JRB9019

Members-

Posts

249 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by JRB9019

-

Hi Many thanks for your response. Yes, I've had a long, long (envious) look at your log as you know. I noted with interest your decision to lash the leading pulley ropes as you did (as per the Victory photo). Don't know if you've seen this, but I als came across an excellent 'Stropping' entry on the Model Boatyard entry - showing exactly your method. Thought yo might be interested so here's the link: http://www.modelboatyard.com/stropping.html Regards

-

Second Planking Starts Following the instructions (a sensible idea really), I carefully marked out the position of the 1st second plank just below the gun-ports. As suggested, a soaking for 10 minutes or so left the walnut strips pliable enough to bend. I actually used the top of the gun-port patterns as my 'former' and pegged the strips around the Gun-port pattern, bending as I went and left then to dry. After 10-15 minutes I was able to use the pre-bent strips quite easily and using medium super glue was able to attach the strips without any problems. Following the fitting of the second plank below, additional planks were then fitted over the top of the first two, thereby forming the Wale and Black Strake. From then on , the manual kindly requested that I simply continue to plank downwards, simply butting up to the previous plank – easy, so I thought!!!! A shot from the Starboard Bow showing the first 10 planks laid. You should also just about be able to make out the Black Strake planking. Starboard Bow showing the first 10 planks laid A shot from the Port Bow again, showing the first 10 planks laid. You should also just about be able to make out the Black Strake planking. Port Bow, showing the first 10 planks laid Second Planking Problems So, my problems and errors from even before my 1st planking started to come to haunt me. As I had not formed the bulk-heads correctly, the 1st planking was a bit of a mess as can be seen. However, things really became apparent now. There was no way that the 2nd planking was going to run straight as had been suggested in the instructions. If I tried, then the wood bowed outwards towards the bow leaving a gap and therefore obviously not sticking to the 1st planking. Again, referring to my shots of the completed 1st planking the problem is obvious to see. I decided to add some additional 1st planks around the bow area and finally sand back thereby giving a better shape. At this stage it was actually easier to do because I had the previously fitted 2nd planking acting as a guideline and template. You should be able to see the newly fitted planks in the following shot. The repair job Second Planking Completed So, after a lot of messing around, I finally completed the 2nd planking. As described above, I could not get the planks to lay correctly. The instructions only mentioned that I would have to insert one stealer after the 12th plank, therefore I assume that all other planks would have been able to lay straight and following the first planks all the way to the keel. In the end, I had to improvise just so that I could finish the job, especially as I knew that I would be covering all my sins with copper plating, I thought it best to finish the job as best I could. Once again, I’m sure that the problem arises from the incorrect shaping of the bulkheads right at the beginning of the build but can’t be too sure. Any comments would be gratefully accepted. Pictures aren’t too good again, but you will be able to see my problem from this bow-shot as the lower planks do not follow the upper ones. 2nd Planking completed as seen from the Port Bow The following picture shows the problem even better. However after sanding down up to 600 grade, I feel that the overall hull shape is not too bad considering all the problems that I had. You will also see that I have completed the decking up to rail height and have also cur away the gun-ports. 2nd Planking completed as seen from the Starboard Bow So finally, a shot from the stern. You can see that the stern-post is now fitted and the planking tidied up ready to start fitting the stern facia later on. If you remember I mentioned that I wasn’t too happy with the planking around the stern-counter. Sure enough, even though I had sanded back to the bearding line prior to starting the 2nd planking, things just weren’t looking right. So again, a little improvisation on my part (just don’t tell anyone!!). I planked the Stern-Counter for a second time and then sanded everything back and ended up with a good fit. Just a small gap left towards the top, which if you look closely you will see tha I have used filler here. All this area gets painted black so it shouldn’t be too bad in the end. 2nd Planking completed as seen from the Stern Time for a cuppa me thinks!!!

-

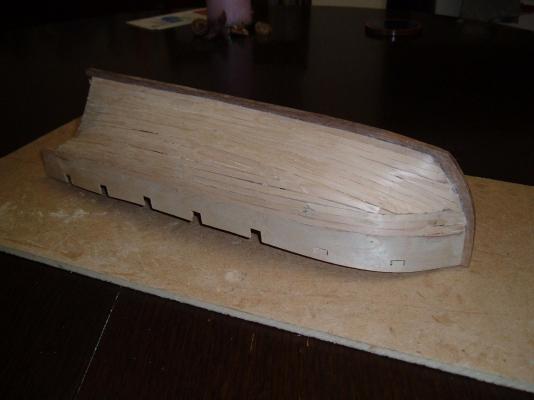

After a break to recover from the terrible first planking . . . . So, finally the Pickles build was back on. Lots of problems of late which have meant that I had not done anything for ages and I lost the motivation to carry on. I decided to sort myself out and started to read various logs to get myself motivated again to carry on. I found and read the really great log from GOGS on his HMS Fly build and then finally found the log of HMS Badger from TORCHY. Reading his log and seeing his excellent progress on a build not unlike mine finally gave me the motivation that I needed – so thanks Torchy for that…. First Planking Completed OK. Last time I posted anything I was just finishing the 1st planking - well sort of,,. This planking was duly completed and the stern counter fitted. Slight problem here – the holes for the stern-counter supports are cut slightly too large and it was therefore very difficult to get an accurate fit – only time will tell if I’ve got it at the right angles. Once the stern-counter was fitted I then had to plank the underside – not too difficult but I’m worried that the whole thing won’t match up once I complete the 2nd planking, but that’s a job for another day. So, a few pictures for you. A shot from the bow showing the completed 1st planking The stern doesn’t look too bad here although it does look messy under the stern - this will be trimmed at a later stage. A shot from the stern showing the completed 1st planking The Problem that I described before in my previous posting can be seen here. From the Stern all looks OK,,, All is well - from the Stern But looking forward - the curve is just not right and something that I will have to address later. But the bow?? And finally another shot of the stern after I had tidied up the Stern-Counter a little. So, first planking done. On to the brave new world of 2nd planking !!!!

-

First Planking Problems So, here you see the finished side – and it doesn’t look too bad at first glance. Looks OK - but . . . However, if you look towards the bow, you should see that all is not well. (Well you could if the phote wasn't so terrible). Looking directly above the first gun-port (not fully opened at this stage), you will see that that there is a distinct angle appearing between the horizontal planks directly below the false gun-port and the remaining planks. . . . looking at the Bow - Hmmmmm Trying another method I am now continuing with planking the port side – and using a slightly different method – i.e. as you will see, I have also started to lay planks from the keel which I will do up to the already laid planks –complete with stealers and hopefully it turns out better. Trying a different approach I think that one of the problems lays with the fact that I have removed too much from the bulkheads which therefore gives me this result. Once the second side is completed – hopefully giving me a good shape, I will then return to the first side and add sanded and fitted planks over the originals to match the shape of the second side. OK, I could use filler – but I think that I won’t get it right that way…… Planking in a right state... How not to plank!! After sorting a few things out Conclusions? I have since seen builds where balsa filler is used in the Bow sections. This really appears to help, both with ensuring that the lines work, but at the same time there is a guide there to help when forming the bulkheads. A pity this isn't mentioned in the build manual or that appropriate Balsa wood isn't provided. Still lesson learnt - it won't happen again!!! Onwards and upwards...

-

First Planking Now here is where the real fun began !! As you know, this is my first build. I decided to try and do the planking as if I was only having one layer and therefore to try and make it as good as possible – again, training for the second planking later on. I did find paper-clips to be a great help. Soaking the wood for 10 minutes and then using the clip to hold the wood in position enabled me to create the right curves without any problems, so no fancy tools needed!!. Planking gets tentativley underway As planking progressed, I began to think that I wasn’t doing this right – I read and re-read the instructions – and the planking guide and carried on. This isn't quite right somehow! Finally, planking was completed for the first side. The photo shows the stern looking very untidy, but I haven’t trimmed up yet, which happens when I start to fit the stern counter later on. I have also already sanded down the bearding line before this photo was taken…. first side done - sort of

-

False Gun-ports So, there was nothing for it. The next step was to fit the false gun-ports. As you will see, I used clothes-pegs for clamps which worked very well. I soaked the wood for 10 minutes or so which gave me plenty of flexibility. False Gun-ports set in place to dry Once the gun-ports were dry, I laid the first plank. First plank fixed as seen from the Bow . . . . . . and from the Stern

-

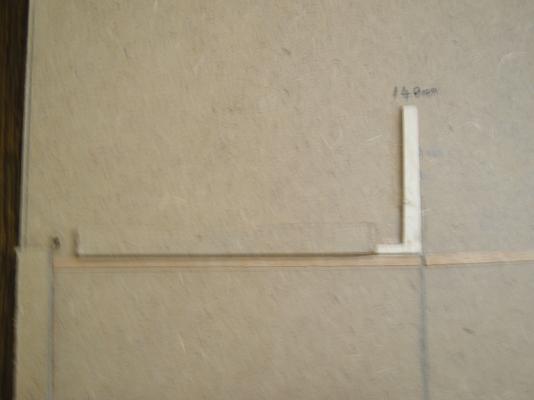

The Gun-port patterns The manual told me that the next step was to add the gunport patterns and attach these to the bulkheads. However, I had already decided that I was going to plank the False-Deck and with my lack of experience, decided to do this before I fitted the gun-port patterns, therefore loosing me space to work in. I’m glad that I did as it was quite cramped below decks – even though I didn’t have any sides to contend with. I also decided to try out my 3-but shift as I will be using this on the main deck, so practice makes perfect !! False Deck Decking So, trying to be a ‘professional model maker’ (stop laughing please!), I had been influenced by many of the build logs that I have read where creating a template for just about anything seems to be the norm, So, I tried my hand at making my own template. Glad I did – it works really well. Sorry, the picture is a little blurred but you should be able to make out the idea. My first template Easy really, a stop on the left hand-side (Set square of course) – along the top another piece of wood set at a “triple-checked” 90 degrees. I left this a little short as I can then use this for other pieces later on. So to finish off, I glued the upright set to the correct measurement. After that, I can cut my decking lengths easily – purists will swoon at this stage, but I actually found that using a very sharp chisel held against the template enables me to make a very clean – and more importantly straight cut. These two pictures show the first decking planks fitted – and the completed job and you should just about be able to make out the 3-butt system used – and before you ask, the false deck is not meant to be totally covered !!! I also left the gaps between the planks on purpose (honest!!) so as to represent caulking once it’s finished…… I am trying out a couple of finishes to the decking before finally deciding what to use. The first planks are laid . . . . . . and a few more Sanding Tools Having fitted the decking, I had to sand it down. Not having any tools at this point made me improvise as you can see in the picture to make a clothes-peg sander. It works really well – unclip and move the sandpaper along as it wears out…..

-

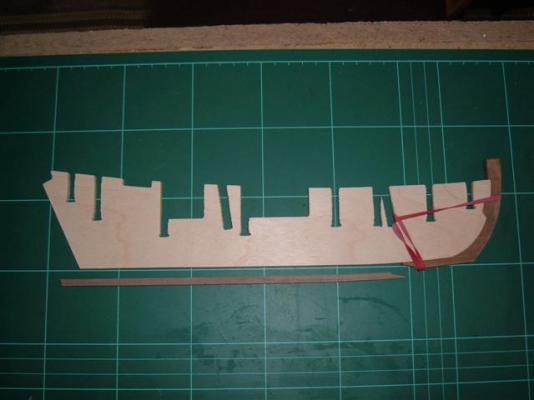

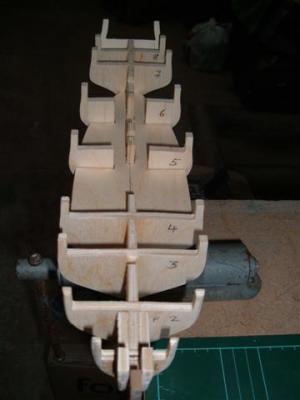

The build (at last) The Keel Firstly, as instructed, I checked out my box of goodies and wondered what the heck I had got myself in to. Wow, these parts are so small!!!! Eventually, I took the plunge and started with the keel (hey, you’ve got to start somewhere). Having found the main keel assembly, I started by gluing the Stem, using a set of Rubber bands to hold it in place. Once the Stem has set, I glued the false keel into position. Next I had to work out what on earth a bearding line was, what to do with it and where to put it. Eventually, I solved the puzzle. Then followed the 9 bulkheads which were carefully sanded and fitted. So far, so good. There follows a few pictures, please excuse the quality!. Post Glueing from the Bow Post Glueing overhead Post Glueing from the Stern Post Glueing from the Stern Starboard side

-

The Building Log of the H.M. Schooner Pickle by JoTiKa. The first half of this log is a copy of the original log that was lost from the Forum. Luckily, I had always used Word to write my log before I had added the text to the Build Log so I still have the original text - and the same terrible photo's!! Introduction There are many newcomers to this hobby including myself. I have therefore included details in this building log which the newcomer or less experienced modeller may find of use. Modelling Background My modelling started as for so many of us as a child back in the good old days of Airfix models. Funnily enough, even then, as all my mates were building planes, cars and tanks etc. I almost always only built sailing ships (or tried to!). 25 years ago, I started again and bought the plastic model Gorch Foch from Heller - a fantastic model and quite complex with full rigging and the like. Hmmm, then we started a family and it wasn't until 20 years later when both my "little ones" had departed for University to study (well, that's the official version!!) that I found time on my hands and my thoughts came back to starting again with modelling. However, in the meantime during many jealous hours spent browsing in model shops (for my son's remote control cars and the like - not for me, of course!!) that I found wooden model ship kits. After a long search, and lots of investigations, I finally decided for JoTiKa and H.M. Pickle. Starting out Needing a helping hand in this new hobby, I carried out some research on the various Web-sites out there and found the Model Ship World site: www.modelshipworld.com. Not only have I posted this building log there but have been inundated with help and tips and tricks. Additionally, I have found lots of postings and links to other sites and publications that have been really useful, some of which are mentioned throughout this log. OK, so my model arrived and then I found what tools I needed - a full list required for this model will follow. Following various helpful postings on the Model Ship World forum, I ordered the Squires Catalogue. Browsing through there is even more confusing as there are 20 types and makes of just about everything!! From my DIY days, I have my Stanley knife, lots of sandpaper, wood-glue, rules, etc. etc. and with a trip to my local (very good) art shop, I will furnish myself with the appropriate brushes etc. However, I will wait and hopefully pick up my "specialised tools (tweezers, needle files, Pin vice and drill bits) from a Model show / exhibition. Reading / Reference Books Library It must be said that the excellent instruction manual that comes with the kit, together with the full-sized detailed plans are without doubt enough to be getting started with building this kit. Indeed, I saw no reason why I could not used the very detailed instructions to complete the kit. However, I thought it was always useful to have additional background information (which has indeed been the case) and so I bought the following: - Keith Julier's Period Ship Kit builder's manual which I shall read as appropriate as I begin a new section of the build, - Lennarth Petersson's Rigging Period Ship Models. Finally, for interest and future reference, after some research I borrowed the following books from my local library which I intend to purchase at a later date. - Peter Goodwin's The Ships of Trafalgar: The British, French and Spanish Fleets, 21 October 1805, - James Lees The Masting and Rigging of English Ships of War, 1625-1860. Finally, for reference the Simple Hull Planking Techniques for Beginners was downloaded from the Model Ship World forum. Background to H.M. Pickle For those who are interested, a bit of background to Pickle. Forever associated with Admiral Nelson’s final and most historic victory, the Battle of Trafalgar 1805, Pickle was chosen to carry the News of Nelson’s victory and death back to England. Commanded by Lieutenant John Richards Lapenotiere, Pickle was not directly involved in the Battle of Trafalgar but was permanently busy rescuing both friend and foe from a watery death. By 6pm the muster list for Pickle showed a total of 160 prisoners taken on board, the majority of these coming from the burning French Achille. Given the size of Pickle and the fact that she had a crew of just 40 it is remarkable that Lapenotiere was not only able to rescue so many but that they were then able to prevent the prisoners from taking Pickle as their own. After the battle, with Admiral Cuthbert Collingwood now in command, every ship, including Pickle, was required to maintain the blockade of Cadiz. Between the 22 and 25 of October, Lapenotiere continued rescuing seaman and prisoners and began offloading them to other ships, including Dreadnought, Euryalus, Revenge and Victory, all the while battling to survive the storm that was blowing in from the south west. On the morning of the 26 October 1805, Lapenotiere was signalled to come aboard Euryalus where he received written orders from Collingwood to sail for Plymouth with the dispatches. Knowing that the bearer of dispatches would receive a promotion, it was customary to choose a favoured officer for the task and Collingwood’s choice of Lapenotiere is often attributed to an act of gratitude. It is said that, while Lapenotiere was a passenger onboard a ship also conveying Lord Collingwood, an order was given on deck to the man at the wheel. Lapenotiere, realising that if the order were obeyed the ship would be on the rocks, immediately gave another order and saved the ship. Collingwood thanked Lapenotiere saying “If ever I have the opportunity I will do you a service.” It is also said that on receipt of his orders Collingwood reminded Lapenotiere of this promise saying “Now take these dispatches to England; you will receive £500 and your commander’s commission. Now I have kept my word.” Unfortunately no evidence of either of these events exists and Collingwood’s choice of Lapenotiere is better explained by the fact that Pickle was probably the only ship that Collingwood could afford to spare given his current circumstance. This is also backed up by Collingwood’s letter to William Marsden stating “dispatches containing the account of the Action of the 21st Inst, and detailing the proceedings of the Fleet to the 24th will be delivered to you by Lieut Lapenotiere, commanding the Pickle Schooner … having no means of speedier, or safer Conveyance with me at present.” At noon the same day, Lapenotiere and Pickle departed for England but his voyage was to be challenging to say the least. For the next seven days Pickle battled through stormy seas and, with her pumps blocked, the crew were reduced to forming a human chain in order to bale with buckets. On October 31st, with continuing gale force winds Lapenotiere ordered four of his 12 pounder carronades to be thrown overboard in an attempt to keep the schooner from being swallowed by the sea. November 2nd brought weather of the opposite extreme, but still no rest for the crew. With calm seas and no wind the sweeps had to be employed just to keep Pickle heading toward England. On 4th November 1805, Pickle finally reached Falmouth where Lapenotiere landed at shore in Pickle’s boat. From this point, Lapenotiere set off on his now famous post chaise using at least 21 changes of horses to travel more than 270 miles in 37 hours and costing £46.19s.1d, more than six months wages for a Lieutenant. Lapenotiere reached his goal of the Admiralty at round 1am on the 6th November and announced to William Marsden, First Secretary to the Admiralty, “Sir, we have gained a great victory, but we have lost Lord Nelson”. On 28 July 1808, Pickle was finally lost, while again carrying dispatches, under the command of Lieutenant Moses Cannadey. During her approach to Cadiz, she was grounded off Cape Santa Maria on the Chipiona Shoal. Pickle quickly sank but all of her crew were saved. The Kit And so to the actual kit which includes the following: Please note - if you want to look at photo's of the kit, please go to Blue Ensign's Pickle Log as they are much clearer than mine! Double plank on bulkhead construction in lime and walnut; all decking in high quality Tanganyika strip; 6 x 12pdr turned brass carronades, fully rigged and complete with walnut carriage assemblies; detailed brass etched components; over 500 copper plates; ship's boats in high quality resin with walnut components and brass fittings including oars, grapnels and boat hooks; precision CNC cut and profiled walnut and ply components; brass nameplate; all required blocks, black & natural hemp rigging; high quality birch dowel for the masting; fully detailed actual scale plans; two comprehensive step by step colour instruction manuals including constructional photos of the prototype and technical drawings. Recommended Tool List Craft knife; A selection of needle files; Razor saw; Small wood plane; Pin vice or small electric drill (the latter is the more recommended item); Selection of drill bitts from 0.5mm to 3mm; Selection of abrasive paper and sanding block; Selection of good quality paint brushes; Long nose pliers and wire cutters/snips; Good quality tweezers; Dividers or compass; Steel rule (300mm); Clothes pegs or crocodile clips; Set-Square; Good quality pencil or Edding pen; Masking tape; Good quality sharp pair of small scissors; Scalpel with selection of blades; Paints, Stains and Adhesives N.B. The paint, stain and adhesives listed below include the appropriate part numbers as supplied by JoTiKa. White PVA wood glue; Walnut wood stain for masts & booms (Admiralty Stains: Walnut, AS9105): Cyanoacrylate (super glue) thick and medium viscosity (Admiralty Glues, Thick (AG9103) & Medium (AG9102); Walnut wood filler; White spirit; Varnish to seal all unpainted wooden parts (Admiralty Varnishes: Matt, AV9110); Black paint for 'woodwork' (Admiralty Paints: Dull Black, AP9105); Black paint for 'ironwork' (Admiralty Paints: Matt (Metal) Black, AP9106); White paint (Admiralty Paints: Matt White, AP9111); Yellow ochre paint for ship's boats (Admiralty Paints: Yellow Ochre, AP9115); Red ochre paint (Admiralty Paints: Red Ochre, AP9116); Copper paint (Admiralty Paints: Copper, AP9125); Brown (wood/leather) paint (Admiralty Paints: Wood (Walnut) Brown, AP9119); Metal primer for etched metal parts.

-

Help I've just spent about three days trying to rig the blocks for the carronades on HM Pickle. Actually, I should say "the carronade" as I'm still only on the first one and can't get that right either. I now seem to have my ropes running the wrong way around and all the lashings don't make sense!!! Below is a picture of what the finished article should look like. Now we get to the stupid question department! What I would like to know is - is there a detailed explanation (with photos if possible) which explains how to tie on the block? So, looking at the block in the right which is attached to the side of the ship, I can see that the 'rope' is coming from the bottom of the block and the is threaded through the left hand block, then returning through the right-hand block again, before ending on the deck or whatever else you decide to do with it. But, how does it start? Is the block lying on the 'rope' and is then lashed at the top and the bottom of the block? Sorry, I just can't seem to make out what to do - and in what sequence, so any help from you would be very much appreciated. Many thanks John

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.