-

Posts

551 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Tallshiptragic

-

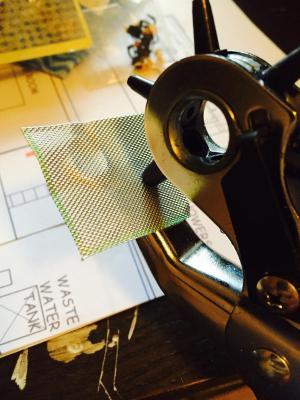

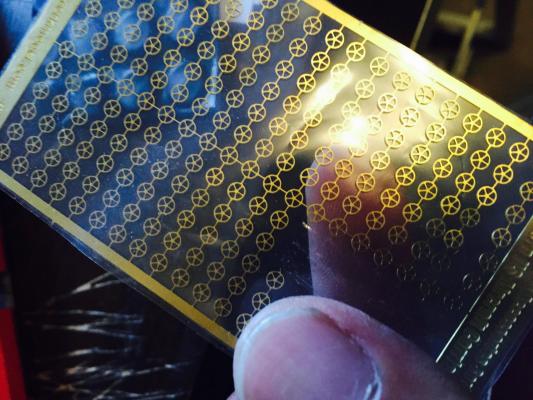

Added the five intake and discharge ports on Leeuwin today. A lot for a tall ship and nothing really for a powered vessel. Leeuwin has two 204hp yanmar marine Diesel engines powering one shaft each. As such there is a salt water intake on either side of the hull bottom for cooling water. These are covered by a convex grate to stop debris and fish from coming into the plumbing. I probably didn't need to drill out the holes for these but I did and then covered them with the grate. I used some small ali grate I have - Model train stuff- and cut it out using a leather hole punch. Because of how the punch works and the pliable grate material, you're left with an almost perfect convex shaped circle there are two discharge ports either side of the hull above the waterline which are simply drilled holes. There are grates though these are further inside and not seen so I just left them as holes. Next to these are the exhaust. These are covered by a half tube with the opening at the lower end forcing any smoke to come out downwards rather than coming straight up towards the deck. Most modern warships have these type of coverings on all hull openings and from a distant look like lunch boxes all over the hull. I just used plastic half round rod to simulate this. The last is the waste water discharge. There is only one on the starboard hull close to the keel and midships. Our grey water is the only water that is discharged after going through a treatment system. Our black water (sewerage) is also treated though stored onboard and pumped out while ashore by truck. As we mainly do inshore (within 200 miles) of the Australian coast, we follow marpol regulations and go beyond to be as green as possible. No garbage is ever thrown over the side even biodegradable food waste. Back to the discharge port, this was drilled out and unlike the engine discharge port a star shaped grate is quite visible just inside the port. I used some PE helo deck tiedowns which I use on my 1/72 warships as it was the perfect size. Let me know what you think.

-

Thanks for checking in Piet! The Java would make an interesting model, an ugly duckling, no wonder you're father hated it. I assume he was on her during the battle of the Java sea? I'm also a member of Task Force 72. A model warship group based in Australia with bases in all major city's. We build scale RC warships - well mainly warships in 1/72 scale. It does look fantastic to have a fleet of all different ships in the water at the same scale. One of the members is in progress of building HMAS Perth WW2 Leander class cruiser to go with my De Ruyter. His father was also killed like yours but on the Perth during the battle.

-

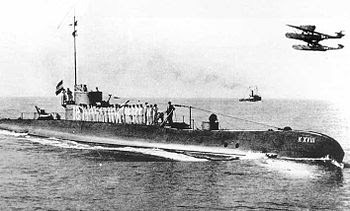

The K XXI was actually used to power Perth during the war! The hull was towed up the swan river a and she was moored off what's now Barrack street jetty and her generators where used as emergency power her main gun is still here mounted as a memorial at one of the yacht clubs on the river. I have been there just can't remember which one - we have quite a few yacht clubs here. Also the deck of the conning tower was used to repair a pilot boat which is now in the new WA maritime museum. A very small world we live in!

-

Thanks Piet, he was awarded the Militaire Willems-Orde by the Dutch and an OBE or Order of the British Empire posthumously awarded. The Dutch navy also commissioned a Van Stralen klase minesweeper in his honour the Van Well Groeneveld which his wife was at the commissioning ceremony. The greatest tribute though was his son also Carel, who was a teenager through the war and a 'guest' of the japs like my father and his family, went on to join the Dutch navy and became the commander of Dutch submarines in the 70's and 80's. I've attached a photo of Carel senior and junior plus the minesweeper. My father built a beautiful 1/24 scale model of the minesweeper in the 90's which is now somewhere in holland, though not sure where. Anton

-

Thanks again everyone. It's nice to see the support and interest is very much alive As for my warship builds, I do have a Russian stealth corvette of the steregushchy class planned and possibly the WW2 era Dutch cruiser De Ruyter I want to build. They would both be 1/72 scale so most likely the steregushchy will be the next ship as its only about 1.3m in length. The De Ruyter is a bit over 2m like my AWD build so takes up a lot of space to build which I don't really have at the moment, but we shall see. Playing with more hull detail. The shafts and supports are mocked up out of Ali rod for the shaft and plastic. Also next will be the few intakes and sea chests she has plus the depth sounder. So a few holes and a nobbly bit.

-

Fantastic build Piet! My fathers uncle was commander of the Dutch submarine K11 when she set off the charges at the Surabaya naval base in Indonesia before the Japanese landed. The K11 then sailed for Fremantle, though without the CO my fathers uncle - went ashore as some charges hadn't blown. The charges blew, and he never returned to the sub... Will follow with great interest.

-

Thanks Keith. Next time you're in WA and we're not on a voyage you can always come for a days ail or twilight sail. Have added the rubbing strakes on the hull today. The rubbing strake on the ship is a half rounded steel which runs the majority of the length of the hull. The strake also marks the position of where the main deck sits. I've used 2mm plastruct half round strip which becomes 112mm at 1/1 scale. The strake on Leeuwin is 116mm... Close enough for me you will also see a small diameter and smaller length strake on the port side only. This strake was added during our last refit. This was done as our home berth in Fremantle harbour, we have four large steel fenders specially built for us attached to the wharf. During winter - our refit time- we don't have any voyages so apart from when she's up on a slip we can spend up to three months tied up during the worst winds and swell of the year. Even in the harbour we can still get 3+ metre swells behind the breakwater. Long story short one of the fenders caused quite a bit of damage to the ship and ended up coming apart from the wharf itself. 3+metre swell and 55 knot winds thrusting the ship against the wharf was not a fun time. So this extra strake is to keep this fender off the ship- well causing damage to the ship.

-

Thanks Patrick, happy to help where and if I can. I've added a couple shots of my last model a 1/72 HMAS Brisbane or should I say nuship Brisbane. This is one of the new AWD's being built here in Australia. This model is full RC with working lights, radars rotating guns and firing verticle missile. She's a big one at 2.04 meters in length built with a fiberglass hull and plastic sheet for the superstructure and brass and resin fittings. So even though I'm a tall ship sailor, the Leeuwin is a jump for me in period of ship models. I'm looking forward to something not grey and with sails!

-

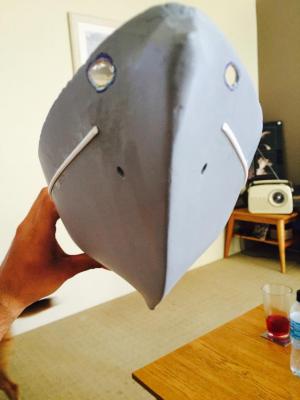

Thanks very much Chris. She's a beautiful ship and sails very well. One of my favourite tall ships I've sailed on also, very different to the others. Just to show what I've done up to now. The templates I've used to make the decks I copied onto plastic sheet to simulate the steel decks. These will have planks as the real ship has 40mm teak planks over the steel decking. It still looks rough as I had to undercut a few mm and filled with plastibond - a heavy duty bog - this will make the hull to deck join super hard and it's also quite easy to sand smooth once set. To support the decks I've used lime stringers. These where attached to the hull plastibond also as I have yet to find an off the shelf glue that will hold wood and fiberglass together sufficiently. This stuff is cheap and does the job brilliantly.

-

Thanks Patrick, Unfortunately I couldn't buy the hull! Haha there aren't any kits or plans available commercially for the Leeuwin on the market. Because of this I've seen a few models of the Leeuwin around with the completely wrong hull - especially the underwater sections. I'm an officer onboard so have access to the official ships plans. I don't have pics from the building of the hull unfortunately but the plug was built using a bread and butter method with pine planks and carved to shape. The molds are in two halves as the way the forepeak is made up, it would have been too hard to pull out of a single mold. A wooden template shaped around the keel profile is placed on the plug to form one half of the mold. Once this is set, the same is done for the other half. Both halves are clamped together to form one complete mold. This is what's used to produce the main model hull, once the fiberglass is set the two mold halves are unclamped and you're left with a one piece hull. Below are photos for a hull mold and plug for the STS Young Endeavour to give you an idea of the process.

-

Hi everyone, This is my first post after a few years. I had been on the original forum though work as usual always got in the way. Anyway signing back up I've decided to post a new build log of what I'm building now. This will be a model of the STS Leeuwin II. The STS (Sail Training Ship) Leeuwin II is a tall ship based in Fremantle, Western Australia. The Leeuwin is a three-masted barquentine. It was built to a design by local naval architect Len Randell by Australian Shipbuilding Industries Pty Ltd (now BAE Systems Australia) and launched on 2 August 1986. It is currently operated by the Leeuwin Ocean Adventure Foundation, a private not-for-profit organisation that runs youth training voyages along the West Australian coast. The ship's overall length is 55 metres (180 ft) and its beam 9 metres (30 ft). The hull is welded steel with a teak deck. The main mast is 33 metres (108 ft) tall and, when fully rigged, the ship carries over 810 square metres (8,700 sq ft) of sails. A full crew consists of 55 people, consisting of 5 permanent crew, up to 10 volunteers (including four watch leaders, a bosun's mate, cook's mate and purser), and 40 trainees. The watch leaders take control of the four watch groups and lead the trainees through activities and ship duties on voyages of five days and more. The model is based around a fiberglass hull and will be built using various media including fiberglass, plastic, wood and brass.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.