-

Posts

86 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by kentyler

-

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

-

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

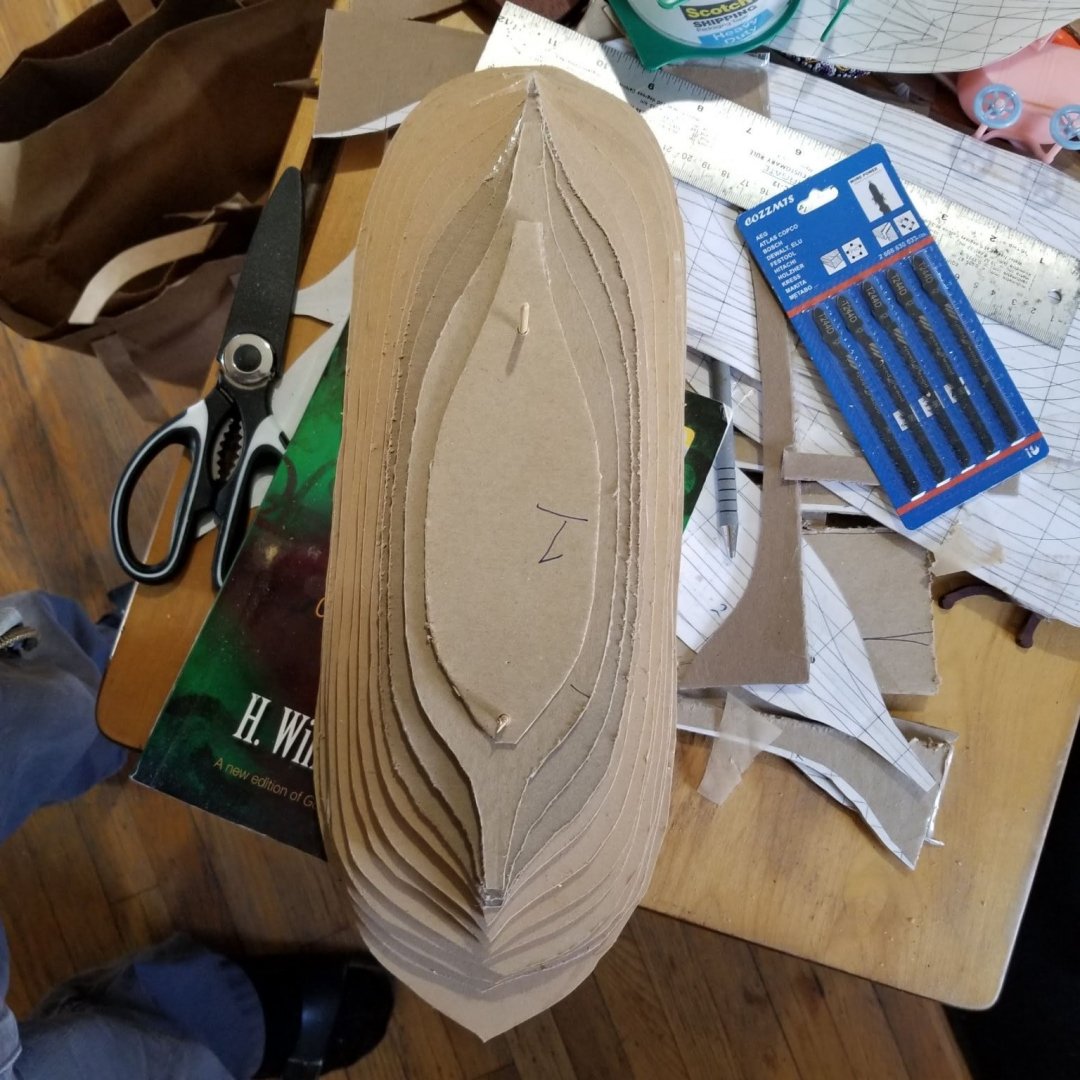

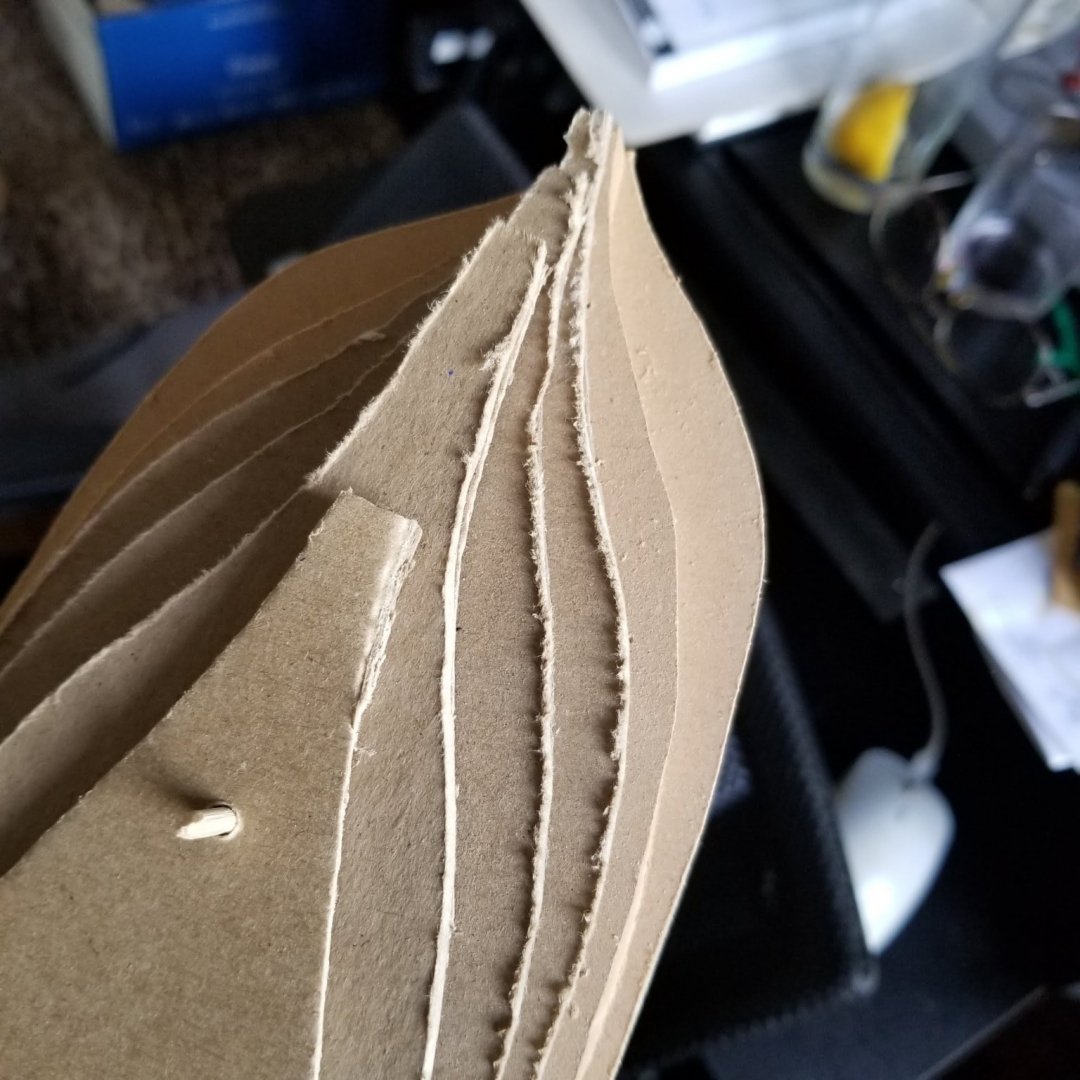

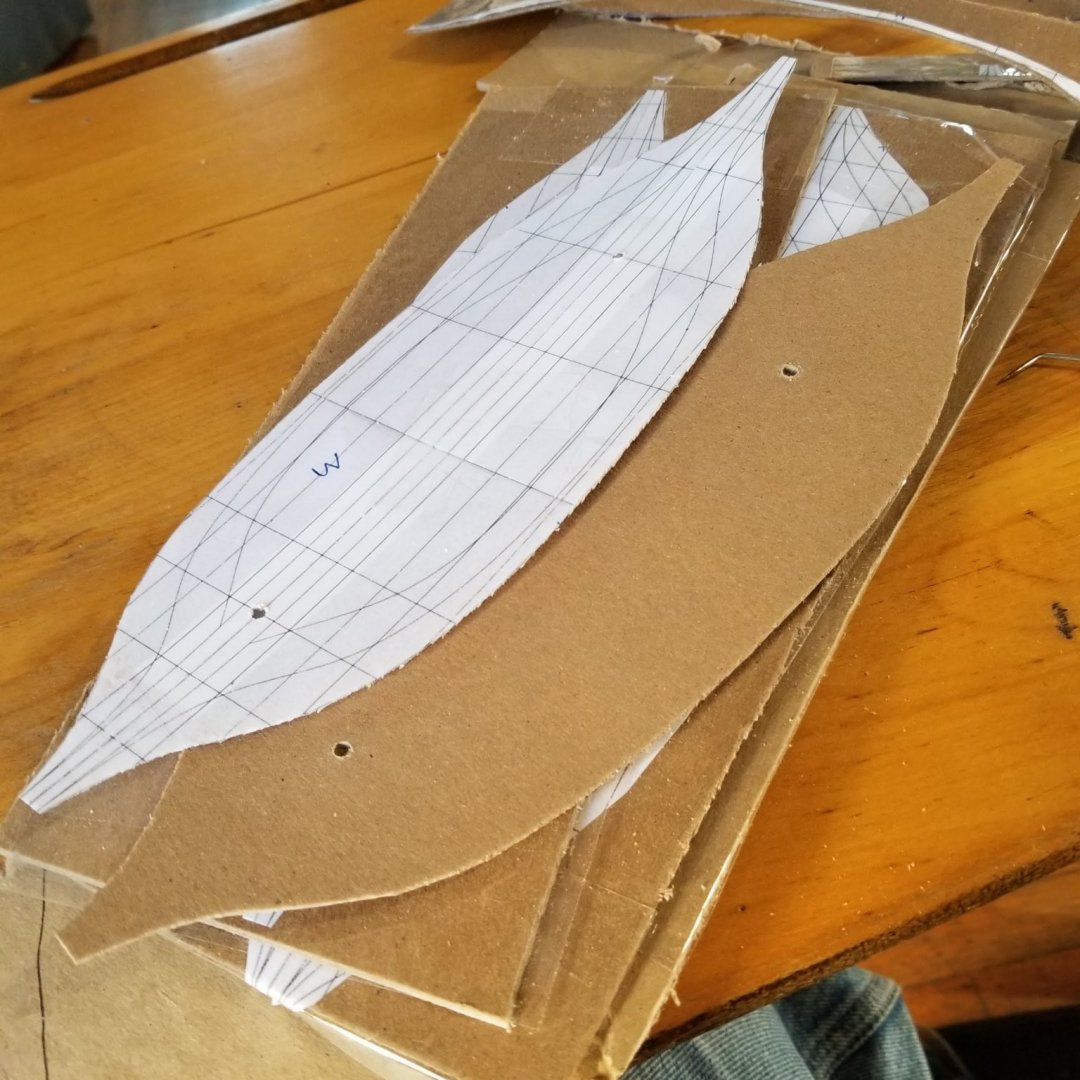

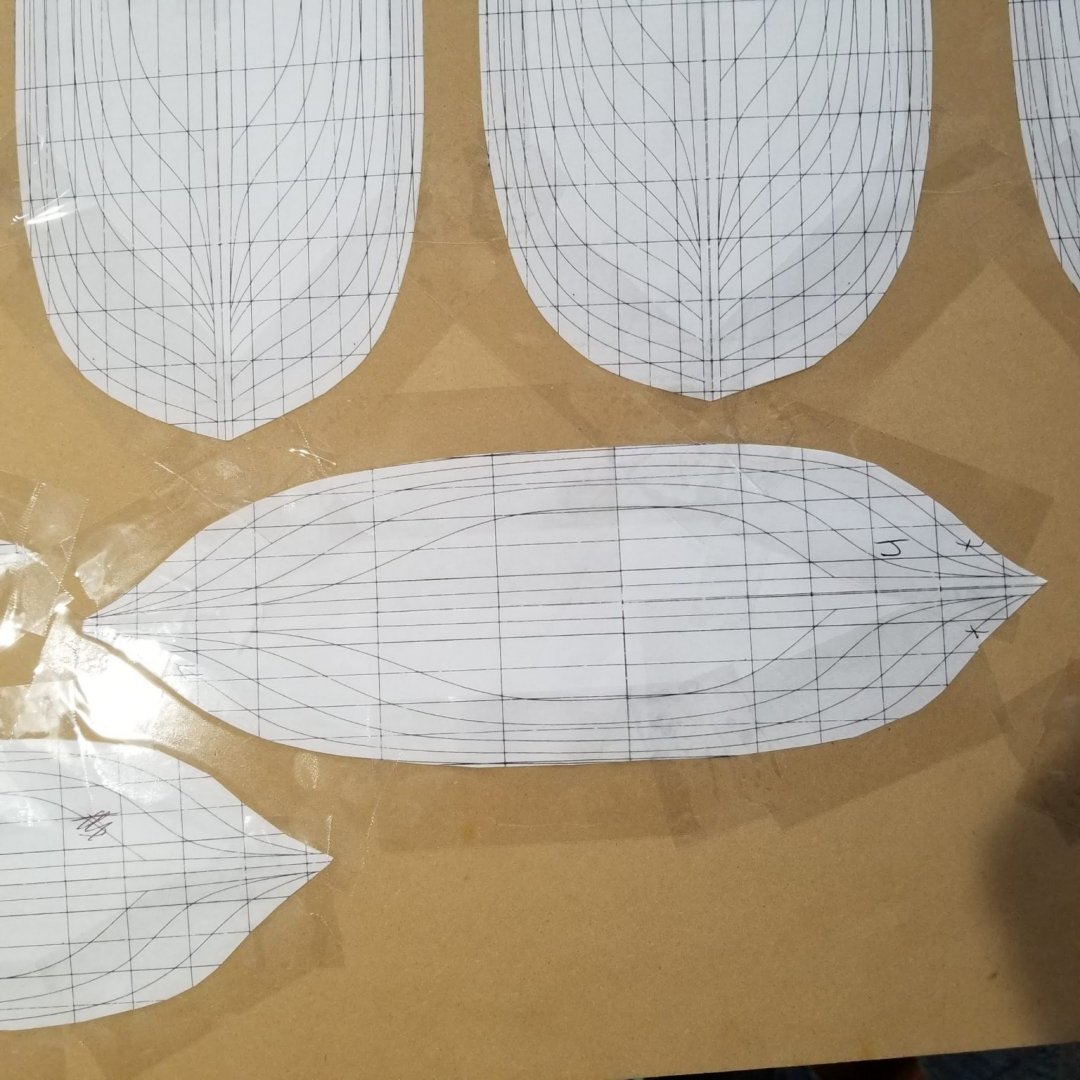

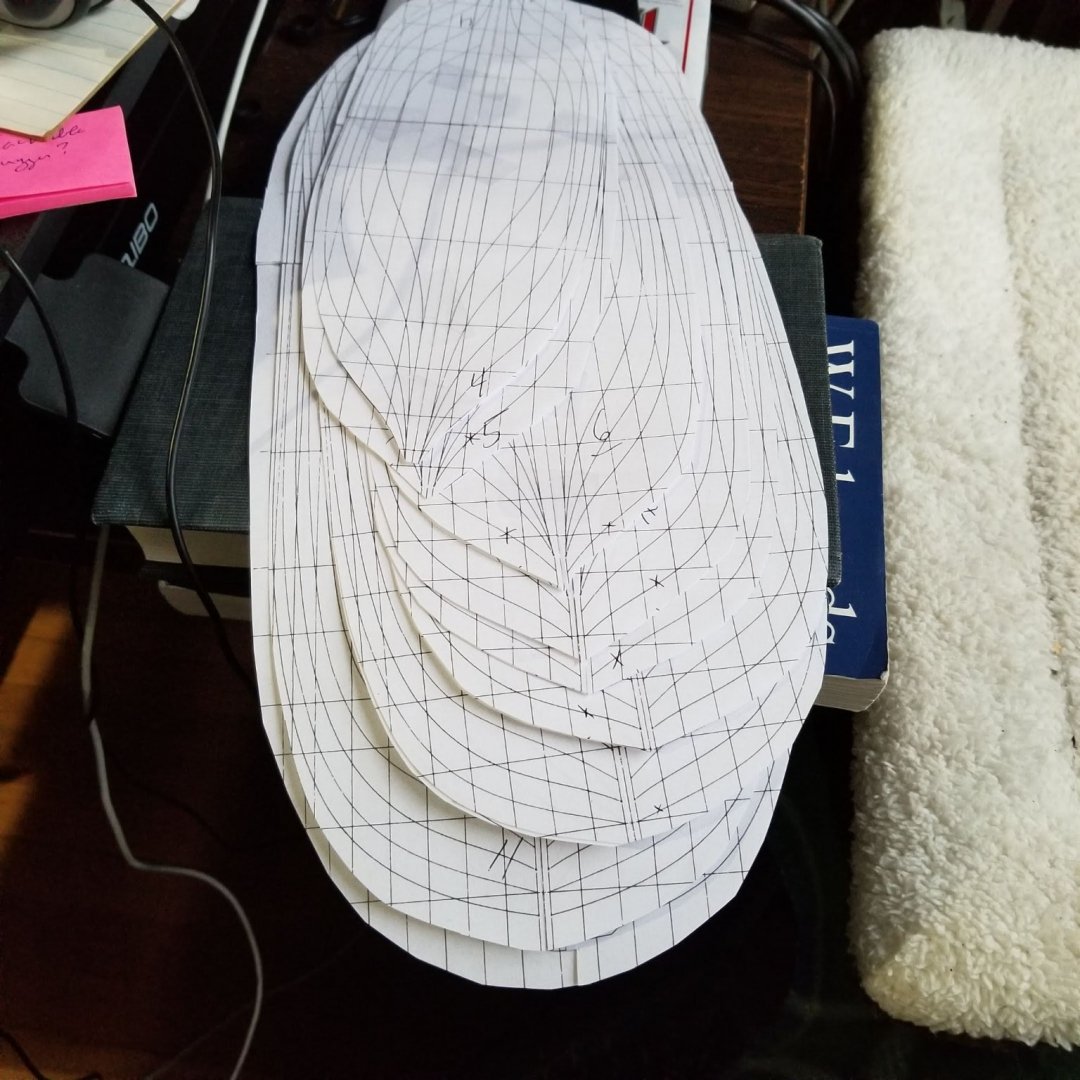

all layers cut now... i will have to use three of the attempts that did not work to raise the ship high enough above the building board to have space for the bow next I need to make the building board...with enough space to use it to position the section templates as I shape the hull -

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

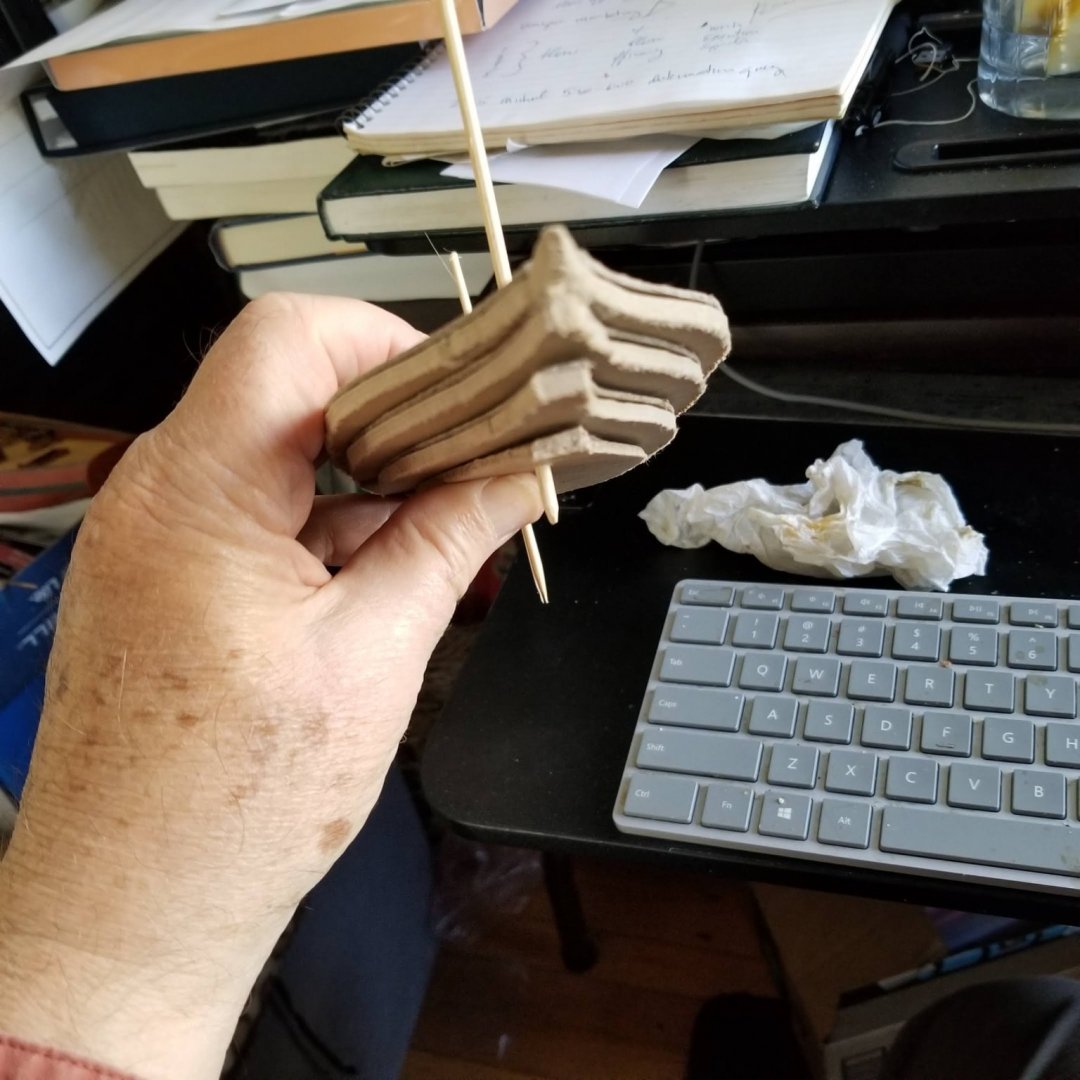

Three more layers. I had an anxious moment so I measured to get a height to compare to the drawings. I'm 3/32 short....easily made up with some paper shims...so that's a relief -

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

no, tooth count is higher, blades are brand new blade is to flexible, i don't have the knack of getting it to follow the line of the cut i don't think it's the saws fault... as my dad used to say... its the nut behind the wheel -

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

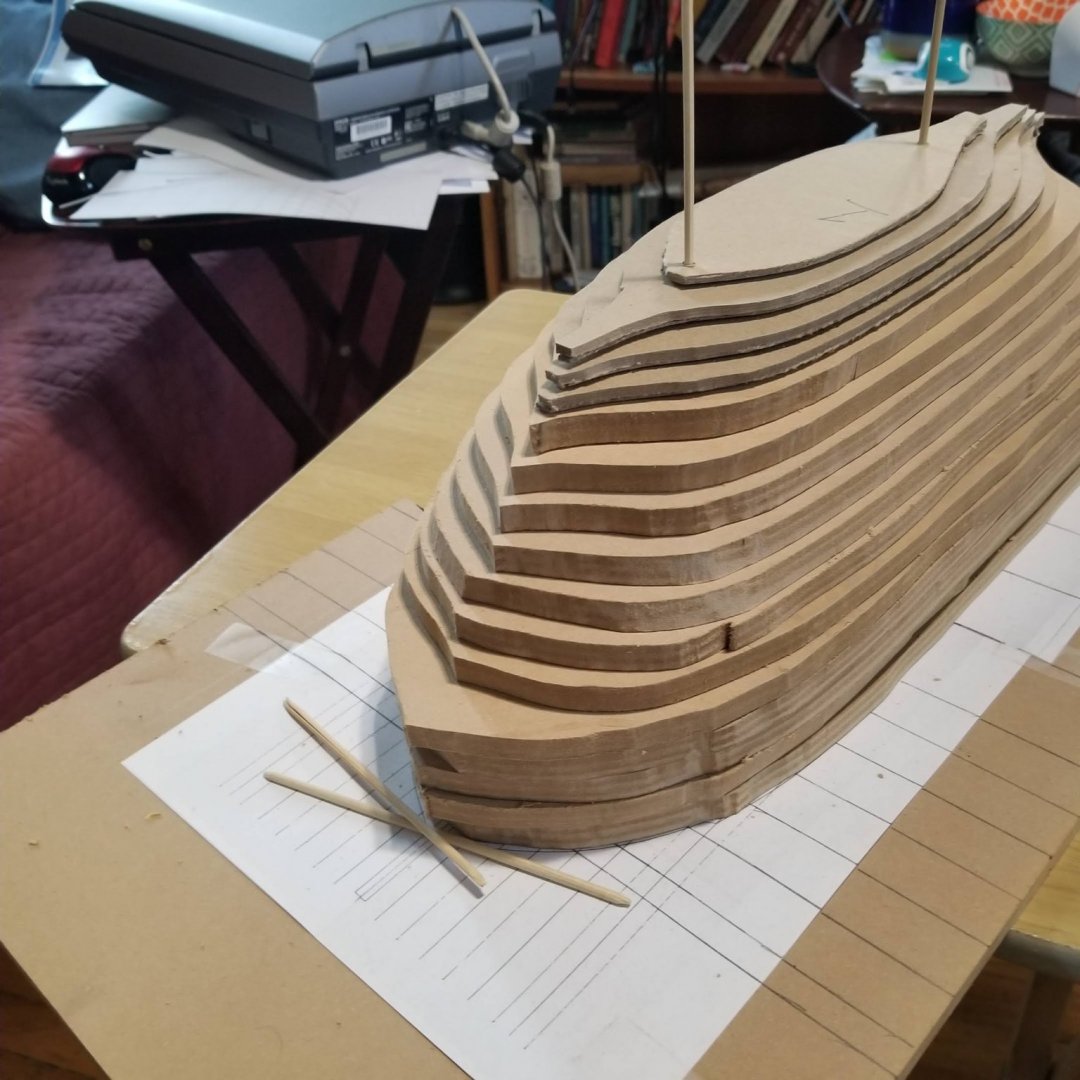

I gave up on the jig saw...there may be something fundamental i don't understand about using it...and switched to a sabre saw. As you can see we are into the thicker cross section. This is #6, so there are 6 more to go -

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

Got some new blades for the jigsaw and cut a few more pieces layer 1 is a single thickness layers 2, 3 and 4 had to be laminated to get them to the right thickness of course, a little smoothing of rough edges will have to happen before gluing -

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

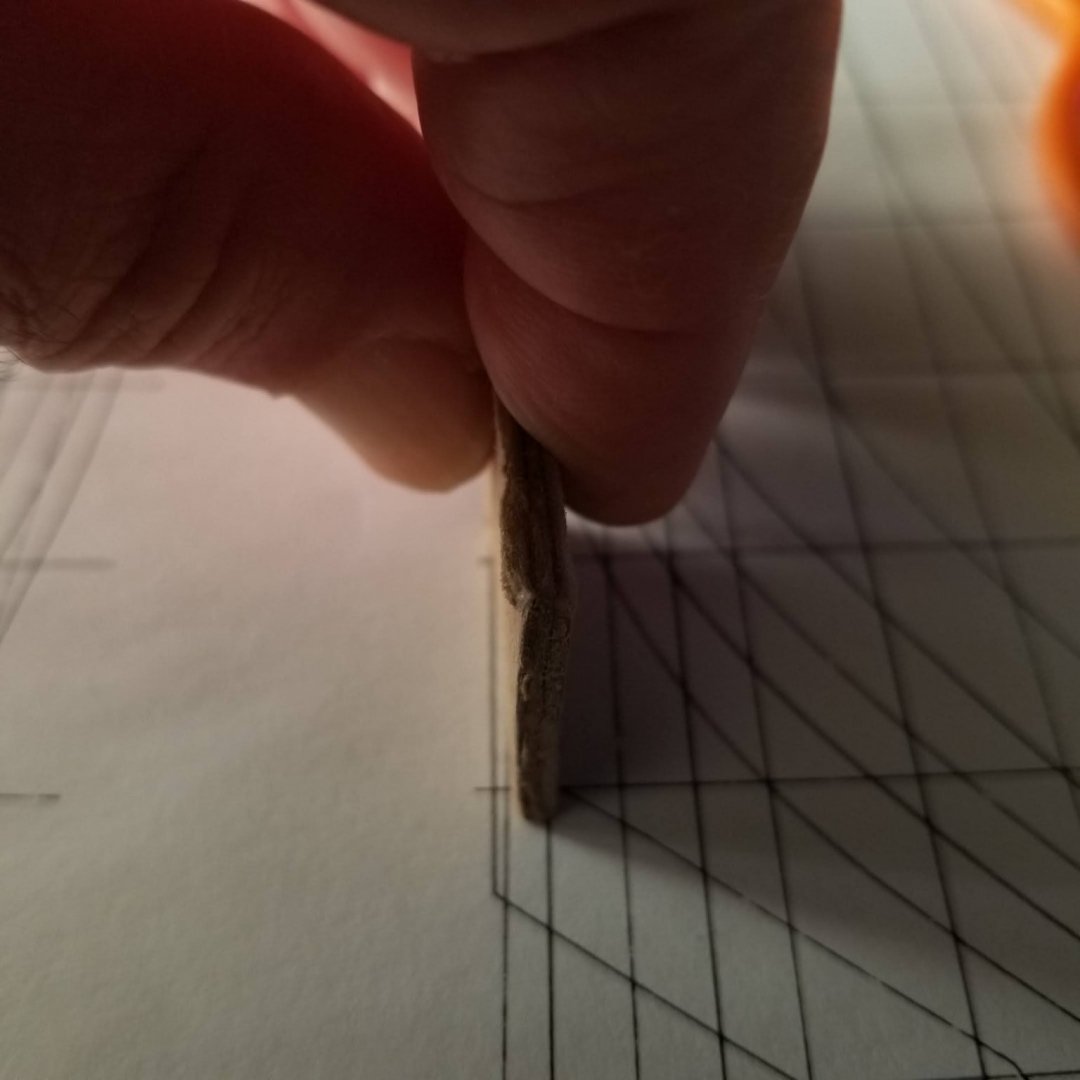

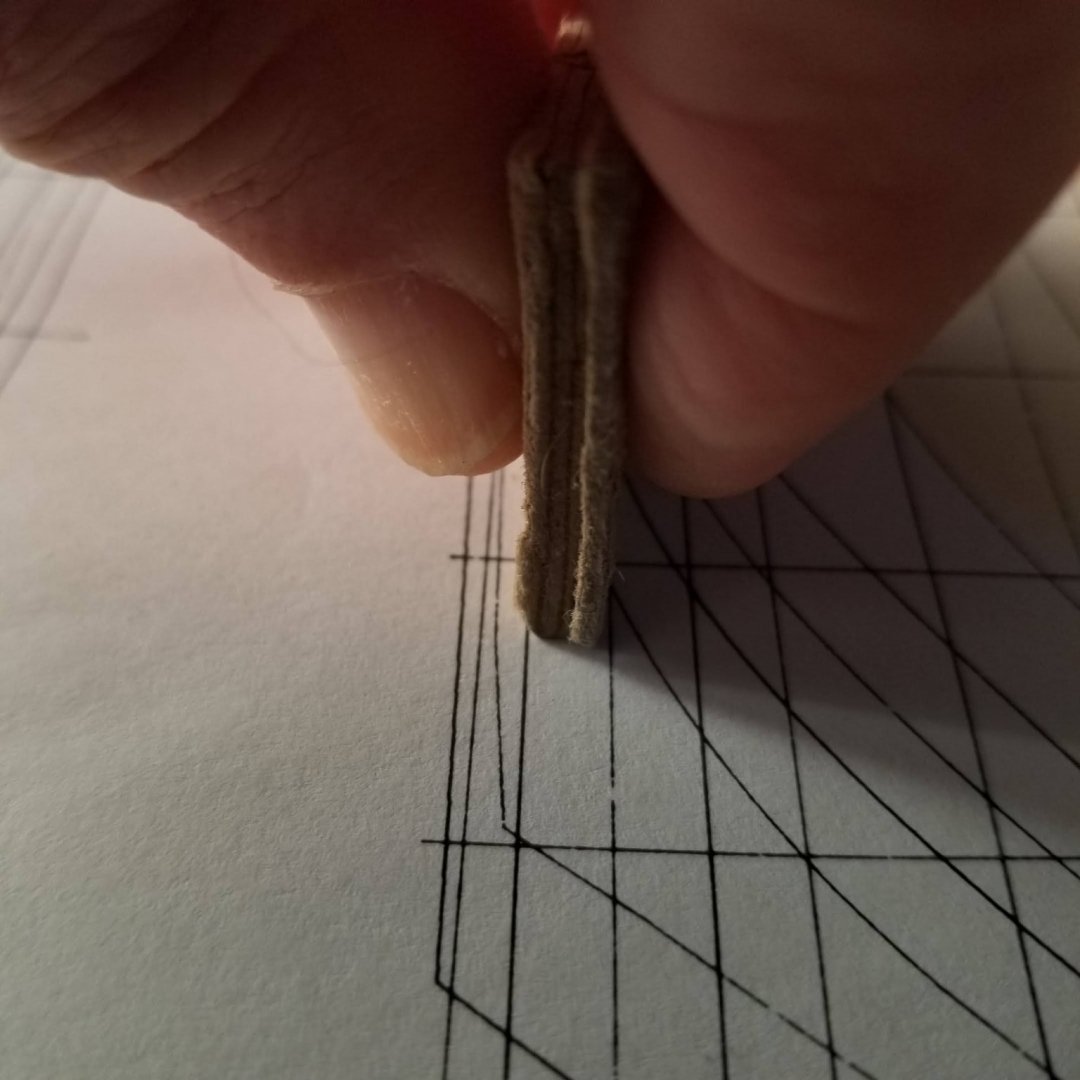

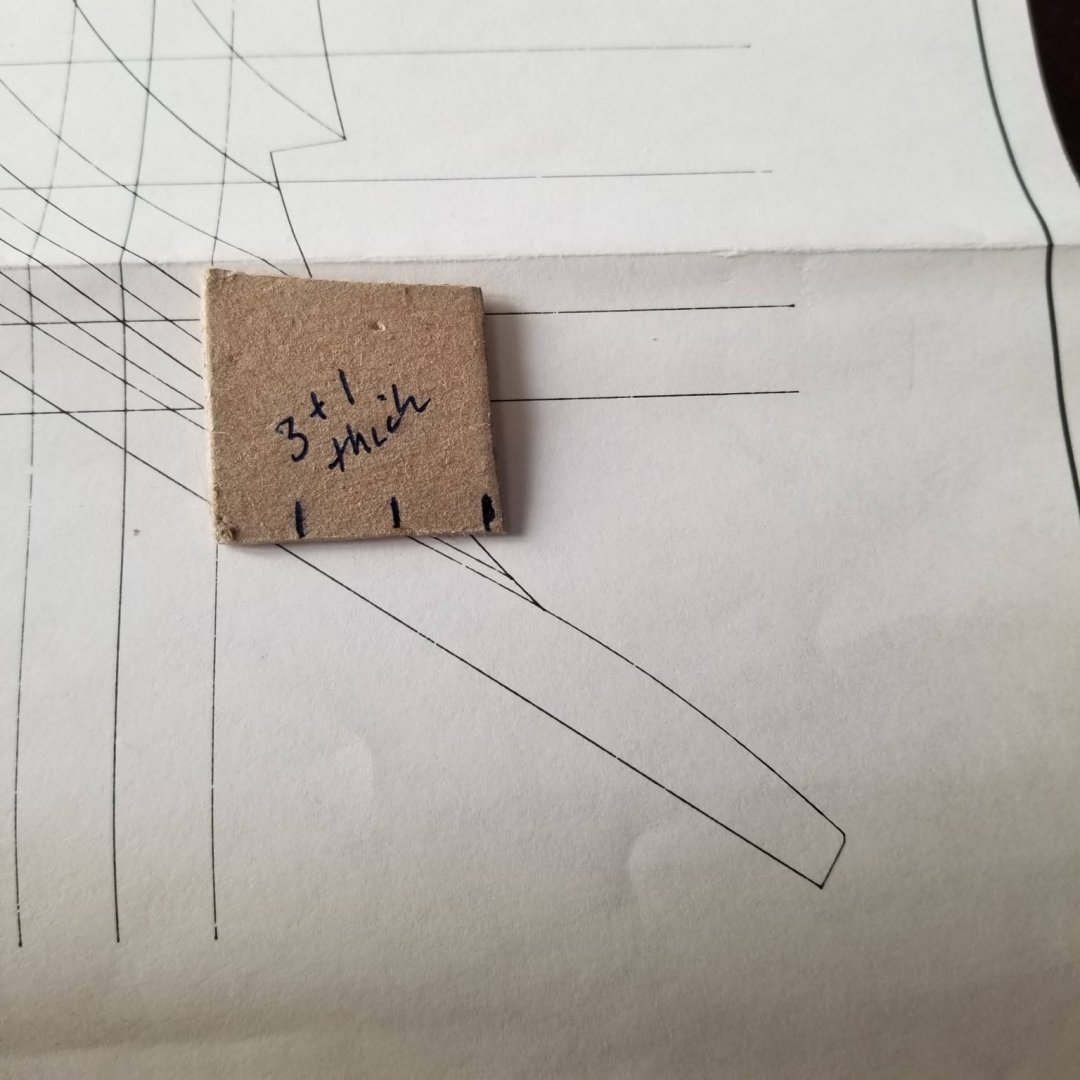

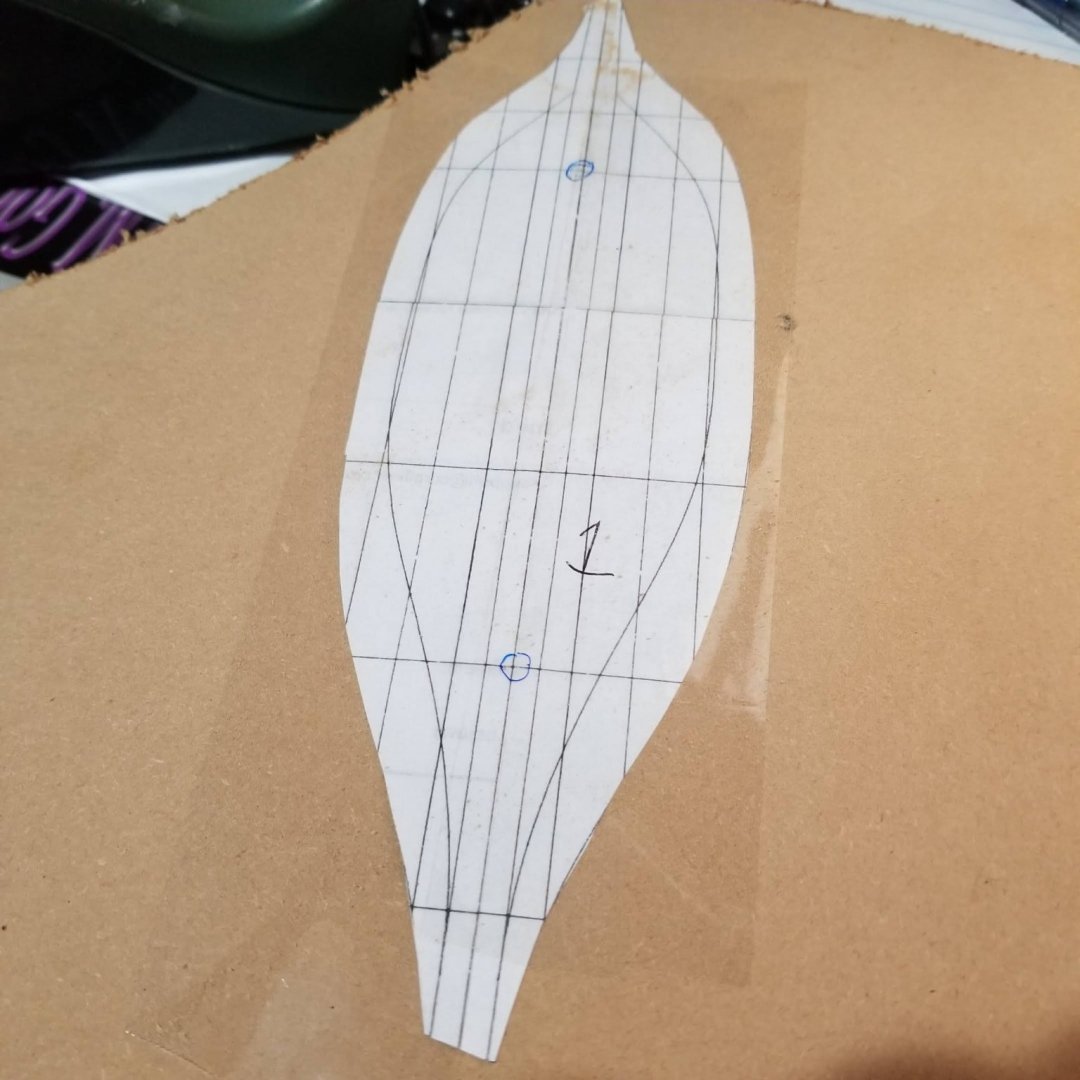

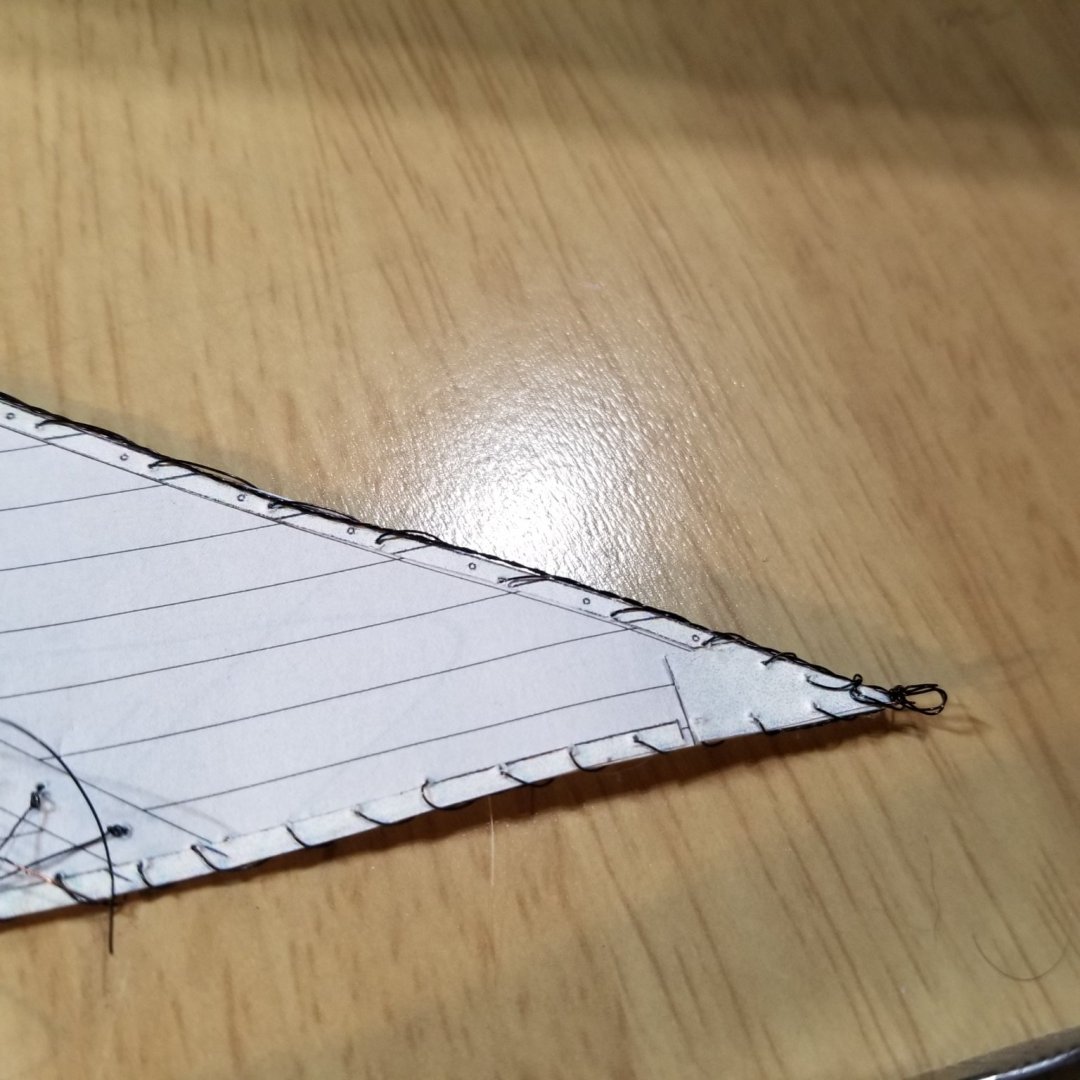

Thanks everyone for all the helpful hints. Making a little progress I realized that the bottom 4 sections were NOT 3/8" thick so I printed up some new plans and sized the bottom sections. I keep a stock of heavy card...and i can use one layer for the bottom section and a combination of 2 thicknesses for each of the 3 layers on top of that The card drills like wood after I cut out a section it separates from the plan I'll have to be sure and write its number on it, so as not to lose track ps in the 2nd to last picture you can see that i'll need 3 additional 3/8's sections in order to accomodate the full rise of the bow -

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

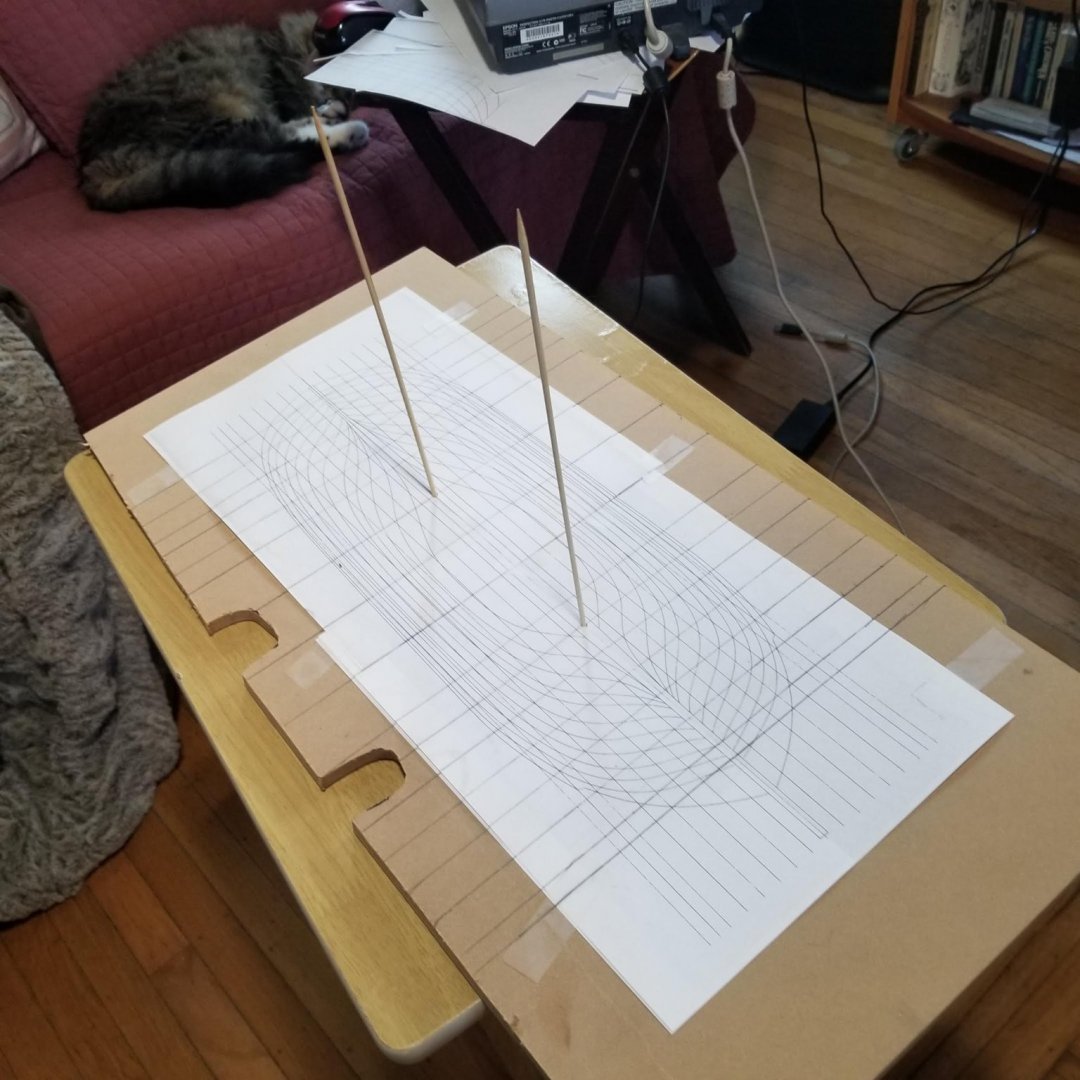

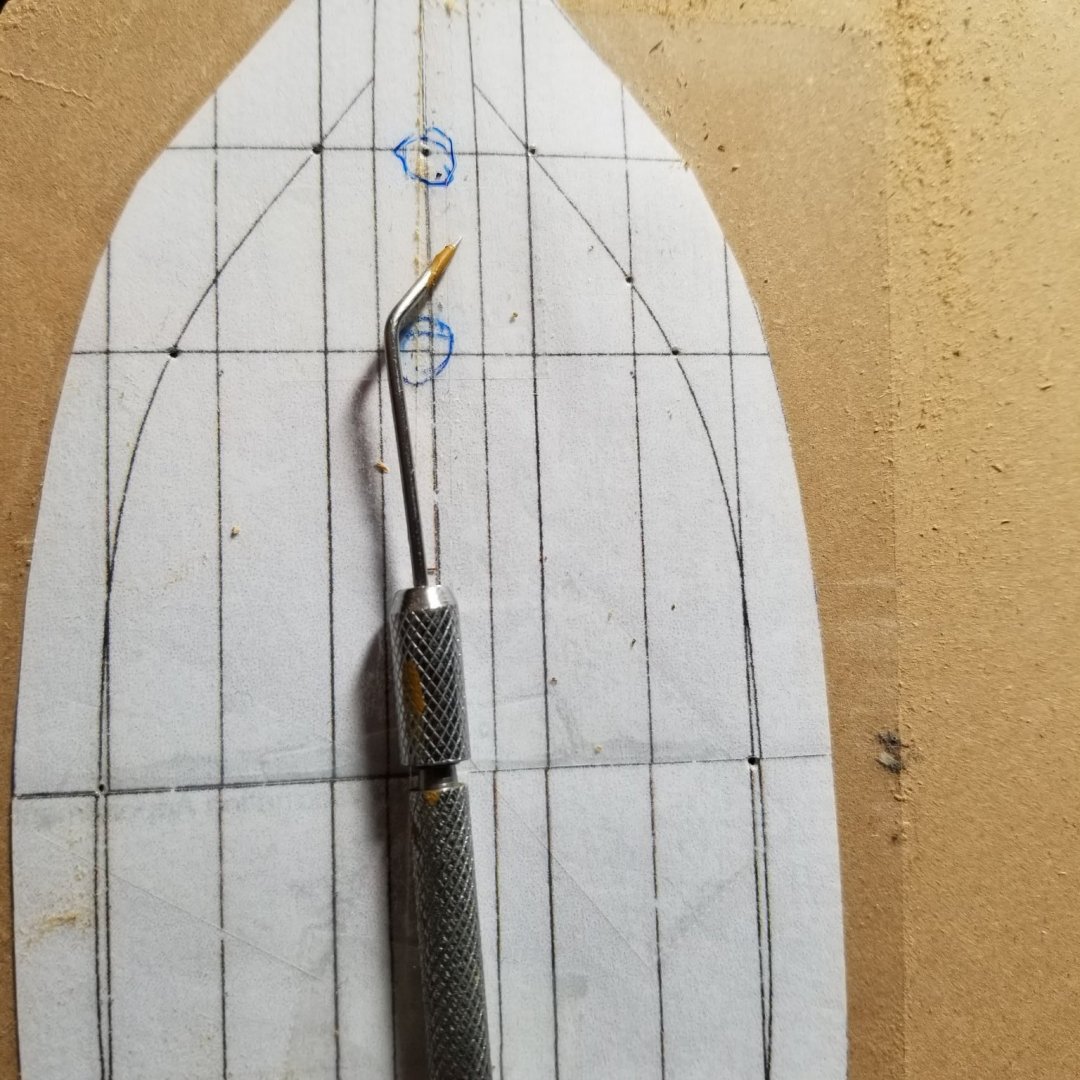

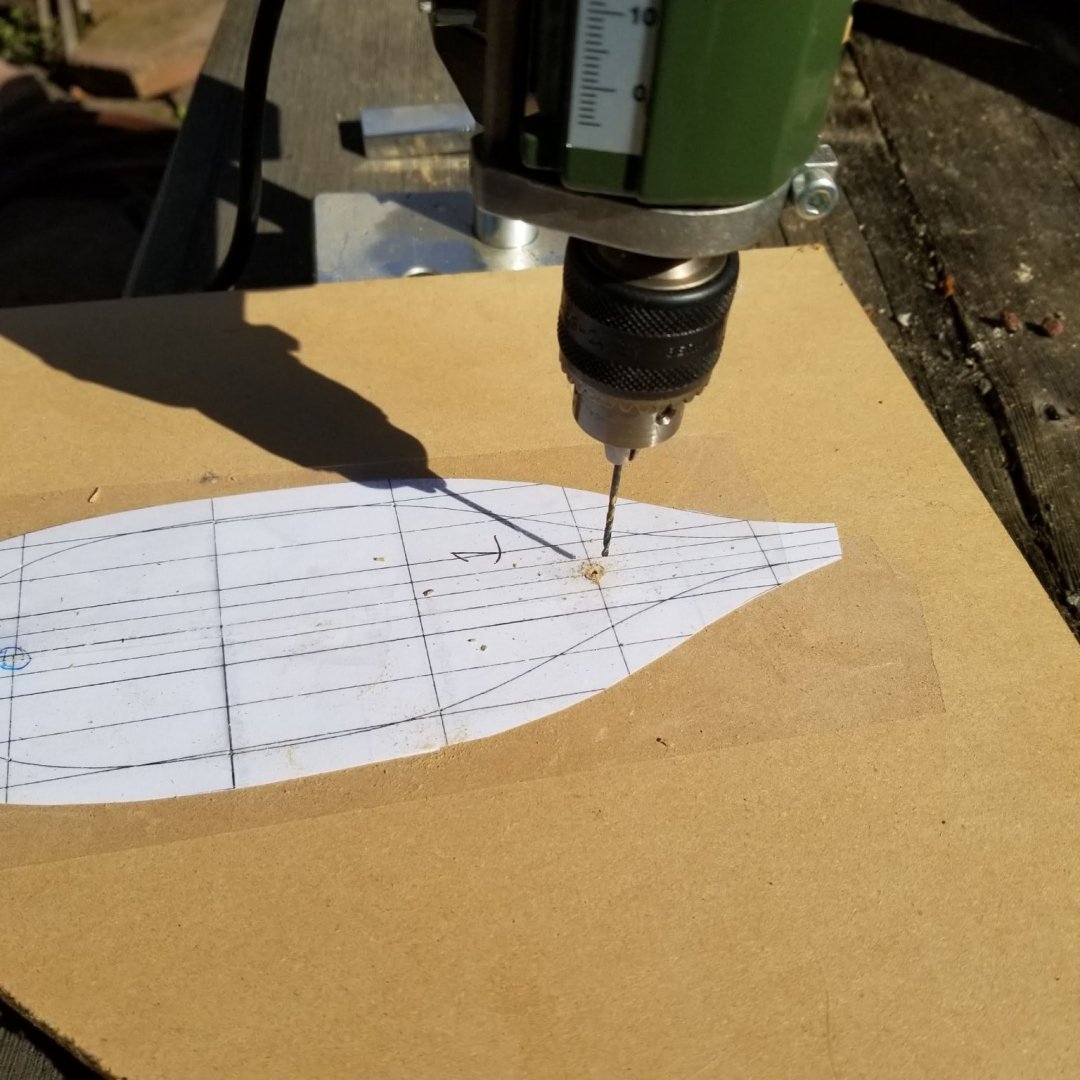

I actually was able to find a drill the right size for the bamboo skewers in my tool box I drilled really small holes first, because on pressboard you don't get much "centering" effect from an initial punch hole And then with a drill the size of the bamboo I'm punching the outline of the next layer down through the paper before I do the cutting (because the paper is not glued on, when it is cut to the outline it will come off the board. So I'll have the 2 pegs and the punch marks to guide me as I glue the layers together -

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

Saw arrived. Now have nice pile of boards. Time to get out the drill press and drill the holes for the bamboo centering pieces. -

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

Still waiting for some help for my jigsaw. I think the battery has completely died. Planning in the mean time. Two holes through each piece for bamboo skewers..holes always "wander" a little. I'll center punch them and drill with a small drill first, then follow up with one that is just a little bigger than the skewers. -

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

Thanks Roger, Good and helpful advice Ken -

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

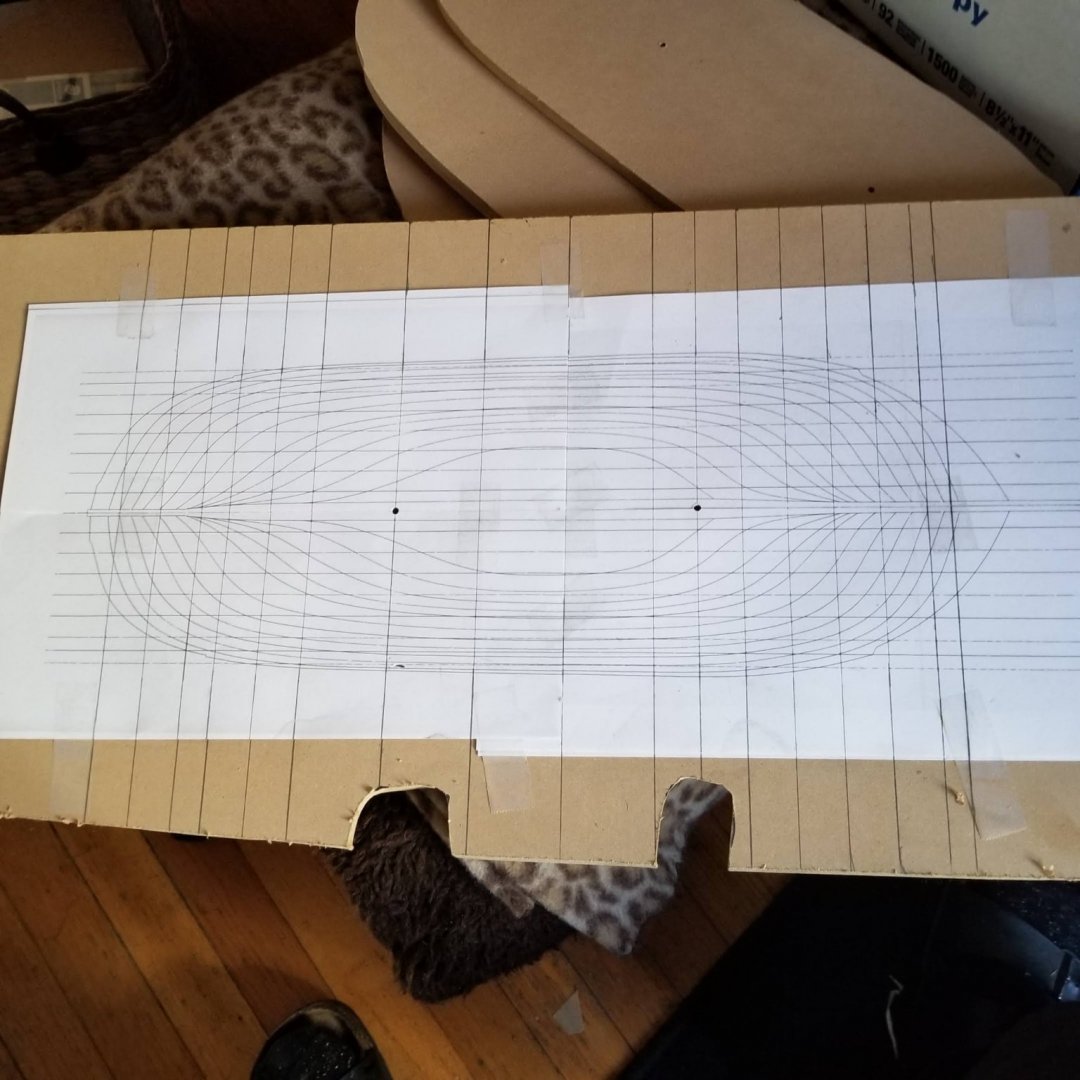

may end up slightly larger than a breadbox the plans are taped down to be cut out with a jigsaw i think the paper will have to be removed before gluing thus the tape, instead of gluing the paper down -

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

Thanks for the clarification Roger that's the plan. I hope to construct a shell around the plug of the hull planking then lift the plug out and put in the internal frames. With luck, I want to make the model so the internal framing can be lifted out to inspect the framing rather than leaving parts of the hull exposed. -

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

-

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

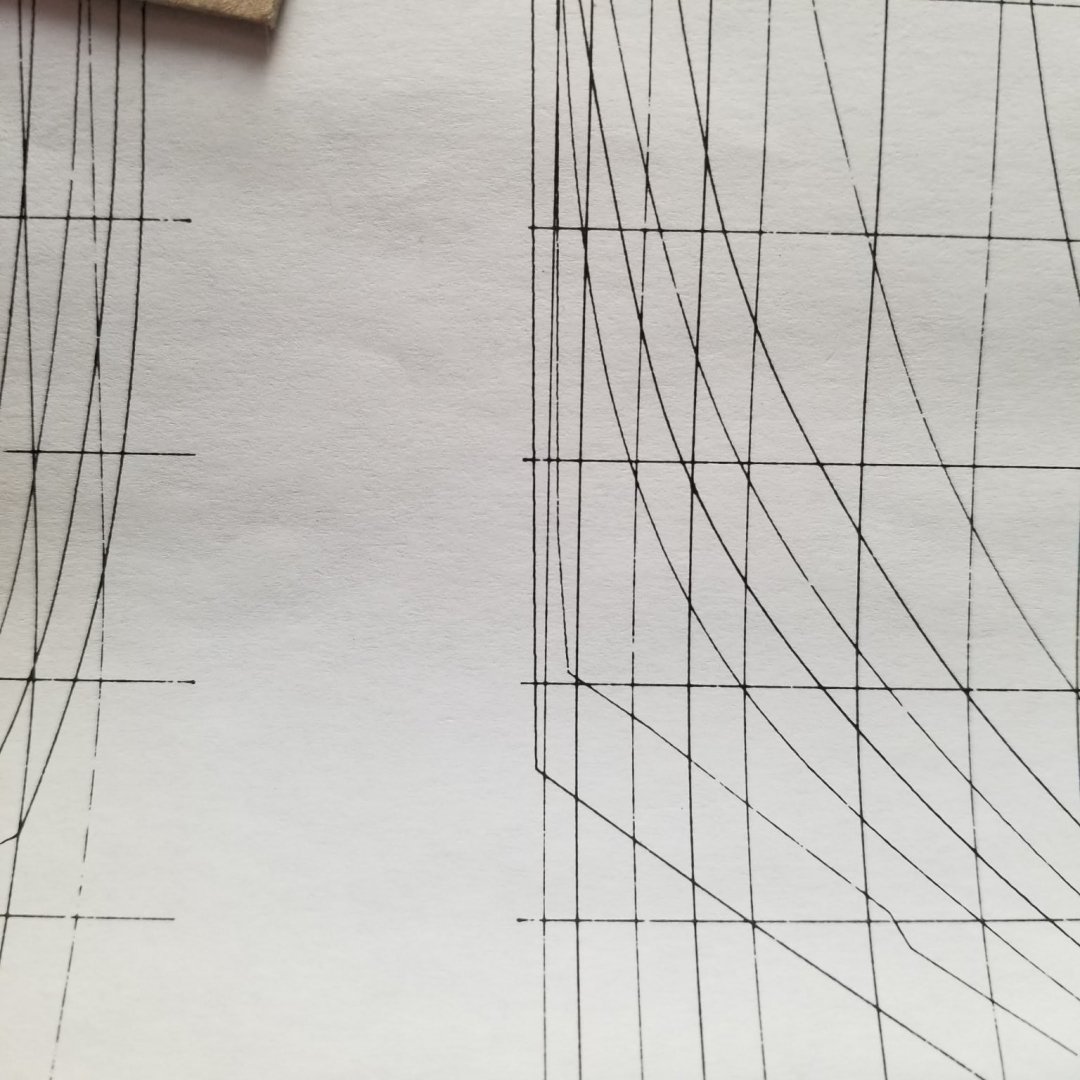

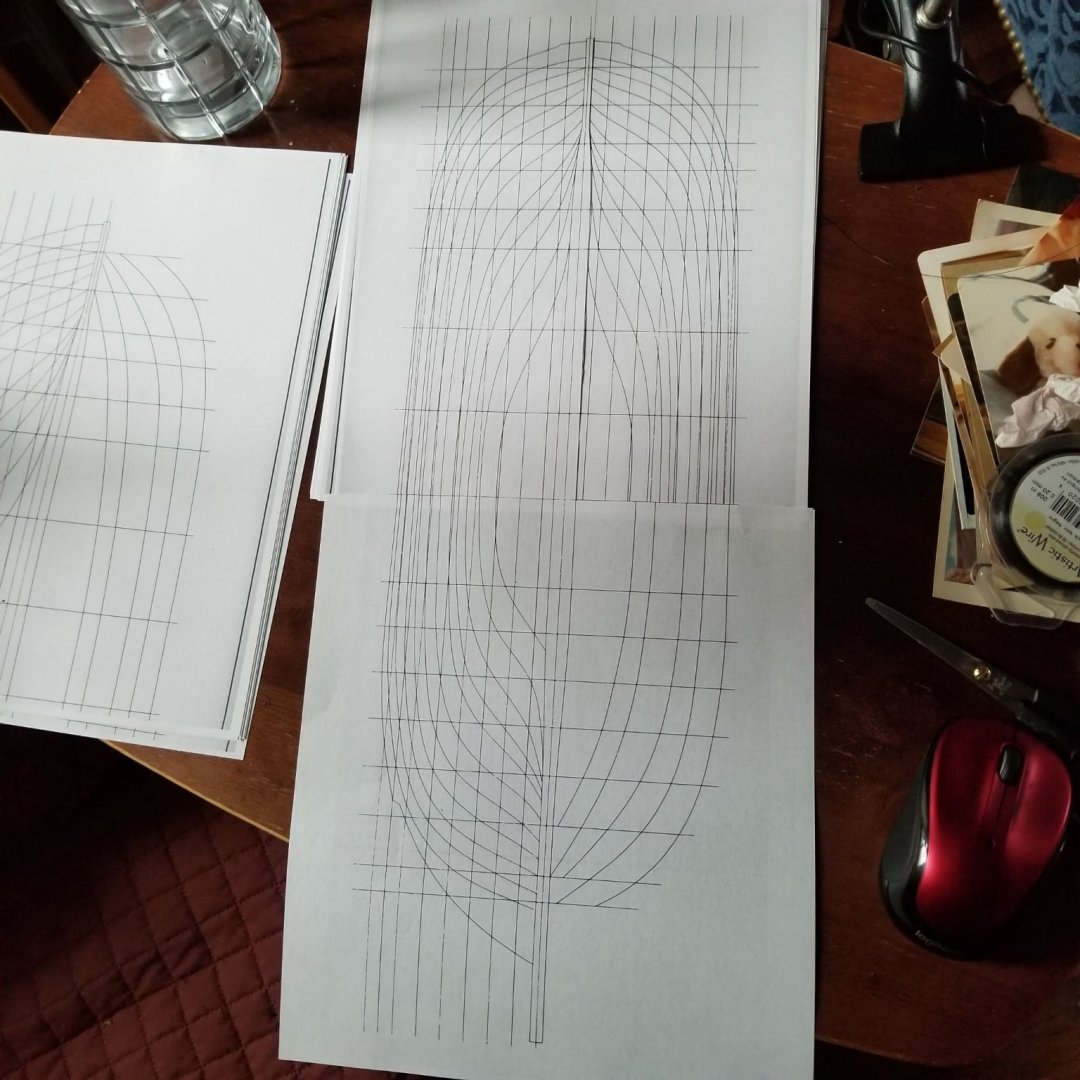

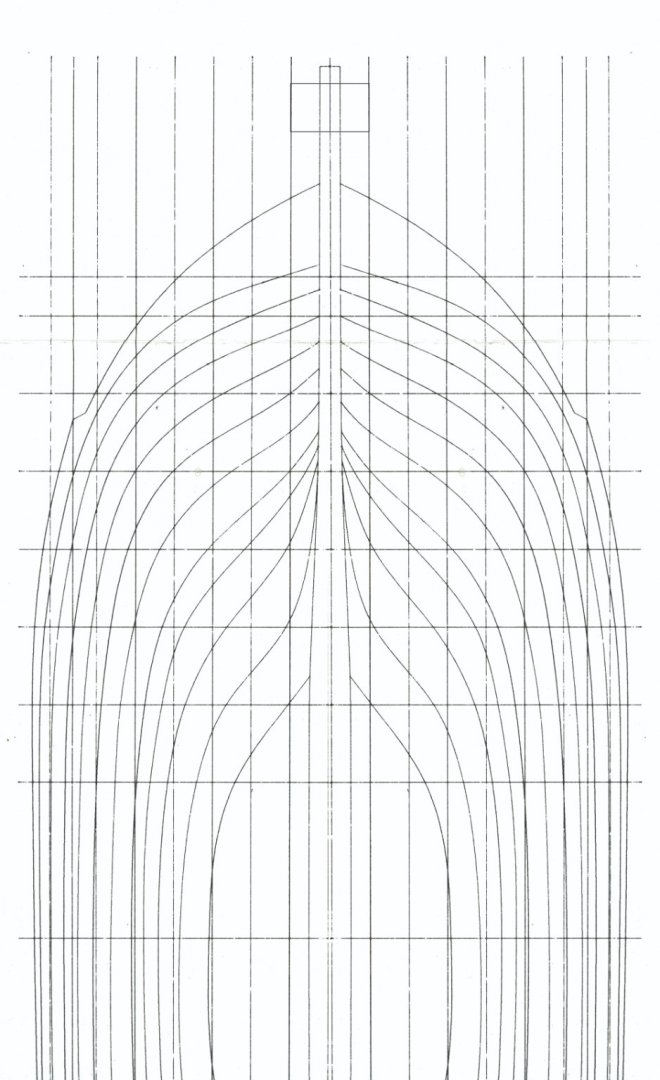

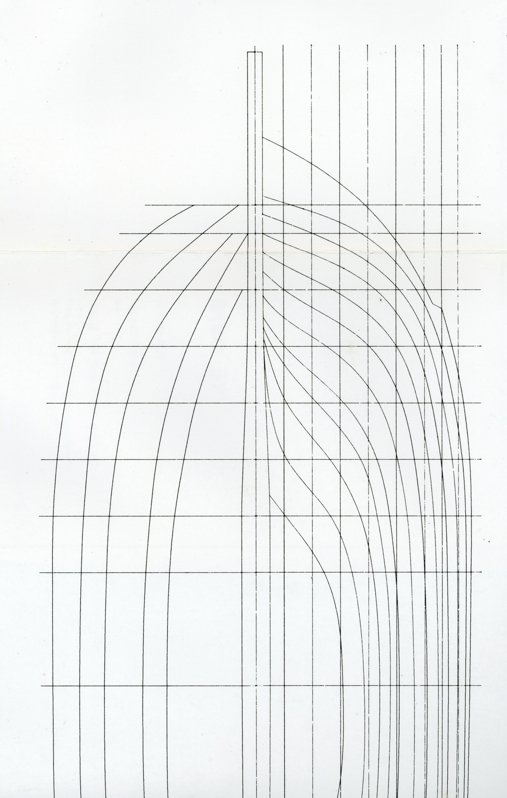

stitching the plans back together digitally always gives me fits. since I can only print them 1 scan at a time anyway, I decided to print the 4 scans that cover the hull and assemble them back together "on paper" by good luck the horizontal height of the layers is 3/8", just the size of some press board I have left over from building another "block" hull. So I'll be assembling 12 plans (1 for each layer) gluing them onto the pressboard and cutting them out with my jigsaw. then a lot of sanding and filling to fair the lines -

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

Thanks Roger, How should they be interpreted ? -

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

Corel Draw to the rescue The 2 superimposed square boxes are temporary. They are my hack to control the alignment of the 2 images that make up the full picture -

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

OK got it buttock lines. -

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

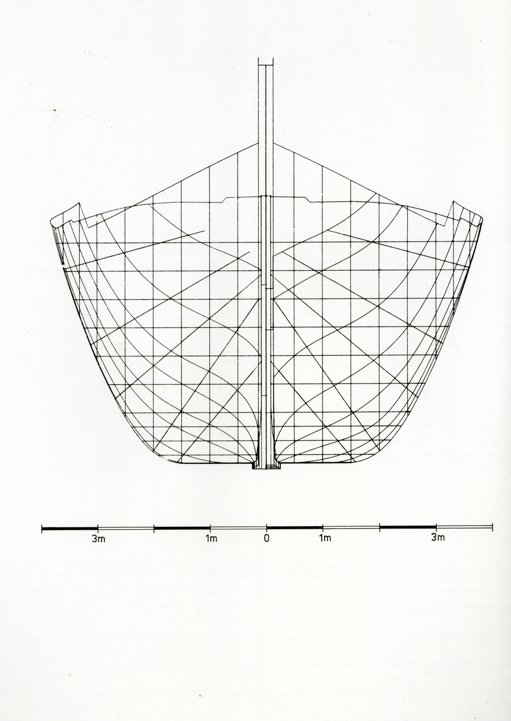

I should know this. But how to I interpret the lines on the left hand side ? Are they cross sections that go between the lines on the right hand side? -

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

Well, I measured this morning and I'm in luck. I have some 3/8's inch thick untempered masonite from a previous project where i was building a "block" model, and the layers in the 1/50 view are just 3/8's of an inch thick. So I will rework the lines to get full outlines for each layer, cut them out and glue them together, and the file/sand the hull smooth, and i will have my plug. I have decided to go ahead with the idea of dividing the stem and the stern posts so that the shell of the hull built around the plug will be separateable from the framing, deck and mast. At this scale, and using wire "ropes" i should be able to make the mast/sail actually riggable, so they can be taken down for storage. -

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

Yes. The plans are detailed enough to build a full size ship, if one wished. -

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

I'm going to assume that the lines provided are to the outside of the hull planking. -

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

So Looking at the plans the model at 1/50th looks ok. Smaller than a suitcase Because of the way the ship is constructed, I'm going to try first carving a plug Then building the planking over the plug Then removing the plug and "filling in" the framing. "Dutch Style" so to speak. If I get really adventurous I will trying building the model so all the interal planking (and the masts and sail) can be "lifted out" of the shell for inspection. Instead of leaving off part of the hull or deck to make the internal construction visible. -

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

I figure its going to be about a 5 year build Chuck. Hope you brought lots of pop-corn -

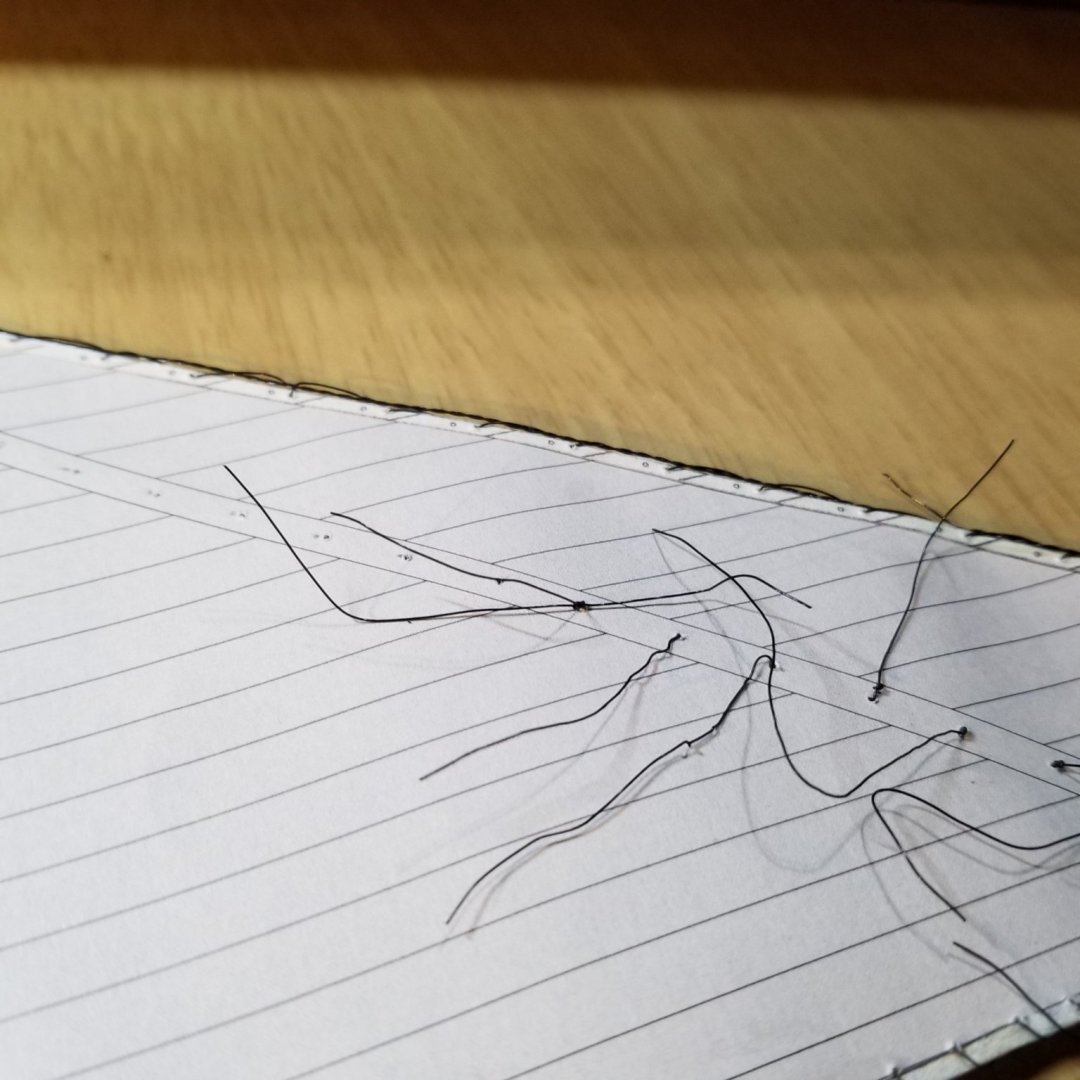

going to keep working on this while I build the Kogge Van Bremen Putting the reef points in the sail i use wire for rope you can tie a knot in the wire for one side...but for the life of me i cannot tie the knot on the other and have it be tight against the sail. so i am tieing the knot in another piece of wire.. i will have to superglue this false knot against the sail and then trim the ends

- 54 replies

-

- allege darles

- wak

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.