-

Posts

1,572 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Garward

-

-

-

-

-

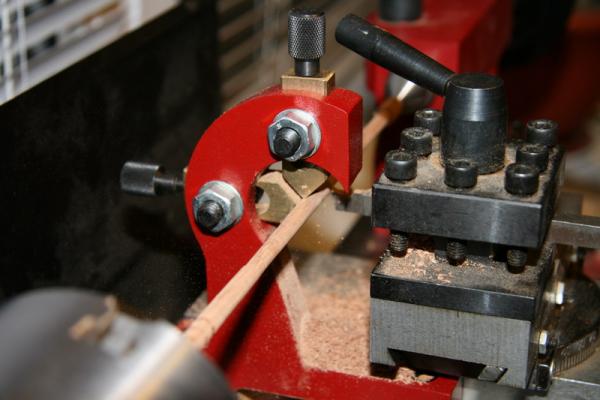

Polishing of square preparation is conducted layer-by-layer: the layer of the set thickness consistently from each corner of preparation, then the following layer and so on is removed. Being formed after removal of each layer of a side have almost identical width (with an accuracy of 0,1-0,2 mm) on all length of preparation, process of increase in width of sides easily both it is rather precisely operated and it is supervised, than this way and attracted me. The surface of new sides needs only small finishing polishing, besides, the received profile facilitates and accelerates process of production of round parts of a yard.

-

-

-

-

-

-

-

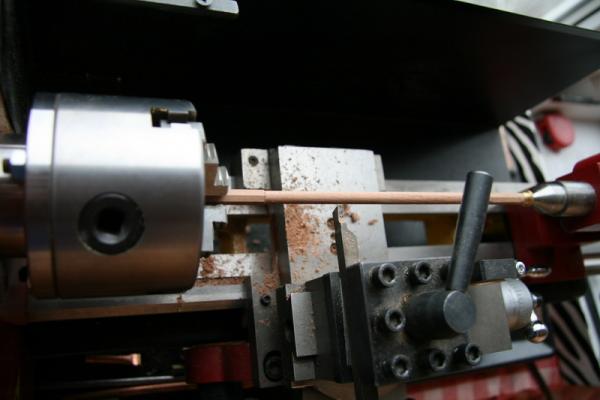

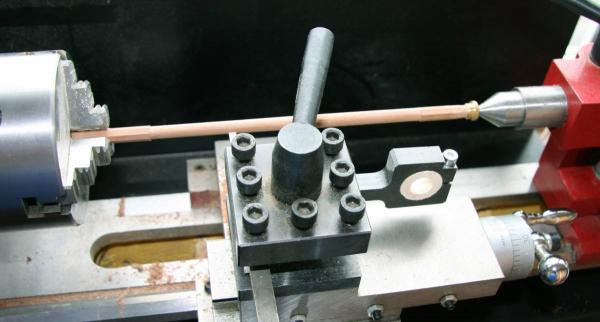

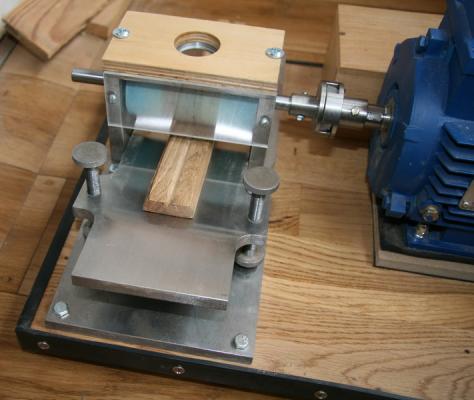

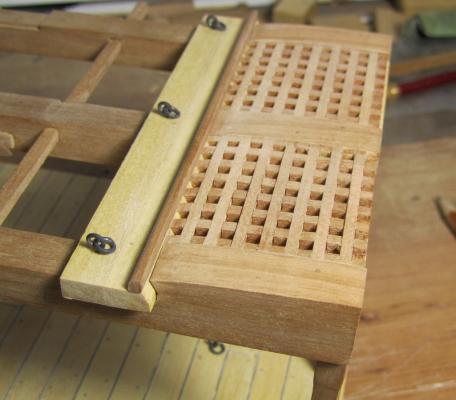

14.3.1. Manufacturing of laths of an octahedral profileThe octahedron received after polishing of pasted levels, wasn't pleasant and I decided to make it directly of a square profile. There are many ways of the decision of this question (by means of a plane, a file, the milling machine tool and etc.), different labor input and accuracy of the manufacturing, everyone modeller chooses a way with reference to available possibilities. I have solved this question by means of THE DRUM-TYPE GRINDING MACHINE http://modelshipworld.com/index.php?/topic/82-montanes-by-garward-occre/page-37and overlays on a desktop in the form of an oak lath with a V-shaped longitudinal groove (groove surfaces form a corner 90 hailstones.) into which square preparation is inserted, and then its corners are ground before education of sides of the demanded width. Polishing is conducted on layers: the layer of the set thickness consistently from each corner of preparation, then the following layer and so on acts in film. Formed after removal of each layer of a side have almost identical width (to within 0,1-0,2 mm) on all length of preparation, process of increase in width of sides is well and precisely enough operated and supervised, than this way and has involved me. The surface of new sides needs only small finishing polishing, except that, the received profile facilitates and accelerates process of manufacturing of round parts of a yard.Process of manufacturing of fore-topsail-yard Montanes is more low shown (nominal diameter of 6 mm, length of 310 mm, the yard middle has an octahedral profile in length of 80 mm) on this technology. The oak lath before groove manufacturing is ground for giving of parallelism to sides, the groove is executed on milling cutter MF 70 with finger-type mill a V-shaped profile (from Proxxon), preparation from a pear section 6,5х6,5 mm in length of 400 mm.

-

-

-

-

-

14.3 . YARDSI began production of yards also, as well as a bowsprit - preparations of a square profile are cut off from a pear parquet hoard, planed by a plane and lunettes are pierced on the machine with use mobile. Then on the central part of round preparations of the bottom yards with a diameter of 8 and 6 mm I tried to make an octahedral profile gluing of levels.

-

-

-

-

-

-

-

-

MONTANES by Garward - OcCre

in - Kit build logs for subjects built from 1751 - 1800

Posted

Continuation