-

Posts

86 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by kentyler

-

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

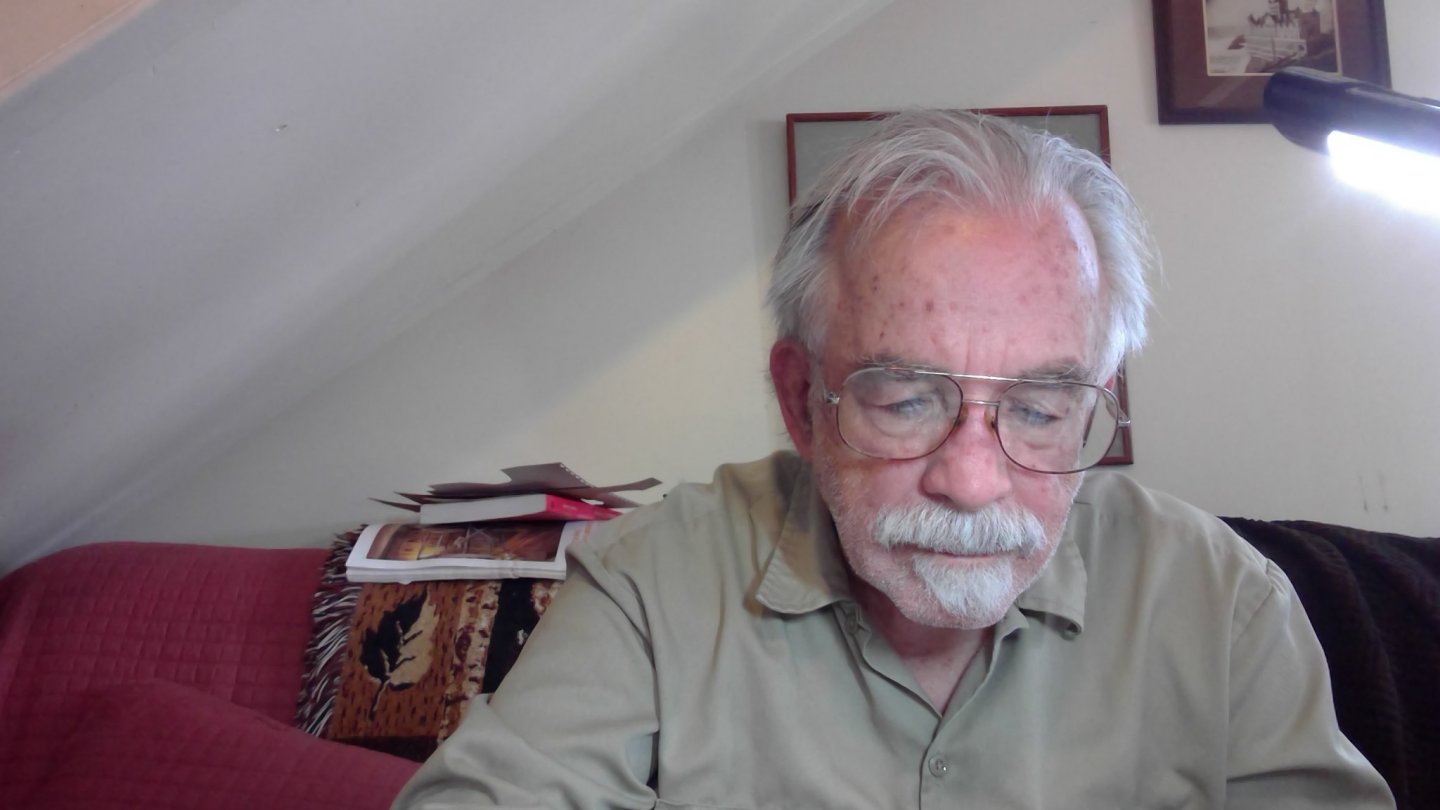

Looks like I will be reducing the plans, which are 1/20 to 1/50 so that the resulting model will still fit in the backseat of my car -

Die Kogge Von Bremen by kentyler

kentyler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

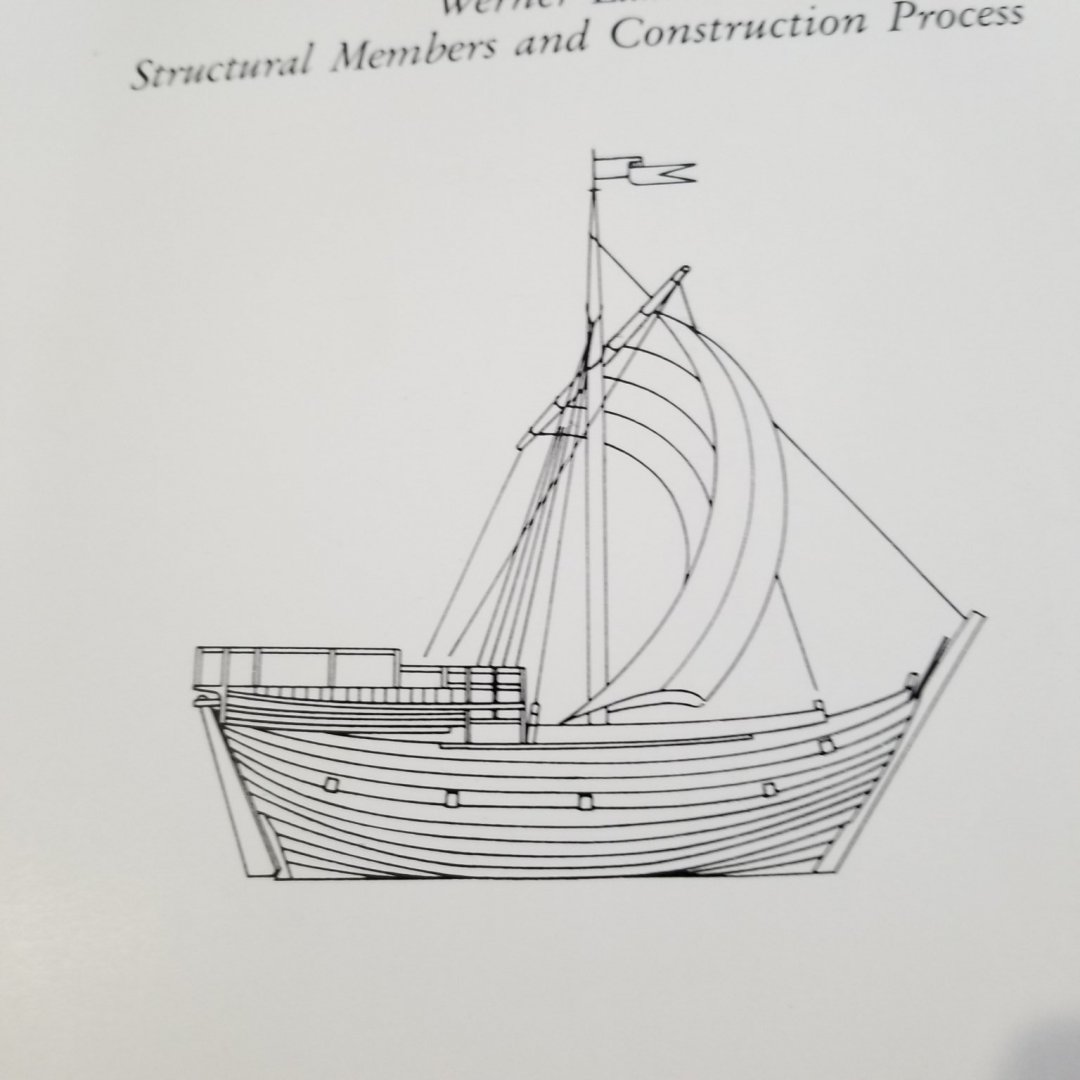

The plans say Werner Lahn: Bauteile Und Bauablauf Schriften des Deutschen Schiffahristsmuseums Band 30 -

- 54 replies

-

- allege darles

- wak

-

(and 1 more)

Tagged with:

-

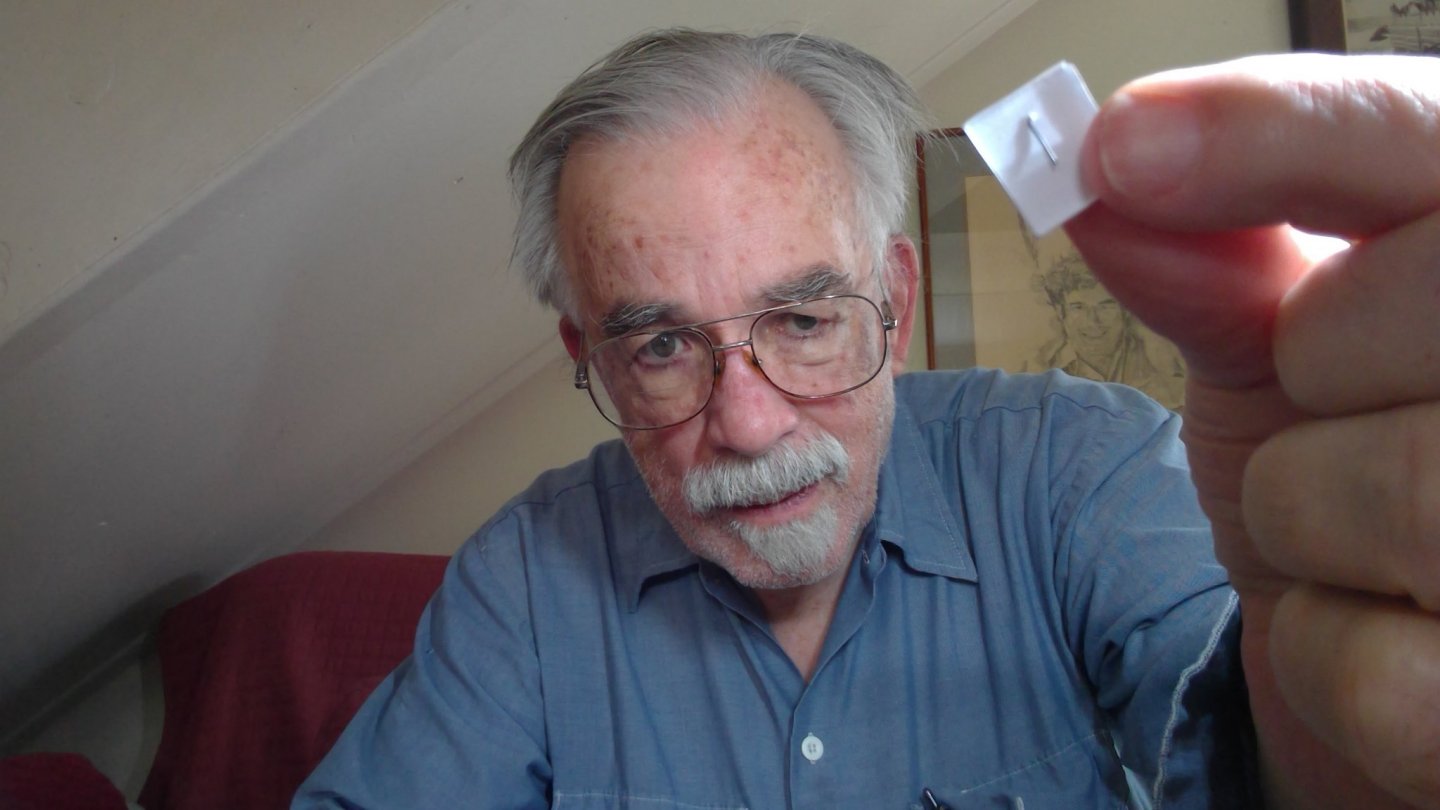

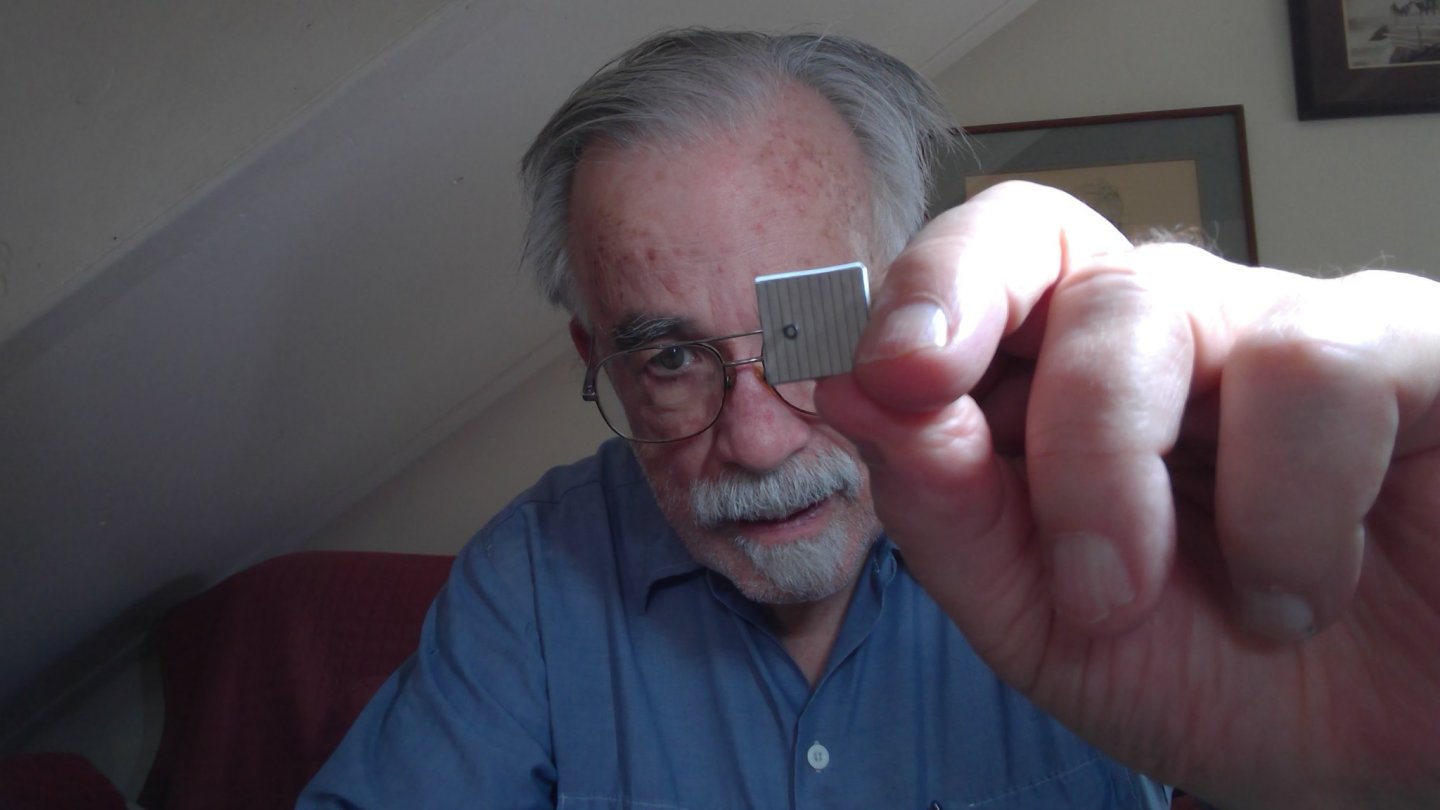

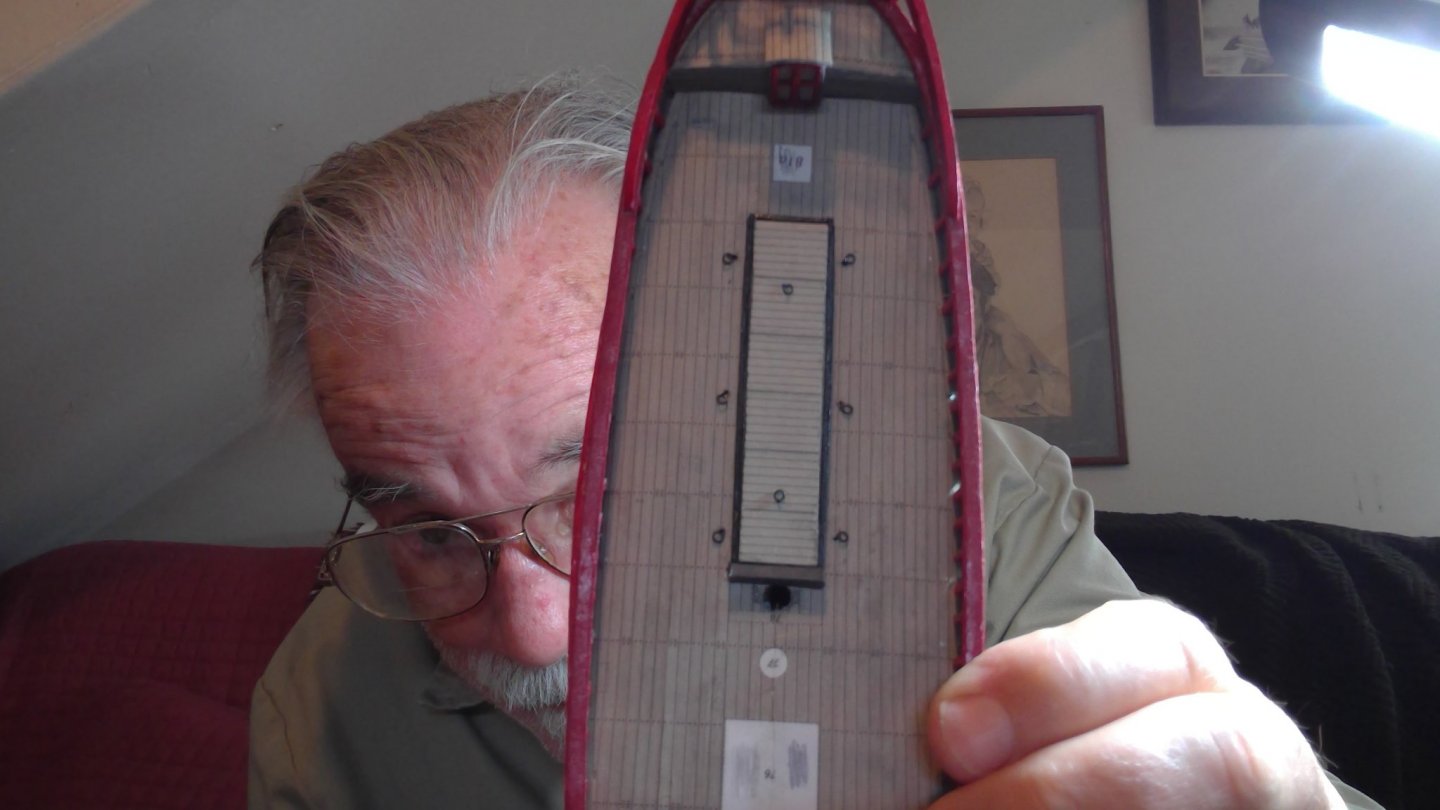

Second time around the cleats for the deck came out much better. I drilled holes in the mast to fasten the three that go there. I have the ring bolts in the deck, now we need to finish the mast and sails, as i try to build as much of the rigging as possible before i fasten the masts into the deck...

- 54 replies

-

- allege darles

- wak

-

(and 1 more)

Tagged with:

-

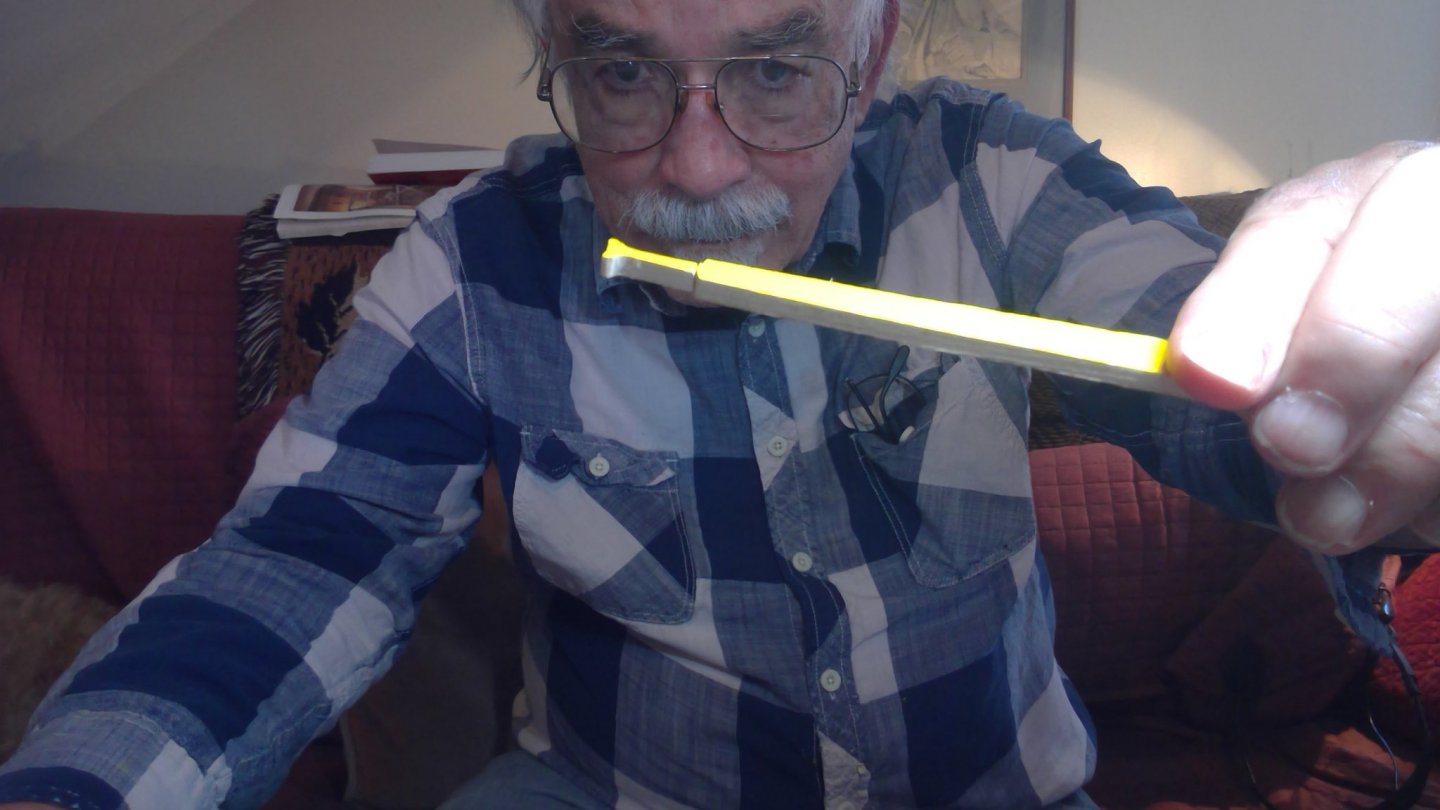

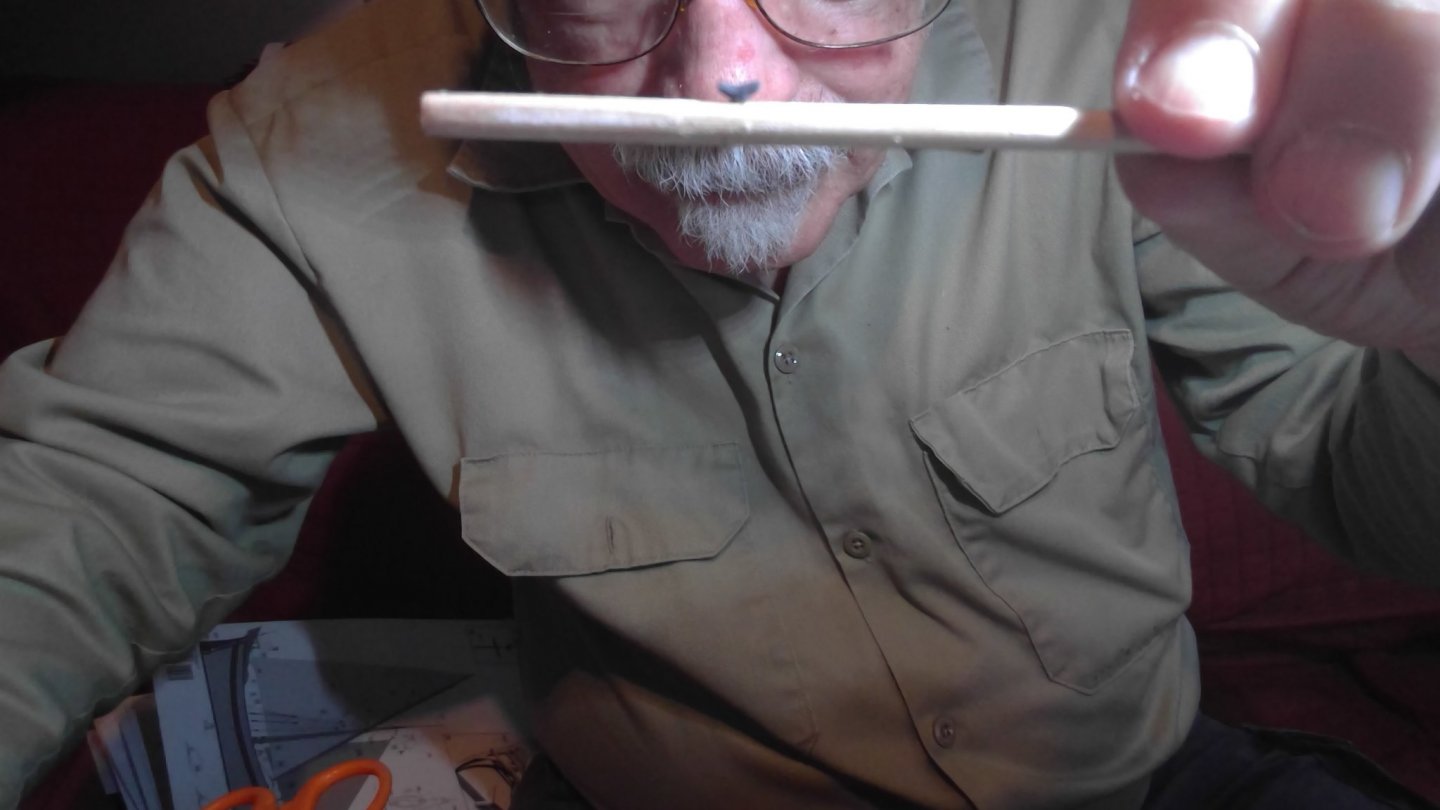

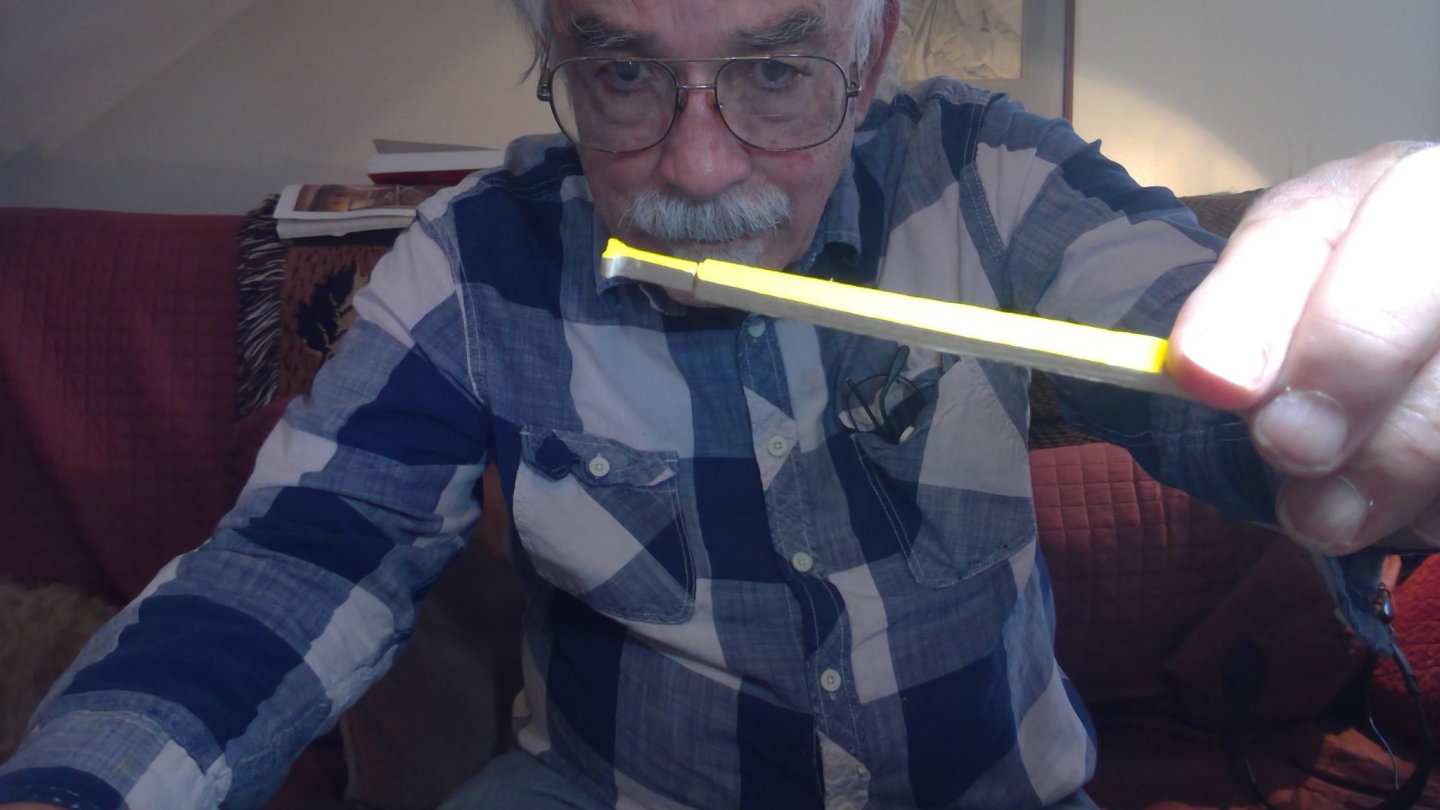

so i am making up the blocks out of paper... the cleats for the decks i tried several things, and eventually ended up carving them from the wood of an old ruler...so to get 9 cleats i suspect i made at least double that many..lost on the floor, the ends breaking off... i carved them and doused them with superglue to try and strengthen them a little...and then just pushed them into holes drill in the deck...no need for glue...the rigging will be black and "yellow" jewelry wire... i'm trying the harold hann trick of having the rigging be pre colored and not having to paint it. the gold wire i'm using could be thought to be "manila" if you're charitable.

- 54 replies

-

- allege darles

- wak

-

(and 1 more)

Tagged with:

-

- 54 replies

-

- allege darles

- wak

-

(and 1 more)

Tagged with:

-

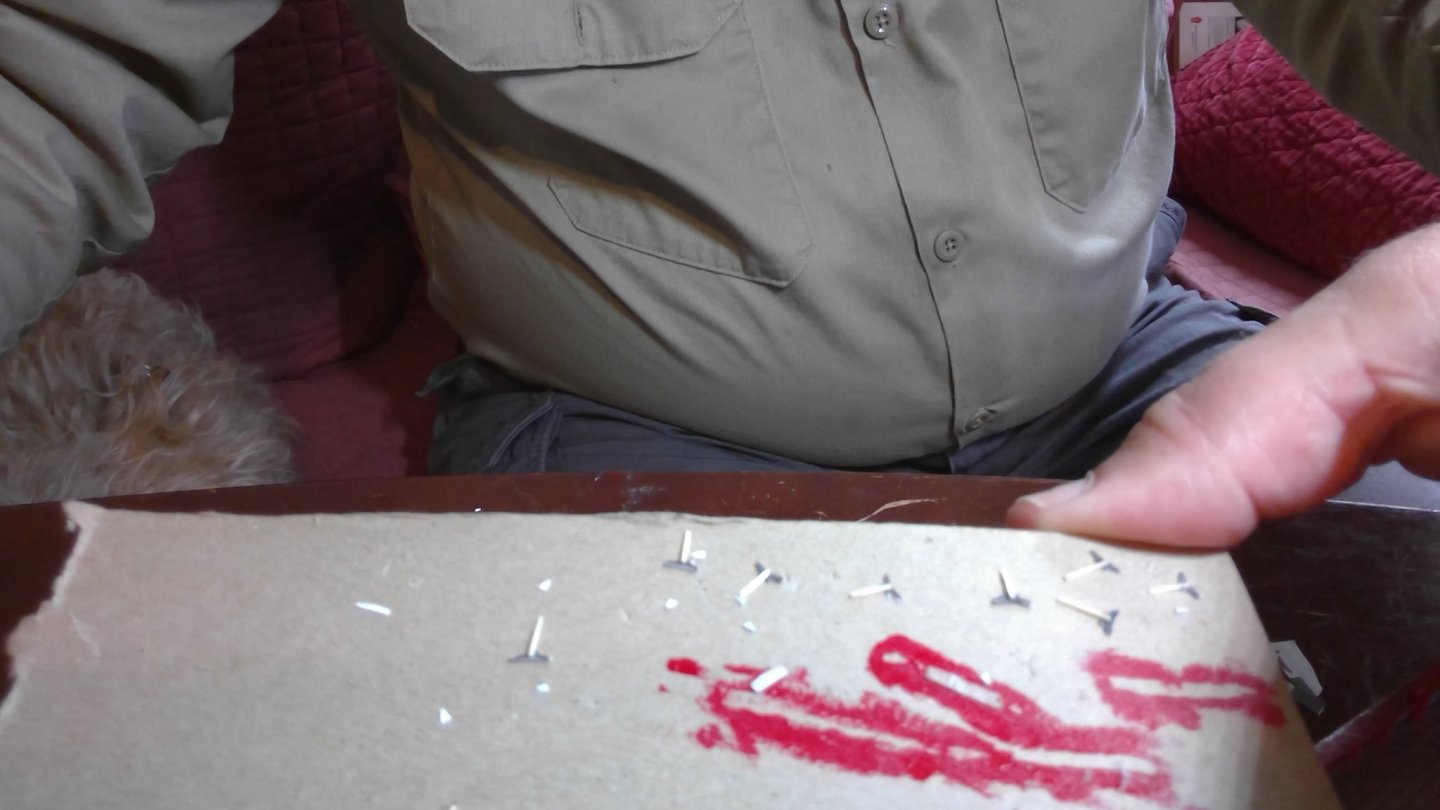

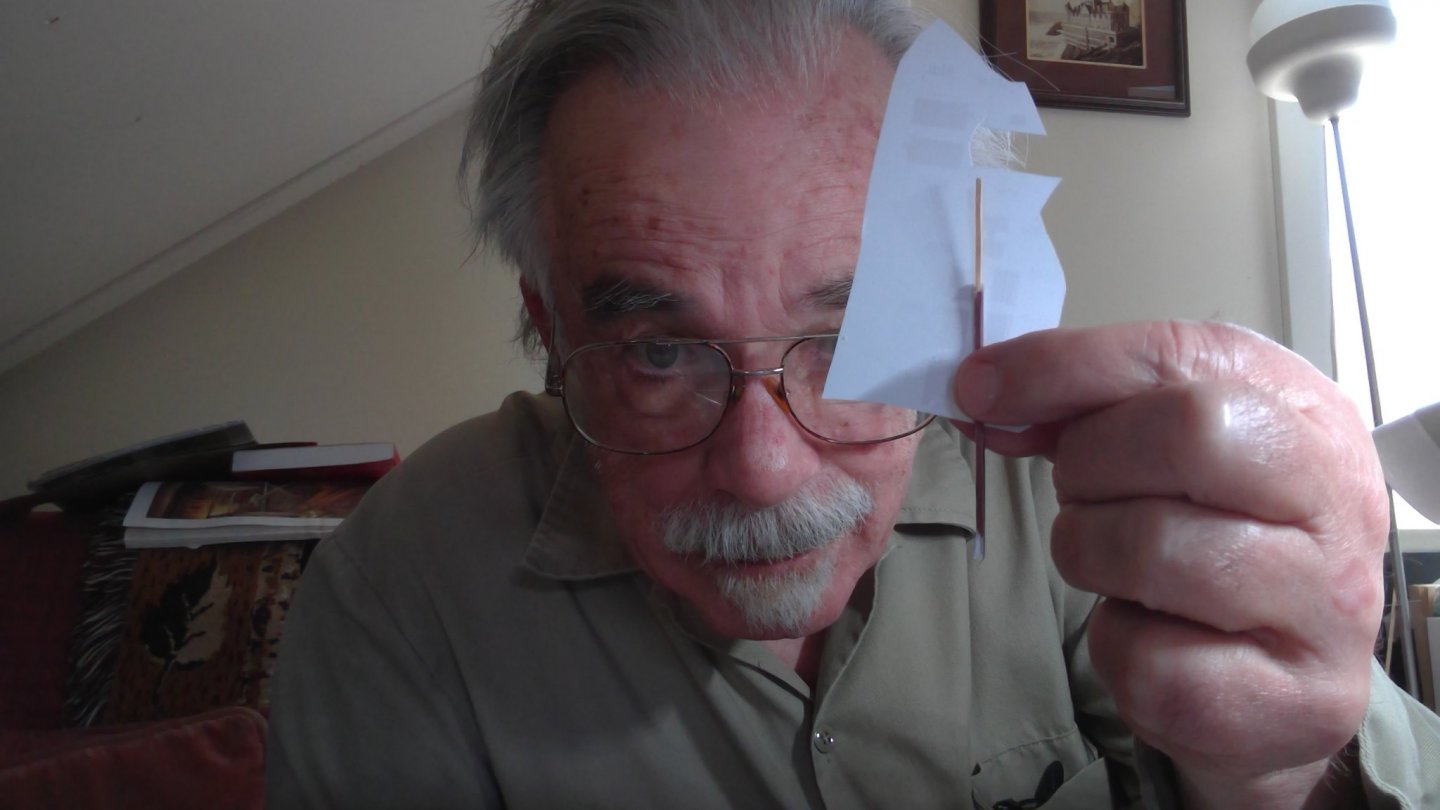

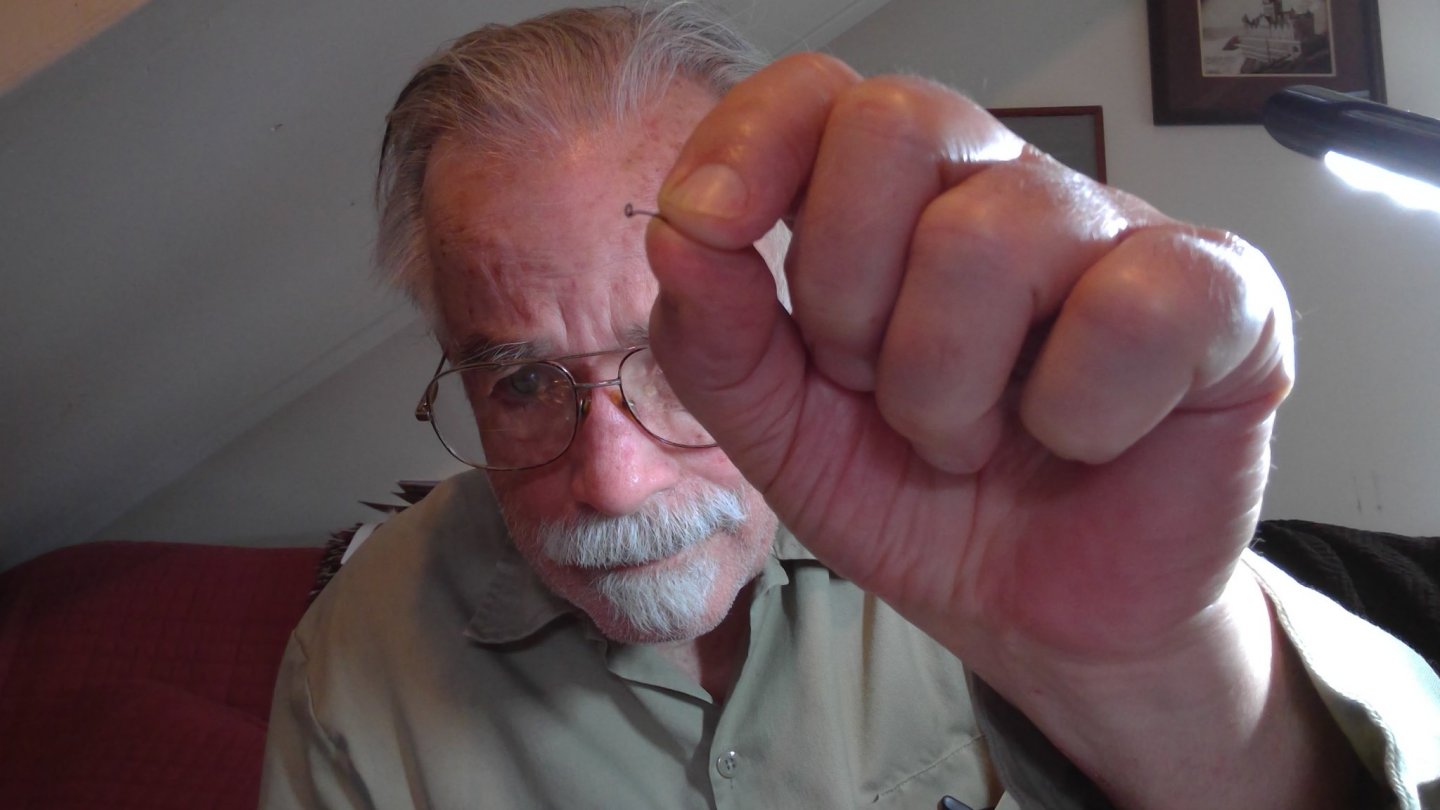

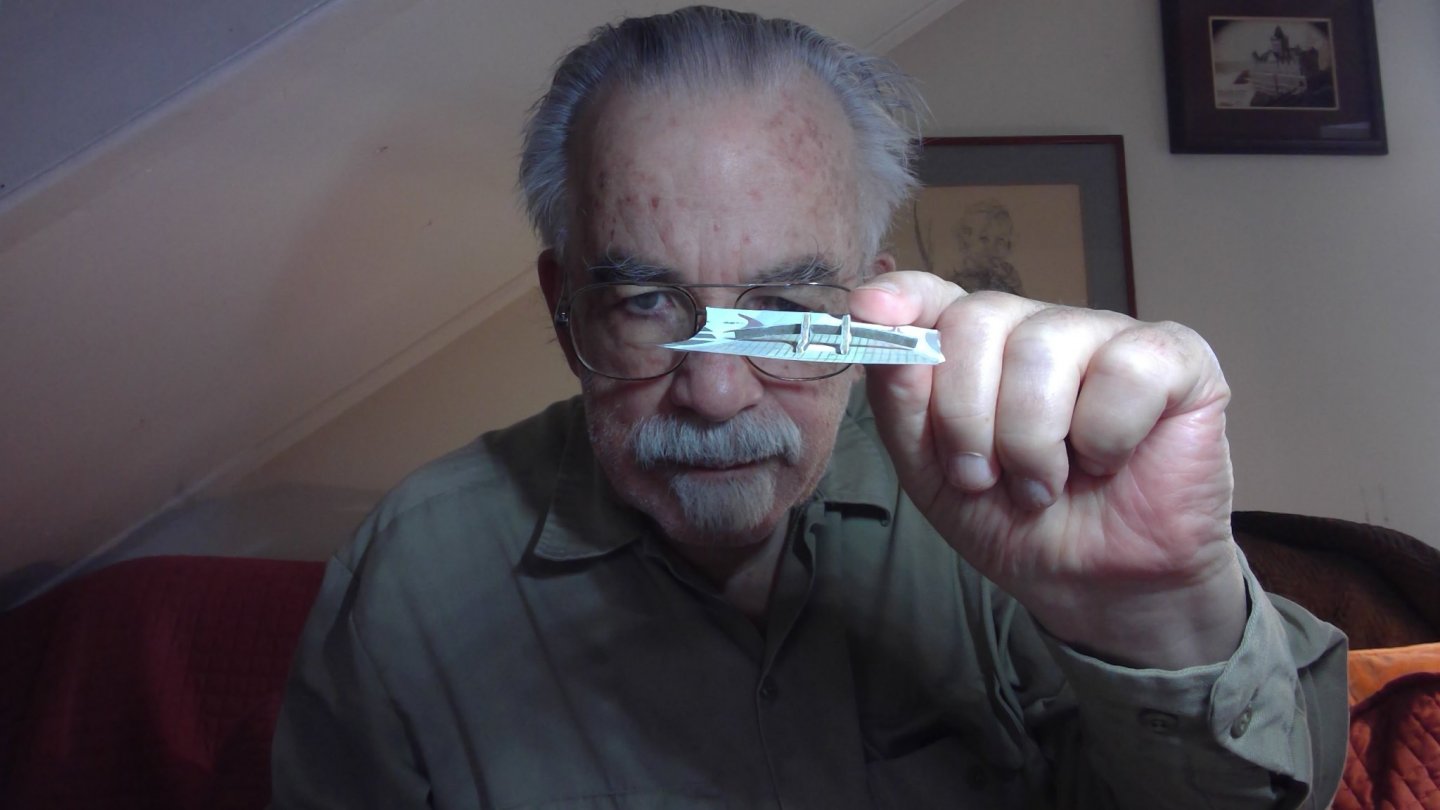

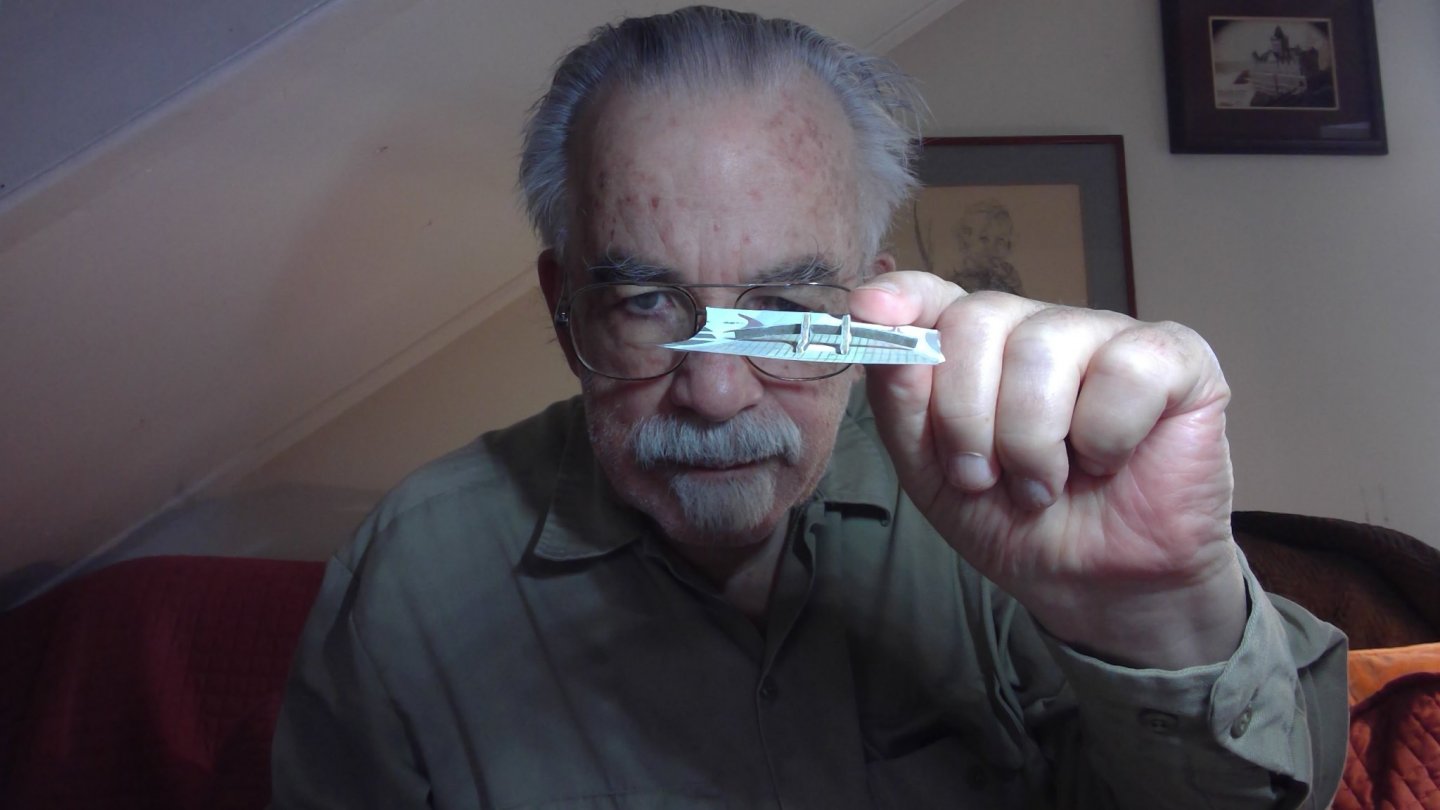

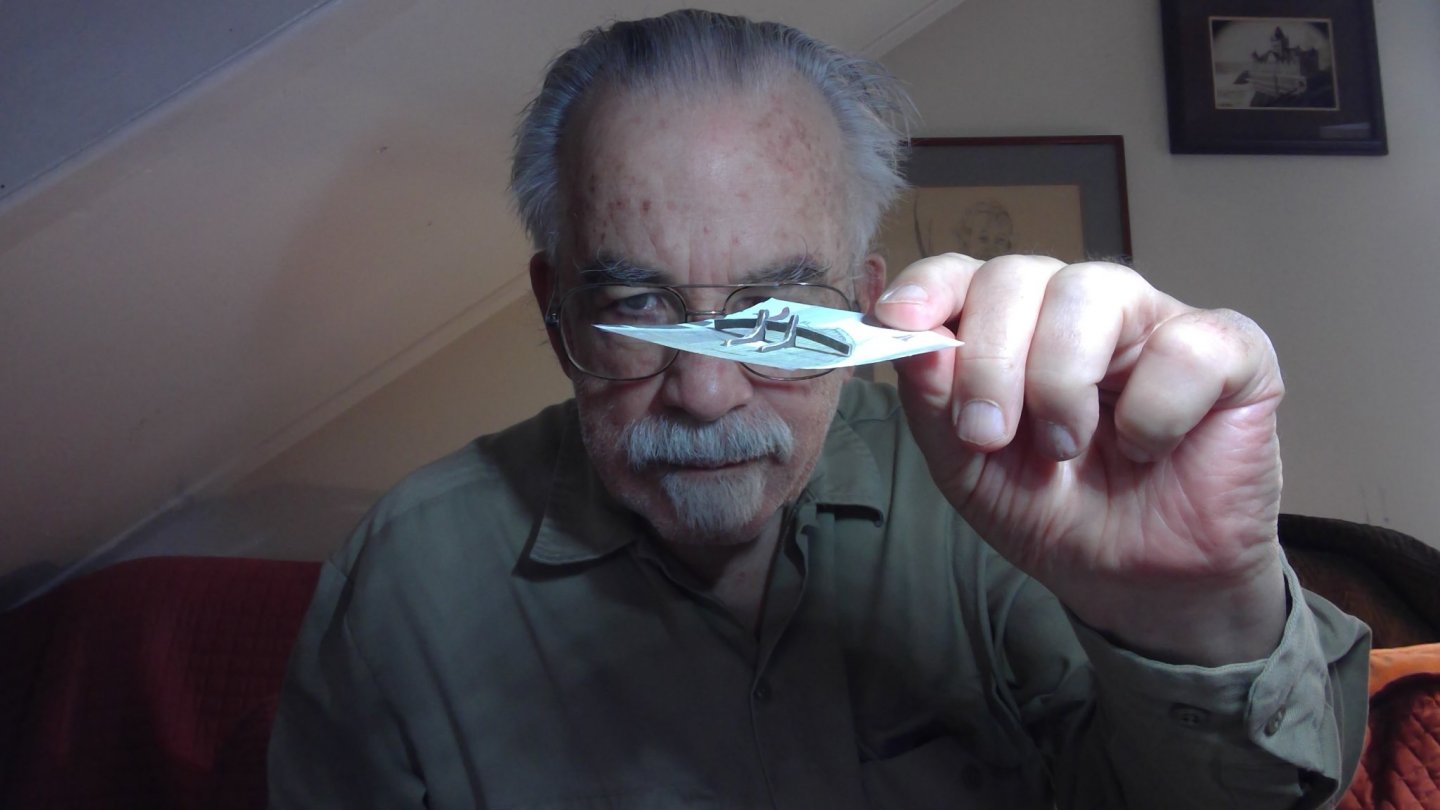

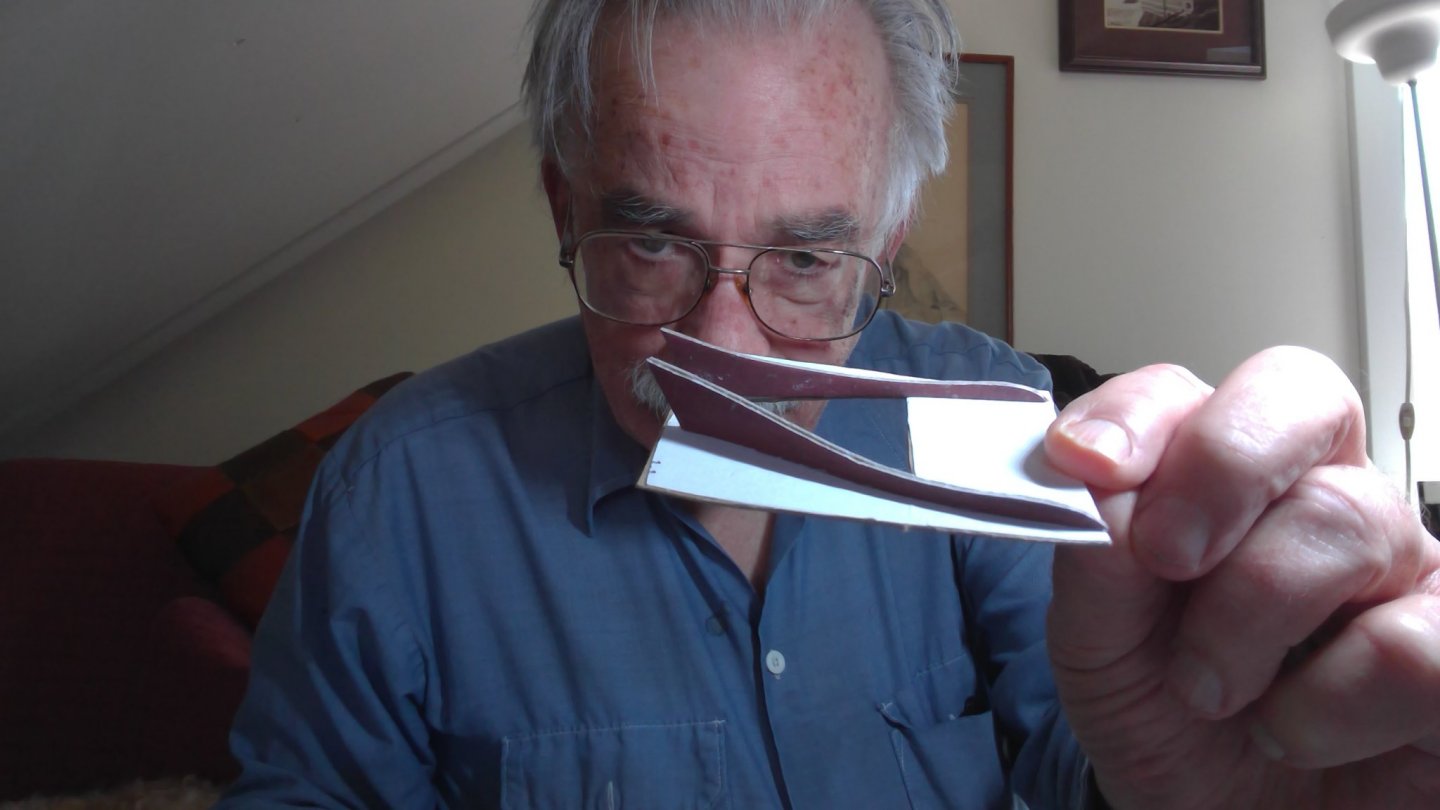

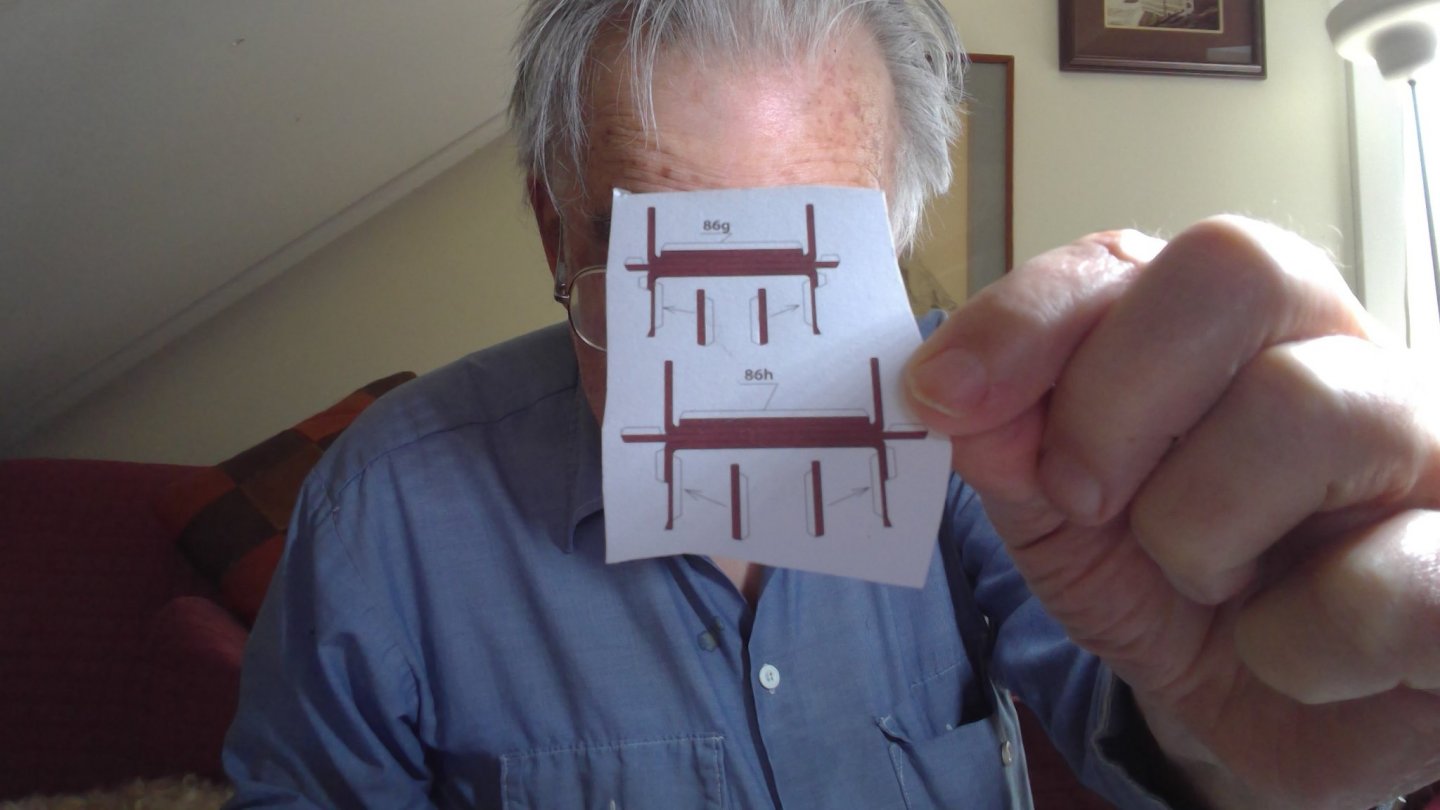

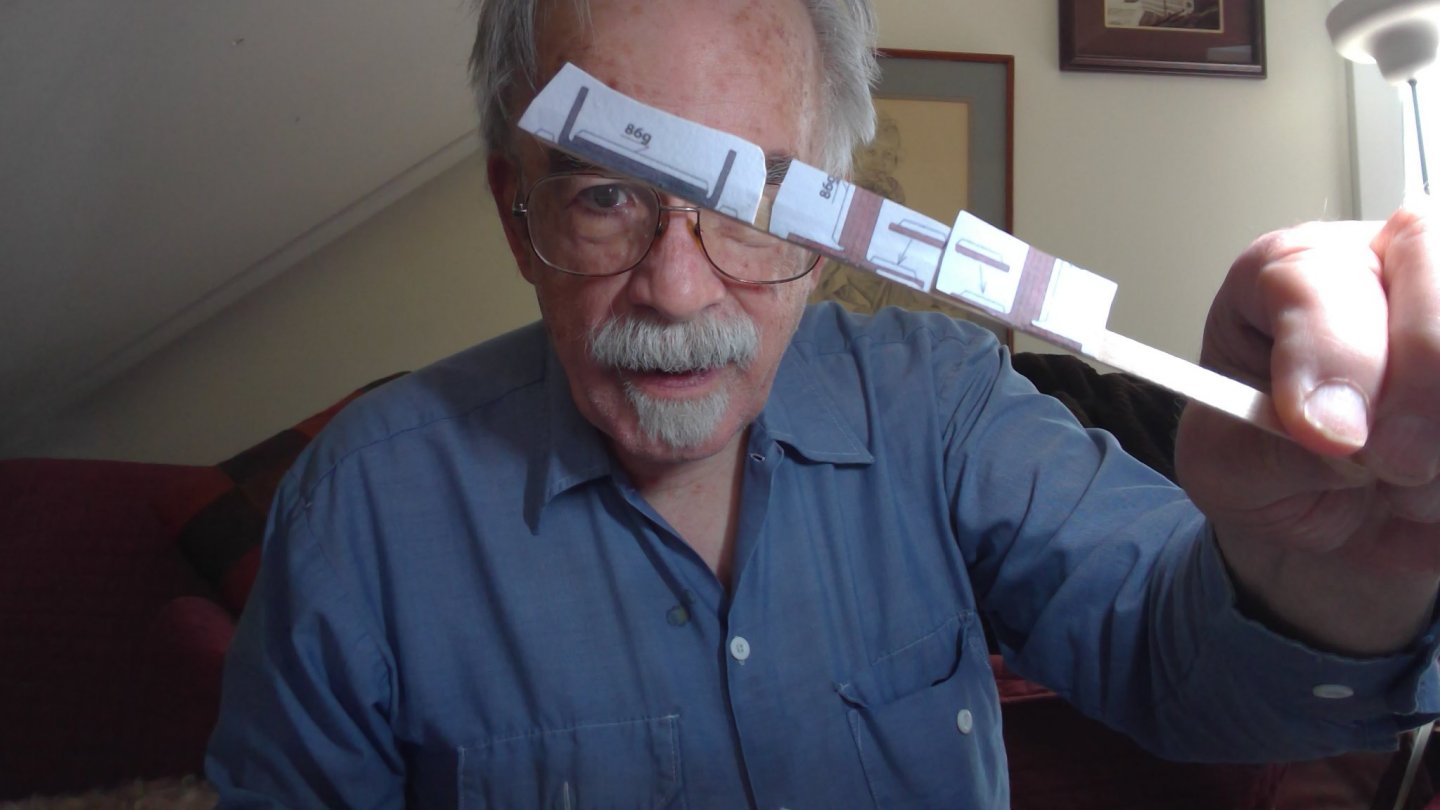

making cleats... 2 sides of card, with a center pin of bamboo...i need to be able to put a little tension on them to set up the rigging and just elmers glue flat on the deck doesn't cut it

- 54 replies

-

- allege darles

- wak

-

(and 1 more)

Tagged with:

-

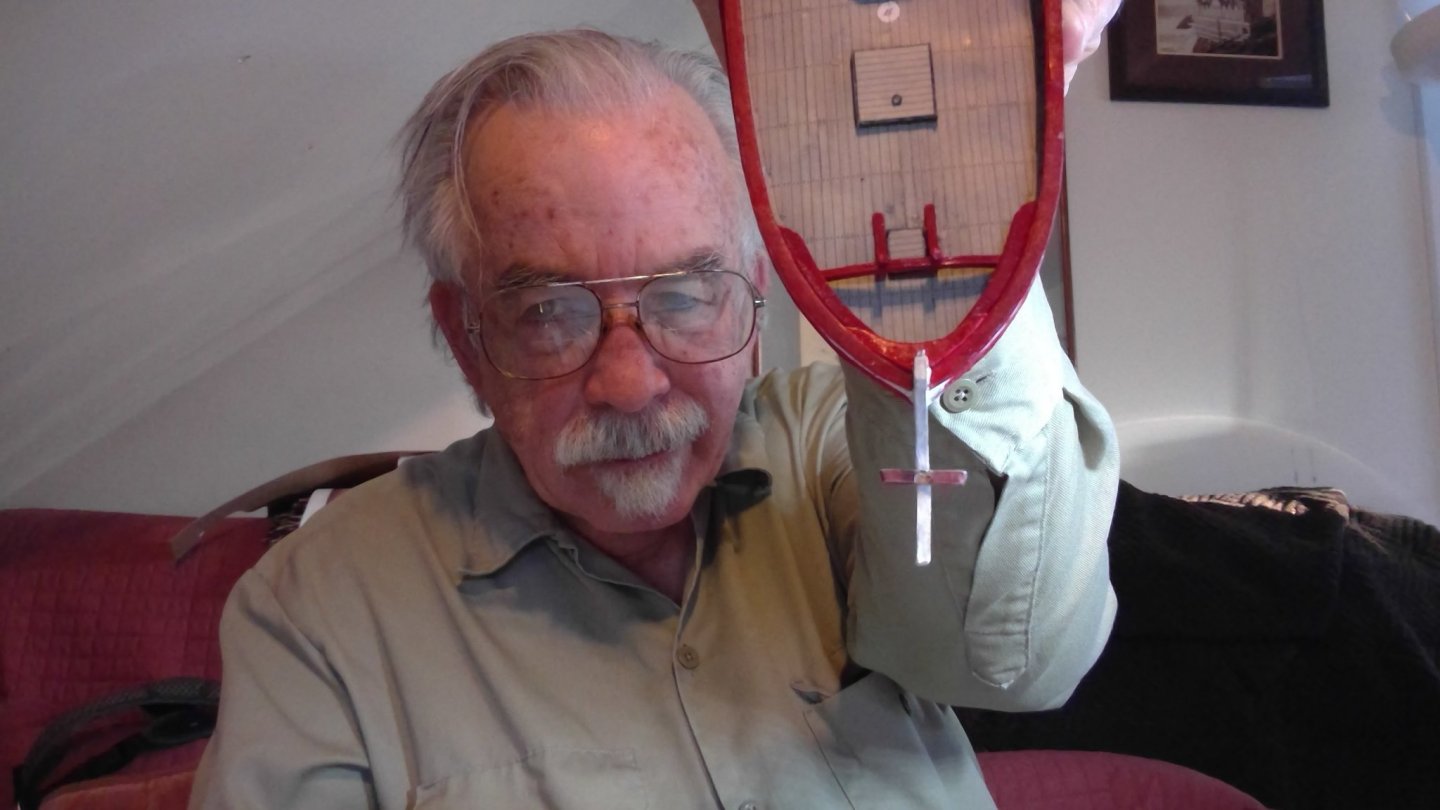

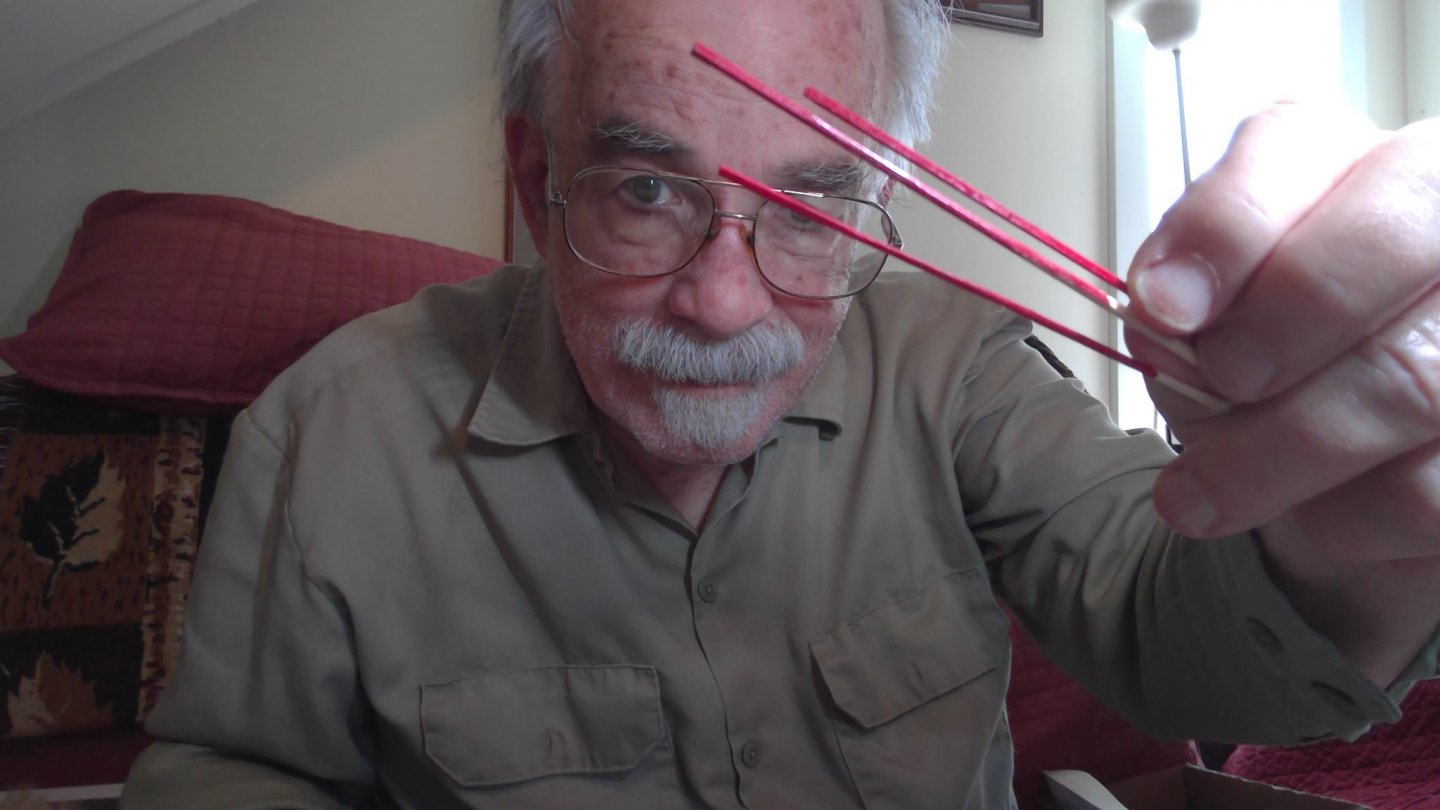

I've decided to use wire for the rigging... which i normally do. But this time i found colored wire (black for standing rigging, gold for running) as painting it (as i have done in the past) would be to clumsy at this scale. 32 ga and 28 guage will still be overscale...but fine enough to look alright i think the problem will be how to fasten it to the sails

- 54 replies

-

- allege darles

- wak

-

(and 1 more)

Tagged with:

-

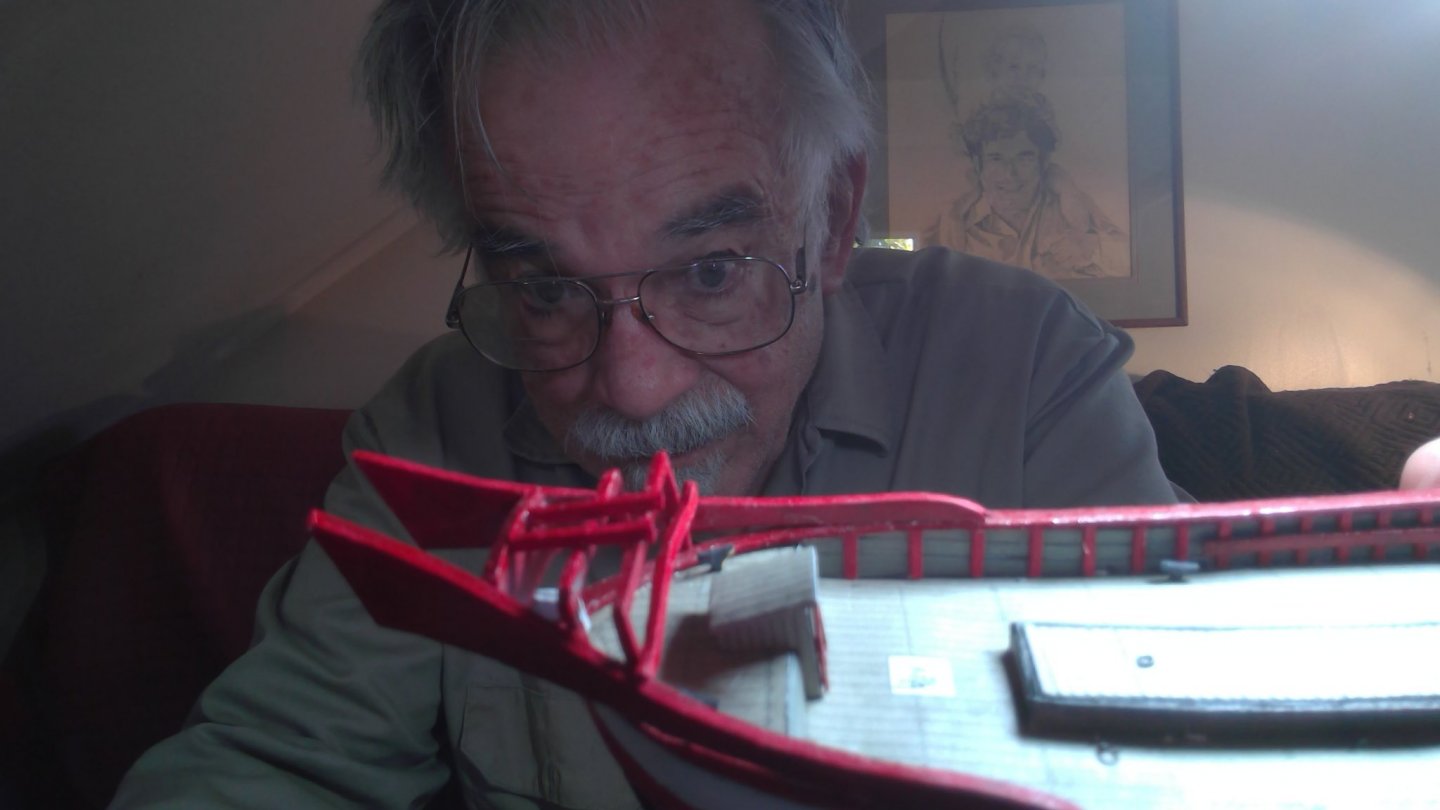

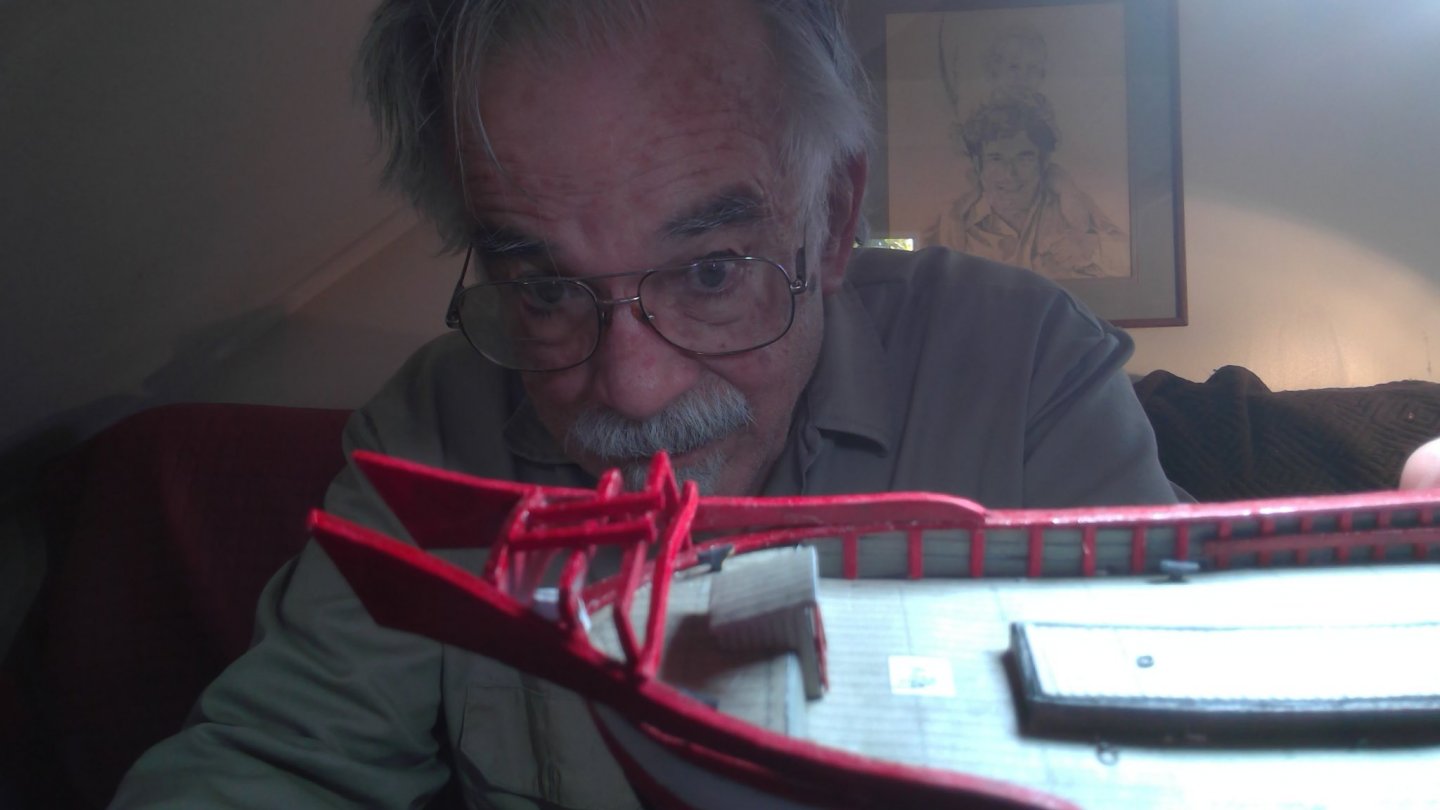

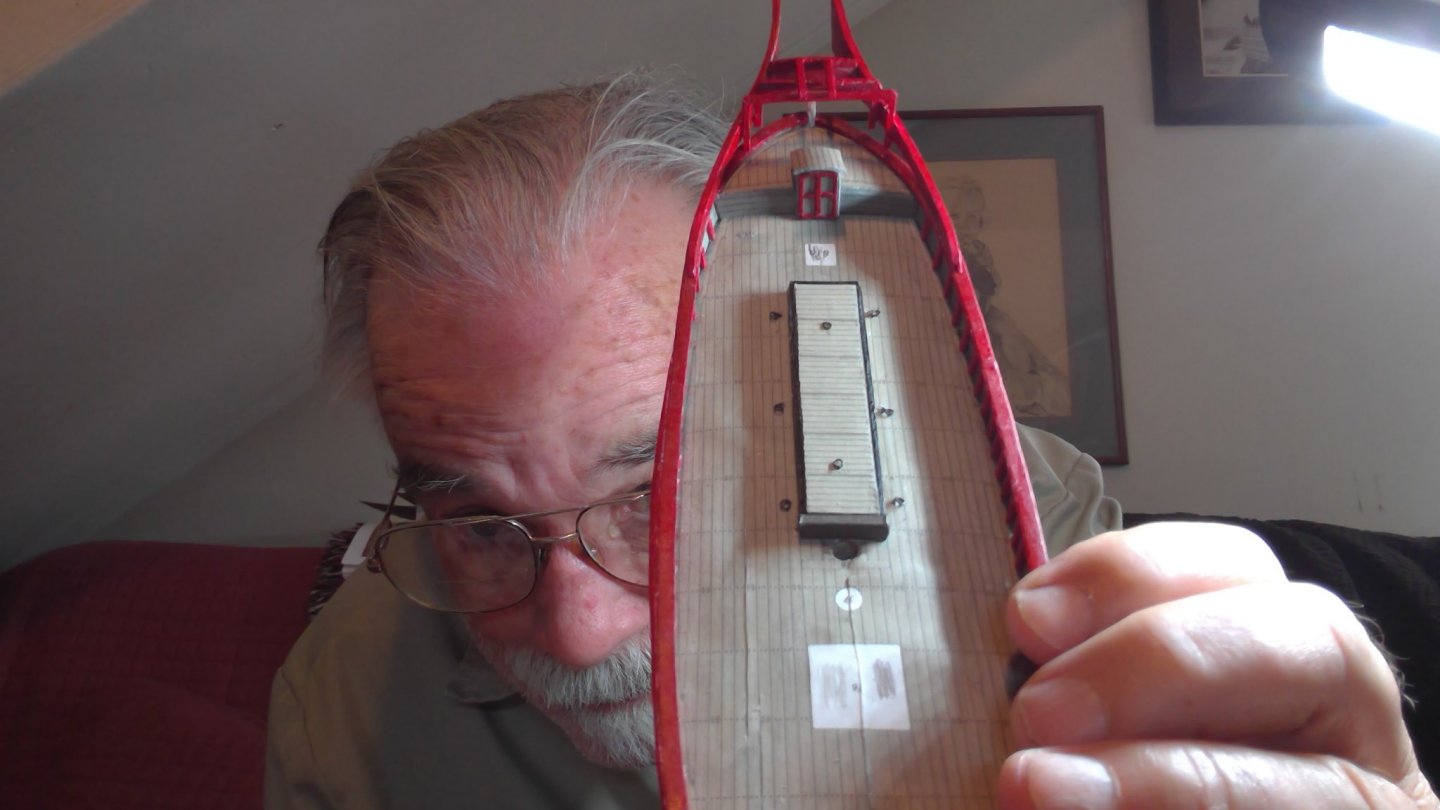

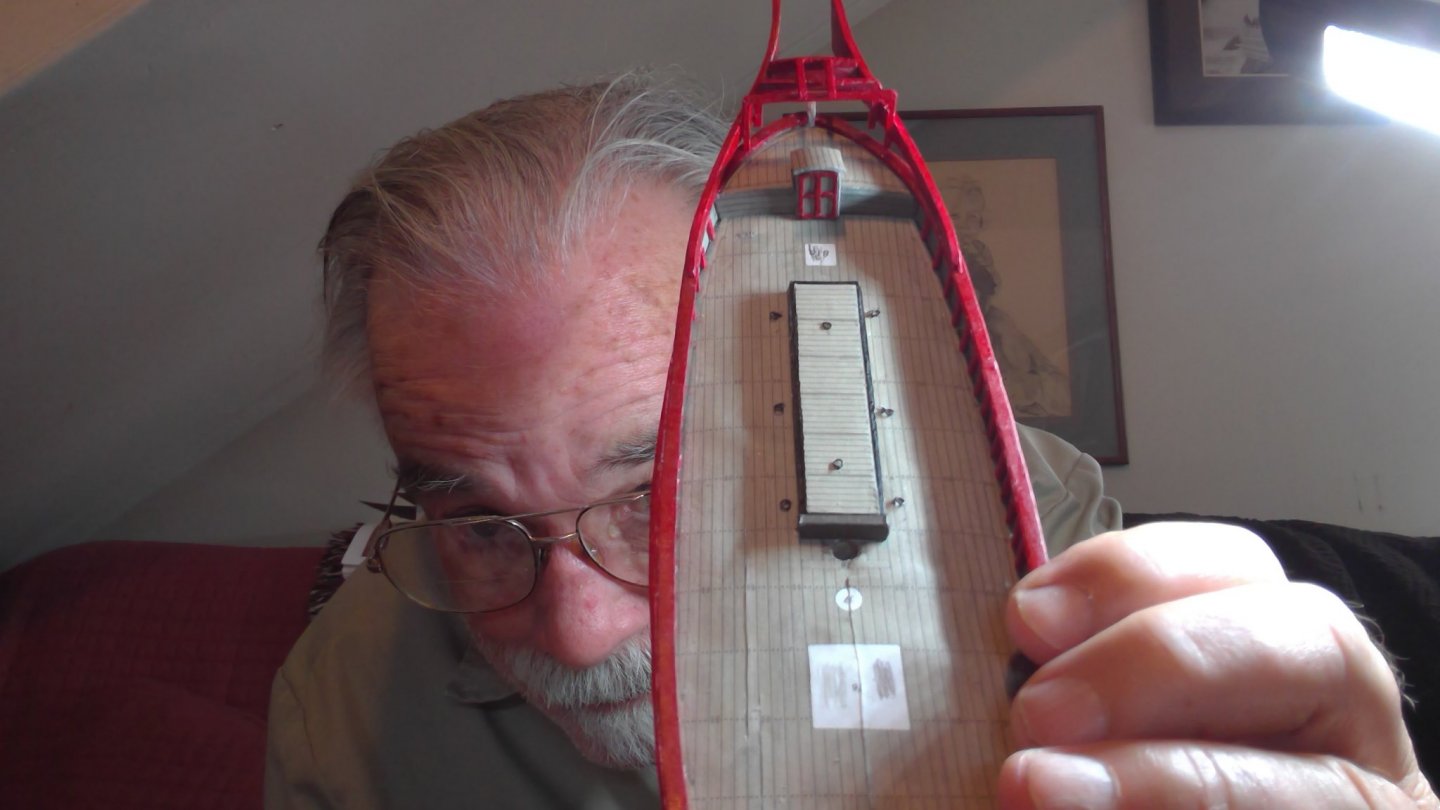

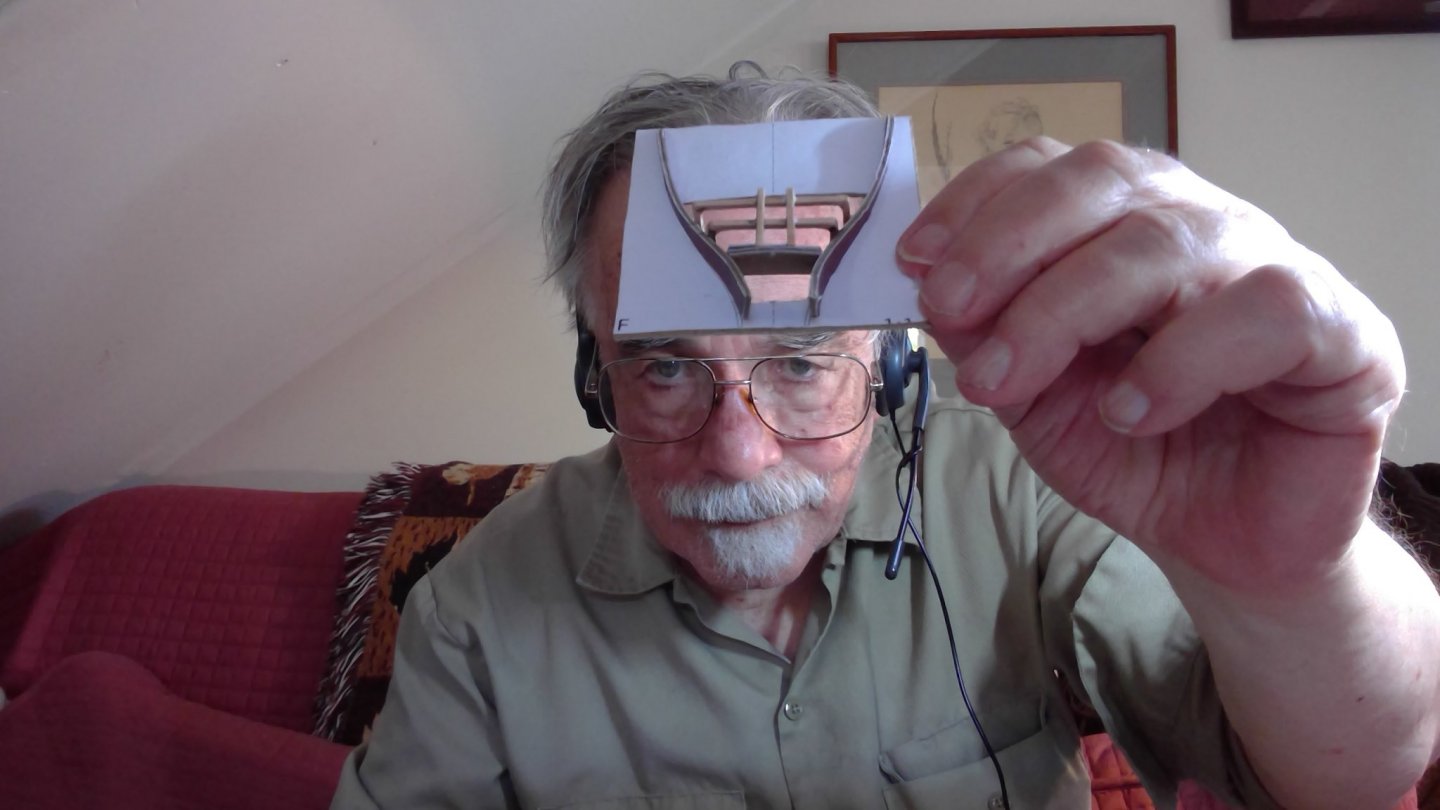

the bracing on both sides of the bow was interesting... some pieces were made of bamboo instead of card, so i folded up the card pieces and painted my biggest problem what the there was no way to register the exact location pieces should be glued on at. I ended up gluing the piece that goes crosswise on the bow first, and then gluing on the 2 long rails that go from the sides out to the bow, and then gluing the smaller crossbars relative to those I added the 6 knights heads... rather than the square posts the paper parts supplied i carved them from wood with (sort of) spheres on top (i had to use walnut, as they were to small for bamboo to support the carving) they had a distressing tendency to go shooting off the desk at the slightest touch...never to be seen again

- 54 replies

-

- allege darles

- wak

-

(and 1 more)

Tagged with:

-

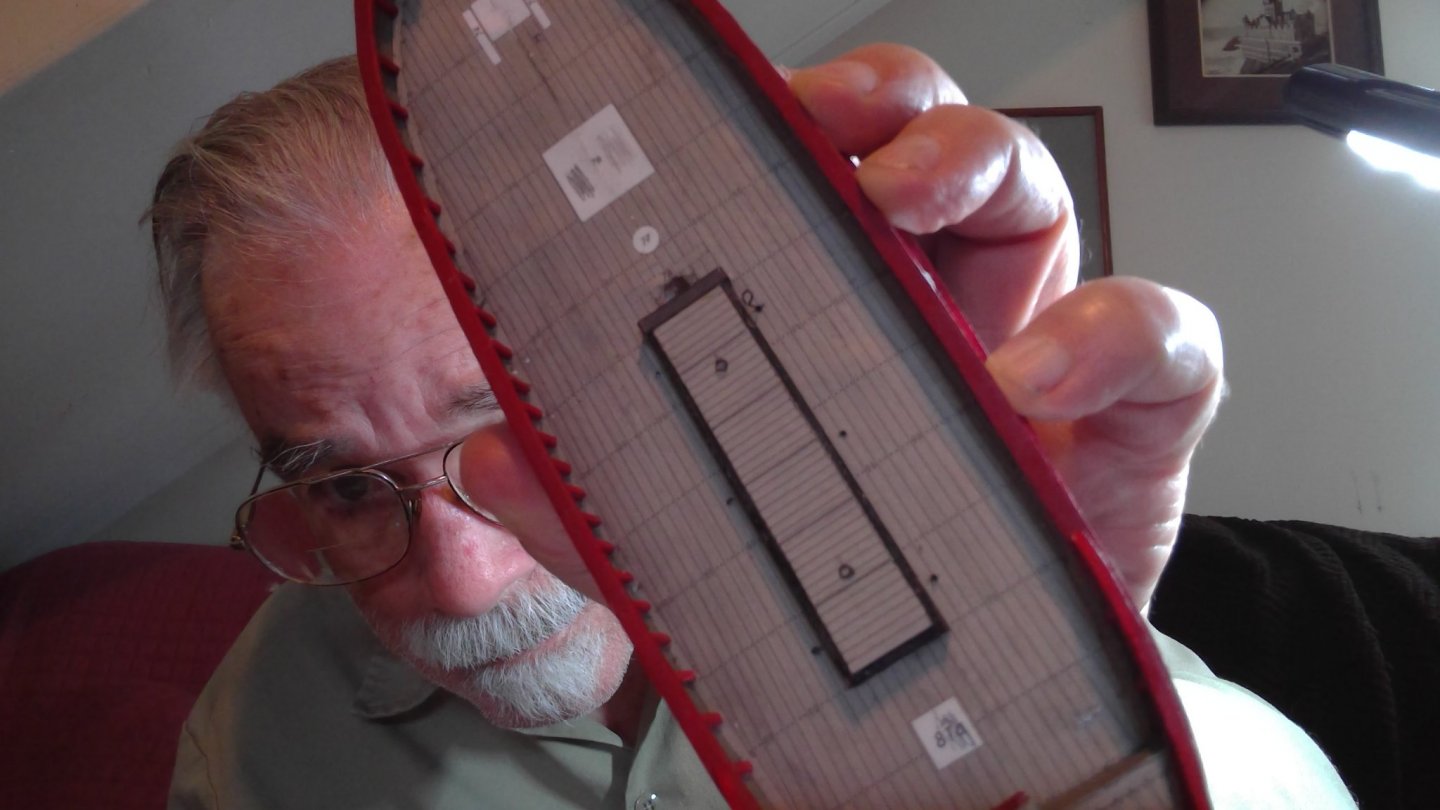

been a while... have to catch up I built the complex deck structures at the bow on a spare piece of card, and once they were glued cut them off and glued them in place on the deck

- 54 replies

-

- allege darles

- wak

-

(and 1 more)

Tagged with:

-

- 54 replies

-

- allege darles

- wak

-

(and 1 more)

Tagged with:

-

so on to the braces in the bow the critical pieces where the 2 knees that are each side of the front hatch so i put them on had to make them 3 times... i have much better luck on thick pieces these days laminating them of a couple of thinner pieces built them on a copy of the front deck and when they were glued and painted cut them of to mount on the ship

- 54 replies

-

- allege darles

- wak

-

(and 1 more)

Tagged with:

-

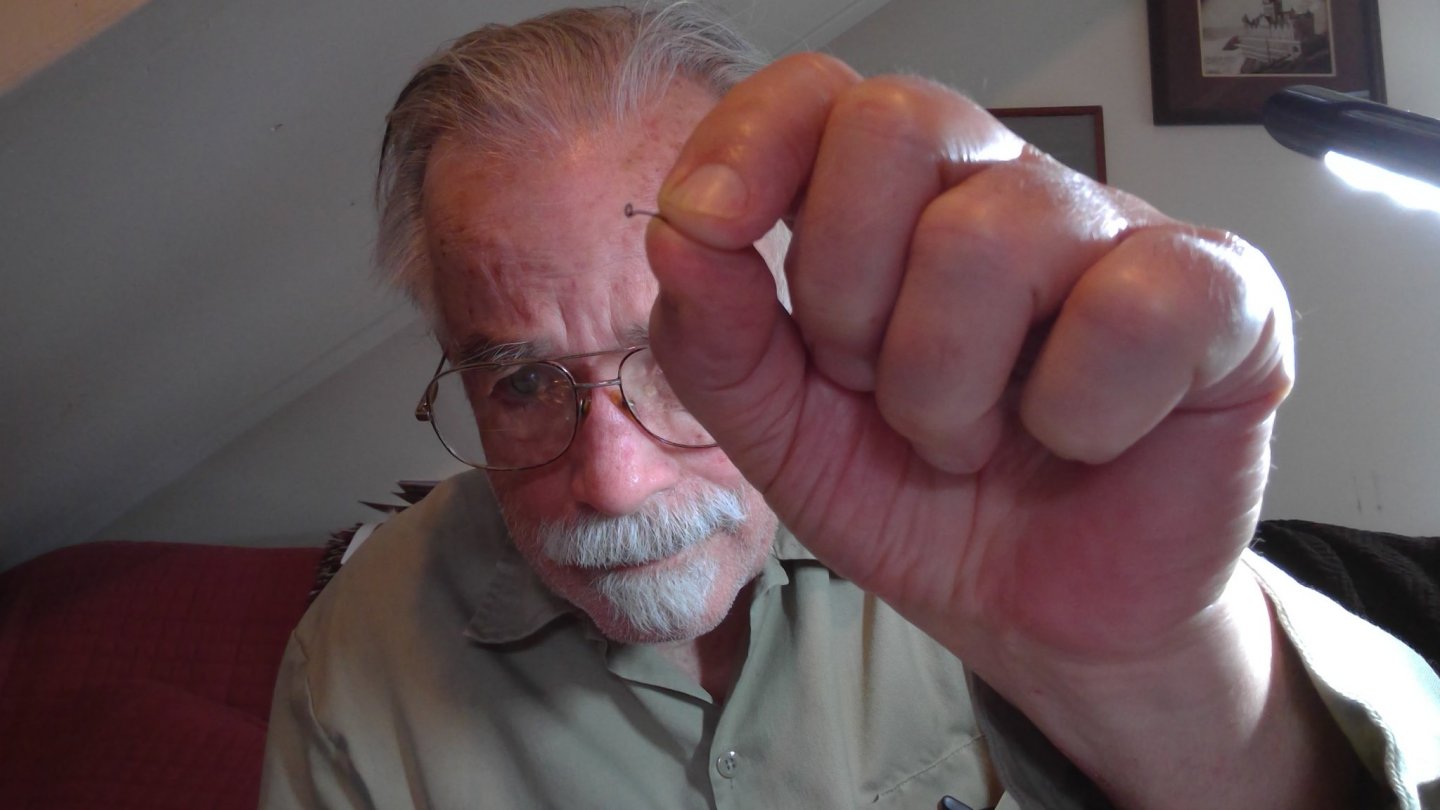

glued down the hatches... used watercolor to paint the upper edges of the frame around them... from the pdf of the Ancre ship I added 6 tie downs, 3 on either side used a colored pencil to blacken the edges of the piece across the front that forms the back of the 4 pieces that contain the mast ring bolts formed around the end of a mechanical pencil and then cut off and bent over.. there is enough resistence when you push them in the holes that have been drilled for them that there is no need of glue

- 54 replies

-

- allege darles

- wak

-

(and 1 more)

Tagged with:

-

From looking at the Ancre model pages I decided the hatches over the below deck access had ring bolts on the 2nd hatch from each end. Once you lift that one up you can easily lift the others The ring bolts are from black-clad wire. they cheat, because they only have the ring, there should be another ring on the bolt itself.,, but I cannot do it at this scale..I could add the 2nd ring , but it would look to big.

- 54 replies

-

- allege darles

- wak

-

(and 1 more)

Tagged with:

-

- 54 replies

-

- allege darles

- wak

-

(and 1 more)

Tagged with:

-

these parts all do NOT have any built in self aligning features.... so it was like trying to juggle all of them in the air and glue them as they came down

- 54 replies

-

- allege darles

- wak

-

(and 1 more)

Tagged with:

-

an intricate juggling act to glue the back framework together' i had to put in a fake piece to give myself some "notches" to match the bars up to the cross piece i removed to dummy piece of card i had glued things to as i went instead of attempting to fold the bars out of paper i glued the pieces on to some coffee stirers (about the right thickness) and carefully carved them out, then glued them together

- 54 replies

-

- allege darles

- wak

-

(and 1 more)

Tagged with:

-

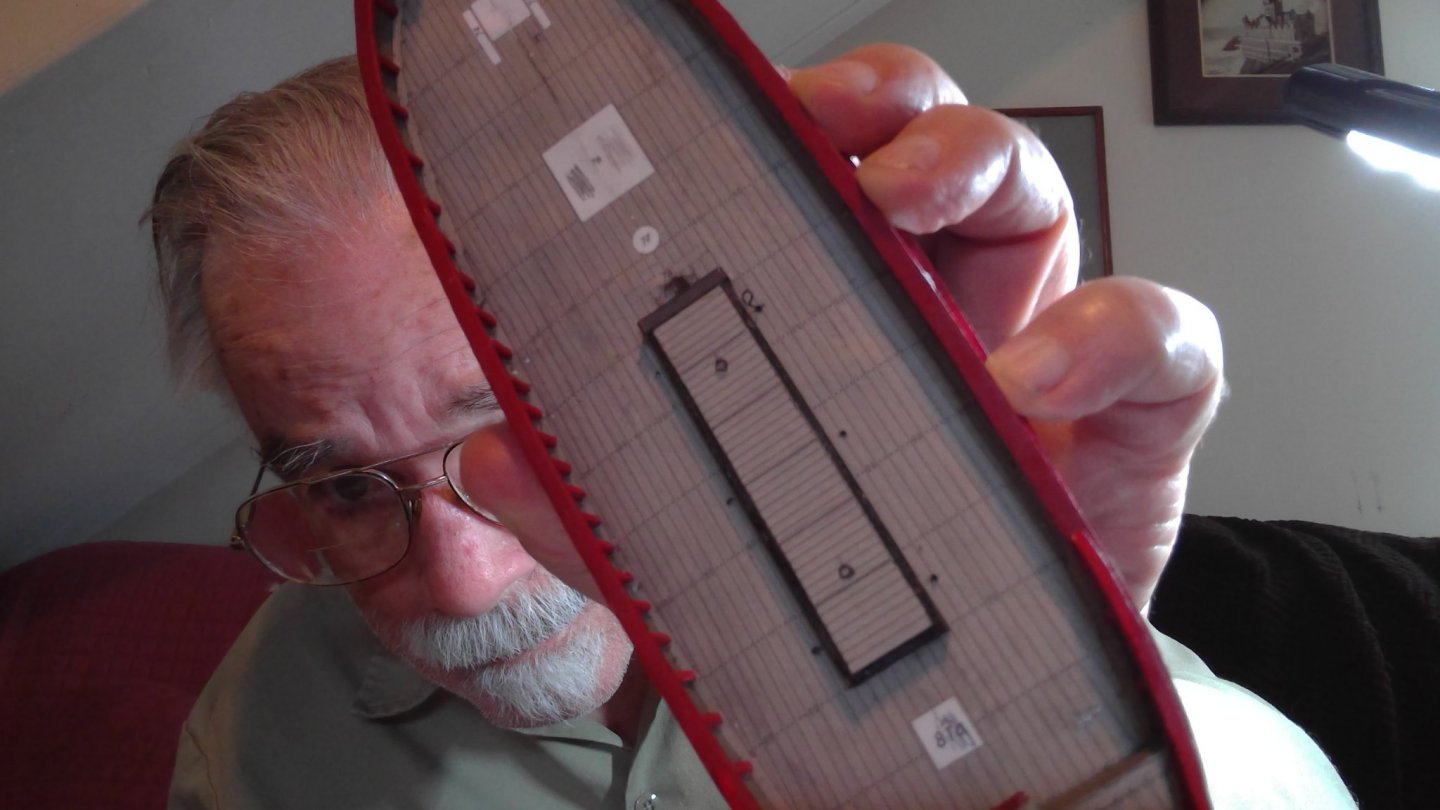

got all the frame ends cut and glued in place. bamboo is a wonderful materia and then the side rails, glued on heavy card and painted to some degree they cover up the fact that the sides bend in a little to much in the middle of the deck now there is a sort of after structure to build, and the rails out along the bow trying to avoid putting the deck houses and stuff in til last so i can use the deck to handle the boat

- 54 replies

-

- allege darles

- wak

-

(and 1 more)

Tagged with:

-

Haven't used my modeling tape for a long time, but I thought it might help in this case. The edges did not come out completely clean.. but they're easy enough to touch up. cutting little tiny square bars from bamboo turns out to be a real trick. I discovered if you hold the bamboo down against your jeans and draw it under the knife it does a fair imitation of a plane. the square bars will became the frame inside the deck bulwarks when cut into small pieces.

- 54 replies

-

- allege darles

- wak

-

(and 1 more)

Tagged with:

-

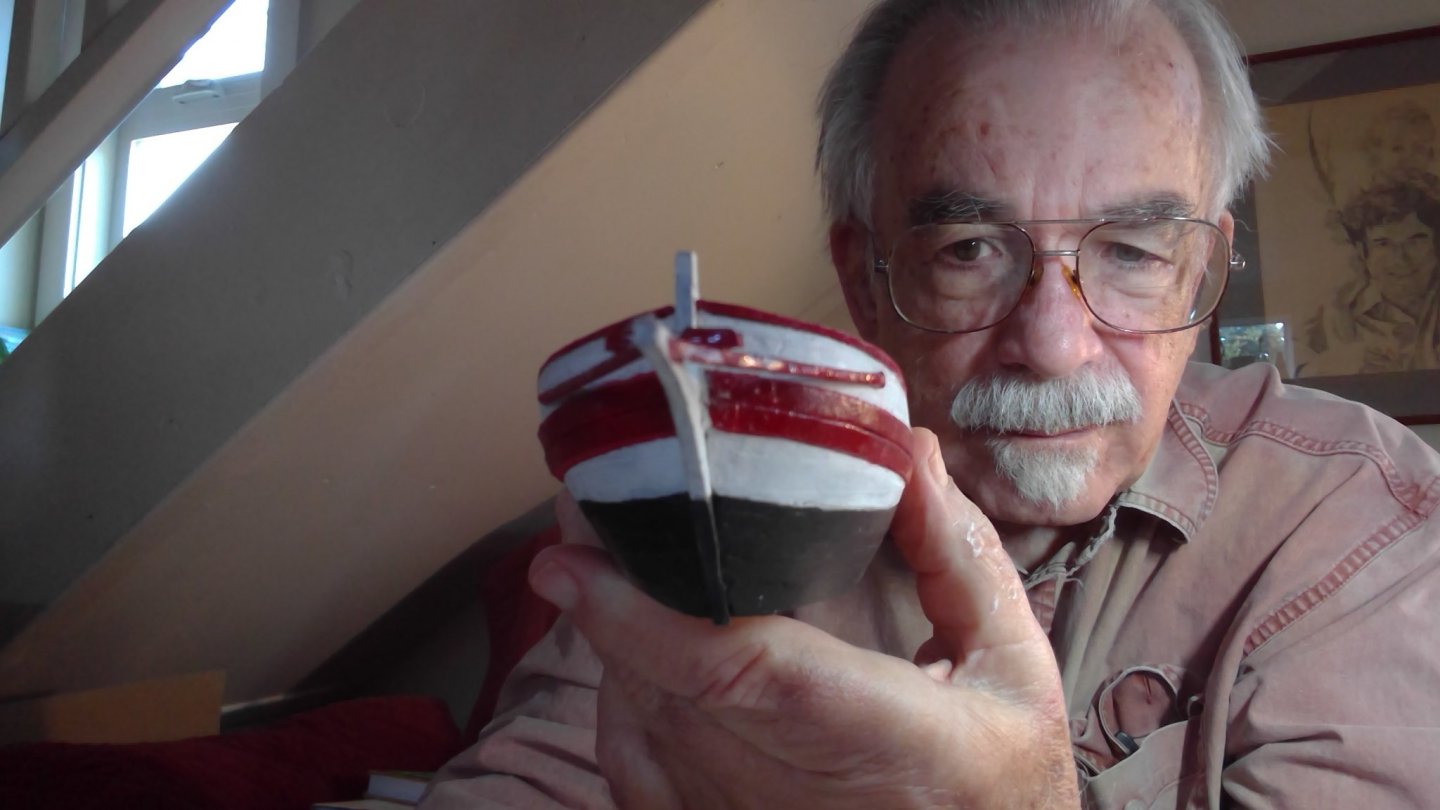

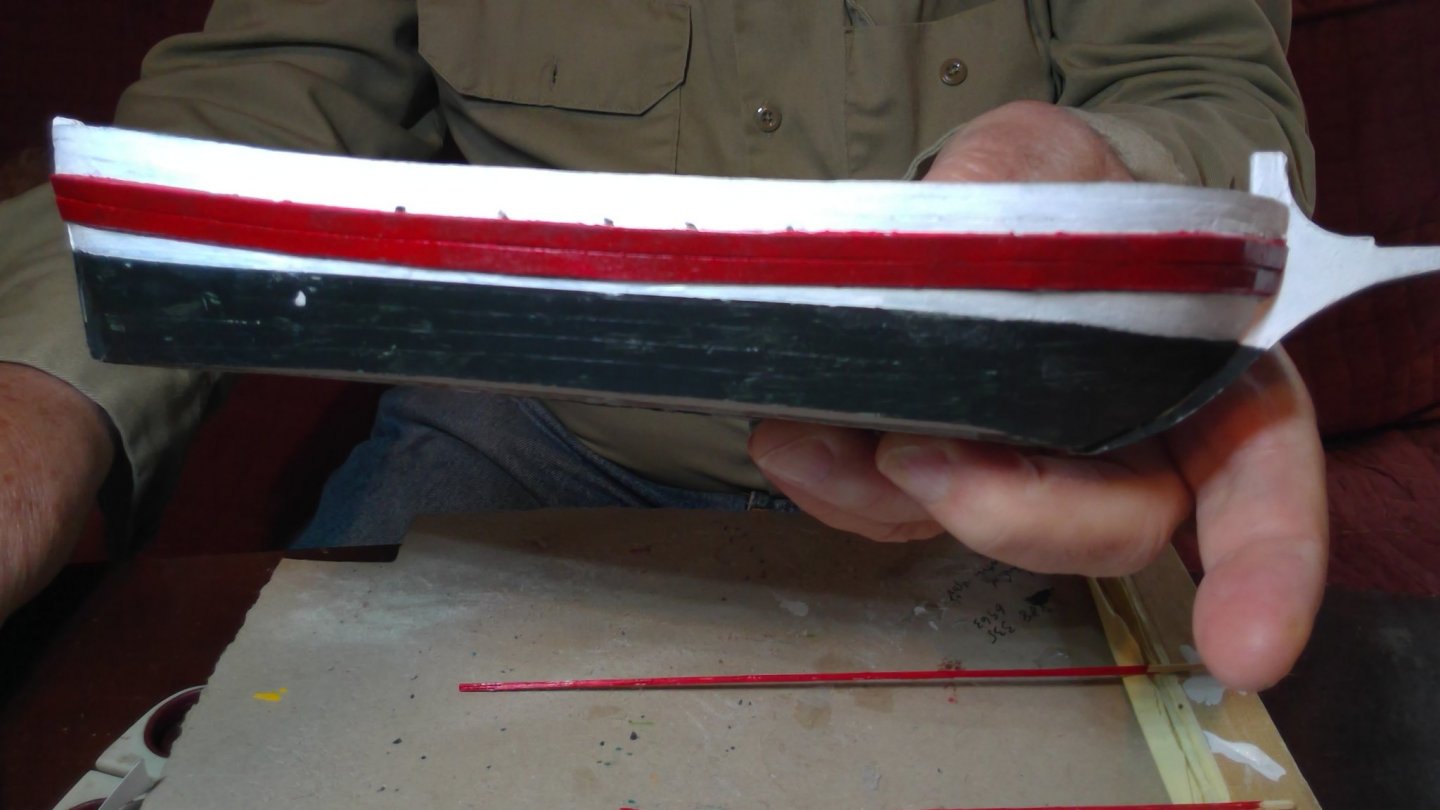

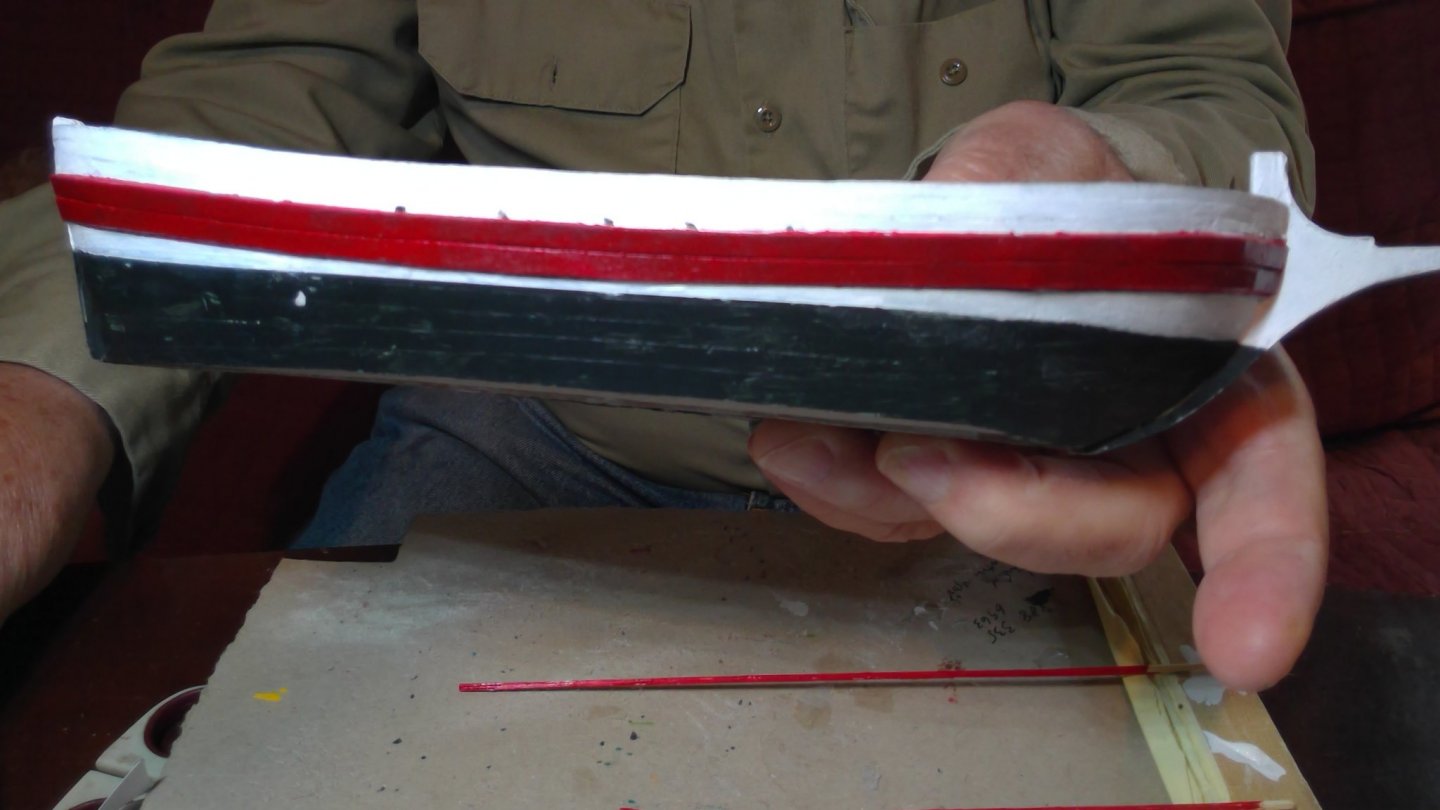

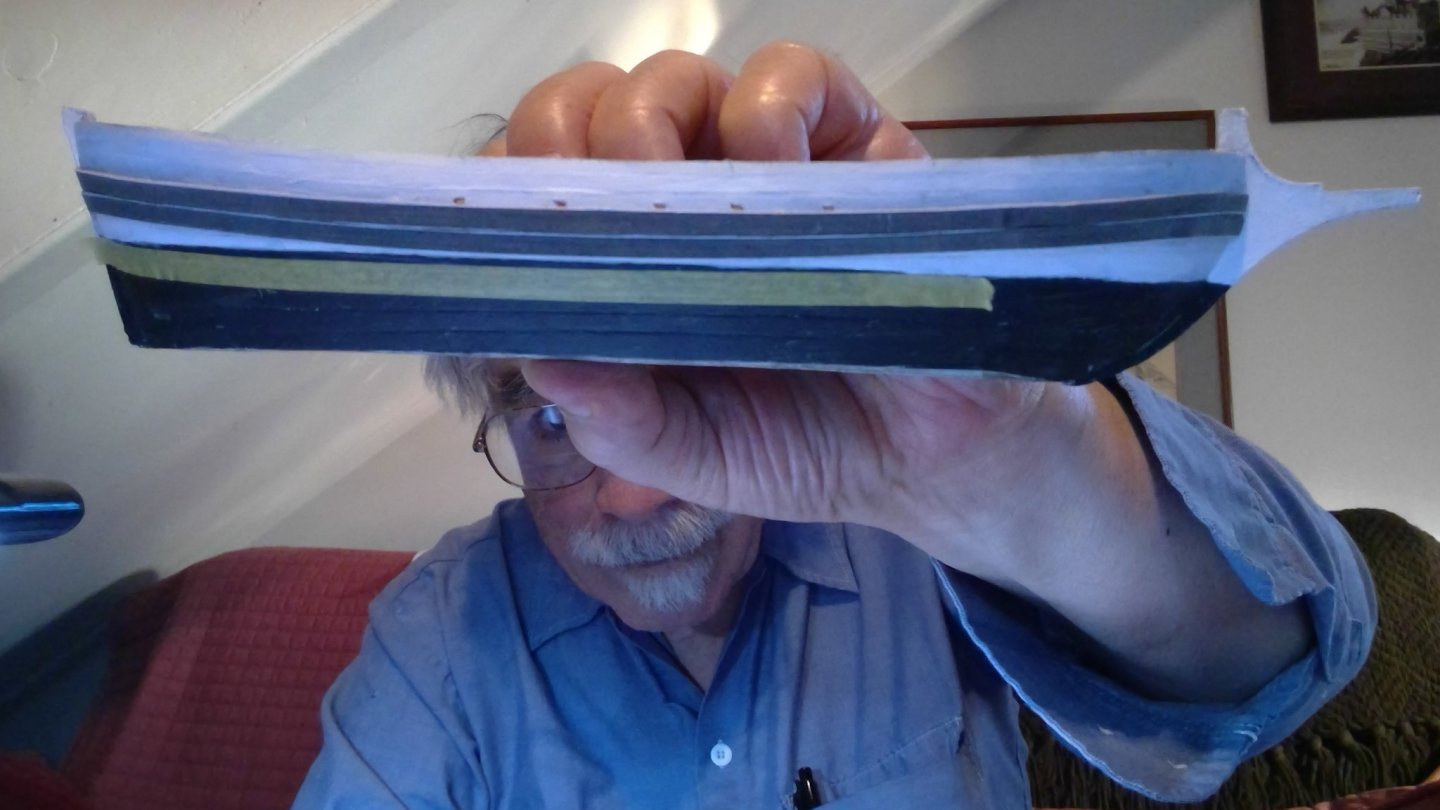

put on the wales... always love that..gives me a special feeling have to adjust the "waterline" on one side to make the space between it and the wale match the other

- 54 replies

-

- allege darles

- wak

-

(and 1 more)

Tagged with:

-

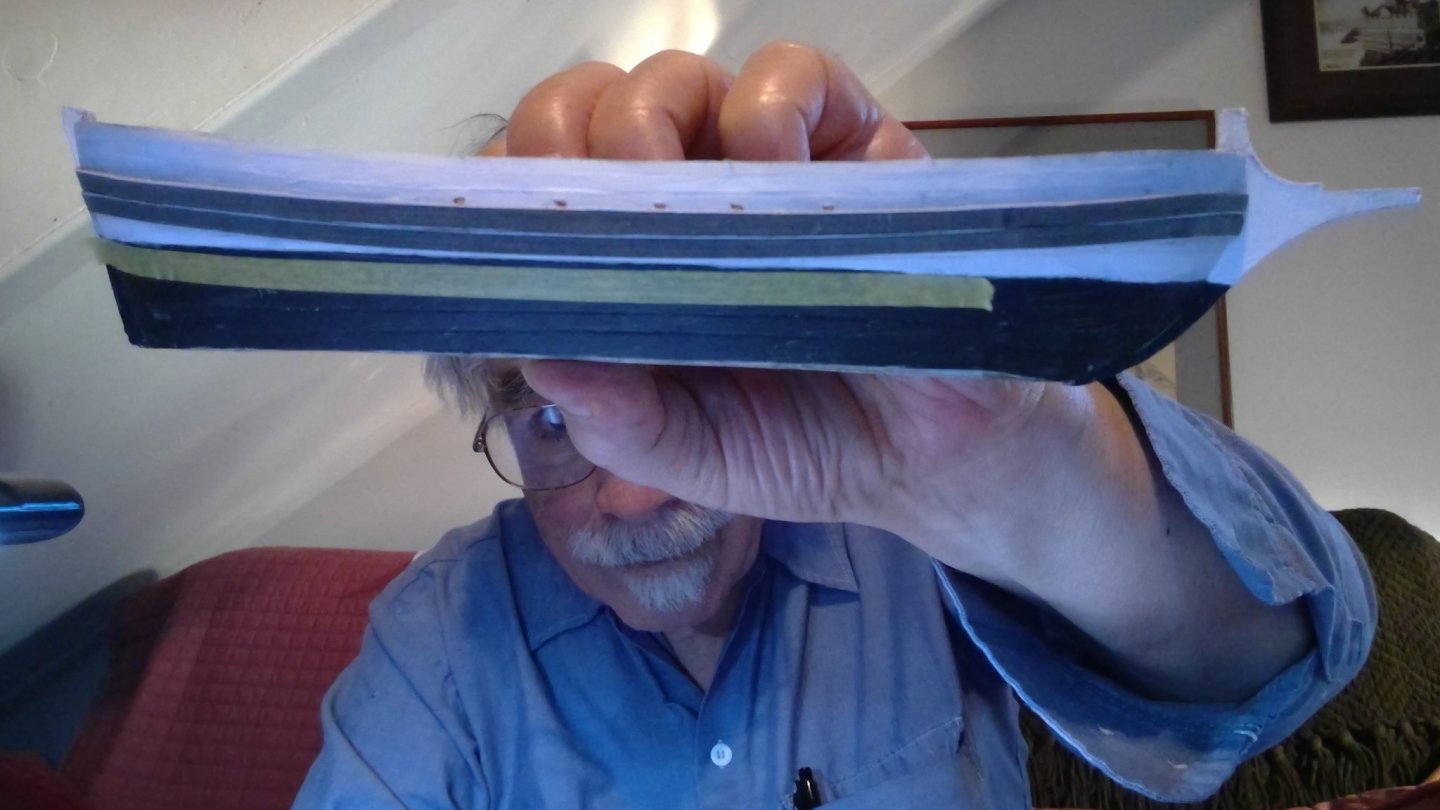

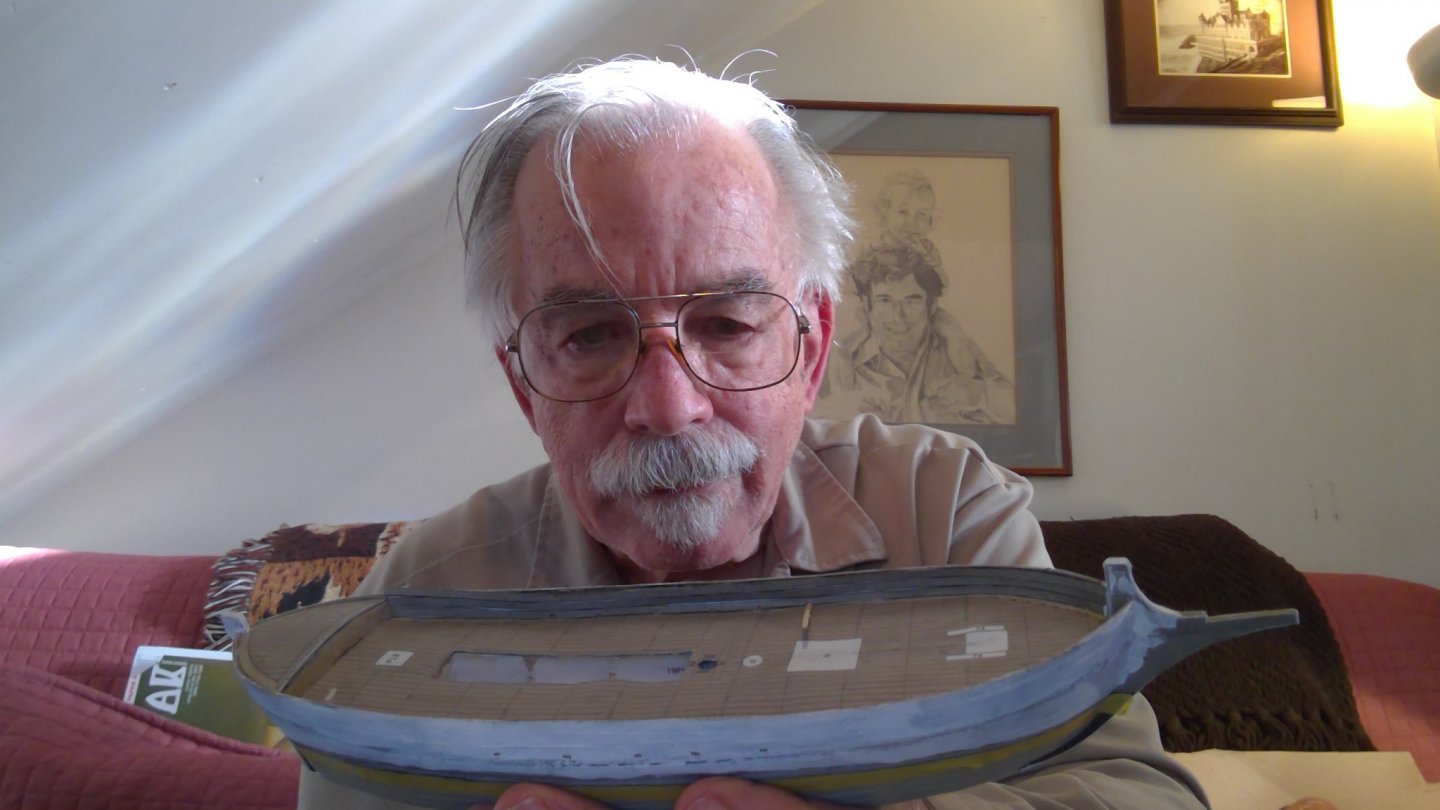

I have planked the inside of the wales and painted the basic hull color. I decided to use the color scheme on the cover instead of the one that comes printed on the parts. You can see in the first image that i used a small piece of bamboo to line up the holes for the scuppers in inner pieces with the holes in the hull sides. The inner "planks" did not fit exactly fore or aft, so I aligned them on the scupper holes My idea of "caulking" the planks to subdue the effect of the edges seems to have worked out. It was a little tricky getting the "dip" in the water line to counter act the optical illusion of the water line bending upward in the middle Next are the wales... again i will probably change the kit to look more like the cover

- 54 replies

-

- allege darles

- wak

-

(and 1 more)

Tagged with:

-

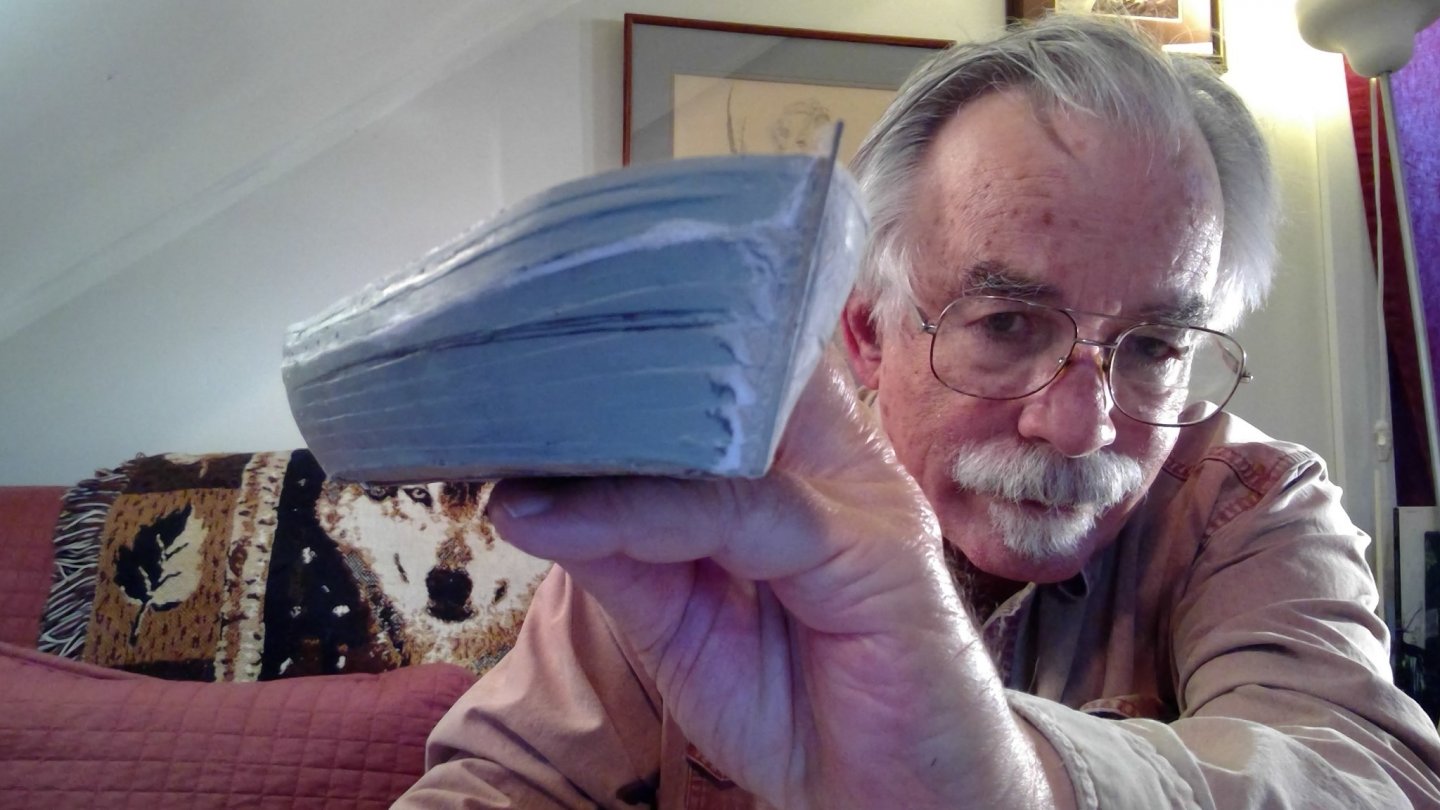

so now we plug in the stern post and the stem at the bow.... i sure prefer making these from a solid piece rather than the two sides and a piece to cover the edges approach taken here. you can see that some pretty drastic surgery was needed at the stern, as it did not tuck in enough

- 54 replies

-

- allege darles

- wak

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.