-

Posts

114 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Hill202

-

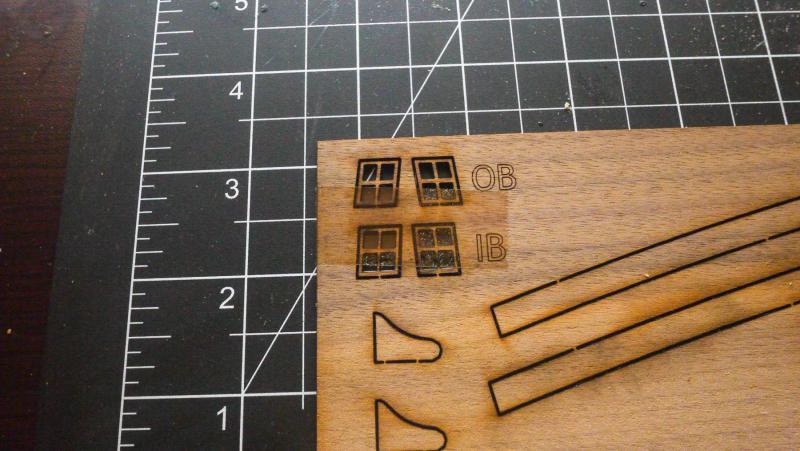

To do list to finish chapter one: Install side filler blocks repair broken window shim face of port side # 3 stern frame, adjust stern frames for window fitment install upper and lower window frames, I plan to install stops for the windows (thanks Brian) glue in main deck trace notches onto bow filler blocks I just thought that I was about finished with chapter one.

-

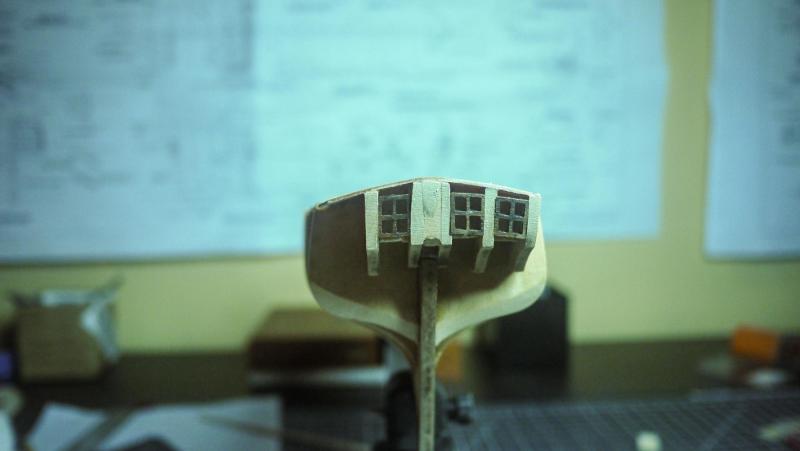

The transom wing and filler are finished. I am going to glue the main deck down next. It has been nice having it out of the way. It has made the model easier to hold and kept me away from the bulkhead extensions. I have a little more tapering to do to stern frame # 3, port side, to fit the windows. I need to find the proper tool to handle them, maybe rubber coated tweezers. I broke one window in an attempt to fit it. You can see it in the photo on that piece of scotch tape.

-

You guys make a good point about bulkhead R. I over faired it during the initial faring. I should have looked ahead. It should have been faired very little until after the wing transom and filler were installed. Those are balsa blocks( terrible to work with) between the stern frames. I have very little scrap basswood.

-

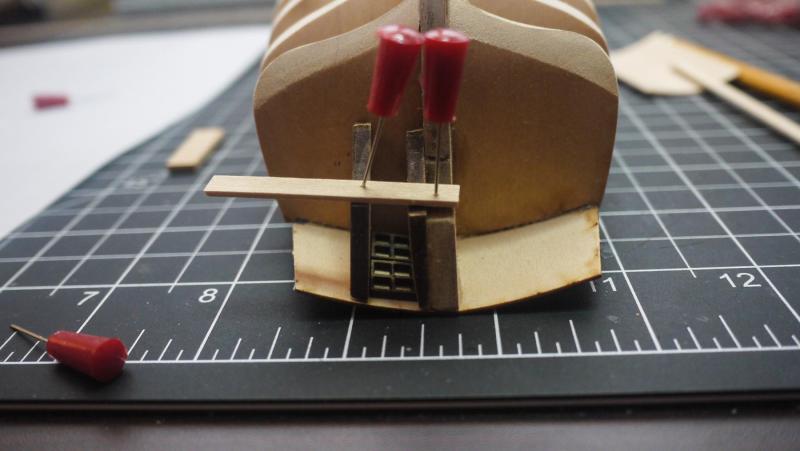

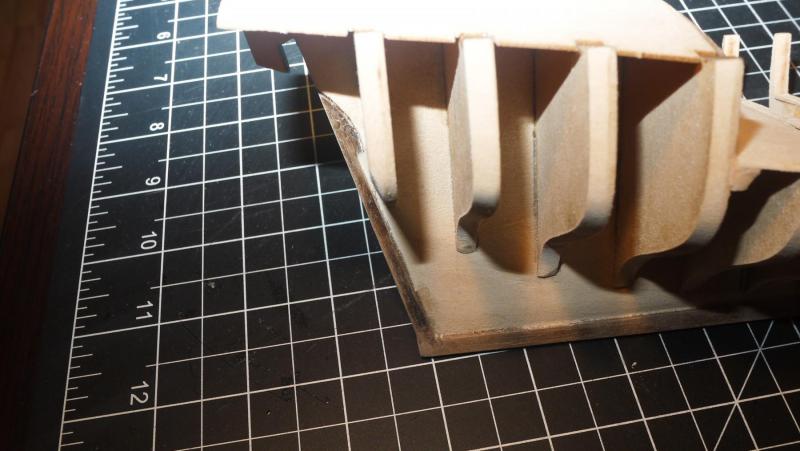

Here is the progress so far. The frames all seem to have the wrong angle cut. Hold them flush against the bulkhead and there is a gap at the top. I had to do quite a bit of adjusting. I hope I did not create issues down the road. They are out of alignment at the bottom also. I have since realized that the kit manual mentions the angle is not right on the stern frames.

-

In my defense, I don't remember any planes with windows this small. Nothing is glued, except frame 1. This is just one attempt to get the spacing right and everything square. Looking at everyone else's build log, it looks as if you guys just breezed right thru this part. Edit - In studying the photo, I believe the answer is to make small blocks the same width as the windows and glue them to bulkhead R. Then set the frames from them.

-

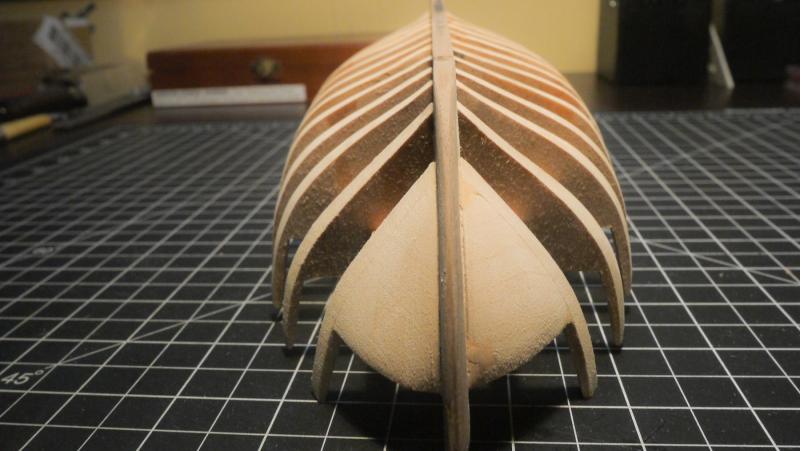

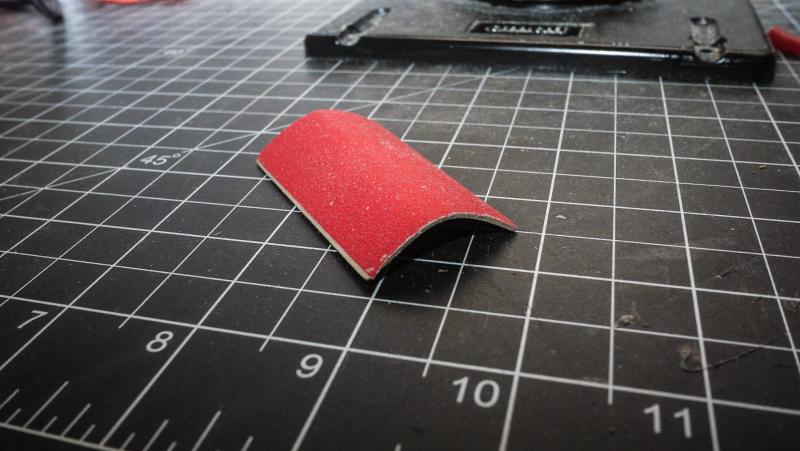

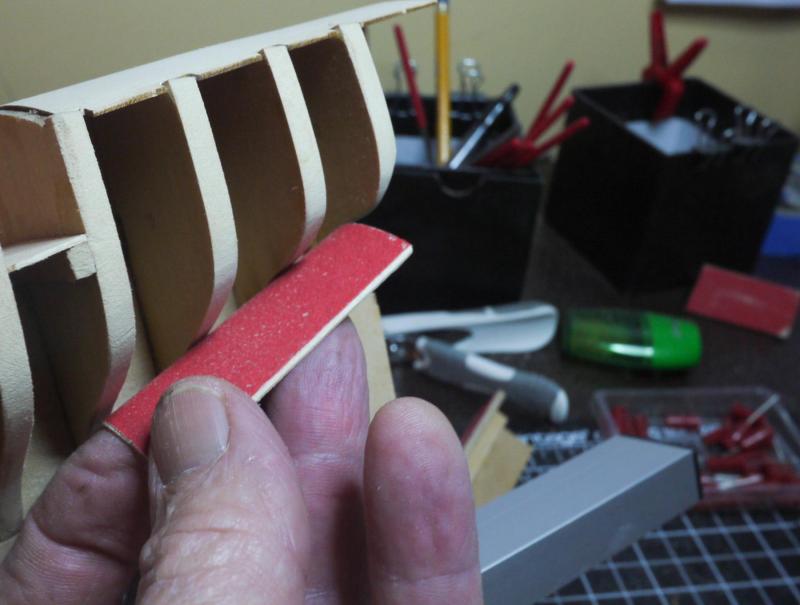

One of the problems I was having with the fairing, is sanding the bevel without flattening the curve of the bulkhead. I took a piece of the wood that the decks are made of and stuck a piece of sandpaper on. I was able to conform it to the bulkhead and sand a bevel in the curve. The picture is a little off but it seemed to have worked. As always, larger photos are available...

-

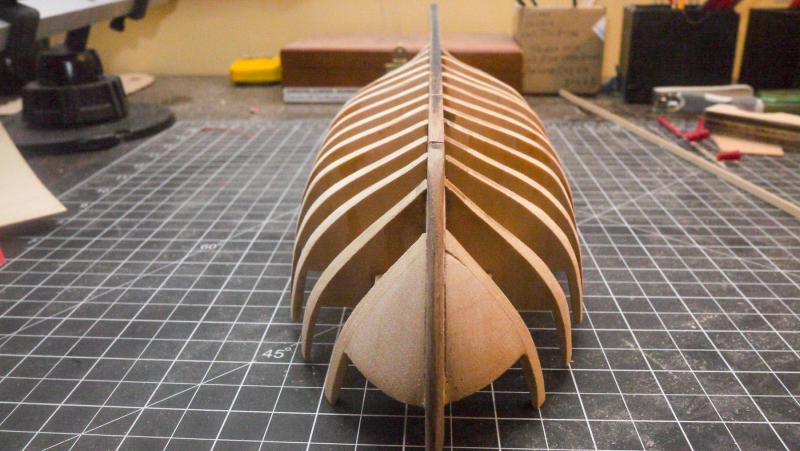

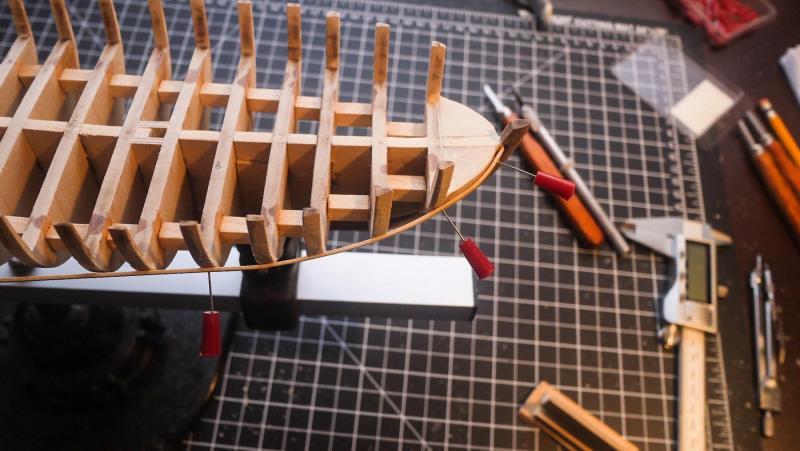

The port side is faired. I am tapering bulkhead R on the same line as the bearding line. That is how the plans show it. Looking at the photo, it seems I need to take a little more off. I also see a hump at the sixth bulkhead from the rear. I believe that's the one I shimmed. I never noticed that hump until i saw the photo.

-

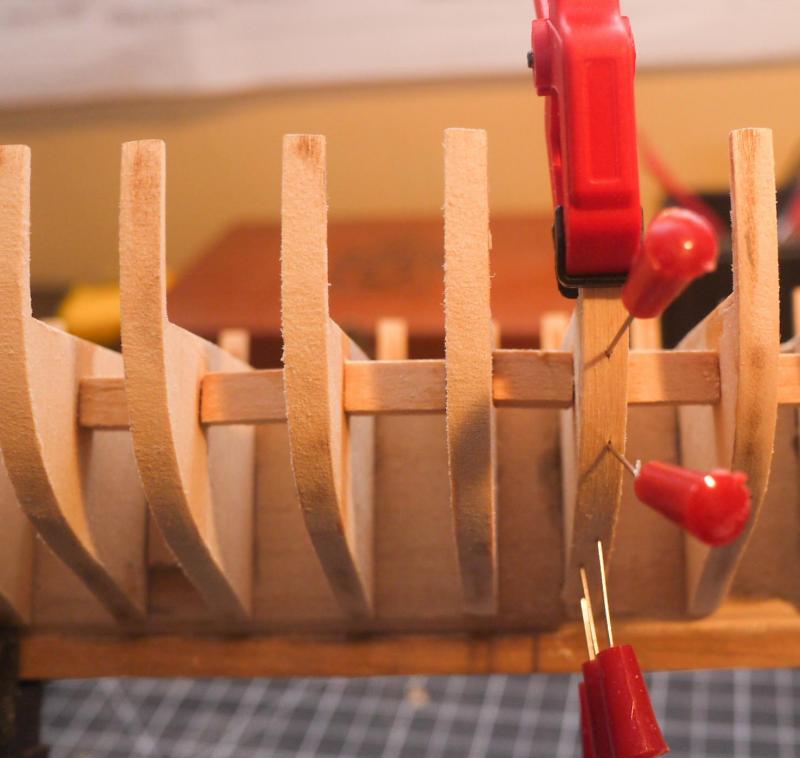

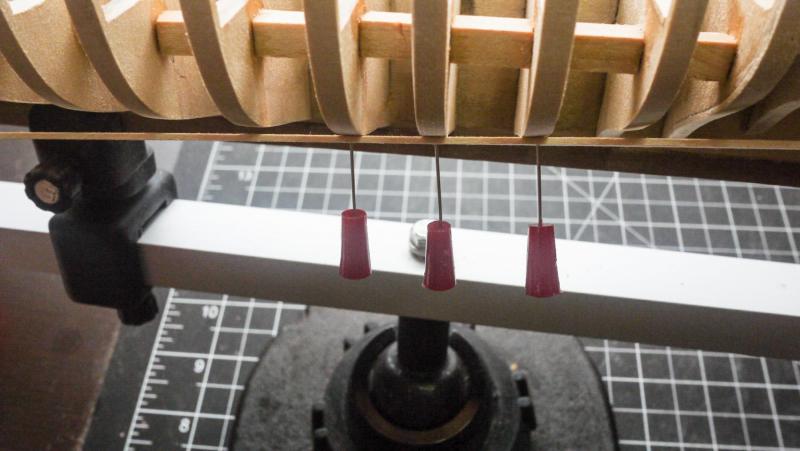

The first photo shows the method and the second photo shows the results so far. The plank needs to lay flat across the profile of the bulkheads, correct? There are 4 or 5 bulkheads amidships that look to me, like no sanding is needed. The plank lays flat there. At bulkhead C and D, where the plank turns, it almost creates a double bevel, when you sand across them. You can see at D that it is not touching across all the way. When I try to blend D with E it changes the angle of the bevel. I have not figured R out yet. I've seen where several people have struggled with the angle there. Let me know if you need a bigger photo. ( kidding)

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.