-

Posts

1,572 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Garward

-

-

-

-

-

-

-

-

Dear colleagues, thanks for an assessment of information and discussion. I am always ready to answer your questions on the given technologies of imitation of nails of a deck flooring. As far as I know, besides given here exists also other technologies, it would be interesting to look at them and to discuss.

-

-

-

-

-

-

-

-

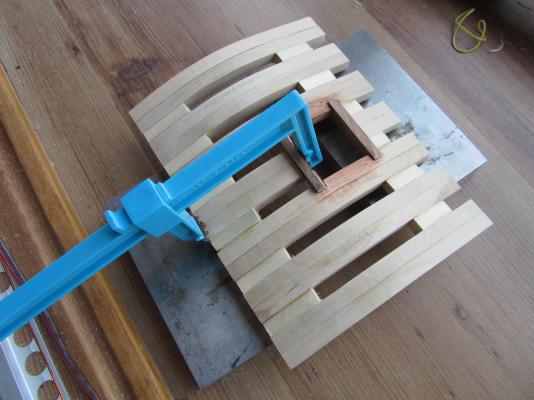

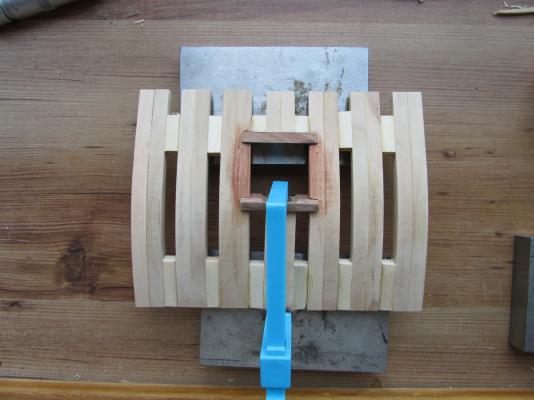

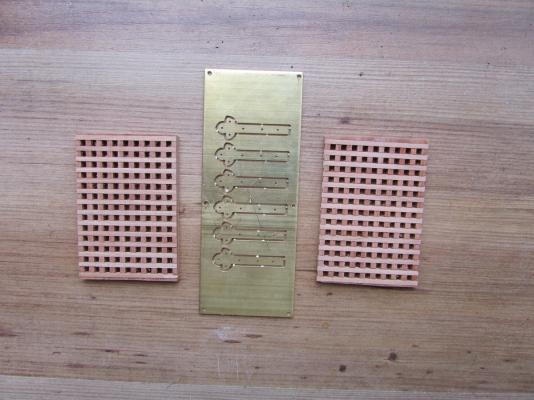

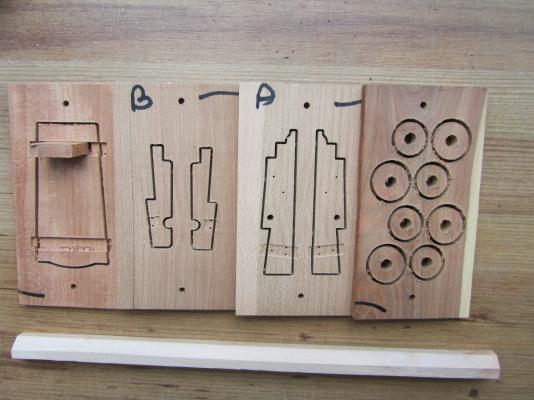

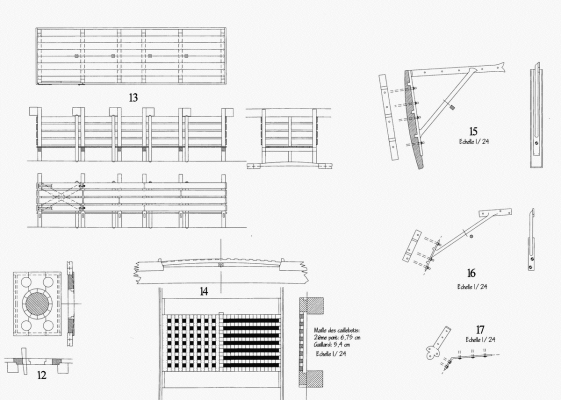

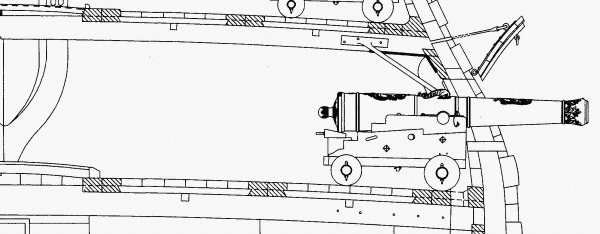

This project is development (the second version) 24-pound bronze gun of Le Fleuron 1729, M 1:24 http://modelshipworld.com/index.php?/topic/454-24-pdr-bronze-gun-le-fleuron-1729-by-garward-m-124/ constructed before modelThe model of a gun represents the artillery post consisting of a bronze gun with some accessories, fragments of a board and two decks. The model is made in M 1:24 according to drawings of the monograph Le Fleuron, the trunk of work of Alexey Baranov, part of wooden details - a gun carriage (except axes and aim wedges), beams, frames, gratings are made on a milling cutter with ChPU our Polish colleague Mirek. In this version I tried to consider experience of construction of the first option of this model.I provide some drawings, allowing to make general idea about the project, and also a photo of initial details below.

-

I like it very much. With this type of mechanism, you can connect every type of tool. A saw, a disk grinder, a drum and so on. Wonderful.

Many thanks for the comment!

-

Thank you very much, Gregory !

-

Hello Captain Garward,

Hum more goodies form the equipment building section. I have one question on your equipment. I noticed the tilt table design which I assume is how you adjust plank thickness. I see in the pictures pieces in the sander without you holding them. To my understanding on typical thickness sanders the drum will grab and throw the plank threw the equipment if not held back from doing so. Is this the case with your's or does the tilt design create an auto feed machanism, which allows hands free working?

Either way, excellent work per usually, I'd expect nothing less. Thanks so much for sharing its build and construction.

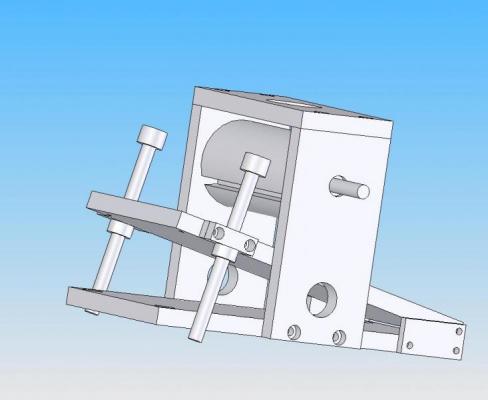

Many thanks for the comment! The drum in this device rotates towards to the direction of giving of processed details therefore it is necessary to put insignificant efforts for detail giving on polishing (usual manual giving, the detail easily is kept by a hand if not to try to remove for one pass of some mm

).

). -

-

To creation of this rig I was jogged by requirement for manufacturing (gauging) of laths and plate plainly-parallel sides for various details with accuracy of 0,05-0,1 mm on a thickness. The range of thickness of laths and preparations, and also ready flat details makes from 0,5 to 25-30 mm. I have applied for the first time the given machine tool to polishing of preparations of details of fodder gallery Montanes.

In the beginning there was an idea to use for these purposes the scribing block, for example DH 40 PROXXON, but after the detailed analysis of possibilities and results of application of various scribing blocks I preferred other production engineering. Plancks or preparations are cut on jig save with the free tolerance (0,5-1 mm) that it is easy to make practically on any applied modeller jig save, and then calibrated on the grinding machine with necessary accuracy. This production engineering provides the big accuracy, than machining of laths on the scribing block, especially for thickness of 1-3 mm.At designing of the grinding machine I used the materials published on various sites, and also experience of the Polish colleagues on manufacturing and application of similar grinding machines:

The general circuit design of a grinding part of the rig simple enough (see also the reference) and does not demand additional explanatories.Full information on the machine here http://modelshipworld.com/index.php?/topic/82-montanes-by-garward-occre/page-37 -

Most often used electric tools at construction of models of the ships are the circular saw, the grinder and the boring machine (or a drill). It makes sense to begin workshop equipment with these tools.

-

Here is a shot of my steamschooner deck. The black streaks are from fuel oil spills when refueling tank on left This is spalted English Walnut.

Interesting drawing turned out on the deck, similar to structure of wood of a nut.

-

U are a master,we think about it,u made it....

All lovely tools from were we only can dream...

A big shipbuilder and a great toolbuilder...

Yes Sir u are unbelievable,such a craftmanship....

I thank for such good mark of my work

!

! -

I may be building this as my first ship if my wife gets it for me

David

I wish you to receive the favorable decision from the wife

!

!

24-pdr bronze gun from Le Fleuron 1729 by Garward - FINISHED - 1:24 - second version

in - Build logs for subjects built 1501 - 1750

Posted

A little the idea of construction changed - frames changed also