-

Posts

114 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Hill202

-

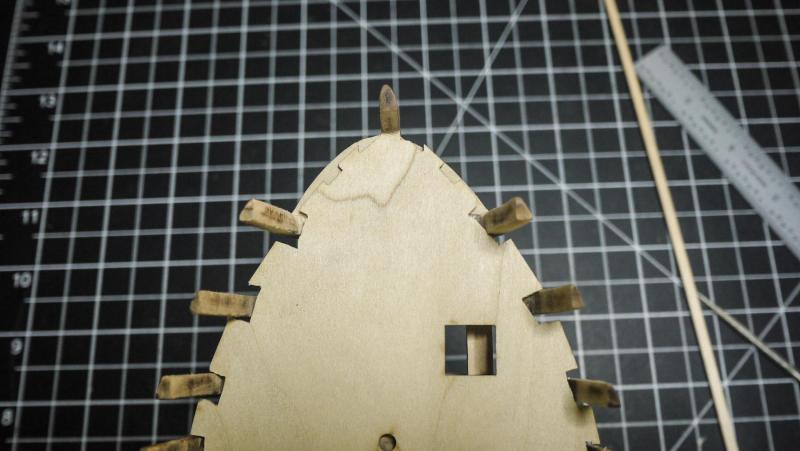

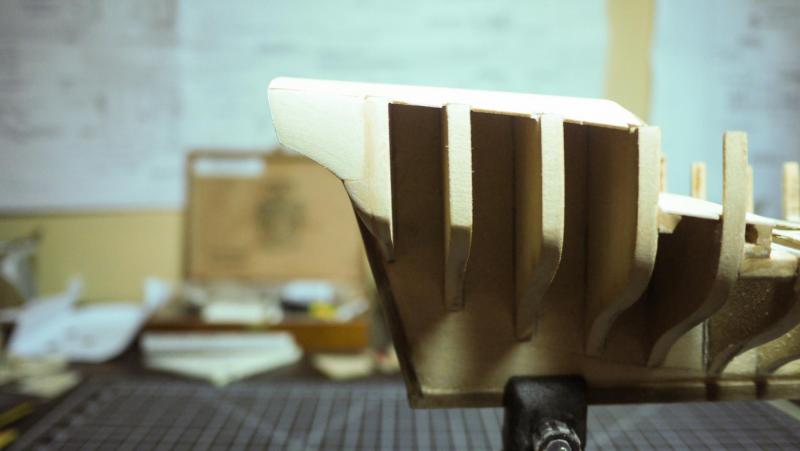

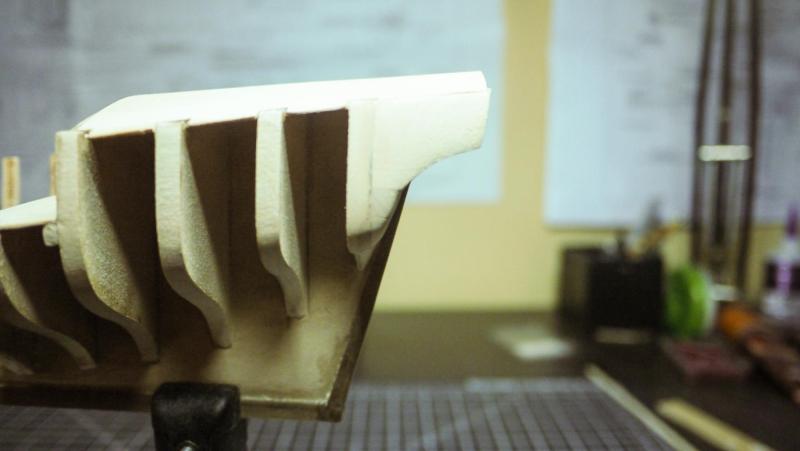

The notches are cut. I think wood filler and a little adjusting will correct any issues. I also included a pic of my practice rabbet. I realize it was just 4 simple notches. I'm just trying to heed the advice to slow down. I think I'll wait to glue the deck down until after the posts are installed and then just trim the deck to the posts.

-

One small obstacle I have been having, is the lack of scrap basswood. My experience from rc planes is mostly balsa and some spruce. I ordered a few basswood planks from a supplier that I found online. I'm not sure if they are a sponsor here. My thoughts were that I wanted plenty of extra to practice with and also I did not want to be in a position where I was forced to use a bad cut plank due to the lack of wood. For some reason I did not order a block of basswood. I wish I had because I would practice cutting the knight head rabbets. ( I've been calling them notches). I think its important for a beginner, like me, to practice with some wood before shaping or notching any basswood, especially if you are not accustomed to working with it. Not that it's difficult to work with, it's just different. Just a thought that may help a future beginner.

-

I'm cranking the steamroller back up. Marking the notches for the timber head and knight head is proving to be a little difficult. My deck alignment somewhat made the notches not quite align. The knight head looks to be too close to the stem. Edit- Comparing it to Brian's. I guess I'm close. http://modelshipworld.com/index.php/topic/8085-armed-virginia-sloop-by-gunthermt-finished-model-shipways-scale-148/page-4#entry246213

-

Slow progress because apparently "it's impolite to work on your model, when family is visiting". The deck is not glued down yet. I'm working on drawing the knight heads notches. The tab is broken off the deck at the tip. I am going to get the plans out and trace the tip and install the missing piece so I can properly mark for the notches. The remaining notches in the main deck or somewhat over sized but that's all covered by waterways and decking so I'm not worried about it...much. I have no idea how I managed to mess up that notch on the port side at bh A.

-

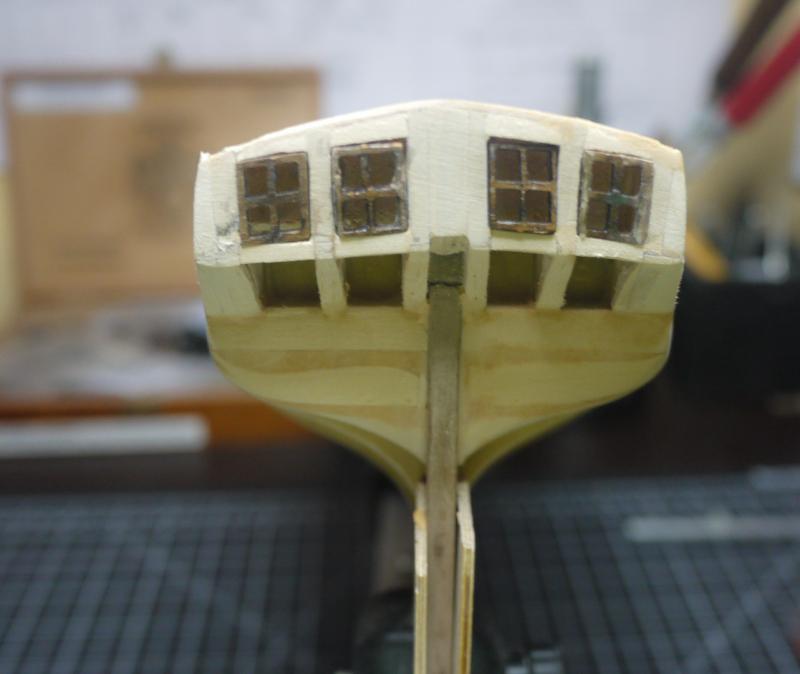

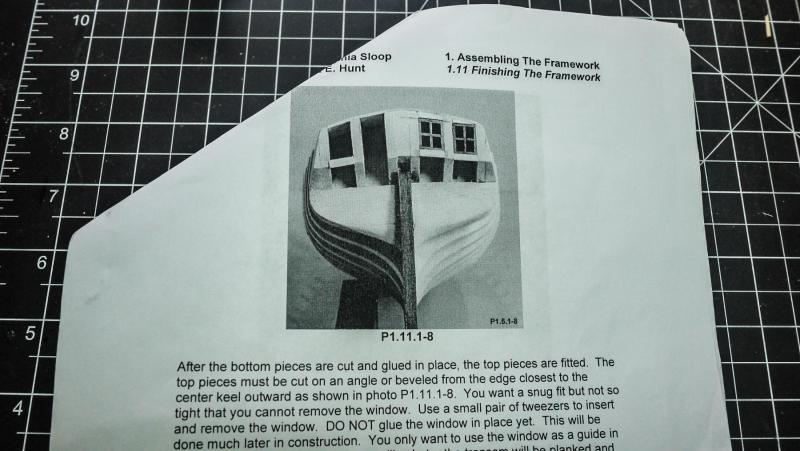

Dave, I have not read much of chapter 2 yet. I just assumed that's how you guys were bending the planks. Are you soaking the planks and clamping them wet and glueing when dry ? I think I read where Bob Hunt glues them wet with Ca glue. I want to avoid this if I can. I'd much rather work with the Titebond. Thanks for the link. That picture is the one I needed. There are very few photos that show that arch like that. Thanks. I believe I am back on track with it now.

-

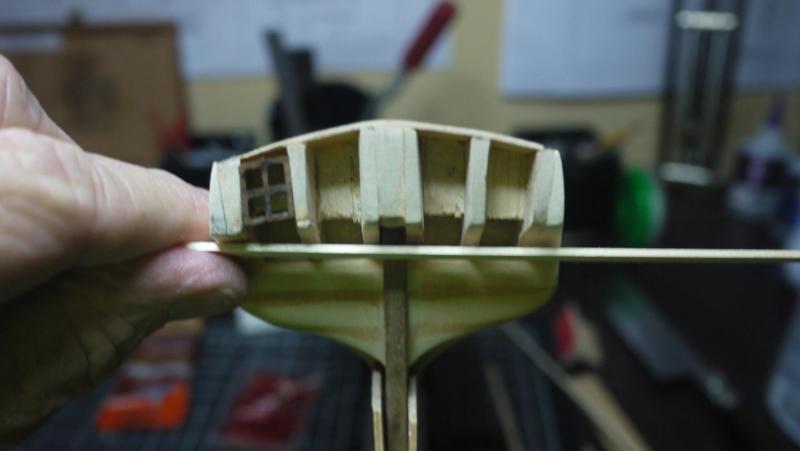

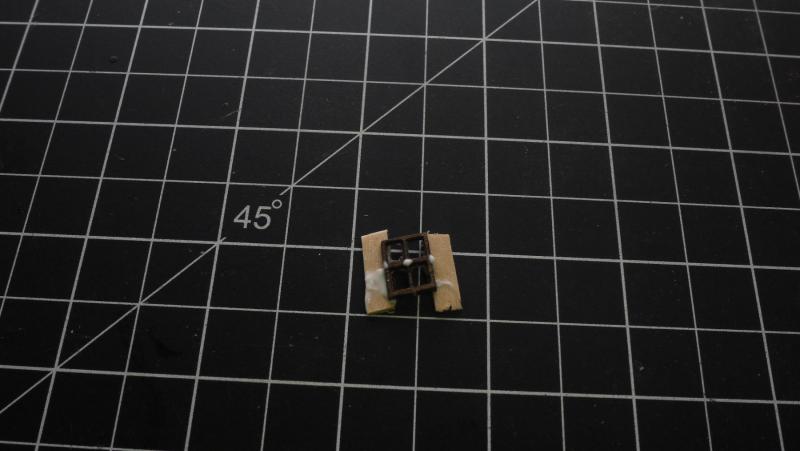

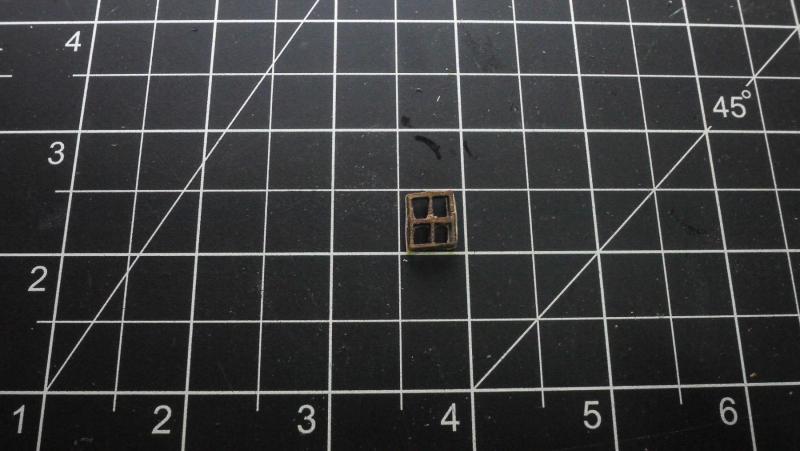

Zoltan ,if the counter forms an arch, why are your planks laying flat underneath? The problem I have is the frames need to be shimmed to fit in the window sills. I'm not sure how far down to take that shim or if I need to add shims to others to match. Looking at Brian's ship, it appears that his stern frames form a straight line across, with no arch. So, in other words, does the bottom of frame 3, hang lower that the bottom of frame 1?

-

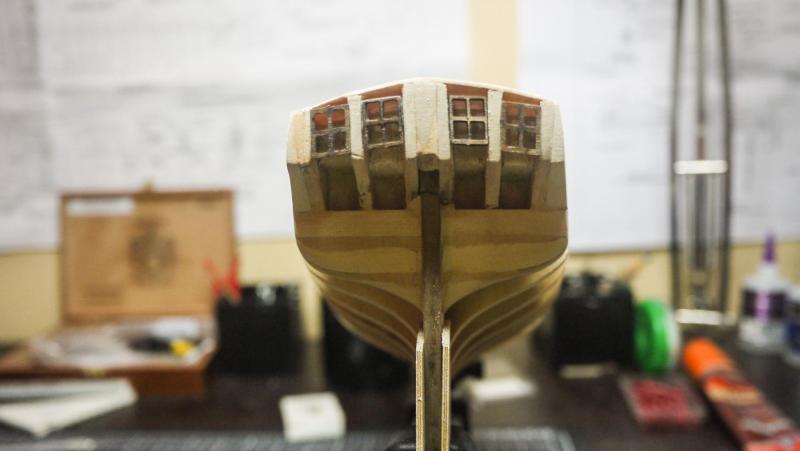

Do the bottom of the stern frames, the curved part, form an arch underneath? or should they all be shimmed to form a straight line? If you go back and look at other's logs, you can see that it was done both ways. If the bottom of the frames form an arch, then the planks there will have a bow. I hope these pics help to clarify my question.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.