JRB9019

Members-

Posts

249 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by JRB9019

-

Hello UrkVisser, One thing that I have noticed on this model is that the scuppers are way too small. I visited Ross Tiger in Grimsby last year and when I went on board, I was amazed just how big they actually are. I've attached three photos for you to see which I hope is of use. Regards John

- 16 replies

-

UrkVisser Thanks for your complement. Sadly, I must say that I cannot accept your complements. It's not my work I'm afraid, just info that I was sent. I look forward to seeing more of your build though! Regards John

- 16 replies

-

Re. the railings, here's a couple of photos of a build that a contact kindly sent me. A huge difference to the provided ones for sure.

- 16 replies

-

Hello UrkVisser, Great progress on the trawler. Love the decks. I also agree that the superstructure. Most trawlers that I remember had the white upper and ochre/dirty yellow colour - all streaked with lots of rust of course!! Re. the deck fittings, I have mine from SAEMANN Ätztechnik - i should think they are available in most European model shops. I've not seen them in the UK though. I've attached the catalogue for your info and hope you find it useful.... Regards John Spare parts and accessories.pdf

- 16 replies

-

At last with a little help from the Flyer Swiss Seamans Recruitment Agency, I was able to organise a Captain and crew to help get the Pickle build completed. Sadly, their previous voyage had been an Antarctic expedition and they all arrived at the dockside looking a lot worse for wear and as can be seen, still suffering from a lot of frostbite. The crew appeared to be happy to be back on dry land and, as was their wont, immediately took to heavy drinking and fighting amongst them selves. The new crew then broke into the wood stores and made a right mess> The lookout kept watch and yelled out a warning but too late, the Captain found them all and he was not amused. The crew were sentenced to hard labour to clear up the the mess they had made and to make themselves presentable for inspection . . . .

-

Back to completing the main mast. As I mentioned back in March in post 51, I had made several attempts to create the hoops for the main driver sail and was really not happy with the results. After a further unsuccessful attempt, still using diluted wood glue for the job (I mean after all, paper was wood once so it should be OK!!) I found some PVA Paper glue and tried it with that. That worked . . . . . except that I couldn't get them off my dowel and had to resort to cutting them off which did rather spoil things!! OK, so one last attempt. This time I would some kitchen foil around my dowel followed by a few turns of cling-film. Finally, I think I'd cracked it and not only was I able to remove my roll from the dowel but after drying for 24 hours I carefully used my fine saw to create 9 hoops!!! Persistence finally paid off and they are much, much better than my original attempts for sure. After some careful sanding and bevelling of the outer edges, I gave the rings a further good coat of my PVA glue and sent them to the drying room overnight. . . . . I was originally going to paint the hoops black, but research from my books and Flyer's comments showed that the the hoops would have been made of Ash. After consulting with the Shipyard Owner (she knows about these things!) it was suggested that a mix of white, dark walnut and a touch of ochre would give the required finish. Sure enough the lady was correct of course, so two coats of the colour was added followed the next day by a good coat of mat varnish. I happened to have some small Ash pieces lying around so used one to compare the colour and am pretty pleased with the result . . . . Done! So the next step was to fit the Driver Boom Saddle and supports. Back to my 4*4 mm Walnut for some delicate cutting and sawing and while I was at it read ahead and noticed that I would need at least another 10 or so of these so I produced them all at the same time, stuck them onto upturned masking tape which made the subsequent painting a lot easier. So, my shift was just about to finish so just before I packed up for the night I carefully glued the Driver Boom Saddle and left the fitting of the supports until the next day . . . . . . which I thought about as I woke up and suddenly remembered with a true Homer Simson 'Duuhhhh' moment that I had forgotten to fit the hoops first!!! First task was to remove the Driver Boom Saddle then. Not an easy task but after carefully soaking the edges with acetone (Nail varnish remover!!) a couple of times and carefully using plyers, the saddle eventually detached. Phew! I cleaned the area up, and reattached the saddle AFTER threading the hoops first!!. Fiddly messing around to fit the 3 supports and the Main mast was done and ready for fitting in due time . . . . . on to the fore-mast...

-

The super-beginners guide to stropping and whipping blocks.

JRB9019 replied to JRB9019's topic in Masting, rigging and sails

Glad you like it - hope it works for you if you try my method. If you find anything missing / confusing please let me know -

The super-beginners guide to stropping and whipping blocks.

JRB9019 replied to JRB9019's topic in Masting, rigging and sails

Many thanks Ron. that's a really useful step that I hadn't thought about! -

In the middle of building my first wooden plank-on-plank model (H.M. Pickle) all was going well until I came across the wonderful instructions “two copper eyelets can now be fitted to the main mast with their respective blocks”. Great I thought, and how am I supposed to do that? So after a lot of (not very good) research, I thought I had worked out what to do and so proceeded to ‘attach’ my first block. Result? Terrible. Further research followed and in the end I worked out how to do this and as suggested by a couple of people have now created this 'Super-beginners guide to stropping and whipping blocks'. I was going to call it 'The Dummy's Guide but I'd get into all sorts of trouble by doing that so I'll have to stick with my snappy title. So the guide is attached and I hope it's of use to some of you. Best Regards The super guide.docx

-

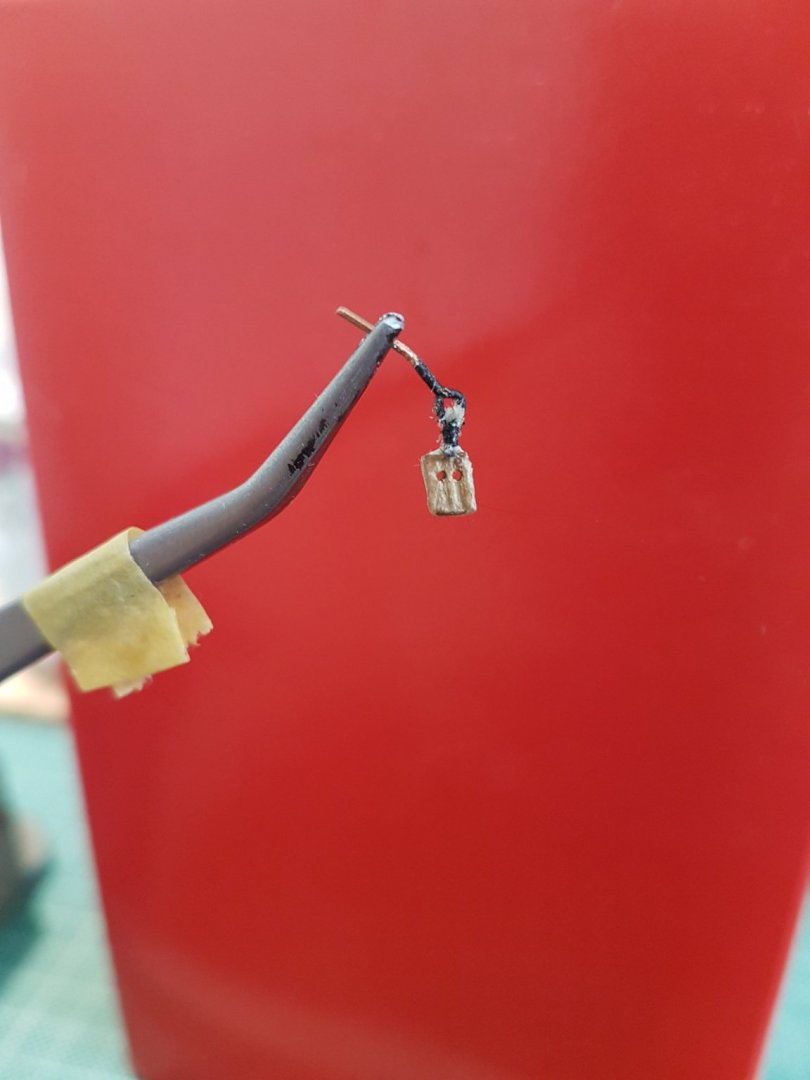

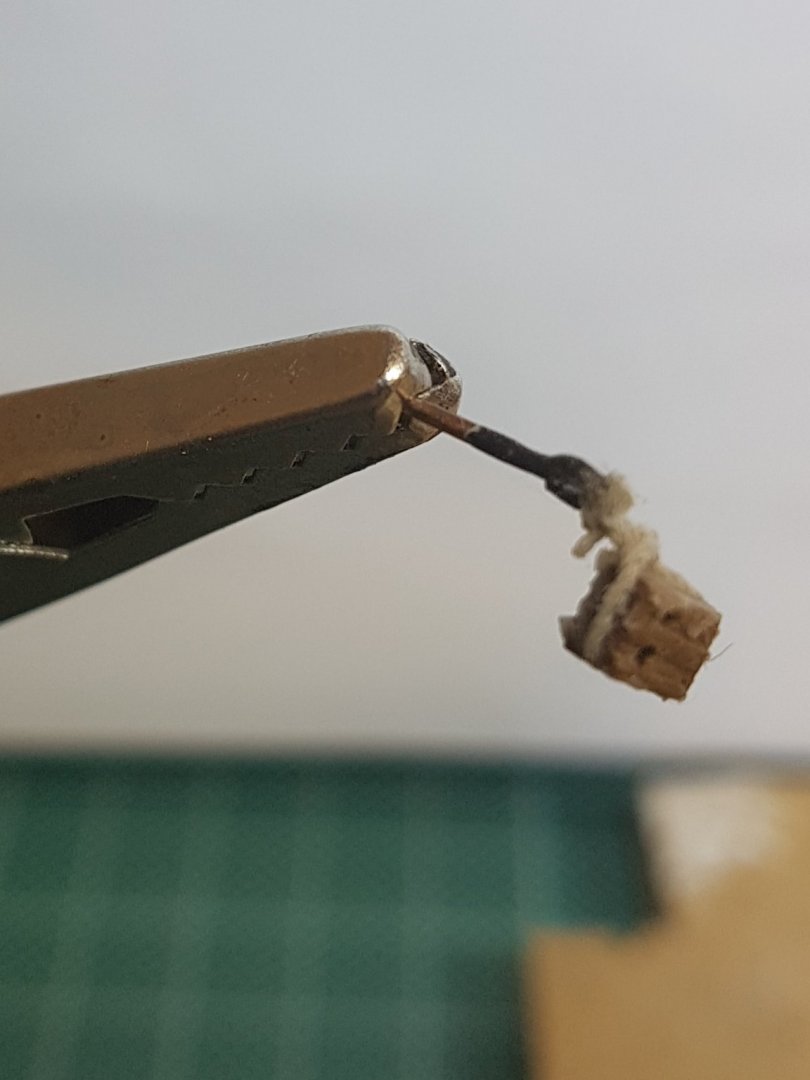

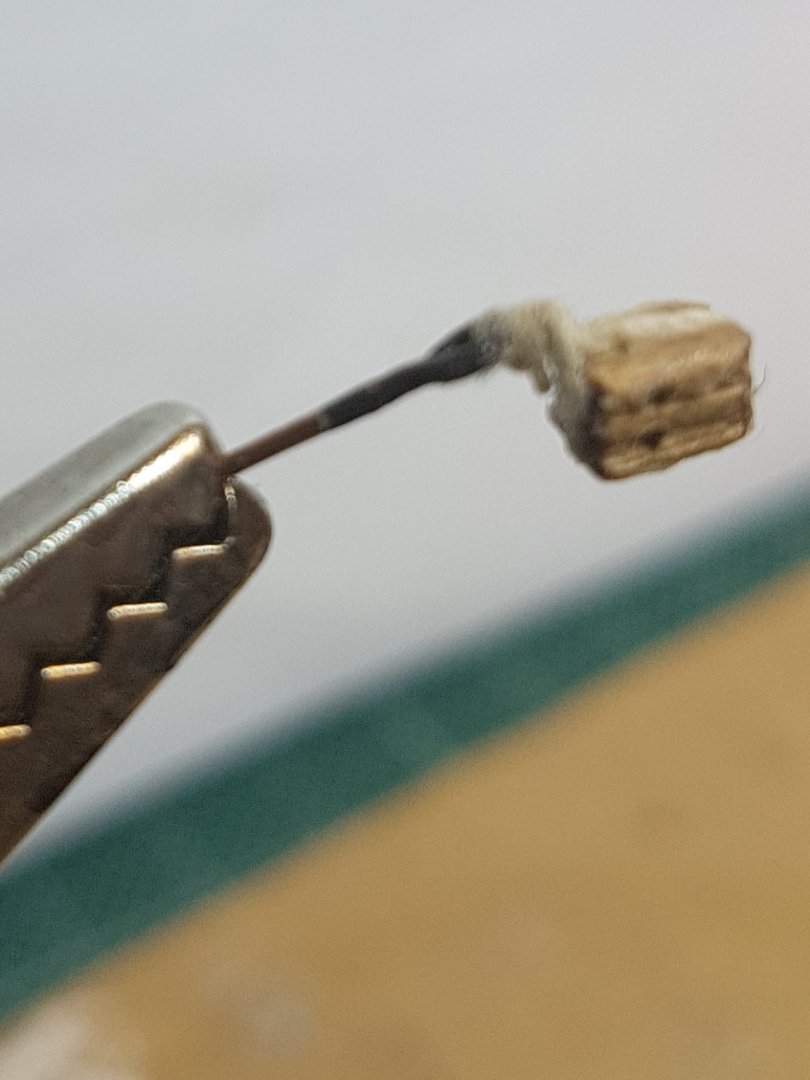

I spend a few days attempting to master the black art of Block Stropping and whipping. In the end, and referring to various comments and videos I succeeded in completing my first Block. I used one small vice to hold one set of tweezers holding a block and my 'jewellers stand and crocodile clips to hold the eye. I used dabs of white wood-glue to attach the Stropping rope to the block and then 3/4 small strips of masking tape to hold the ropes in thier right place. I then attached my whipping twine with another piece of masking tape, then made a loop in the other end and taped that down out of the way too. Now 'all' that I had to do was whip the stropping together with 7-8 turns, finishing by threading the strop end through the loop. Finally, I undid the opposite end of the whipping twine and pulled gently until the loop had tightened, holding everything in place. A final trim of all the twines and I was done. Not perfect, but now I finally understand the technique I'm sure my work will improve by the time I've completed the last block. Thank goodness this has all taken place in the workshops and not onboard!!! I have made a detailed set of photographs of the full process if anyone is interested, but in the meantime, here's a photo to finish.

-

Many thanks for all your responses. I certainly like the idea of a pin/nail in the foot of the mast. It does seem to be the best solution. End of term report "The pupil must pay more attention to the details of his work. He shows promise but there is a long way to go".!!!

-

Thanks for your reply. I like your suggestion about checking the mast before decking and planking which is what I thought I had done! As mentioned, the mainmast slots in perfectly. I can feel it being held on all sides but for some reason the foremast just doesn't want to sit as it should - and I'm not about to cut a hole in the deck to find out what is wrong!!! I have a couple of ideas to see if I can pack the hole below but it won't be easy!

-

Hi all, I'm getting to the exciting part of building my first model H.M. Pickle After a little fine sanding on deck, I was able to seat the main mast and it sits firm and true. However, I've just made a start on the foremast and although it sits at the correct angle (bow to stern) and is deep enough according to the plans, it is not sitting in anything and is easy to move around, especially port to starboard. I know that the rigging will tighten the mast up and stabilise it, but has anyone any other advise? I've seen other modellers making chocks for their masts but don't really want to start that if I can help it..... Thanks

-

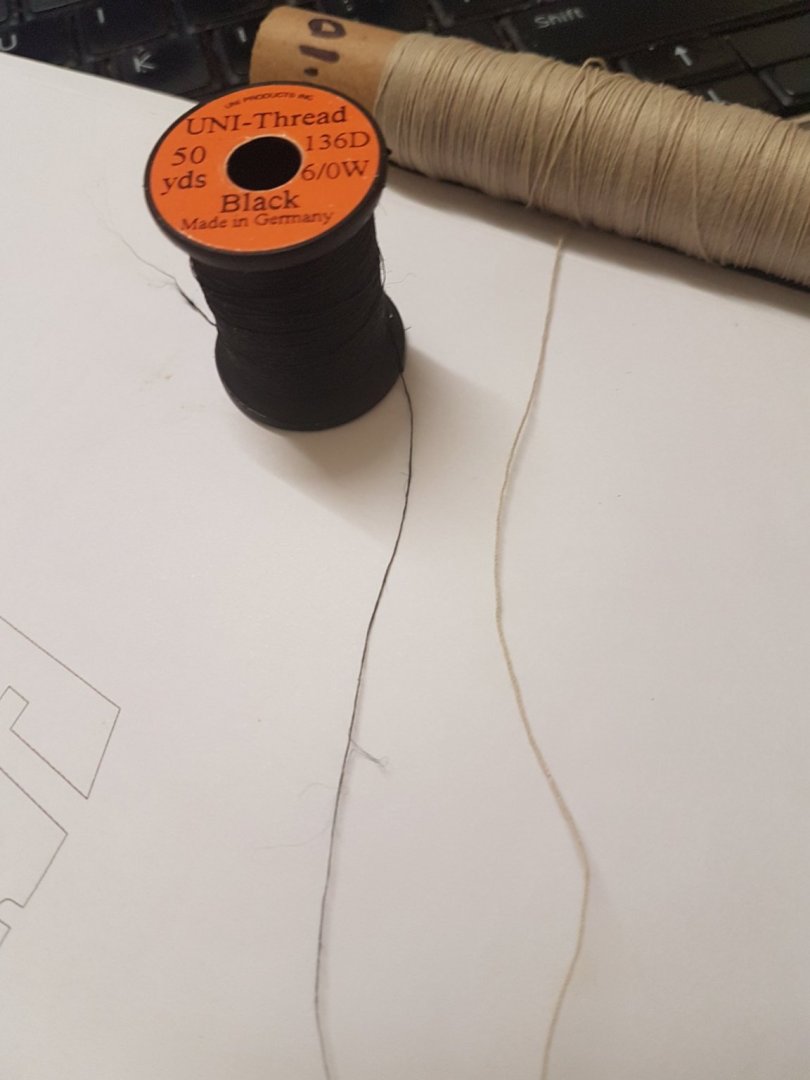

Fitting Blocks and Eyelets So after finishing the mast build, the next instructions told me to "fit two eyelets . . . . together with their respective blocks". Great, wonderful. But how was I supposed to do that? No idea! I was a little cross at this point. So far the fantastic very detailed build instructions had been a real help in my new hobby. Sure, I had some steep learning curves, but that was to be expected but as a long as I read the instructions carefully, the method was there. . . . . and suddenly I was left with 'fit the blocks' Thanks for nothing! OK, so I spend a day or two scouring the various books that I had and then went online and finally found what I thought were the answer. I finished my first attempt and I was really not happy with the result. . . . No, not acceptable. Back to research and finally found a couple of really useful videos. After studying these, the penny dropped as I had finally found someone who seized blocks and tackle with whipping twine as would happen in real life. Great. Further investigation led me to to news that these modellers were using twine that was meant for tying flies (for fly-fishing!). A few clicks later, I found a great UK supplier and within 24 hours I was the proud owner of 50 metres of black 6/0 thread shown here next to the original 0.10 mm kit thread. I requested and was granted release from my duties to attend nautical school for a while to learn how to do some proper rigging and attaching blocks, hooks and spars etc. Hopefully I pass the final exam!!/

-

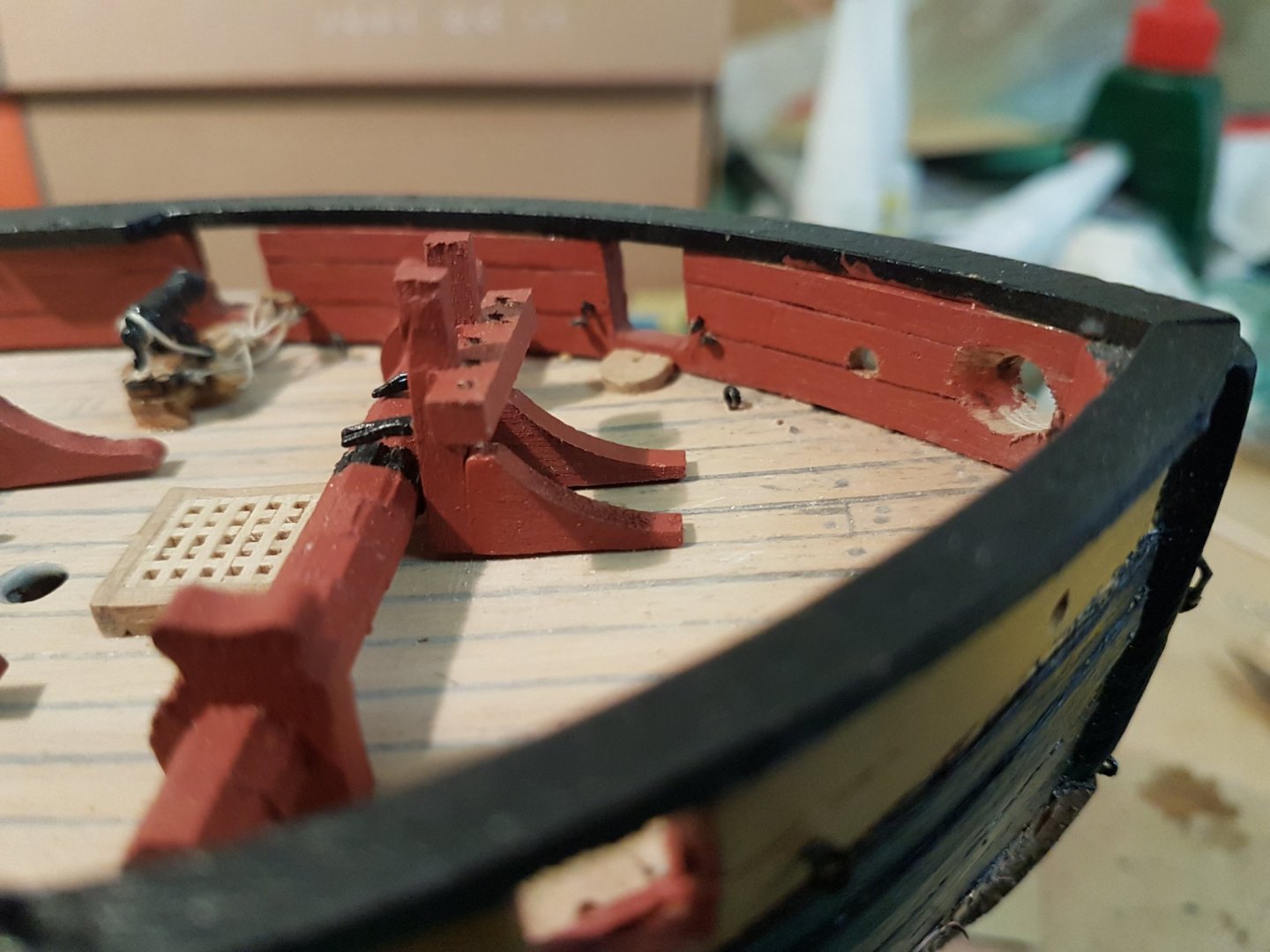

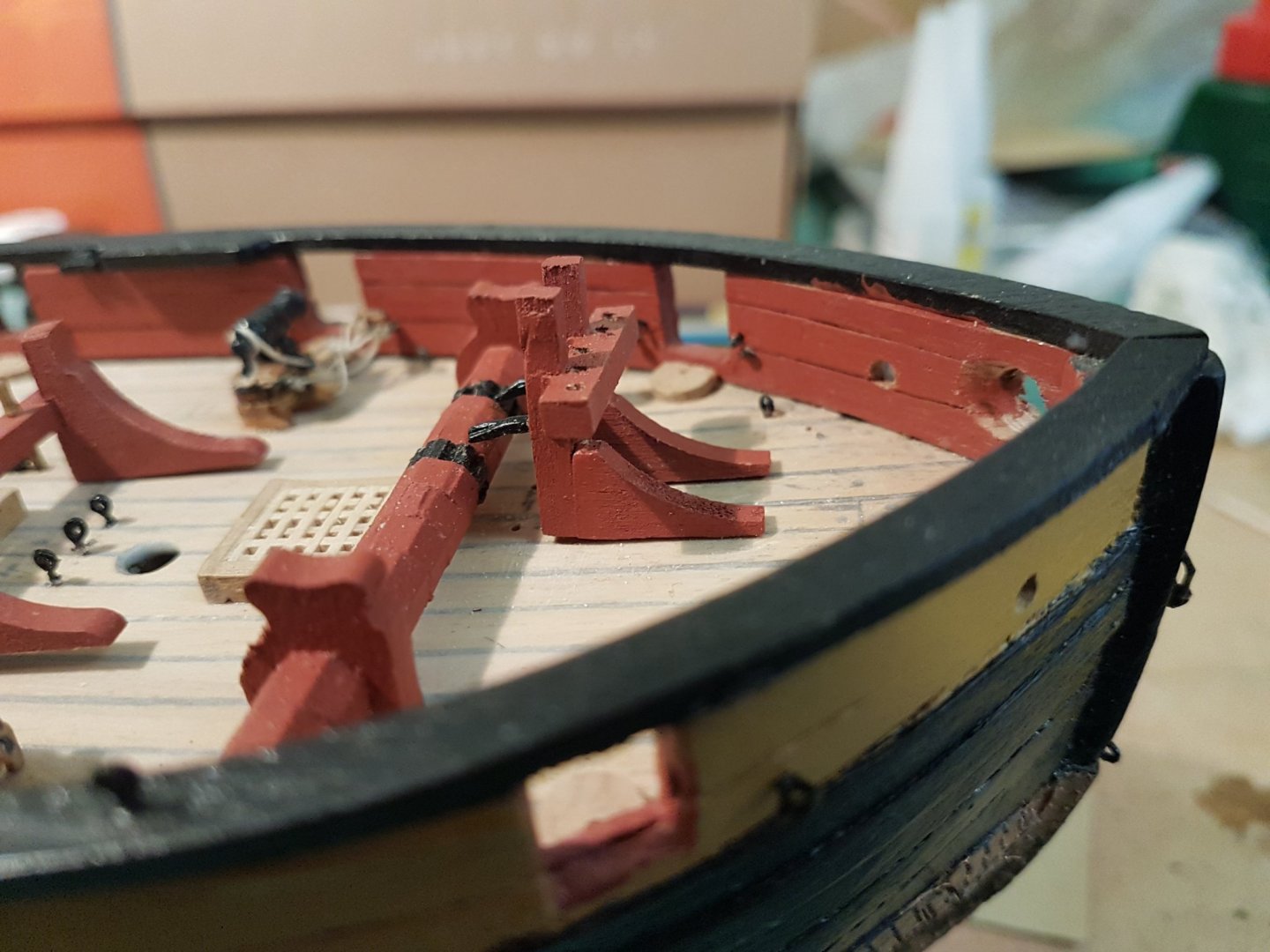

Completing the Main Mast Back at the shipyard, as per the instructions, I shaped the lower main topmast, then tapered the top section and after drilling the two sections were pinned together, this time everything looked straight! Next I had fun and games learning what a 'Fid' was, then I made one and after drilling the appropriate hole dry fitted it. Then it was on to making the Main lower top trestletrees that wasn't as easy as I thought it was going to be. I needed a lot of test fitting and fine filing before everything fitted but we got there in the end. Once again referring to Flyer and Blue Ensign's builds I also decided to create cheeks to support the lower top trestletrees. I made four whilst I was at it as I will obviously use cheeks on both masts. Finally a few final dry runs and everything was ready for the final main mast assembly. As can be seen, I stained the masts but this time, I used a cloth instead of a brush which has left a better, lighter finish. I also sanded flat a section either side of the main mast which will let the cheeks sit better. After the final careful assembly, I then painted the relevant mast sections in black and being pleased with the result let the workers off early for a well earned cup of tea!!

-

Thinking that I am still interested in attempting to make sails for Pickle, in the next step, I wanted attempt to craft some Sail Hoops for the Main Driver. I had seen them on my real-life reference ship Ruth that I was lucky enough to find in a local Ships festival in Gloucester England. Here's a shot of Ruth and a close-up of the sail hoops I had been inspired by Flyer and Blue Ensign and how they had created the hoops for their models, so putting the main mast aside for now, I decided to set my apprentices to work to craft the hoops, following the instructions that I gave them as learned from the two master craftsmen. Below are the results. I shouldn't be too harsh. They are apprentices after all but after this attempt, they have been tasked with cleaning the shipyard from top to bottom!!! Back to the main Topmast then. . . . .

-

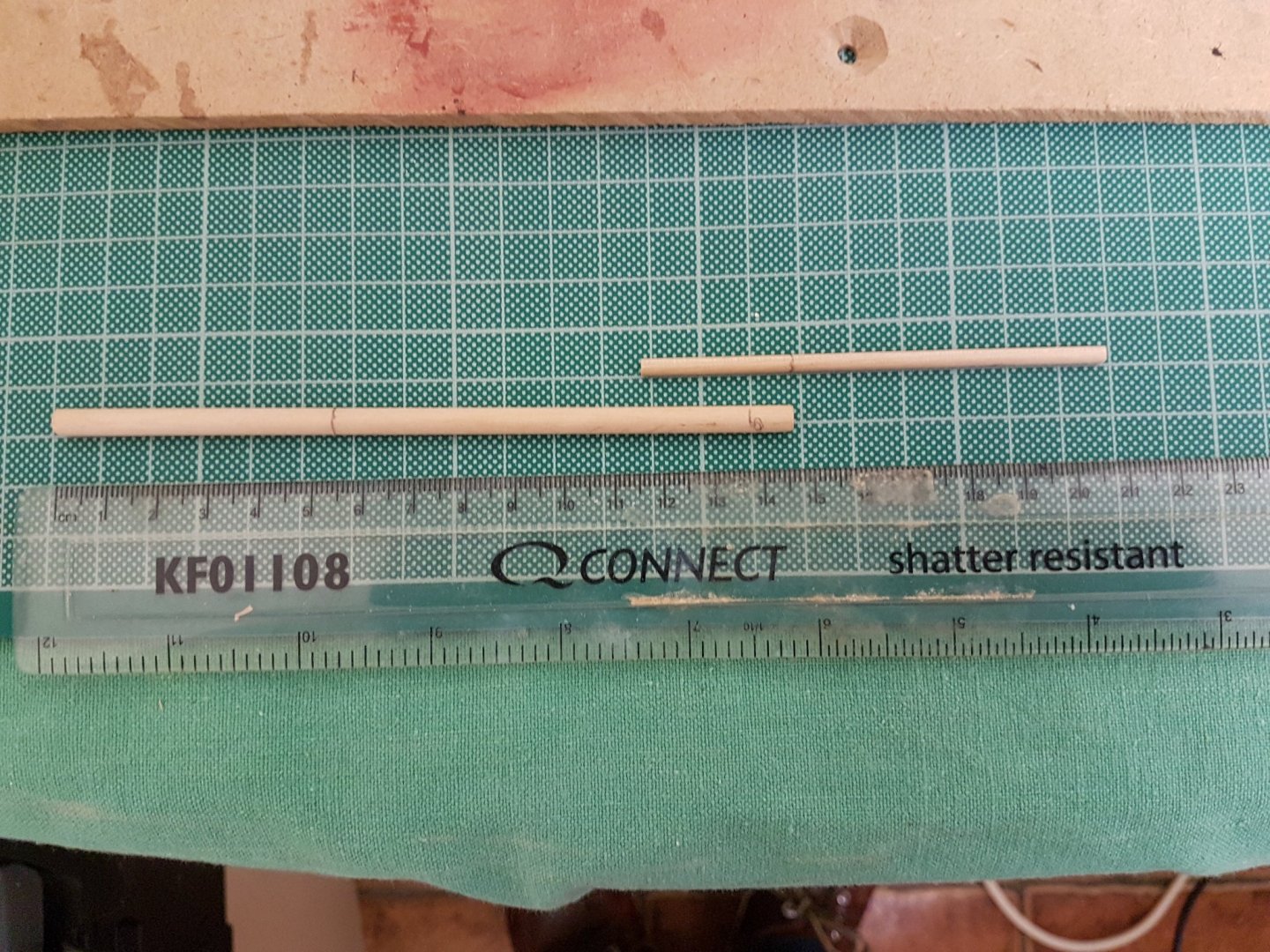

Having reviewed my attempt at my mainmast I decided that it wasn't good enough. The method of connecting the two mast sections might be good enough for the excellent modellers at Jotika models or the Mr Longridge of "The Anatomy of Nelson's Ships" and Victory scratch-build models but, as suggested by Jason (Beef Wellington) and the method used by others, I decided to purchase some new dowel and start again!! Down to my local DIY shop and I rummaged through their 6mm dowelling before eventually finding a piece that was decent enough and wasn't bent by 20-30%!! Back at the shipyard, I cut the mainmast to size (including the top section!! and started off cutting the square 4mm section with my baby plane and lots of sandpaper, but eventually I finished and after checking with my micrometre signed the work off.

-

Hi all, Having seen examples of the use of model figures on ship builds, I've realised they seem to be the best way for gauging realistic distances and set-up, for example in boom foot-ropes or ratline spacing etc. etc. I've searched the web and found a couple of examples (e.g. Cornwall Boats or Mantua) but I never seem to find the right figures. Has anyone got a good source for such things (UK preferably)?? Thanks!

-

Hi Allen Many thanks for the advice. I went to my local DIY store yesterday and purchased a new length of 6mm dowel. Although it is of much inferior quality to the dowel supplied with the kit, I am going to attempt an all-in-one version, therefore cutting/carving/sanding the top square section. Still, I have other sections of mast to do so will try and find a method of drilling/joining that works!!! Thanks for the help anyway.

-

Hi Gregory, Many thanks for the advice. Yes, the addition of cross-trees will hide the joint. However, it's not the joint that I'm concerned about but rather the angle between the main mast and the joined main mast top section which, due to the various angles in play is not straight. I went to my local DIY store yesterday and purchased a length of 6mm dowel. Although it is of much inferior quality to the dowel supplied with the kit, I am going to attempt an all-in-one version, therefore cutting/carving/sanding the top square section. Still, I have other sections of mast to do so will try and find a method of drilling/joining that works!!! Thanks for the help anyway.

-

Hi all, I'm on the building the masts for my current (first wooden) build HMS Pickle from Jotika / Caldercraft. Not easy, but OK so far - until I get to building the masts. The lower main mast is made up in two parts; the upper from 4*4mm walnut and the lower from 6mm dowel. The idea is to drill a 1.5mm hole in the top of the 6mm dowel and bottom of the 4*4 walnut piece. Then, a section of brass rod in inserted to join the two together.. I’ve tried doing this a couple of times but cannot seem to get both pieces straight. I do not have a bench drill or anything else so am having to do this by hand and eye. I did try to use a small vice to clamp the dowel section and have a set-square sitting upright on my bench as a guide to keeping the drill straight but the result is not good as can be seen!! It has been suggested that I make the sections of the mast by the lengthy process of planning and sanding the dowel to the correct shape. So my question is, has anyone used any other great methods to ensure a perfect match to the two mast pieces??

-

Main Mast Still avoiding the deadeye strops, I made a start on the masts. I started with the main mast. This is supposedly cut from the provided 6mm dowel. Trouble is, the dowel varies from 6.2 to 6.8 mm. I guess I have no option other than to sand for hours by hand to get the mast down to the correct diameter. I then noticed that my planking had been too generous around the mast step so out came my file and I carefully sanded away until I could get the mast to fit. I was shocked at first when I saw the resulting mast angled the way it was but after checking with the plans, I blew a huge sigh of relief as I realised that this was how it was supposed to be!! The fun and games continued when I found I had to drill a hole down the centre of the dowel and again with the 4x4 mm walnut. An easy job for those of you with bench drill rigs but by hand?? I had a practice run but the holes weren’t dead straight. After a lot of rummaging in the garage, I dug out an old table vice and a rusty set square. Setting the vice on the table (sorry, it’s a work bench!) and clamping the dowel, I then stood the set square as a guide and slowly re-drilled the hole. I think. I finished by drilling the hole in the walnut upper mast section, too small to be worth clamping so I did this by hand as best I could. Moment of truth time, I tried to fit the two pieces together and found they really didn’t align as the top section veered off at an alarming angle. I took a closed look at the two sections and found that my cutting wasn’t 100% true and had left a slight angle which wasn’t really noticeable before. Out with a fine file and attempted to level things off and then I glued everything together holding the upper section as straight as I could. After trial-fitting fitting the mast, I thought everything looked OK from the bow: However, looking at the mast from the starboard side, I saw that I had produced a fine mast rake, perfect in a racing yacht but I have a feeling it's not appropriate for Pickle. However, I don’t really think I can change this so that’s the way it’s going to have to stay unless anyone has some bright ideas?? Hopefully, when I add the upper mast and cross trees it won't look too bad. The difficult bit is going to be to get the fore-mast looking exactly the same!!

-

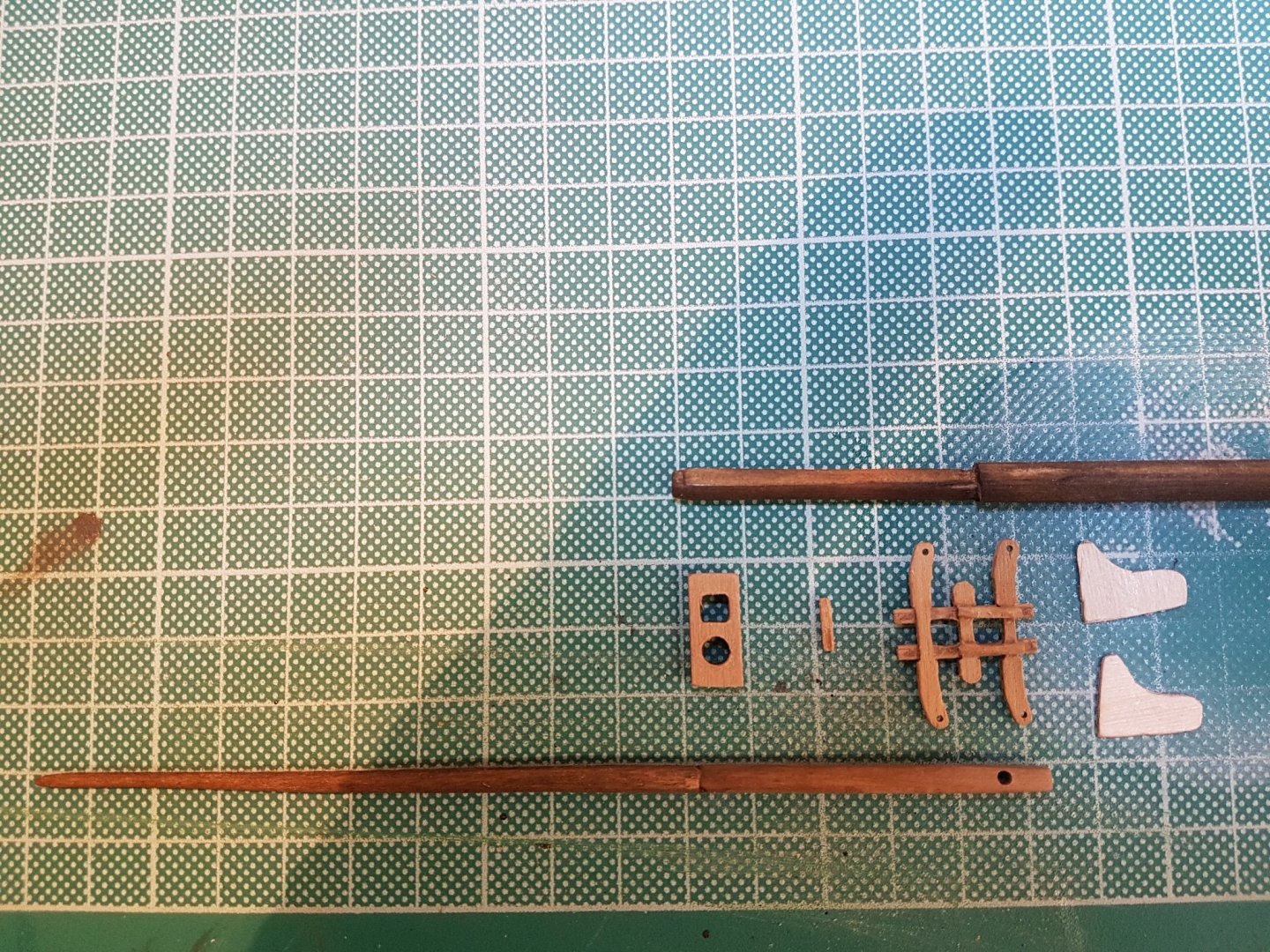

Before facing my nemesis of the Deadeye Strops once again, I decided that after such a long time away, I needed an easier way to get motivated and relearn some modelling skills. So, I decided to leave other parts of the ship alone for a while and make a start on the masts and spars etc. I decided to build up each piece as much as I could and add as many fixtures and fittings too on dry land before bringing them on board. Bowsprit & Jib-boom Starting with the bowsprit and jib-boom, I identified and cut my two pieces of dowel to size. Then I had to learn how to do some tapering! With my newly purchased baby plane, a chisel and lots of sandpaper I eventually managed to turn out two tapered pieces to the required measurements. I added the required eyelet and drilled the hole ready for the forestay. Next it was time to build the bowsprit cap and I faced this task with some trepidation as I had read of others having quite a time with this, especially trying to find the correct angle to drill the required holes without snapping the wood. Luckily, although it took a lot of time, things went well for a change. Using the plans, I firstly shaped the cap at the top and bottom and using these as a guide found the correct angles to drill the holes. A little fine-sanding later I dry-fitted the bowsprit and job-boom. Result!! After drilling guide-holes, I added the two eyelets to the bowsprit cap. Then I was asked to perform the simple task of creating two stop cleats. Now that took a while but after four failed attempts I managed to produce two acceptable cleats which I quickly attached before I lost them! Great idea, except that when I picked up my first cleat with my tweezers, the cleat pinged off into outer space never to be seen again and so I had to go back and make a further cleat! While I was in cleat building mode, I also produced the two gammoning cleats that I saw I would need later in the build. Time to assemble what I had built and with that done, I fixed the stop and gammoning cleats. Finally, I painted the required sections in black and stained the rest in walnut. Like many, I’m not too happy with the result and may use some fine sandpaper to lighten things up a little before final fitting. During a test fitting of the completed bowsprit to confirm the correct placing of the gammoning cleats I realised that after consulting the plans, I had fitted the pawl bitts too far back and therefore the bowsprit was not positioned correctly. Luckily the pawl bitt assembly was not fixed in place so it was simply a task of re-measuring and drilling new holes. So now the pawl bitt assembly is in the correct place!!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.