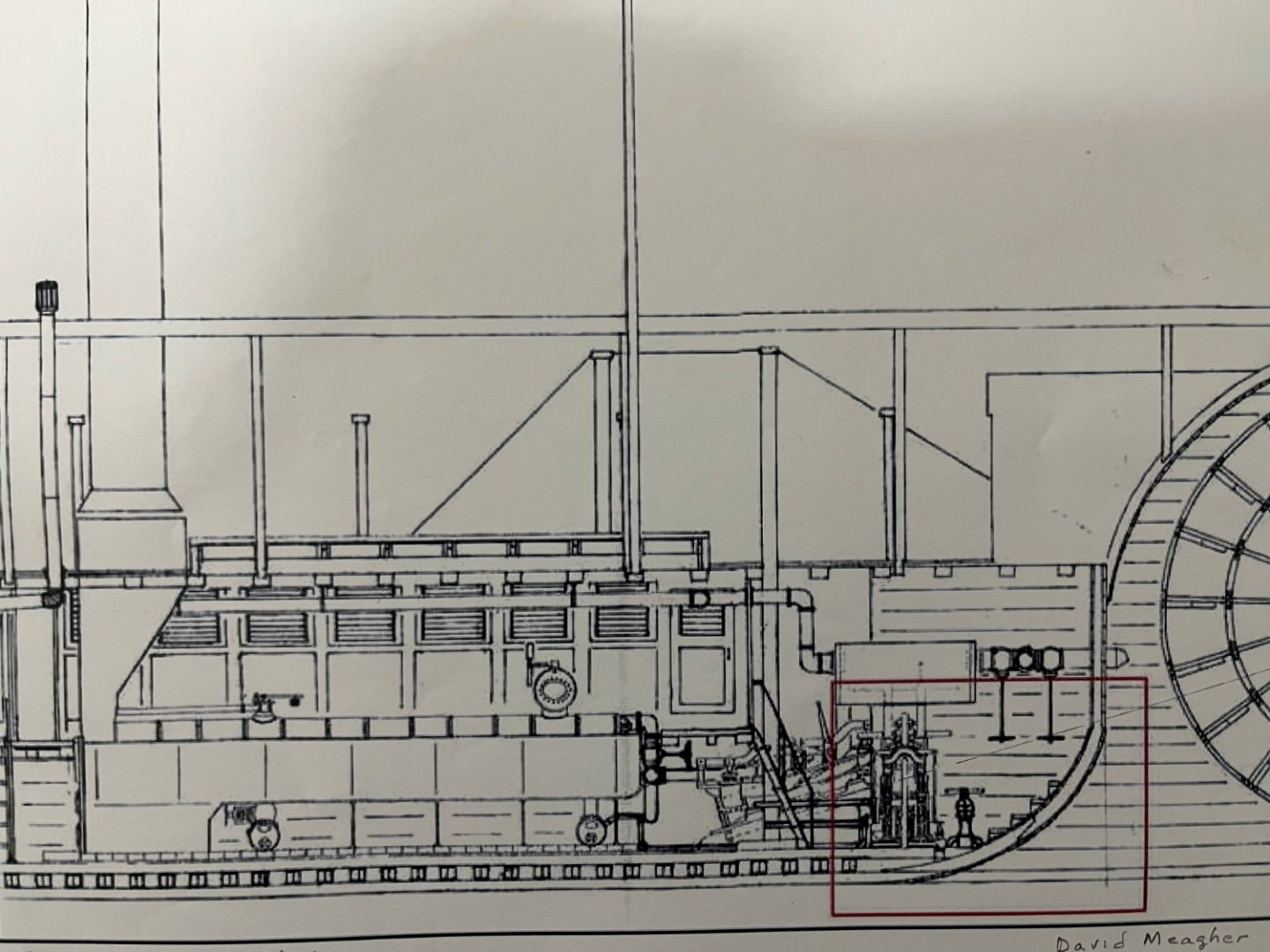

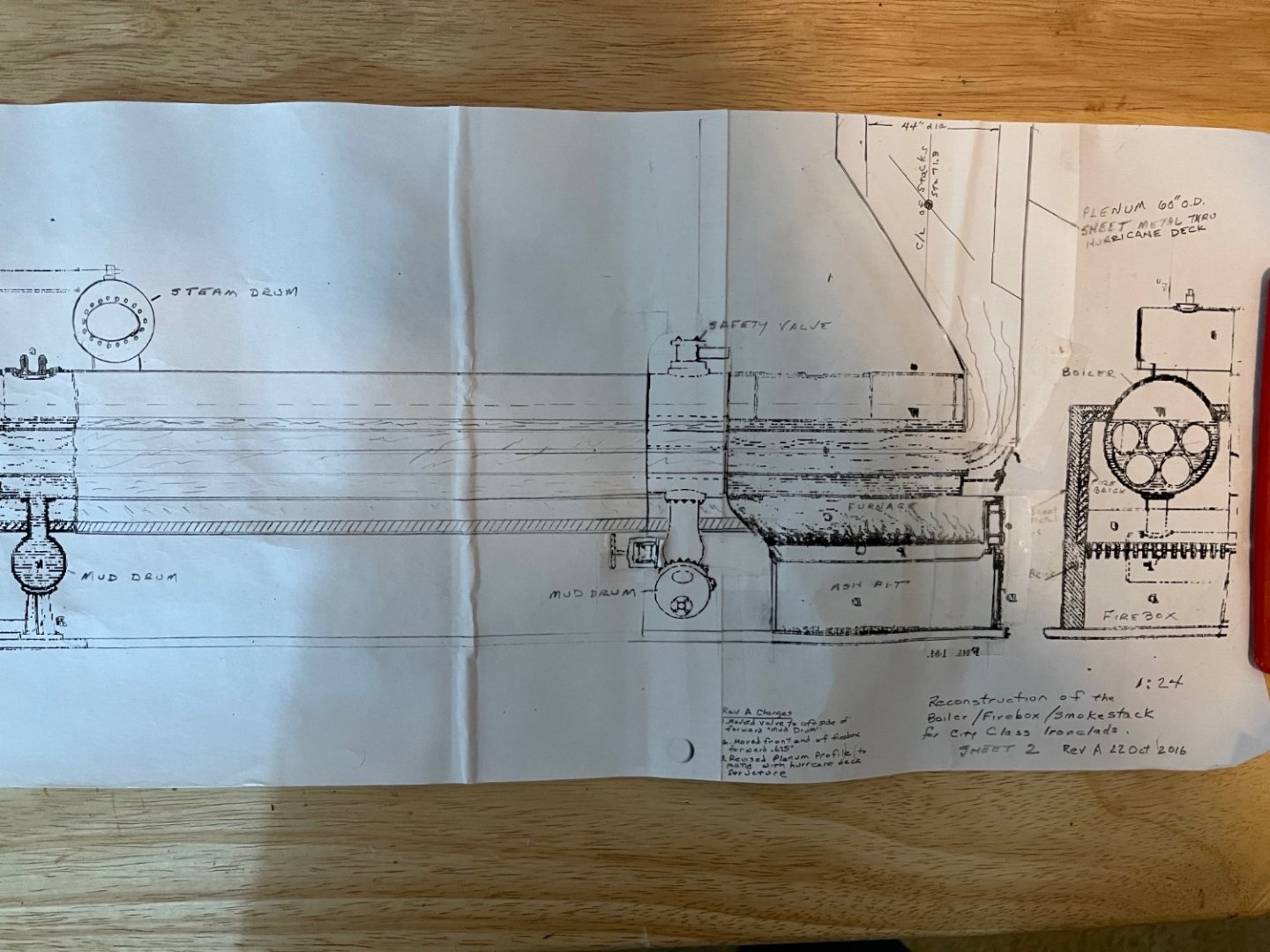

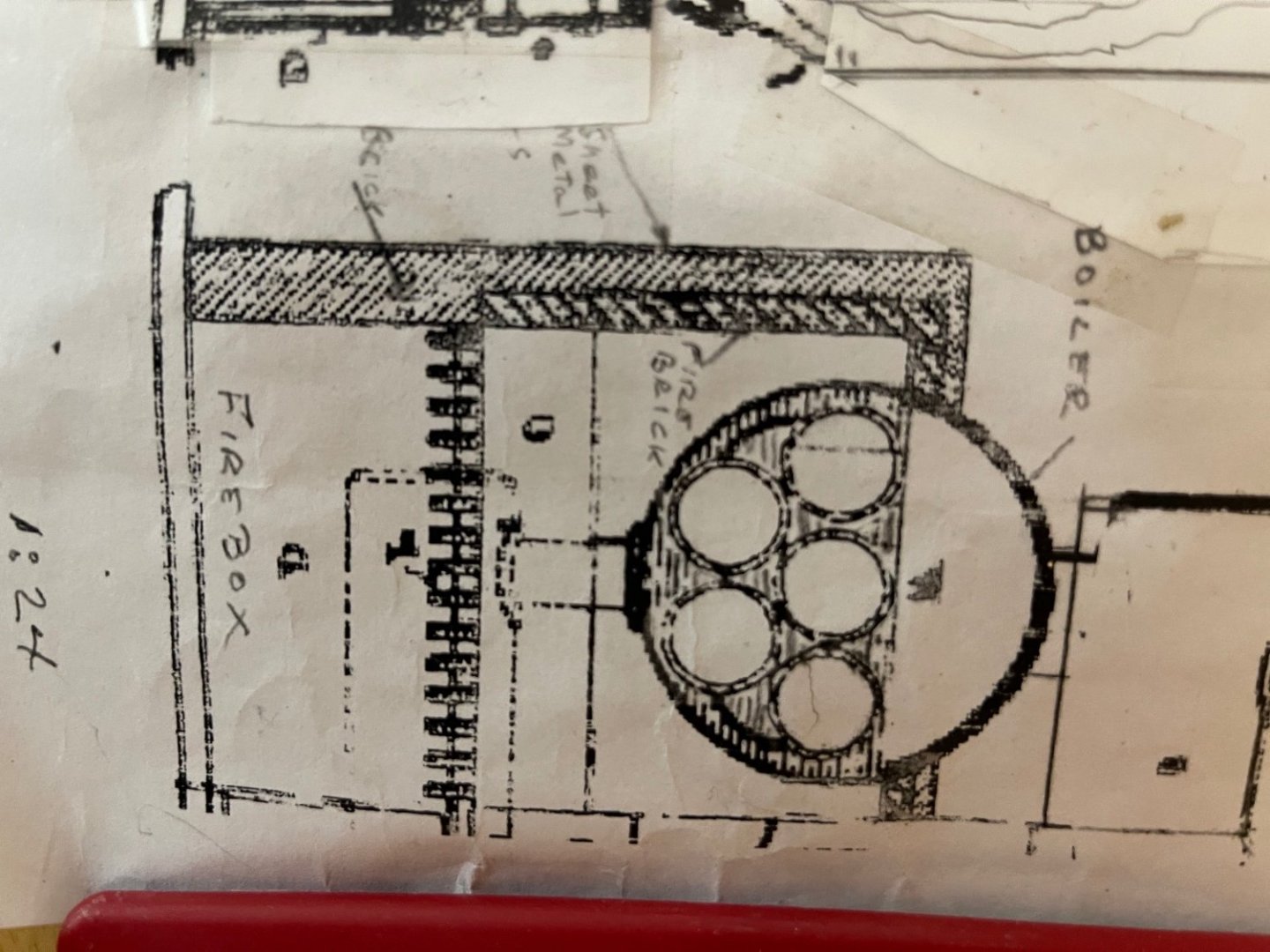

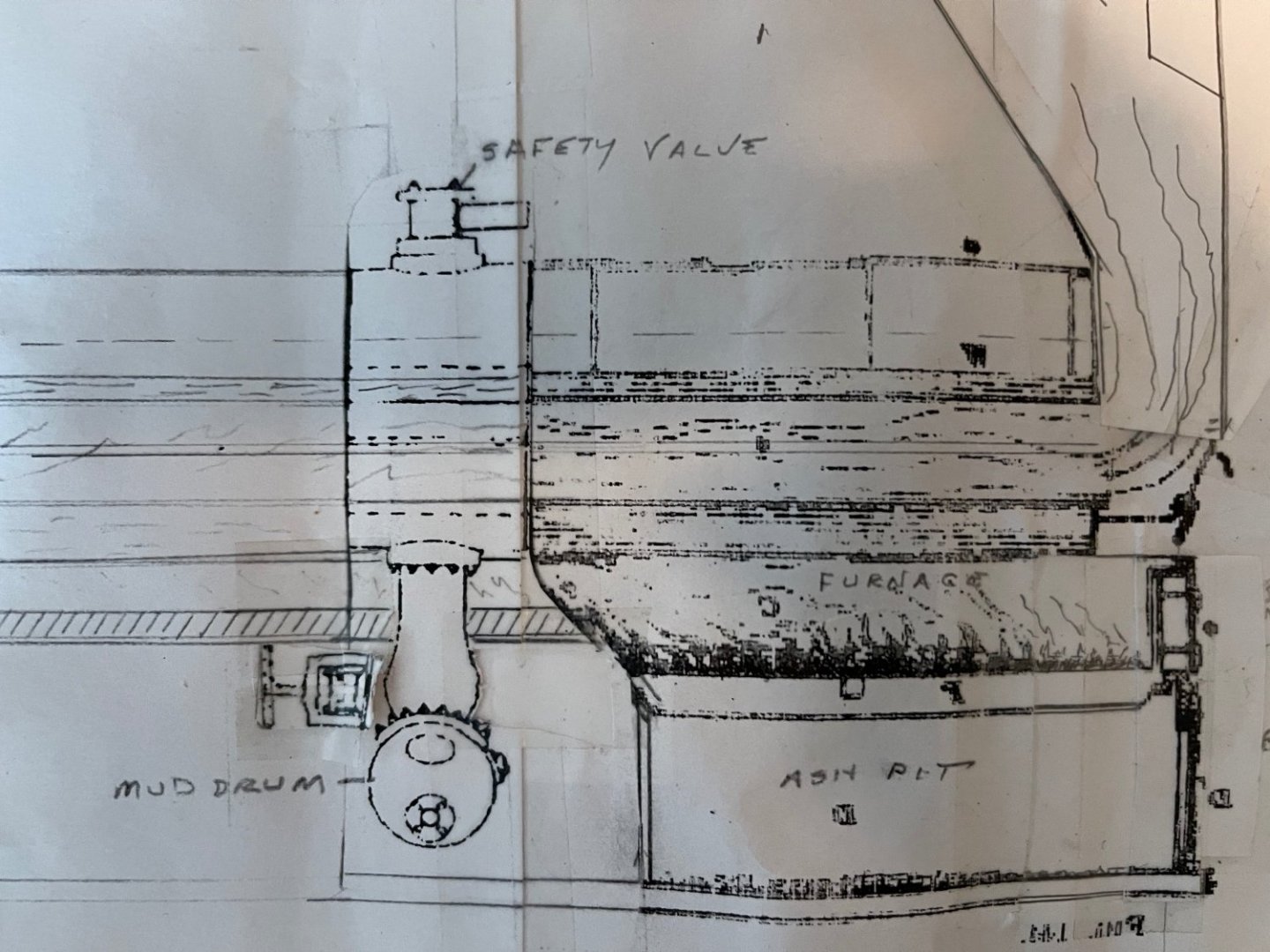

Regarding Slag & Ash Removal KURTVD Posting # 205 , Fig 60 Boiler/Firebox Configuration compares generally very well with my #206 Flue Fire Tube Boiler/Firebox Reconstruction for the USS Cairo which shows its' ash pit sitting on top of the lower hull interior planking and keel structure, as there is no ash well below the floor on the "City Class"Ironclads. The floor planking of the USS Cairo hull actually forms the surface of the Fire-room floor which is clad with iron sheeting where the ash & slag from the fireboxes is raked for further disposal. The "Doctor" Auxiliary steam driven pump sits on this same surface in the engine room immediately aft off the boilers. ( See enclosed: David Meager's excellent sketch of this area} The "Doctor" draws river water up thru the exterior bottom planking, past the hull structural frames and thru the interior floor planking and continually feeds the boilers and provides other auxiliary functions.(See attached photo of USS St. Louis Model) I hope this clarifies the slag and ash removal configuration limitations on these "City Class" Ironclads. JOHNHOWARD

-

Regarding boiler protection; Brian, The boilers themselves were pretty well protected by the Side Armor and the gun deck structure, however the boiler steam drum, not shown in the photograph, is mounted on top of, and across the aft end of the 5 boilers, contains " live steam" which is the most explosive part of the system, and is almost entirely exposed above the deck. To make matters worse, although the 2.5 inch thick steel armor covers the side casements above the chine and 5-ft below, the side casement backup wood frame is not continuous(like the bow & stern) leaving about 50% air space weakness. The boat carpenters were continuously working on auxiliary gun deck barricades to correct this weakness. JOHNHOWARD

-

USS St. Louis Ironclad Model followers: Thanks for all of your interesting comments and new ideas on coaling and ash removal. If you don't recall our previous interesting dialogue on these issues, please check page 3 of this Forum especially before and after Roger Pellett's Posting #87 on January 11, 2018. We are still trying to identify the methods that would have been appropriate in 1861 for "City Class" Ironclads. JOHNHOWARD

-

Kurt, Regarding your second message on wheelbarrows or buckets for ash and slag removal, there is no way to get a loaded wheelbarrow out of the fireproof. There is no room in the fireroom for a stair case on any wall and the only entry/exit is via one or two vertical iron wall mounted escape ladders in the forward corners. These would be very difficult to climb with a heavy bucket load in one hand. (See my recent photos of the fire room on this Forum.) Our latest theory is a manual winch on the Hurricane deck above the center of the fireroom which could be used to hoist a heavy bucket of ash straight up thru a ceiling hatch in the Hurricane deck.. However, to date, we haven't found any evidence of such a hatch. JOHNHOWARD

-

Kurt, Thanks for the input. Did you ever see a date associated with your "Fig. 60" drawing which shows an "Ash Well"extending thru the bottom of the hull and infers that they had controls to increase pressure to expel the ash and slag automatically. If this system was available in 1861, it could very well be the solution we were looking for. However the fireboxes and ash pits on the City Class Ironclads seem to simply have had doors that open onto the fire room floor so the firemen can rake the residue onto the fire room floor where they would try to hose it down and dispose it overboard- a really messy and dangerous job! Regardless, I think this is a possibility worth looking into, so I will check the cyclopediums for a date and find out if a US patent was issued for it around 1860. This is also different from the later, post Civil War, successful systems for ash removal, that we did find, which expelled it upwards over the side by air pressure rather than down against the water pressure. This system would also have to have a fool-proof one-way valve to prevent river water entering the hull and extinguishing the firebox fires or possibly sinking the ironclad. JOHNHOWARD

-

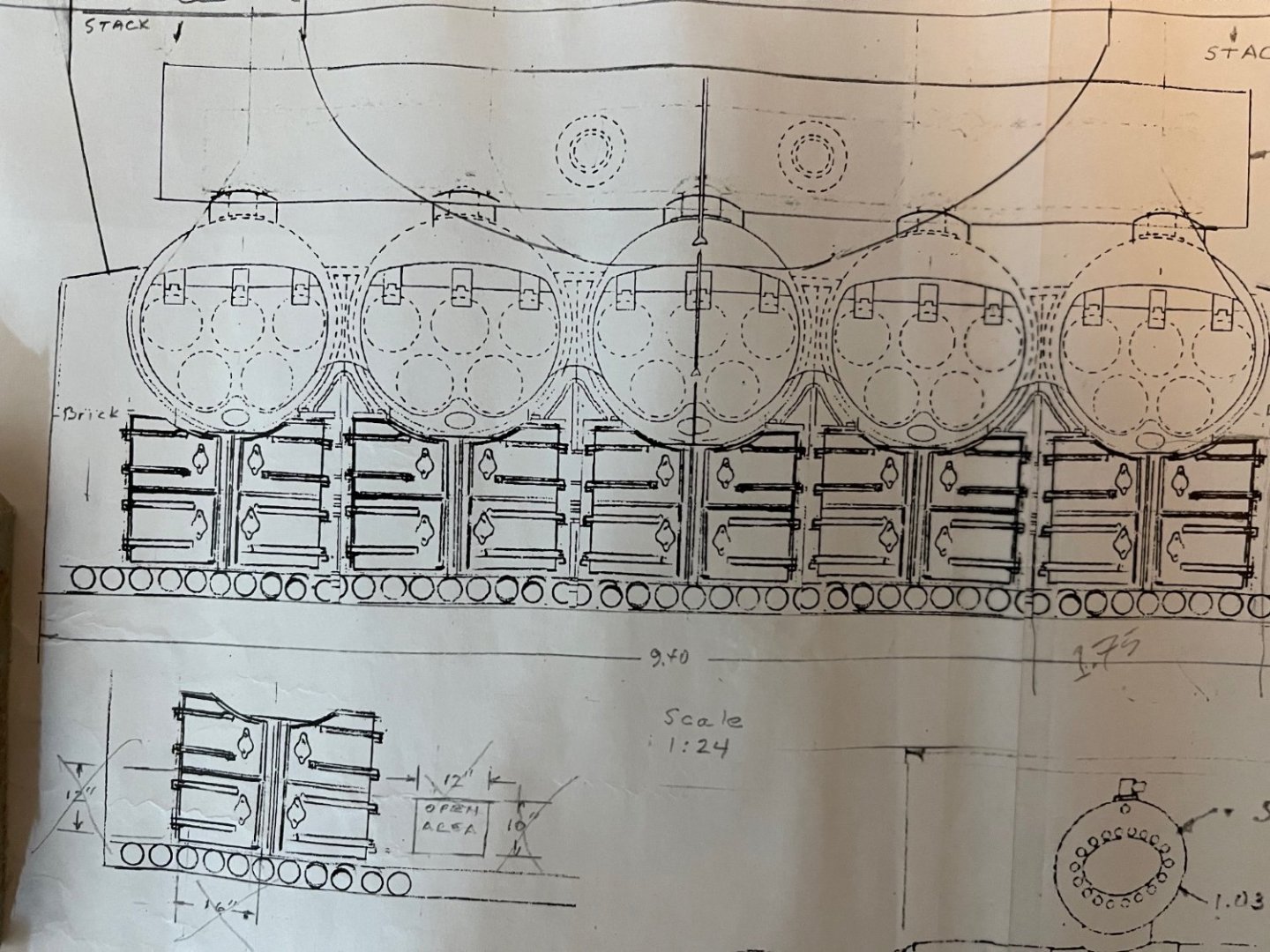

Brian, You pose some good questions and, in time, I think I can give you some good answers. When we started our USS St. Louis model , we thought Doug Ashley's Historical Structural Report drawings must be great coming from the National Park Service and since they had the real USS Cairo remains at hand. We started the hull structure in 2014 and soon discovered a lot of problematic issues we needed to resolve before we could build anything. By 2016 we started looking at the firebox, boiler' and engine drawings and photos of the USS Cairo remains and realized that Ashley couldn't have made his drawings from the pile of rubble he had access to, probably now on a barge in Pasgacola? Mississippi. But Ashley was pretty clever, he found similar drawings in the US National Archives and just pieced them together to make a conceivable representation of the USS Cairo machinery. He even noted this fact on some of his drawings. As the mechanical engineer on our USS St. Louis Ironclad Model Team, I took on the job of reconstruction of the Firebox, Boilers, Smokestack configuration for our model. The result was the drawing in the photos below dated: Rev A, 22 Oct 2016. (another of ourForum Gap time issues) It will take me a little time to remember all the features of this little drawing but the second from the left shows the Firebox, boiler, steel, and firebrick's relationship. There's a considerable amount of information on the internet steam power plants of the Civil War era that depending on boiler type and fuel source , etc, supports this reconstruction. When you see these drawings let me know if you can read my notes which will make it much easier to answer your questions. On the steel floor issue I believe ii covered the complete fire room flooring and the firebox/ash pit area. The metal boilers are inside a bath-tub of firebrick and supported on iron stands under the"Mud Drum" so the floor in this area would not have been covered with steel. These Mud Drums were periodically flushed with boiler water directly on the deck into the bilges and pumped back into the river. To Be Continued: JOHNHOWARD

-

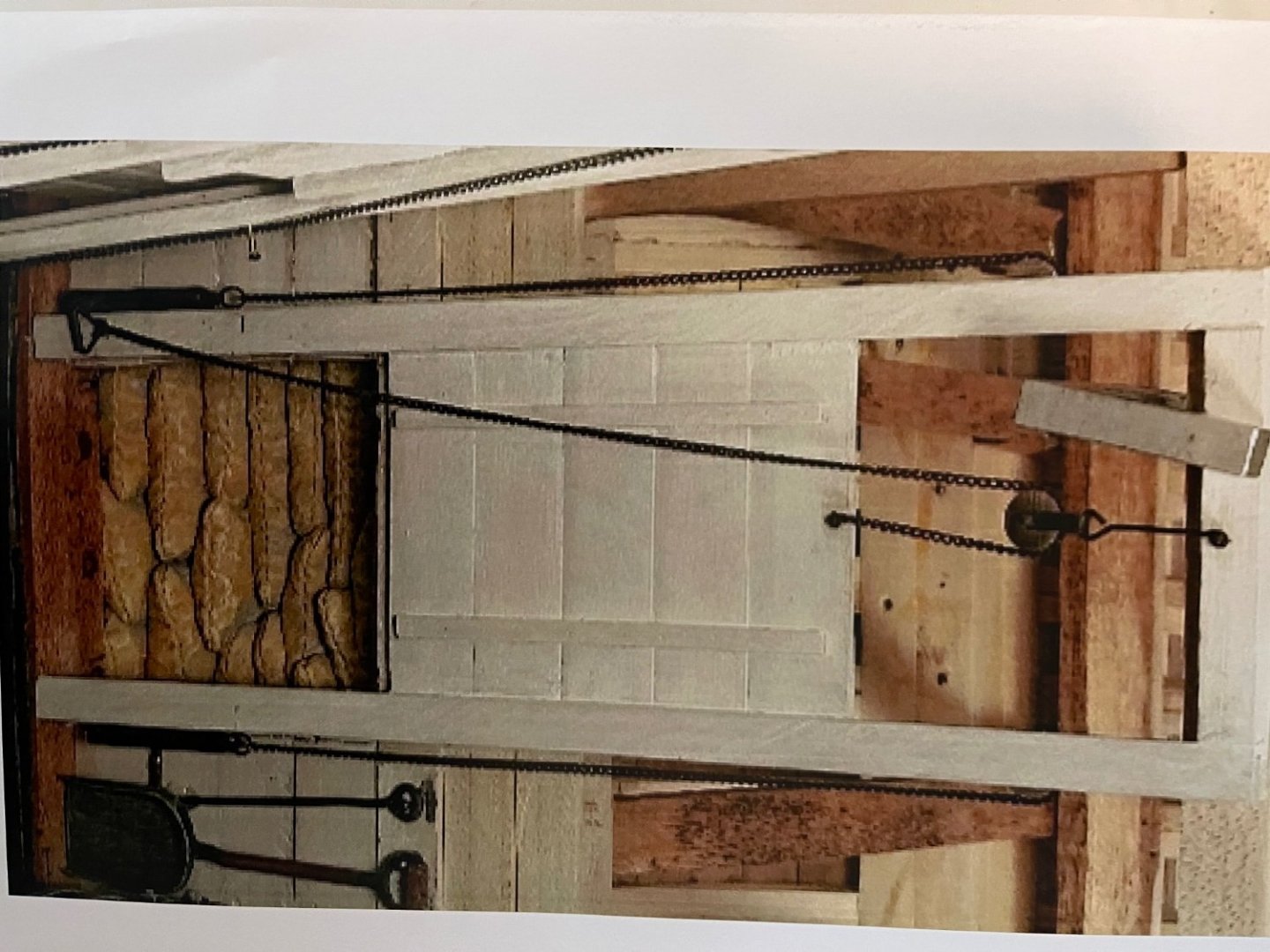

As a continuation of some of our missing but interesting Forum entries between 2015 and 2017, we added counterbalanced, manually opened doors for access to the coal bins from the Fireroom floor, based generally on the designs for similar Civil War era steamboats and shore coal storage bunkers. Initially we were assuming transport of loose coal using wheel-barrows and later added bagged "Steamboat sized" coal which was easier to load & stack in the coal bunkers and then either manually or "wheel-barrowed" into the fireroom. Unfortunately, as the model assembly continued and we added the Hurricane Deck, et al. much of this detail is hidden except by using a bore-scope type instrument, but it was fun to build and we still have some surviving photographs of our build. JOHNHOWARD

-

Ironclad Forum followers: In relation to our recent search for additional access hatches and stairways: Upon rereading my Post #192 , I found an error when I mentioned that the City Class Ironclads "burned one Ton of coal per day". This should have read "one ton of coal per hour" and would "have required potentially dangerous slag and ash removal from the fire room on the hull floor, on a daily basis." This still remains as one of our most perplexing ironclad operating issues and since this activity is never mentioned in the USS St. Louis' log or any other document, it must therefore have been a mundane task like normal house-keeping, not worthy of comment . We still haven't found any evidence of our latest theory for a hatch in the ceiling of the Fireroom which would be thru the Hurricane Deck and a manually operated winch to safely hoist a bucket of slag and ash to dump overboard. This hatch, if it existed would have been roughly aft of the pilot house, near the cook stove chimney exhaust, and between the firebox smoke-stacks. We previously studied, and rejected, more advanced techniques for ash and slag removal, which were only invented after the Civil war. Any other ideas? Attached are 2 photos of the fire room while being constructed on our USS St. Louis model which had a steel floor, fireboxes on the aft side, coal bin access doors on the other three sides and an iron escape ladder in the Portside corner leading thru a door forward to the gundeck. The cook stove can be seen thru the open forward wall structure above the shovel storage rack. Eventually the stove exhaust stack extended thru the wall and up thru the Hurricane deck and we added counterbalanced segmented doors to the coal bins.. The steel floor covering for the main keel can be seen in the center of the fire room. We also later switched to bagged coal storage in the coal bins for better stacking efficiency and delivery the fire room by wheelbarrows. l JOHNHOWARD

-

Followers of the "USS St. Louis" Ironclad Scratch Build Forum, This project was The Gateway Model Shipcrafters first group attempt at managing a scratch build model and simultaneous tracking of progress on a daily Forum. Today for the first time in years that I went back and reread the entire Forum Log and realized to my horror that we continually left excessively long gaps in our progress reporting. The first was between March 2015 and April 2017 when after completing the upright lower hull framing, we inverted it and planked the bottom of the hull. At the time we planned to bring the log up to date while continuing the structural build so we maintained separate photographic log books that were never incorporated into the Forum. I don't know if now there is any way to close these gaps and maintain a log in sequential order. For example, the attached photos depict how we used "stealers" to plank the stern starboard and port sponsons on the rudder posts.in 2016 with the hull inverted. I hope this helps fill one of our gaps. JOHNHOWARD

-

Brian, Just a brief thought on step ladders and small access hatches: There were 175 crewmen on these ironclads. My understanding is that, weather permitting, they generally cooked and ate their meals in shifts of small groups, either cold or around portable coal fired grills scattered around the decks, hopefully near their battle stations. Many crewmen would have inevitably slept on any open the deck space available. This would be OK in non-hostile territory but an ambush on the river is a constant threat, exactly when their personal reaction time is vital. The path up and down open external ladders on the forward and stern casements and then thru open gun ports would be congested enough, without on & off duty crewmen, queuing up to climb or descend a step ladder through a small access hatch between the Hurricane Deck and the Gun Deck-"Pure Panic!".. The only other ladders/hatches combinations we have detected are from the gun deck to the pilot house for the captain, pilot and steersman, the escape ladders from the fire-room to the gun deck and the multiple single person access hatches between the gun deck into the hold. There were short wider stairways in the engine and boiler rooms for their relatively small crew numbers. "MY PROOF": Somehow the USS Cairo was sunk after striking a mine in something like 13 minutes without losing a single crewman! "No small hatch ladders for general access." JOHNHOWARD

-

Brian, I have a CD with a hand marked title of "Cairo IPS Drawings & Reports dated 1/16/2015" which was given to me by a member of our local Missouri Civil War Historical Society when we participated in their Annual Meeting several years ago, which focused on the USS Cairo.. The CD contains numerous reports & drawings on the USS Cairo reconstruction/preservation project, apparently created for or by NPS Vicksburg including the Philadelphia drawings and the Vicksburg cannon carriage reconstruction program in the 1990's which corrected most of their original drawing errors that certainly may be of interest you. Only recently have I unsuccessfully searched for this information by Drawing or Report numbers on the internet, which I had always assumed was available to anyone directly from NPS Vicksburg. When Elizabeth Joyner was the Cairo Museum Curator in 2014/5, she facilitated us in acquiring this type data freely with a few phone calls, however. after she retired, we could never locate an equivalent replacement for her. I have no problem sharing this data but you'll have to guide me thru the process of doing so. JOHNHOWARD

-

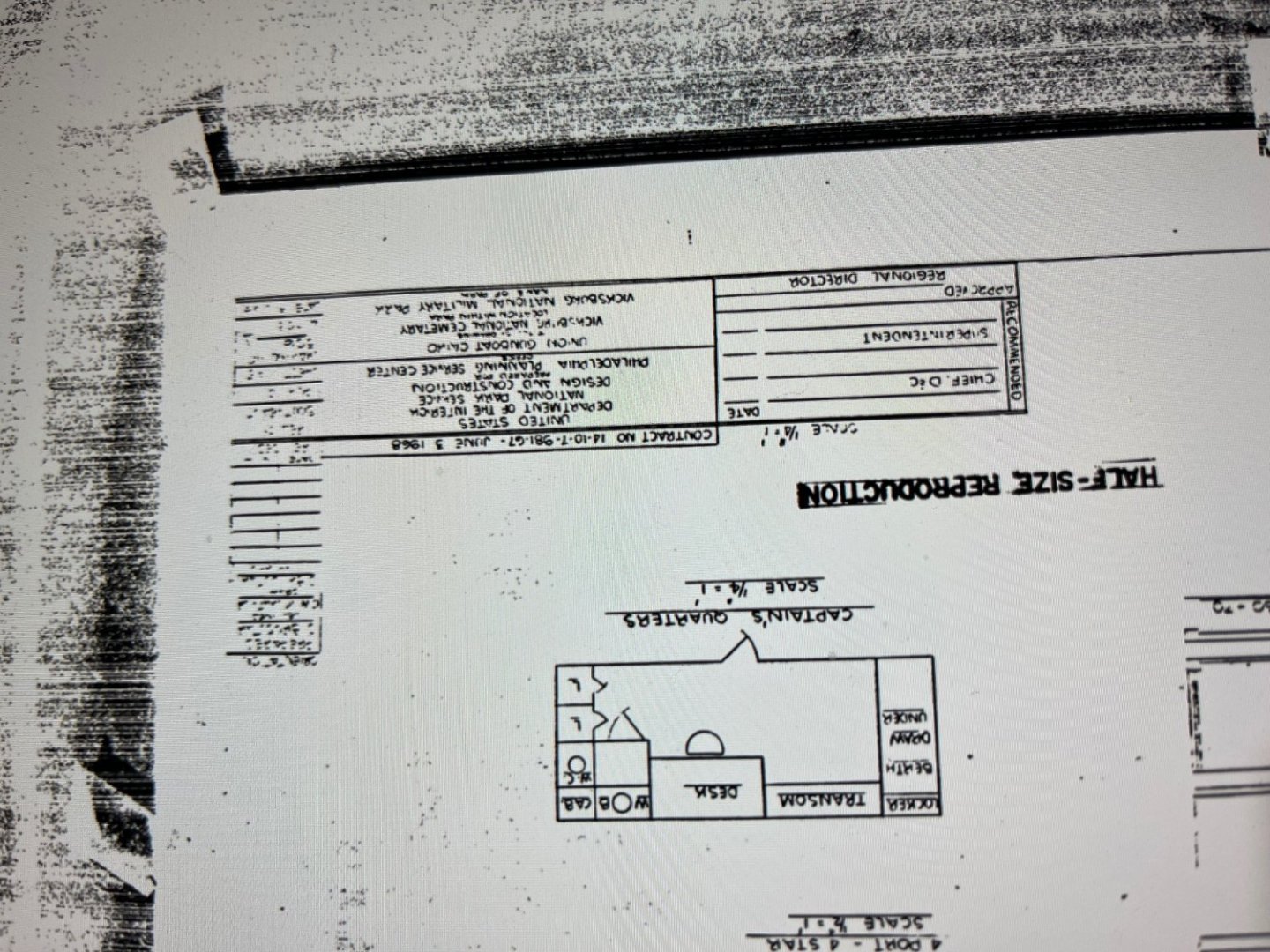

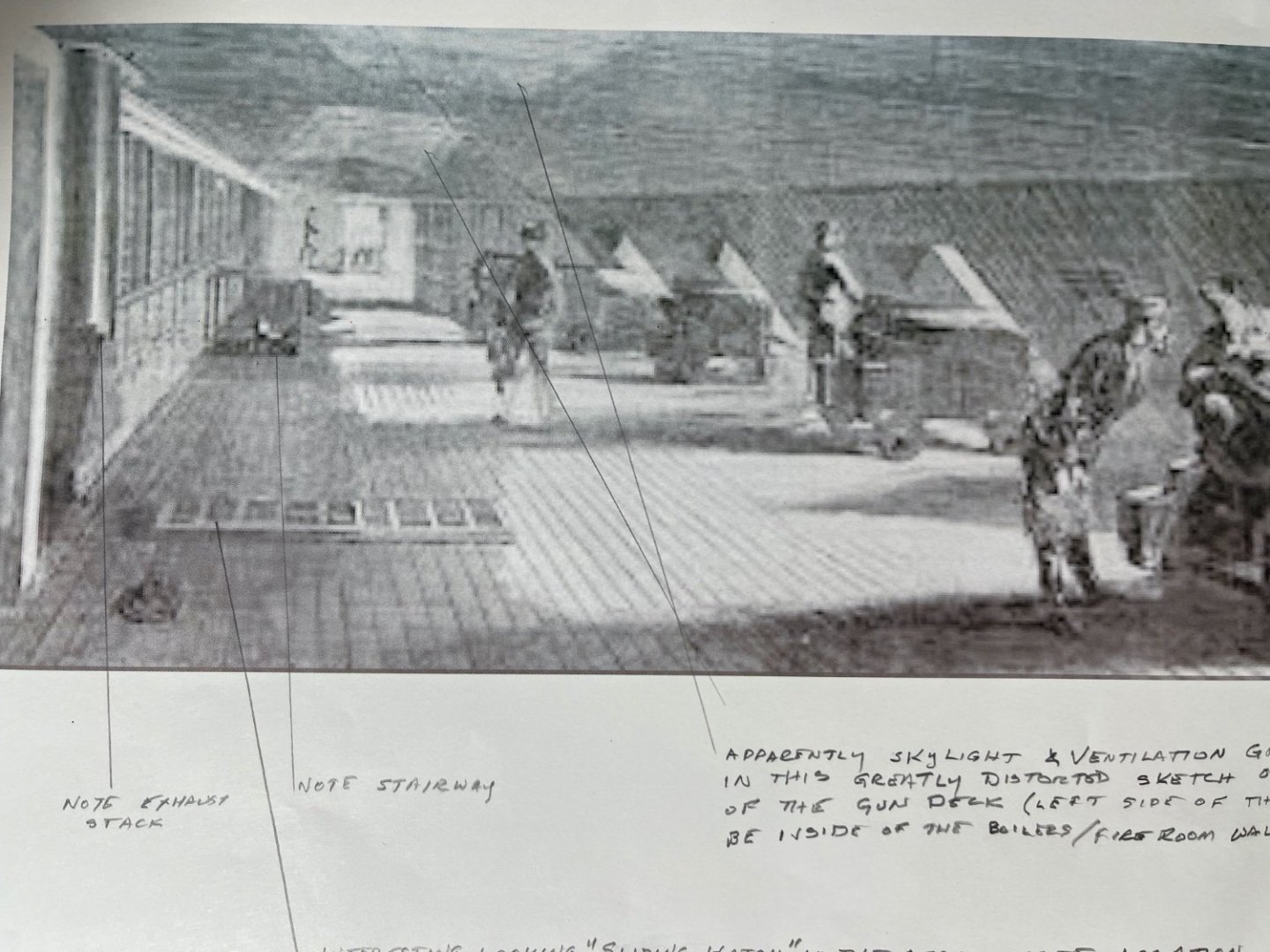

Brian, I just realized that Captian Walke's sketch represents the exact path he must have taken many times daily between his stern cabin and the forward end of the gun deck mezzanine leading up a simple ladder/hatch into the pilot house. This adds a lot of credibility to his memory and his sketch details on my previous post. It would have been a very dark and dangerous place to walk with the gunport hatches closed and no skylights. One possibility could be use of the large diamond shaped glass deck inserts embedded into upper woking decks of whaling ships, during this period, which also couldn't risk fires from use of fragile kerosene lamps and barrels of whale oil. The only other thought I have on the bright ceiling areas is that they may represent reflection from sun off the river and thru the open gun ports. The stairway on the left could also possibly lead to the munitions magazine below the gundeck. The two photos added with post come from NPS Dwg VICK 306-410002 dated 5-12-69(unfortunately inverted but I can't seem to rotate them) contracted by the Philadelphia NPS Office rather than Denver! Also note the Block in the Captains Cabin drawing titled "Transom" which is usually associated with a ventilation window above a door- way but this one would open forward into the paddlewheel house rather than a possible stairway up to the aft deck house on the Hurricane Deck. JOHNHOWARD

-

Thanks Brian, Your review of these photos is exactly what I hoped they would inspire. By combining them with our large scale model of the USS St. Louis with open decking layer upon layer, it was relative easy to identify drawing inconsistencies and possible reinterpretations of how the the ironclads were actually operated. We made numerous notes at the time of construction on theories for future research follow up but had to make some initial decisions to continue model construction. The ventilation funnels are a good example. We found some of them were either in impossible locations or the lower deck drawings were incorrect. I tend to believe that Captain Walke did actually witness and remember one such funnel protruding out of a wall as he sketched, but maybe not this wall! Regarding the deck view photo of the USS DeKalb, we believe it was taken during a periodic refurbishing clean-up so some of the items on the deck like the skylights and crew heads are probably shown in temporary storage locations. Regarding your comment on access to the pilot house, one of the early NPS(I believe from the Philadelphia Office) surveys of the USS Cairo shortly after its recovery depicts the outline of a simple extension ladder from the gun deck up to the hatch in the pilot house floor. With no external pilot house doors, this would have been a risky way for the 3 occupants to escape in an emergency! There was also an iron ventilation grate in the top of the pilot house, but not much good for daily access.The best evidence we have found for tent type junior officers cabins in aft corners of the gun deck are photos of mock-up exhibits taken by Bob Hill's Tampa bay Boat Club in about 2012 on his team's visit to the Vicksburg Museum. He later couldn't remember the story context that went with these photos but they matched perfectly with earlier sailing ship practices of lightweight structures which were disassembled in preparation for battle.. Most of the information that I accumulated from Vicksburg came from Elizabeth Joyner who was the Cairo Museum Curator at the time. Although she claimed to have no maritime experts at Vicksburg, she and her sister did a fine job of recording the artifacts they accumulated during the salvage operations. Unfortunately, after she retired, I was no longer able to identify her successor. Our primary evidence for the lack of hard-walled junior officers cabins is the lack of wall structure outlines on the rear corners of the relatively undamaged Gun Deck Photos when it was in storage during reconstruction. Pook's specifications didn't specify how the cabins were to be constructed and there were no spec deviations recorded by the contractor James Eads in the Historical Structural Report which identified the species of wood and stock sizes for almost everything else. Isn't this fun? JOHNHOWARD

-

Brian, Attached is a better copy of Captain Walke's sketch which includes some of my original notes on the contents of the photo of the Ventilation Funnel Exhaust embedded in the left hand, wall possibly directly into the fire-room.. Since the gun deck was only 50-feet wide, casement to casement, his attempt at perspective drawing, as he remembers the USS Carondelet, is greatly distorted and would have been only half this wide in the fore-ground. In our model reconstruction, the open iron ventilation grate on the ceiling was really on the centerline of the ironclad, directly above the boilers behind the wall on the left. This was the primary path for boiler heat exhaust. The "apparent skylight" would have been directly above the center of the "Fire-room" which contained an iron floor, fireboxes, and access doors to the coal bins on the hull floor and its ceiling at the Hurricane Deck level. The sliding hatch on the floor would also be above the "Fire-Room" and probably contained steel ladders for crew entry and emergency exit from the fire-room, similar to that shown partway down the left hand wall for engine or boiler room entry. This interpretation still doesn't find evidence of an internal gun deck stairway to the Hurricane deck. The main cook stove (not shown) was immediately forward of the fire-room wall on the gun deck centerline and its exhaust chimney extended thru the fire room forward wall and up thru its ceiling, the Hurricane Deck. The most important aspect of this reconstruction is that we could find no good way of safely removing the ashes and slag from the Fire-Room following consumption of about a ton of coal on a daily basis except possibly winching an iron bucket directly up thru a hatch on the Hurricane Deck. Contemporary photos do indicate some activity in the area between the pilothouse and smoke stacks but so far nothing conclusive. As previously reviewed on this forum, Roger Pellett & others identified post war iron dreadnaught inventions for ash & slag removal but we found no evidence of its use during the Civil War. JOHNHOWARD

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.